Page 1

GB

Cordless Impact Wrench Instruction Manual

F

Boulonneuse sans fil Manuel d’instructions

D Akku-Schlagschrauber

I

Avvitatrice ad impulso a batteria

NL Snoerloze slagmoersleutel

E Llave de impacto a batería

P Chave de impacto a bateria

DK Elektronisk akku slagnøgle

S Sladdlös mutterdragare

N Batteridrevet slagskrunøkkel

SF Akku-iskuväännin

GR Ασύρµατο κρουστικ Οδηγίες χρήσεως

Betriebsanleitung

Istruzioni per l’uso

Gebruiksaanwijzing

Manual de instrucciones

Manual de instruções

Brugsanvisning

Bruksanvisning

Bruksanvisning

Käyttöohje

6915D

Page 2

4

1

3

5

2

12

6

7

34

Kg.cm

1000

8

800

600

400

200

0

M12X45

M10X45

1234

9

M14X45

11

11

11

10

M14

M12

M10

Kg.cm

8

1200

1000

800

600

400

200

0

1234 56

9

M8X45

M12X50

M10X45

11

11

11

M12

M10

M8

10

56

2

Page 3

ENGLISH

1 Push button

2 Battery cartridge

3 O-ring

4 Socket

Explanation of general view

5Pin

6 Switch trigger

7 Reversing switch

8 Fastening torque

9 Fastening time

10 Seconds

11 Proper fastening torque for

SPECIFICATIONS

Model 6915D

Capacities

Standard bolt ............................................... M8 – M14

High tensile bolt ........................................... M6 – M12

Square drive ..................................................... 12.7 mm

No load speed (min

Impacts per minute .......................................... 0 – 2,500

Max. fastening torque ....................................... 117 N•m

Overall length .................................................... 221 mm

Net weight (with battery cartridge) ....................... 1.9 kg

Rated voltage .................................................. D.C. 12 V

• Due to our continuing program of research and deve-

lopment, the specifications herein are subject to

change without notice.

• Note: Specifications may differ from country to country.

Intended use

The tool is intended for fastening bolts and nuts.

Safety Hints

For your own safety, please refer to the enclosed safety

instructions.

–1

) ..................................... 0 – 1,800

IMPORTANT SAFETY INSTRUCTIONS FOR

CHARGER & BATTERY CARTRIDGE

1. Before using battery cartridge, read all instruc-

tions and cautionary markings on (1) battery

charger, (2) battery, and (3) product using battery.

2. Do not disassemble battery cartridge.

3. If operating time has become excessively

shorter, stop operating immediately. It may

result in a risk of overheating, possible burns

and even an explosion.

4. If electrolyte gets into your eyes, rinse them out

with clear water and seek medical attention right

away. It may result in loss of your eyesight.

5. Always cover the battery terminals with the bat-

tery cover when the battery cartridge is not

used.

6. Do not short the battery cartridge:

(1) Do not touch the terminals with any conduc-

tive material.

(2) Avoid storing battery cartridge in a container

with other metal objects such as nails, coins,

etc.

(3) Do not expose battery cartridge to water or

rain.

A battery short can cause a large current flow,

overheating, possible burns and even a breakdown.

7. Do not store the tool and battery cartridge in

locations where the temperature may reach or

exceed 50°C (122°F).

ENC004-1

8. Do not incinerate the battery cartridge even if it

is severely damaged or is completely worn out.

The battery cartridge can explode in a fire.

9. Be careful not to drop or strike battery.

SAVE THESE INSTRUCTIONS.

Tips for maintaining maximum battery life

1. Charge the battery cartridge before completely

discharged.

Always stop tool operation and charge the battery cartridge when you notice less tool power.

2. Never recharge a fully charged battery cartridge.

Overcharging shortens the battery service life.

3. Charge the battery cartridge with room temperature at 10°C – 40°C (50°F – 104°F). Let a hot battery cartridge cool down before charging it.

4. Charge the Nickel Metal Hydride battery cartridge when you do not use it for more than six

months.

ADDITIONAL SAFETY RULES FOR TOOL

1. Be aware that this tool is always in an operating

condition, because it does not have to be

plugged into an electrical outlet.

2. Hold tool by insulated gripping surfaces when

performing an operation where the cutting tool

may contact hidden wiring. Contact with a “live”

wire will also make exposed metal parts of the

tool “live” and shock the operator.

3. Wear ear protectors.

4. Check the socket carefully for wear, cracks or

damage before installation.

5. Hold the tool firmly.

6. Always be sure you have a firm footing.

7. Be sure no one is below when using the tool in

high locations.

8. The proper fastening torque may differ depending upon the kind or size of the bolt. Check the

torque with a torque wrench.

ENB025-1

SAVE THESE INSTRUCTIONS.

3

Page 4

OPERATING INSTRUCTIONS

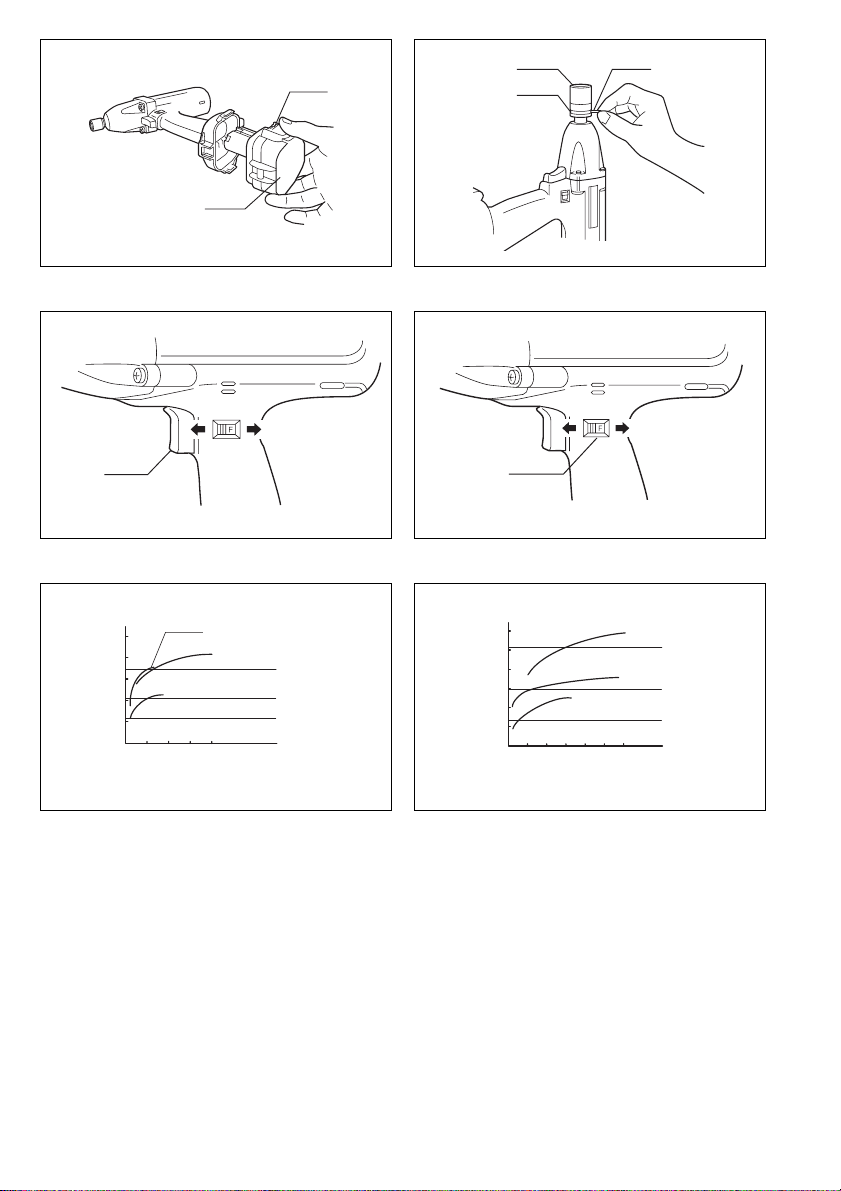

Installing or removing battery cartridge (Fig. 1)

• Always switch off the tool before insertion or removal of

the battery cartridge.

• To remove the battery cartridge, withdraw it from the

tool while pressing the push buttons on both sides of

the cartridge.

• To insert the battery cartridge, align the tongue on the

battery cartridge with the groove in the housing and slip

it into place. Always insert it all the way until it locks in

place with a little click. If not, it may accidentally fall out

of the tool, causing injury to you or someone around

you.

• Do not use force when inserting the battery cartridge. If

the cartridge does not slide in easily, it is not being

inserted correctly.

Selecting correct socket

Always use the correct size socket for bolts and nuts. An

incorrect size socket will result in inaccurate and inconsistent fastening torque and/or damage to the bolt or nut.

Installing or removing socket (Fig. 2)

Important:

Always be sure that the tool is switched off and the battery cartridge is removed before installing or removing

the socket.

Move the O-ring out of the groove in the socket and

remove the pin from the socket. Fit the socket onto the

anvil of the tool so that the hole in the socket is aligned

with the hole in the anvil. Insert the pin through the hole

in the socket and anvil. Then return the O-ring to the original position in the socket groove to retain the pin. To

remove the socket, follow the installation procedures in

reverse.

Switch action (Fig. 3)

CAUTION:

Before inserting the battery cartridge into the tool, always

check to see that the switch trigger actuates properly and

returns to the “OFF” position when released.

To start the tool, simply pull the trigger. Tool speed is

increased by increasing pressure on the trigger. Release

the trigger to stop.

Reversing switch action (Fig. 4)

CAUTION:

• Always check the direction of rotation before operation.

• Use the reversing switch only after the tool comes to a

complete stop. Changing the direction of rotation

before the tool stops may damage the tool.

This tool has a reversing switch to change the direction

of rotation. Slide the reversing switch to the left for

clockwise rotation or to the right for counterclockwise

rotation.

Operation (Fig. 5 & 6)

The proper fastening torque may differ depending upon

the kind or size of the bolt. The relation between fastening torque and fastening time is shown in the figures.

Hold the tool firmly and place the socket over the bolt or

nut. Turn the tool on and fasten for the proper fastening

time.

NOTE:

• Hold the tool pointed straight at the bolt or nut without

applying excessive pressure on the tool.

• Excessive fastening torque may damage the bolt or

nut. Before starting your job, always perform a test

operation to verify the adequate fastening speed and

time for your bolt or nut.

The fastening torque is affected by a wide variety of

factors including the following. After fastening, always

check the torque with a torque wrench.

1. When the battery cartridge is discharged almost

completely, voltage will drop and the fastening

torque will be reduced.

2. Socket

• Failure to use the correct size socket will cause a

reduction in the fastening torque.

• A worn socket (wear on the hex end or square

end) will cause a reduction in the fastening

torque.

3. Bolt

• Even though the torque coefficient and the class

of bolt are the same, the proper fastening torque

will differ according to the diameter of the bolt.

• Even though the diameters of bolts are the same,

the proper fastening torque will differ according to

the torque coefficient, the class of bolt and the

bolt length.

4. The use of the universal joint or the extension bar

somewhat reduces the fastening force of the impact

wrench. Compensate by fastening for a longer

period of time.

5. Type of materials to be fastened, the manner of holding the tool and the tool speed will affect the torque.

CAUTION:

If the tool is operated continuously until the battery cartridge has discharged, allow the tool to rest for 15 minutes

before proceeding with a fresh battery.

MAINTENANCE

CAUTION:

Always be sure that the tool is switched off and the battery cartridge is removed before carrying out any work on

the tool.

To maintain product safety and reliability, repairs, maintenance or adjustment should be carried out by a Makita

Authorized Service Center.

ACCESSORIES

CAUTION:

• These accessories or attachments are recommended

for use with your Makita tool specified in this manual.

The use of any other accessories or attachments might

present a risk of injury to persons. Only use accessory

or attachment for its stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita service center.

• Socket (with pin and O-ring)

• Extension bar (with pin and O-ring)

• Universal joint (with pin and O-ring)

• Bit adapter (with pin and O-ring)

• Phillips bit

• Various type of Makita genuine batteries and chargers

• Plastic carrying case

4

Page 5

NEDERLANDS

1 Knop

2 Accu

3O-ring

4Sok

Verklaring van algemene gegevens

5 Pen

6 Trekschakelaar

7 Omkeerschakelaar

8 Aantrekkoppel

9 Aantrektijd

10 Seconden

11 Juist aantrekkoppel voor

TECHNISCHE GEGEVENS

Model 6915D

Capaciteiten

Standaardbout ............................................. M8 – M14

Trekvaste bout ............................................. M6 – M12

Vierkant ............................................................ 12,7 mm

Toerental onbelast (min

Aantal slagen per minuut ................................. 0 – 2 500

Maximaal aantrekkoppel .................................. 117 N•m

Totale lengte ...................................................... 221 mm

Netto gewicht (accu inbegrepen) .......................... 1,9 kg

Nominale spanning ......................................... D.C. 12 V

• In verband met ononderbroken research en ontwikke-

ling behouden wij ons het recht voor bovenstaande

technische gegevens te wijzigen zonder voorafgaande

kennisgeving.

• Opmerking: De technische gegevens kunnen van land

tot land verschillen.

Doeleinden van gebruik

Dit gereedschap is bedoeld voor het vastdraaien van

bouten en moeren.

Veiligheidswenken

Volg veiligheidshalve de bijgevoegde veiligheidsvoorschriften nauwkeurig op.

–1

) ............................... 0 – 1 800

BELANGRIJKE

VEILIGHEIDSVOORSCHRIFTEN VOOR

ACCULADER EN ACCU

1. Lees alle voorschriften en waarschuwingen op

(1) de acculader, (2) de accu, en (3) het product

waarvoor de accu wordt gebruikt, aandachtig

door alvorens de acculader in gebruik te nemen.

2. Neem de accu niet uit elkaar.

3. Als de gebruikstijd van een opgeladen accu aan-

zienlijk korter is geworden, moet u het gebruik

ervan onmiddellijk stopzetten. Voortgezet

gebruik kan oververhitting, brandwonden en

zelfs een ontploffing veroorzaken.

4. Als er elektrolyt in uw ogen is terechtgekomen,

spoel dan uw ogen met schoon water en roep

onmiddellijk de hulp van een dokter in. Elektrolyt

in de ogen kan blindheid veroorzaken.

5. Bedek de accuklemmen altijd met de accukap

wanneer u de accu niet gebruikt.

6. Voorkom kortsluiting van de accu:

(1) Raak de accuklemmen nooit aan met een

geleidend materiaal.

(2) Bewaar de accu niet in een bak waarin

andere metalen voorwerpen zoals spijkers,

munten e.d. worden bewaard.

(3) Stel de accu niet bloot aan water of regen.

Kortsluiting van de accu kan oorzaak zijn van

een grote stroomafgifte, oververhitting, brandwonden, en zelfs defecten.

7. Bewaar het gereedschap en de accu niet op

plaatsen waar de temperatuur kan oplopen tot

50°C of hoger.

8. Werp de accu nooit in het vuur, ook niet wanneer

hij zwaar beschadigd of volledig versleten is. De

accu kan namelijk ontploffen in het vuur.

9. Wees voorzichtig dat u de accu niet laat vallen

en hem niet blootstelt aan schokken of stoten.

BEWAAR DEZE VOORSCHRIFTEN.

Tips voor een maximale levensduur van de accu

1. Laad de accu op voordat hij volledig ontladen is.

Stop het gebruik van het gereedschap en laad de

accu op telkens wanneer u vaststelt dat het vermogen van het gereedschap is afgenomen.

2. Laad een volledig opgeladen accu nooit opnieuw

op. Als u de accu te veel oplaadt, zal hij minder

lang meegaan.

3. Laad de accu op bij een kamertemperatuur tussen 10°C en 40°C. Laat een warme accu afkoelen

alvorens hem op te laden.

4. Laad de nikkel-metaalhydride accu op telkens

wanneer u hem langer dan zes maanden niet

hebt gebruikt.

AANVULLENDE

VEILIGHEIDSVOORSCHRIFTEN VOOR HET

GEREEDSCHAP

1. Denk eraan dat dit gereedschap altijd gebruiksklaar is, aangezien het niet op een stopcontact

hoeft te worden aangesloten.

2. Houd het gereedschap bij de geïsoleerde handgrepen vast wanneer u boort op plaatsen waar

de boor op verborgen elektrische bedrading kan

stoten. Door contact met een onder spanning

staande draad zullen ook de niet-geïsoleerde

metalen delen van het gereedschap onder spanning komen te staan, zodat de gebruiker een

elektrische schok kan krijgen.

3. Draag oorbeschermers.

4. Controleer de sok nauwkeurig op slijtage,

scheuren of beschadiging alvorens deze op het

gereedschap te monteren.

5. Houd het gereedschap stevig vast.

6. Zorg ervoor dat u altijd stevige steun voor de

voeten hebt.

7. Controleer of er niemand beneden u aanwezig is

wanneer u het gereedschap op een hoge plaats

gaat gebruiken.

8. Het juiste aantrekkoppel kan verschillen afhankelijk van de soort of grootte van de bout. Controleer het aantrekkoppel met een

momentsleutel.

BEWAAR DEZE VOORSCHRIFTEN.

14

Page 6

BEDIENINGSVOORSCHRIFTEN

Installeren of verwijderen van de accu (Fig. 1)

• Schakel het gereedschap altijd uit alvorens de accu te

installeren of te verwijderen.

• Om de accu te verwijderen, neemt u deze uit het

gereedschap terwijl u de knoppen aan beide zijden van

de accu indrukt.

• Om de accu te installeren, past u de tong op de accu in

de groef in de houder, en dan schuift u de accu erin.

Schuif de accu zo ver mogelijk erin, totdat deze met

een klikgeluid vergrendelt. Indien u dit niet doet, kan de

accu per ongeluk uit het gereedschap vallen en uzelf of

anderen verwonden.

• Als de accu moeilijk in de houder gaat, moet u niet proberen hem met geweld erin te duwen. Indien de accu

er niet gemakkelijk ingaat, betekent dit dat u hem niet

op de juiste wijze erin steekt.

Selecteren van de juiste sok

Gebruik altijd een sok van de juiste maat voor het vastdraaien van bouten en moeren. Het gebruik van een sok

van de onjuiste maat zal een onnauwkeurig of onregelmatig aantrekkoppel en/of beschadiging van de bout of

moer tot gevolg hebben.

Installeren of verwijderen van de sok (Fig. 2)

Belangrijk:

Controleer altijd of het gereedschap is uitgeschakeld en

de accu is verwijderd alvorens de sok te installeren of te

verwijderen.

Verwijder de O-ring uit de groef in de sok en verwijder de

pen uit de sok. Schuif de sok over het draaistuk van het

gereedschap zodat het gat in de sok op één lijn komt met

het gat in het draaistuk. Steek de pen door het gat in de

sok en in het draaistuk. Breng de O-ring weer op zijn oorspronkelijke plaats in de groef aan, zodat de pen op zijn

plaats wordt gehouden. Om de sok te verwijderen, voert

u deze procedure in omgekeerde volgorde uit.

Werking van de trekschakelaar (Fig. 3)

LET OP:

Alvorens de accu in het gereedschap te plaatsen, moet u

altijd controleren of de trekschakelaar juist werkt en bij

loslaten naar de “OFF” positie terugkeert.

Om het gereedschap te starten, drukt u gewoon de trekschakelaar in. Oefen meer druk uit op de trekschakelaar

om het toerental te vermeerderen. Om het gereedschap

te stoppen, de trekschakelaar loslaten.

Werking van de omkeerschakelaar (Fig. 4)

LET OP:

• Controleer altijd de draairichting alvorens het gereedschap te gebruiken.

• Verander de stand van de omkeerschakelaar pas

nadat het gereedschap volledig tot stilstand is gekomen. Indien u de draairichting verandert terwijl het

gereedschap nog draait, kan het gereedschap beschadigd raken.

Dit gereedschap heeft een omkeerschakelaar voor het

veranderen van de draairichting. Schuif de omkeerschakelaar naar links voor rechtse draairichting, of naar

rechts voor linkse draairichting.

Bediening (Fig. 5 en 6)

Het juiste aantrekkoppel voor de bout hangt af van de

soort of grootte van de bout. De verhouding tussen het

aantrekkoppel en de aantrektijd is op de grafieken aangegeven.

Houd het gereedschap stevig vast en plaats de sok over

de bout of moer. Schakel het gereedschap in en draai de

bout of moer in de juiste aantrektijd vast.

OPMERKING:

• Plaats het gereedschap recht op de bout of moer en

zorg ervoor dat u niet te veel druk op het gereedschap

uitoefent.

• Een te groot aantrekkoppel kan de bout of moer

beschadigen. Alvorens het eigenlijke werk te doen,

moet u daarom altijd een proefje doen met een gelijke

bout of moer voor het vaststellen van de juiste aantreksnelheid en aantrektijd.

Het aantrekkoppel wordt beïnvloed door een aantal verschillende factoren, waaronder de volgende. Controleer

na het vastdraaien altijd het aantrekkoppel met een

momentsleutel.

1. Wanneer de accu bijna leeg is, neemt het voltage af

en vermindert het aantrekkoppel.

2. Sok

• Het gebruik van een sok van de onjuiste maat zal

resulteren in een te laag aantrekkoppel.

• Een versleten sok (slijtage op het zeskante of vierkante uiteinde) zal resulteren in een te laag aantrekkoppel.

3. Bout

• Zelfs wanneer de koppelverhouding en de klasse

van de bout overeenkomen, kan door verschillen

in de diameter van de bouten het juiste aantrekkoppel per bout toch afwijken.

• Ook al zijn de diameters van twee bouten gelijk,

dan kunnen er nog verschillen in het juiste aantrekkoppel van de twee bouten optreden ten

gevolge van verschillen in de koppelverhouding en

de klasse en lengte van de bouten.

4. Het aantrekkoppel is iets lager wanneer een kogelgewrichtverbinding of verlengstaaf wordt gebruikt. U

kunt dit verlies aan aantrekkoppel compenseren

door de aantrektijd te verlengen.

5. Het materiaal van de vast te draaien bout of moer,

de manier van vasthouden van het gereedschap en

het toerental hebben invloed op het aantrekkoppel.

LET OP:

Indien u het gereedschap zonder onderbreking gebruikt

totdat de accu is uitgeput, dient u het gereedschap 15

minuten te laten rusten alvorens met een verse accu verder te werken.

ONDERHOUD

LET OP:

Controleer altijd of het gereedschap is uitgeschakeld en

de accu is losgekoppeld vooraleer onderhoud uit te voeren aan het gereedschap.

Opdat het gereedschap veilig en betrouwbaar blijft, dienen alle reparaties, onderhoud of afstellingen te worden

uitgevoerd bij een erkend Makita service centrum.

15

Page 7

ACCESSOIRES

LET OP:

• Deze accessoires of hulpstukken worden aanbevolen

voor gebruik met het Makita gereedschap dat in deze

gebruiksaanwijzing is beschreven. Bij gebruik van

andere accessoires of hulpstukken bestaat er gevaar

voor persoonlijke verwonding. Gebruik de accessoires

of hulpstukken uitsluitend voor hun bestemde doel.

Raadpleeg het dichtstbijzijnde Makita Servicecentrum

voor verder advies of bijzonderheden omtrent deze

accessoires.

• Sok (met pen en O-ring)

• Verlengstaaf (met pen en O-ring)

• Aantrekkoppel (met pen en O-ring)

• Bitadapter (met pen en O-ring)

• Phillips schroefbit

• Diverse types originele Makita accu’s en acculaders

• Plastic draagkoffer

16

Page 8

ENGLISH

EC-DECLARATION OF CONFORMITY

The undersigned, Yasuhiko Kanzaki, authorized by Makita

Corporation, 3-11-8 Sumiyoshi-Cho, Anjo, Aichi 446-8502

Japan declares that this product

manufactured by Makita Corporation in Japan is in compliance with the following standards or standardized documents,

in accordance with Council Directives, 89/336/EEC and

98/37/EC.

(Serial No. : series production)

EN50260, EN55014,

FRANÇAISE

DÉCLARATION DE CONFORMITÉ CE

Je soussigné, Yasuhiko Kanzaki, mandaté par Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo, Aichi 446-8502

Japan, déclare que ce produit

fabriqué par Makita Corporation au Japon, est conformes

aux normes ou aux documents normalisés suivants,

conformément aux Directives du Conseil, 89/336/CEE et

98/37/EG.

(No. de série: production en série)

EN50260, EN55014,

DEUTSCH

Hiermit erklärt der Unterzeichnete, Yasuhiko Kanzaki,

Bevollmächtigter von Makita Corporation, 3-11-8

Sumiyoshi-Cho, Anjo, Aichi 446-8502 Japan, daß dieses von der Firma Makita Corporation in Japan hergestellte Produkt

gemäß den Ratsdirektiven 89/336/EWG und 98/37/EG

mit den folgenden Normen bzw. Normendokumenten

übereinstimmen:

CE-KONFORMITÄTSERKLÄRUNG

(Serien-Nr.: Serienproduktion)

EN50260, EN55014.

ITALIANO

DICHIARAZIONE DI CONFORMITÀ CON LE NORME

Il sottoscritto Yasuhiko Kanzaki, con l’autorizzazione

della Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo,

Aichi 446-8502 Japan, dichiara che questo prodotto

fabbricato dalla Makita Corporation in Giappone è conformi alle direttive europee riportate di seguito:

secondo le direttive del Consiglio 89/336/CEE e 98/37/CE.

DELLA COMUNITÀ EUROPEA

(Numero di serie: Produzione in serie)

EN50260, EN55014

NEDERLANDS

EG-VERKLARING VAN CONFORMITEIT

De ondergetekende, Yasuhiko Kanzaki, gevolmachtigd

door Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo,

Aichi 446-8502 Japan verklaart dat dit produkt

vervaardigd door Makita Corporation in Japan voldoet

aan de volgende normen of genormaliseerde documenten,

in overeenstemming met de richtlijnen van de Raad

89/336/EEC en 98/37/EC.

(Serienr. : serieproduktie)

EN50260, EN55014

ESPAÑOL

DECLARACIÓN DE CONFORMIDAD DE LA CE

El abajo firmante, Yasuhiko Kanzaki, autorizado por

Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo, Aichi

446-8502 Japan, declara que este producto

(Número de serie: producción en serie)

fabricado por Makita Corporation en Japón cumple las

siguientes normas o documentos normalizados,

de acuerdo con las directivas comunitarias, 89/336/EEC

y 98/37/CE.

EN50260, EN55014

Yasuhiko Kanzaki

Director Amministratore

Directeur Directeur

Direktor Director

CE 99

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

35

Page 9

PORTUGUÊS

DECLARAÇÃO DE CONFORMIDADE DA CE

O abaixo assinado, Yasuhiko Kanzaki, autorizado pela

Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo, Aichi

446-8502 Japan, declara que este produto

fabricado pela Makita Corporation no Japão obedece às

seguintes normas ou documentos normalizados,

de acordo com as directivas 89/336/CEE e 98/37/CE do

Conselho.

(N. de série: produção em série)

EN50260, EN55014

NORSK

Undertegnede, Yasuhiko Kanzaki, med fullmakt fra

Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo, Aichi

446-8502 Japan bekrefter herved at dette produktet

fabrikert av Makita Corporation, Japan, er i overensstemmelse med følgende standarder eller standardiserte

dokumenter:

i samsvar med Råds-direktivene, 89/336/EEC og 98/37/EC.

EUs SAMSVARS-ERKLÆRING

(Serienr. : serieproduksjon)

EN50260, EN55014,

DANSK

EU-DEKLARATION OM KONFORMITET

Undertegnede, Yasuhiko Kanzaki, med fuldmagt fra

Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo, Aichi

446-8502 Japan, erklærer hermed, at dette produkt

fremstillet af Makita Corporation i Japan, er i overens-

(Løbenummer: serieproduktion)

stemmelse med de følgende standarder eller normsættende dokumenter,

EN50260, EN55014

i overensstemmelse med Rådets Direktiver 89/336/EEC

og 98/37/EC.

SVENSKA

EG-DEKLARATION OM ÖVERENSSTÄMMELSE

Undertecknad, Yasuhiko Kanzaki, auktoriserad av

Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo,

Aichi 446-8502 Japan deklarerar att denna produkt

tillverkad av Makita Corporation i Japan, uppfyller kraven

i följande standard eller standardiserade dokument,

i enlighet med EG-direktiven 89/336/EEC och 98/37/EC.

(serienummer: serieproduktion)

EN50260, EN55014

SUOMI

VAKUUTUS EC-VASTAAVUUDESTA

Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo, Aichi

446-8502 Japan valtuuttamana allekirjoittanut, Yasuhiko

Kanzaki, vakuuttaa että tämä tämä tuote

(Sarja nro : sarjan tuotantoa)

valmistanut Makita Corporation Japanissa vastaa seuraavia standardeja tai stardardoituja asiakirjoja

EN50260, EN55014

neuvoston direktiivien 89/336/EEC ja 98/37/EC mukaisesti.

ΕΛΛΗΝΙΚΑ

Ο υπογράφων, Yasuhiko Kanzaki, εξουσιοδοτηµένος

απ την εταιρεία Makita Corporation, 3-11-8

Sumiyoshi-Cho, Anjo, Aichi 446-8502 Japan, δηλώνει

τι αυτ το προϊν

κατασκευασµένο απ την Εταιρεία Makita στην

Ιαπωνία, βρίσκεται σε συµφωνία µε τα ακλουθα

πρτυπα ή τυποποιηµένα έγγραφα,

σύµφωνα µε τις Οδηγίες του Συµβουλίου, 89/336/EEC

και 98/37/KE.

∆ΗΛΩΣΗ ΣΥΜΜΟΡΦΩΣΗΣ ΕΚ

(Αύξων Αρ.: παραγωγή σειράς)

EN50260, EN55014

36

Yasuhiko Kanzaki

CE 99

Director Direktor

Direktør Johtaja

Direktör ∆ιευθυντής

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

Page 10

ENGLISH

The typical A-weighted noise levels are

The typical weighted root mean square acceleration

value is 6 m/s

Noise and Vibration

sound pressure level: 93 dB (A)

sound power level: 106dB (A)

– Wear ear protection. –

2

.

FRANÇAISE

Les niveaux de bruit pondérés A types sont:

niveau de pression sonore: 93 dB (A)

niveau de puissance du son: 106 dB (A)

Bruit et vibrations

– Porter des protecteurs anti-bruit. –

L’accélération pondérée est de 6 m/s

2

.

DEUTSCH

Geräusch- und Vibrationsentwicklung

Die typischen A-bewerteten Geräuschpegel betragen:

Schalldruckpegel: 93 dB (A)

Schalleistungspegel: 106 dB (A)

– Gehörschutz tragen. –

Der gewichtete Effektivwert der Beschleunigung beträgt

2

.

6m/s

ITALIANO

I livelli del rumore pesati secondo la curva A sono:

Il valore quadratico medio di accellerazione è di 6 m/s

Rumore e vibrazione

Livello pressione sonora: 93 dB (A)

Livello potenza sonora: 106 dB (A)

– Indossare i paraorecchi. –

2

NEDERLANDS

De typische A-gewogen geluidsniveau’s zijn

De typische gewogen effectieve versnellingswaarde is

2

6m/s

Geluidsniveau en trilling

geluidsdrukniveau: 93 dB (A)

geluidsenergie-niveau: 106 dB (A)

– Draag oorbeschermers. –

.

ESPAÑOL

Los niveles típicos de ruido ponderados A son

El valor ponderado de la aceleración es de 6 m/s

Ruido y vibración

presión sonora: 93 dB (A)

nivel de potencia sonora: 106 dB (A)

– Póngase protectores en los oídos. –

2

.

PORTUGUÊS

Os níveis normais de ruído A são

O valor médio da aceleração é 6 m/s

Ruído e vibração

nível de pressão de som: 93 dB (A)

nível do sum: 106 dB (A)

– Utilize protectores para os ouvidos –

2

.

DANSK

De typiske A-vægtede lydniveauer er

Den vægtede effektive accelerationsværdi er 6 m/s

Lyd og vibration

lydtryksniveau: 93 dB (A)

lydeffektniveau: 106 dB (A)

– Bær høreværn. –

SVENSKA

De typiska A-vägda bullernivåerna är

Det typiskt vägda effektivvärdet för acceleration är

2

.

6m/s

Buller och vibration

ljudtrycksnivå: 93 dB (A)

ljudeffektnivå: 106 dB (A)

– Använd hörselskydd –

NORSK

De vanlige A-belastede støynivå er

.

Den vanlig belastede effektiv-verdi for akselerasjon er

2

.

6m/s

Støy og vibrasjon

lydtrykksnivå: 93 dB (A)

lydstyrkenivå: 106dB (A)

– Benytt hørselvern. –

SUOMI

Tyypilliset A-painotetut melutasot ovat

Tyypillinen kiihtyvyyden painotettu tehollisarvo on

2

.

6m/s

melutaso ja tärinä

äänenpainetaso: 93 dB (A)

äänen tehotaso: 106 dB (A)

– Käytä kuulosuojaimia. –

ΕΛΛΗΝΙΚΑ

Οι τυπικές A-µετρούµενες εντάσεις ήχου είναι

Η τυπική αξία της µετρούµενης ρίζας του µέσου

τετραγώνου της επιτάχυνσης είναι 6 m/s

Θρυβος και κραδασµς

πίεση ήχου: 93dB (A)

δύναµη του ήχου: 106dB (A)

– Φοράτε ωτοασπίδες. –

2

.

2

.

37

Page 11

38

Page 12

39

Page 13

Makita Corporation

884287D997

Loading...

Loading...