Makita 6800DB, 6801DB, 6801DBV, 6800DBV Instruction Manual

Wkrętarka do murów suchych

6800DB

6800DBV

6801DB

6801DBV

Drywall Screwdriver

Instruction Manual

Schrauber

Betriebsanleitung

Instrukcja obsługi

Отвертка для сухих стен

Инструкция по эксплуатации

1

2

3

5

7

4

6

8

2

Symbols

The followings show the symbols used for the tool. Be sure that you understand their meaning before use.

Symbole

Die folgenden Symbole werden für die Ma schine verwendet . Machen Sie si ch vor der Benutzun g unbeding t mit ihrer

Bedeutung vertraut.

Symbole

Poniższe symbole używane są do opisu urządzenia. Przed użyciem należy upewnić się, że rozumie się ich znaczenie.

Символы

Следующие объяснения показывают символы, используемые для инструмента. Убедитесь перед

использованием, что Вы понимаете их значение.

❏ Read instruction manual.

❏ Bitte Bedienungsanleitung lesen.

❏ Przeczytaj instrukcję obsługi.

❏ Прочитайте инструкцию по эксплуатации.

❏ DOUBLE INSULATION

❏ DOPPELT SCHUTZISOLIERT

❏ PODWÓJNA IZOLACJA

❏ ДВОЙНАЯ ИЗОЛЯЦИЯ

❏ Only for EU countries

Do not dispose of electric equipment together with household waste material!

In observance of European D irective 2002/96/EC on waste electr ical and electronic equi pment and

its implementation in accordan ce with nationa l law, electric equipm ent that h ave reached the e nd of

their life must be collected separately and returned to an environmentally compatible recycling facility.

❏ Nur für EU-Länder

Werfen Sie Elektrowerkzeuge nicht in den Hausmüll!

Gemäß Europäischer Richtlinie 2002/96/EG über Elektro- und Elektronik-Altgeräte und Umsetzung in

nationales Recht müssen verbrauchte Elek trower kzeuge getr ennt gesa mmelt un d einer um weltger echten Wiederverwertung zugeführ t werde n.

❏ Dotyczy tylko państw UE

Nie wyrzucaj urządzeń elektrycznych wraz z odpadami z gospodarstwa domowego!

Zgodnie z Europejską Dyrektywą 2002/96/WE w sprawie zużytego sprzętu elektrotechnicznego i

elektronicznego oraz dostosowaniem jej do prawa krajowego, zużyte urządzenia elektryczne należy

posegregować i zutylizować w sposób przyjazny dla środowiska.

❏ Только для стран ЕС

Не выкидывайте электрическое оборудование вместе с бытовым мусором!

В соответствии с европейской директивой 2002/96/EC об утилизацияи старого

электрического и электронного оборудования и её применения в соответствии с местными

законами электрическое оборудование, бывшее в эксплуатации, должно утилизовываться

отдельно безопасным для окружающей среды способом.

3

ENGLISH

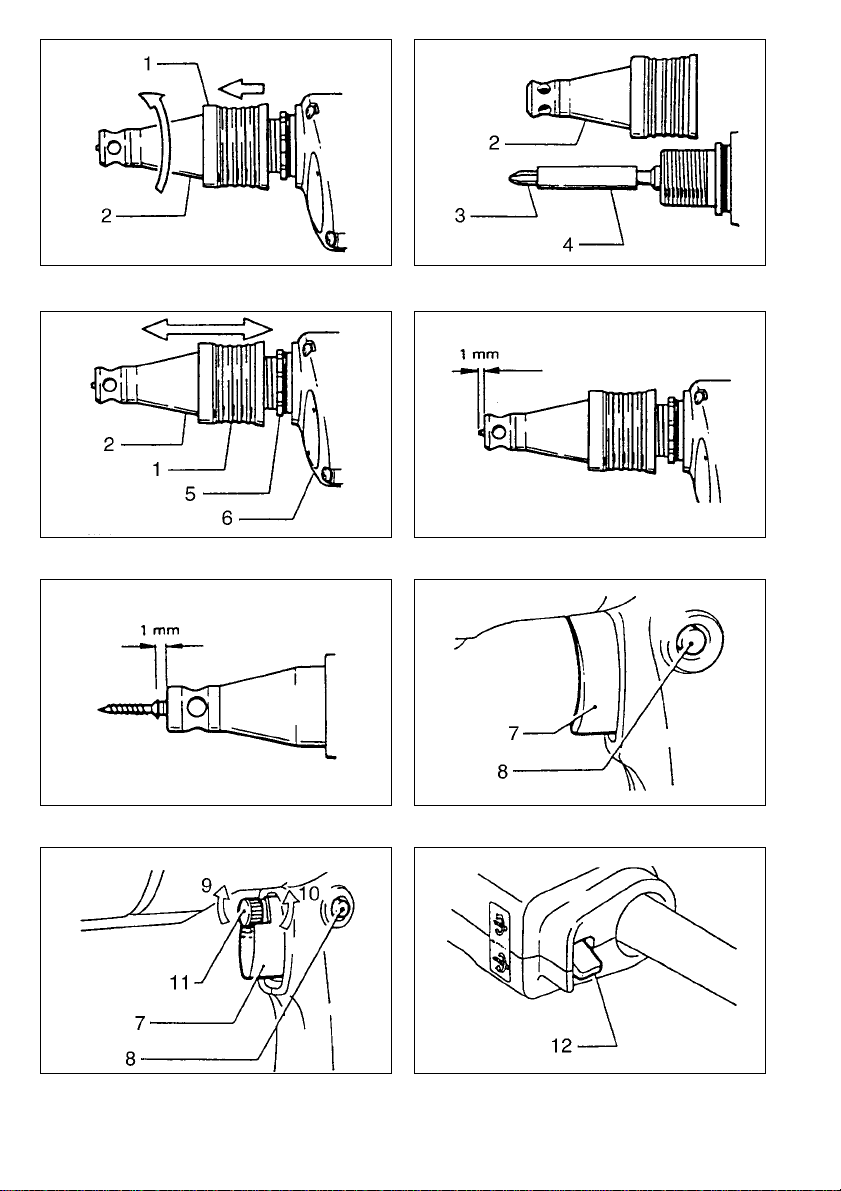

Explanation of general view

1 Locking sleeve

2 Locator

3Bit

4 Magnetic bit holder

5 Locking position

6 Gear housing

7 Switch trigger

8 Lock button

9 High

10 Low

11 Speed control screw

12 Reversing switch lever

SPECIFICATIONS

Model 6800DB 6800DBV 6801DB 6801DBV

Capacities

Drywall screw ......................No. 6 No.6 No.6 No.6

Self drilling screw ................5 mm 5mm 5mm 5mm

Bit shank size.........................1/4”Hex 1/4”Hex 1/4”Hex 1/4”Hex

No load speed (RPM) ............2,500 0–2,500 4,000 0– 4,000

Overall length.........................280 mm 280mm 280mm 280mm

Net weight.............................. 1 .3 kg 1.3kg 1.5kg 1.5kg

• Due to the continuing program of research and

development, the specifications herein are subject

to change without prior notice .

• Note: Specifications may differ from country to

country.

Power supply

The tool should be connected only to a power supply

of the same voltage as indicated on the nameplate,

and can only be operated on si ngle-p has e A C s uppl y.

They are double-insulated in accordance with European Standard and can, therefore, also be used from

sockets without earth wire.

SAFETY INSTRUCTIONS

Warning! When using electric tools, basic safety

precautions should always be followed to reduce

the risk of fire, electr ic shock and personal injury,

including the following. Read all these instructions before attempting to operate this product

and save these instructions.

For safe operation:

1. Keep work area clean

Cluttered areas and benches in vite injuries.

2. Consider work area environment

Don’t expose power tools to rain. Don’t use

power tools in damp or wet locations. Keep work

area well lit. Don’t use power tools in presen ce of

flammable liquids or gases.

3. Guard agai n st el ectric shock

Prevent body contact with grounded surfaces

(e.g. pipes, radiators, ranges, refrigerators).

4. Keep children away

Do not let visitors contact tool or extension cord.

All visitors should be kept away from work area.

5. Store idle tools

When not in use, tools should be stored in dry,

high, or locked-up place, out of the reach of children.

6. Don’t force tool

It will do the job better and safer at the rate for

which it was intended.

7. Use right tool

Don’t force small tools or attachments to do the

job of a heavy duty tool. Don’t use tools for purposes not intended; for example, don’t use circular saw for cutting tree limbs or logs.

8. Dress properly

Do not wear loose clothing or jewelry. They can

be caught in moving parts. Rubber gloves and

non-skid footw ear are reco mmended when w orking outdoors. Wear protective hair covering to

contain long hair.

9. Use safety glasses and hearing protection

Also use face or dust mask if cutting operation is

dusty.

10. Connect dust extraction equipment

If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used.

11. Don’t abuse cord

Never carry tool by cord or y ank it to disconne ct i t

from receptacle. Keep cord from heat, oil and

sharp edges.

12. Secure work

Use clamps or a vise to hold work. It’s safer than

using your hand and it frees both hands to operate tool.

13. Don’t overreach

Keep proper footing and balance at all time s.

14. Maintain tools with care

Keep tools sharp and clean for better and safer

performance. Follow instructions for lubricating

and changing accessories. Inspect tool cords

periodically and, if damaged, have repaired by

authorized service facility. Inspect extension

cords periodically and replace if damaged. Keep

handles dry, clean and free from oil and grease.

15. Disconnect tools

When not in use, before servicing, and when

changing accessories such as blades, bits and

cutters.

4

16. Remove adjusting keys and wrenches

Form the habit of checking to see that keys and

adjusting wrenches are removed from tool bef ore

turning it on.

17. Avoid unintentional starting

Don’t carry plugged-in tool with finger on switch.

Be sure switch is off when plugging in.

18. Outdoor use extension cords

When tool is used outdoors, use only extension

cords intended for us e outdoors and so marked.

19. Stay alert

Watch what you are doing. Use common sense.

Do not operate tool when you are tired.

20. Check damaged parts

Before further use of the tool, a guard or other

part that is damaged should be caref ull y checked

to determine that it will operate properly and perform its intended function . Che c k for alignment of

moving parts, binding of moving parts, breakage

of parts, mounting, and any other conditions that

may affect its operation. A guard or other part

that is damaged should be properly repaired or

replaced by an authorized service center unless

otherwise indicated elsewhere in this instruction

manual. Have defective switches replaced by

and authorized service center. Do not use tool if

switch does not turn it on and off.

21. Warning

The use of any other accessor y or attachment

other than recommended in this operating

instruction or the catalog may present a risk of

personal injury.

22. Have your tool repaired by an expert

This electric appliance is in accordance with the

relevant safety rules. Repairing of electric appliances may be carried out only by experts otherwise it may cause considerable danger for the

user.

ADDITIONAL SAFETY RULES

1. Always be sure you have a firm footing. Be

sure no one is below when using the tool in

high locations.

2. Hold the tool firmly.

3. Keep hands away from rotating parts.

4. When driving into walls, floors or wherever

“live” electrical wires may be encountered,

DO NOT TOUCH ANY METAL PARTS OF THE

TOOL! Hold the tool by the insulated grasping surfaces to prevent electric shock if you

drive into a “live” wire.

5. Do not touch the bit or the workpiece immediately after operation; they may be extremely

hot and could burn your skin.

SAVE THESE INSTRUCTIONS.

OPERATING INSTRUCTIONS

Removing or installing locator assembly

(Fig.1)

To remove the locator assembly, pull the locking

sleeve forward and then turn it counterclockwise. To

install the locator assembly, screw it clockwise and

then push the loc king sl eeve back in lightly tow ard the

motor. Turn the locking sleeve slightly to match the

locking positions and then push in firmly to lock the

locator in place.

Removing or installing bit (Fig. 2)

Important:

Always be sure that the tool is switched off and

unplugged before removing or installing the bit.

After removing the locator assembly, pull firmly to

remove the magnet ic bit ho lder. Hold the magnetic bit

holder in your hand and grasp the bit with a pair of

pliers. Pull the bit out of the magnetic bit holder.

Sometimes, it helps to wiggle the bit with the pliers as

you pull. To install the bit, follow the removal procedures in reverse.

Depth adjustment (Fig.3,4& 5)

Pull the locking sleeve forward and then turn it to

adjust the depth.

Initially, adjust the locator assembly to create a distance of approximately 1 mm from the tip of the locator to the base of the s crew head. One full turn of the

locator equals 1.5mm change in depth. After adjusting the locator assembly, push the locking slee v e in to

lock the locator in place. Drive a trial screw into your

material or a piece of duplicate material. If the depth

is not suitable for the screw, continue adjusting until

the proper depth setting is obt ained.

Switch action

CAUTION:

Before plugging in the tool, always check to see that

the switch trigger act uates p roperly and ret urns to the

“OFF” position when released.

For Model 6800DB, 6801DB (Fig.6)

To start the tool, simply pull the trigger. Releas e the

trigger to stop. For continuous operation, pull the trigger and then push in the lock button. To stop the tool

from the locked position, pull the trigger fully, then

release it.

For Model 6800DBV, 6801DBV (Fig. 7)

To start the tool, simply pull the trigger. Tool speed is

increased by increasing pressure on the trigger.

Release the trigger to stop. For continuous operation,

pull the trigger and then push in the lock button. To

stop the tool fr om the lo cked posit ion, p ull the tr igge r

fully, then release it. A speed control screw is provided so that maximum tool speed can be limited

(variable). Turn the speed control screw clockwise for

higher speed, and counterclockwise for lower speed.

5

NOTE:

Even with the switch on and motor running, the bit

will not rotate until you fit the point of the bit in the

screw head and apply forward pressure to engage

the clutch.

Reversing switch action (Fig.8)

CAUTION:

• Always check the direction of rotation before operation.

• Use the reversing switch only after the tool comes

to a complete stop. Changing the direction of rotation before the tool stops may damage the tool.

This tool has a reversing switch to change the direction of rotation. Move the reversing switch lever to the

i position for c lockwise r otatio n or the j position

for counterclockwise rotation.

Operation

For Model 6800DB, 6801DB

Fit the screw on the point of the bit and place the

point of the screw on the surface of the workpiece to

be fastened. Apply pressure to the tool and start it.

Withdraw the tool as soon as the clutch cuts in.

For Model 6800DBV, 6801DBV

Fit the screw on the point of the bit and place the

point of the screw on the surface of the workpiece to

be fastened. Apply pressure to the tool. Start the tool

slowly and then increase the speed gradually. Withdraw the tool as soon as the clutch cuts in.

CAUTION:

• Use the proper bit for the head of the screw that y ou

wish to use.

• When fitting the screw onto the point of the bit, be

careful not to push in on the screw. If the screw is

pushed in, the clutch will engage and the screw will

rotate suddenly. This could damage a workpiece or

cause an injury.

• Do not continue unnecessar y clutching operation.

NOTE:

Make sure that the bit is inserted straight in the scre w

head, or the screw and/or bit may be damaged.

MAINTENANCE

CAUTION:

Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

To maintain product safety and reliability, repairs,

maintenance or adjustment should be carried out by

Makita Authorized Service Center.

6

Loading...

Loading...