Page 1

GB

Cordless Driver Drill Instruction Manual

F

Perceuse-visseuse sans fil Manuel d’instructions

D

Akku-Bohrschrauber Betriebsanleitung

I

Trapano-avvitatore a batteria Istruzioni per l’uso

NL

Snoerloze boor-schroevedraaier Gebruiksaanwijzing

E

Taladro-atornillador a batería Manual de instrucciones

P

Berbequim aparafusador a bateria Manual de instruções

DK

Akku bore-skruemaskine Brugsanvisning

S

Sladdlös borrmaskin/skruvdragare Bruksanvisning

N

Akku boreskrutrekker Bruksanvisning

SF

Akkuporakone Käyttöohje

GR Βιδοτρύπανο µε µπαταρία Οδηγίες χρήσεως

6207D

6217D

6317D

6337D

6347D

Page 2

2

1

3

12

4

7

A

56

B

34

9

8

8

10

11

12

56

13

14

15

16

78

2

Page 3

17

910

18

19

11

3

Page 4

ENGLISH

Explanation of general view

1 Battery cartridge

2Button

3 Switch trigger

4 Reversing switch lever

5 Clockwise

6 Counterclockwise

7 Speed change lever

SPECIFICATIONS

Model 6207D 6217D 6317D 6337D 6347D

Capacities

Steel.....................................10 mm 10 mm 13 mm 13 mm 13 mm

Wood....................................25.4 mm 25.4 mm 25.4 mm 32 mm 38 mm

Wood screw..........................6 x 75 mm 6 x 75 mm 6 x 75 mm 6 x 75 mm 10 x 89 mm

Machine screw .....................13 mm 13 mm 13 mm 13 mm 13 mm

No load speed (min

High......................................0 – 1,300 0 – 1,300 0 – 1,300 0 – 1,300 0 – 1,300

Low.......................................0 – 400 0 – 400 0 – 400 0 – 400 0 – 400

Overall length ............................233 mm 233 mm 243 mm 243 mm 243 mm

Net weight .................................1.7 kg 1.9 kg 2.0 kg 2.1 kg 2.4 kg

Rated voltage ............................D.C.9.6 V D.C.12 V D.C.12 V D.C.14.4 V D.C.18V

-1

)

8 Action mode change lever

9 Lock button

10 Adjusting ring

11 Graduations

12 Pointer

13 Sleeve

14 Ring

15 Bit

16 Bit holder

17 Limit ma rk

18 Brush holder cap

19 Screwdriver

• Due to our conti nuing program of rese arch and devel-

opment, the specifications herein are subject to change

without notice.

• Note: Specifications may differ from country to country.

Intended use

The tool is intended for drilling and screw driving in wood,

metal and plastic.

Safety hints

For your own safety, please refer to the enclosed safety

instructions.

IMPORTANT SAFETY INSTRUCTIONS FOR

CHARGER & BATTERY CARTRIDGE

1. Before using batter y cartridge, rea d all instruc-

tions and cautionary markings on (1) battery

charger, (2) battery, and (3) product using battery.

2. Do not disassemble battery cartridge.

3. If operating time has become excessively

shorter, stop operating immediately. It may

result in a risk of overheating, possible burns

and even an explosion.

4. If electrolyte gets into your eyes, rinse them out

with clear water and seek medical attention r ig ht

away. It may result in loss of your eyesight.

5. Always cover the batter y terminals with the b at-

tery cover when the battery cartridge is not

used.

ENC004-1

6. Do not short t h e battery cartridge:

(1) Do not touch the terminals with any conduc-

tive material.

(2) Avoid storing batt ery c artr idg e in a cont ainer

with other metal objects su ch as nails , co ins ,

etc.

(3) Do not expose battery cartridge to water or

rain.

A battery short can cause a large current flow,

overheating, possi ble burns and even a breakdown.

7. Do not store the tool and battery cartridge in

locations where the temperature may reach or

exceed 50°C (122°F).

8. Do not incinera te the batter y cartrid ge even if it

is seve rely damag ed or is com plete ly worn out.

The battery cartridge can explode in a fire.

9. Be careful not to drop or strike battery.

SAVE THESE INSTRUCTIONS.

Tips for maintaining maximum battery life

1. Charge the bat tery cartridge before com pletely

discharged.

Always stop tool operation and charge the battery cartridge when you notice less tool power.

2. Never recharge a fully charged battery cartridge.

Overcharging shortens the battery service life.

3. Charge the batte ry car tr idge with room te mper ature at 10°C – 40°C (50 °F – 104°F). Let a h ot battery cartridge cool down before charging it.

4. Charge the Nickel Metal Hydride battery cartridge when you d o not use i t for more than six

months.

4

Page 5

SPECIFIC SAFETY RULES

DO NOT let comfort or familiarity with product

(gained from repeated use) replace strict adherence

to drill safety rules. If you use this power tool

unsafely or incorrec tly, you can suffer serious per sonal injury.

1. Hold power tools by insulated gripping surfaces

when performing an operation where the cutting

tool may contact hi dden wiring or i ts own cord.

Contact with a “live” wire will make exposed

metal parts of the tool “live” and shock the operator.

2. Always be sure you have a firm footing.

Be sure no o ne is below wh en using t he tool in

high locations.

3. Hold the tool firmly.

4. Keep hands away from rotating parts.

5. Do not leave the too l running. Operate the tool

only when hand-held.

6. Do not touch the drill bit or th e wor kpi ece im m ediately after operation; they may be extremely

hot and could burn your skin.

7. Some material contains chemicals which may be

toxic. Take caution to prevent dust inhalation

and skin contact. F ol low m ate ri al s up pl ier sa fety

data.

GEB002-2

SAVE THESE INSTRUC T IONS.

WARNING:

MISUSE or failure to follo w the s afety r ules stated

in this instruction manual may cause serious

personal injury.

OPERATING INSTRUCTIONS

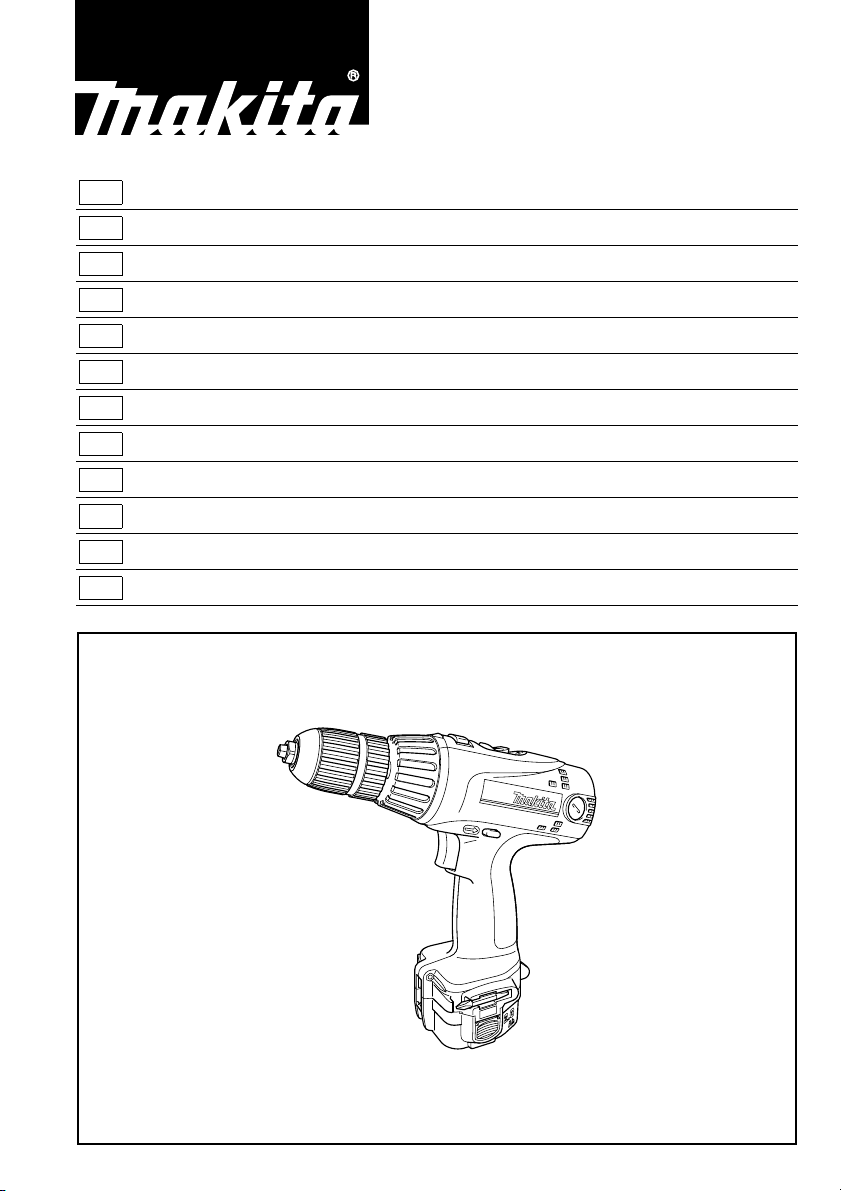

Installing or removing battery cartridge (Fig. 1)

• Always switch off the tool before insertion or removal of

the battery cartridge.

• To remove the battery cartr idge, withdraw it from the

tool while pressing the buttons on both sides of the cartridge.

• To insert the batte ry car tridge, ali gn the tongue on the

battery cartridge with the groove in the housing and slip

it into place. Always insert it all the way until it locks in

place with a little click. If not, it may accidentally fall out

of the tool, causing injur y to you or someone around

you.

• Do not use force when inserting the battery cartridge. If

the cartridge does not slide in easily, it is not being

inserted correctly.

Switch action (F ig. 2)

CAUTION:

Before inserting the battery cartridge into the tool, always

check to see that the switch trigger actuates properly and

returns to the "OFF" pos iti on when rel eas ed.

To start the tool, simply pull the switch trigger. Tool speed

is increased by increasing pressure on the switch trigger.

Release the switch trigger to stop.

Reversing switch action (Fig. 3)

This tool has a reversing switch to change the direction of

rotation. Depress the r eversing switch lever from the A

side for clockwise rotation or from the B side for counte rclockwise rotation.

When the reversing switch lever is in the neutral position,

the switch trigger cannot be pulled.

CAUTION:

• Always check the direction of rotation before operation.

• Use the reversing switch only after the tool comes to a

complete stop. Changing the direction of rotation

before the tool stops may damage the tool.

• When not operating the tool, always set the reversing

switch lever to the neutral position.

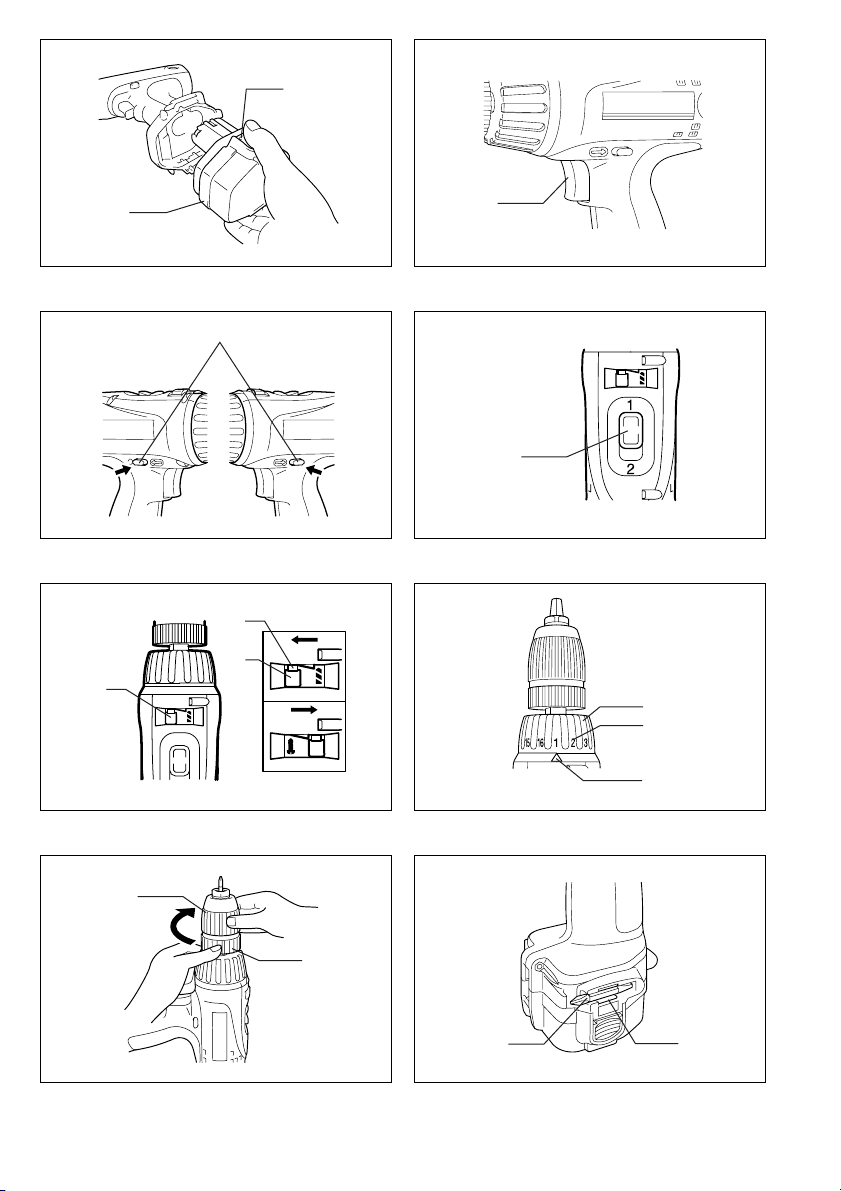

Speed change (Fig. 4)

To change the speed, first switch off the tool and then

slide the speed change lever to the "2" side for high

speed or "1" side for low speed. Be sure that the speed

change lever is set to the correct position before operation. Use the right speed for your job.

CAUTION:

• Always set the speed change lever fully to the correct

position. If you operate the tool w ith the speed change

lever positioned halfway between the "1" side and "2"

side, the tool may be damaged.

• Do not use the speed change lever while the tool is running. The tool may be damaged.

Selecting action mode (Fig. 5)

This tool has an mode change lever. For drilling, depress

the lock button and then slid e the action mode change

lever to the left (

action mode change lever to the ri ght (

it is locked. If it is hard to turn the lever, first turn the

chuck slightly in either d irection and then tur n the lever

again.

CAUTION:

• Always slide the action mode change lever all the way

to your desired mode positi on. If you operate the tool

with the

symbols, the tool may be damaged.

• Do not use the action mode change lever while the tool

is running. The tool may be damaged.

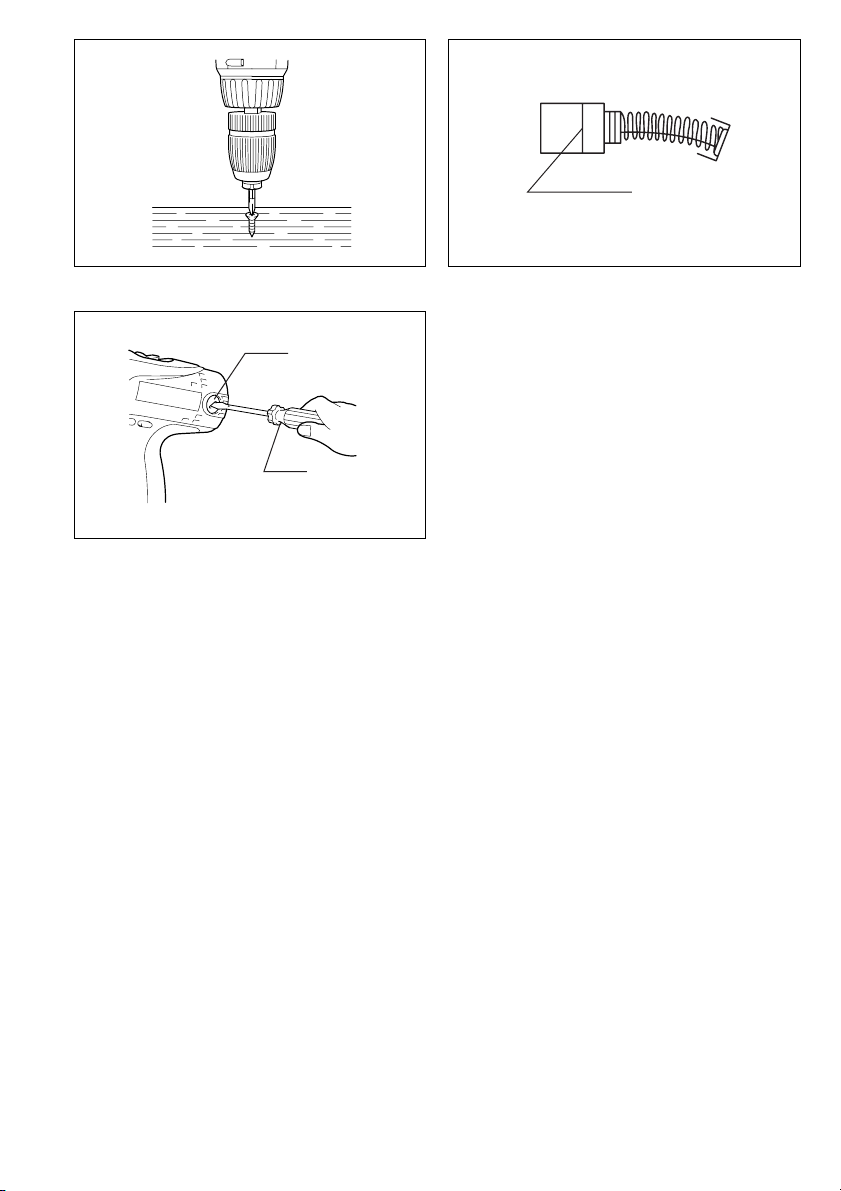

Adjusting the fastening torque (Fig. 6)

The fastening torque can be adjusted in 16 steps by turning the adjusting ring so that its graduations are aligned

with the pointer on the tool body.

FIrst, slide the a ction mode change lever to th e position

of

U symbol.

The fastening torque is mini mum when the number 1 is

aligned with the pointer, and maximum when the marking

is aligned with the pointer. The clutch will slip at various

torque levels when set at the number 1 to 16. Before

actual operation, drive a trial screw into your material or a

piece of duplicate material to determine which torque

level is required for a particular application.

CAUTION:

• The adjusting ring d oes not lock when the pointer is

positioned only halfway between the graduations.

f symbol). For screwing, slide the

U symbol) until

lever positioned halfway between the mode

5

Page 6

ASSEMBLY

CAUTION:

Always be sure that the tool is switched off and th e battery cartridge is removed before carrying out any work on

the tool.

Installing or removing driver bit or drill bit (Fig. 7)

Hold the ring and turn the sleeve counterclockwise to

open the chuck jaws. Place the bit i n th e chuck as far as

it will go. Hold the ring firmly and turn the sleeve clockwise to tighten the chuck.

To remove the bit, hold the ring and turn the sleeve counterclockwise.

When not using the dri ver bit, keep it in the bit holders.

Bits 45 mm long can be kept there. (Fig. 8)

OPERATION

Screwdriving operation (Fig. 9)

First slide the action mode change lever to the position of

U symbol and select the fastening torque.

Place the point of the dr iver bit in the screw head and

apply pressure to the tool. Star t t he tool slowly and then

increase the speed graduall y. Release the switch trigger

as soon as the clutch cuts in.

CAUTION:

• Make sure that the dr iver bit is insert ed straight in the

screw head, or the screw and/or bit may be damaged.

• When driving wood screws, predrill pilot holes to make

driving easier and to prevent splitting o f the wor kpi ece.

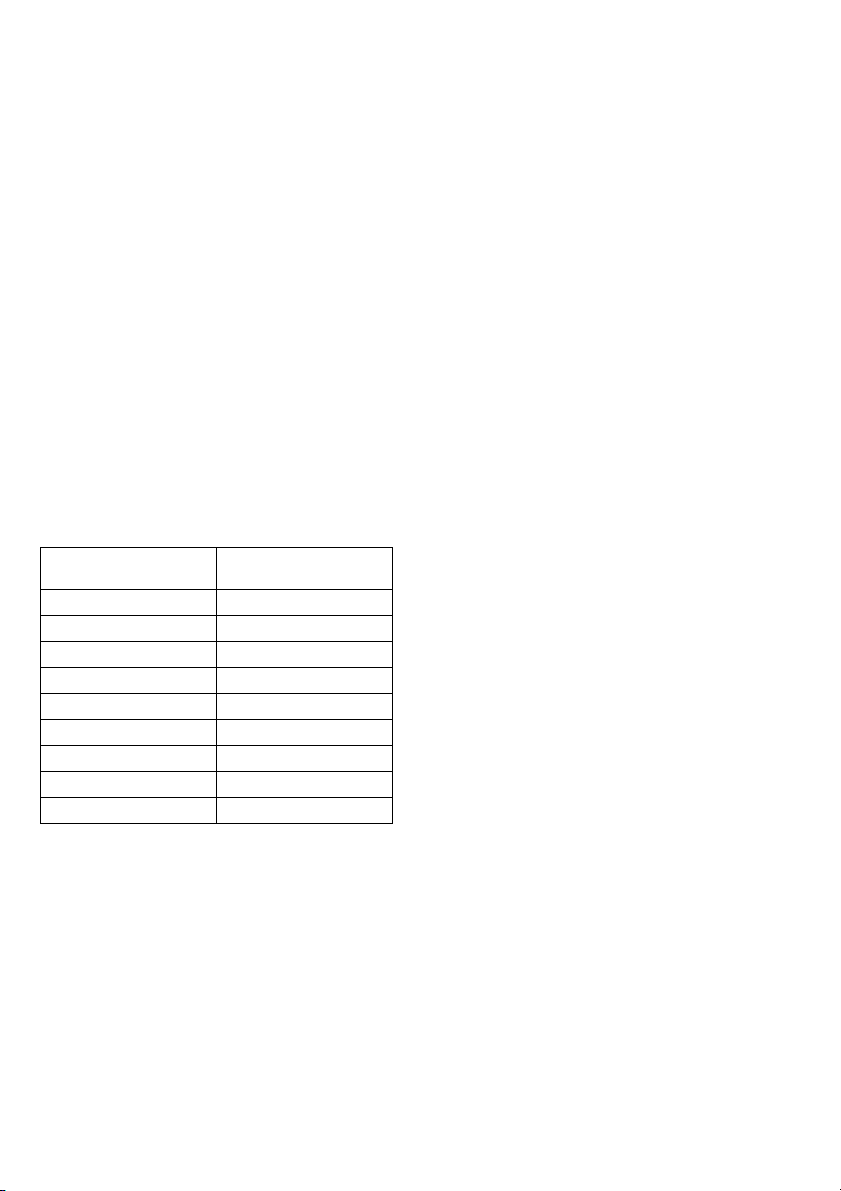

See the chart.

Nominal diameter of wood

screw (mm)

3.1 2.0 – 2.2

3.5 2.2 – 2.5

3.8 2.5 – 2.8

4.5 2.9 – 3.2

4.8 3.1 – 3.4

5.1 3.3 – 3.6

5.5 3.7 – 3.9

5.8 4.0 – 4.2

6.1 4.2 – 4.4

• If the tool is operated continuously until the battery cartridge has discharg ed, al low the tool to res t for 15 minutes before proceeding with a fresh battery.

Drilling operation

First, slide the action mode change lever to the po sition

f symbol.

of

• Drilling in wood

When drilling in wood, the best results are obtained

with wood drills equipped with a guide screw. The

guide screw makes drilling easier by pulling the bit into

the workpiece.

Recommended size of

pilot hole (mm)

• Drilling in metal

To prevent the bit from slipp ing when starting a hole,

make an indentation wit h a center-pun ch and hammer

at the point to be drilled. Place the point of the bit in the

indentation and start drilling. Use a cutting lubricant

when drilling metals. The exceptions are iron and brass

which should be drilled dry.

CAUTION:

• Pressing excessively on the tool will not speed up the

drilling. In fact, this excessive pressure will only serve

to damage the t ip of your bit, decrea se the tool performance and shorte n the service life of the tool.

• There is a tremendous force exerted on the tool/bit at

the time of hole break throu gh. Ho ld the tool fi r mly and

exert care when the bit begins to b reak through the

workpiece.

• A stuck bit can be removed simply by setting the

reversing switch to reverse rotation in order to back out.

However, the tool may back out abruptly if you do not

hold it firmly.

• Always secure small workpieces in a vise or similar

hold-down device.

• If the tool is operated continuously until the battery cartridge has discharg ed, al low the t ool to re st for 15 minutes before proceeding with a fresh battery.

MAINTENANCE

CAUTION:

Always be sure that the tool is switched off an d the battery cartridge is removed before attempting to perform

inspection or maintenan ce.

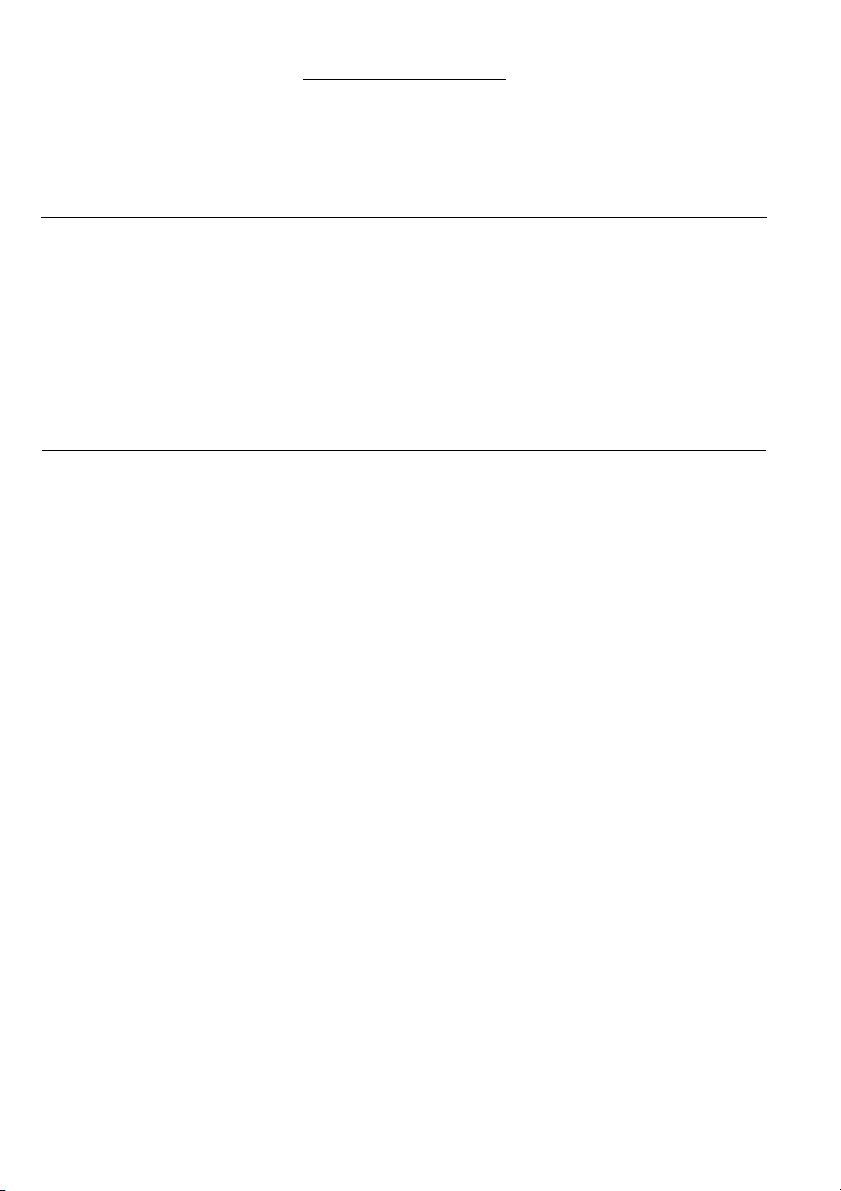

Replacing carbon brushes

Remove and check the carbon brushes regularly.

Replace when they wear dow n to the limit mark. Keep

the carbon bru shes clean a nd free t o slip in t he hold ers.

Both carbon br ushes should be replaced at the same

time. Use only identical carbon brushes. (Fig. 10)

Use a screwdriver to remove the brush holder caps. Take

out the worn carbon bru shes, insert the new ones and

secure the brush holder caps. (Fig. 11)

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be performed by Makita Authorized or Factory Service Centres,

always using Makita replacement parts.

ACCESSORIES

CAUTION:

• These accessories or attachm ents are recommended

for use with your Makita tool specified i n this manual.

The use of any other accessories or attachments might

present a risk of injury to persons. Only use accessory

or attachment for its stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita service center.

• Screw bits

• Rubber pad assembly

• Foam polishing pad 125

• Wool bonnet 100

• Various type of Makita genuine batteries and chargers

• Plastic carrying case

6

Page 7

NEDERLANDS

Verklaring van algemene gegevens

1 Accu

2 Knop

3 Trekschakelaar

4 Omkeerschakelaar

5 Rechtse draairichting

6 Linkse draairichting

7 Toerentalschakelaar

TECHNISCHE GEGEVENS

Model 6207D 6217D 6317D 6337D 6347D

Capaciteiten

Staal ......................................10 mm 10 mm 13 mm 13 mm 13 mm

Hout .......................................25,4 mm 25,4 mm 25,4mm 32 mm 38 mm

Houtschroef ...........................6 x 75 mm 6 x75 mm 6 x 75 mm 6 x 75 mm 10 x 89 mm

Kolomschroef .........................13mm 13 mm 13mm 13mm 13mm

Toerental onbelast (min

Hoog ......................... .............0–1300 0–1300 0–1300 0–1300 0–1300

Laag ..................... .......... ........ 0 – 400 0– 400 0– 400 0– 400 0– 400

Totale lengte .............................233 mm 233 mm 243 mm 243 mm 243 mm

Netto gewicht ............................1,7 kg 1,9 kg 2,0kg 2,1 kg 2,4kg

Nominale spanning ...................D.C . 9,6V D.C. 12V D.C. 12V D.C. 14,4V D.C. 18V

-1

)

8 Werkingskeuzehendel

9 Vergrendelknop

10 Stelring

11 Schaalverdelingen

12 Wijzer

13 Bus

14 Ring

15 Schroefbit

16 Bithouder

17 Limietstreep

18 Borstelhouderdop

19 Schroevendraaier

• In verband met ononderbroken resea rch en ontwikke-

ling behouden wij ons het recht voor bovenstaande

technische gegevens te wijzigen zonder voorafgaande

kennisgeving.

• Opmerking: De technisch e gegevens kunnen van land

tot land verschillen.

Doeleinden van gebruik

Dit gereedschap is bedoeld voor het boren en het

indraaien van schro even in hout, metaal en plastic.

Veiligheidswenken

Voor uw veiligheid dient u de bijgevoegde Veiligheidsvoorschriften nauwkeurig op te volgen.

BELANGRIJKE

VEILIGHEIDSVOORSCHRIFTEN VOOR

ACCULADER EN ACCU

1. Lees alle voorschriften en waarschuwingen op

(1) de acculader, (2) de accu, en (3) het produ ct

waarvoor de accu wordt gebruikt, aandachtig

door alvorens de acculader in gebruik te nemen.

2. Neem de accu niet uit elkaar.

3. Als de gebru ikstijd van een opgeladen accu aan-

zienlijk korter is geworden, moet u het gebruik

ervan onmiddellijk stopzetten. Voortgezet

gebruik kan oververhitting, brandwonden en

zelfs een ontploffing veroorzaken.

4. Als er elektrolyt in uw ogen is t erechtgekomen,

spoel dan uw ogen met schoon water en roep

onmiddellijk de hulp van een dokter in. Elektrolyt

in de ogen kan blindheid veroorzaken.

5. Bedek de accuklemmen altijd met de accukap

wanneer u de ac cu niet gebruikt.

6. Voorkom kortsluiting van de accu:

(1) Raak de accuklemmen nooit aan met een

geleidend materiaal.

(2) Bewaar de accu niet in een bak waarin

andere metalen voorwerpen zoals spijkers,

munten e.d. worden bewaard.

(3) Stel de accu niet bloot aan water of regen.

Kortsluiting van de accu kan oorzaak zijn van

een grote stroomafgifte, oververhitting, brandwonden, en zelfs defecten.

7. Bewaar het gereedschap en de accu niet op

plaatsen waar de temperatuur kan oplopen tot

50°C of hoger.

8. Werp de ac cu noo it i n he t vu ur, ook niet wann ee r

hij zwaar beschadigd of volledig v erslete n is. De

accu kan namelijk ontploffen in het vuur.

9. Wees voorzichtig dat u de accu niet laat vallen

en hem niet blootstelt aan schokken of stoten.

BEWAAR DEZE V OORSCHRIFTEN.

Tips voor een maximale levensduur van de accu

1. Laad de accu op voordat hij volledig ontladen is.

Stop het gebruik van het gereedschap en laad de

accu op telkens w annee r u vaststelt dat het vermogen van het gereedschap is afgenomen.

2. Laad een volledig opgel a den a c cu no oi t opn ieu w

op. Als u de a ccu te vee l oplaadt, zal hij mind er

lang meegaan.

3. Laad de accu op bij een kam ertemperatu ur tussen 10°C en 40°C. Laat een warme accu afkoelen

alvorens hem op te laden.

4. Laad de nikkel-metaalhydride accu op telkens

wanneer u hem langer dan zes maanden niet

hebt gebruikt.

19

Page 8

AANVULLENDE

VEILIGHEIDSVOORSCHRIFTEN

Volg de veiligheidsvoorschriften voor boren ALTIJD

strict op en laat u N I ET m isleiden door gema k o f ve rtrouwdheid met het product (verworven na langdurig

gebruik). Als u dit elektrisch gereedschap op een

onveilige of onjuiste manier gebruikt, bestaat er

gevaar voor ernstige persoonlijke verwon ding.

1. Houd elektrisch g ereedschap vast bij de geïs oleerde handgreepoppervlakken wanneer u een

werk uitvoert waarbij het snijgereedschap met

verborgen bedrading of met zijn eigen netsnoer

in aanraking kan k ome n. D oo r co nt act me t on de r

spanning staande draden zullen de metalen

delen van het gereedschap onder spanning

komen te staan zodat de g ebruiker een elektrische schok kan krijgen.

2. Zorg ervoor dat u altijd stevige steun voor de

voeten hebt.

Controleer of er zich nie m and beneden u bevindt

wanneer u het gereedschap op een hoge plaats

gaat gebruike n .

3. Houd het gereedschap stevig vast.

4. Houd uw handen uit de buurt van de draaiende

onderdelen.

5. Laat het gereed schap niet achte r terwijl het n og

in bedrijf is. Bedien het gereedschap alleen wanneer u het met beide handen vasthoudt.

6. Raak de boor of het werkstuk niet aa n o nmi dd ellijk na het gebruik; deze kunnen erg heet zijn en

brandwonden veroorzak en.

7. Sommige materialen bevatten chemische stoffen

die giftig kunnen zijn. Neem de nodige voorzorgsmaatregelen te gen inademing van stof en

contact met de huid. Volg de veiligheidsinstructies van de leverancier van het materiaal op.

BEWAAR DEZE V OORSCHRIFTEN.

WAARSCHUWING:

VERKEERD GEBRUIK of het niet naleven van de

veiligheidsvoorschriften in deze gebruiksaanwijzing

kan leiden tot ernstige verwondingen.

BEDIENINGSVOORSCHRIFTEN

Installeren of verwijderen van de accu (Fig.1)

• Schakel het gereedschap alt ijd uit alvorens de accu te

installeren of te verwijderen.

• Om de accu te verwijderen, neemt u deze uit het

gereedschap terwijl u de knoppen aan beide zijden van

de accu indrukt.

• Om de accu te installe ren, pa st u de ru g op de a ccu in

de groef in de behuizing van het gereeds chap, en dan

schuift u de accu naar binnen. Schuif de accu zo ver

mogelijk erin, totdat deze met een klikg eluid vergrendelt. Indien u dit niet do et, kan de accu per on gel uk uit

het gereedschap vallen en uzelf of anderen verwonden.

• Als de accu moeilijk in de houder gaat, moet u niet pro-

beren hem met geweld erin te du wen. Indien de accu

er niet gemakkelijk ingaat, betekent dit dat u hem niet

op de juiste wijze erin steekt.

Werking van de trekschakelaar (Fig. 2)

LET OP:

Alvorens de accu in het gereedschap te plaatsen, moet u

altijd controleren of de trekschakelaar juist werkt en bij

het loslaten naar de “OFF” positie terugkeert.

Om het gereedschap in te sch akelen, d r ukt u gewoon de

trekschakelaar in. Hoe dieper de trekschakelaar wordt

ingedrukt, hoe sneller het gereedschap draa it. Om het

gereedschap uit te schakelen, de trekschakelaar loslaten.

Werking van de omkeerschakelaar (Fig.3)

Dit gereedschap heeft een omkeerschakelaar voor het

veranderen van de draairichting. Druk de omkeerschakelaar in vanaf zijde A voor rechtse dra airichting, of vanaf

zijde B voor linkse dra airichting. Wanneer d eze schakelaar in de neutrale stand staat, kan de trekschakelaar niet

worden ingedrukt.

LET OP:

• Controleer altijd de draairichting alvorens het gereedschap te gebruiken.

• Verander de stand van de omkeerschakelaar alleen

nadat het gereedschap volledig tot stilstand is gekomen. Indien u de draairichting verander t terwijl d e boor

nog draait, kan het gereedschap beschadigd raken.

• Zet de omkeerschakelaar altijd in de neutrale stand

wanneer u het gereedschap niet gebruikt.

Veranderen van he t toerental (Fig . 4)

Om het toerental te veranderen, schakelt u eerst het

gereedschap uit en dan schuift u de toerentalschakelaar

naar de “2” zijde voor h oo g to ere nta l, of naa r de “1 ” zi jde

voor laag toerental. Zo rg ervoor da t de toerentalsch akelaar in de juiste stand staat alvorens met het werk te

beginnen. Gebruik het toe rental dat geschikt is voor uw

werk.

LET OP:

• Schuif de toerentalschakelaar altijd volledig naar de

juiste positie. Als u het gereedscha p gebruikt met de

toerentalschakelaar ha lverwege tussen de “1” en “2”

posities, kan het gereedschap besc had igd raken.

• Verschuif de toerentalschakelaar niet terwijl het

gereedschap draait. Hierdoor kan het gereedschap

beschadigd raken.

Kiezen van de gewenste werking (Fig. 5)

Dit gereedschap heeft e en werk ingskeuzehendel . Om te

boren, drukt u de vergrendelknop in en daa rna schuift u

de werkingskeuzehendel naa r links (

te schroeven, schuift u de werkingskeuzehendel naar

rechts (

U symbool) totdat deze vergrendelt. Als de

hendel niet gemakkelijk verschuift, moet u de boorkop

eerst een beetje naar links of naar rechts draaien en

daarna opnieuw prob er en om de hendel te verschuiven.

LET OP:

• Schuif de werki ngskeuzehendel altijd volle dig naar de

gewenste positie. Als u het gereedschap gebruikt met

de werkingskeuzehendel halverwege tussen de twee

symbolen geplaa tst, kan het gere edschap beschadigd

raken.

• Verander de stand van de werkingskeuzehendel niet

terwijl het gereedschap draait. Als u dit doet, kan het

gereedschap beschadigd raken.

f symbool). Om

20

Page 9

Instellen van het draaimoment (Fig.6)

Het draaimoment kan worden ingesteld in 16 stappen

door de stelring zodanig te draaien da t zijn schaalverdelingen overeenkomen met de wijzer op het huis van het

gereedschap.

Schuif eerst de werkingskeuzehendel naar de positie van

U symbool.

het

Het draaimoment is minimaal wanneer het cijfer 1 met de

wijzer overeenkomt, en is maximaal wanneer de markering met de wijzer overeenkomt. Wanneer de stelring op

een cijfer van 1 tot 16 is ing esteld, zal de koppeling bij

verschillende draaimomentniveaus slippen. Alvorens met

het eigenlijke werk te beginnen, moet u het geschikte

draaimoment bepalen d oor een proefschroef in uw werkstuk of in een ander stuk van hetzelfde materiaal te

schroeven.

LET OP:

• De stelring vergrendelt niet wanneer de wijzer halverwege tussen de schaalverdelingen is geplaatst.

INEENZETTEN

LET OP:

Controleer altijd of het ge reedschap is uitgesc hakeld en

de accu is losgekoppeld vooralee r onderh oud uit te voeren aan het gereedschap.

Installeren of verwijderen van de schroefbit of

boor (Fig.7)

Houd de ring vast en draai de bus naar links om de kla uwen van de boorkop te op enen. Steek de boor zo ver

mogelijk in de b oo r kop. Houd daa rna de ring weer stevig

vast en draai de bus naar rechts om de boorkop vast te

zetten.

Om de boor te verwijderen, houdt u de ring vast en draait

u de bus naar links.

Plaats de schroefbi t in de bith ouder wannee r u hem niet

gebruikt. Bits me t een ma ximale le ngte van 45 m m kunnen daar worden opgeborgen. (Fig. 8)

BEDIENING

Indraaien van schroeven (Fig.9)

Schuif eerst de werkingskeuzehendel naar de positie van

U symbool en kies het geschikte draaimoment.

het

Plaats de punt van de schroefbit in de schroefkop en

oefen druk op het geree dschap uit. Be gin met lag e snelheid en voer dan de snelheid geleidelijk op. Laat de trekschakelaar los zodra de koppeling ingrijpt.

LET OP:

• Zorg ervoor dat u de schroefbi t recht op de schroe fkop

plaatst, aangezien anders de schroef en /of de sch ro efbit beschadigd kan worden.

• Wanneer u houtschroeven indraait, maak dan voorboorgaten in het hout. Dit vergemakkelijkt het inschroeven en voorkomt dat het hout splijt. Zie de

onderstaande tabel.

Nominale diameter van

houtschroef (mm)

3,1 2,0–2,2

3,5 2,2–2,5

3,8 2,5–2,8

4,5 2,9–3,2

4,8 3,1–3,4

5,1 3,3–3,6

5,5 3,7–3,9

5,8 4,0–4,2

6,1 4,2–4,4

• Indien het gereedschap ononderbroken wordt

gebruikt totdat d e ac cu i s o ntladen, dient u het geree dschap 15 minuten te laten rusten alvorens met een

nieuwe accu verder te werken.

Aanbevolen diameter

van voorboorgat (mm)

Boren

Schuif eer st de w e rkin g skeuzehend el na ar de po s i ti e v a n

f symbool.

het

• Boren in hout

Voor boren in hout krijgt u de beste resultaten met

houtboren die voorzien zijn van een geleideschroef.

Het boren gaat dan gemakkelijker aangezien de geleideschroef de boor in het hout trekt.

• Boren in metaal

Om te voorkomen dat de boor slipt wanneer u begint te

boren, moet u van te voren met een drevel een deukje

in het metaal slaan op de plaats waar u wilt boren.

Plaats vervolgens de boo rpunt in het deukje en sta rt

het boren. Gebruik altijd boorolie wanneer u in metaal

boort. De enige ui tzonderingen zijn ijzer en koper die

droog geboord dienen te worden.

LET OP:

• Door overmatige druk op het gereedschap uit te oefenen verloopt het boren niet sneller. Integend eel, teveel

druk op het ge reedschap zal a lleen maar de boor punt

beschadigen, de prestatie van het gereedschap verminderen en de gebruiksduur verkorten.

• Wanneer de boor uit het gaatje tevoorschijn komt,

wordt een enorme krach t uitgeoefend op het gereedschap en op de boor. Houd daaro m het gereedschap

stevig vast en wees op uw hoede wanneer de boor

door het werkstuk begint te dringen.

• Wanneer de boor klemraak t, keert u met de omkeerschakelaar de draairichting om, om de boor uit het

gaatje te krijgen . Het gereedschap kan echter plotseling terugspringen indien u het niet stevig vasthoudt.

• Kleine werkstukken dient u altijd eer st vast te zetten in

een klemschroef of iets dergelijks.

• Indien het gereeds chap ononder broken wordt gebr uikt

totdat de accu is ont laden, dient u het gereedschap

15 minuten te laten rusten alvorens met een nieuwe

accu verder te werken.

21

Page 10

ONDERHOUD

LET OP:

Controleer altijd of het g ereedschap is uitge schakeld en

de accu is losgekoppeld voordat u begint met inspectie of

onderhoud.

Vervangen van koolborstels

Verwijder en controleer regelmatig de koolborstels. Vervang de koolborstels wanneer ze to t a an de li mie tma r kering versleten zijn. Hou d de koolborstels schoon, zodat

ze gemakkelijk in de houders glijden. Beide koolborstels

dienen gelijktijdig te worden vervangen. Gebruik uitsluitend gelijksoor tige koolborstels. (Fig. 10)

Gebruik een schroevendraaier om de kappen van de

koolborstelhouders te verwijderen. Haal de versleten

koolborstels eruit, sc huif de nieuwe erin, en zet daarna

de kappen weer goed vast. (Fig. 11)

Om de VEILIGHEID en BETROUWBAARHEID van het

gereedschap te verzekeren, dienen alle reparaties,

onderhoudsbeur ten of afst ellingen te wor den uitgevoerd

bij een erkend Makita S er vice centr um of Fabriekse r vicecentrum, en dit uitslu itend met gebruik van Makita vervangingsonderdelen.

ACCESSOIRES

LET OP:

• Deze accessoires of hulpstukken worde n aanbevolen

voor gebruik met het Makita gereedschap dat in deze

gebruiksaanwijzing is beschreven. Bij gebruik van

andere accessoires of hulpstukken bestaat er gevaar

voor persoonlijke verwonding. Gebruik de accessoires

of hulpstukken uitsluitend voor hun bestemde doel.

Raadpleeg het dichtstbijzijnde Makita Servicecentrum

voor verder advies of bijzonderheden omtrent deze

accessoires.

•Schroefbits

• Rubber steunschijf set

• Schuimrubber polijstkussen 125

• Wollen poetsschijf 100

• Diverse types originele Makita accu’s en acculaders

• Plastic draagkoffer

22

Page 11

ENGLISH

EC-DECLARATION OF CONFORMITY

We declare under our sole responsibility that this product

is in compliance with the following standards of standardized documents,

in accordance with Council Directives, 89/336/EEC and

98/37/EC.

EN60745, EN55014

ENH102-4

ITALIANO

DICHIARAZIONE DI CONFORMITÀ

CON LE NORME DELLA COMUNITÀ EUROPEA

Dichiariamo sotto la nostra sola responsabilità che

questo prodotto è conforme agli standard di documenti

standardizzati seguenti:

secondo le diret tive del Consiglio 89/336/C EE e 98/37/

CE.

EN60745, EN55014

FRANÇAISE

DÉCLARATION DE CONFORMITÉ CE

Nous déclarons sous notre entière responsabilité que ce

produit est conforme aux n ormes des documents standardisés suivants,

conformément aux Directives du Conseil, 89/336/CEE et

98/37/EG.

EN60745, EN55014

DEUTSCH

Hiermit erklärt wir unter unserer alleinigen Verantwortung, daß dieses Produkt ge mäß den Ra tsdirektiven 89/

336/EWG und 98/37/EG m it den folgenden Nor men von

Normendokument en übe rei n stimm en :

CE-KONFORMITÄTSERKLÄRUNG

EN60745, EN55014.

Yasuhiko Kanzaki

NEDERLANDS

EG-VERKLARING VAN CONFORMITEIT

Wij verklaren hierbij uitsluitend op eigen verantwoordelijkheid dat dit produkt voldoet aan de volgende

normen van genormaliseerde documenten,

in overeenstemming met de rich tlijnen van de Raad 89/

336/EEC en 98/37/EC.

EN60745, EN55014

ESPAÑOL

DECLARACIÓN DE CONFORMIDAD DE LA CE

Declaramos bajo nuestra sola responsabilidad que este

producto cumple con las siguientes normas de documentos normalizados,

de acuerdo con la s direc tivas comunitari as, 89/336 /EEC

y 98/37/CE.

CE 2005

EN60745, EN55014

Director Amministratore

Directeur Directeur

Direktor Director

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

Responsible manufacturer: Produttore responsabile:

Fabricant responsable

Vera ntwortlicher Hersteller: Fabricante responsable:

Makita Corporation Anjo Aichi Japan

: Verantwoordelijk e fabrikant:

47

Page 12

PORTUGUÊS

DECLARAÇÃO DE CONFORMIDADE DA CE

Declaramos sob inteira responsabilidade que este

produto obedece às se guintes normas de documentos

normalizados,

de acordo com as direc tivas 89/336/CEE e 98/37/CE do

Conselho.

EN60745, EN55014

NORSK

ENH102-4

EUs SAMSVARS-ERKLÆRING

erklærer på

Vi

ensstemmelse med følgende standar d i de standardiserte dokumenter:

i samsvar med Råds-direktivene, 89/336/ EEC og 98/37/

EC.

eget ansvar at dette produktet er i over-

EN60745, EN55014,

DANSK

EU-DEKLARATION OM KONFORMITET

Vi erklærer herm ed på eget ansvar, at dette produkt er i

overensstemmelse med de følgende standarder i de

normsættende dokumenter,

i overensstemmelse med Rådet s Direktiver 89/336/EEC

og 98/37/EC.

EN60745, EN55014

SVENSKA

EG-DEKLARATION OM ÖVERENSSTÄMMELSE

Under eget ansvar deklarerar vi härmed att denna

produkt överensstämmer me d följan de standa rdi serin gar

för standardiserade dokument,

i enlighet med EG-direktiven 89/336/EEC och 98/37/EC.

EN60745, EN55014

Yasuhiko Kanzaki

SUOMI

VAKUUTUS EC-VASTAAVUUDESTA

Yksinomaisesti vastuullisina ilmoitamme, että tämä tuote

on seuraavien standardoitujen dokumenttien standardien

mukainen,

neuvoston direktiivien 89/336/EEC ja 98/37/EC mukaisesti.

EN60745, EN55014

ΕΛΛΗΝΙΚΑ

∆ηλώνουµε υπ την µοναδική µας ευθύνη τι αυτ

το προιν βρίσκεται σε Συµφωνία µε τα ακλουθα

πρτυπα τυποποιηµένων εγγράφων,

EN60745, EN55014

σύµφωνα µε τις Οδηγίες του Συµβουλίου, 89/336/

EEC και 98/37/ΚE.

CE 2005

∆ΗΛΩΣΗ ΣΥΜΜΟΡΦΩΣΗΣ ΕΚ

48

Director Direktor

Direktør Johtaja

Direktör ∆ιευθυντής

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

Fabricante responsável: Ansvarlig produsent:

Ansvarlig fabrikant: Vastaava valmistaja:

Ansvarig tillverkare: Υπεύθυνος κατασκευαστής:

Makita Corporation Anjo Aichi Japan

Page 13

ENGLISH

For European countries only

Noise and Vibration of Model 6207D/6217D

The typical A-weighted sound pressure level is not more

than 70dB (A).

The noise level under working may exceed 85dB (A).

The typical weighted root mean square acceleration

value is not more than 2.5 m/s

These values have been obtained according to

– Wear ear protection. –

2

.

EN60745.

ENG001-2

ITALIANO

Modello per l’E uropa soltanto

Rumore e vibrazione del modello 6207D/6217D

Il livello di pressione sonora pesata seco ndo la cur va A

non supera i 70 dB (A).

Il livello di rumor e duran te il lavoro potre bbe sup erare g li

85dB (A ).

– Indossare i paraorecchi. –

Il valore quadratico medio d i accelle razione no n supera i

2

.

2,5m/s

Questi valori sono stati ottenuti in conformità EN60745.

FRANÇAISE

Pour les pays d’Europe uniquement

Bruit et vibrations du modèle 6207D/6217D

Le niveau de pression sonore pondere type A ne

dépasse pas 70 dB (A).

Le niveau de bruit en fonctionnement peut dépasser

85dB (A).

L’accélération pondérée ne dépasse pas 2,5m/s

Ces valeurs ont été obtenues selon EN60745.

– Porter des protecteurs anti-bruit. –

2

.

DEUTSCH

Nur für europäische Länder

Geräusch- und Vibrationsentwicklung

Der typische A-bewer tete Scha lldru ckpegel beträgt n icht

des Modells

mehr als 70 dB (A).

6207D/6217D

Der Lärmpegel kann während des Betriebs 85 dB (A)

überschreiten.

Der gewichtete Effektivwer t der Besc hleunigung beträgt

nicht mehr als 2,5 m/s

Diese Werte wurden gemäß EN60745 erhalten.

– Gehörschutz tragen. –

2

.

NEDERLANDS

Alleen voor Europese landen

Geluidsniveau e n trilling

van het model

6207D/6217D

Het typische A-gewogen geluid sdrukniveau is niet meer

dan 70 dB (A).

Tijdens het werken kan het geluidsniveau 85dB (A) overschrijden.

De typische gewogen effectieve versnellingswaarde is

niet meer dan 2,5 m/s

Deze waarden werden verkregen in overeenstemming

met EN60745.

– Draag oorbeschermers. –

2

.

ESPAÑOL

Para países europeos solamente

Ruido y vibración del modelo 6207D/6217D

El nivel de presión sonora ponderada A no sobrepasa los

70 dB (A).

El nivel de ruido en c ondiciones de trabajo puede q ue

sobrepase los 85 dB (A).

– Póngase protectores en los oídos. –

El valor ponderado de la aceleración no sobrepasa los

2

.

2,5 m/s

Estos valores han sido obtenidos de acuerdo con

EN60745.

49

Page 14

PORTUGUÊS

Só para países Europeus

Ruído e vibração do modelo 6207D/6217D

O nível normal de pressão sonora A é inferior a

70 dB (A).

O nível de ruído durante o trabalho pode exceder

85dB (A ).

– Utilize protectores para os ouvidos –

O valor médio da aceleração é inferior a 2,5 m/s

Estes valores foram obtidos de acordo com EN60745.

2

.

ENG001-2

NORSK

Gjelder bare land i Europa

Støy og vibrasjon fra modell 6207D/6217D

Det vanlige A-belastede lydtrykksnivå overskrider ikke

70 dB (A).

Under bruk kan støynivået overskride 85dB (A).

Den vanlig belastede effektiv-verdi for akselerasjon overskrider ikke 2,5 m/s

Disse verdiene er beregnet eller målt i samsvar med

– Benytt hørselvern. –

2

.

EN60745.

DANSK

Kun for lande i Europa

Lyd og vibration fra model 6207D/6217D

Det typiske A-vægtede lydtryksniveau overstiger ikke

70 dB (A).

Støjniveauet under arbejde kan overstige 85dB (A).

Den vægtede effektive accelerationsværdi overstiger ikke

2

.

2,5m/s

Disse værdier er beregnet i overensstemmelse med

– Bær høreværn. –

EN60745.

SVENSKA

Endast för Europa

Buller och vibration hos modell 6207D/6217D

Den typiska-A-vägda ljudtrycksnivån överstiger inte

70 dB (A).

Bullernivån under pågående arbete kan överstiga

85dB (A ).

Det typiskt vägda effektivvärdet för acceleration överstiger inte 2,5 m/s

– Använd hörselskydd –

2

.

Dessa värden har erhållits i enlighet med EN60745.

SUOMI

Vain Euroopan maat

Mallin

6207D/6217D melutaso ja tärinä

Tyypillinen A-painotettu äänenpainetaso ei ylitä

70 dB (A).

Melutaso työpaikalla saattaa ylittää 85 dB (A).

– Käytä kuulosuojaimia. –

Tyypillinen kiihtyvyyden painotettu tehollisarvo ei ylitä

2,5m/s2.

Nämä arvot on mitattu normin EN60745 mukaisesti.

ΕΛΛΗΝΙΚΑ

Μ*νο για χώρες της Ευρώπης

Θ*ρυβος και κραδασµ*ς

του µοντέλου 6207D/6217D

Η τυπική Α-µετρούµενη ηχητική πίεση δεν ξεπερνά

τα 70 dB (A).

Η ένταση ήχου υπο συνθήκες εργασίας µπορεί να

µπερβεί τα 85dB (A).

Η τυπική αξία της µετρούµενης ρίζας του µέσου

τετραγώνου της επιτάχυνσης δεν ξεπερνά τα

2,5 m/s

Αυτές οι τιµές έχουν σηµειωθεί σύµφωνα µε το

– Φοράτε ωτοασπίδες. –

2

.

EN60745.

50

Page 15

ENGLISH

For European countries only

Noise and Vibration

The typical A-weighted sound pressure level is 71 dB (A).

Uncertainty is 3 dB (A).

The noise level under working may exceed 85 dB (A).

The typical weighted root mean square acceleration

– Wear ear protection. –

value is not more than 2.5 m/s

These values have been obtained according to

EN60745.

of Model 6317D/6337D

2

.

ENG003-2

ITALIANO

Modello per l’E uropa soltanto

Rumore e vibrazione del modello

Il livello di pressione sonora pesata sec ondo la curva A è

di 71 dB (A) .

L’incertezza è di 3 dB (A).

Il livello di rumor e duran te il lavoro potre bbe sup erare g li

85 dB (A).

– Indossare i paraorecchi. –

Il valore quadratico medio d i accelle razione no n supera i

2

2,5 m/s

.

Questi valori sono stati ottenuti in conformità EN60745.

6317D/6337D

FRANÇAISE

Pour les pays d’Europe uniquement

Bruit et vibrations du modèle

Le niveau de pression sonore pondere type A est de

71 dB (A).

6317D/6337D

L’incertitude de mesure est de 3 dB (A).

Le niveau de bruit en fonctionnement peut dépasser

85 dB (A).

L’accélération pondérée ne dépasse pas 2,5 m/s

– Porter des protecteurs anti-bruit. –

2

.

Ces valeurs ont été obtenues selon EN60745.

DEUTSCH

Nur für europäische Länder

Geräusch- und Vibrationsentwicklung

des Modells

Der typische A-bewertete Schalldruckpegel beträgt

71 dB (A).

Die Abweichung beträgt 3 dB (A).

Der Lärmpegel kann während des Betriebs 85 dB (A)

überschreiten.

– Gehörschutz tragen. –

Der gewichtete Effektivwer t der Besc hleunigung beträgt

nicht mehr als 2,5 m/s

Diese Werte wurden gemäß EN60745 erhalten.

6317D/6337D

2

.

NEDERLANDS

Alleen voor Europese landen

Geluidsniveau en trilling

van het model

6317D/6337D

Het typische A-gewogen geluidsdrukniveau is 71 dB (A).

Onzekerheid is 3 dB (A).

Tijdens het werken kan het geluidsniveau 85 dB (A) overschrijden.

– Draag oorbeschermers. –

De typische gewogen effectieve versnellingswaarde is

niet meer dan 2,5 m/s

2

.

Deze waarden werden verkregen in overeenstemming

met EN60745.

ESPAÑOL

Para países europeos solamente

Ruido y vibración del modelo

El nivel de presión sonora ponderada A es de 71 dB (A).

Incerteza 3 dB (A).

El nivel de ruido en c ondiciones de trabajo puede q ue

sobrepase los 85 dB (A).

– Póngase protectores en los oídos. –

El valor ponderado de la a celeración no sobrepasa los

2

.

2,5 m/s

Estos valores han sido obtenidos de acuerdo con

EN60745.

6317D/6337D

51

Page 16

PORTUGUÊS

Só para países Europeus

Ruído e vibração do modelo

O nível normal de pressão sonora A é 71 dB (A).

A incerteza é de 3 db (A).

O nível de ruído durante o trabalho pode exceder

85 dB (A).

– Utilize protectores para os ouvidos –

O valor médio da aceleração é inferior a 2,5 m/s

Estes valores foram obtidos de acordo com EN60745.

6317D/6337D

2

.

ENG003-2

NORSK

Gjelder bare land i Europa

Støy og vibrasjon fra modell

Det vanlige A-verktet lydtrykksnivå er 71 dB (A).

Usikkerheten er på 3 dB (A).

Under bruk kan støynivået overskride 85 dB (A).

Den typiske vektede effektive akselerasjonsverdi overskrider ikke 2,5 m/s

Disse verdiene er beregnet eller målt i samsvar med

EN60745.

– Benytt hørselvern. –

2

.

6317D/6337D

DANSK

Kun for lande i Europa

Lyd og vibration fra model

Det typiske A-vægtede lydtryksniveau er 71 dB (A).

Der er en usikkerhed på 3 dB (A).

6317D/6337D

Støjniveauet under arbejde kan overstige 85 dB (A).

– Bær høreværn. –

Den vægtede effektive accelerationsværdi overstiger ikke

2

.

2,5m/s

Disse værdier er beregnet i overensstemmelse med

EN60745.

SVENSKA

Endast för Europa

Buller och vibration hos modell

Den typiska-A-vägda ljudtrycksnivån är 71 dB (A).

Osäkerheten är 3 dB (A).

Bullernivån under pågående arbete kan överstiga

85 dB (A).

Det typiskt vägda effektivvärdet för acceleration överstiger inte 2,5 m/s

– Använd hörselskydd –

2

.

Dessa värden har erhållits i enlighet med EN60745.

6317D/6337D

SUOMI

Vain Euroopan maat

Mallin

Tyypillinen A-painotettu äänenpainetaso on 71 dB (A).

Epävarmuus on 3 dB (A).

6317D/6337D melutaso ja tärinä

Melutaso työpaikalla saattaa ylittää 85 dB (A).

– Käytä kuulosuojaimia. –

Tyypillinen kiihtyvyyden painotettu tehollisarvo ei ylitä

2

.

2,5m/s

Nämä arvot on mitattu normin EN60745 mukaisesti.

ΕΛΛΗΝΙΚΑ

Μ*νο για χώρες της Ευρώπης

Θ*ρυβος και κραδασµ*ς

του µοντέλου 6317D/6337D

Η τυπική Α-µετρούµενη ηχητική πίεση είναι

71 dB (A).

Η Αβεβαιτητα είναι 3 dB (A).

Η ένταση ήχου υπο συνθήκες εργασίας µπορεί να

µπερβεί τα 85 dB (A).

– Φοράτε ωτοασπίδες. –

Η τυπική αξία της µετρούµενης ρίζας του µέσου

τετραγώνου της επιτάχυνσης δεν ξεπερνά τα

2

.

2,5 m/s

Αυτές οι τιµές έχουν σηµειωθεί σύµφωνα µε το

ΕΝ60745.

52

Page 17

ENGLISH

For European countries only

Noise and Vibration

The typical A-weighted sound pressure level is 73 dB (A).

Uncertainty is 3 dB (A).

The noise level under working may exceed 85 dB (A).

The typical weighted root mean square acceleration

– Wear ear protection. –

value is not more than 2.5 m/s

These values have been obtained according to

EN60745.

of Model 6347D

2

.

ENG003-2

ITALIANO

Modello per l’E uropa soltanto

Rumore e vibrazione del modello

Il livello di pressione sonora pesata sec ondo la curva A è

di 73 dB (A) .

L’incertezza è di 3 dB (A).

Il livello di rumor e duran te il lavoro potre bbe sup erare g li

85 dB (A).

– Indossare i paraorecchi. –

Il valore quadratico medio d i accelle razione no n supera i

2

2,5 m/s

.

Questi valori sono stati ottenuti in conformità EN60745.

6347D

FRANÇAISE

Pour les pays d’Europe uniquement

Bruit et vibrations du modèle

Le niveau de pression sonore pondere type A est de

73 dB (A).

6347D

L’incertitude de mesure est de 3 dB (A).

Le niveau de bruit en fonctionnement peut dépasser

85 dB (A).

L’accélération pondérée ne dépasse pas 2,5 m/s

– Porter des protecteurs anti-bruit. –

2

.

Ces valeurs ont été obtenues selon EN60745.

DEUTSCH

Nur für europäische Länder

Geräusch- und Vibrationsentwicklung

Der typische A-bewertete Schalldruckpegel beträgt

des Modells

73 dB (A).

Die Abweichung beträgt 3 dB (A).

Der Lärmpegel kann während des Betriebs 85 dB (A)

überschreiten.

Der gewichtete Effektivwer t der Besc hleunigung beträgt

– Gehörschutz tragen. –

nicht mehr als 2,5 m/s

Diese Werte wurden gemäß EN60745 erhalten.

6347D

2

.

NEDERLANDS

Alleen voor Europese landen

Geluidsniveau en trilling van het model

Het typische A-gewogen geluidsdrukniveau is 73 dB (A).

6347D

Onzekerheid is 3 dB (A).

Tijdens het werken kan het geluidsniveau 85 dB (A) overschrijden.

De typische gewogen effectieve versnellingswaarde is

niet meer dan 2,5 m/s

Deze waarden werden verkregen in overeenstemming

– Draag oorbeschermers. –

2

.

met EN60745.

ESPAÑOL

Para países europeos solamente

Ruido y vibración del modelo

El nivel de presión sonora ponderada A es de 73 dB (A).

Incerteza 3 dB (A).

El nivel de ruido en c ondiciones de trabajo puede q ue

sobrepase los 85 dB (A).

– Póngase protectores en los oídos. –

El valor ponderado de la a celeración no sobrepasa los

2

.

2,5 m/s

Estos valores han sido obtenidos de acuerdo con

EN60745.

6347D

53

Page 18

PORTUGUÊS

Só para países Europeus

Ruído e vibração do modelo

O nível normal de pressão sonora A é 73 dB (A).

A incerteza é de 3 db (A).

O nível de ruído durante o trabalho pode exceder

85 dB (A).

– Utilize protectores para os ouvidos –

O valor médio da aceleração é inferior a 2,5 m/s

Estes valores foram obtidos de acordo com EN60745.

6347D

2

.

ENG003-2

NORSK

Gjelder bare land i Europa

Støy og vibrasj on fra modell

Det vanlige A-verktet lydtrykksnivå er 73 dB (A).

Usikkerheten er på 3 dB (A).

Under bruk kan støynivået overskride 85 dB (A).

Den typiske vektede effektive akselerasjonsverdi overskrider ikke 2,5 m/s

Disse verdiene er beregnet eller målt i samsvar med

EN60745.

– Benytt hørselvern. –

2

.

6347D

DANSK

Kun for lande i Europa

Det typiske A-vægtede lydtryksniveau er 73 dB (A).

Lyd og vibration fra model

Der er en usikkerhed på 3 dB (A).

6347D

Støjniveauet under arbejde kan overstige 85 dB (A).

– Bær høreværn. –

Den vægtede effektive accelerationsværdi overstiger ikke

2

.

2,5m/s

Disse værdier er beregnet i overensstemmelse med

EN60745.

SVENSKA

Endast för Europa

Buller och vibration hos modell

Den typiska-A-vägda ljudtrycksnivån är 73 dB (A).

Osäkerheten är 3 dB (A).

Bullernivån under pågående arbete kan överstiga

85 dB (A).

Det typiskt vägda effektivvärdet för acceleration överstiger inte 2,5 m/s

– Använd hörselskydd –

2

.

Dessa värden har erhållits i enlighet med EN60745.

6347D

SUOMI

Vain Euroopan maat

Mallin

Tyypillinen A-painotettu äänenpainetaso on 73 dB (A).

Epävarmuus on 3 dB (A).

6347D melutaso ja tärinä

Melutaso työpaikalla saattaa ylittää 85 dB (A).

– Käytä kuulosuojaimia. –

Tyypillinen kiihtyvyyden painotettu tehollisarvo ei ylitä

2

.

2,5m/s

Nämä arvot on mitattu normin EN60745 mukaisesti.

ΕΛΛΗΝΙΚΑ

Μ*νο για χώρες της Ευρώπης

Θ*ρυβος και κραδασµ*ς

Η τυπική Α-µετρούµενη ηχητική πίεση είναι

73 dB (A).

Η Αβεβαιτητα είναι 3 dB (A).

Η ένταση ήχου υπο συνθήκες εργασίας µπορεί να

µπερβεί τα 85 dB (A).

– Φοράτε ωτοασπίδες. –

Η τυπική αξία της µετρούµενης ρίζας του µέσου

τετραγώνου της επιτάχυνσης δεν ξεπερνά τα

2

.

2,5 m/s

Αυτές οι τιµές έχουν σηµειωθεί σύµφωνα µε το

ΕΝ60745.

του µοντέλου 6347D

54

Page 19

55

Page 20

Makita Corporation

Anjo, Aichi, Japan

884436C996

Loading...

Loading...