Page 1

INSTRUCTION MANUAL

MANUEL D'INSTRUCTION

MANUAL DE INSTRUCCIONES

Impact Wrench

Boulonneuse à chocs

Llave de impacto

6904VH

6905H

002287

DOUBLE INSULATION

DOUBLE ISOLATION

DOBLE AISLAMIENTO

WARNING:

For your personal safety, READ and UNDERSTAND before using.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

AVERTISSEMENT:

Pour votre propre sécurité, prière de lire attentivement avant l’utilisation.

GARDER CES INSTRUCTIONS POUR RÉFÉRENCE ULTÉRIEURE.

ADVERTENCIA:

Para su seguridad personal, LEA DETENIDAMENTE este manual antes de usar la herramienta.

GUARDE ESTAS INSTRUCCIONES PARA FUTURA REFERENCIA.

Page 2

ENGLISH

SPECIFICATIONS

Model 6904VH 6905H

Standard bolt M10 - M16 (3/8” - 5/8”) M12 - M20 (1/2” - 3/4”)

Capacities

Square drive 12.7 mm (1/2”) 12.7 mm (1/2”)

No load speed (RPM)

Impacts per minute

Max. fastening torque

Overall length 265 mm (10-3/8”) 275 mm (10-13/16”)

Net weight 1.8 kg (4.0 lbs) 2.3 kg (5 lbs)

• Due to our continuing programme of research and development, the specifications herein are subject to change

without notice.

• Note: Specifications may differ from country to country.

High tensile bolt M10 - M12 (3/8” - 1/2”) M12 - M16 (1/2” - 5/8”)

Wood screw 6 mm x 100 mm (1/4” x 3-15/16”)-

Self-drilling screw 6 mm (1/4”)-

High 0 - 2,400/min.

Low 0 - 2,100/min.

High 0 - 3,000

Low 0 - 2,500

High 196 N.m (145 ft.lbs)

Low 147 N.m (109 ft.lbs)

2,200/min.

2,600

294 N.m (217 ft.lbs)

GENERAL SAFETY RULES

GEA001-3

WARNING:

Read all instructions. Failure to follow all

instructions listed below may result in electric shock, fire and/or serious injury. The

term “power tool” in all of the warnings listed

below refers to your mains-operated

(corded) power tool or battery-operated

(cordless) power tool.

SAVE THESE INSTRUCTIONS

Work area safety

1. Keep work area clean and well lit. Cluttered and

dark areas invite accidents.

2. Do not operate power tools in explosive atmo-

spheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

3. Keep children and bystanders away while oper-

ating a power tool. Distractions can cause you to

lose control.

Electrical safety

4. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodified plugs and matching outlets will

reduce risk of electric shock.

5. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

6. Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the

risk of electric shock.

7. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords

increase the risk of electric shock.

8. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of

electric shock.

Personal safety

9. Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the influence of drugs, alcohol or medication. A

2

Page 3

moment of inattention while operating power tools

may result in serious personal injury.

10. Use safety equipment. Always wear eye protection. Safety equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used

for appropriate conditions will reduce personal injuries.

11. Avoid accidental starting. Ensure the switch is in

the off-position before plugging in. Carrying

power tools with your finger on the switch or plugging in power tools that have the switch on invites

accidents.

12. Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

13. Do not overreach. Keep proper footing and balance at all times. This enables better control of the

power tool in unexpected situations.

14. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing, and gloves

away from moving parts. Loose clothes, jewellery

or long hair can be caught in moving parts.

15. If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

these devices can reduce dust-related hazards.

Power tool use and care

16. Do not force the power tool. Use the correct

power tool for your application. The correct power

tool will do the job better and safer at the rate for

which it was designed.

17. Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be

repaired.

18. Disconnect the plug from the power source and/

or the battery pack from the power tool before

making any adjustments, changing accessories,

or storing power tools. Such preventive safety

measures reduce the risk of starting the power tool

accidentally.

19. Store idle power tools out of the reach of children and do not allow persons unfamiliar with

the power tool or these instructions to operate

the power tool. Power tools are dangerous in the

hands of untrained users.

20. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the power

tools operation. If damaged, have the power tool

repaired before use. Many accidents are caused by

poorly maintained power tools.

21. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

22. Use the power tool, accessories and tool bits

etc. in accordance with these instructions and in

the manner intended for the particular type of

power tool, taking into account the working conditions and the work to be performed. Use of the

power tool for operations different from those

intended could result in a hazardous situation.

Service

23. Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

24. Follow instruction for lubricating and changing

accessories.

25. Keep handles dry, clean and free from oil and

grease.

SPECIFIC SAFETY RULES

GEB009-2

DO NOT let comfort or familiarity with

product (gained from repeated use)

replace strict adherence to recipro saw

safety rules. If you use this tool unsafely

or incorrectly, you can suffer serious personal injury.

1. Hold power tools by insulated gripping surfaces

when performing an operation where the cutting

tool may contact hidden wiring or its own cord.

Contact with a “live” wire will make exposed metal

parts of the tool “live” and shock the operator.

2. Wear ear protectors.

3. Check the socket carefully for wear, cracks or

damage before installation.

4. Hold the tool firmly.

5. Always be sure you have a firm footing.

Be sure no one is below when using the tool in

high locations.

6. The proper fastening torque may differ depending upon the kind or size of the bolt. Check the

torque with a torque wrench.

SAVE THESE INSTRUCTIONS

WARNING:

MISUSE or failure to follow the safety

rules stated in this instruction manual

may cause serious personal injury.

3

Page 4

SYMBOLS

The followings show the symbols used for tool.

V............................volts

A ...........................amperes

Hz..........................hertz

..................alternating current

.......................no load speed

.......................Class II Construction

.../min....................revolutions or reciprocation per

..................number of blow

minute

USD202-2

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and

unplugged before adjusting or checking function on

the tool.

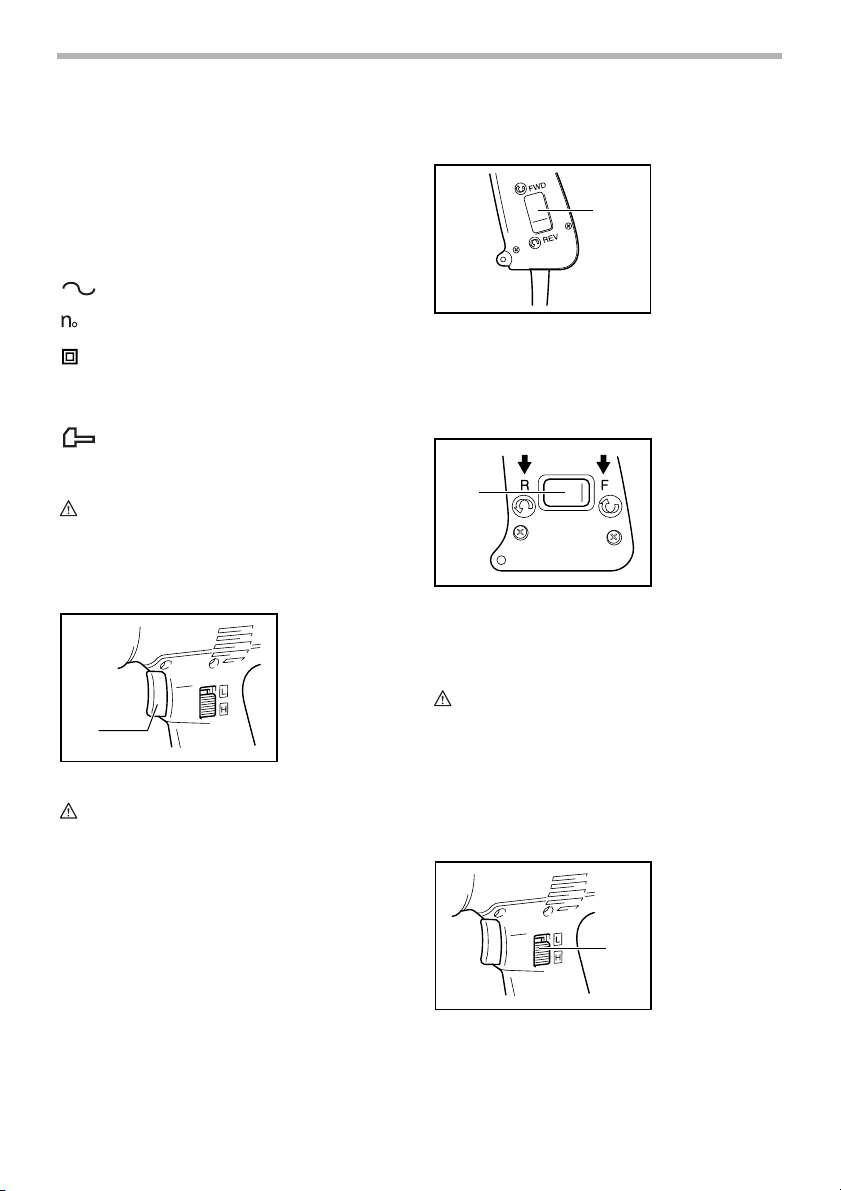

Switch action

1

CAUTION:

• Before plugging in the tool, always check to see

that the switch trigger actuates properly and returns

to the “OFF” position when released.

For 6904VH

To start the tool, simply pull the switch trigger. Tool speed

is increased by increasing pressure on the switch trigger.

Release the switch trigger to stop.

For 6905H

To start the tool, simply pull the switch trigger. Release

the switch trigger to stop.

002311

1. Switch trigger

Reversing switch action

For 6904VH

This tool has a reversing switch to change the rotational

direction. Press the upper side (FWD side) for clockwise

(forward) rotation or the lower side (REV side) for counterclockwise (reverse) rotation.

For 6905H

1

This tool has a reversing switch to change the rotational

direction. Press the right side of the switch for clockwise

(forward) rotation or the left side for counterclockwise

(reverse) rotation.

CAUTION:

• Always check the direction of rotation before opera-

tion.

• Use the reversing switch only after the tool comes

to a complete stop. Changing the direction of rotation before the tool stops may damage the tool.

002322

1. Reversing

switch

1

002323

1. Reversing

switch

Speed change

For 6904VH only

002329

1. Speed change

lever

1

To change the speed, first switch off the tool and then

slide the speed change lever fully to the “H” side (lower

side) for high speed or to the “L” side (upper side) for low

speed. Before starting operation, ensure that the speed

4

Page 5

change lever is slid fully to the desired side. Select the

speed optimum for your job.

CAUTION:

• Do not use the speed change lever while the tool is

running. The tool may be damaged.

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Selecting correct socket

Always use the correct size socket for bolts and nuts. An

incorrect size socket will result in inaccurate and inconsistent fastening torque and/or damage to the bolt or nut.

Installing or removing socket

1

2

To install the socket, push it onto the anvil of the tool until

it locks into place.

To remove the socket, simply pull it off.

002335

1. Socket

2. Anvil

OPERATION

007444

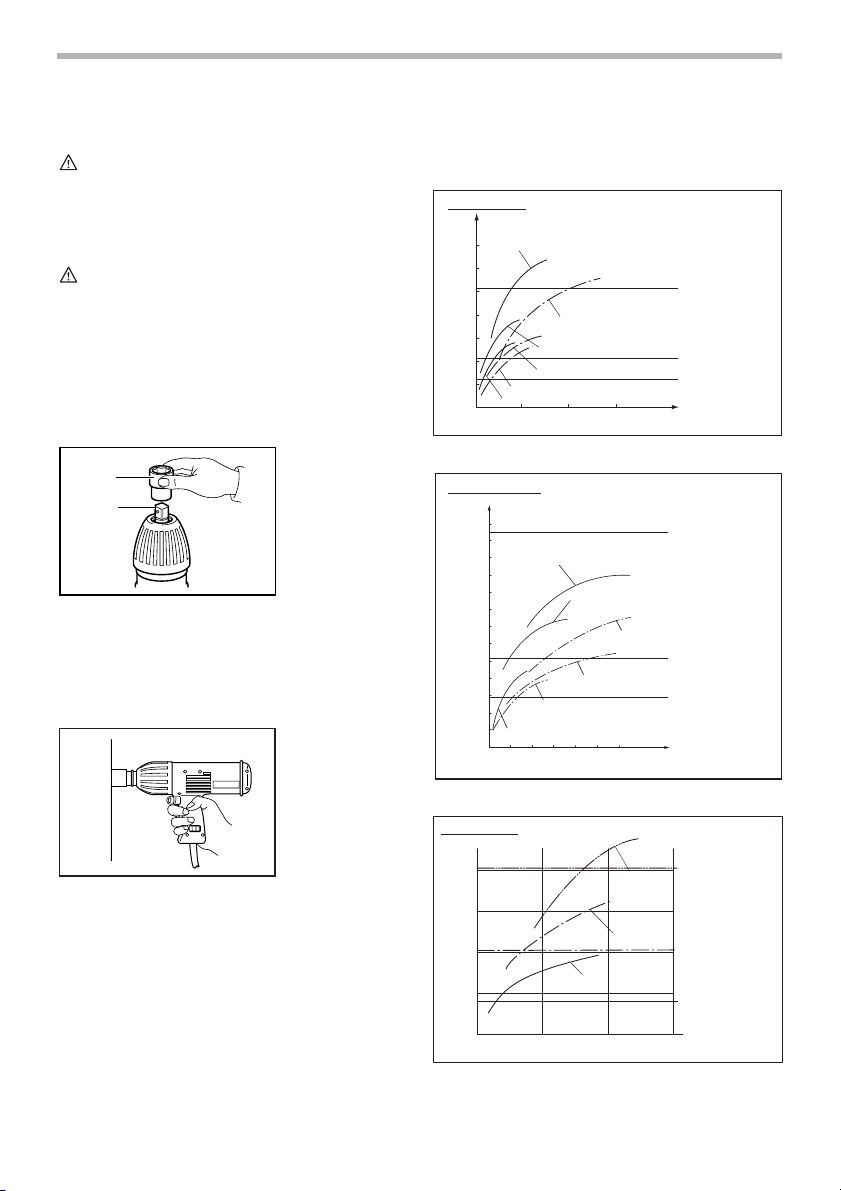

The proper fastening torque may differ depending upon

the kind or size of the bolt, the material of the workpiece

to be fastened, etc. The relation between fastening

torque and fastening time is shown in the figures.

Standard bolt

N.m

(ft.lbs)

Fastening torque

High tensile bolt

M16X50 (5/8” X 2”) at high speed

140

(101)

120

(87)

100

(72)

80

(58)

60

(43)

40

(29)

20

(14)

01 2

N.m

260

(188)

240

(174)

220

(159)

200

(145)

180

(130)

160

(116)

140

(101)

120

(87)

Fastening torque

100

(72)

80

(58)

60

(43)

40

(29)

20

(14)

012

M16X50 (5/8” X 2”) at low speed

M12X50 (1/2” X 2”) at high speed

M12X50 (1/2” X 2”) at low speed

M10X50 (3/8” X 2”) at low speed

M10X50 (3/8” X 2”) at high speed

Fastening time

M16X50 (5/8” X 2”) at high speed

M12X50 (1/2” X 2”) at low speed

M10X50 (3/8” X 2”) at low speed

M10X50 (3/8” X 2”) at high speed

3

Fastening time

M16 (5/8”)

M12 (1/2”)

M10 (3/8”)

3

(S)

For 6904VH

M16 (5/8”)

M12X50 (1/2” X 2”) at high speed

M16X50 (5/8” X 2”) at low speed

M12 (1/2”)

M10 (3/8”)

45 6

(S)

002346

For 6904VH

Proper fastening torque

002347

Proper fastening torque

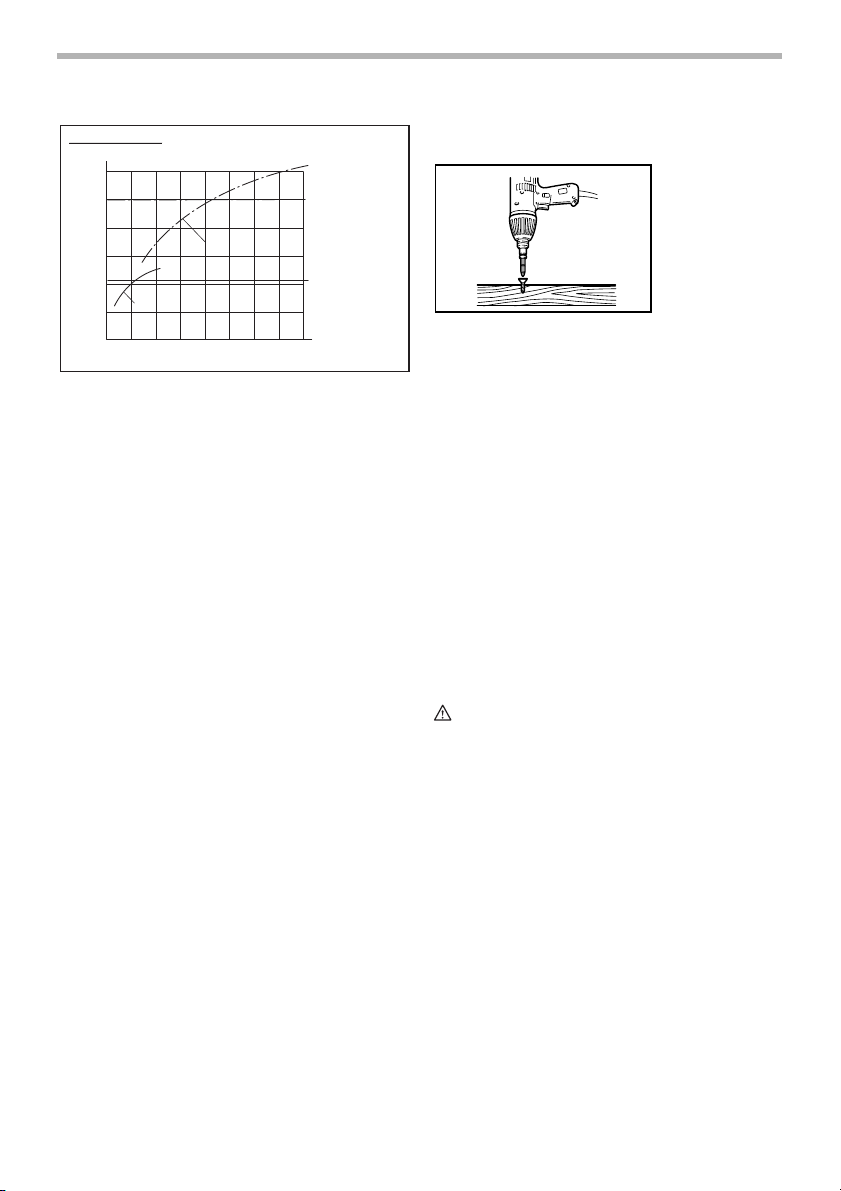

Standard bolt

N.m

(ft.lbs)

200

(144)

150

(108)

100

(72)

Fastening torque

50

(36)

0 0.5 1

5

M12X50

(7/16” X 2”)

Fastening time

M20X50

(3/4” X 2”)

M16X50

(5/8” X 2”)

M20 (3/4”)

M16 (5/8”)

M12 (7/16”)

1.5

(S)

002349

For 6905H

Proper fastening torque

Page 6

High tensile bolt

N.m

(ft.lbs)

300

(217)

250

(181)

200

(144)

150

(108)

100

(72)

Fastening torque

M12X50 (7/16” X 2”)

50

(36)

0 12345 67

Hold the tool firmly and place the socket over the bolt or

nut. Turn the tool on and fasten for the proper fastening

M16X50 (5/8” X 2”)

Fastening time

For 6905H

M12 (7/16”)

8

(S)

M16 (5/8”)

002350

Proper fastening torque

time.

NOTE:

• Hold the tool pointed straight at the bolt or nut.

• Excessive fastening torque may damage the bolt/

nut or socket. Before starting your job, always perform a test operation to determine the proper fastening time for your bolt or nut.

The fastening torque is affected by a wide variety of factors including the following. After fastening, always check

the torque with a torque wrench.

1. Vol ta ge

Voltage drop will cause a reduction in the fastening

torque.

2. Socket

• Failure to use the correct size socket will cause

a reduction in the fastening torque.

• A worn socket (wear on the hex end or square

end) will cause a reduction in the fastening

torque.

3. Bolt

• Even though the torque coefficient and the

class of bolt are the same, the proper fastening

torque will differ according to the diameter of

bolt.

• Even though the diameters of bolts are the

same, the proper fastening torque will differ

according to the torque coefficient, the class of

bolt and the bolt length.

4. The use of the universal joint or the extension bar

somewhat reduces the fastening force of the impact

wrench. Compensate by fastening for a longer

period of time.

5. The manner of holding the tool or the material of

driving position to be fastened will affect the torque.

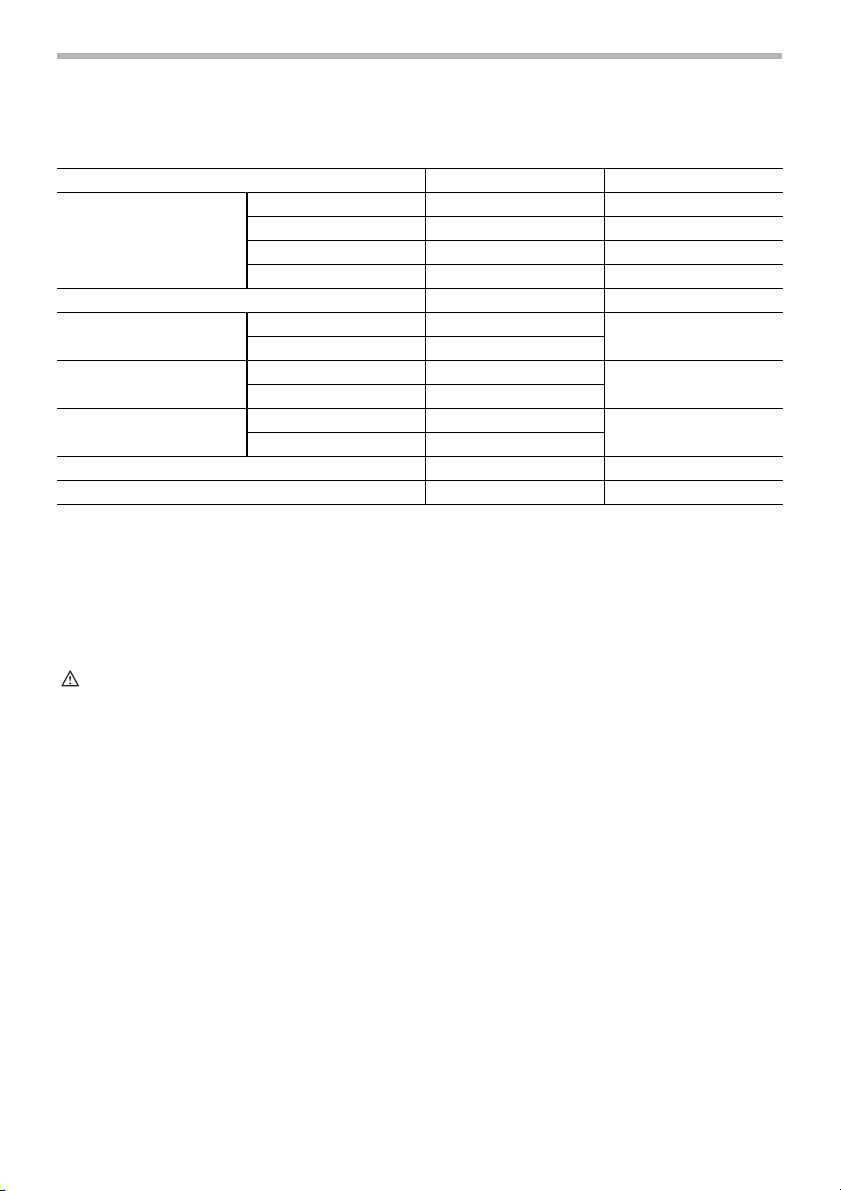

Screwdriving operation

For 6904VH only

When driving screws, install a bit adapter (optional

accessory) on the tool and insert a driver bit (optional

accessory) into the bit adapter.

Hold the tool firmly and place the point of the driver bit in

the screw head. Apply forward pressure to the tool to the

extent that the bit will not slip off the screw. Start the tool

slowly and then increase the speed gradually. Release

the switch trigger just as the screw bottoms out.

NOTE:

• Use the proper bit for the head of the screw/bolt

that you wish to use.

• Hold the tool pointed straight at the screw or the

screw and/or bit may be damaged.

• When driving wood screws, predrill pilot holes to

make driving easier and to prevent splitting of the

workpiece. The pilot holes should be slightly

smaller than the wood screws in diameter.

002371

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and

unplugged before attempting to perform inspection

or maintenance.

To maintain product SAFETY and RELIABILITY, repairs,

carbon brush inspection and replacement, any other

maintenance or adjustment should be performed by Makita Authorized or Factory Service Centers, always using

Makita replacement parts.

6

Page 7

ACCESSORIES

CAUTION:

• These accessories or attachments are recom-

mended for use with your Makita tool specified in

this manual. The use of any other accessories or

attachments might present a risk of injury to persons. Only use accessory or attachment for its

stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita Service Center.

• Sockets

• Extension bar

• Universal joint

• Bit adapter (for 6904VH only)

• Phillips bits (for 6904VH only)

• Socket bits (for 6904VH only)

MAKITA LIMITED ONE YEAR WARRANTY

Warranty Policy

Every Makita tool is thoroughly inspected and tested

before leaving the factory. It is warranted to be free of

defects from workmanship and materials for the period of

ONE YEAR from the date of original purchase. Should

any trouble develop during this one year period, return

the COMPLETE tool, freight prepaid, to one of Makita’s

Factory or Authorized Service Centers. If inspection

shows the trouble is caused by defective workmanship or

material, Makita will repair (or at our option, replace)

without charge.

This Warranty does not apply where:

• repairs have been made or attempted by others:

• repairs are required because of normal wear and

tear:

• the tool has been abused, misused or improperly

maintained:

• alterations have been made to the tool.

IN NO EVENT SHALL MAKITA BE LIABLE FOR ANY

INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES FROM THE SALE OR USE OF THE PRODUCT.

THIS DISCLAIMER APPLIES BOTH DURING AND

AFTER THE TERM OF THIS WARRANTY.

MAKITA DISCLAIMS LIABILITY FOR ANY IMPLIED

WARRANTIES, INCLUDING IMPLIED WARRANTIES

OF “MERCHANTABILITY” AND “FITNESS FOR A SPECIFIC PURPOSE,” AFTER THE ONE YEAR TERM OF

THIS WARRANTY.

This Warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not apply to you. Some states do

not allow limitation on how long an implied warranty lasts,

so the above limitation may not apply to you.

EN0006-1

7

Page 8

FRANÇAIS

SPÉCIFICATIONS

Modèle 6904VH 6905H

Boulon standard M10 - M16 (3/8” - 5/8”) M12 - M20 (1/2” - 3/4”)

Capacités

Tournevis carré 12.7 mm (1/2”) 12.7 mm (1/2”)

Vitesse à vide (T/MIN)

Percussions par minute

Couple de serrage max.

Longueur totale 265 mm (10-3/8”) 275 mm (10-13/16”)

• Le fabricant se réserve le droit de modifier sans avertissement les spécifications.

• Note: Les spécifications peuvent varier selon les pays.

Boulon à haute résistance M10 - M12 (3/8” - 1/2”) M12 - M16 (1/2” - 5/8”)

Vis à bois 6 mm x 100 mm (1/4” x 3-15/16”)-

Vis taraudeuse 6 mm (1/4”)-

Grande 0 - 2,400/min.

Bas 0 - 2,100/min.

Grande 0 - 3,000

Bas 0 - 2,500

Grande 196 N.m (145 ft.lbs)

Bas 147 N.m (109 ft.lbs)

Poids net 1.8 kg (4.0 lbs) 2.3 kg (5 lbs)

2,200/min.

2,600

294 N.m (217 ft.lbs)

CONSIGNES DE SÉCURITÉ

GÉNÉRALES

GEA001-3

AVERTISSEMENT:

Veuillez lire l’ensemble des présentes

instructions. Il y a risque de choc

électrique, d’incendie et/ou de blessure

grave si toutes les instructions énumérées

ci-dessous ne sont pas respectées. Dans

tous les avertissements ci-dessous, le terme

“outil électrique” fait référence aux outils

électriques qui fonctionnent sur le secteur

(avec un cordon d’alimentation) et aux outils

électriques alimentés par batterie (sans

cordon d’alimentation).

CONSERVEZ CES

INSTRUCTIONS

Sécurité de la zone de travail

1. Maintenez la zone de travail propre et bien

éclairée. Les zones de travail encombrées et

sombres ouvrent grande la porte aux accidents.

2. N’utilisez pas les outils électriques dans des

atmosphères explosives, telles qu’en présence

de liquides, de gaz ou de poussières

inflammables. Les outils électriques produisent des

étincelles au contact desquelles la poussière ou les

vapeurs risqueraient de s’enflammer.

3. Assurez-vous qu’aucun enfant ou passant ne

s’approche pendant que vous utilisez un outil

électrique. Vous risquez de perdre la maîtrise de

l’outil si votre attention est détournée.

Sécurité en matière d’électricité

4. La fiche des outils électriques doit être conçue

pour la prise de courant utilisée. Ne modifiez

jamais la fiche de quelque façon que ce soit.

N’utilisez aucun adaptateur de fiche sur les

outils électriques avec mise à la terre. En ne

modifiant pas les fiches et en les insérant dans des

prises de courant pour lesquelles elles ont été

conçues vous réduirez les risques de choc

électrique.

5. Évitez tout contact corporel avec les surfaces

mises à la terre, telles que les tuyaux, radiateurs,

cuisinières et réfrigérateurs. Le risque de choc

électrique augmentera si votre corps se trouve mis à

la terre.

6. N’exposez pas les outils électriques à la pluie et

évitez qu’ils ne soient mouillés. Les risques de

choc électrique augmentent lorsque de l’eau

pénètre dans un outil électrique.

8

Page 9

7. Ne maltraitez pas le cordon. N’utilisez jamais le

cordon pour transporter l’outil électrique, pour

tirer dessus ou pour le débrancher. Maintenez le

cordon à l’écart des sources de chaleur, de

l’huile, des objets à bords tranchants et des

pièces en mouvement. Le risque de choc

électrique augmente lorsque les cordons sont

endommagés ou enchevêtrés.

8. Lorsque vous utilisez un outil électrique à

l’extérieur, utilisez un cordon prolongateur

prévu à cette fin. Les risques de choc électrique

diminuent lorsqu’un cordon conçu pour l’extérieur

est utilisé.

Sécurité personnelle

9. Restez alerte, attentif à vos mouvements et

faites preuve de bon sens lorsque vous utilisez

un outil électrique. Évitez d’utiliser un outil

électrique si vous êtes fatigué ou si vous avez

pris une drogue, de l’alcool ou un médicament.

Un moment d’inattention pendant l’utilisation d’un

outil électrique peut entraîner une grave blessure.

10. Utilisez des dispositifs de sécurité. Portez

toujours des lunettes de protection. Les risques

de blessure diminueront si vous utilisez des

dispositifs de sécurité tels qu’un masque

antipoussières, des chaussures à semelle

antidérapante, une coiffure résistante ou une

protection d’oreilles.

11. Prévenez tout démarrage accidentel. Assurezvous que l’interrupteur est en position d’arrêt

avant de brancher l’outil. Vous ouvrez toute

grande la porte aux accidents si vous transportez

les outils électriques en gardant le doigt sur la

gâchette ou si vous les branchez alors que

l’interrupteur se trouve en position de marche.

12. Retirez toute clé de réglage ou autre type de clé

avant de mettre l’outil sous tension. Toute clé

laissée en place sur une pièce rotative de l’outil

électrique peut entraîner une blessure.

13. Maintenez une position stable. Assurez-vous

d’avoir une bonne prise au sol et une bonne

position d’équilibre en tout temps. Vou s aurez

ainsi une meilleure maîtrise de l’outil en cas de

situation imprévue.

14. Portez des vêtements adéquats. Ne portez ni

vêtements amples ni bijoux. Vous devez

maintenir cheveux, vêtements et gants à l’écart

des pièces en mouvement. Les pièces en

mouvement risqueraient de happer les vêtements

amples, les bijoux ou les cheveux longs.

15. Si des accessoires sont fournis pour raccorder

un appareil d’aspiration et de collecte de la

poussière, assurez-vous que les raccordements

sont corrects et que l’appareil est bien utilisé.

L’utilisation de tels accessoires permet de réduire

les risques liés à la présence de poussière dans

l’air.

Utilisation et entretien des outils

électriques

16. Ne forcez pas l’outil électrique. Utilisez l’outil

électrique adéquat suivant le type de travail à

effectuer. Si vous utilisez l’outil électrique adéquat

et respectez le régime pour lequel il a été conçu, il

effectuera un travail de meilleure qualité et de façon

plus sécuritaire.

17. N’utilisez pas l’outil électrique s’il n’est pas

possible de mettre sa gâchette en position de

marche et d’arrêt. Un outil électrique dont

l’interrupteur est défectueux représente un danger

et doit être réparé.

18. Débranchez la fiche de la source d’alimentation

et/ou retirez le bloc-pile de l’outil électrique

avant d’effectuer tout réglage, de changer un

accessoire ou de ranger l’outil électrique. Ces

mesures préventives réduiront les risques de

démarrage accidentel de l’outil électrique.

19. Après l’utilisation d’un outil électrique, rangez-le

hors de portée des enfants et ne laissez aucune

personne l’utiliser si elle n’est pas familiarisée

avec l’outil électrique ou les présentes

instructions d’utilisation. Les outils électriques

représentent un danger entre les mains de

personnes qui n’en connaissent pas le mode

d’utilisation.

20. Ne négligez pas l’entretien des outils

électriques. Assurez-vous que les pièces

mobiles ne sont ni désalignées ni coincées,

qu’aucune pièce n’est cassée et que l’outil

électrique n’a subi aucun dommage pouvant

affecter son bon fonctionnement. Si l’outil

électrique est endommagé, faites-le réparer

avant de l’utiliser à nouveau. De nombreux

accidents sont causés par des outils électriques mal

entretenus.

21. Maintenez les outils tranchants bien aiguisés et

propres. Un outil tranchant dont l’entretien est

effectué correctement et dont les bords sont bien

aiguisés risquera moins de se coincer et sera plus

facile à maîtriser.

22. Utilisez l’outil électrique, ses accessoires, ses

embouts, etc., en respectant les présentes

instructions et de la façon prévue pour ce type

particulier d’outil électrique, en tenant compte

des conditions de travail et du type de travail à

effectuer. L’utilisation d’un outil électrique à des fins

autres que celles prévues est potentiellement

dangereuse.

Service

23. Faites réparer votre outil électrique par un

réparateur qualifié qui utilise des pièces de

rechange identiques aux pièces d’origine. Cela

permettra d’assurer le maintien de la sûreté de l’outil

électrique.

9

Page 10

24. Suivez les instructions de lubrification et de

changement des accessoires.

25. Maintenez les poignées sèches, propres et

exemptes d’huile ou de graisse.

RÈGLES DE SÉCURITÉ

PART ICU LI ÈRES

GEB009-2

NE vous laissez PAS tromper (au fil

d’une utilisation répétée) par un

sentiment d’aisance et de familiarité avec

le produit, en négligeant le respect

rigoureux des consignes de sécurité qui

accompagnent la scie récipro. Si vous

n’utilisez pas cet outil de façon sûre et

adéquate, vous courez un risque de

blessure grave.

1. Tenez l’outil électrique par ses surfaces de prise

isolées pendant toute opération où l’outil de

coupe pourrait venir en contact avec un câblage

dissimulé ou avec son propre cordon. En cas de

contact avec un conducteur sous tension, les pièces

métalliques à découvert de l’outil transmettraient un

choc électrique à l’utilisateur.

2. Portez une protection d’oreilles.

3. Avant installation, vérifiez soigneusement que la

douille ne porte ni marque d’usure, ni fissures

ou tout autre dommage.

4. Tenez l’outil fermement.

5. Adoptez toujours une position de travail vous

assurant d’un bon équilibre.

Assurez-vous qu’il n’y a personne plus bas

lorsque vous utilisez l’outil en position élevée.

6. Le couple de serrage correct peut varier selon le

type ou la taille du boulon. Vérifiez-le à l’aide

d’une clé dynamométrique.

CONSERVEZ CE MODE

D’EMPLOI

AVERTISSEMENT:

Une MAUVAISE UTILISATION de l’outil

ou l’ignorance des consignes de sécurité

du présent manuel d’instructions

peuvent entraîner une grave blessure.

SYMBOLES

Les symboles utilisés pour l’outil sont présentés cidessous.

V ...........................volts

A........................... ampères

Hz .........................hertz

...................courant alternatif

.......................vitesse à vide

.......................construction, catégorie II

.../min ...................tours ou alternances par minute

.................. nombre de frappes

USD202-2

DESCRIPTION DU

FONCTIONNEMENT

ATTENTION:

• Assurez-vous toujours que l’outil est hors tension et

débranché avant de l’ajuster ou de vérifier son

fonctionnement.

Interrupteur

1

ATTENTION:

• Avant de brancher l’outil, assurez-vous toujours

que la gâchette fonctionne correctement et revient

en position d’arrêt une fois relâchée.

Pour 6904VH

Pour mettre l’outil en marche, appuyez simplement sur la

gâchette. La vitesse de l’outil augmente à mesure que

l’on accroît la pression exercée sur la gâchette. Pour

l’arrêter, relâchez la gâchette.

Pour 6905H

Pour faire démarrer l’outil, appuyez simplement sur la

gâchette. Pour l’arrêter, relâchez la gâchette.

002311

1. Gâchette

10

Page 11

Inverseur

Pour 6904VH

Cet outil possède un inverseur qui permet de changer le

sens de rotation. Appuyez du côté supérieur (côté FWD)

pour un rotation dans le sens des aiguilles d’une montre

(vers l’avant), ou du côté inférieur (côté REV) pour un

rotation en sens inverse (vers l’arrière).

Pour 6905H

1

Cet outil possède un inverseur qui permet de changer le

sens de rotation. Appuyez du côté droit de l’inverseur

pour une rotation dans le sens des aiguilles d’une montre

(vers l’avant), ou du coté gauche pour une rotation en

sens inverse (vers l’arrière).

ATTENTION:

• Vérifiez toujours le sens de rotation avant de mettre

l’outil en marche.

• N’actionnez l’inverseur qu’une fois que l’outil est

complètement arrêté. Si vous changez le sens de

rotation avant l’arrêt de l’outil, vous risquez de

l’endommager.

002322

1. Inverseur

1

002323

1. Inverseur

Changement de vitesse

Pour 6904VH uniquement

002329

1. Levier de

changement de

vitesse

Pour changer la vitesse, éteignez d’abord l’outil puis

glissez complètement le levier de changement de vitesse

du côté “H” (côté inférieur) pour la vitesse rapide, ou du

côté “L” (côté supérieur) pour la vitesse lente. Avant de

commencer votre travail, assurez-vous que le levier de

changement de vitesse est glissé complètement du côté

désiré. Sélectionnez la vitesse la plus appropriée pour le

travail à effectuer.

ATTENTION:

• Ne modifiez pas la position du levier de

changement de vitesse pendant que l’outil tourne.

Vous risqueriez de l’endommager.

ASSEMBLAGE

ATTENTION:

• Avant d’effectuer toute intervention sur l’outil,

assurez-vous toujours qu’il est hors tension et

débranché.

Sélection de la douille

Pour certains modèles il existe différents types de

douilles ou embouts, suivant le travail à effectuer.

Veuillez choisir et installer une douille ou un embout qui

convient au travail à effectuer.

Installation et retrait de la douille

1

2

Pour installer la douille, enfoncez-la sur le piton de l’outil

jusqu’à ce qu’elle se verrouille en position.

Pour retirer la douille, tirez simplement dessus.

002335

1. Douille

2. Enclume

UTILISATION

007444

1

Le couple de serrage adéquat peut varier suivant la sorte

ou taille de boulon, suivant le matériau dont se compose

la pièce faisant l’objet du serrage, etc. La relation entre le

11

Page 12

couple de serrage et le temps de serrage est indiquée

dans les figures.

Boulon standard

N.m

(ft.lbs)

Couple de serrage

M16X50 (5/8” X 2”) à grande vitesse

140

(101)

120

(87)

100

(72)

80

(58)

60

(43)

40

(29)

20

(14)

01 2

M16X50 (5/8” X 2”) à vitesse réduite

M12X50 (1/2” X 2”) à grande vitesse

M12X50 (1/2” X 2”) à vitesse réduite

M10X50 (3/8” X 2”) à vitesse réduite

M10X50 (3/8” X 2”) à grande vitesse

Temps de serrage

Boulon à haute résistance

N.m

260

(188)

240

(174)

220

M16X50 (5/8” X 2”) à grande vitesse

(159)

200

(145)

180

(130)

160

(116)

140

(101)

120

(87)

Couple de serrage

100

(72)

80

(58)

60

(43)

40

(29)

20

(14)

012

M12X50 (1/2” X 2”) à vitesse réduite

M10X50 (3/8” X 2”) à vitesse réduite

M10X50 (3/8” X 2”) à grande vitesse

3

Temps de serrage

Boulon standard

N.m

(ft.lbs)

200

(144)

150

(108)

100

(72)

Couple de serrage

50

(36)

0 0.5 1

M12X50

(7/16” X 2”)

Temps de serrage

M16 (5/8”)

M12 (1/2”)

M10 (3/8”)

3

(S)

Pour 6904VH

M16 (5/8”)

M12X50 (1/2” X 2”) à grande vitesse

M16X50 (5/8” X 2”) à vitesse

réduite

M12 (1/2”)

M10 (3/8”)

M20X50

(3/4” X 2”)

(S)

M20 (3/4”)

M16 (5/8”)

M12 (7/16”)

1.5

(S)

45 6

M16X50

(5/8” X 2”)

002346

Pour 6904VH

Couple de serrage adéquat

002347

002349

Pour 6905H

Couple de serrage adéquat

Boulon à haute résistance

N.m

(ft.lbs)

300

(217)

250

(181)

200

(144)

150

(108)

100

(72)

Couple de serrage

M12X50 (7/16” X 2”)

50

(36)

0 12345 67

M16X50 (5/8” X 2”)

Temps de serrage

Pour 6905H

M16 (5/8”)

M12 (7/16”)

8

(S)

Saisissez fermement l’outil et placez la douille sur le

boulon ou l’écrou. Mettez l’outil en marche et procédez

au serrage, en appliquant le temps de serrage adéquat.

NOTE:

• Tenez votre outil bien droit sur le boulon ou l’écrou.

• Un couple de serrage excessif risque

d’endommager le boulon/l’écrou ou la douille.

Avant de commencer le travail, effectuez toujours

un essai pour vérifier que le temps de serrage

conviennent pour le boulon ou l’écrou en question.

Le couple de serrage dépend d’un certain nombre de

facteurs, comme suit. Une fois le serrage terminé,

vérifiez toujours le couple avec une clé dynamométrique.

1. Tension

Couple de serrage adéquat

Une baisse de tension entraînera une réduction du

couple de serrage.

2. Douille

• L’utilisation d’une douille de mauvaise

dimension entraînera une réduction du couple

de serrage.

• Une douille usée (usure sur l’extrémité

hexagonale ou l’extrémité carrée) entraînera

une réduction du couple de serrage.

3. Boulon

• Même si le coefficient du couple et la catégorie

du boulon sont les mêmes, le couple de

serrage variera en fonction du diamètre de

boulon.

• Même si les diamètres des boulons sont les

mêmes, le couple de serrage variera en

fonction du coefficient de couple, de la

catégorie du boulon et de la longueur du

boulon.

4. L’utilisation d’un joint universel ou d’une barre de

rallonge réduit quelque peu la force de serrage de

la boulonneuse. Compenser en serrant plus

longtemps.

5. Le couple de serrage est affecté par la façon dont

vous tenez l’outil ou la pièce, ou par la position de

vissage.

12

002350

Couple de serrage adéquat

Page 13

Vissage

Pour 6904VH uniquement

Pour serrer des vis, installez un adaptateur à embout

(accessoire en option) sur l’outil et insérez-y un embout

(accessoire en option).

Tene z l ’outil fermement et placez la panne de l’embout

dans la tête de la vis. Appliquez à l’outil une pression

vers l’avant pour que la panne ne glisse pas hors de la

vis. Faites démarrer l’outil à vitesse réduite puis

augmentez graduellement la vitesse. Relâchez la

gâchette dès que la vis atteint son point le plus bas.

NOTE:

• Utilisez l’embout qui convient à la tête de la vis/du

boulon utilisé(e).

• Tene z l ’outil bien droit par rapport à la vis, sinon

vous risquez d’endommager la vis et/ou l’embout.

• Lorsque vous insérez des vis à bois, percez

d’abord des trous de guidage pour faciliter

l’insertion des vis et pour éviter que la pièce ne se

fende. Les trous de guidage doivent être un peu

plus petits que le diamètre des vis à bois.

002371

ENTRETIEN

ATTENTION:

• Assurez-vous toujours que l’outil est hors tension et

débranché avant d’y effectuer tout travail

d’inspection ou d’entretien.

Pour maintenir la SÉCURITÉ et la FIABILITÉ du produit,

les réparations, l’inspection et le remplacement des

charbons, et tout autre travail d’entretien ou de réglage

doivent être effectués dans une usine ou un centre de

service après-vente Makita agréé, exclusivement avec

des pièces de rechange Makita.

ACCESSOIRES

ATTENTION:

• Ces accessoires ou pièces complémentaires sont

recommandés pour l’utilisation avec l’outil Makita

spécifié dans ce mode d’emploi. L’utilisation de tout

autre accessoire ou pièce complémentaire peut

comporter un risque de blessure. N’utilisez les

accessoires ou pièces qu’aux fins auxquelles ils ont

été conçus.

Si vous désirez obtenir plus de détails concernant ces

accessoires, veuillez contacter le centre de service

après-vente Makita le plus près.

• Douilles

• Barre de rallonge

• Joint universel

• Adaptateur à embout (pour 6904VH uniquement)

• Embouts cruciformes (pour 6904VH uniquement)

• Embouts à douille (pour 6904VH uniquement)

GARANTIE LIMITÉE D’UN AN MAKITA

Politique de garantie

Chaque outil Makita est inspecté rigoureusement et testé

avant sa sortie d’usine. Nous garantissons qu’il sera

exempt de défaut de fabrication et de vice de matériau

pour une période d’UN AN à partir de la date de son

achat initial. Si un problème quelconque devait survenir

au cours de cette période d’un an, veuillez retourner

l’outil COMPLET, port payé, à une usine ou à un centre

de service après-vente Makita. Makita réparera l’outil

gratuitement (ou le remplacera, à sa discrétion) si un

défaut de fabrication ou un vice de matériau est

découvert lors de l’inspection.

Cette garantie ne s’applique pas dans les cas où:

• des réparations ont été effectuées ou tentées par

un tiers:

• des réparations s’imposent suite à une usure

normale:

• l’outil a été malmené, mal utilisé ou mal entretenu:

• l’outil a subi des modifications.

MAKITA DÉCLINE TOUTE RESPONSABILITÉ POUR

TOUT DOMMAGE ACCESSOIRE OU INDIRECT LIÉ À

LA VENTE OU À L’UTILISATION DU PRODUIT. CET

AVIS DE NON-RESPONSABILITÉ S’APPLIQUE À LA

FOIS PENDANT ET APRÈS LA PÉRIODE COUVERTE

PAR CETTE GARANTIE.

MAKITA DÉCLINE TOUTE RESPONSABILITÉ QUANT

À TOUTE GARANTIE TACITE, INCLUANT LES

GARANTIES TACITES DE “QUALITÉ MARCHANDE”

ET “ADÉQUATION À UN USAGE PARTICULIER”

APRÈS LA PÉRIODE D’UN AN COUVERTE PAR

CETTE GARANTIE.

Cette garantie vous donne des droits spécifiques

reconnus par la loi, et possiblement d’autres droits, qui

varient d’un État à l’autre. Certains États ne permettant

pas l’exclusion ou la limitation des dommages

accessoires ou indirects, il se peut que la limitation ou

exclusion ci-dessus ne s’applique pas à vous. Certains

États ne permettant pas la limitation de la durée

d’application d’une garantie tacite, il se peut que la

limitation ci-dessus ne s’applique pas à vous.

13

EN0006-1

Page 14

ESPAÑOL

ESPECIFICACIONES

Modelo 6904VH 6905H

Especificaciones eléctricas en México

Perno estándar M10 - M16 (3/8” - 5/8”) M12 - M20 (1/2” - 3/4”)

Capacidades

Adaptador cuadrado 12,7 mm (1/2”) 12,7 mm (1/2”)

Revoluciones por minuto (r.p.m.)

Impactos por minuto

To rs i ón de fijación máxima

Longitud total 265 mm (10-3/8”) 275 mm (10-13/16”)

• Debido a un programa continuo de investigación y desarrollo, las especificaciones aquí dadas están sujetas a

cambios sin previo aviso.

• Nota: Las especificaciones pueden ser diferentes de país a país.

Perno de gran resistencia M10 - M12 (3/8” - 1/2”) M12 - M16 (1/2” - 5/8”)

Tornillo para madera 6 mm x 100 mm (1/4” x 3-15/16”)-

Tornillo de autoperforación 6 mm (1/4”)-

Alta 0 - 2 400/min.

Baja 0 - 2 100/min.

Alta 0 - 3 000

Baja 0 - 2 500

Alta 196 N.m (145 ft.lbs)

Baja 147 N.m (109 ft.lbs)

Peso neto 1,8 kg (4,0 lbs) 2,3 kg (5 lbs)

115 V 4,6 A 50/60 Hz 115 V 6 A 50/60 Hz

2 200/min.

2 600

294 N.m (217 ft.lbs)

NORMAS GENERALES DE

SEGURIDAD

GEA001-3

AVISO:

Lea todas las instrucciones. Si no cumple

con las instrucciones aquí detalladas, se

puede producir una descarga eléctrica,

incendio y/o heridas de gravedad. El

término “herramienta eléctrica” en todas las

advertencias que figuran a continuación se

refiere a la herramienta eléctrica alimentada

por la red principal (con cable) o a la

operada por batería (sin cable).

GUARDE ESTAS

INSTRUCCIONES

Seguridad del área de trabajo

1. Mantenga el área de trabajo limpia y bien

iluminada. Las áreas oscuras y desordenadas son

propensas a accidentes.

2. No opere herramientas eléctricas en atmósferas

explosivas tales como en presencia de polvo,

gases o líquidos inflamables. Las herramientas

eléctricas producen chispas que puede encender el

polvo o los gases.

3. Mantenga a los niños y personas cercanas

alejadas mientras opera la herramienta eléctrica.

Si se distrae, puede perder el control de la

herramienta.

Seguridad eléctrica

4. El enchufe de la herramienta eléctrica debe

coincidir con la ficha. Nunca modifique el

enchufe. No use ningún adaptador con las

herramientas eléctricas a tierra (a masa). Los

enchufes sin modificar y las fichas correspondientes

reducen el riesgo de descarga eléctrica.

5. Evite el contacto corporal con superficies a

masa (a tierra) tales como radiadores, tuberías,

refrigeradores y hornillos. Se corre más riesgo de

sufrir una descarga eléctrica si el cuerpo está a

tierra.

6. No exponga las herramientas eléctricas a la

lluvia o a la humedad. Si ingresa agua en la

herramienta eléctrica, aumenta el riesgo de sufrir

una descarga eléctrica.

7. No tire del cable. Nunca utilice el cable para

transportar, tirar o desenchufar la herramienta

14

Page 15

eléctrica. Mantenga el cable alejado del calor,

aceite, objetos cortantes o piezas móviles. Los

cables dañados o atrapados aumentan el riesgo de

sufrir una descarga eléctrica.

8. A la hora de operar una herramienta eléctrica en

el exterior, utilice un prolongador apropiado. Si

lo utiliza, se reduce el riesgo de sufrir una descarga

eléctrica.

Seguridad personal

9. Esté atento, preste atención a lo que está

haciendo y utilice su sentido común cuando

opere una herramienta eléctrica. No utilice la

herramienta eléctrica cuando esté cansado o

bajo la influencia de drogas, alcohol o

medicamentos. Un momento de distracción

mientras opera la máquina puede dar como

resultado heridas personales graves.

10. Utilice equipos de seguridad. Utilice siempre

protección ocular. Los equipos de seguridad como

máscaras para protegerse del polvo, calzado

antideslizante o protección para los oídos, que se

utilizan en condiciones adecuadas, reducen el

riesgo de sufrir heridas personales.

11. Evite el encendido accidental de la herramienta.

Asegúrese de que el interruptor se encuentra en

posición de apagado (OFF) antes de enchufar la

herramienta. Si transporta la herramienta eléctrica

con su dedo en el interruptor o si enchufa la

herramienta cuando está encendida (ON) puede

haber accidentes.

12. Retire todas las llaves y tuercas de ajuste antes

de encender la herramienta eléctrica. Si deja

alguna de éstas adherida a una parte giratoria de la

herramienta eléctrica puede sufrir daños en su

persona.

13. No haga demasiadas cosas al mismo tiempo.

Mantenga la postura y el equilibrio en todo

momento. De esta manera, tendrá un mejor control

de la herramienta eléctrica en situaciones

inesperadas.

14. Utilice ropa adecuada. No utilice ropa holgada ni

joyas. Mantenga su cabello, ropa y guantes

alejados de las piezas móviles. La ropa holgada,

las joyas y el cabello pueden atascarse en las

piezas móviles.

15. Si se proveen dispositivos para la conexión de

extracción y recolección de polvo, asegúrese de

que estén correctamente conectados y sean

adecuadamente utilizados. La utilización de estos

dispositivos puede reducir los riesgos relacionados

con el polvo.

Mantenimiento y uso de la herramienta

eléctrica

16. No fuerce la herramienta eléctrica. Utilice la

herramienta eléctrica correcta para su

aplicación. La herramienta eléctrica adecuada hará

un trabajo mejor a la velocidad para la que ha sido

fabricada.

17. No utilice la herramienta eléctrica si el

interruptor no la enciende y apaga. Cualquier

herramienta eléctrica que no pueda ser controlada

con el interruptor es peligrosa y debe ser

reemplazada.

18. Desconecte el enchufe de la fuente de energía y/

o la batería de la herramienta eléctrica antes de

realizar ajustes, cambiar accesorios o guardar

las herramientas eléctricas. Dichas medidas de

seguridad preventivas reducen el riesgo de que la

herramienta se opere accidentalmente.

19. Guarde la herramienta eléctrica que no use fuera

del alcance de los niños y no permita que las

personas que no están familiarizadas con ella o

con las instrucciones la operen. Las herramientas

eléctricas son peligrosas en manos de personas

que no saben operarlas.

20. Realice el mantenimiento de la herramienta

eléctrica. Verifique que no esté mal alineada,

uniones de las partes móviles, piezas rotas y

demás condiciones que puedan afectar el

funcionamiento de la herramienta eléctrica. Si

está dañada, haga reparar la herramienta

eléctrica antes de utilizarla. Muchos accidentes

son causados por herramientas eléctricas que no

han recibido un mantenimiento adecuado.

21. Mantenga las herramientas de corte limpias y

filosas. Si recibe un mantenimiento adecuado y

tiene los bordes afilados, es probable que la

herramienta se atasque menos y sea más fácil

controlarla.

22. Utilice la herramienta eléctrica, accesorios,

brocas, etc. de acuerdo con estas instrucciones

y de la manera establecida para cada tipo de

unidad en particular; tenga en cuenta las

condiciones laborales y el trabajo a realizar. Si

utiliza la herramienta eléctrica para realizar

operaciones distintas de las indicadas, podrá

presentarse una situación peligrosa.

Servicio técnico

23. Haga que una persona calificada repare la

herramienta utilizando sólo piezas de repuesto

idénticas. Esto asegura que se mantenga la

seguridad de la herramienta eléctrica.

24. Siga las instrucciones para la lubricación y

cambio de accesorios.

25. Mantenga las asas secas, limpias y sin aceite o

grasa.

15

Page 16

NORMAS ESPECÍFICAS DE

SEGURIDAD

GEB009-2

NO deje que la comodidad o familiaridad

con el producto (a base de utilizarlo

repetidamente) sustituya la estricta

observancia de las normas de seguridad

para la sierra. Si utiliza esta herramienta

de forma no segura o incorrecta, podría

sufrir graves heridas personales.

1. Cuando realice una operación donde la

herramienta eléctrica pudiera entrar en contacto

con cableado oculto o su propio cable, sujete la

herramienta por las superficies de asimiento

aisladas. El contacto con un cable con corriente

hará que la corriente circule por las partes metálicas

de la herramienta y electrocute al operador.

2. Póngase protectores de oídos.

3. Compruebe con cuidado que el enchufe no esté

desgastado, agrietado ni dañado antes de la

instalación.

4. Sostenga la herramienta con firmeza.

5. Asegúrese siempre de que tiene suelo firme.

Asegúrese de que no haya nadie debajo cuando

utilice la herramienta en lugares altos.

6. El par de apriete de torsión apropiado podrá

variar en función del tipo o tamaño del perno.

Compruebe el par de apriete con una llave de

torsión.

GUARDE ESTAS

INSTRUCCIONES

AVISO:

El mal uso o incumplimiento de las

reglas de seguridad descriptas en el

presente manual de instrucciones puede

ocasionar graves lesiones personales.

SÍMBOLOS

A continuación se muestran los símbolos utilizados para

la herramienta.

V............................voltios

A ...........................amperios

Hz..........................hercios

..................corriente alterna

USD202-2

.......................velocidad en vacío

.......................Construcción clase II

.../min ...................revoluciones o alternaciones por

.................. número de percusiones

minuto

DESCRIPCIÓN DEL

FUNCIONAMIENTO

PRECAUCIÓN:

• Asegúrese siempre de que la herramienta esté

apagada y desenchufada antes de ajustar o

comprobar cualquier función en la herramienta.

Accionamiento del interruptor

1

PRECAUCIÓN:

• Antes de enchufar la herramienta, compruebe

siempre que el gatillo interruptor se acciona

debidamente y que vuelve a la posición “OFF”

(apagado) cuando lo suelta.

Para 6904VH

Para poner en marcha la herramienta, simplemente

apriete el gatillo interruptor. La velocidad de la

herramienta aumenta incrementando la presión en el

gatillo. Suelte el gatillo interruptor para parar.

Para 6905H

Para comenzar a utilizar la herramienta, simplemente

presione el gatillo interruptor. Suéltelo para detenerla.

Accionamiento del interruptor de inversión

Para 6904VH

002311

1. Gatillo

interruptor

002322

1. Interruptor de

inversión

1

16

Page 17

Esta herramienta tiene un interruptor de inversión para

cambiar la dirección de rotación. Oprima el lado superior

(lado FWD) para rotación en dirección de las manecillas

del reloj (avante) o el lado inferior (lado REV) para

rotación en dirección contraria de las manecillas del reloj

(reversa).

Para 6905H

1

Esta herramienta tiene un interruptor de inversión para

cambiar la dirección de rotación. Oprima el lado derecho

del interruptor para rotación en dirección de las

manecillas del reloj (avante) o el lado izquierdo para

rotación contraria a las manecillas del reloj (reversa).

PRECAUCIÓN:

• Confirme siempre la dirección de giro antes de la

operación.

• Utilice el interruptor de inversión solamente

después de que la herramienta se haya parado

completamente. Si cambia la dirección de giro

antes de que la herramienta se haya parado podrá

dañarla.

002323

1. Interruptor de

inversión

Cambio de velocidad

Para 6904VH solamente

002329

1. Palanca de

cambio de

velocidad

MONTAJE

PRECAUCIÓN:

• Asegúrese siempre de que la herramienta esté

apagada y desenchufada antes de realizar

cualquier trabajo en la herramienta.

Selección del manguito correcto

Utilice siempre el dado de tamaño correcto para pernos

y tuercas. El utilizar un dado de tamaño incorrecto

resultará en una torsión de apriete impreciso e

inconsistente y/o en daños al perno o a la tuerca.

Instalación o extracción del dado

1

2

Para instalar el dado, empújelo contra el acoplador de la

herramienta hasta que quede bloqueado en posición.

Para extraer el dado, sáquelo tirando de él simplemente.

002335

1. Enchufe

2. Eje

OPERACIÓN

007444

1

Para cambiar la velocidad, primero apague la

herramienta y después deslice la palanca de cambio de

velocidad totalmente al lado “H” (lado inferior) para

velocidad alta o “B” lado “L” (lado superior) para

velocidad baja. Antes de iniciar el funcionamiento,

asegúrese que la palanca de cambio de velocidad esté

deslizada totalmente a la posición deseada. Seleccione

la velocidad óptima para su trabajo.

PRECAUCIÓN:

• No utilice la palanca de cambio de velocidad

mientras la herramienta esté en marcha. Podría

dañarse la herramienta.

17

Page 18

El par de fuerzas de apretar adecuado puede diferir

dependiendo del tipo y tamaño del tornillo, el material de

la pieza de trabajo que se va a apretar, etc.. La relación

entre el par de fuerzas de apretar y el tiempo de apretar

se muestra en las figuras.

Tornillo estándar

N.m

(ft. lbs)

Par de fuerzas para apretar

Tornillo de alta tracción

Tornillo estándar

N.m

(ft. lbs)

Par de fuerzas para apretar

M16 X 50 (5/8 pulg. X 2 pulg.) a alta velocidad

140

(101)

120

(87)

100

(72)

80

(58)

60

(43)

40

(29)

20

(14)

01 2

N.m

260

(188)

240

(174)

220

(159)

200

(145)

180

(130)

160

(116)

140

(101)

120

(87)

100

(72)

80

Par de fuerzas para apretar

(58)

60

(43)

40

(29)

20

(14)

012

200

(144)

150

(108)

100

(72)

50

(36)

0 0,5 1

M16 X 50 (5/8 pulg. X 2 pulg.) a baja velocidad

M12 X 50 (1/2 pulg. X 2 pulg.) a alta velocidad

M12 X 50 (1/2 pulg. X 2 pulg.) a baja velocidad

M10 X 50 (3/8 pulg. X 2 pulg.) a baja velocidad

M10 X 50 (3/8 pulg. X 2 pulg.) a alta velocidad

Tiempo de apretar

M16 X 50 (5/8 pulg. X 2 pulg.) a alta velocidad

M12X 50 (1/2 pulg. X 2 pulg.) a alta velocidad

M12X 50 (1/2 pulg. X 2 pulg.) a baja velocidad

M10X 50 (3/8 pulg. X 2 pulg.) a baja velocidad

M10X 50 (3/8 pulg. X 2 pulg.) a alta velocidad

3

45 6

Tiempo de apretar

M12X50

(7/16” X 2”)

Tiempo de apretar

M16 (5/8”)

M12 (1/2”)

M10 (3/8”)

3

(S)

Para 6904VH

M16 (5/8”)

M16X 50 (5/8 pulg. X 2 pulg.)

a baja velocidad

M12 (1/2”)

M10 (3/8”)

(S)

M20X50

(3/4” X 2”)

M16X50

(5/8” X 2”)

M20 (3/4”)

M16 (5/8”)

M12 (7/16”)

1,5

(S)

002346

Para 6904VH

Par de fuerzas para apretar adecuado

002347

Par de fuerzas para apretar adecuado

002349

Para 6905H

Par de fuerzas para apretar adecuado

Tornillo de alta tracción

N.m

(ft. lbs)

300

(217)

250

(181)

200

(144)

150

(108)

100

(72)

Par de fuerzas para apretar

Sujete firmemente la herramienta y ponga el dado sobre

el tornillo o la tuerca. Ponga en marcha la herramienta y

M12X50 (7/16” X 2”)

50

(36)

0 12345 67

M16X50 (5/8” X 2”)

Tiempo de apretar

Para 6905H

M16 (5/8”)

M12 (7/16”)

8

(S)

apriete durante el tiempo de apriete apropiado.

NOTA:

• Sujete la herramienta orientada en línea recta al

tornillo o tuerca.

• Una torsión de apriete excesiva puede dañar el

perno/tuerca o la llave hexagonal. Antes de

comenzar la tarea, realice siempre una operación

de prueba para determinar el tiempo de apriete

apropiado para el perno o la tuerca que quiere

apretar.

La torsión de apriete se ve afectada por una amplia

variedad de factores incluyendo los siguientes. Después

del apriete, compruebe siempre la torsión de apriete con

una llave de torsión.

1. Tensión

La caída de tensión producirá una reducción del

par de apriete.

2. Dado

• Si no se utiliza un dado del tamaño correcto, la

torsión de apriete se verá reducida.

• Si es utiliza un dado desgastado (desgaste en

el extrermo hexagonal o en extremo

cuadrangular), la torsión de apriete se verá

reducido.

3. Perno o tomillo.

• Incluso si el coeficiente de torsión y la clase del

priete correcto variará de acuerdo con el

diámetro del perno o tornillo.

• Incluso si el diámetro del tornillo o perno es el

mismo, la torsión de apriete correcta variará de

acuerdo con el coeficiente de torsión, la clase y

la longitud del perno o tornillo.

4. La utilización de una junta universal o de una barra

de extensión reduce de alguna manera la fuerza de

apriete de la llave de impacto. Compense esto

alargando el tiempo de apriete.

5. La forma de sostener la herramienta o el material

en la posición a apretar afectará a la torsión.

18

002350

Par de fuerzas para apretar adecuado

Page 19

Operación de atornillado

Para 6904VH solamente

Cuando se necesite atornillar, instale un adaptador de

punta (accesorio opcional) en la herramienta e inserte

una punta de desarmador (accesorio opcional) en el

adaptador.

Sostenga la herramienta firmemente y coloque la punta

de la broca en la cabeza del tornillo. Aplique presión

frontal a la herramienta suficiente como para que la

punta no se deslice del tornillo. Encienda la herramienta

lentamente y luego aumente la velocidad en forma

gradual. Suelte el gatillo interruptor a medida que el

tornillo sale.

NOTA:

• Utilice la punta apropiada para la cabeza del

tornillo/perno que desee utilizar.

• Sostenga la herramienta dirigida en línea recta al

tornillo o podrían dañarse el tornillo y/ o la broca.

• Cuando maneje tornillos de madera, perfore antes

los orificios piloto para facilitar la operación y evitar

que se parta la pieza de trabajo. Los orificios piloto

deberán ser apenas más pequeños en diámetro

que los tornillos de madera.

002371

MANTENIMIENTO

PRECAUCIÓN:

• Asegúrese siempre que la herramienta esté

apagada y desenchufada antes de intentar realizar

una inspección o mantenimiento.

Para mantener la SEGURIDAD y FIABILIDAD del

producto, las reparaciones, la inspección y sustitución de

las escobillas de carbón, y cualquier otro mantenimiento

o ajuste deberán ser realizados en Centros o Servicios

de fábrica Autorizados por Makita, empleando siempre

piezas de repuesto de Makita.

ACCESORIOS

PRECAUCIÓN:

• Estos accesorios o acoplamientos están

recomendados para utilizar con su herramienta

Makita especificada en este manual. El empleo de

cualesquiera otros accesorios o acoplamientos

conllevará un riesgo de sufrir heridas personales.

Utilice los accesorios o acoplamientos solamente

para su fin establecido.

Si necesita cualquier ayuda para más detalles en

relación con estos accesorios, pregunte a su centro de

servicio Makita local.

• Dados

• Barra de extensión

• Unión universal

• Adaptador de punta (para 6904VH solamente)

• Puntas Phillips (para 6904VH solamente)

• Puntas para dados (para 6904VH solamente)

GARANTÍA LIMITADA MAKITA DE UN AÑO

Política de garantía

Cada herramienta Makita es inspeccionada y probada

exhaustivamente antes de salir de fábrica. Se garantiza

que va a estar libre de defectos de mano de obra y

materiales por el periodo de UN AÑO a partir de la fecha

de adquisición original. Si durante este periodo de un

año se desarrollase algún problema, retorne la

herramienta COMPLETA, porte pagado con antelación,

a una de las fábricas o centros de servicio autorizados

Makita. Si la inspección muestra que el problema ha sido

causado por mano de obra o material defectuoso, Makita

la reparará (o a nuestra opción, reemplazará) sin cobrar.

Esta garantía no será aplicable cuando:

• se hayan hecho o intentado hacer reparaciones por

otros:

• se requieran reparaciones debido al desgaste

normal:

• la herramienta haya sido abusada, mal usada o

mantenido indebidamente:

• se hayan hecho alteraciones a la herramienta.

EN NINGÚN CASO MAKITA SE HARÁ RESPONSABLE

DE NINGÚN DAÑO INDIRECTO, FORTUITO O

CONSECUENCIAL DERIVADO DE LA VENTA O USO

DEL PRODUCTO.

ESTA RENUNCIA SERÁ APLICABLE TANTO

DURANTE COMO DESPUÉS DEL TÉRMINO DE ESTA

GARANTÍA.

MAKITA RENUNCIA LA RESPONSABILIDAD POR

CUALQUIER GARANTÍA IMPLÍCITA, INCLUYENDO

GARANTÍAS IMPLÍCITAS DE “COMERCIALIDAD” E

“IDONEIDAD PARA UN FIN ESPECÍFICO”, DESPUÉS

DEL TÉRMINO DE UN AÑO DE ESTA GARANTÍA.

Esta garantía le concede a usted derechos legales

específicos, y usted podrá tener también otros derechos

que varían de un estado a otro. Algunos estados no

permiten la exclusión o limitación de daños fortuitos o

consecuenciales, por lo que es posible que la antedicha

limitación o exclusión no le sea de aplicación a usted.

Algunos estados no permiten limitación sobre la

duración de una garantía implícita, por lo que es posible

que la antedicha limitación no le sea de aplicación a

usted.

19

EN0006-1

Page 20

< USA only >

WARNING

Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to the State of California

to cause cancer, birth defects or other reproductive harm. Some examples

of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this

type of work. To reduce your exposure to these chemicals: work in a well

ventilated area, and work with approved safety equipment, such as those

dust masks that are specially designed to filter out microscopic particles.

< USA solamente >

ADVERTENCIA

Algunos tipos de polvo creados por el lijado, serrado, amolado, taladrado, y

otras actividades de la construccion contienen sustancias quimicas

reconocidas por el Estado de California como causantes de cancer, defectos

de nacimiento y otros peligros de reproduccion. Algunos ejemplos de estos

productos quimicos son:

• plomo de pinturas a base de plomo,

• silice cristalino de ladrillos y cemento y otros productos de albanileria, y

• arsenico y cromo de maderas tratadas quimicamente.

El riesgo al que se expone variara, dependiendo de la frecuencia con la que

realice este tipo de trabajo. Para reducir la exposicion a estos productos

quimicos: trabaje en un area bien ventilada, y pongase el equipo de seguridad

indicado, tal como esas mascaras contra el polvo que estan especialmente

disenadas para filtrar particulas microscopicas.

Makita Corporation

3-11-8, Sumiyoshi-cho,

Anjo, Aichi 446-8502 Japan

883796A943

Loading...

Loading...