Page 1

Impact Wrench

Instruction Manual

Schlagschrauber

Betriebsanleitung

Klucz udarowy

Instrukcja obsługi

Гаечный ключ ударного действия

Инструкция по эксплуатации

6905B

6906

Page 2

1

2

1

3

4

5

2

6

3

7

8

4

5

2

Page 3

Symbols

The followings show the symbols used for the tool. Be sure that you understand their meaning before use.

Symbole

Die folgenden Symbole werden für die Maschine verwendet. Machen Sie sich vor der Benutzung unbedingt

mit ihrer Bedeutung vertraut.

Symbole

Poniższe symbole używane są do opisu urządzenia. Przed użyciem należy upewnić się, że rozumie się ich

znaczenie.

Символы

Следующие объяснения показывают символы, используемые для инструмента. Убедитесь перед

использованием, что Вы понимаете их значение.

❏ Read instruction manual.

❏ Bitte Betriebsanleitung lesen.

Przeczytaj instrukcję obsługi.

❏

❏

Прочитайте инструкцию по эксплуатации.

❏ DOUBLE INSULATION

❏ DOPPELT SCHUTZISOLIERT

PODWÓJNA IZOLACJA

❏

❏

ДВОЙНАЯ ИЗОЛЯЦИЯ

3

Page 4

ENGLISH

Explanation of general view

1 Socket

2Anvil

3 Counterclockwise

4 Reversible switch

5 Clockwise

6 Limit mark

7 Screwdriver

8 Brush holder cap

SPECIFICATIONS

MODEL 6905B 6906

Capacities

Bolt size ............................................................................. 12 mm – 20 mm 16 mm – 22 mm

Square drive ...................................................................... 12.7 mm 19 mm

Impacts per minute .............................................................. 2,000 1,600

No load speed (min

Tightening torque ................................................................. 3,000 kg•cm 6,000 kg•cm

Overall length ....................................................................... 270 mm 327 mm

Net weight ............................................................................ 2.7 kg 5.0 kg

• Due to our continuing program of research and

development, the specifications herein are subject

to change without notice.

• Note: Specifications may differ from country to

country.

Power supply

The tool should be connected only to a power supply

of the same voltage as indicated on the nameplate,

and can only be operated on single-phase AC supply.

They are double-insulated in accordance with European Standard and can, therefore, also be used from

sockets without earth wire.

SAFETY INSTRUCTIONS

Warning! When using electric tools, basic safety

precautions should always be followed to reduce

the risk of fire, electric shock and personal injury,

including the following. Read all these instructions before attempting to operate this product

and save these instructions.

For safe operation:

1. Keep work area clean

Cluttered areas and benches invite injuries.

2. Consider work area environment

Don’t expose power tools to rain. Don’t use

power tools in damp or wet locations. Keep work

area well lit. Don’t use power tools in presence of

flammable liquids or gases.

3. Guard against electric shock

Prevent body contact with grounded surfaces

(e.g. pipes, radiators, ranges, refrigerators).

4. Keep children away

Do not let visitors contact tool or extension cord.

All visitors should be kept away from work area.

5. Store idle tools

When not in use, tools should be stored in dry,

high, or locked-up place, out of the reach of children.

–1

) ......................................................... 1,700 1,700

6. Don’t force tool

It will do the job better and safer at the rate for

which it was intended.

7. Use right tool

Don’t force small tools or attachments to do the

job of a heavy duty tool. Don’t use tools for purposes not intended; for example, don’t use circular saw for cutting tree limbs or logs.

8. Dress properly

Do not wear loose clothing or jewelry. They can

be caught in moving parts. Rubber gloves and

non-skid footwear are recommended when working outdoors. Wear protective hair covering to

contain long hair.

9. Use safety glasses and hearing protection

Also use face or dust mask if cutting operation is

dusty.

10. Connect dust extraction equipment

If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used.

11. Don’t abuse cord

Never carry tool by cord or yank it to disconnect it

from receptacle. Keep cord from heat, oil and

sharp edges.

12. Secure work

Use clamps or a vise to hold work. It’s safer than

using your hand and it frees both hands to operate tool.

13. Don’t overreach

Keep proper footing and balance at all times.

14. Maintain tools with care

Keep tools sharp and clean for better and safer

performance. Follow instructions for lubricating

and changing accessories. Inspect tool cords

periodically and, if damaged, have repaired by

authorized service facility. Inspect extension

cords periodically and replace if damaged. Keep

handles dry, clean and free from oil and grease.

4

Page 5

15. Disconnect tools

When not in use, before servicing, and when

changing accessories such as blades, bits and

cutters.

16. Remove adjusting keys and wrenches

Form the habit of checking to see that keys and

adjusting wrenches are removed from tool before

turning it on.

17. Avoid unintentional starting

Don’t carry plugged-in tool with finger on switch.

Be sure switch is off when plugging in.

18. Outdoor use extension cords

When tool is used outdoors, use only extension

cords intended for use outdoors and so marked.

19. Stay alert

Watch what you are doing. Use common sense.

Do not operate tool when you are tired.

20. Check damaged parts

Before further use of the tool, a guard or other

part that is damaged should be carefully checked

to determine that it will operate properly and perform its intended function. Check for alignment of

moving parts, binding of moving parts, breakage

of parts, mounting, and any other conditions that

may affect its operation. A guard or other part

that is damaged should be properly repaired or

replaced by an authorized service center unless

otherwise indicated elsewhere in this instruction

manual. Have defective switches replaced by

and authorized service center. Do not use tool if

switch does not turn it on and off.

21. Warning

The use of any other accessory or attachment

other than recommended in this operating

instruction or the catalog may present a risk of

personal injury.

22. Have your tool repaired by an expert

This electric appliance is in accordance with the

relevant safety rules. Repairing of electric appliances may be carried out only by experts otherwise it may cause considerable danger for the

user.

ADDITIONAL SAFETY RULES

FOR TOOL

1. Wear ear protectors.

2. Check the socket carefully for wear, cracks or

damage before installation.

3. Hold the tool firmly.

4. Always be sure you have a firm footing. Be

sure no one is below when using the tool in

high locations.

5. The proper tightening torque may differ

depending upon the kind or size of the bolt.

Check the torque with a torque wrench.

SAVE THESE INSTRUCTIONS.

OPERATING INSTRUCTIONS

Holding the tool

Hold the tool firmly with one hand on the gripping

part of the tool and the other hand on the side grip

when performing the tool.

Selecting correct socket

Use a correct size socket for bolts and nuts. A wrong

size socket will result in inaccurate and inconsistent

tightening torque.

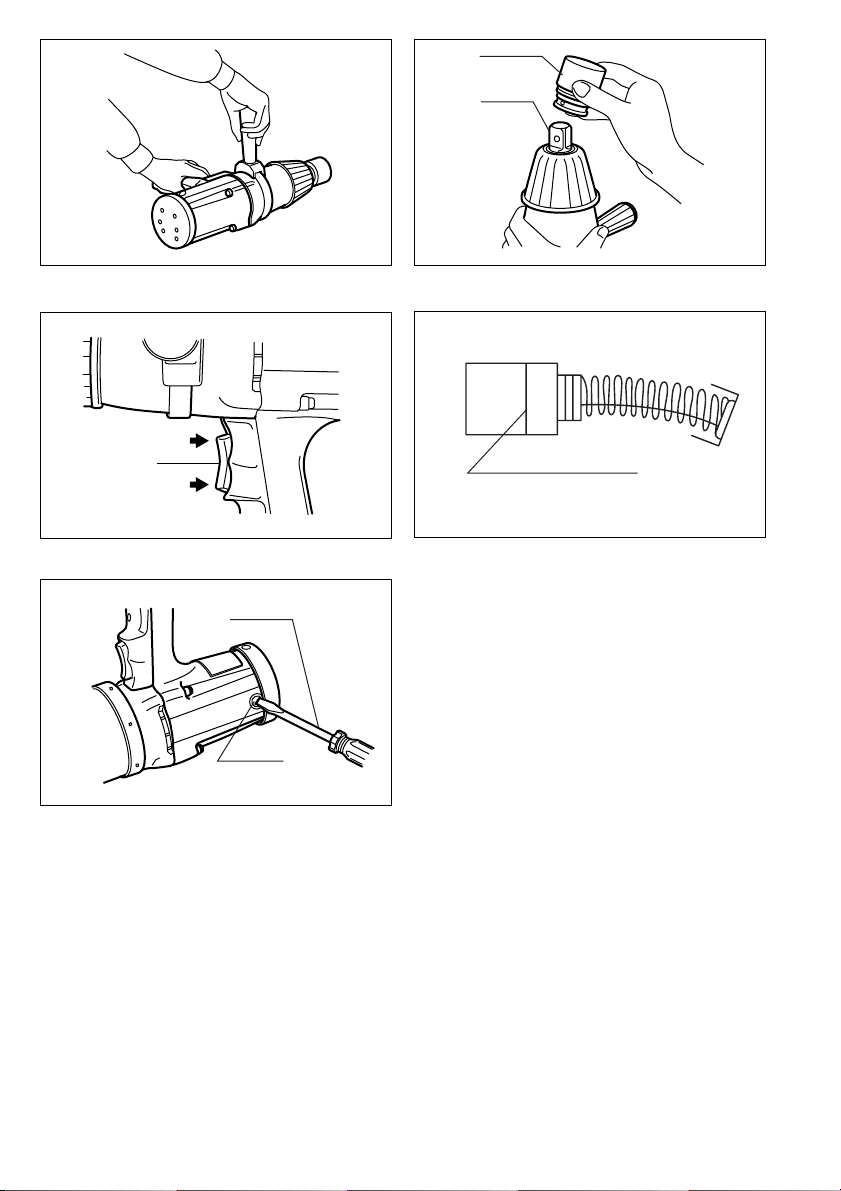

Installing the side grip (Fig. 1)

For 6906 only

Fit the side grip into the groove on the middle of the

hammer case and fasten securely.

Attaching the socket (Fig. 2)

Selecting a proper socket in size, please insert it into

the anvil so as to fix securely.

Switch action (Fig. 3)

CAUTION:

• Before plugging in the tool, always check to see

that the switch trigger actuates properly and returns

to the “OFF” position when released.

• Change the direction of rotation only after the tool

comes to a complete stop. Changing it before the

tool stops may damage the tool.

The switch is reversible, providing either clockwise or

counterclockwise rotation. To start the tool, simply

pull the lower part of the switch for clockwise, the

upper part for counterclockwise. Release the switch

to stop.

5

Page 6

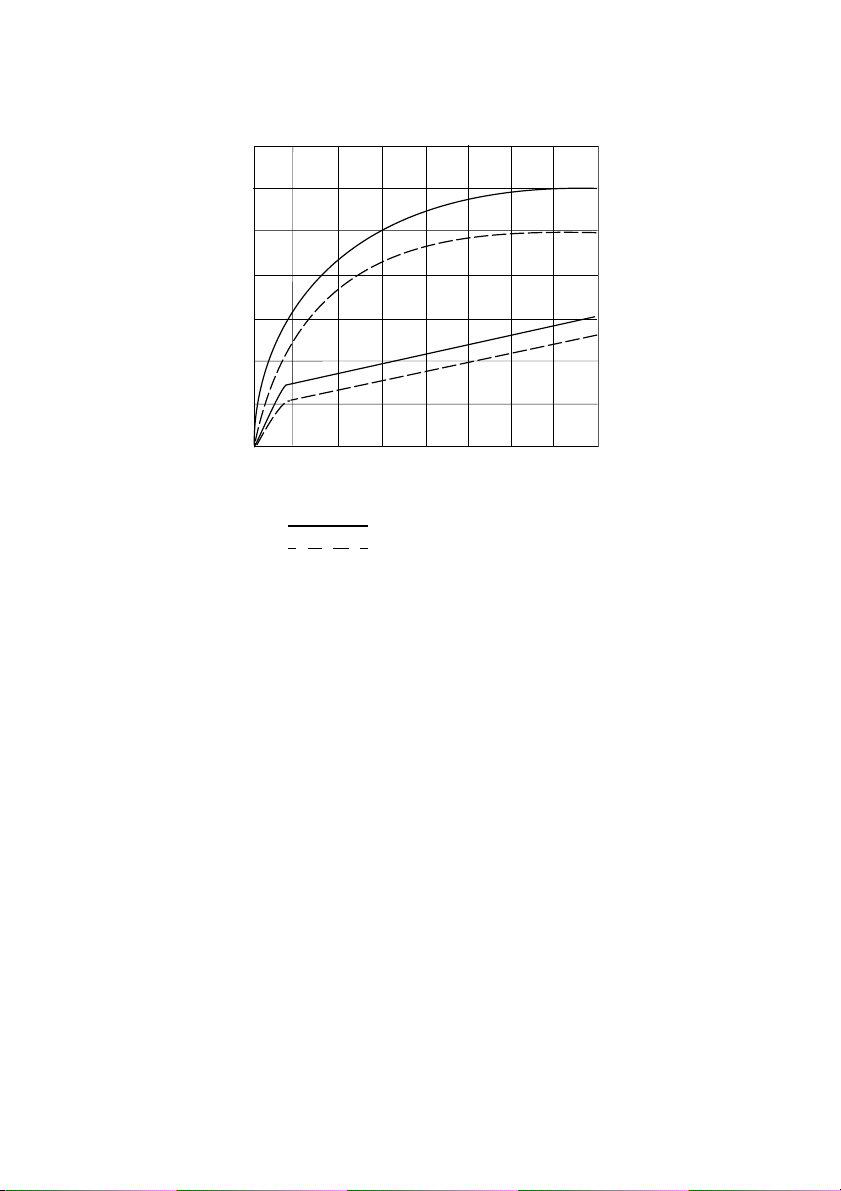

Operation

The proper tightening torque may differ depending upon the kind or size of the bolt. The relation between tightening torque and tightening time is shown in the figure below.

kg•cm

7,000

6,000

For 6906

5,000

4,000

3,000

Tightening torque

2,000

1,000

012345678

Tightennig time

Rated voltage

90% of rated voltage

For 6905B

seconds

Hold the tool firmly and place the socket over the bolt or nut. Turn the tool on and tighten for the proper tightening time.

NOTE:

• Hold the tool pointed straight at the bolt or nut without applying excessive pressure on the tool.

• Excessive tightening torque may damage the bolt or nut.

The tightening torque is affected by a wide variety of

factors including the following. After tightening,

always check the torque with a torque wrench.

1. Socket

• Failure to use the correct size socket will cause

a reduction in the tightening torque.

3. The use of the universal joint or the extension

bar somewhat reduces the tightening force of the

impact wrench. Compensate by tightening for a

longer period of time.

4. The manner of holding the tool will affect the

torque.

• A worn socket (wear on the hex end or square

end) will cause a reduction in the tightening

torque.

2. Bolt

• Even though the torque coefficient and the

class of bolt are the same, the proper tightening torque will differ according to the diameter

of bolt.

• Even though the diameters of bolts are the

same, the proper tightening torque will differ

according to the torque coefficient, the class of

bolt and the bolt length.

MAINTENANCE

CAUTION:

Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Replacement of carbon brushes (Fig. 4 & 5)

Replace carbon brushes when they are worn down to

the limit mark. Both identical carbon brushes should

be replaced at the same time.

To maintain product safety and reliability, repairs,

maintenance or adjustment should be carried out by

a Makita Authorized Service Center.

6

Page 7

Noise and Vibration of Model 6905B

The typical A-weighted noise levels are

The typical weighted root mean square acceleration value is 5 m/s

sound pressure level: 95 dB (A)

sound power level: 108 dB (A)

– Wear ear protection. –

2

.

Noise and Vibration of Model 6906

The typical A-weighted noise levels are

The typical weighted root mean square acceleration value is 3 m/s

sound pressure level: 94 dB (A)

sound power level: 107 dB (A)

– Wear ear protection. –

2

.

EC-DECLARATION OF CONFORMITY

We declare under our sole responsibility that this

product is in compliance with the following standards or standardized documents,

HD400, EN50144, EN55014, EN61000

in accordance with Council Directives, 73/23/EEC,

89/336EEC and 98/37/EC.

Yasuhiko Kanzaki

Director

CE94

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

7

Page 8

DEUTSCH

Übersicht

1 Steckschlüsseleinsatz

2 Werkzeugaufnahme

3 Linkslauf

4 Wippschalter

5 Rechtslauf

6 Verschleißgrenze

7 Schraubendreher

8 Bürstenhalterkappe

TECHNISCHE DATEN

Modell 6905B 6906

Arbeitsleistung

Schraubengröße................................................................. 12 mm – 20 mm 16 mm – 22 mm

Vierkantantrieb ................................................................... 12,7 mm 19 mm

Schlagzahl ............................................................................ 2 000 min

Leerlaufdrehzahl ................................................................... 1 700 min

Drehmoment ......................................................................... 300Nm 600 Nm

Gesamtlänge......................................................................... 270mm 327 mm

Gewicht ................................................................................. 2,7 kg 5,0 kg

• Wir behalten uns vor, Änderungen im Zuge der Ent-

wicklung und des technischen Fortschritts ohne

vorherige Ankündigung vorzunehmen.

• Hinweis: Die technischen Daten können von Land

zu Land abweichen.

Netzanschluß

Die Maschine darf nur an die auf dem Typenschild

angegebene Netzspannung angeschlossen werden

und arbeitet nur mit Einphasen- Wechselspannung.

Sie ist entsprechend den Europäischen Richtlinien

doppelt schutzisoliert und kann daher auch an Steckdosen ohne Erdanschluß betrieben werden.

SICHERHEITSHINWEISE

Achtung! Beim Gebrauch von Elektrowerkzeugen

sind zum Schutz gegen elektrischen Schlag. Verletzungsund Brandgefahr folgende grundsätzlichen Sicherheitsmaßnahmen zu geachten.

Lesen und beachten Sie diese Hinweise, bevor

Sie das Gerät benutzen.

1. Halten Sie Ihren Arbeitsbereich in Ordnung

Unordnung im Arbeitsbereich ergibt Unfallgefahr.

2. Berücksichtigen Sie Umgebungseinflüsse

Setzen sie Elektrowerkzeuge nicht dem Regen

aus. Benützen Sie Elektrowerkzeuge nicht in

feuchter oder nasser Umgebung. Sorgen Sie für

gute Beleuchtung. Benützen Sie Elektrowerkzeuge nicht in Nähe von brennbaren Flüssigkeiten oder Gasen.

3. Schützen Sie sich vor elektrischem Schlag

Vermeiden Sie Körperberührung mit geerdeten

Teilen, zum Beispiel Rohren, Heizkörpern, Herden, kühlschränken.

4. Halten Sie Kinder fern!

Lassen Sie andere Personen nicht das Werkzeug oder Kabel berühren, halten Sie sie von

Ihrem Arbeitsbereich fern.

5. Bewahren Sie Ihre Werkzeuge sicher auf

6. Überlasten Sie Ihr Werkzeug nicht

7. Benützen Sie das richtige Werkzeug

8. Tragen Sie geeignete Arbeitskleidung

9. Schutzbrille und Gehörschutz tragen

10. Schlleßen Sie eine Staubabsaugvorrichtung

11. Zweckentfremden Sie nicht das Kabel

12. Sichern Sie das Werkstück

-1

1 600 min-1

-1

1 700 min-1

Unbenutzte Werkzeuge sollten in trockenem,

verschlossenem Raum und für Kinder nicht

erreichbar aufbewahrt werden.

Sie arbeiten besser und sicherer im angegebenen Leistungsbereich.

Verwenden Sie keine zu schwachen Werkzeuge

oder Vorsatzgeräte für schwere Arbeiten.

Benützen Sie Werkzeuge nicht für Zwecke und

Arbeiten, Wofür sie nicht bestimmt sind; zum

Beispiel benützen Sie keine Handkreissäge, um

Bäume zu flällen oder Äste zu schneiden.

Tragen Sie keine weite Kleidung oder Schmuck.

Sie können von beweglichen Teilen erfaßt werden. Bei Arbeiten im Freien sind Gummihandschuhe und rutschfestes Schuhwerk

empfehlenswert. Tragen Sie bei langen Haaren

ein Haarnetz.

Verwenden Sie eine Atemmaske bei stauberzeugenden Arbeiten.

an

Wenn Geräte für den Anschluß von Staubabsaug-und-sammelvorrichtungen ausgelegt sind,

sorgen Sie dafür, daß Jiese angeschlossen und

korrekt benutzi werden.

Tragen Sie das Werkzeug nicht am Kabel, und

benützen Sie es nicht, um den Stecker aus der

Steckdose zu ziehen. Schützen Sie das Kabel

vor Hitze, Öl und scharfen Kanten.

Benützen Sie Spannvorrichtungen oder einen

Schraubstock, um das Werkstück festzuhalten.

Es ist damit sicherer gehalten als mit Ihrer Hand

und ermöglicht die Bedienung der Maschine mit

beiden Händen.

8

Page 9

13. Überdehnen Sie nicht Ihren Standbereich

Vermeiden Sie abnormale Körperhaltung. Sorgen Sie für sicheren Stand, und halten Sie jederzeit das Gleichgewicht.

14. Pflegen Sie Ihre Werkzeuge mit Sorgtalt

Halten Sie Ihre Werkzeuge scharf und sauber,

um gut und sicher zu arbeiten. Befolgen Sie die

Wartungsvorschriften und die Hinweise für

Werkzeugwechsel. Kontrollieren Sie regelmäßig

den Stecker und das Kabel, und lassen Sie

diese bei Beschädigung von einem anerkannten

Fachmann erneuern.

Kontrollieren Sie Verlängerungskabel regelmäßig und ersetzen Sie beschädigte. Halten Sie

Handgriffe trocken und frei von Öl und Fett.

15. Ziehen Sie den Netzstecker

Bei Nichtgebrauch, vor der Wartung und beim

Werkzeugwechsel, wie zum Beispiel Sägeblatt,

Bohrer und Maschinenwerkzeugen aller Art.

16. Lassen Sie keine Werkzeugschlüssel stecken

Überprüfen Sie vor dem Einschalten, daß die

Schlüssel und Einstellwerkzeuge entfernt sind.

17. Vermeiden Sie unbeabsichtigten Anlauf

Tragen Sie keine an das Stromnetz angeschlossene Werkzeuge mit dem Finger am Schalter.

Vergewissern Sie sich, daß der Schalter beim

Anschluß an das Stromnetz ausgeschaltet ist.

18. Verlängerungskabel im Freien

Verwenden Sie im Freien nur dafür zugelassene

und entsprechend gekennzeichnete Varlängerungskabel.

19. Seien Sie stets aufmerksam

Beobachten Sie Ihre Arbeit. Gehen Sie vernünftig vor. Verwenden Sie das Werkzeug nicht,

wenn Sie unkonzentriert sind.

20. Kontrollieren Sie Ihr Gerät auf Beschädigungen

Vor weiterem Gebrauch des Werkzeugs die

Schutzeinrichtungen oder leicht beschädigte

Teile sorgfältig auf ihre einwandfreie und bestimmungsgemäße Funktion überprüfen. Überprüfen Sie, ob die Funktion beweglicher Teile in

Ordnung ist, ob sie nicht klemmen onder ob Teile

beschädigt sind. Sämtliche Teile müssen richtig

montiert sein und alle Bedingungen erfüllen, um

den einwandfreien Betrieb des Gerätes zu

gewährleisten.

Beschädigte Schutzvorrichtungen und Teile sollen sachgemäß durch eine Kundendienstwerkstatt repariert oder ausgewechselt werden,

soweit nichts anderes in den Betriebsanleitungen angegeben ist. Beschädigte Schalter müssen bei einer Kundendienstwerkstatt ersetzt

werden. Benutzen Sie keine Werkzeuge, bei

denen sich der Schalter nicht ein und ausschalten läßt.

21. Achtung!

Zu Ihrer eigenen Sicherheit, benützen Sie nur

Zubehör und Zusatzgeräte, die in der Bedienungsanleitung angegeben oder vom WerkzeugHersteller empfohlen oder angegeben werden.

Der Gebrauch anderer als der in der Bedienungsanleitung oder im Katalog empfohlenen

Einsatzwerkzeuge oder Zubehöre kann eine persönliche Verletzungsgefahr für Sie bedeuten.

22. Reparaturen nur vom Elektrofachmann.

Dieses Elektrowerkzeug entspricht den einschlägigen Sicherheitsbestimmungen. Reparaturen

dürfen nur von einer Elektrofachkraft ausgeführt

werden, andernfalls können Unfälle für den

Betreiber entstehen.

ZUSÄTZLICHE

SICHERHEITSBESTIMMUNGEN

1. Tragen Sie stets einen Gehörschultz.

2. Prüfen Sie den Steckschlüsseleinsatz vor der

Montage sorfältig auf Abnutzung, Risse oder

Beschädigungen.

3. Halten Sie die Maschine fest.

4. Sorgen Sie für sicheren Stand und halten Sie

jederzeit Gleichgewicht. Stellen Sie sicher,

daß sich bei Einsatz der Maschine en hochgelegenen Arbeitsplätzen keine Personen

darunter aufhalten.

5. Das richtige Drehmoment ist von der Schraubenlänge und Schraubenart abhängig. Kontrollieren Sie das Drehmoment mit einem

Drehmomentschlüssel.

BEWAHREN SIE DIESE HINWEISE

SORGFÄ LTIG AUF.

9

Page 10

BEDIENUNGSHINWEISE

Halten der Maschine

Halten Sie die Maschine bei der Arbeit mit der einen

Hand am Griffteil und mit der anderen am Seitengriff.

Wahl des Steckschlüsseleinsatzes

Verwenden Sie für Schrauben oder Muttern gleiche

Schlüsselweiten der Steckschlüsseleinsätze. Nicht

aufeinander abgestimmte Schlüsselweiten verfälschen das Drehmoment und beschädigen den Steckschlüsseleinsatz sowie den Schraubenkopf.

Montage des Seitengriffs (Abb. 1)

Schalterfunktion (Abb. 3)

VORSICHT:

• Vor dem Anschlißen der Maschine an das Stromnetz stets überprüfen, ob der Wippschalter ordnungsgemäß funktioniert und beim Loslassen in die

AUS-Stellung zurückkehrt.

• Wechseln Sie niemals die Drehrichtung, bevor der

Motor zum Stillstand gekommen ist. Andernfalls

kann die Maschine beschädigt werden.

Die Maschine ist für Rechts- und Linslauf ausgelegt.

Für Rechtslauf den unteren Teil des Wippschalters

drücken, für linkslauf den oberen. Zum Aussschalten

lassen Sie den Schalter los.

Nur für 6906

Das Spannband des Zusatzgriffs ist in der Aussparung des Maschinengehäuses zu positionieren und

anschließend zu sichern.

Montage des Steckschlüsseleinsatzes (Abb. 2)

Wählen Sie die passende Steckschlüsseleinsatzgröße. Zur Befestigung den Steckschlüsseleinsatz

auf die Werkzeugaufnahme setzen.

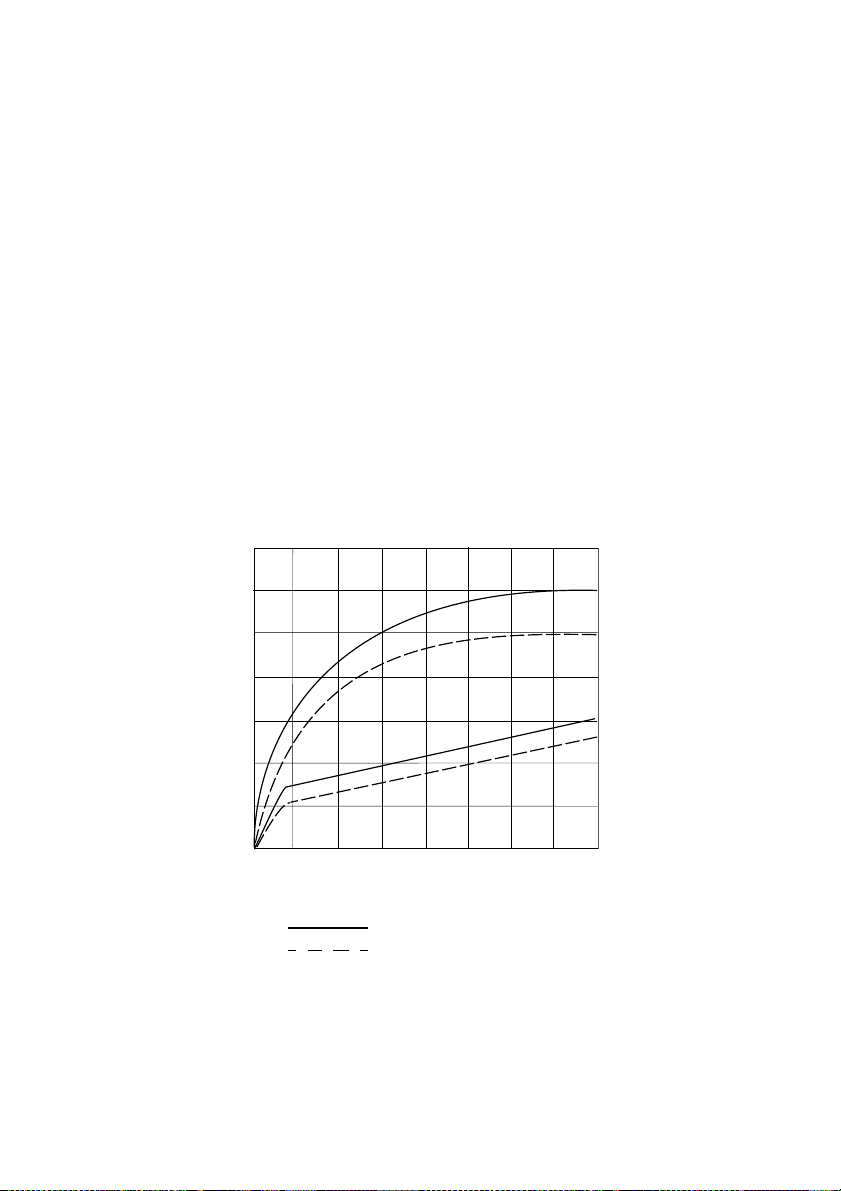

Bedienung

Das richtige Drehmoment wird von der Schraubengröße und -festigkeit bestimmt. Das nachfolgende Diagramm zeigt die entsprechenden Zusammenhänge.

Nm

7 00

6 00

Für 6906

5 00

4 00

Drehmoment

3 00

2 00

1 00

012345678

Einschraubzeit

Nennspannung

90% der Nennspannung

Für 6905B

Sakunden

Halten Sie die Maschine fest und setzen Sie den Steckschlüsseleinsatz auf die Schraube oder Mutter. Ziehen

Sie unter Berücksichtigung der Einschraubzeit die Schraubverbindung an.

HINWEIS:

• Die Maschine senkrecht zur Verschraubung halten und keinen übermäßigen Druck ausüben.

• Ein zu hohes Drehmoment kann zur Beschädigung der Schraubverbindung führen.

10

Page 11

Nach dem Anzugsvorgang sollte das richtige Drehmoment mit einem Drehmomentschlüssel kontrolliert

und ggf. nachgezogen werden.

Das drehmoment unterliegt verschiedener Einfluß-

größen und Faktoren wie z. B.

1. Steckschlüsseleinsatz

• Ungleiche Schlüsselweiten der Steckschlüsseleinsätze und Schraubverbindungen vermindern das Drehmoment.

• Ein abgenutzter Steckschlüsseleinsatz (Abnutzung am Sechskant oder Antriebs-Vierkant)

verringert das Drehmoment.

2. Schrauben

• Das Drehmoment ist bei gleichem Schraubentyp bzw. Schraubfall abhängig vom Schraubendurchmesser.

• Schraubenlänge und Schraubenart bestimmen bei gleichem Schraubdurchmesser das

erzielbare Drehmoment.

3. Bei Benutzung von Gelenkstücken, Verlängerun-

gen, etc. wird das Drehmoment verrigert. Durch

längere Einschraubzeit kann entgegengewirkt

werden.

4. Die Handhabung der Maschine beeinflusst das

Drehmoment.

WARTUNG

VORSICHT:

Vor Arbeiten an der Maschine vergewissern Sie sich,

daß sich der Schalter in der “OFF-’’ Position befindet

und der Netzstecker gezogen ist.

Kohlebürsten wechseln (Abb.4 u.5)

Kohlebürsten ersetzen, wenn sie bis auf die Verschleißgrenze abgenutzt sind. Beide Kohlebürsten

nur paarweise ersetzen.

Um die Sicherheit und Zuverlässigkeit dieses Gerä-

tes zu gewährleisten, sollten Reparatur-, Wartungs-,

und Einstellarbeiten nur von durch Makita autorisierten Werkstätten oder Kundendienstzentren unter

ausschließlicher Verwendung von Makita-Originalersatzteilen ausgeführt werden.

11

Page 12

Geräusch- und Vibrationsentwicklung

des Modells 6905B

Die typischen A-bewerteten Geräuschpegel betragen:

Schalldruckpegel: 95 dB (A)

Schalleistungspegel: 108 dB (A)

– Gehörschutz tragen. –

Der gewichtete Effektivwert der Beschleunigung

beträgt 5 m/s

2

.

Geräusch- und Vibrationsentwicklung

des Modells 6906

Die typischen A-bewerteten Geräuschpegel betragen:

Schalldruckpegel: 94 dB (A)

Schalleistungspegel: 107 dB (A)

– Gehörschutz tragen. –

Der gewichtete Effektivwert der Beschleunigung

beträgt 3 m/s

2

.

CE-KONFORMITÄTSERKLÄRUNG

Hiermit erklärt wir unter unserer alleinigen Verantwortung, daß dieses Produkt gemäß den Ratsdirektiven

73/23/EWG, 89/336/EWG und 98/37/EG mit den folgenden Normen bzw. Normendokumenten überein-

stimmen:

HD400, EN50144, EN55014, EN61000.

12

Yasuhiko Kanzaki

CE94

Direktor

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

Page 13

POLSKI

Wyjaśnienia dotyczące urządzenia i jego użycia

1Gniazdo

2Kowadełko

3 Przeciwnie do ruchu

wskazówek zegara

4 Przełącznik dwukierunkowy

5 Zgodnie z ruchem

wskazówek zegara

6 Znak limitu

7Śrubokręt

8 Pokrywa pojemnika na

szczoteczkę

DANE TECHNICZNE

Model 6905B 6906

Rozmiary dokręcanych śrub

Rozmiar śruby ................................................................... 12 mm – 20 mm 16 mm – 22 mm

Gniazdo kwadratowe......................................................... 12,7 mm 19mm

Liczba uderzeń na minutę .................................................... 2000 1600

Prędkość bez obciążenia (min

Moment dokręcenia ............................................................. 3000 kg

–1

) ......................................... 1700 1700

•

cm 6000kg•cm

Całkowita długość ............................................................... 270 mm 327mm

Ciężar netto ......................................................................... 2,7 kg 5,0 kg

•

Ze względu na prowadzony program udoskonaleń i

badań, podane dane techniczne mogą zostać

zmienione bez uprzedzenia.

•

Uwaga: Dane techniczne mogą się różnić w

zależności od kraju.

Zasilanie

Urządzenie to, powinno być podłączone tylko do

źródła zasilania o takim samym napięciu jak

pokazano na tabliczce znamionowej i może być

używane tylko dla zmiennego prądu jednofazowego.

Zgodnie ze standardami Unii Europejskiej

zastosowano podwójną izolację i dlatego też

możliwe jest zasilanie z gniazda bez uziemienia.

3. Chroń się przed porażeniem prądu.

Zapobiegaj kontaktom ciała z uziemionymi

powierzchniami (np. rurami, grzejnikami,

kuchenkami, lodówkami).

4. Nie pozwalaj zbliżać się dzieciom

Nie pozwalaj wizytującym osobom dotykać

urządzenia lub przedłużacza. Wszystkie

wizytujące osoby nie powinny zbliżać się do

miejsca pracy.

5. Zachowaj nieczynne urządzenia.

Nieużywane urządzenia powinny być

przechowywane w suchych, wysokich lub

zamykanych miejscach tak, aby były

niedostępne dla dzieci.

6. Nie przeciążaj urządzenia.

INSTRUKCJE BEZPIECZEŃSTWA

Ostrzeżenie! Używając urządzeń elektrycznych

podstawowe środki ostrożności muszą być

zawsze zachowane, aby zmniejszyć ryzyko

ognia, porażenia prądem i uszkodzenia ciała,

włączając poniższe urządzenia. Przeczytaj

wszystkie podane instrukcje przed próbą użycia

tego produktu i zachowaj je do wglądu.

Dla bezpiecznego użycia:

1. Utrzymuj miejsce pracy w czystości

Zabałaganione miejsca i stoły warsztatowe

sprzyjają wypadkom.

2. Zastanów się nad warunkami pracy

Nie wystawiaj urządzeń elektrycznych na

deszcz. Nie używaj urządzeń elektrycznych w

wilgotnych lub mokrych miejscach. Utrzymuj

miejsce pracy dobrze oświetlone. Nie używaj

urządzeń elektrycznych w obecności

łatwopalnych płynów lub gazów.

Wykona ono pracę lepiej i bezpieczniej, pracując

w sposób, dla którego zostało ono

zaprojektowane.

7. Używaj poprawnego urządzenia.

Nie nadużywaj małych lub dodatkowych

urządzeń do wykonania pracy urządzeń do

dużej pracy. Nie używaj urządzeń do celów, do

których nie zostały przeznaczone; na przykład,

nie używaj piły tarczowej do przecinania gałęzi

lub kłód drzew.

8. Ubierz się odpowiednio

Nie noś luźnych ubrań lub biżuterii. Mogą one

zostać zahaczone o ruchome części. Gumowe

rękawiczki i przeciwpoślizgowe buty są

wskazane przy pracy na dworze. Zaleca się

noszenie ochrony na głowę przytrzymującej

długie włosy.

9. Użyj okularów ochronnych i ochraniaczy

uszu.

Użyj masek na twarz lub masek

przeciwpyłowych jeżeli czynność cięcia

wytwarza pyły.

1313

Page 14

10. Podłącz urządzenie usuwające pył.

Jeżeli urządzenia posiadają podłączenia do

urządzeń do usuwania i składowania pyłu,

upewnij się, że są one poprawnie podłączone i

użyte.

11. Uważaj na przewód sieciowy

Nigdy nie noś urządzenia trzymając za przewód i

nie odłączaj go od gniazda przez pociągnięcie

przewodu. Chroń przewód przed ciepłem,

olejem i ostrymi krawędziami.

12. Pewnie mocuj cięte elementy.

Użyj ścisków lub imadła do zamocowania

ciętych elementów. Jest to bezpieczniejsze niż

używanie rąk, a dodatkowo zwalnia obie ręce do

obsługiwania piły.

13. Używając piłę, nie oddalaj jej zbytnio od

siebie.

Cały czas trzymaj dobrze ustawione nogi i

równowagę.

14. Pamiętaj o dobrej konserwacji urządzenia.

Utrzymuj urządzenie ostre i czyste dla jego

lepszego i bezpieczniejszego działania. Wykonaj

podane instrukcje w celu smarowania lub

wymiany elementów wyposażenia. Regularnie

sprawdzaj przewody urządzenia, i jeżeli są

uszkodzone, oddaj je do naprawy do

autoryzowanego serwisu. Regularnie sprawdzaj

przewody przedłużające i wymień je, jeżeli są

uszkodzone. Utrzymuj uchwyty suche, czyste i

nie zabrudzone olejem lub smarem.

15. Odłącz urządzenia

Przed konserwacją urządzenia lub zmianą

wyposażenia takiego jak tarcze, noże do struga i

noże do frezowania, gdy nie jest ono używane.

16. Wyjmij klucze regulacyjne

Nabierz zwyczaju sprawdzania czy klucze

regulacyjne są usunięte z urządzenia przed jego

użyciem.

17. Unikaj przypadkowych uruchomień.

Nie noś podłączonego urządzenia z palcem na

włączniku. Upewnij się, że urządzenie jest

wyłączone, gdy je podłączasz do zasilania.

18. Zastosuj przedłużacz używając urządzenia

na dworze.

Gdy urządzenie używane jest na dworze, stosuj

tylko przedłużacze przeznaczone i oznaczone

do pracy na dworze.

19. Bądź uważny

Patrz co robisz. Bądź rozsądny. Nie używaj

urządzenia, gdy jesteś zmęczony.

20. Sprawdzaj uszkodzone części.

Przed dalszym użyciem urządzenia, osłona lub

inne części, które są uszkodzone, muszą być

uważnie sprawdzone, aby upewnić się, że będą

poprawnie działać i wykonywać przeznaczone

im funkcje. Sprawdzaj ustawienia ruchomych

części, oprawy ruchomych części, pęknięcia

części, zamocowania, i jakiekolwiek inne

warunki, które mogą wpływać na działanie.

Osłona lub inne części, które są uszkodzone,

powinny być naprawione lub wymienione przez

autoryzowany serwis, jeżeli w instrukcji nie

podano inaczej. Uszkodzone przełączniki

powinny być wymienione przez autoryzowany

serwis. Nie używaj urządzenia, jeżeli włącznik

nie może go włączyć lub wyłączyć.

21. Ostrzeżenie

Użycie jakiegokolwiek innego wyposażenia lub

części dodatkowych innych niż zalecane w tej

instrukcji obsługi lub katalogu, może stworzyć

ryzyko uszkodzenia ciała.

22. Naprawy urządzenia powinny być

wykonywane tylko przez specjalistę.

To urządzenie jest wykonane zgodnie z

odpowiednimi zasadami bezpieczeństwa.

Naprawa urządzeń elektrycznych może być

wykonana wyłącznie przez specjalistę, gdyż w

przeciwnym wypadku może ono stanowić

zagrożenie dla użytkownika.

DODATKOWE INSTRUKCJE

BEZPIECZEŃSTWA

1. Zakładaj ochraniacze na uszy.

2. Przed założeniem sprawdź, czy gniazdo nie

jest zużyte, popękane lub uszkodzone.

3. Trzymaj urządzenie pewnie.

4. Zawsze upewnij się, że stoisz na pewnej

podstawie. Podczas używania urządzenia na

wysokościach, upewnij się, czy pod Tobą nie

ma żadnych osób.

5. Właściwy moment dokręcenia może różnić

się w zależności od rodzaju i rozmiaru śruby.

Sprawdź moment kluczem

dynamometrycznym.

ZACHOWAJ TĘ INSTRUKCJĘ.

1414

Page 15

INSTRUKCJA OBSŁUGI

Trzymanie urządzia

Podczas pracy trzymaj mocno urządzie jedną ręką

za uchwyt, a drugą za rękojeść boczną.

Wybór właściwego gniazda

Do śrub i nakrętek używaj gniazda o właściwym

rozmiarze. Gniazdo o niewłaściwym rozmiarze może

dać niedokładny i niezgodny moment dokręcenia.

Zakładanie uchwytu bocznego (Rys. 1)

Tylko model 6906

Włóż uchwyt boczny w bruzdę w środku obudowy

młotka i pewnie zamocuj.

Zakładanie gniazda (Rys.2)

Po wybraniu gniazda o właściwym rozmiarze załóż je

na kowadełko tak, aby było pewnie zamocowane.

Działanie przełącznika (Rys. 3)

OSTRZEŻENIE:

•

Przed podłączeniem urządzenia do zasilania

zawsze sprawdź, czy spust włącznika działa

poprawnie i powraca do położenia „OFF” (Wył.) po

zwolnieniu.

•

Zmieniaj kierunek obrotów tylko po całkowitym

zatrzymaniu urządzenia. Zmiana dokonana przed

zatrzymaniem urządzenia może doprowadzić do

jego uszkodzenia.

Przełącznik jest dwukierunkowy, dając obroty

zgodne z ruchem wskazówek zegara lub przeciwne

do ruchu wskazówek zegara. Aby uruchomić

urządzenie, po prostu pociągnij za dolną część

spustu dla obrotów zgodnie z ruchem wskazówek

zegara, albo górną cześć dla obrotów przeciwnie do

ruchu wskazówek zegara. Aby zatrzymać, zwolnij

przełącznik.

Postępowanie

Właściwy moment dokręcenia może różnić się w zależności od rodzaju i rozmiaru śruby. Zależność pomiędzy

momentem dokręcenia a czasem dokręcania jest pokazana na poniższym wykresie.

•

cm

kg

7 00

6 00

5 00

4 00

Moment dokręcenia

3 00

2 00

1 00

012345678

Model 6906

Model 6905B

sekundy

Czas dokręcania

Napięcie znamionowe

90% napięcia znamionowego

Uchwyć pewnie urządzenie i umieść gniazdo nad śrubą lub nakrętką. Włącz urządzenie i dokręcaj przez

właściwy czas.

UWAGA:

•

Trzymaj urządzenie skierowane prosto w kierunku śruby lub nakrętki, nie wywierając na nie nadmiernego

nacisku.

•

Zbyt duży moment dokręcenia może uszkodzić śrubę lub nakrętkę.

1515

Page 16

Na moment dokręcenia ma wpływ wiele czynników,

między innymi poniższe. Po dokręceniu zawsze

sprawdź moment dokręcenia kluczem

dynamometrycznym.

1. Gniazdo

•

Nieużywanie właściwego rozmiaru gniazda może

doprowadzić do obniżenia momentu dokręcenia.

•

Zużyte gniazdo (zużycie końca sześciokątnego lub

kwadratowego) może doprowadzić do obniżenia

momentu dokręcenia.

2. Śruba

•

Nawet jeśli współczynnik momentu i klasa śruby są

takie same, właściwy moment dokręcenia może

się różnić zależnie od średnicy śruby.

•

Nawet jeśli średnice śrub są takie same, właściwy

moment dokręcenia może się różnić zależnie od

współczynnika momentu, klasy śruby i jej długości.

3. Stosowanie przegubu uniwersalnego lub

przedłużacza w pewnym stopniu obniża siłę

dokręcającą klucza udarowego. Skompensuj to

dokręcając dłużej.

4. Sposób trzymania urządzenia może mieć wpływ

na moment.

KONSERWACJA

OSTRZEŻENIE:

Zawsze upewnij się, że urządzenie jest wyłączone i

odłączone od zasilania przed wykonywaniem

jakichkolwiek prac nad urządzeniem.

Wymiana szczoteczek węglowych (Rys. 4 i 5)

Wymień szczoteczki węglowe, gdy są one starte do

znaku limitu. Dwie identyczne szczoteczki węglowe

powinny być wymienione w tym samym czasie.

Aby zapewnić bezpieczeństwo i niezawodność

produktu, naprawy i konserwacje lub ustawianie

powinny być wykonywane przez autoryzowany

serwis Makita.

1616

Page 17

Typowe A-ważone poziomy szumów

Szumy i Drgania 6905B

poziom ciśnienia dźwięku: 95 dB (A).

poziom dźwięku w trakcie pracy: 108 dB (A).

–

Noś ochraniacze uszu.

Typowa wartość ważonej średniej kwadratowej

przyspieszenia nie jest większa niż 5 m/s

–

2

.

Typowe A-ważone poziomy szumów

Szumy i Drgania 6906

poziom ciśnienia dźwięku: 94 dB (A).

poziom dźwięku w trakcie pracy: 107 dB (A).

–

Noś ochraniacze uszu.

–

Typowa wartość ważonej średniej kwadratowej

przyspieszenia nie jest większa niż 3 m/s

UE-DEKLARACJA ZGODNOŚCI

Oświadczamy, biorąc za to wyłączną

odpowiedzialność, że niniejszy wyrób jest zgodny

z następującymi standardami i standardowymi

dokumentami:

HD400, EN50144, EN55014, EN61000

zgodnie z Zaleceniami Rady:

73/23/EEC,

EEC i 98/37/EC.

2

.

,

89/336/

Yasuhiko Kanzaki

CE94

Dyrektor

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

1717

Page 18

РУССКИЙ ЯЗЫК

Объяснения общего плана

1Гнездо

2Пятка

3 Против часовой стрелки

ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ

Модель 6905B 6906

Функциональные возможности

Размер болта .................................................................... 12 мм – 20 мм 16 мм – 22 мм

Квадратный привод ......................................................... 12,7 мм 19 мм

Ударов в минуту ................................................................. 2000 1600

Скорость в незагруженном состоянии (мин

Крутящий момент ............................................................... 3000кг•см 6000 кг•см

Общая длина....................................................................... 270 мм 327 мм

Вес нетто ............................................................................. 2,7 кг 5,0 кг

• Вследствие нашей продолжающейся программы

поиска и разработок технические характеристики

могут быть изменены без уведомления.

• Примечание: Технические характеристики могут

различаться в зависимости от страны.

Источник питания

Инструмент должен быть подсоединен только к

источнику питания с напряжением, указанным в

табличке номиналов, и может функционировать

только от однофазного источника питания

переменного тока. В соответствии с

Европейским стандартом имеется двойная

изоляция, следовательно, возможно

использование с розетками без провода

заземления.

ИНСТРУКЦИИ ПО МЕРАМ

БЕЗОПАСНОСТИ ДЛЯ ИНСТРУМЕНТА

Предостережение! При использовании

электрических инструментов следует всегда

соблюдать основные меры безопасности для

уменьшения опасности пожара, поражения

электрическим током и персональных травм,

включая следующие.

Прочитайте эти инструкции перед тем, как

пытаться управлять этим изделием, и

сохраните эти инструкции.

Для безопасного функционирования:

1. Поддерживайте чистоту на рабочем месте

Захламленные места и подставки могут

привести к травмам.

2. Учитывайте рабочую окружающую среду

Не подвергайте инструменты с электроприводом

воздействию дождя. Не используйте

инструменты с электроприводом в сырых или

влажных местах. Поддерживайте хорошее

освещение на рабочем месте. Не используйте

инструменты с электроприводом в присутствии

возгараемы жидкостей или газов.

4 Обратимый переключатель

5 По часовой стрелке

6 Ограничительная метка

–1

) ................ 1700 1700

3. Предохраняйтесь от поражения

электрическим током

Предотвращайте контакт тела с заземленными

поверхностями (например, трубами, радиаторами,

батареями, холодильниками).

4. Держитесь подальше от детей

Не позволяйте посетителям прикасаться к

инструменту или шнуру-удлинителю. Все

посетители должны находиться подальше от

рабочей области.

5. Правильно храните неработающие

инструменты

Если инструменты не используются, они

должны храниться в сухом, высоком или

закрытом месте, вне достижения детей.

6. Не прилагайте усилие к инструменту

Он будет выполнять работу лучше и

безопаснее при скорости, для которой он

предназначен.

7. Используйте правильный инструмент

Не пытайтесь прилагать усилие к маленьким

инструментам или присоединениям для

выполнения работы инструмента тяжелого

назначения. Не используйте инструменты

для непредназначенных целей; например, не

используйте дисковую пилу для резки веток

или корней деревьев.

8. Одевайтесь правильно

Не одевайте свисающую одежду или

украшения. Они могут попасть в движущиеся

части. При работе на улице рекомендуется

одевать резиновые перчатки и нескользящую

обувь. Одевайте предохранительный головной

убор для убирания длинных волос.

9. Используйте защитные очки и

предохранительные приборы для слуха.

Если работа по резке является пыльной,

используйте также маску для лица или

пылезащитную маску

7 Отвертка

8 Крышка держателя щеток

18

Page 19

10. Подсоедините пылевсасывающее

оборудование

Если имеются подсоединения чстройств для

всасывания и сбора пыли, убедитесь в том,

что они подсоединены и используются

правильно.

11. Не прилагайте усилие к шнуру

Никогда не носите инструмент за шнур и не

дергайте за него для отсоединения его из

розетки. Держите шнур подальше от жарких

мест, масла и острых краев.

12. Закрепите рабочее изделие

Используйте зажимы или тиски для

крепления рабочего изделия. Это является

более безопасным, чем использование

Вашей руки, и при этом освобождаются две

руки для управления инструментом.

13. Не заходите слишком далеко

Сохраняйте правильную стойку и баланс все

время.

14. Осторожно обращайтесь с инструментами

Держите инструменты острыми и чистыми для

более лучшей и безопасной работы. Следуйте

инструкциям для смазки и смены

принадлежностей. Периодически проверяйте

шнуры инструмента, и, если они повреждены,

обращайтесь относительно ремонта в

уполномоченный центр по техобслуживанию.

Периодически проверяйте шнуры-удлинители

и заменяйте, если они повреждены. Держите

ручки сухими чистыми и свободными от масла

или смазки.

15. Отсоединяйте инструменты

Если не используются, перед техобслуживанием,

и при смене принадлежностей, таких, как

лезвия, резцы и резаки.

16. Убирайте регулировочные ключи и

гаечные ключи

Сформируйте привычку проверять, что

регулировочные ключи и гаечные ключи

убраны с инструмента перед его включением.

17. Избегайте случайных запусков

Не носите подсоединенный к сети инструмент

с пальцем, находящемся на переключателе.

Перед подсоединением инструмента к сети

убедитесь, что переключатель находится в

положении “выкл”.

18. Шнуры-удлинители для использования на

улице

Когда инструмент используется на улице,

используйте только шнуры-удлинители,

предназначенные для использования на

улице с указанием этого.

19. Будьте бдительны

Наблюдайте за тем, что Вы делаете.

Используйте разумный подход. Не управляйте

инструментом, если Вы устали.

20. Проверяйте поврежденные части

Перед дальнейшим использованием

инструмента, предохранитель или другая

часть должны быть тщательно проверены

для определения того, что они будут

функционировать правильно и выполнять

предназначенную функцию. Проверьте на

предмет совмещения движущихся частей,

соединения движущихся частей, поломки

частей, монтажа и других условий, которые

могут повлиять не их функционирование.

Предохранитель или другая часть должны

быть правильно отремонтированы или

заменены в уполномоченном центре по

техобслуживанию, если только не указано

другое в этой инструкции по эксплуатации.

Дефектные переключатели должны быть

заменены в уполномоченном центре по

техобслуживанию. Не используйте

инструмент, если невозможно его включение

и выключение с помощью переключателя.

21. Предостережение

Использование любой другой принадлежности

или присоединения, отличного от

рекомендуемого в этой инструкции по

эксплуатации или каталоге, может привести к

опасности персональной травмы.

22. Используйте для ремонта услуги

специалиста

Это электрическое оборудование

соответствует относящимся к нему правилам

безопасности. Ремонт электрического

оборудования может проводиться только

специалистами, в противном случае, он

может вызвать существенную опасность для

пользователя.

ДОПОЛНИТЕЛЬНЫЕ ПРАВИЛА

БЕЗОПАСНОСТИ

1. Одевайте приборы для защиты слуха.

2. Перед установкой внимательно проверьте

гнездо на предмет износа, трещин или

повреждений.

3. Держите инструмент крепко.

4. Всегда будьте уверены, что у Вас имеется

устойчивая опора. Убедитесь в том, что

внизу никого нет, когда используете

инструмент в возвышенных местах.

5. Правильный крутящий момент может

различаться в зависимости от вида или

размера болта. Проверьте момент с

помощью гаечного ключа с ограничением

по крутящему моменту.

СОХРАНИТЕ ЭТИ ИНСТРУКЦИИ.

191919

Page 20

ИНСТРУКЦИЯ ПО ЭКСПЛУАТАЦИИ

Удерживание инструмента

При выполнении операций удерживайте

инструмент крепко одной рукой за часть для

захвата инструмента и другой рукой за боковой

захват.

Выбор правильного гнезда

Используйте гнездо правильного размера для

болтов и гаек. Гнездо неправильного размера

может привести к неточному и непостоянному

крутящему моменту.

Установка бокового захвата (Рис. 1)

Только для модели 6906

Вставьте боковой захват в канавку по середине

корпуса молотка и надежно закрепите.

Присоединение гнезда (Рис. 2)

Действия при переключении (Рис. 3)

ПРЕДУПРЕЖДЕНИЕ:

• Перед подсоединением инструмента всегда

проверяйте, чтобы видеть, что пусковой

механизм действует правильно и возвращается

в положение “OFF” (выкл.) при высвобождении.

• Изменяйте направление вращения только

после полной остановки инструмента. Его

изменение до остановки инструмента может

привести к повреждению инструмента.

Переключатель является обратимым,

обеспечивая вращение либо по часовой, либо

против часовой стрелки. Для запуска

инструмента просто нажмите на нижнюю часть

переключателя для вращения по часовой

стрелке, и на верхнюю часть для вращения

против часовой стрелки. Для остановки

высвободите переключатель.

Выбрав гнездо правильного размера,

пожалуйста, вставьте его в пятку так, чтобы оно

надежно зафиксировалось.

Эксплуатация

Правильный крутящий момент может различаться в зависимости от вида или размера болта.

Соотношение между крутящим моментом и временем завинчивания показано на рисунке внизу.

кг•см

7 00

6 00

5 00

4 00

Для Модель 6906

Крутящий момент

3 00

2 00

1 00

012345678

Время завинчивания

Для Модель 6905B

секунды

Номинальное напряжение

90 % от номинального напряжения

Держите инструмент крепко и поместите гнездо сверху болта или гайки. Включите инструмент и

завинчивайте в течение правильного времени завинчивания.

ПРИМЕЧАНИЕ:

• Держите инструмент направленным прямо на болт или гайку без прикладывания излишнего

давления на инструмент.

• Излишний крутящий момент может привести к повреждению болта или гайки.

202020

Page 21

Крутящий момент подвержен воздействию

различных факторов, включая следующие.

После завинчивания всегда проверяйте

крутящий момент с помощью гаечного ключа с

ограничением по крутящему моменту.

1. Гнездо

• Выбор гнезда неправильного размера

приведет к уменьшению крутящего

момента.

• Изношенное гнездо (износ на

шестиугольном конце или квадратном

конце) приведет к уменьшению крутящего

момента.

2. Болт

• Даже если коэффициент момента и класс

болта являются одинаковыми, правильный

крутящий момент будет различаться в

соответствии с диаметром болта.

• Даже если диаметры болтов являются

одинаковыми, правильный крутящий

момент будет различаться в соответствии

с коэффициентом момента, классом болта

и длиной болта.

3. Использование универсального соединителя

или удлинительной шины сократит в

некоторой степени силу завинчивания

гаечного ключа ударного действи.

Скомпенсируйте путем завинчивания в

течение более длительного периода

времени.

4. Способ удерживания инструмента будет

воздействовать на момент.

ОБСЛУЖИВАНИЕ

ПРЕДУПРЕЖДЕНИЕ:

Всегда проверяйте, что инструмент выключен и

отсоединен перед выполнением любой работы с

инструментом.

Замена угольных щеток (Рис.4 и 5)

Заменяйте угольные щетки, когда они износятся

до ограничительной метки. Обе одинаковые

угольные щетки следует заменять

одновременно.

Для поддержания безопасности и долговечности

изделия, ремонт, уход или регулировка должны

проводиться в уполномоченном центре по

техобслуживанию Makita.

212121

Page 22

Типичные А-взвешенные уровни шума составляют

Шум и вибрация Moдели 6905B

уровень звукового давления 95 дБ (А).

уровень звуковой мощности 108 дБ (А).

– Надевайте защиту для слуха. –

Типичное взвешенное значение квадратного корня

ускорения составляет 5 м/с

2

.

Типичные А-взвешенные уровни шума составляют

Шум и вибрация Moдели 6906

уровень звукового давления 94 дБ (А).

уровень звуковой мощности 107 дБ (А).

– Надевайте защиту для слуха. –

Типичное взвешенное значение квадратного корня

ускорения составляет 3 м/с

2

.

ЕС ДЕКЛАРАЦИЯ СООТВЕТСТВИЯ

Мы заявляем под свою собственную

ответственность, что этот продукт находится в

соответствии со следующими стандартами или

документами по стандартизации:

HD400, EN50144, EN55014, EN61000,

согласно сборникам директив 73/23EEC,

89/336/EEC и 98/37/EC.

222222

Ясухико Канзаки

CE94

Директор

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

Page 23

232323

Page 24

Makita Corporation

Anjo, Aichi Japan

Made in Japan

883054A202

Loading...

Loading...