Makita 6992D User Manual

GB

Cordless Impact Wrench Instruction Manual

F

Boulonneuse sans fil Manuel d’instructions

D

Akku-Schlagschrauber Betriebsanleitung

I

Avvitatrice ad impulso a batteria Istruzioni per l’uso

NL

Snoerloze slagmoersleutel Gebruiksaanwijzing

E

Llave de impacto a batería Manual de instrucciones

P

Chave de impacto a bateria Manual de instruções

DK

Elektronisk akku slagnøgle Brugsanvisning

S

Sladdlös mutterdragare Bruksanvisning

N

Batteridrevet slagskrunøkkel Bruksanvisning

SF

Akku-iskuväännin Käyttöohje

GR Ασύρµατο κρουστικ κλειδί Οδηγίες χρήσεως

6991D

6992D

1

3

4

2

12

3

6

5

7

34

88

910

11 12

5

2

16

100

(1020)

80

(816)

60

(612)

40

(408)

20

(204)

0

N • m

(kgf • cm)

M14

M12

M10

1.0 2.0 3.0

13

15

15

15

14

(M14)

(M12)

(M10)

(kgf • cm)

N • m

16

100

(1020)

80

(816)

60

(612)

40

(408)

20

(204)

N • m

(kgf • cm)

0

1.0 2.0 3.0 4.0 5.0

13

M10

M8

15

15

(M10)

(M8)

14

67

GB Standard bolt

F Boulon standard

D Standardschrauben

I Bullone standard

NL Standaard bout

E Tornillo estándar

P Porca normal

DK Standardbolt

S Standardbult

N Standardbolt

SF Nornaali pultti

GR Κανονικ µπουλνι

GB High tensile bolt

F Boulon à haute résistance

D HV-Schruben

I Bullone altamente tensile

NL Bout met grote treksterkte

E Tornillo de alta resistencia

P Porca de grande elasticidade

DK Kvalitetsstålbolt

S Bult met hög hållfasthet

N Høy streskkbolt

SF Suurvetolujuuspultti

GR Μπουλνι υψηλής

εκτατικτητος

19

18

17

8

9

3

ENGLISH

Explanation of general view

1 Push button

2 Battery cartridge

3 Socket

4Anvil

5Pin

6O-ring

7 Switch trigger

SPECIFICATIONS

Model 6991D 6992D

Capacities

Standard bolt ............................................................................ M8 – M14 M8 – M14

High tensile bolt ........................................................................ M6 – M10 M6 – M10

Square drive ................................................................................ 9.5 mm 12.7 mm

No load speed (min

–1

) ................................................................. 0 – 2,300 0 – 2,300

Impacts per minute ...................................................................... 0 – 3,000 0 – 3,000

Max. fastening torque .................................................................. 100 N•m 100 N•m

Overall length .............................................................................. 168 mm 176 mm

Net weight (with battery cartridge) .............................................. 1.3 kg 1.4 kg

Rated voltage .............................................................................. D.C. 9.6 V D.C. 9.6 V

• Due to our continuing program of research and devel-

opment, the specifications herein are subject to change

without notice.

• Note: Specifications may differ from country to country.

Intended use

The tool is intended for fastening bolts and nuts.

Safety Hints

For your own safety, please refer to the enclosed safety

instructions.

IMPORTANT SAFETY INSTRUCTIONS FOR

CHARGER & BATTERY CARTRIDGE

1. Before using battery cartridge, read all instruc-

tions and cautionary markings on (1) battery

charger, (2) battery, and (3) product using battery.

2. Do not disassemble battery cartridge.

3. If operating time has become excessively

shorter, stop operating immediately. It may

result in a risk of overheating, possible burns

and even an explosion.

4. If electrolyte gets into your eyes, rinse them out

with clear water and seek medical attention right

away. It may result in loss of your eyesight.

5. Always cover the battery terminals with the bat-

tery cover when the battery cartridge is not

used.

6. Do not short the battery cartridge:

(1) Do not touch the terminals with any conduc-

tive material.

(2) Avoid storing battery cartridge in a container

with other metal objects such as nails, coins,

etc.

(3) Do not expose battery cartridge to water or

rain.

A battery short can cause a large current flow,

overheating, possible burns and even a breakdown.

8 Reversing switch lever

9A side

10 B side

11 Clockwise

12 Counterclockwise

13 Fastening time

14 Seconds

7. Do not store the tool and battery cartridge in

8. Do not incinerate the battery cartridge even if it

9. Be careful not to drop or strike battery.

SAVE THESE INSTRUCTIONS.

Tips for maintaining maximum battery life

1. Charge the battery cartridge before completely

ENC004-1

2. Never recharge a fully charged battery cartridge.

3. Charge the battery cartridge with room tempera-

4. Charge the Nickel Metal Hydride battery car-

ADDITIONAL SAFETY RULES FOR TOOL

1. Be aware that this tool is always in an operating

2. Hold tool by insulated gripping surfaces when

3. Wear ear protectors.

4. Check the socket carefully for wear, cracks or

5. Hold the tool firmly.

6. Always be sure you have a firm footing.

7. Be sure no one is below when using the tool in

15 Proper fastening torque for

16 Fastening torque

17 Limit mark

18 Screwdriver

19 Brush holder cap

locations where the temperature may reach or

exceed 50°C (122°F).

is severely damaged or is completely worn out.

The battery cartridge can explode in a fire.

discharged.

Always stop tool operation and charge the battery cartridge when you notice less tool power.

Overcharging shortens the battery service life.

ture at 10°C – 40°C (50°F – 104°F). Let a hot battery cartridge cool down before charging it.

tridge when you do not use it for more than six

months.

ENB025-1

condition, because it does not have to be

plugged into an electrical outlet.

performing an operation where the cutting tool

may contact hidden wiring. Contact with a “live”

wire will also make exposed metal parts of the

tool “live” and shock the operator.

damage before installation.

high locations.

4

8. The proper fastening torque may differ depending upon the kind or size of the bolt. Check the

torque with a torque wrench.

SAVE THESE INSTRUCTIONS.

OPERATING INSTRUCTIONS

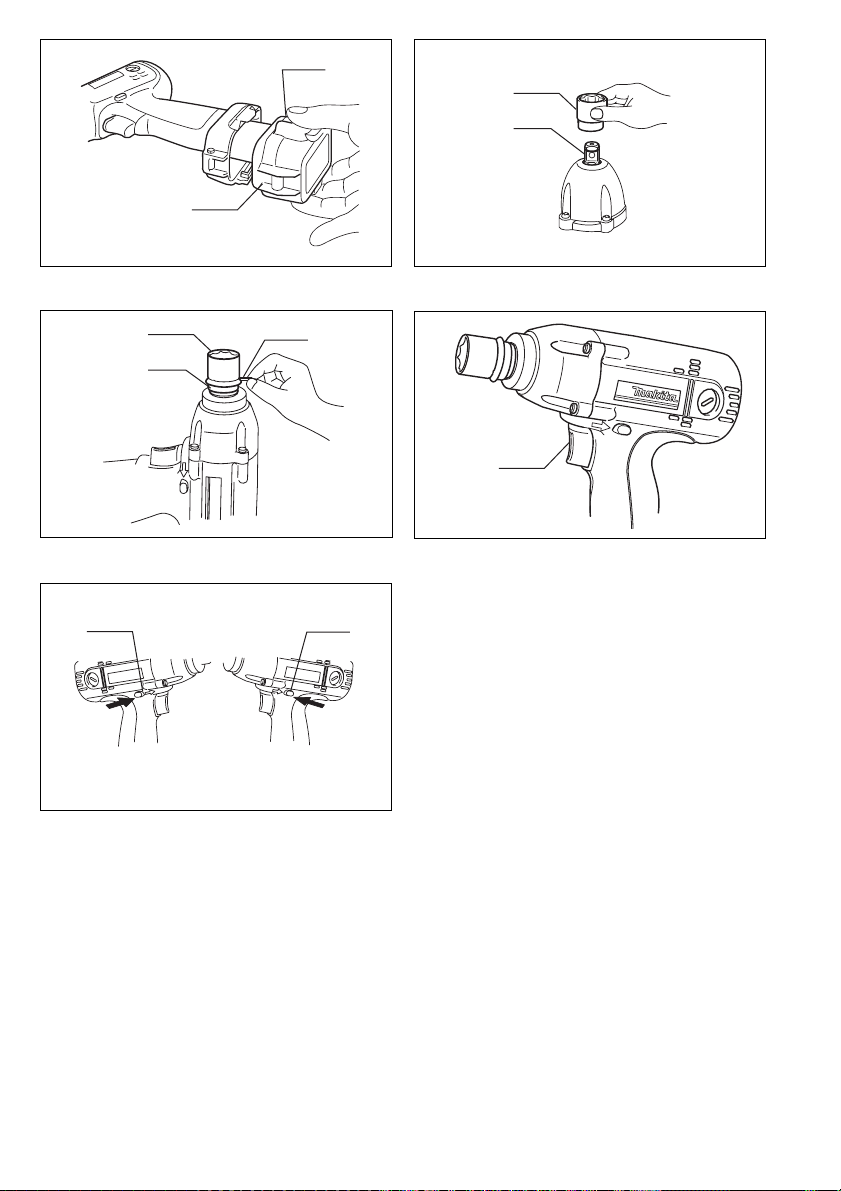

Installing or removing battery cartridge (Fig. 1)

• Always switch off the tool before insertion or removal of

the battery cartridge.

• To remove the battery cartridge, withdraw it from the

tool while pressing the push buttons on both sides of

the cartridge.

• To insert the battery cartridge, align the tongue on the

battery cartridge with the groove in the housing and slip

it into place. Always insert it all the way until it locks in

place with a little click. If not, it may accidentally fall out

of the tool, causing injury to you or someone around

you.

• Do not use force when inserting the battery cartridge. If

the cartridge does not slide in easily, it is not being

inserted correctly.

Selecting correct socket

Always use the correct size socket for bolts and nuts. An

incorrect size socket will result in inaccurate and inconsistent fastening torque and/or damage to the bolt or nut.

Installing or removing socket (Fig. 2 & 3)

CAUTION:

Always be sure that the tool is switched off and the battery cartridge is removed before installing or removing

the socket.

1. For socket without O-ring and pin

(Model 6991D & 6992D)

To install the socket, push it onto the anvil of the tool

until it locks into place.

To remove the socket, simply pull it off.

2. For socket with O-ring and pin (Model 6992D)

Move the O-ring out of the groove in the socket and

remove the pin from the socket. Fit the socket onto

the anvil of the tool so that the hole in the socket is

aligned with the hole in the anvil. Insert the pin

through the hole in the socket and anvil. Then return

the O-ring to the original position in the socket

groove to retain the pin. To remove the socket, follow the installation procedures in reverse.

Switch action (Fig. 4)

CAUTION:

Before inserting the battery cartridge into the tool, always

check to see that the switch trigger actuates properly and

returns to the “OFF” position when released.

To start the tool, simply pull the trigger. Tool speed is

increased by increasing pressure on the trigger. Release

the trigger to stop.

Reversing switch action (Fig. 5)

CAUTION:

• Always check the direction of rotation before operation.

• Use the reversing switch only after the tool comes to a

complete stop. Changing the direction of rotation

before the tool stops may damage the tool.

• When not operating the tool, always set the reversing

switch lever to the neutral position.

This tool has a reversing switch to change the direction

of rotation. Depress the reversing switch lever from the A

side for clockwise rotation or from the B side for counterclockwise rotation. When the switch lever is in the neutral

position, the switch trigger cannot be pulled.

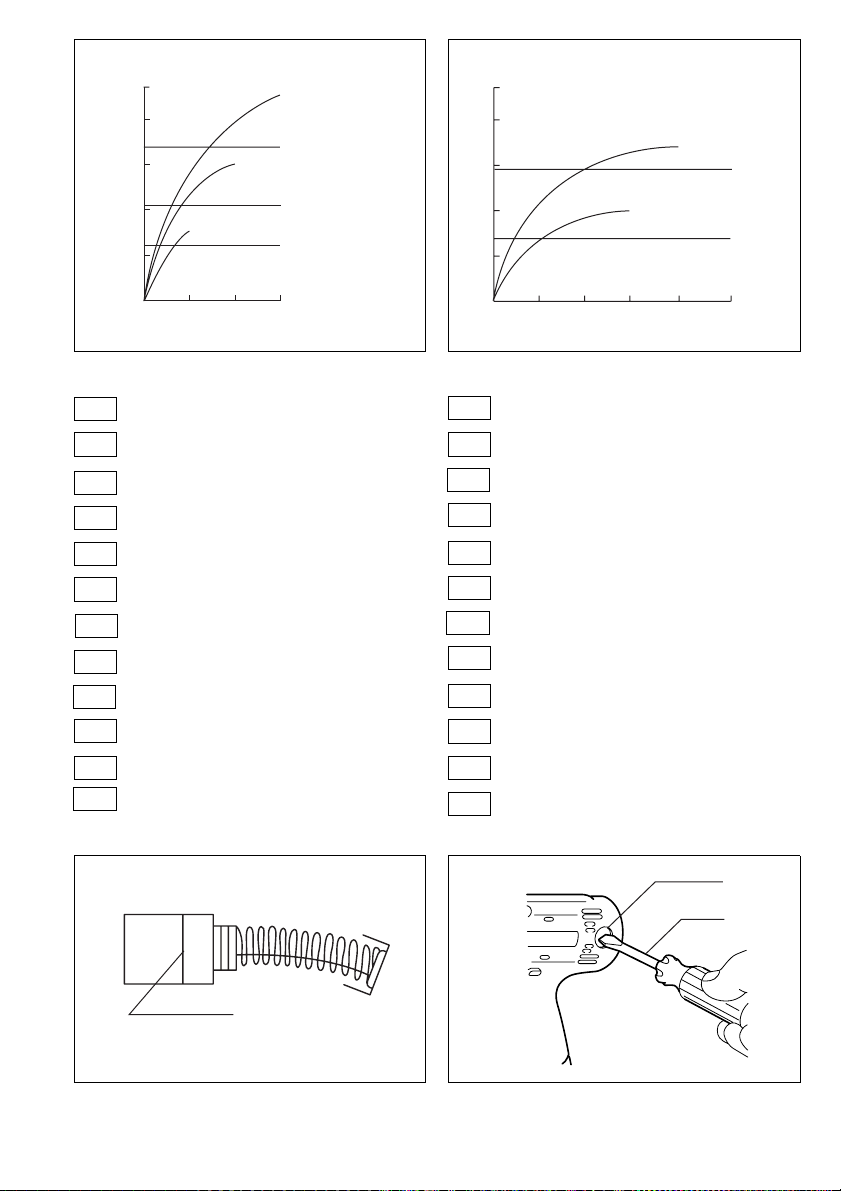

Operation (Fig. 6 & 7)

The proper fastening torque may differ depending upon

the kind or size of the bolt. The relation between fastening torque and fastening time is shown in the figures.

Hold the tool firmly and place the socket over the bolt or

nut. Turn the tool on and fasten for the proper fastening

time.

NOTE:

• Hold the tool pointed straight at the bolt or nut without

applying excessive pressure on the tool.

• Excessive fastening torque may damage the bolt or

nut. Before starting your job, always perform a test

operation to verify the adequate fastening speed and

time for your bolt or nut.

The fastening torque is affected by a wide variety of factors including the following. After fastening, always check

the torque with a torque wrench.

1. When the battery cartridge is discharged almost

completely, voltage will drop and the fastening

torque will be reduced.

2. Socket

• Failure to use the correct size socket will cause a

reduction in the fastening torque.

• A worn socket (wear on the hex end or square

end) will cause a reduction in the fastening torque.

3. Bolt

• Even though the torque coefficient and the class of

bolt are the same, the proper fastening torque will

differ according to the diameter of the bolt.

• Even though the diameters of bolts are the same,

the proper fastening torque will differ according to

the torque coefficient, the class of bolt and the bolt

length.

4. The use of the universal joint or the extension bar

somewhat reduces the fastening force of the impact

wrench. Compensate by fastening for a longer

period of time.

5. Type of materials to be fastened, the manner of

holding the tool and the tool speed will affect the

torque.

CAUTION:

If the tool is operated continuously until the battery cartridge has discharged, allow the tool to rest for

15 minutes before proceeding with a fresh battery.

MAINTENANCE

CAUTION:

Always be sure that the tool is switched off and the battery cartridge is removed before carrying out any work on

the tool.

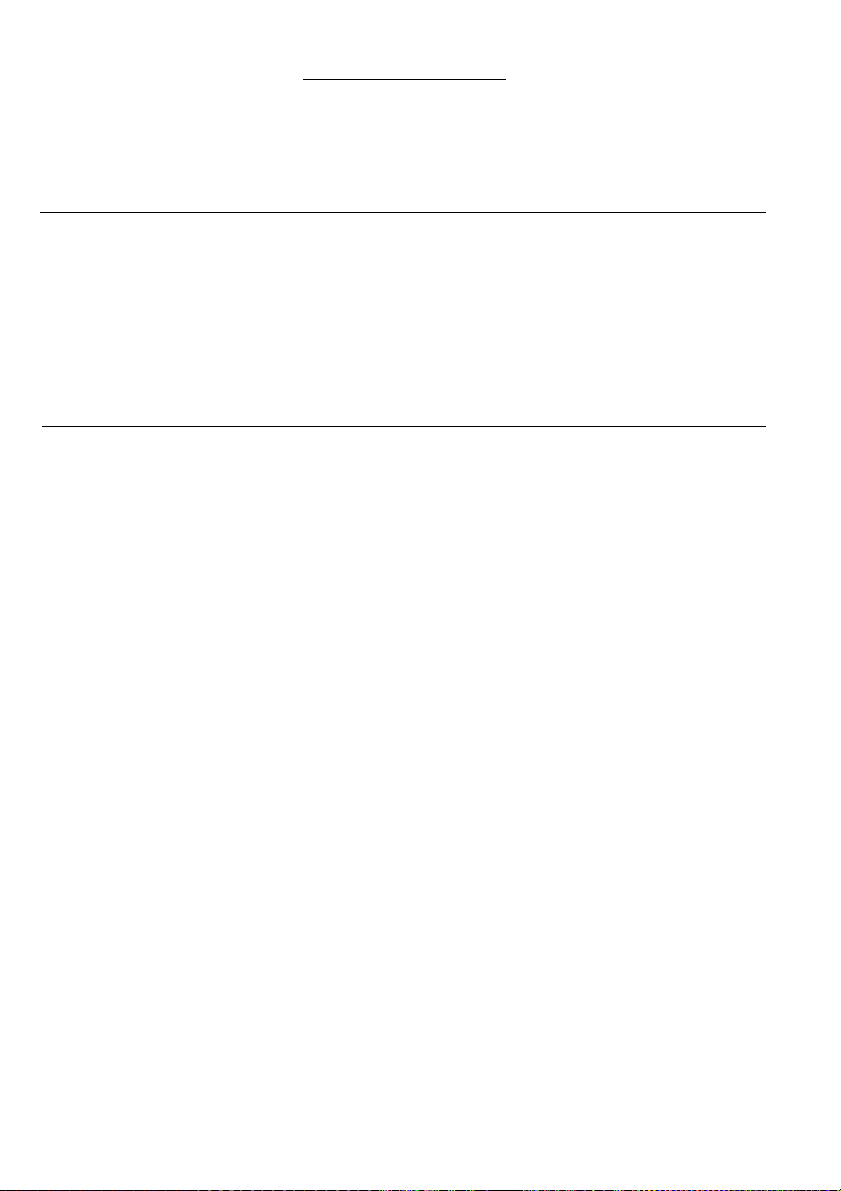

Replacement of carbon brushes (Fig. 8 & 9)

Replace carbon brushes when they are worn down to the

limit mark. Both identical carbon brushes should be

replaced at the same time.

To maintain product safety and reliability, repairs, maintenance or adjustment should be carried out by a Makita

Authorized Service Center.

5

Loading...

Loading...