Page 1

GB Cordless Driver Drill Instruction manual

F Perceuse-visseuse sans fil Manuel d’instructions

D Akku-Bohrschrauber Betriebsanleitung

I Trapano avvitatore a batteria Istruzioni per l’uso

NL Accuschroefboormachine Gebruiksaanwijzing

E Taladro sin cables Manual de instrucciones

P Berbegvim sem cabos Manual de instruções

DK Ledningsfrit bor Brugsanvisning

S Sladdlös skruvdragare Bruksanvisning

N Batteridrevet boreskrutrekker Bruksanvisning

SF Johdoton ruuvinväännin/pora Käyttöohje

GR ∆ραπανοκατσάβιδο µπαταρίας Οδηγίες χρήσης

TR

Kablosuz Delme/Vidalama Makinesi

Kullanım kılavuzu

6017D

6018D

6019D

Page 2

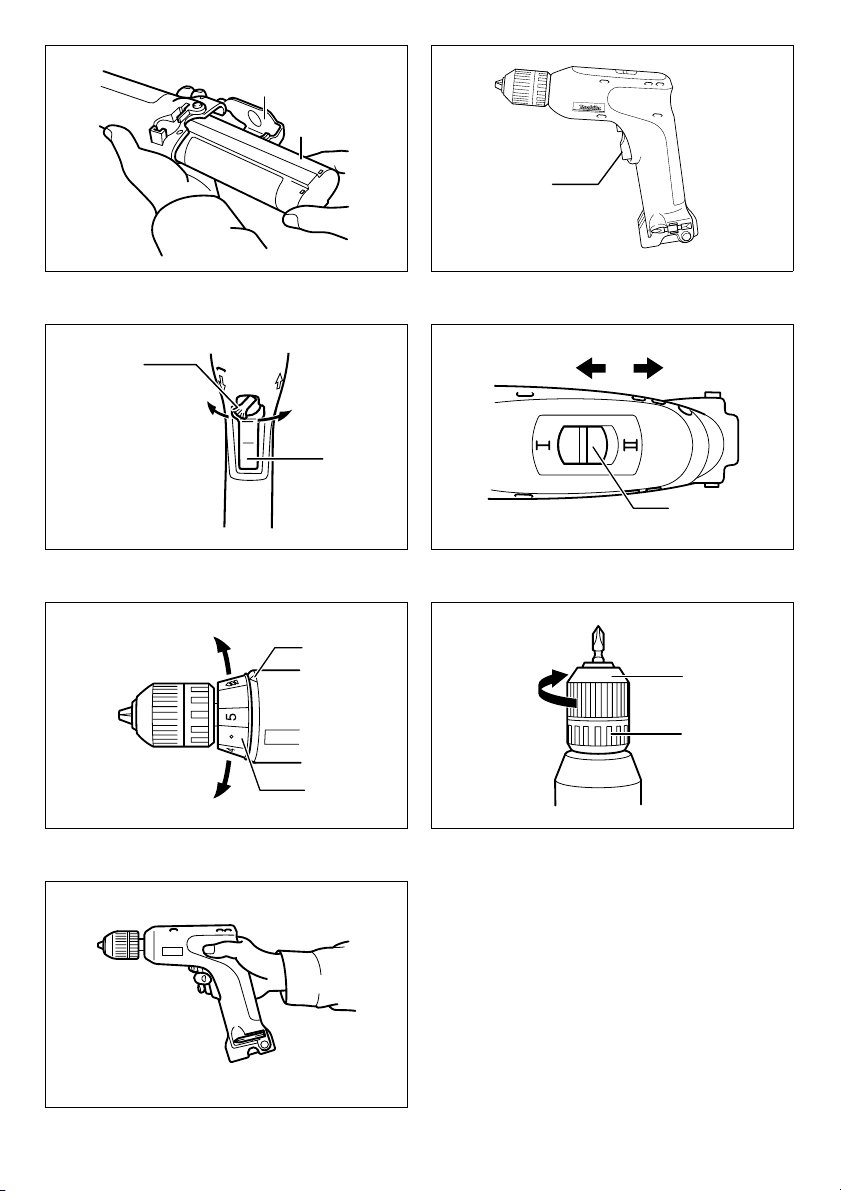

1

2

3

12

4

5

6

BA

3

7

34

9

10

8

11

12

13

14

56

7

2

Page 3

ENGLISH

Explanation of general view

1. Set plate

2. Battery cartridge

3. Switch trigger

4. Reversing switch lever

5. Low speed

6. High speed

7. Speed change lever

8. Pointer

9. Weak

10. Strong

11. Torque adjusting ring

12. Tighten

13. Sleeve

14. Ring

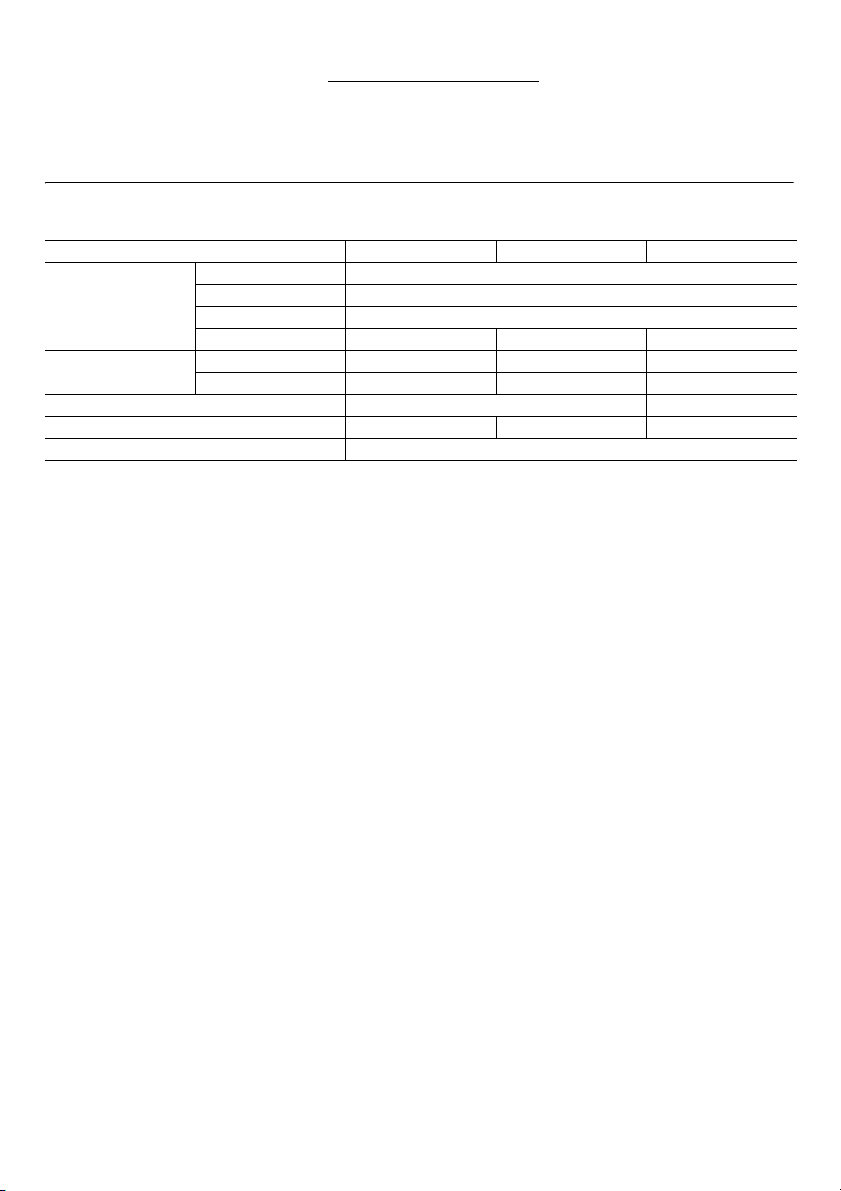

SPECIFICATIONS

Model 6017D 6018D 6019D

Steel 10 mm

Capacities

No load speed (min

• Due to our continuing program of research and development, the specifications herein are subject to change without

notice.

• Note: Specifications may differ from country to country.

Intended use

The tool is intended for drilling and screw driving in wood,

metal and plastic.

-1

)

Overall length 251 mm 251 mm

Net weight 1.0 kg 1.1 kg 1.1 kg

Rated voltage D.C. 7.2 V

Wood 15 mm

Wood screw 5.1 mm x 35 mm

Machine screw --- --- 6 mm

High 600 0 - 600 0 - 600

Low 200 0 - 200 0 - 200

SPECIFIC SAFETY RULES GEB002-2

DO NOT let comfort or familiarity with product (gained

from repeated use) replace strict adherence to drill

safety rules. If you use this power tool unsafely or

incorrectly, you can suffer serious personal injury.

1. Hold power tools by insulated gripping surfaces

when performing an operation where the cutting

tool may contact hidden wiring or its own cord.

Contact with a “live” wire will make exposed metal

parts of the tool “live” and shock the operator.

2. Always be sure you have a firm footing. Be sure

no one is below when using the tool in high locations.

3. Hold the tool firmly.

4. Keep hands away from rotating parts.

5. Do not leave the tool running. Operate the tool

only when hand-held.

6. Do not touch the drill bit or the workpiece immediately after operation; they may be extremely hot

and could burn your skin.

7. Some material contains chemicals which may be

toxic. Take caution to prevent dust inhalation and

skin contact. Follow material supplier safety data.

SAVE THESE INSTRUCTIONS

WARNING:

MISUSE or failure to follow the safety rules stated in

this instruction manual may cause serious personal

injury.

3

Page 4

IMPORTANT SAFETY

INSTRUCTIONS FOR BATTERY

CARTRIDGE

1. Before using battery cartridge, read all instructions and cautionary markings on (1) battery

charger, (2) battery, and (3) product using battery.

2. Do not disassemble battery cartridge.

3. If operating time has become excessively shorter,

stop operating immediately. It may result in a risk

of overheating, possible burns and even an explosion.

4. If electrolyte gets into your eyes, rinse them out

with clear water and seek medical attention right

away. It may result in loss of your eyesight.

5. Always cover the battery terminals with the battery cover when the battery cartridge is not used.

6. Do not short the battery cartridge:

(1) Do not touch the terminals with any conduc-

tive material.

(2) Avoid storing battery cartridge in a container

with other metal objects such as nails, coins,

etc.

(3) Do not expose battery cartridge to water or

rain.

A battery short can cause a large current flow,

overheating, possible burns and even a breakdown.

7. Do not store the tool and battery cartridge in locations where the temperature may reach or exceed

50°C (122°F).

8. Do not incinerate the battery cartridge even if it is

severely damaged or is completely worn out. The

battery cartridge can explode in a fire.

9. Be careful not to drop or strike battery.

ENC004-1

SAVE THESE INSTRUCTIONS

Tips for maintaining maximum battery life

1. Charge the battery cartridge before completely

discharged. Always stop tool operation and

charge the battery cartridge when you notice less

tool power.

2. Never recharge a fully charged battery cartridge.

Overcharging shortens the battery service life.

3. Charge the battery cartridge with room temperature at 10°C - 40°C (50°F - 104°F). Let a hot battery

cartridge cool down before charging it.

4. Charge the Nickel Metal Hydride battery cartridge

when you do not use it for more than six months.

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and the bat-

tery cartridge is removed before adjusting or checking

function on the tool.

Installing or removing battery cartridge

(Fig. 1)

• Always switch off the tool before insertion or removal of

the battery cartridge.

• To remove the battery cartridge, pull out the set plate

on the tool and grasp both sides of the cartridge while

withdrawing it from the tool.

• To insert the battery cartridge, align the tongue on the

battery cartridge with the groove in the housing and slip

it into place. Snap the set plate back into place. Be sure

to close the set plate fully before using the tool to prevent the battery cartridge from accidentally falling out of

the tool.

• Do not use force when inserting the battery cartridge. If

the cartridge does not slide in easily, it is not being

inserted correctly.

Switch action (Fig. 2)

CAUTION:

• Before inserting the battery cartridge into the tool,

always check to see that the switch trigger actuates

properly and returns to the “OFF” position when

released.

To start the tool, simply pull the switch trigger. Tool speed

is increased by increasing pressure on the switch trigger.

Release the switch trigger to stop.

Reversing switch action (Fig. 3)

This tool has a reversing switch to change the direction of

rotation. Move the reversing switch lever to the A side for

clockwise rotation or the B side for counterclockwise rotation.

When the reversing switch lever is in the neutral position,

the switch trigger cannot be pulled.

CAUTION:

• Always check the direction of rotation before operation.

• Use the reversing switch only after the tool comes to a

complete stop. Changing the direction of rotation

before the tool stops may damage the tool.

• When not operating the tool, always set the reversing

switch lever to the neutral position.

Speed change (Fig. 4)

To change the speed, first switch off the tool and then

slide the speed change lever to the “II” side for high speed

or “I” side for low speed. Be sure that the speed change

lever is set to the correct position before operation. Use

the right speed for your job.

CAUTION:

• Always set the speed change lever fully to the correct

position. If you operate the tool with the speed change

lever positioned halfway between the “I” side and “II”

side, the tool may be damaged.

• Always make sure that the gear is engaged properly by

running the tool under no load after sliding the speed

change lever to the desired speed position. If you operate the tool with the gear engaged improperly, the tool

may be damaged.

4

Page 5

• Do not use the speed change lever while the tool is

running. The tool may be damaged.

Adjusting the fastening torque (Fig. 5)

For model 6019D only

The fastening torque can be adjusted in 6 steps by turning

the adjusting ring so that its graduations are aligned with

the pointer on the tool body. The fastening torque is minimum when the number 1 is aligned with the pointer, and

maximum when the marking is aligned with the pointer.

The clutch will slip at various torque levels when set at the

number 1 to 5. The clutch is designed not to slip at the

marking.

Before actual operation, drive a trial screw into your material or a piece of duplicate material to determine which

torque level is required for a particular application.

NOTE:

• The adjusting ring does not lock when the pointer is

positioned only halfway between the graduations.

• Do not operate the tool with the adjusting ring set

between the number 5 and the marking. The tool

may be damaged.

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and the battery cartridge is removed before carrying out any work

on the tool.

Installing or removing driver bit or drill bit

(Fig. 6)

Hold the ring and turn the sleeve counterclockwise to

open the chuck jaws.

Place the bit in the chuck as far as it will go. Hold the ring

firmly and turn the sleeve clockwise to tighten the chuck.

To remove the bit, hold the ring and turn the sleeve counterclockwise.

When not using the driver bit, keep it in the bit holders.

Bits 45 mm long can be kept there.

OPERATION

Screwdriving operation

For model 6017D/6018D

Place the point of the driver bit in the screw head and

apply pressure to the tool. Start the tool. Release the trigger just as the screw bottoms out. If the trigger is not

released, the screw may strip out the hole or the screw

and/or bit may be damaged.

For model 6019D

Place the point of the driver bit in the screw head and

apply pressure to the tool. Start the tool slowly and then

increase the speed gradually. Release the switch trigger

as soon as the clutch cuts in.

CAUTION:

• Make sure that the driver bit is inserted straight in the

screw head, or the screw and/or bit may be damaged.

NOTE:

• When driving wood screws, predrill pilot holes to make

driving easier and to prevent splitting of the workpiece.

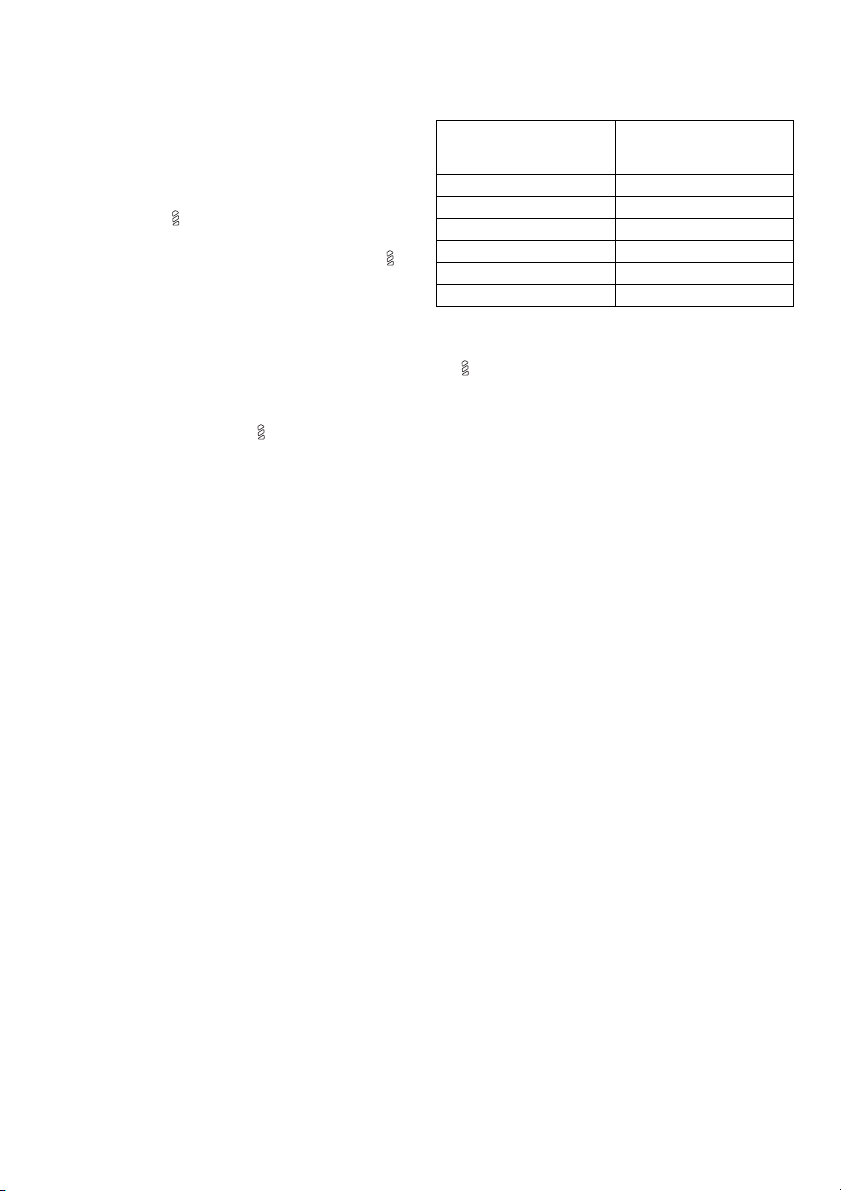

See the chart.

Nominal diameter of

wood screw

(mm)

3.1 2.0 - 2.2

3.5 2.2 - 2.5

3.8 2.5 - 2.8

4.5 2.9 - 3.2

4.8 3.1 - 3.4

5.1 3.3 - 3.6

Recommended size of

pilot hole

(mm)

Drilling operation (Fig. 7)

First, turn the adjusting ring so that the pointer points to

the marking (6019D). Then proceed as follows.

Drilling in wood

When drilling in wood, the best results are obtained with

wood drills equipped with a guide screw. The guide screw

makes drilling easier by pulling the bit into the workpiece.

Drilling in metal

To prevent the bit from slipping when starting a hole, make

an indentation with a center-punch and hammer at the

point to be drilled. Place the point of the bit in the indentation and start drilling.

Use a cutting lubricant when drilling metals. The exceptions are iron and brass which should be drilled dry.

CAUTION:

• Pressing excessively on the tool will not speed up the

drilling. In fact, this excessive pressure will only serve

to damage the tip of your bit, decrease the tool performance and shorten the service life of the tool.

• There is a tremendous force exerted on the tool/bit at

the time of hole break through. Hold the tool firmly and

exert care when the bit begins to break through the

workpiece.

• A stuck bit can be removed simply by setting the

reversing switch to reverse rotation in order to back

out. However, the tool may back out abruptly if you do

not hold it firmly.

• Always secure small workpieces in a vise or similar

hold-down device.

• If the tool is operated continuously until the battery cartridge has discharged, allow the tool to rest for 15 minutes before proceeding with a fresh battery.

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and the battery cartridge is removed before attempting to perform

inspection or maintenance.

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be performed by Makita Authorized Service Centers, always

using Makita replacement parts.

5

Page 6

ACCESSORIES

CAUTION:

• These accessories or attachments are recommended

for use with your Makita tool specified in this manual.

The use of any other accessories or attachments might

present a risk of injury to persons. Only use accessory

or attachment for its stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita service center.

• Drill bits

• Screw bits

• Various type of Makita genuine batteries and chargers

• Set plate

6

Page 7

NEDERLANDS

Verklaring van het onderdelenoverzicht

1. Vergrendelplaat

2. Accu

3. Aan/uit-schakelaar

4. Omkeerschakelaar

5. Lage snelheid

6. Hoge snelheid

7. Snelheidsinstelknop

8. Aanwijspunt

9. Zwak

10. Sterk

11. Draaikoppel-instelring

12. Vastdraaien

13. Mof

14. Ring

TECHNISCHE GEGEVENS

Model 6017D 6018D 6019D

Metaal 10 mm

Capaciteiten

Onbelaste snelheid

• Als gevolg van ons doorlopende onderzoeks- en ontwikkelingsprogramma, zijn de technische gegevens van dit

gereedschap onderhevig aan veranderingen zonder voorafgaande kennisgeving.

• Opmerking: De technische gegevens kunnen van land tot land verschillen.

Gebruiksdoeleinden

Het gereedschap is bedoeld voor boren en schroeven in

hout, metaal en kunststof.

-1

(min

)

Totale lengte 251 mm 251 mm

Netto gewicht 1,0 kg 1,1 kg 1,1 kg

Nominale spanning 7,2 V gelijkstroom

Hout 15 mm

Houtschroef 5,1 mm x 35 mm

Machineschroef --- --- 6 mm

Hoog 600 0 - 600 0 - 600

Laag 200 0 - 200 0 - 200

AANVULLENDE

VEILIGHEIDSVOORSCHRIFTEN

Laat u NIET misleiden door een vals gevoel van

comfort en bekendheid met het gereedschap (na

veelvuldig gebruik) en neem alle

veiligheidsvoorschriften van de schroefboormachine

altijd strikt in acht. Bij onveilig of verkeerd gebruik

van het elektrisch gereedschap, bestaat de kans op

ernstig persoonlijk letsel.

1. Houd elektrisch gereedschap vast aan het

geïsoleerde oppervlak van de handgrepen

wanneer u werkt op plaatsen waar het

zaaggereedschap met verborgen bedrading of zijn

eigen snoer in aanraking kan komen. Door contact

met onder spanning staande draden, zullen de nietgeïsoleerde metalen delen van het gereedschap

onder spanning komen te staan zodat de gebruiker

een elektrische schok kan krijgen.

2. Zorg er altijd voor dat u stevig staat. Zorg ervoor

dat er niemand zich onder u bevindt wanneer u het

gereedschap op een hoge plaats gebruikt.

3. Houd het gereedschap stevig vast.

4. Houd uw handen uit de buurt van draaiende delen.

5. Laat het gereedschap niet ingeschakeld liggen.

Bedien het gereedschap alleen wanneer u het

vasthoudt.

6. Raak het schroef- of boorbit en het werkstuk niet

onmiddellijk na gebruik aan. Zij kunnen bijzonder

heet zijn en brandwonden op uw huid

veroorzaken.

7. Sommige materialen bevatten chemische stoffen

die giftig kunnen zijn. Neem

19

Page 8

voorzorgsmaatregelen tegen het inademen van

stof en contact met de huid. Volg de

veiligheidsinstructies van de leverancier van het

materiaal op.

BEWAAR DEZE

VOORSCHRIFTEN

WAARSCHUWING:

VERKEERD GEBRUIK of het niet volgen van de

veiligheidsinstructies in deze gebruiksaanwijzing kan

leiden tot ernstig persoonlijk letsel.

BELANGRIJKE

VEILIGHEIDSINSTRUCTIES VOOR

ACCU’S

1. Alvorens de accu in gebruik te nemen, leest u

eerst alle instructies en

waarschuwingsopschriften op (1) de acculader, (2)

de accu en (3) het apparaat waarin de accu wordt

aangebracht.

2. Haal de accu niet uit elkaar.

3. Als de gebruikstijd aanzienlijk korter is geworden,

stopt u onmiddellijk met het gebruik. Anders kan

dit leiden tot kans op oververhitting, mogelijke

brandwonden en zelfs een explosie.

4. Als de elektrolyt in uw ogen komt, wast u deze uit

met schoon water en raadpleegt u onmiddellijk

een arts. Dit kan leiden tot verlies van

gezichtsvermogen.

5. Wanneer de accu niet wordt gebruikt, dienen de

accupolen altijd te worden afgedekt met de

accudeksel.

6. Sluit de accu niet kort:

(1) Raak de accupolen niet aan met enig geleidend

materiaal.

(2) Bewaar de accu niet op een plaats waar deze in

aanraking kan komen met andere metalen

voorwerpen, zoals spijkers, munten, enz.

(3) Stel de accu niet bloot aan water of regen.

Kortsluiting van de accu kan leiden tot een hoge

stroomsterke, oververhitting, mogelijke

brandwonden en zelfs een defect.

7. Bewaar het gereedschap en de accu niet op

plaatsen waar de temperatuur kan oplopen tot

50 °C of hoger.

8. Werp de accu niet in een vuur, zelfs niet als deze al

ernstig beschadigd of helemaal versleten is. De

accu kan in een vuur exploderen.

9. Wees voorzichtig dat u de accu niet laat vallen of

ergens tegenaan stoot.

BEWAAR DEZE

VOORSCHRIFTEN

Tips voor een lange levensduur van de

accu

1. Laad de accu op voordat deze volledig leeg is.

Wanneer u merkt dat het gereedschap minder

20

vermogen heeft, stopt u met het gebruik ervan en

laadt u eerst de accu op.

2. Laad nooit een volledig opgeladen accu op. Te

lang opladen verkort de levensduur van de accu.

3. Laad de accu op bij een omgevingstemperatuur

van 10 °C t/m 40 °C. Laat een warme accu eerst

afkoelen voordat u deze oplaadt.

4. Als de nikkel-metaalhydride-accu zes maanden

niet is gebruikt, laadt u deze eerst op alvorens

deze te gebruiken.

BESCHRIJVING VAN DE

FUNCTIES

LET OP:

• Controleer altijd of het gereedschap is uitgeschakeld

en de accu is verwijderd alvorens de functies van het

gereedschap te controleren of af te stellen.

De accu aanbrengen en verwijderen (zie

afb. 1)

• Schakel het gereedschap altijd uit voordat u de accu

aanbrengt of verwijdert.

• Om de accu eruit te halen trekt u de vergrendelplaat op

het gereedschap naar buiten en pakt u de accu aan

beide zijkanten vast om deze uit het gereedschap te

trekken.

• Om de accu aan te brengen lijnt u de lip op de accu uit

met de groef in de behuizing en duwt u de accu op zijn

plaats. Duw vervolgens de vergrendelplaat terug op

zijn plaats. Zorg ervoor dat u de vergrendelplaat

volledig sluit alvorens het gereedschap weer te

gebruiken om te voorkomen dat de accu per ongeluk

uit het gereedschap valt.

• Oefen geen grote kracht uit bij het aanbrengen van de

accu. Als de accu niet gemakkelijk in het gereedschap

kan worden gestoken, wordt deze niet goed

aangebracht.

In- en uitschakelen (zie afb. 2)

LET OP:

• Controleer altijd, voordat u de accu in het gereedschap

steekt, of de aan/uit-schakelaar op de juiste manier

schakelt en weer terugkeert naar de uit-stand nadat

deze is losgelaten.

Om het gereedschap in te schakelen, knijpt u gewoon de

aan/uit-schakelaar in. De draaisnelheid van het

gereedschap neemt toe naarmate u meer druk uitoefent

op de aan/uit-schakelaar. Laat de aan/uit-schakelaar los

om het gereedschap te stoppen

Werking van de omkeerschakelaar (zie

afb. 3)

Dit gereedschap is uitgerust met een omkeerschakelaar

waarmee u de draairichting kunt omkeren. Duw de

omkeerschakelaar naar kant A voor de draairichting

rechtsom, of naar kant B voor de draairichting linksom.

Wanneer de omkeerschakelaar in de middenstand staat,

kunt u de aan/uit-schakelaar niet inknijpen.

Page 9

LET OP:

• Controleer altijd de draairichting alvorens het

gereedschap te gebruiken.

• Gebruik de omkeerschakelaar alleen nadat het

gereedschap volledig tot stilstand is gekomen. Als u de

draairichting verandert voordat het gereedschap

volledig stilstaat, kan het gereedschap worden

beschadigd.

• Als u het gereedschap niet gebruikt, zet u de

omkeerschakelaar altijd in de middenstand.

De draaisnelheid veranderen (zie afb. 4)

Om de draaisnelheid van het gereedschap te veranderen,

schakelt u eerst het gereedschap uit en verschuift u

daarna de snelheidsinstelknop naar stand “II” voor een

hoge draaisnelheid, of naar stand “I” voor een lage

draaisnelheid. Zorg ervoor dat de snelheidsinstelknop in

de juiste stand staat alvorens het gereedschap te

bedienen. Gebruik de juiste draaisnelheid voor uw klus.

LET OP:

• Zet de snelheidsinstelknop altijd volledig in de

gewenste stand. Als u het gereedschap bedient terwijl

de snelheidsinstelknop halverwege de standen “I” en

“II” staat, kan het gereedschap worden beschadigd.

• Nadat u de snelheidsinstelknop naar de gewenste

stand hebt verschoven, moet u altijd controleren of het

aandrijftandwiel goed aangrijpt door het gereedschap

onbelast te laten draaien. Als u het gereedschap

bedient terwijl het aandrijftandwiel niet goed aangrijpt,

kan het gereedschap worden beschadigd.

• Bedien de snelheidsinstelknop niet terwijl het

gereedschap draait. Het gereedschap kan hierdoor

worden beschadigd.

Het draaikoppel instellen (zie afb. 5)

Alleen voor model 6019D

Het draaikoppel kan in 6 stappen worden ingesteld door

de instelring te draaien zodat de gewenste stand op de

schaalverdeling is uitgelijnd met de aanwijspunt op de

behuizing van het gereedschap. Het draaikoppel is

minimaal wanneer stand 1 is uitgelijnd met de

aanwijspunt, en maximaal wanneer het symbool is

uitgelijnd met de aanwijspunt.

In de standen 1 t/m 5 zal de koppeling slippen bij steeds

oplopende draaikoppelniveaus. De koppeling is

ontworpen om niet te slippen op het symbool .

Bepaal het juiste draaikoppelniveau door bij wijze van

proef een schroef in het materiaal of een stuk

gelijkwaardig materiaal te draaien, alvorens het

gereedschap voor de daadwerkelijke klus te gebruiken.

OPMERKING:

• De instelring wordt niet vergrendeld wanneer de

pijlpunt halverwege tussen twee standen staat.

• Bedien het gereedschap niet terwijl de instelring tussen

stand 5 en het symbool in staat. Het gereedschap

kan hierdoor worden beschadigd.

ONDERDELEN AANBRENGEN/

VERWIJDEREN

LET OP:

• Controleer altijd of het gereedschap is uitgeschakeld

en de accu is verwijderd alvorens enige

werkzaamheden aan het gereedschap te verrichten.

Het schroefbit of boorbit aanbrengen en

verwijderen (zie afb. 6)

Houd de ring op zijn plaats en draai de mof linksom om de

klauwen in de spankop te openen.

Steek het bit zo ver mogelijk in de spankop. Houd de ring

stevig op zijn plaats en draai de mof rechtsom om de

klauwen in de spankop te sluiten.

Om het bit te verwijderen, houdt u de ring op zijn plaats en

draait u de mof linksom.

Wanneer u een bit niet gebruikt, klemt u deze in de

bithouder. U kunt hierin bits van 45 mm lengte bewaren.

BEDIENING

Gebruik als schroevendraaier

Voor model 6017D/6018D

Plaats de punt van het schroefbit in de schroefkop en

oefen druk uit op het gereedschap. Schakel het

gereedschap in. Laat de aan/uit-schakelaar los op het

moment dat de schroef helemaal in het materiaal zit. Als u

de aan/uit-schakelaar niet loslaat, kan de schroef

doldraaien in het gat of kunnen de schroef en/of het bit

worden beschadigd.

Voor model 6019D

Plaats de punt van het schroefbit in de schroefkop en

oefen druk uit op het gereedschap. Start het gereedschap

op lage snelheid en voer vervolgens de snelheid

geleidelijk op. Laat de aan/uit-schakelaar los zodra de

koppeling begint te slippen.

LET OP:

• Zorg ervoor dat het schroefbit recht op de schroefkop

staat omdat anders de schroef en/of het bit kunnen

worden beschadigd.

OPMERKING:

• Bij het schroeven van houtschroeven moet u de

boorgaten voorboren om het schroeven te

vergemakkelijken en te voorkomen dat het werkstuk

splijt. Zie de tabel.

Nominale diameter van

houtschroef

(mm)

3,1 2,0 - 2,2

3,5 2,2 - 2,5

3,8 2,5 - 2,8

4,5 2,9 - 3,2

4,8 3,1 - 3,4

5,1 3,3 - 3,6

Aanbevolen diameter van

voorgeboorde gat

(mm)

21

Page 10

Gebruik als boor (zie afb. 7)

Draai eerst de instelring zodat de pijlpunt op het symbool

staat (6019D). Ga daarna als volgt te werk.

Boren in hout

Bij het boren in hout verkrijgt u de beste resultaten met

houtboren voorzien van een geleideschroef. De

geleideschroef zorgt ervoor dat het boren gemakkelijker

verloopt door het bit in het werkstuk te trekken.

Boren in metaal

Om te voorkomen dat bij het beginnen van het boren het

bit wegglijdt, maakt u een putje met een centerpons en

hamer op het punt waar u wilt boren. Plaats de punt van

het bit in het putje en begin te boren.

Gebruik bij het boren in metaal een snijolie als

smeermiddel. De uitzonderingen hierop zijn ijzer en

messing, die droog moeten worden geboord.

LET OP:

• Het boren zal niet sneller verlopen als u hard op het

gereedschap drukt. In feite zal dergelijk duwen alleen

maar leiden tot beschadiging van het bit, verlagen van

de prestaties van het gereedschap, en verkorten van

de levensduur van het gereedschap.

• Op het moment dat het boorgat doorbreekt wordt een

enorme kracht uitgeoefend op het gereedschap/bit.

Houd het gereedschap stevig vast en let goed op

wanneer het bit door het werkstuk breekt.

• Een vastgelopen bit kan eenvoudigweg worden

verwijderd door de omkeerschakelaar in de stand voor

achteruitdraaien te zetten om het bit te verwijderen. Het

gereedschap kan echter plotseling achteruit komen als

u het niet stevig vasthoudt.

• Zet kleine werkstukken altijd vast in een bankschroef of

soortgelijk bevestigingsmiddel.

• Als het gereedschap continu wordt bediend totdat de

accu leeg is, laat u het gereedschap gedurende 15

minuten liggen alvorens verder te werken met een volle

accu.

hulpstukken uitsluitend voor de aangegeven

gebruiksdoeleinden.

Mocht u meer informatie willen hebben over deze

accessoires, dan kunt u contact opnemen met uw

plaatselijke Makita-servicecentrum.

• Boorbits

•Schroefbits

• Diverse types originele Makita-accu’s en acculaders

• Vergrendelplaat

ONDERHOUD

LET OP:

• Zorg er altijd voor dat de machine is uitgeschakeld en

de accu is verwijderd, voordat u een inspectie of

onderhoud uitvoert.

Om de VEILIGHEID en BETROUWBAARHEID van het

gereedschap te handhaven, dienen alle reparaties,

onderhoud en afstellingen te worden uitgevoerd door een

erkend Makita-servicecentrum, en altijd met

gebruikmaking van originele Makitavervangingsonderdelen.

ACCESSOIRES

LET OP:

• Deze accessoires of hulpstukken worden aanbevolen

voor gebruik met het Makita-gereedschap dat in deze

gebruiksaanwijzing wordt beschreven. Het gebruik van

andere accessoires of hulpstukken kan gevaar voor

persoonlijk letsel opleveren. Gebruik de accessoires of

22

Page 11

ENGLISH

EC-DECLARATION OF CONFORMITY

We declare under our sole responsibility that this product is in

compliance with the following standards of standardized

documents, EN60745, EN55014 in accordance with Council

Directives, 89/336/EEC, 98/37/EC.

ITALIANO

LE NORME DELLA COMUNITÀ EUROPEA

Dichiariamo sotto la nostra sola responsabilità che questo

prodotto è conforme agli standard di documenti standardizzati

seguenti: EN60745, EN55014 secondo le direttive del

Consiglio 89/336/CEE e 98/37/CE.

FRANÇAIS

DÉCLARATION DE CONFORMITÉ CE

Nous déclarons sous notre entière responsabilité que ce

produit est conforme aux normes des documents standardisés

suivants, EN60745, EN55014 conformément aux Directives

du Conseil, 89/336/CEE et 98/37/EG.

DEUTSCH

Hiermit erklärt wir unter unserer alleinigen Verantwortung, daß

dieses Produkt gemäß den Ratsdirektiven 89/336/EWG und

98/37/EG mit den folgenden Normen von Normendokumenten

übereinstimmen: EN60745, EN55014

CE-KONFORMITÄTSERKLÄRUNG

NEDERLANDS

EG-VERKLARING VAN CONFORMITEIT

Wij verklaren hierbij uitsluitend op eigen verantwoordelijkheid

dat dit produkt voldoet aan de volgende normen van

genormaliseerde documenten, EN60745, EN55014 in

overeenstemming met de richtlijnen van de Raad 89/336/EEC

en 98/37/EC.

ESPAÑOL

DECLARACIÓN DE CONFORMIDAD DE LA CE

Declaramos bajo nuestra sola responsabilidad que este

producto cumple con las siguientes normas de documentos

normalizados, EN60745, EN55014 de acuerdo con las

directivas comunitarias, 89/336/EEC y 98/37/CE.

Yasuhiko Kanzaki CE 2005

Director Amministratore

Directeur Directeur

Direktor Director

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

Responsible manufacturer: Produttore responsabile:

Fabricant responsable : Verantwoordelijke fabrikant:

Verantwortlicher Hersteller: Fabricante responsable:

Makita Corporation Anjo Aichi Japan

54

Page 12

PORTUGUÊS

DECLARAÇÃO DE CONFORMIDADE DA CE

Declaramos sob inteira responsabilidade que este produto

obedece às seguintes normas de documentos normalizados,

EN60745, EN55014 de acordo com as directivas

89/336/CEE e 98/37/CE do Conselho.

NORSK

Vi erklærer på eget ansvar at dette produktet er i

overensstemmelse med følgende standard i de standardiserte

dokumenter: EN60745, EN55014, i samsvar med Rådsdirektivene, 89/336/EEC og 98/37/EC.

EUs SAMSVARS-ERKLÆRING

DANSK

EU-DEKLARATION OM KONFORMITET

Vi erklærer hermed på eget ansvar, at dette produkt er i

overensstemmelse med de følgende standarder i de

normsættende dokumenter, EN60745, EN55014 i

overensstemmelse med Rådets Direktiver, 89/336/EEC og

98/37/EC.

SVENSKA

EG-DEKLARATION OM ÖVERENSSTÄMMELSE

Under eget ansvar deklarerar vi härmed att denna produkt

överensstämmer med följande standardiseringar för

standardiserade dokument, EN60745, EN55014 i enlighet

med EG-direktiven 89/336/EEC och 98/37/EC.

SUOMI

Yksinomaisesti vastuullisina ilmoitamme, että tämä tuote on

seuraavien standardoitujen dokumenttien standardien

mukainen, EN60745, EN55014 neuvoston direktiivien

89/336/EEC ja 98/37/EC mukaisesti.

VAKUUTUS EC-VASTAAVUUDESTA

ΕΛΛΗΝΙΚΑ

∆ηλώνουµε υπ την µοναδική µας ευθύνη τι αυτ το

προϊν βρίσκεται σε Συµφωνία µε τα ακλουθα πρτυπα

τυποποιηµένων εγγράφων, EN60745, EN55014 σύµφωνα

µε τις Οδηγίες του Συµβουλίου, 89/336/EEC και 98/37/EC.

∆ΗΛΩΣΗ ΣΥΜΜΟΡΦΩΣΗΣ ΕΚ

TÜRKÇE

AVRUPA KONSEYİ – UYGUNLUK BEYANI

Bütün sorumluluğu üzerimize alarak, bu ürünün, Avrupa

Konseyi Yönergeleri, 89/336/EEC ve 98/37/EC, uyarınca,

aşağıdaki standartlaştırılmış belgelerdeki standartlara

uygunluğuna beyan ederiz: EN60745, EN55014

Yasuhiko Kanzaki CE 2005

Director Direktor

Direktør Johtaja

Direktör ∆ιευθυντής Müdür

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

Fabricante responsável:: Ansvarlig produsent:

Ansvarlig fabrikant: Vastaava valmistaja:

Ansvarig tillverkare: Yπεύθυνος κατασκευαστής: Sorumlu imalatçı:

Makita Corporation Anjo Aichi Japan

55

Page 13

ENGLISH

For European countries only

Noise and Vibration

The typical A-weighted sound pressure level is not more than

70 dB (A).

The noise level under working may exceed 85 dB (A).

– Wear ear protection.–

The typical weighted root mean square acceleration value is

not more than 2.5 m/s

These values have been obtained according to EN60745.

2

.

ITALIANO

Modello per l’Europa soltanto

Rumore e vibrazione

Il livello tipico di pressione sonora ponderato A non supera

70 dB (A).

Il livello acustico in funzionamento può superare 85 dB (A).

– Indossare una protezione acustica.

In genere, il valore efficace ponderato dell'accelerazione non

supera i 2,5 m/s

Questi valori sono stati ottenuti in conformità con la norma

EN60745.

2

.

FRANÇAIS

Pour les pays d’Europe uniquement

Bruit et vibrations

Le niveau de pression sonore pondérée A typique ne dépasse

pas 70 dB (A).

Le niveau de bruit peut dépasser 85 dB (A) lors de l’utilisation.

– Portez des protections d’oreilles. –

La valeur d’accélération quadratique pondérée typique est

inférieure à 2,5 m/s

Ces valeurs ont été obtenues selon EN60745.

2

.

DEUTSCH

Nur für europäische Länder

Geräusch- und Vibrationsentwicklung

Der typische Schalldruck beträgt höchstens 70 dB (A).

Unter Arbeitsbedingungen kann der Schalldruck 85 dB (A)

überschreiten.

– Tragen Sie Gehörschutz. –

Der typische effektive Beschleunigungswert beträgt höchstens

2

2,5 m/s

.

Diese Werte wurden entsprechend der Norm EN60745

gewonnen.

Yasuhiko Kanzaki CE 2005

NEDERLANDS

Alleen voor Europese landen

Geluidsniveau en trilling

Het typische, A-gewogen geluidsdrukniveau is niet hoger dan

70 dB (A).

Het geluidsniveau kan tijdens gebruik hoger worden dan

85 dB (A).

– Draag gehoorbescherming.–

De typisch, gewogen, kwadratisch-gemiddelde

versnellingswaarde is niet meer dan 2,5 m/s

Deze waarden zijn verkregen volgens EN60745.

2

ESPAÑOL

Para países europeos solamente

Ruido y vibración

El nivel de presión acústica típico ponderado A no supera los

70 dB (A).

El nivel de ruido durante el trabajo puede superar los 85 dB

(A).

– Utilice protectores para los oídos. –

El valor ponderado de aceleración no es superior a 2,5 m/s

Estos valores se han obtenido conforme a EN60745.

2

.

Director Amministratore

Directeur Directeur

Direktor Director

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

Responsible manufacturer: Produttore responsabile:

Fabricant responsable : Verantwoordelijke fabrikant:

Verantwortlicher Hersteller: Fabricante responsable:

Makita Corporation Anjo Aichi Japan

56

Page 14

PORTUGUÊS

Só para países Europeus

O nível acústico ponderado A não é superior a 70 dB (A).

O nível de ruído quando em funcionamento pode exceder os

85 dB (A).

– Use protecções para os ouvidos.–

A do valor médio quadrático ponderado da variação da

aceleração não é superior a 2,5 m/s

Estes valores foram obtidos segundo a norma EN60745.

Ruído e vibração

2

.

NORSK

Gjelder bare land i Europa

Typisk A-vektet lydtrykknivå overstiger ikke 70 dB (A).

Støynivået under arbeid kan overskride 85 dB (A).

– Bruk hørselvern.–

Typisk vektet kvadratisk middelverdi av akselerasjonen er ikke

mer enn 2,5 m/s

Disse verdiene er fremkommet i samsvar med EN60745.

Støy og vibrasjon

2

.

DANSK

Kun for lande i Europa

Det typiske A-vægtede lydtryksniveau er ikke højere end

70 dB (A).

Støjniveauet under arbejdet kan være større end 85 dB (A).

– Bær høreværn. –

Den typiske vægtede effektive accelerationsværdi er ikke over

2

2,5 m/s

.

Disse værdier er målt i overensstemmelse med EN60745.

Lyd og vibration

SVENSKA

Endast för Europa

Den typiska ljudtrycksnivån är 70 dB (A).

Bullernivån under drift kan överstiga 85 dB (A).

– Använd hörselskydd.–

Typisk viktar effektivvärde för accelerationen är inte mer än

2

2,5 m/s

.

Dessa värden är inhämtade enligt EN60745.

Buller och vibration

Yasuhiko Kanzaki CE 2005

SUOMI

Vain Euroopan maat

Tyypillinen A-painotettu äänenpainetaso on enintään 70 dB

(A).

Työskentelyn aikana melutaso voi ylittää 85 dB (A).

– Käytä kuulosuojaimia. –

Tyypillinen painotettu tehollisarvo on enintään 2,5 m/s

Nämä arvot on saatu standardin EN60745 mukaisesti.

Melutaso ja tärinä

2

.

ΕΛΛΗΝΙΚΑ

Μνο για χώρες της Ευρώπης

Το σύνηθες σταθµισµένο επίπεδο ηχητικής πίεσης δεν

υπερβαίνει τα 70 dB (A).

Το επίπεδο θορύβου σε λειτουργία ενδέχεται να υπερβεί

τα 85 dB (A).

– Να φοράτε ωτοασπίδες –

Η συνήθης σταθµισµένη µέση τετραγωνική ρίζα της τιµής

επιτάχυνσης δεν υπερβαίνει τα 2,5 m/s

Οι τιµές αυτές έχουν ληφθεί σύµφωνα µε το EN60745.

Θρυβος και κραδασKς

2

.

TÜRKÇE

Yalnızca Avrupa ülkeleri için

Tipik A ağırlıklı ses basınç seviyesi 70 dB'i aşmaz.

Çalışma sırasında gürültü seviyesi 85 dB'i (A) aşabilir.

– Koruyucu kulaklık kullanın. –

Tipik ağırlıklı ivme değerlerinin karelerinin kare kökü cinsinden

ortalama ivmesi 2,5 m/s

Bu değerler EN60745 standardına göre elde edilmiştir.

Gürültü ve Titreşim

2

’yi aşmaz.

Director Direktor

Direktør Johtaja

Direktör ∆ιευθυντής Müdür

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

Fabricante responsável:: Ansvarlig produsent:

Ansvarlig fabrikant: Vastaava valmistaja:

Ansvarig tillverkare: Yπεύθυνος κατασκευαστής: Sorumlu imalatçı:

Makita Corporation Anjo Aichi Japan

57

Page 15

58

Page 16

59

Page 17

Makita Corporation

Anjo, Aichi, Japan

884061G993

Loading...

Loading...