Page 1

GB

Circular Saw Instruction Manual

F

Scie circulaire Manuel d’instructions

D

Handkreissäge Betriebsanleitung

I

Sega circolare Istruzioni per l’uso

NL

Cirkelzaagmachine Gebruiksaanwijzing

E

Sierra circular Manual de instrucciones

P

Serra circular Manual de instruções

DK

Rundsav Brugsanvisning

S

Cirkelsåg Bruksanvisning

N

Sirkelsag Bruksanvisning

FIN

Pyörösahat Käyttöohje

GR ∆ισκοπρίονο Οδηγίες χρήσεως

TR

Dairesel bıçkı El kitabı

165 mm 5603R

190 mm 5703R

235 mm 5903R

270 mm 5103R

355 mm 5143R

Page 2

12

34

56

78

2

Page 3

910

11 12

13 14

15 16

3

Page 4

17 18

4

Page 5

ENGLISH

Explanation of general view

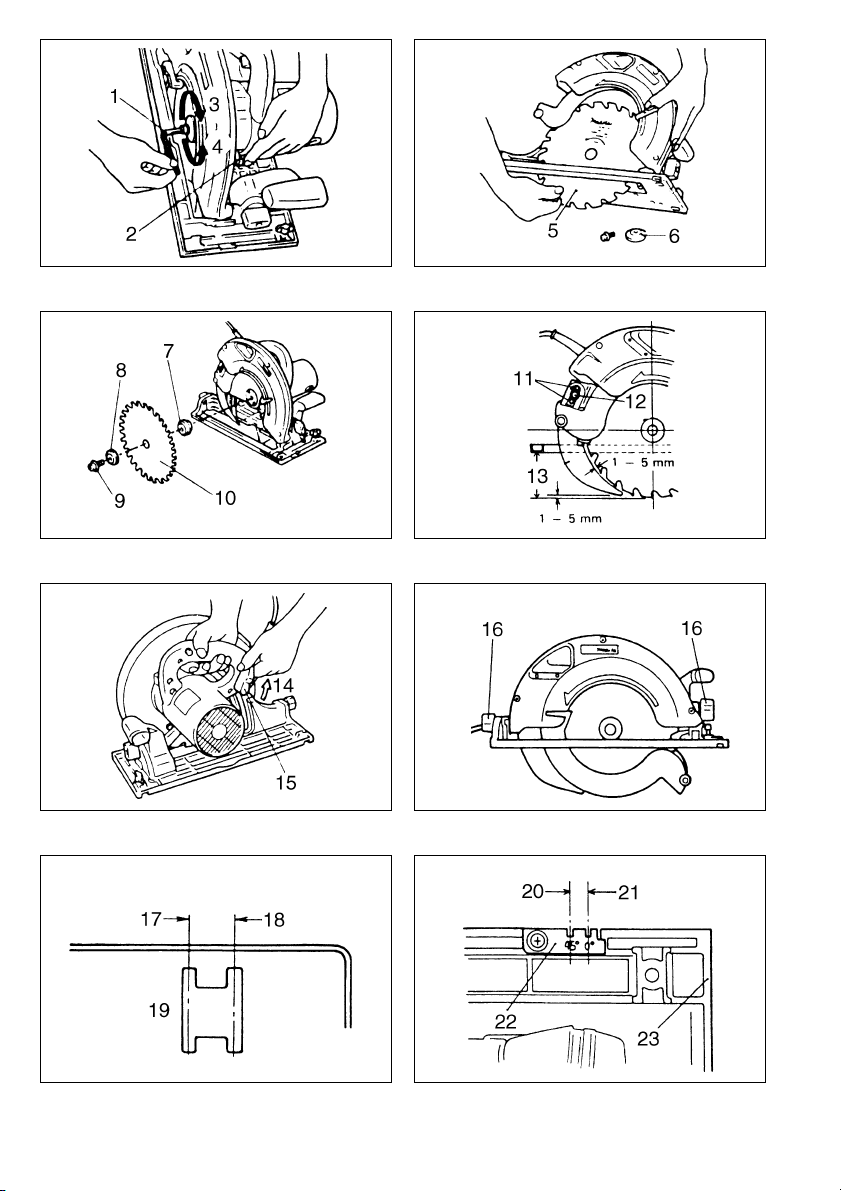

1 Hex wrench

2 Shaft lock

3Tighten

4Loosen

5 Saw blade

6 Outer flange

7 Inner flange

8 Outer flange

9 Hex socket head bolt

10 Saw blade

11 Setting protuberances

12 Hex socket head bolt

(For adjusting riving knife)

SPECIFICATIONS

Model 5603R 5703R 5903R 5103R 5143R

Blade diameter ............................................... 165 mm 190 mm 235 mm 270 mm 355 mm

Max. cutting depth

At 90° .......................................................... 54 mm 66 mm 85 mm 100 mm 130 mm

At 45° .......................................................... 38 mm 46 mm 64 mm 73 mm 90 mm

No load speed (min

Overall length ................................................ 330 mm 356 mm 400 mm 442 mm 607 mm

Net weight ...................................................... 4.2 kg 5.2 kg 7.6 kg 9.4 kg 14.5 kg

• Due to our continuing program of research and development, the specifications herein are subject to change

without notice.

• Note: Specifications may differ from country to country.

Powe r s up ply

The tool should be connected only to a power supply of

the same voltage as indicated on the nameplate, and can

only be operated on single-phase AC supply. They are

double-insulated in accordance with European Standard

and can, therefore, also be used from sockets without

earth wire.

Safety hints

For your own safety, please refer to the enclosed Safety

instructions.

–1

) ................................... 5,000 4,800 4,500 3,800 2,700

13 Cutting depth

14 Loosen

15 Lever

16 Thumb nut

17 For 45° bevel cuts

18 For straight cuts

19 Base plate

20 45° angle cuts

21 Straight cuts

22 Top guide

23 Base

24 60° angle cuts

25 45° angle cuts

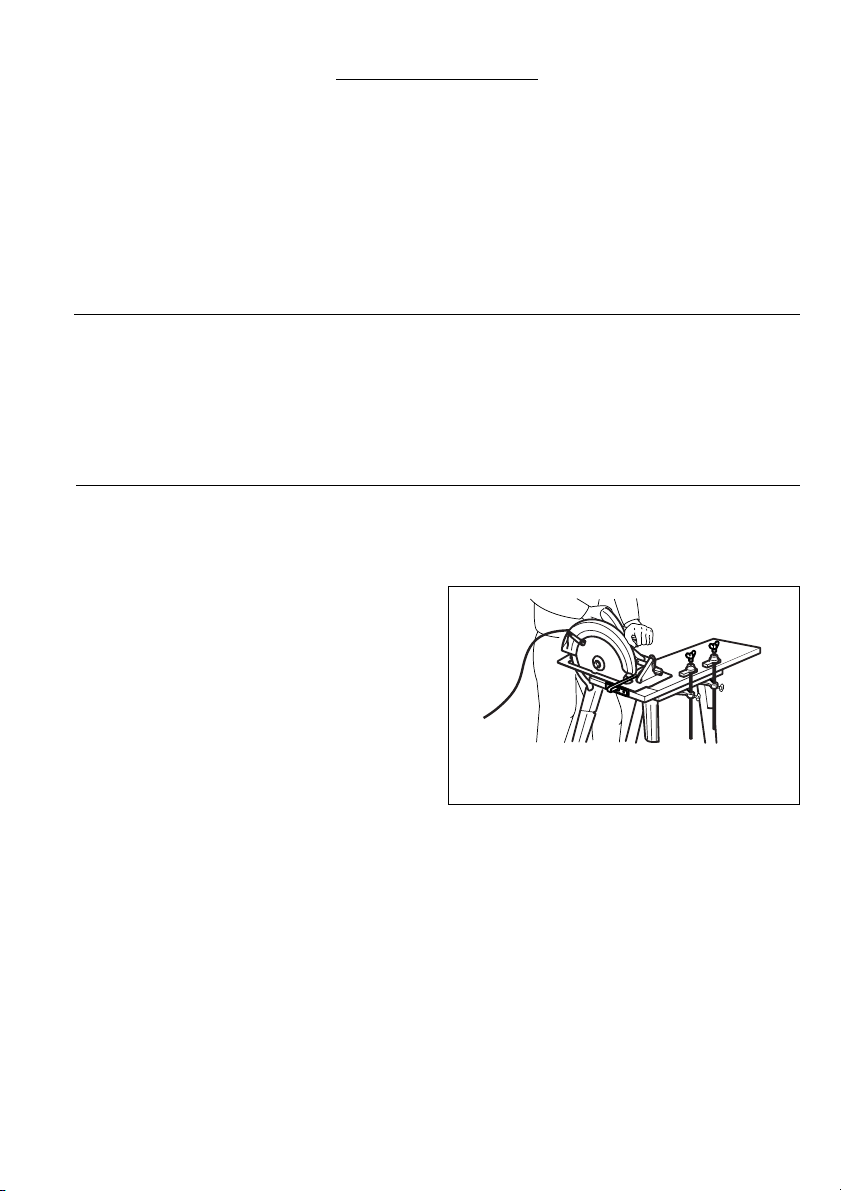

4. Never hold piece being cut in your hands or

26 30° angle cuts

27 Straight cuts

28 Blade

29 Base

30 Top guide

31 Lock-off button

32 Switch trigger

33 Vacuum cleaner

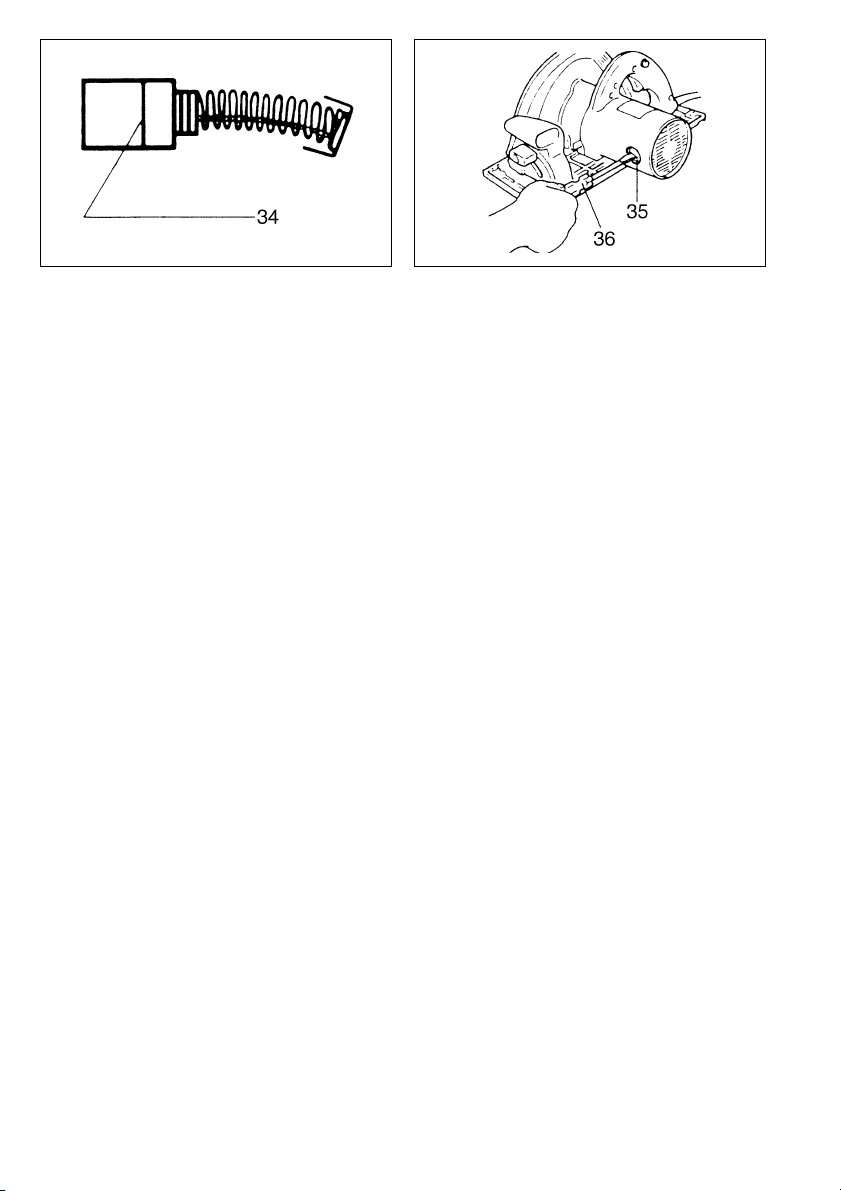

34 Limit mark

35 Brush holder cap

36 Screwdriver

across your leg. Secure the workpiece to stable

platform. It is important to support the work proper ly

to minimize body exposure, blade binding, or loss of

control. (Fig. A)

SPECIFIC SAFETY RULES

DO NOT let comfort or familiarity with product

(gained from repeated use) replace strict adherence

to circular saw safety rules. If you use this tool

unsafely or incorrectly, you can suffer serious personal injury.

Danger:

1. Keep hands away from cutting area and the

blade. Keep your second hand on auxiliary handle, or motor housing. If both hands are holding

the saw, they cannot be cut by the blade.

2. Do not reach underneath the workpiece. The

guard cannot protect you from the blade below the

workpiece. Do not attempt to remove cut material

when blade is moving.

CAUTION: Blades coast after turn off. Wait until

blade stops before grasping cut material.

3. Adjust the cutting depth to the thickness of the

workpiece. Less than a full tooth of the blade teeth

should be visible below the workpiece.

GEB029-1

A typical illustration of proper hand support, workpiece support, and supply cord routing (if applicable).

Fig. A

5. Hold power tool by insulated gripping surfaces

when performing an operation where the cutting

tool may contact hidden wiring or its own cord.

Contact with a “live” wire will also make exposed

metal parts of the power tool “live” and shock the

operator.

6. When ripping always use a rip fence or straight

edge guide. This improves the accuracy cut and

reduces the chance of blade binding.

7. Always use blades with correct size and shape

(diamond versus round) of arbour holes. Blades

that do not match the mounting hardware of the saw

will run eccentrically, causing loss of control.

8. Never use damaged or incorrect blade washers

or bolt. The blade washers and bolt were specially

designed for your saw, for optimum performance and

safety of operation.

5

Page 6

9. Causes and Operator Prevention of Kickback:

– kickback is a sudden reaction to a pinched, bound

or misaligned saw blade, causing an uncontrolled

saw to lift up and out of the workpiece toward the

operator;

– when the blade is pinched or bound tightly by the

kerf closing down, the blade stalls and the motor

reaction drives the unit rapidly back toward the

operator;

– if the blade becomes twisted or misaligned in the

cut, the teeth at the back edge of the blade can dig

into the top surface of the wood causing the blade

to climb out of the kerf and jump back toward the

operator.

Kickback is the result of saw misuse and/or incorrect

operating procedures or conditions and can be

avoided by taking proper precautions as given

below.

• Maintain a firm grip with both hands on the

saw and position your arms to resist kickback

forces. Position your body to either side of the

blade, but not in line with the blade. Kickback

could cause the saw to jump backwards, but kickback forces can be controlled by the operator, if

proper precautions are taken.

• When blade is binding, or when interrupting a

cut for any reason, release the trigger and hold

the saw motionless in the material until the

blade comes to a complete stop. Never attempt

to remove the saw from the work or pull the

saw backward while the blade is in motion or

kickback may occur. Investigate and take correc-

tive actions to eliminate the cause of blade binding.

• When restarting a saw in the workpiece, centre

the saw blade in the kerf and check that saw

teeth are not engaged into the material. If saw

blade is binding, it may walk up or kickback from

the workpiece as the saw is restarted.

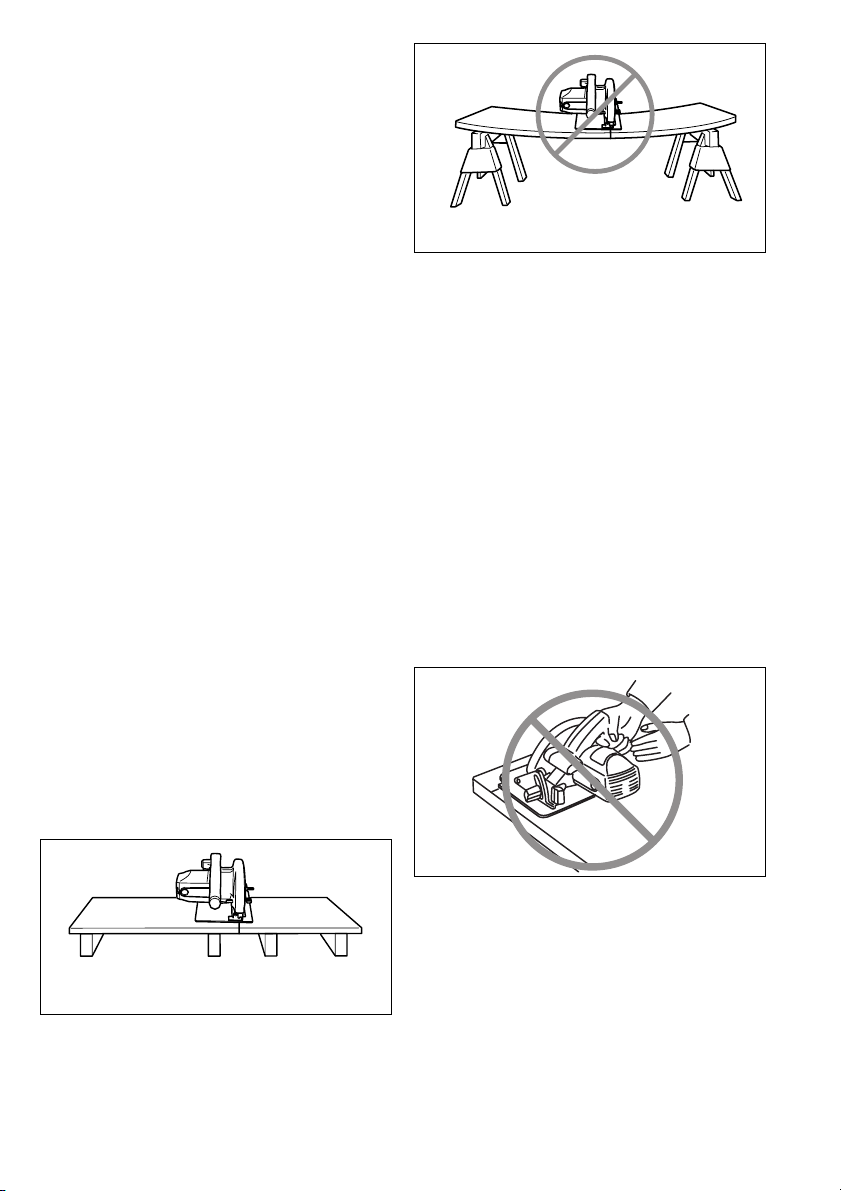

• Support large panels to minimise the risk of

blade pinching and kickback. Large panels tend

to sag under their own weight. Supports must be

placed under the panel on both sides, near the line

of cut and near the edge of the panel.

• To minimize the risk of blade pinching and kickback. When cutting operation requires the resting

of the saw on the workpiece, the saw should be

rested on the larger portion and the smaller piece

cut off. (Fig. B & C)

Don’t support board or panel away from the cut.

Fig. C

• Do not use dull or damaged blades. Unsharp-

ened or improperly set blades produce narrow kerf

causing excessive friction, blade binding and kickback. Keep blade sharp and clean. Gum and wood

pitch hardened on blades slows saw and

increases potential for kickback. Keep blade clean

by first removing it from tool, then cleaning it with

gum and pitch remover, hot water or kerosene.

Never use gasoline.

• Blade depth and bevel adjusting locking levers

must be tight and secure before making cut. If

blade adjustment shifts while cutting, it may cause

binding and kickback.

• Use extra caution when making a “plunge cut”

into existing walls or other blind areas. The

protruding blade may cut objects that can cause

kickback. For plunge cuts, retract lower guard

using retracting handle.

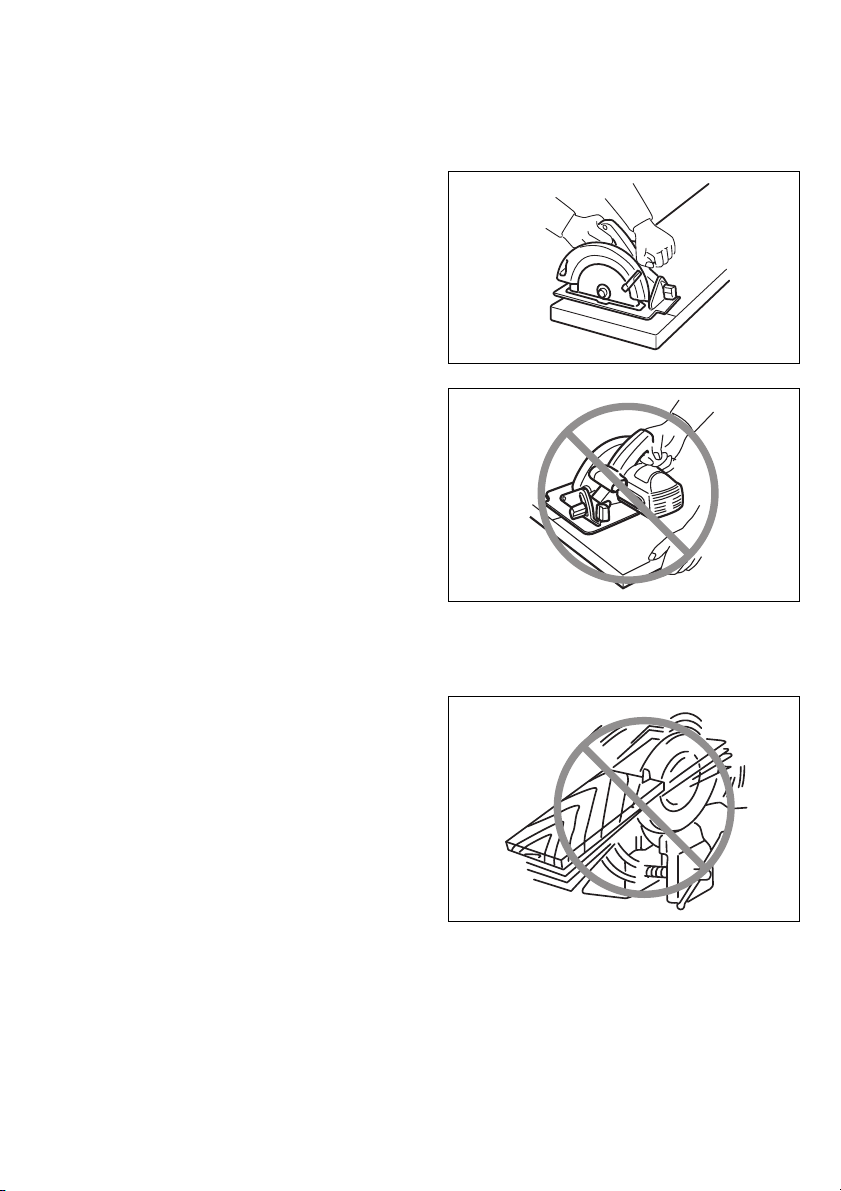

• ALWAYS hold the tool firmly with both hands.

NEVER place your hand or fingers behind the

saw. If kickback occurs, the saw could easily jump

backwards over your hand, leading to serious personal injury. (Fig. D)

To avoid kickback, do support board or panel

near the cut.

6

Fig. B

Fig. D

• Never force the saw. Forcing the saw can

cause uneven cuts, loss of accuracy, and possible kickback. Push the saw forward at a speed

so that the blade cuts without slowing.

Page 7

10. Check lower guard for proper closing before

each use. Do not operate the saw if lower guard

does not move freely and close instantly. Never

clamp or tie the lower guard into the open position. If saw is accidentally dropped, lower guard may

be bent. Raise the lower guard with the retracting

handle and make sure it moves freely and does not

touch the blade or any other part, in all angles and

depths of cut. To check lower guard, open lower

guard by hand, then release and watch guard closure. Also check to see that retracting handle does

not touch tool housing. Leaving blade exposed is

VERY DANGEROUS and can lead to serious personal injury.

11. Check the operation of the lower guard spring. If

the guard and the spring are not operating properly, they must be serviced before use. Lower

guard may operate sluggishly due to damaged

parts, gummy deposits, or a build-up of debris.

12. Lower guard should be retracted manually only

for special cuts such as “plunge cuts” and

“compound cuts.” Raise lower guard by retracting handle and as soon as blade enters the

material, the lower guard must be released. For

all other sawing, the lower guard should operate

automatically.

13. Always observe that the lower guard is covering

the blade before placing saw down on bench or

floor. An unprotected, coasting blade will cause the

saw to walk backwards, cutting whatever is in its

path. Be aware of the time it takes for the blade to

stop after switch is released. Before setting the tool

down after completing a cut, be sure that the lower

guard has closed and the blade has come to a complete stop.

14. Use the appropriate riving knife for the blade

being used. For the riving knife to work, it must be

thicker than the body of the blade but thinner than

the tooth set of the blade.

15. Adjust the riving knife as described in this

instruction manual. Incorrect spacing, positioning

and alignment can make the riving knife ineffective

in preventing kickback.

16. Always use the riving knife except when plunge

cutting. Riving knife must be replaced after plunge

cutting. Riving knife causes interference during

plunge cutting and can create kickback.

17. For the riving knife to work, it must be engaged

in the workpiece. The riving knife is ineffective in

preventing kickback during short cuts.

18. Do not operate the saw if riving knife is bent.

Even a light interference can slow the closing rate of

a guard.

19. Use extra caution when cutting damp wood,

pressure treated lumber, or wood containing

knots. Adjust speed of cut to maintain smooth

advancement of tool without decrease in blade

speed.

20. Avoid Cutting Nails. Inspect for and remove all

nails from lumber before cutting.

21. Place the wider portion of the saw base on that

part of the workpiece which is solidly supported,

not on the section that will fall off when the cut is

made. As examples, Fig. E illustrates the RIGHT

way to cut off the end of a board, and Fig. F the

WRONG way. If the workpiece is short or small,

clamp it down. DO NOT TRY TO HOLD SHORT

PIECES BY HAND! (Fig. E & F)

Fig. E

Fig. F

22. Never attempt to saw with the circular saw held

upside down in a vise. This is extremely dangerous and can lead to serious accidents. (Fig. G)

Fig. G

23. Some material contains chemicals which may be

toxic. Take caution to prevent dust inhalation

and skin contact. Follow material supplier safety

data.

24. Do not stop the blades by lateral pressure on the

saw blade.

25. Always use blades recommended in this manual.

Do not use any abrasive wheels.

7

Page 8

26. Wear a dust mask and hearing protection when

use the tool.

SAVE THESE INSTRUCTIONS.

WARNING:

MISUSE or failure to follow the safety rules stated in

this instruction manual may cause serious personal

injury.

OPERATING INSTRUCTIONS

Removing or installing saw blade

The following blade can be used with this tool.

Model Max. dia. Min. dia. Blade thickness Kerf

5603R 165 mm 150 mm Less than 1.7 mm More than 1.9 mm

5703R 190 mm 170 mm Less than 1.7 mm More than 1.9 mm

5903R 235 mm 210 mm Less than 1.9 mm More than 2.1 mm

5103R 270 mm 260 mm Less than 1.8 mm More than 2.2 mm

5143R 355 mm 350 mm Less than 2.3 mm More than 2.7 mm

The thickness of the riving knife is 1.8 mm for Models

5603R and 5703R or 2.0 mm for Model 5903R and

5103R or 2.5 mm for Model 5143R.

CAUTION:

• Do not use saw blades which do not comply with the

characteristics specified in these instructions.

• Do not use saw blades the disc of which is thicker or

the set of which is smaller than the thickness of the riving knife.

To remove the saw blade, depress the shaft lock fully to

prevent shaft rotation, then use the hex wrench to loosen

the hex socket head bolt. (Fig. 1)

Now remove the outer flange, raise the safety cover as

much as possible, and remove the saw blade. (Fig. 2)

Install the saw blade using the reverse of the removal

procedure. Install the inner flange, saw blade, outer

flange and hex socket head bolt, in that order. Be sure to

secure the hex socket head bolt tightly with the shaft lock

fully depressed. (Fig. 1 & 3)

CAUTION:

• Make sure that the blade teeth point forward in the

same direction as the tool rotation (the arrow on the

blade should point in the same direction as the arrow

on the tool).

• Never depress the shaft lock while the saw is running.

• Use only the Makita socket wrench to remove or install

the blade.

Riving knife adjustment (Fig. 4)

Use the socket wrench to loosen the hex head socket

bolt for the riving knife adjustment, then raise the safety

cover. Move the riving knife up or down over the two protuberances for settings indicated in the illustration, so as

to obtain the proper clearance between the riving knife

and saw blade.

CAUTION:

Ensure that the riving knife is adjusted such that: The distance between the riving knife and the toothed rim of the

saw blade is not more than 5 mm. The toothed rim does

not extend more than 5 mm beyond the lower edge of the

riving knife.

Adjusting depth of cut (Fig. 5)

Loosen the lever on the depth guide and move the base

up or down. At a desired depth of cut, secure the base by

tightening the lever.

CAUTION:

• Use a shallow depth of cut when cutting thin workpiece

for cleaner, safer cuts.

• After adjusting the depth of cut, always tighten the lever

securely.

Adjusting for bevel cuts (Fig. 6)

Loosen the thumb nuts in front and back, and tilt the tool

to the desired angle for bevel cuts (0– 45°). Secure the

thumb nuts tightly in front and back after making the

adjustment.

Sighting (5603R, 5703R) (Fig. 7)

For straight cuts, align the right notch on the front of the

base with your cutting line on the workpiece. For 45°

bevel cuts, align the left notch with it.

Top guide (5903R, 5103R) (Fig. 8)

Align your sight line with either the 0° notch for straight

cutting or the 45° notch for 45° angle cuts.

Top guide (5143R) (Fig. 9)

Align your sight line with either the 0° notch for straight

cutting or the 30° notch for 30° angle cuts or the 45°

notch for 45° angle cuts or the 60° notch for 60° angle

cuts.

Switch action (Fig. 10)

To prevent the switch trigger from being accidentally

pulled, a lock-off button is provided. To start the tool,

depress the lock-off button and pull the switch trigger.

Release the switch trigger to stop.

CAUTION:

• Before plugging in the tool, always check to see that

the switch trigger actuates properly and returns to the

“OFF” position when released.

8

Page 9

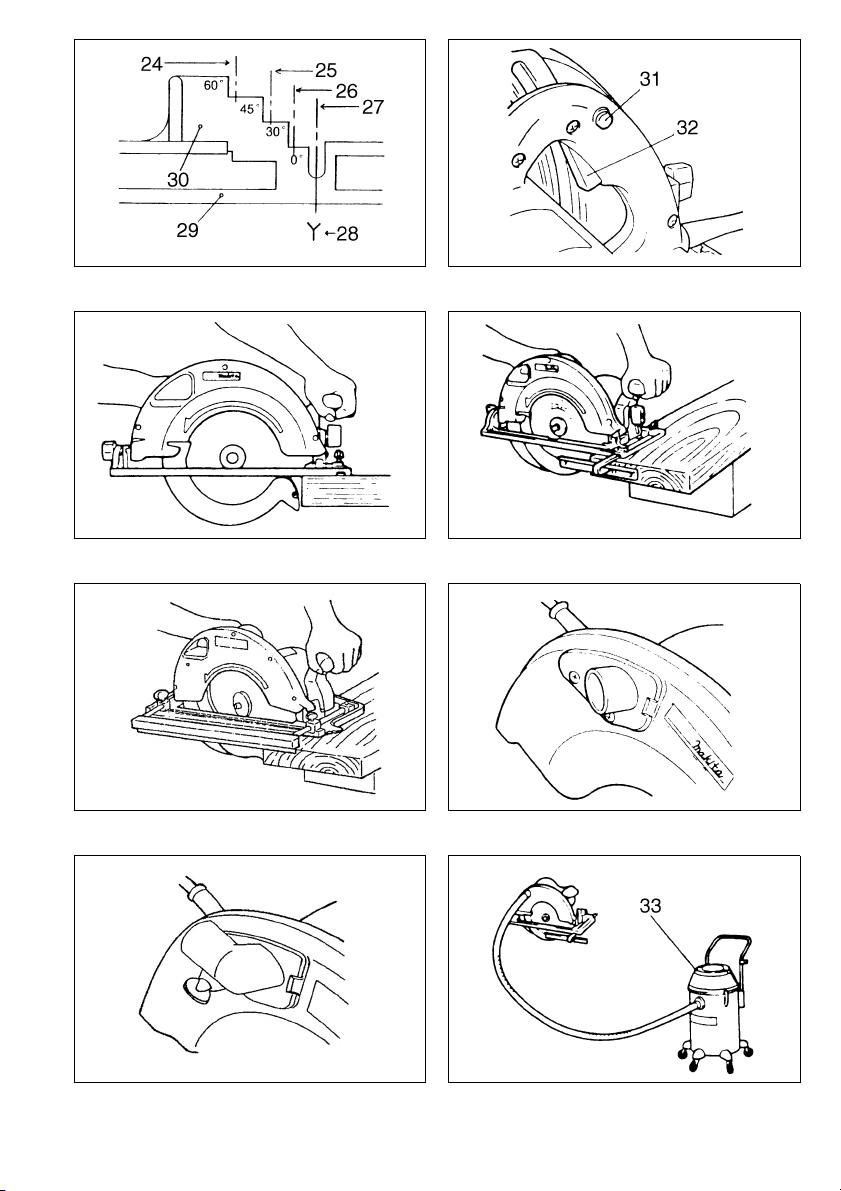

Operation (Fig. 11)

Hold the tool firmly. Set the base plate on the workpiece

to be cut without the blade making any contact. Then turn

the tool on and wait until the blade attains full speed.

Now simply move the tool forward over the workpiece

surface, keeping it flat and advancing smoothly until the

sawing is completed. To get clean cuts, keep your sawing

line straight and your speed of advance uniform.

CAUTION:

• The riving knife should always be used except when

plunging in the middle of the workpiece.

• Do not stop the saw blade by lateral pressure on the

disc.

Guide rule (Fig. 12 & 13)

The handy guide rule allows you to do extra-accurate

straight cuts. Simply slide the guide rule up snugly

against the side of the workpiece and secure it in position

with the screw on the front of the base. It also makes

repeated cuts of uniform width possible.

Joint assembly (Fig. 14, 15 & 16)

(for connecting a vacuum cleaner)

When you wish to perform clean cutting operation, connect a vacuum cleaner to your tool. Install the joint on the

tool using the screw. Then connect a hose of vacuum

cleaner to the joint.

MAINTENANCE

CAUTION:

Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

To maintain product safety and reliability, repairs, maintenance or adjustment should be carried out by a Makita

Authorized Service Center.

9

Page 10

NEDERLANDS

Verklaring van algemene gegevens

1 Inbussleutel

2 Asvergrendeling

3 Vastzetten

4Losmaken

5 Zaagblad

6 Buitenste flens

7 Binnenste flens

8 Buitenste flens

9 Bout met zeskante kop

10 Zaagblad

11 Uitsteeksels voor afstelling

12 Bout met zeskante kop

(Voor afstelling van spouwmes)

TECHNISCHE GEGEVENS

Model 5603R 5703R 5903R 5103R 5143R

Bladdiameter ..................................................165 mm 190 mm 235 mm 270 mm 355 mm

Max. zaagdiepte

Bij 90° ..........................................................54 mm 66 mm 85 mm 100 mm 130 mm

Bij 45° ..........................................................38 mm 46 mm 64 mm 73 mm 90 mm

Nullasttoerental (min

Totale lengte ...................................................330 mm 356 mm 400 mm 442 mm 607 mm

Netto gewicht ..................................................4,2 kg 5,2 kg 7,6 kg 9,4 kg 14,5 kg

–1

) ..................................5 000 4 800 4 500 3 800 2 700

13 Zaagdiepte

14 Losmaken

15 Hendel

16 Vleugelmoer

17 Voor zagen in een hoek van 45°

18 Voor recht zagen

19 Grondplaat

20 45° schuine zaagsneden

21 Rechte zaagsneden

22 Bovengeleider

23 Grondplaat

24 60° schuine zaagsneden

25 45° schuine zaagsneden

26 30° schuine zaagsneden

27 Rechte zaagsneden

28 Zaagblad

29 Grondplaat

30 Bovengeleider

31 Vergrendelingsknop

32 Trekkerschakelaar

33 Stofzuiger

34 Limietmarkering

35 Kap van koolborstelhouder

36 Schroevedraaier

• In verband met ononderbroken research en ontwikke-

ling behouden wij ons het recht voor bovenstaande

technische gegevens te wijzigen zonder voorafgaande

kennisgeving.

• Opmerking: De technische gegevens kunnen van land

tot land verschillen.

Stroomvoorziening

De machine mag alleen worden aangesloten op een

stroombron van hetzelfde voltage als aangegeven op de

naamplaat, en kan alleen op enkel-fase wisselstroom

worden gebruikt. De machine is dubbel-geïsoleerd volgens de Europese standaard en kan derhalve ook op

een niet-geaard stopcontact worden aangesloten.

Veiligheidswenken

Voor uw veiligheid dient u de bijgevoegde Veiligheidsvoorschriften nauwkeurig op te volgen.

AANVULLENDE

VEILIGHEIDSVOORSCHRIFTEN

Laat u NIET misleiden door een vals gevoel van comfort en bekendheid met het gereedschap (na veelvuldig gebruik) en neem alle veiligheidsvoorschriften

van de cirkelzaag altijd strikt in acht. Bij onveilig of

verkeerd gebruik van het elektrisch gereedschap,

bestaat de kans op ernstig persoonlijk letsel.

Gevaar:

1. Houd uw handen uit de buurt van het zaaggebied

en het zaagblad. Houd met uw andere hand de

voorhandgreep of de behuizing van het gereedschap vast. Als u de cirkelzaag met beide handen

vasthoudt, kunt u nooit in uw handen zagen.

2. Reik nooit met uw handen onder het werkstuk.

De beschermkap kan u niet beschermen onder het

werkstuk tegen het zaagblad. Probeer niet afgezaagd materiaal te verwijderen terwijl het zaagblad

nog draait.

LET OP: Het zaagblad draait nog na nadat het

gereedschap is uitgeschakeld. Wacht totdat het

zaagblad volledig tot stilstand is gekomen voordat u

het afgezaagde materiaal vastpakt.

3. Stel de zaagdiepte in overeenkomstig de dikte

van het werkstuk. Minder dan een volledige tand-

hoogte dient onder het werkstuk uit te komen.

4. Houd het werkstuk waarin wordt gezaagd nooit

vast met uw handen of benen. Zorg dat het werkstuk stabiel is ten opzichte van de ondergrond.

Het is belangrijk het werkstuk goed te ondersteunen

om de kans te minimaliseren dat uw lichaam eraan

blootgesteld wordt, het zaagblad vastloopt of u de

controle over het gereedschap verliest. (Fig. A)

Een typische afbeelding van goede handplaatsing, werkstukondersteuning en netsnoerroute

(indien van toepassing).

Fig. A

26

Page 11

5. Houd elektrisch gereedschap vast aan het geïsoleerde oppervlak van de handgrepen wanneer u

werkt op plaatsen waar het zaaggereedschap

met verborgen bedrading of zijn eigen snoer in

aanraking kan komen. Door contact met onder

spanning staande draden, zullen ook de niet-geïsoleerde metalen delen van het elektrisch gereedschap onder spanning komen te staan zodat de

gebruiker een elektrische schok kan krijgen.

6. Gebruik bij het schulpen altijd de breedtegeleider of de langsgeleider. Hierdoor wordt de nauw-

keurigheid van het zagen vergroot en de kans op

vastlopen van het zaagblad verkleint.

7. Gebruik altijd zaagbladen met doorngaten van

de juiste afmetingen en vorm (diamand or rond).

Zaagbladen die niet goed passen op de bevestigingsmiddelen van de cirkelzaag, zullen excentrisch

draaien waardoor u de controle over het gereedschap verliest.

8. Gebruik nooit een beschadigde of verkeerde

bouten en ringen om het zaagblad mee te bevestigen. De bouten en ringen voor de bevestiging van

het zaagblad zijn speciaal ontworpen voor gebruik

met uw cirkelzaag voor optimale prestaties en veilig

gebruik.

9. Oorzaken van terugslag en wat de gebruiker

hieraan kan doen:

– Terugslag is een plotselinge reactie op een

bekneld, vastgelopen of niet-uitgelijnd zaagblad,

waardoor de oncontroleerbare cirkelzaag omhoog,

uit het werkstuk en in de richting van de gebruiker

gaat.

– Wanneer het zaagblad bekneld raakt of vastloopt

doordat de zaagsnede naar beneden toe smaller

wordt, vertraagt het zaagblad en komt als reactie

de motor snel omhoog in de richting van de

gebruiker.

– Als het zaagblad gebogen of niet-uitgelijnd raakt in

de zaagsnede, kunnen de tanden aan de achterrand van het zaagblad zich in het bovenoppervlak

van het hout vreten, waardoor het zaagblad uit de

zaagsnede klimt en omhoog springt in de richting

van de gebruiker.

Terugslag is het gevolg van misgebruik van de cirkelzaag en/of onjuiste gebruiksprocedures of omstandigheden, en kan worden voorkomen door

goede voorzorgsmaatregelen te treffen, zoals hieronder vermeld:

• Houd de cirkelzaag stevig vast met beide han-

den en houdt uw armen zodanig dat een terugslag wordt opgevangen. Plaats uw lichaam

zijwaarts versprongen van het zaagblad en niet

in een rechte lijn erachter. Door terugslag kan de

cirkelzaag achterwaarts springen, maar de kracht

van de terugslag kan met de juiste voorzorgsmaatregelen door de gebruiker worden opgevangen.

• Wanneer het zaagblad vastloopt, of wanneer u

om een of andere reden het zagen onderbreekt, laat u de aan/uit-schakelaar los en

houdt u de cirkelzaag stil in het materiaal totdat het zaagblad volledig tot stilstand is gekomen. Probeer nooit het zaagblad uit het

werkstuk te halen of de cirkelzaag naar achteren te trekken, terwijl het zaagblad nog draait

omdat hierdoor een terugslag kan optreden.

Onderzoek waarom het zaagblad is vastgelopen

en tref afdoende maatregelen om de oorzaak

ervan op te heffen.

• Wanneer u de cirkelzaag weer inschakelt ter-

wijl het zaagblad in het werkstuk zit, plaatst u

het zaagblad in het midden van de zaagsnede

en controleert u dat de tanden niet in het materiaal grijpen. Als het zaagblad is vastgelopen, kan

wanneer de cirkelzaag wordt ingeschakeld het

zaagblad uit het werkstuk lopen of terugslaan.

• Ondersteun grote platen om de kans te mini-

maliseren dat het zaagblad bekneld raakt of

terugslaat. Grote platen neigen door te zakken

onder hun eigen gewicht. U moet de plaat ondersteunen aan beide zijranden, vlakbij de zaaglijn en

vlakbij het uiteinde.

• De kans te minimaliseren dat het zaagblad vastloopt. Wanneer het noodzakelijk is om tijdens het

zagen de cirkelzaag tot stilstand te brengen op het

werkstuk, moet de cirkelzaag op het grootste deel

rusten terwijl het kleinste deel wordt afgezaagd.

(Fig. B en C)

Om terugslag te voorkomen, ondersteun de

plank of het paneel dichtbij de zaagsnede.

Fig. B

Ondersteun de plank of het paneel niet van de

zaagsnede weg.

Fig. C

27

Page 12

• Gebruik een bot of beschadigd zaagblad niet

meer. Niet-geslepen of verkeerd gezette tanden

maken een smalle zaagsnede wat leidt tot grote

wrijving, vastlopen en terugslag. Houd het zaagblad scherp en schoon. Gom of hars dat op het

zaagblad is opgedroogd vertraagt het zaagblad en

verhoogt de kans op terugslag. Houd het zaagblad

schoon door dit eerst van het gereedschap te

demonteren en het vervolgens schoon te maken

met een reinigingsmiddel voor gom en hars, heet

water of kerosine. Gebruik nooit benzine.

• De vergrendelhendels voor het instellen van de

zaagbladdiepte en verstelhoek moeten vastzitten alvorens te beginnen met zagen. Als de

instellingen van het zaagblad zich tijdens het

zagen wijzigen, kan dit leiden tot vastlopen of

terugslag.

• Wees extra voorzichtig wanneer u een “blinde”

zaagsnede maakt in een bestaande wand of

een andere plaats waarvan u de onderkant van

het zaagoppervlak niet kunt zien. Wanneer het

zaagblad door het materiaal heen breekt, kan het

een voorwerp raken waardoor een terugslag

optreedt. Bij het maken van een “blinde”

zaagsnede opent u de onderste beschermkap met

behulp van de terugtrekhendel.

• Houd het gereedschap ALTIJD met beide han-

den stevig vast. Plaats NOOIT uw hand of vingers achter het zaagblad. Als een terugslag

optreedt, kan het zaagblad gemakkelijk achteruit

en over uw hand springen waardoor ernstig persoonlijk letsel ontstaat. (Fig. D)

Fig. D

• Dwing de cirkelzaag nooit. Als u het zaagblad

dwingt, kan dat leiden tot een ongelijkmatige

zaagsnede, verminderde nauwkeurigheid en

mogelijke terugslag. Duw de cirkelzaag vooruit

met een snelheid waarbij het zaagblad niet vertraagt.

10. Controleer voor ieder gebruik of de onderste

beschermkap goed sluit. Gebruik de cirkelzaag

niet als de onderste beschermkap niet vrij kan

bewegen en onmiddellijk sluit. Zet de onderste

beschermkap nooit vast in de geopende stand.

Als u de cirkelzaag per ongeluk laat vallen, kan de

onderste beschermkap worden verbogen. Til de

onderste beschermkap op aan de terugtrekhendel

en controleer dat deze vrij kan bewegen en niet het

zaagblad of enig ander onderdeel raakt, onder alle

verstekhoeken en op alle zaagdiepten. U kunt de

onderste beschermkap controleren, door deze met

de hand te openen, los te laten en te kijken hoe hij

sluit. Controleer tevens of de terugtrekhendel de

behuizing van het gereedschap niet raakt. Het zaagblad onbeschermd laten is UITERST GEVAARLIJK

en kan leiden tot ernstig persoonlijk letsel.

11. Controleer de werking van de veer van de onderste beschermkap. Als de beschermkap en de

veer niet goed werken, dienen deze te worden

gerepareerd voordat de cirkelzaag wordt

gebruikt. De onderste beschermkap kan traag wer-

ken als gevolg van beschadigde onderdelen, gomof hardafzetting, of opeenhoping van vuil.

12. De onderste beschermkap mag alleen met de

hand worden geopend voor het maken van speciale zaagsneden, zoals een “blinde” zaagsnede

en “samengestelde” zaagsnede. Til de onderste

beschermkap op aan de terugtrekhendel en laat

deze los zodra het zaagblad in het materiaal

zaagt. Bij alle andere typen zaagsneden, dient de

onderste beschermkap automatisch te werken.

13. Let er altijd op dat de onderste beschermkap het

zaagblad bedekt voordat u de cirkelzaag op een

werkbak of vloer neerlegt. Een onbeschermd

zaagblad dat nog nadraait, zal de cirkelzaag achteruit doen lopen waarbij alles op zijn weg wordt

gezaagd. Denk aan de tijd die het duurt nadat de cirkelzaag is uitgeschakeld voordat het zaagblad stilstaat. Voordat u het gereedschap neerlegt na het

voltooien van een zaagsnede, controleert u dat de

onderste beschermkap gesloten is en het zaagblad

volledig tot stilstand is gekomen.

14. Gebruik het geschikte spouwmes voor het zaagblad dat wordt gebruikt. Om het spouwmes goed

te laten werken, moet het dikker zijn dan het zaagbladlichaam, maar dunner zijn dan de breedte van

de gezette zaagtanden.

15. Stel het spouwmes in zoals beschreven in deze

gebruiksaanwijzing. Door een onjuiste afstand,

positie of uitlijning, zal het spouwmes eventuele

terugslag niet effectief kunnen voorkomen.

16. Gebruik het spouwmes altijd, behalve bij het

maken van een “blinde” zaagsnede. Het spouw-

mes moet worden teruggeplaatst nadat de 'blinde'

zaagsnede is gemaakt. Het spouwmes zit in de weg

bij het maken van een “blinde” zaagsnede en kan

terugslag veroorzaken.

17. Voor een goede werking van het spouwmes,

moet het in het werkstuk lopen. Het spouwmes is

niet effectief in het voorkomen van terugslag tijdens

korte zaagsneden.

18. Bedien de zaag niet als het spouwmes verbogen

is. Zelfs bij heel licht aanlopen kan de sluitsnelheid

van een beschermkap worden verlaagd.

28

Page 13

19. Wees extra voorzichtig bij het zagen in nat hout,

druk-behandeld timmerhout en hout met knoesten. Pas de snelheid van het zagen aan zodat de cir-

kelzaag soepel vooruit blijft gaan zonder dat de

snelheid van het zaagblad lager wordt.

20. Voorkom dat u in spijkers zaag. Inspecteer het

hout op spijkers en verwijder deze zonodig voordat u begint te zagen.

21. Plaats het bredere deel van de zool van de cirkelzaag op het deel van het werkstuk dat goed is

ondersteund, en niet op het deel dat omlaag valt

nadat de zaagsnede gemaakt is. Als voorbeeld

laat afbeelding E zien hoe u het uiteinde van een

plank GOED afzaagt, en afbeelding F hoe u dit

VERKEERD doet. Als het werkstuk kort of smal

is, klemt u het vast. PROBEER NOOIT EEN KORT

WERKSTUK IN UW HANDEN VAST TE HOUDEN!

(Fig. E en F)

Fig. E

22. Probeer nooit te zagen waarbij de cirkelzaag

ondersteboven in een bankschroef is geklemd.

Dit is uiterst gevaarlijk en kan leiden tot ernstig

persoonlijk letsel. (Fig. G)

Fig. G

23. Sommige materialen bevatten chemische stoffen

die giftig kunnen zijn. Neem voorzorgsmaatregelen tegen het inademen van stof en contact met

de huid. Volg de veiligheidsinstructies van de

leverancier van het materiaal op.

24. Breng het zaagblad niet tot stilstand door zijdelings op het zaagblad te drukken.

25. Gebruik altijd zaagbladen die in deze gebruiksaanwijzing aanbevolen worden. Gebruik geen

slijpschijven.

26. Draag een stofmasker en gehoorbescherming

tijdens gebruik van het gereedschap.

BEWAAR DEZE VOORSCHRIFTEN.

WAARSCHUWING:

VERKEERD GEBRUIK of het niet naleven van de veiligheidsvoorschriften in deze gebruiksaanwijzing

kan leiden tot ernstige verwondingen.

Fig. F

BEDIENINGSVOORSCHRIFTEN

Verwijderen of installeren van het zaagblad

Het volgende blad kan met deze machine worden gebruikt.

Model Max. diameter Min. diameter Bladdikte Zaagsnede

5603R 165 mm 150 mm minder dan 1,7 mm meer dan 1,9 mm

5703R 190 mm 170 mm minder dan 1,7 mm meer dan 1,9 mm

5903R 235 mm 210 mm minder dan 1,9 mm meer dan 2,1 mm

5103R 270 mm 260 mm minder dan 1,8 mm meer dan 2,2 mm

5143R 355 mm 350 mm minder dan 2,3 mm meer dan 2,7 mm

De dikte van het spouwmes is 1,8 mm voor Modellen 5603R en 5703R, 2,0 mm voor Modellen 5903R en 5103R, en

2,5 mm voor Model 5143R.

29

Page 14

LET OP:

• Gebruik geen zaagbladen die niet voldoen aan de specificaties in deze gebruiksaanwijzing.

• Gebruik geen zaagbladen waarvan de schijf dikker is of

de zetting kleiner is dan de dikte van het spouwmes.

Om het zaagblad te verwijderen, druk de asvergrendeling

volledig in om te voorkomen dat de as gaat draaien, en

draai dan de bout met zeskante kop los met behulp van

de inbussleutel. (Fig. 1)

Breng de veiligheidskap zo ver mogelijk omhoog om de

buitenste flens te verwijderen en verwijder dan het zaagblad. (Fig. 2)

Installeer het zaagblad in de omgekeerde volgorde van

verwijderen. Monteer achtereenvolgens de binnenste

flens, het zaagblad, de buitenste flens en de bout met

zeskante kop. Draai de bout met zeskante kop stevig vast

terwijl u de asvergrendeling volledig ingedrukt houdt.

(Fig. 1 en 3)

LET OP:

• Zorg ervoor dat de tanden van het zaagblad naar voren

wijzen in dezelfde richting als de draairichting van de

machine. (De pijl op het zaagblad moet in dezelfde

richting wijzen als de pijl op de machine.)

• Druk de asvergrendeling nooit in terwijl de zaag draait.

• Gebruik alleen de Makita dopsleutel voor het verwijderen of installeren van het zaagblad.

Afstellen van het spouwmes (Fig. 4)

Gebruik de dopsleutel voor het losdraaien van de zeskante bout voor afstelling van het spouwmes en breng

dan de veiligheidskap omhoog. Beweeg het spouwmes

omhoog of omlaag over de twee uitsteeksels voor afstelling (zie de afbeelding), zodat de juiste afstand tussen

het spouwmes en het zaagblad wordt verkregen.

LET OP:

Het spouwmes moet zodanig worden afgesteld dat:

De afstand tussen het spouwmes en de getande rand

van het zaagblad niet meer dan 5 mm bedraagt.

De getande rand niet meer dan 5 mm onder de onderste

rand van het spouwmes uitsteekt.

Afstellen van zaagdiepte (Fig. 5)

Zet de hendel op de dieptegeleider los en beweeg de

grondplaat op of neer. Zet de grondplaat op de gewenste

diepte vast door de hendel vast te zetten.

LET OP:

• Gebruik een geringe zaagdiepte voor het zagen van

dunne werkstukken, om veiliger te zagen en schonere

zaagsneden te krijgen.

• Na het afstellen van de zaagdiepte, dient u de hendel

altijd stevig vast te zetten.

Afstelling voor verstekzagen (Fig. 6)

Draai de vleugelmoeren vooraan en achteraan los en zet

dan de machine in de gewenste hoek voor verstekzagen

(0 – 45°). Na afstelling, de vleugel-moeren vooraan en

achteraan stevig vastdraaien.

Zaaghoek instellen (5603R, 5703R) (Fig. 7)

Voor rechte zaagsneden, laat de zaaglijn op het werkstuk

samenvallen met de rechter inkeping op de voorkant van

de grondplaat.

Voor 45° schuine zaagsneden, laat de zaaglijn op het

werkstuk samenvallen met de linker inkeping.

Bovengeleider (5903R, 5103R) (Fig. 8)

Laat uw richtlijn samenvallen met de 0° inkeping voor

rechte zaagsneden of de 45° inkeping voor 45° schuine

zaagsneden.

Bovengeleider (5143R) (Fig. 9)

Laat uw richtlijn samenvallen met de 0° inkeping voor

rechte zaagsneden, de 30° inkeping voor 30° schuine

zaagsneden, de 45° inkeping voor 45° schuine zaagsneden, of de 60° inkeping voor 60° schuine zaagsneden.

Werking van de trekkerschakelaar (Fig. 10)

Een vergrendelingsknop is voorzien om te voorkomen

dat de trekkerschakelaar per toeval wordt ingedrukt. Om

de machine aan te zetten, de vergrendelingsknop indrukken en dan de trekkerschakelaar indrukken. Om de

machine af te zetten, de trekkerschakelaar loslaten.

LET OP:

• Alvorens de stekker in een stopcontact te steken, altijd

eerst controleren of de trekkerschakelaar juist werkt en

terugkeert naar de “OFF” stand wanneer hij wordt losgelaten.

Bediening (Fig. 11)

Houd de machine stevig vast. Zet de grondplaat op het te

zagen werkstuk zonder dat het zaagblad ermee in contact komt. Zet dan de machine aan en wacht tot het

zaagblad op volle snelheid is gekomen. Beweeg nu

gewoon de machine naar voren over het oppervlak van

het werkstuk; houd hierbij de machine vlak en beweeg

deze langzaam totdat het zagen is voltooid. Om schone

zaagsneden te krijgen, dient u uw zaaglijn recht te houden en de machine met gelijkmatige snelheid naar voren

te bewegen.

LET OP:

• Gebruik altijd het spouwmes, behalve voor zaagsneden die in het midden van het werkstuk beginnen.

• Stop het zaagblad niet door zijwaartse kracht op de

schijf uit te oefenen.

Richtliniaal (Fig. 12 en 13)

Het handige richtliniaal stelt u in staat uiterst nauwkeurige rechte zaagsneden te krijgen. Schuif gewoon het

richtliniaal omhoog tot vlak tegen de zijkant van het werkstuk en zet het vast met de schroef op de voorkant van

de grondplaat. Met het richtliniaal kunt u ook herhaaldelijk zaagsneden van dezelfde breedte zagen.

Koppelstuk (Fig. 14, 15 en 16)

(voor het aansluiten van een stofzuiger)

Om schoon te werken, kunt u een stofzuiger op uw

machine aansluiten. Monteer het koppelstuk op de

machine met behulp van de schroef, en sluit dan de

slang van een stofzuiger erop aan.

ONDERHOUD

LET OP:

Zorg er altijd voor dat de machine is uitgeschakeld en de

stekker uit het stopcontact is verwijderd alvorens werken

aan de machine uit te voeren.

Opdat het gereedschap veilig in betrouwbaar blijft, dienen alle reparaties, onderhoud of afstellingen te worden

uitgevoerd in een erkend Makita service centrum.

30

Page 15

ENGLISH

EC-DECLARATION OF CONFORMITY

We declare under our sole responsibility that this product

is in compliance with the following standards of standardized documents,

in accordance with Council Directives, 89/336/EEC and

98/37/EC.

EN60745, EN55014, EN61000

ENH101-5

ITALIANO

DICHIARAZIONE DI CONFORMITÀ

CON LE NORME DELLA COMUNITÀ EUROPEA

Dichiariamo sotto la nostra sola responsabilità che

questo prodotto è conforme agli standard di documenti

standardizzati seguenti:

secondo le direttive del Consiglio 89/336/CEE e 98/37/CE.

EN60745, EN55014, EN61000

FRANÇAISE

DÉCLARATION DE CONFORMITÉ CE

Nous déclarons sous notre entière responsabilité que ce

produit est conforme aux normes des documents standardisés suivants,

conformément aux Directives du Conseil, 89/336/CEE et

98/37/EG.

EN60745, EN55014, EN61000

DEUTSCH

CE-KONFORMITÄTSERKLÄRUNG

Hiermit erklärt wir unter unserer alleinigen Verantwortung, daß dieses Produkt gemäß den Ratsdirektiven

89/336/EWG und 98/37/EG mit den folgenden Normen

von Normendokumenten übereinstimmen:

EN60745, EN55014, EN61000.

Yasuhiko Kanzaki

NEDERLANDS

EG-VERKLARING VAN CONFORMITEIT

Wij verklaren hierbij uitsluitend op eigen verantwoordelijkheid dat dit produkt voldoet aan de volgende

normen van genormaliseerde documenten,

in overeenstemming met de richtlijnen van de Raad

89/336/EEC en 98/37/EC.

EN60745, EN55014, EN61000

ESPAÑOL

DECLARACIÓN DE CONFORMIDAD DE LA CE

Declaramos bajo nuestra sola responsabilidad que este

producto cumple con las siguientes normas de documentos normalizados,

de acuerdo con las directivas comunitarias,

89/336/EEC y 98/37/CE.

CE 2005

EN60745, EN55014, EN61000

72

Director Amministratore

Directeur Directeur

Direktor Director

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

Responsible manufacturer: Produttore responsabile:

Fabricant responsable

Verantwortlicher Hersteller: Fabricante responsable:

Makita Corporation Anjo Aichi Japan

Verantwoordelijke fabrikant:

:

Page 16

PORTUGUÊS

DECLARAÇÃO DE CONFORMIDADE DA CE

Declaramos sob inteira responsabilidade que este

produto obedece às seguintes normas de documentos

normalizados,

de acordo com as directivas 89/336/CEE e 98/37/CE do

Conselho.

EN60745, EN55014, EN61000

ENH101-5

NORSK

EUs SAMSVARS-ERKLÆRING

Vi erklærer på eget ansvar at dette produktet er i overensstemmelse med følgende standard i de standardiserte dokumenter:

i samsvar med Råds-direktivene, 89/336/EEC og

98/37/EC.

EN60745, EN55014, EN61000,

DANSK

EU-DEKLARATION OM KONFORMITET

Vi erklærer hermed på eget ansvar, at dette produkt er i

overensstemmelse med de følgende standarder i de normsættende dokumenter,

i overensstemmelse med Rådets Direktiver 89/336/EEC

og 98/37/EC.

EN60745, EN55014, EN61000

SVENSKA

EG-DEKLARATION OM ÖVERENSSTÄMMELSE

Under eget ansvar deklarerar vi härmed att denna

produkt överensstämmer med följande standardiseringar

för standardiserade dokument,

i enlighet med EG-direktiven 89/336/EEC och 98/37/EC.

EN60745, EN55014, EN61000

Yasuhiko Kanzaki

SUOMI

VAKUUTUS EC-VASTAAVUUDESTA

Yksinomaisesti vastuullisina ilmoitamme, että tämä tuote

on seuraavien standardoitujen dokumenttien standardien mukainen,

neuvoston direktiivien 89/336/EEC ja 98/37/EC mukaisesti.

EN60745, EN55014, EN61000

ΕΛΛΗΝΙΚΑ

∆ΗΛΩΣΗ ΣΥΜΜΟΡΦΩΣΗΣ ΕΚ

∆ηλώνουµε υπ την µοναδική µας ευθύνη τι αυτ

το προιν βρίσκεται σε Συµφωνία µε τα ακλουθα

πρτυπα τυποποιηµένων εγγράφων,

σύµφωνα µε τις Οδηγίες του Συµβουλίου,

89/336/EEC και 98/37/ΚE.

EN60745, EN55014, EN61000

TÜRKÇE

AVRUPA KONSEYİ – UYGUNLUK BEYANI

Bütün sorumluluğu üzerimize alarak, bu ürünün, Avrupa

Konseyi Yönergeleri, 89/336/EEC ve 98/37/EC,

uyarınca, aşağıdaki standartlaştırılmış belgelerdeki

standartlara uygunluğuna beyan ederiz:

CE 2005

EN60745, EN55014, EN61000.

Director Direktor

DirektørJohtaja

Direktör ∆ιευθυντής

Müdür

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

Fabricante responsável: Ansvarlig produsent:

Ansvarlig fabrikant: Vastaava valmistaja:

Ansvarig tillverkare: Υπεύθυνος κατασκευαστής:

Makita Corporation Anjo Aichi Japan

Sorumlu imalatçı:

73

Page 17

ENGLISH

For European countries only

Noise and Vibration of Model 5603R

The typical A-weighted noise levels are

The typical weighted root mean square acceleration

value is not more than 2.5 m/s

These values have been obtained according to

EN60745.

sound pressure level: 96 dB (A)

sound power level: 107 dB (A)

Uncertainty is 3 dB (A).

– Wear ear protection. –

2

.

ENG005-2-V3

ITALIANO

Modello per l’Europa soltanto

Rumore e vibrazione del modello 5603R

I livelli del rumore pesati secondo la curva A sono:

Il valore quadratico medio di accellerazione non supera i

2,5 m/s

Questi valori sono stati ottenuti in conformità EN60745.

Livello pressione sonora: 96 dB (A)

Livello potenza sonora: 107dB (A)

L’incertezza è di 3 dB (A).

– Indossare i paraorecchi. –

2

.

FRANÇAISE

Pour les pays d’Europe uniquement

Bruit et vibrations du modèle 5603R

Les niveaux de bruit ponderes types A sont:

niveau de pression sonore: 96 dB (A)

niveau de puissance du son: 107 dB (A)

L’incertitude de mesure est de 3 dB (A).

L’accélération pondérée ne dépasse pas 2,5 m/s

– Porter des protecteurs anti-bruit. –

Ces valeurs ont été obtenues selon EN60745.

2

.

DEUTSCH

Nur für europäische Länder

Geräusch- und Vibrationsentwicklung

Die typischen A-bewerteten Geräuschpegel betragen:

Der gewichtete Effektivwert der Beschleunigung beträgt

nicht mehr als 2,5 m/s

Diese Werte wurden gemäß EN60745 erhalten.

des Modells 5603R

Schalldruckpegel: 96 dB (A)

Schalleistungspegel: 107dB (A)

Die Abweichung beträgt 3 dB (A).

– Gehörschutz tragen. –

2

.

NEDERLANDS

Alleen voor Europese landen

Geluidsniveau en trilling van het model 5603R

De typische A-gewogen geluidsniveau’s zijn

geluidsdrukniveau: 96 dB (A)

geluidsenergie-niveau: 107 dB (A)

Onzekerheid is 3 dB (A).

De typische gewogen effectieve versnellingswaarde is

niet meer dan 2,5 m/s

– Draag oorbeschermers. –

2

.

Deze waarden werden verkregen in overeenstemming

met EN60745.

ESPAÑOL

Para países europeos solamente

Ruido y vibración del modelo 5603R

Los niveles típicos de ruido ponderados A son

El valor ponderado de la aceleración no sobrepasa los

2,5 m/s

Estos valores han sido obtenidos de acuerdo con

EN60745.

presión sonora: 96dB (A)

nivel de potencia sonora: 107dB (A)

Incerteza 3 dB (A).

– Póngase protectores en los oídos. –

2

.

74

Page 18

PORTUGUÊS

Só para países Europeus

Ruído e vibração do modelo 5603R

Os níveis normais de ruído A são

O valor médio da aceleração é inferior a 2,5 m/s

Estes valores foram obtidos de acordo com EN60745.

nível de pressão de som: 96 dB (A)

nível do sum: 107 dB (A)

A incerteza é de 3 dB (A).

– Utilize protectores para os ouvidos –

2

.

ENG005-2-V3

NORSK

Gjelder bare land i Europa

Støy og vibrasjon fra modell 5603R

De vanlige A-belastede støynivå er

Den vanlig belastede effektiv-verdi for akselerasjon overskrider ikke 2,5 m/s

Disse verdiene er beregnet eller målt i samsvar med

EN60745.

lydtrykksnivå: 96 dB (A)

lydstyrkenivå: 107 dB (A)

Usikkerheten er på 3 dB (A).

– Benytt hørselvern. –

2

.

DANSK

Kun for lande i Europa

Lyd og vibration fra model 5603R

De typiske A-vægtede lydniveauer er

lydtryksniveau: 96 dB (A)

lydeffektniveau: 107 dB (A)

Der er en usikkerhed på 3dB (A).

Den vægtede effektive accelerationsværdi overstiger ikke

2

.

2,5 m/s

– Bær høreværn. –

Disse værdier er beregnet i overensstemmelse med

EN60745.

SVENSKA

Endast för Europa

Buller och vibration hos modell 5603R

De typiska A-vägda bullernivåerna är

Det typiskt vägda effektivvärdet för acceleration översti-

ger inte 2,5 m/s

Dessa värden har erhållits i enlighet med EN60745.

ljudtrycksnivå: 96 dB (A)

ljudeffektnivå: 107 dB (A)

Osäkerheten är 3 dB (A).

– Använd hörselskydd –

2

.

SUOMI

Vain Euroopan maat

Mallin 5603R melutaso ja tärinä

Tyypilliset A-painotetut melutasot ovat

äänenpainetaso: 96 dB (A)

äänen tehotaso: 107 dB (A)

Epävarmuus on 3 dB (A).

Tyypillinen kiihtyvyyden painotettu tehollisarvo ei ylitä

2,5 m/s

Nämä arvot on mitattu normin EN60745 mukaisesti.

– Käytä kuulosuojaimia. –

2

.

ΕΛΛΗΝΙΚΑ

Μ3νο για χώρες της Ευρώπης

Θ3ρυβος και κραδασµ3ς του µοντέλου 5603R

Οι τυπικέσ A-µετρούµενεσ εντάσεισ ήχου είναι

πίεση ήχου: 96 dB (A)

δύναµη του ήχου: 107dB (A)

Η Αβεβαιτητα είναι 3 dB (A).

Η τυπική αξία τησ µετρούµενησ ρίζασ του µέσου

τετραγώνου τησ επιτάχυνσησ δεν ξεπερνά τα

2,5 m/s

– Φοράτε ωτοασπίδεσ. –

2

.

Αυτέσ οι τιµέσ έχουν σηµειωθεί σύµφωνα µε το

EN60745.

TÜRKÇE

Sadece Avrupa ülkeleri için

modelin gürültü ve ti treşimi

5603R

Tipik Aağırlıklı gürültü seviyeleri şöyledir;

Tipik ağırlıklı karekök ortalama ivme 2,5 m/s

değildir.

Bu değerler EN60745 standardına göre elde edilmiştir.

ses basınç seviyesi: 96 dB (A)

ses güç seviyesi: 107 dB (A)

Belirsizlik: 3 dB (A)

– Kulak koruyucusu takın. –

2

’den fazla

75

Page 19

ENGLISH

For European countries only

Noise and Vibration of Model 5703R

The typical A-weighted noise levels are

The typical weighted root mean square acceleration

value is not more than 2.5 m/s

These values have been obtained according to

EN60745.

sound pressure level: 93 dB (A)

sound power level: 104 dB (A)

Uncertainty is 3 dB (A).

– Wear ear protection. –

2

.

ENG005-2-V3

ITALIANO

Modello per l’Europa soltanto

Rumore e vibrazione del modello 5703R

I livelli del rumore pesati secondo la curva A sono:

Il valore quadratico medio di accellerazione non supera i

2,5 m/s

Questi valori sono stati ottenuti in conformità EN60745.

Livello pressione sonora: 93 dB (A)

Livello potenza sonora: 104dB (A)

L’incertezza è di 3 dB (A).

– Indossare i paraorecchi. –

2

.

FRANÇAISE

Pour les pays d’Europe uniquement

Bruit et vibrations du modèle 5703R

Les niveaux de bruit ponderes types A sont:

niveau de pression sonore: 93 dB (A)

niveau de puissance du son: 104 dB (A)

L’incertitude de mesure est de 3 dB (A).

L’accélération pondérée ne dépasse pas 2,5 m/s

– Porter des protecteurs anti-bruit. –

Ces valeurs ont été obtenues selon EN60745.

2

.

DEUTSCH

Nur für europäische Länder

Geräusch- und Vibrationsentwicklung

Die typischen A-bewerteten Geräuschpegel betragen:

Der gewichtete Effektivwert der Beschleunigung beträgt

nicht mehr als 2,5 m/s

Diese Werte wurden gemäß EN60745 erhalten.

des Modells 5703R

Schalldruckpegel: 93 dB (A)

Schalleistungspegel: 104dB (A)

Die Abweichung beträgt 3 dB (A).

– Gehörschutz tragen. –

2

.

NEDERLANDS

Alleen voor Europese landen

Geluidsniveau en trilling van het model 5703R

De typische A-gewogen geluidsniveau’s zijn

geluidsdrukniveau: 93 dB (A)

geluidsenergie-niveau: 104 dB (A)

Onzekerheid is 3 dB (A).

De typische gewogen effectieve versnellingswaarde is

niet meer dan 2,5 m/s

– Draag oorbeschermers. –

2

.

Deze waarden werden verkregen in overeenstemming

met EN60745.

ESPAÑOL

Para países europeos solamente

Ruido y vibración del modelo 5703R

Los niveles típicos de ruido ponderados A son

El valor ponderado de la aceleración no sobrepasa los

2,5 m/s

Estos valores han sido obtenidos de acuerdo con

EN60745.

presión sonora: 93dB (A)

nivel de potencia sonora: 104dB (A)

Incerteza 3 dB (A).

– Póngase protectores en los oídos. –

2

.

76

Page 20

PORTUGUÊS

Só para países Europeus

Ruído e vibração do modelo 5703R

Os níveis normais de ruído A são

O valor médio da aceleração é inferior a 2,5 m/s

Estes valores foram obtidos de acordo com EN60745.

nível de pressão de som: 93 dB (A)

nível do sum: 104 dB (A)

A incerteza é de 3 dB (A).

– Utilize protectores para os ouvidos –

2

.

ENG005-2-V3

NORSK

Gjelder bare land i Europa

Støy og vibrasjon fra modell 5703R

De vanlige A-belastede støynivå er

Den vanlig belastede effektiv-verdi for akselerasjon overskrider ikke 2,5 m/s

Disse verdiene er beregnet eller målt i samsvar med

EN60745.

lydtrykksnivå: 93 dB (A)

lydstyrkenivå: 104 dB (A)

Usikkerheten er på 3 dB (A).

– Benytt hørselvern. –

2

.

DANSK

Kun for lande i Europa

Lyd og vibration fra model 5703R

De typiske A-vægtede lydniveauer er

lydtryksniveau: 93 dB (A)

lydeffektniveau: 104 dB (A)

Der er en usikkerhed på 3dB (A).

Den vægtede effektive accelerationsværdi overstiger ikke

2

.

2,5 m/s

– Bær høreværn. –

Disse værdier er beregnet i overensstemmelse med

EN60745.

SVENSKA

Endast för Europa

Buller och vibration hos modell 5703R

De typiska A-vägda bullernivåerna är

Det typiskt vägda effektivvärdet för acceleration översti-

ger inte 2,5 m/s

Dessa värden har erhållits i enlighet med EN60745.

ljudtrycksnivå: 93 dB (A)

ljudeffektnivå: 104 dB (A)

Osäkerheten är 3 dB (A).

– Använd hörselskydd –

2

.

SUOMI

Vain Euroopan maat

Mallin 5703R melutaso ja tärinä

Tyypilliset A-painotetut melutasot ovat

äänenpainetaso: 93 dB (A)

äänen tehotaso: 104 dB (A)

Epävarmuus on 3 dB (A).

Tyypillinen kiihtyvyyden painotettu tehollisarvo ei ylitä

2,5 m/s

Nämä arvot on mitattu normin EN60745 mukaisesti.

– Käytä kuulosuojaimia. –

2

.

ΕΛΛΗΝΙΚΑ

Μ3νο για χώρες της Ευρώπης

Θ3ρυβος και κραδασµ3ς του µοντέλου 5703R

Οι τυπικέσ A-µετρούµενεσ εντάσεισ ήχου είναι

πίεση ήχου: 93 dB (A)

δύναµη του ήχου: 104dB (A)

Η Αβεβαιτητα είναι 3 dB (A).

– Φοράτε ωτοασπίδεσ. –

Η τυπική αξία τησ µετρούµενησ ρίζασ του µέσου

τετραγώνου τησ επιτάχυνσησ δεν ξεπερνά τα

2

.

2,5 m/s

Αυτέσ οι τιµέσ έχουν σηµειωθεί σύµφωνα µε το

EN60745.

TÜRKÇE

Sadece Avrupa ülkeleri için

5703R

Tipik Aağırlıklı gürültü seviyeleri şöyledir;

Tipik ağırlıklı karekök ortalama ivme 2,5 m/s

değildir.

Bu değerler EN60745 standardına göre elde edilmiştir.

modelin gürültü ve ti treşimi

ses basınç seviyesi: 93 dB (A)

ses güç seviyesi: 104 dB (A)

Belirsizlik: 3 dB (A)

– Kulak koruyucusu takın. –

2

’den fazla

77

Page 21

ENGLISH

For European countries only

Noise and Vibration of Model 5903R

The typical A-weighted noise levels are

The typical weighted root mean square acceleration

value is not more than 2.5 m/s

These values have been obtained according to

EN60745.

sound pressure level: 95 dB (A)

sound power level: 106 dB (A)

Uncertainty is 3 dB (A).

– Wear ear protection. –

2

.

ENG005-2-V3

ITALIANO

Modello per l’Europa soltanto

Rumore e vibrazione del modello 5903R

I livelli del rumore pesati secondo la curva A sono:

Il valore quadratico medio di accellerazione non supera i

2,5 m/s

Questi valori sono stati ottenuti in conformità EN60745.

Livello pressione sonora: 95 dB (A)

Livello potenza sonora: 106dB (A)

L’incertezza è di 3 dB (A).

– Indossare i paraorecchi. –

2

.

FRANÇAISE

Pour les pays d’Europe uniquement

Bruit et vibrations du modèle 5903R

Les niveaux de bruit ponderes types A sont:

niveau de pression sonore: 95 dB (A)

niveau de puissance du son: 106 dB (A)

L’incertitude de mesure est de 3 dB (A).

L’accélération pondérée ne dépasse pas 2,5 m/s

– Porter des protecteurs anti-bruit. –

Ces valeurs ont été obtenues selon EN60745.

2

.

DEUTSCH

Nur für europäische Länder

Geräusch- und Vibrationsentwicklung

Die typischen A-bewerteten Geräuschpegel betragen:

Der gewichtete Effektivwert der Beschleunigung beträgt

nicht mehr als 2,5 m/s

Diese Werte wurden gemäß EN60745 erhalten.

des Modells 5903R

Schalldruckpegel: 95 dB (A)

Schalleistungspegel: 106dB (A)

Die Abweichung beträgt 3 dB (A).

– Gehörschutz tragen. –

2

.

NEDERLANDS

Alleen voor Europese landen

Geluidsniveau en trilling van het model 5903R

De typische A-gewogen geluidsniveau’s zijn

geluidsdrukniveau: 95 dB (A)

geluidsenergie-niveau: 106 dB (A)

Onzekerheid is 3 dB (A).

De typische gewogen effectieve versnellingswaarde is

niet meer dan 2,5 m/s

– Draag oorbeschermers. –

2

.

Deze waarden werden verkregen in overeenstemming

met EN60745.

ESPAÑOL

Para países europeos solamente

Ruido y vibración del modelo 5903R

Los niveles típicos de ruido ponderados A son

El valor ponderado de la aceleración no sobrepasa los

2,5 m/s

Estos valores han sido obtenidos de acuerdo con

EN60745.

presión sonora: 95dB (A)

nivel de potencia sonora: 106dB (A)

Incerteza 3 dB (A).

– Póngase protectores en los oídos. –

2

.

78

Page 22

PORTUGUÊS

Só para países Europeus

Ruído e vibração do modelo 5903R

Os níveis normais de ruído A são

O valor médio da aceleração é inferior a 2,5 m/s

Estes valores foram obtidos de acordo com EN60745.

nível de pressão de som: 95 dB (A)

nível do sum: 106 dB (A)

A incerteza é de 3 dB (A).

– Utilize protectores para os ouvidos –

2

.

ENG005-2-V3

NORSK

Gjelder bare land i Europa

Støy og vibrasjon fra modell 5903R

De vanlige A-belastede støynivå er

Den vanlig belastede effektiv-verdi for akselerasjon overskrider ikke 2,5 m/s

Disse verdiene er beregnet eller målt i samsvar med

EN60745.

lydtrykksnivå: 95 dB (A)

lydstyrkenivå: 106 dB (A)

Usikkerheten er på 3 dB (A).

– Benytt hørselvern. –

2

.

DANSK

Kun for lande i Europa

Lyd og vibration fra model 5903R

De typiske A-vægtede lydniveauer er

lydtryksniveau: 95 dB (A)

lydeffektniveau: 106 dB (A)

Der er en usikkerhed på 3dB (A).

Den vægtede effektive accelerationsværdi overstiger ikke

2

.

2,5 m/s

– Bær høreværn. –

Disse værdier er beregnet i overensstemmelse med

EN60745.

SVENSKA

Endast för Europa

Buller och vibration hos modell 5903R

De typiska A-vägda bullernivåerna är

Det typiskt vägda effektivvärdet för acceleration översti-

ger inte 2,5 m/s

Dessa värden har erhållits i enlighet med EN60745.

ljudtrycksnivå: 95 dB (A)

ljudeffektnivå: 106 dB (A)

Osäkerheten är 3 dB (A).

– Använd hörselskydd –

2

.

SUOMI

Vain Euroopan maat

Mallin 5903R melutaso ja tärinä

Tyypilliset A-painotetut melutasot ovat

äänenpainetaso: 95 dB (A)

äänen tehotaso: 106 dB (A)

Epävarmuus on 3 dB (A).

Tyypillinen kiihtyvyyden painotettu tehollisarvo ei ylitä

2,5 m/s

Nämä arvot on mitattu normin EN60745 mukaisesti.

– Käytä kuulosuojaimia. –

2

.

ΕΛΛΗΝΙΚΑ

Μ3νο για χώρες της Ευρώπης

Θ3ρυβος και κραδασµ3ς του µοντέλου 5903R

Οι τυπικέσ A-µετρούµενεσ εντάσεισ ήχου είναι

πίεση ήχου: 95 dB (A)

δύναµη του ήχου: 106dB (A)

Η Αβεβαιτητα είναι 3 dB (A).

– Φοράτε ωτοασπίδεσ. –

Η τυπική αξία τησ µετρούµενησ ρίζασ του µέσου

τετραγώνου τησ επιτάχυνσησ δεν ξεπερνά τα

2

.

2,5 m/s

Αυτέσ οι τιµέσ έχουν σηµειωθεί σύµφωνα µε το

EN60745.

TÜRKÇE

Sadece Avrupa ülkeleri için

5903R

Tipik Aağırlıklı gürültü seviyeleri şöyledir;

Tipik ağırlıklı karekök ortalama ivme 2,5 m/s

değildir.

Bu değerler EN60745 standardına göre elde edilmiştir.

modelin gürültü ve ti treşimi

ses basınç seviyesi: 95 dB (A)

ses güç seviyesi: 106 dB (A)

Belirsizlik: 3 dB (A)

– Kulak koruyucusu takın. –

2

’den fazla

79

Page 23

ENGLISH

For European countries only

Noise and Vibration of Model 5103R/5143R

The typical A-weighted noise levels are

The typical weighted root mean square acceleration

value is not more than 2.5 m/s

These values have been obtained according to

EN60745.

sound pressure level: 94 dB (A)

sound power level: 105 dB (A)

Uncertainty is 3 dB (A).

– Wear ear protection. –

2

.

ENG005-2-V3

ITALIANO

Modello per l’Europa soltanto

Rumore e vibrazione del modello 5103R/5143R

I livelli del rumore pesati secondo la curva A sono:

Il valore quadratico medio di accellerazione non supera i

2,5 m/s

Questi valori sono stati ottenuti in conformità EN60745.

Livello pressione sonora: 94 dB (A)

Livello potenza sonora: 105 dB (A)

L’incertezza è di 3 dB (A).

– Indossare i paraorecchi. –

2

.

FRANÇAISE

Pour les pays d’Europe uniquement

Bruit et vibrations du modèle 5103R/5143R

Les niveaux de bruit ponderes types A sont:

niveau de pression sonore: 94 dB (A)

niveau de puissance du son: 105 dB (A)

L’incertitude de mesure est de 3 dB (A).

L’accélération pondérée ne dépasse pas 2,5 m/s

– Porter des protecteurs anti-bruit. –

Ces valeurs ont été obtenues selon EN60745.

2

.

DEUTSCH

Nur für europäische Länder

Geräusch- und Vibrationsentwicklung

Die typischen A-bewerteten Geräuschpegel betragen:

Der gewichtete Effektivwert der Beschleunigung beträgt

nicht mehr als 2,5 m/s

Diese Werte wurden gemäß EN60745 erhalten.

des Modells 5103R/5143R

Schalldruckpegel: 94 dB (A)

Schalleistungspegel: 105 dB (A)

Die Abweichung beträgt 3 dB (A).

– Gehörschutz tragen. –

2

.

NEDERLANDS

Alleen voor Europese landen

Geluidsniveau en trilling van het model 5103R/5143R

De typische A-gewogen geluidsniveau’s zijn

geluidsdrukniveau: 94 dB (A)

geluidsenergie-niveau: 105 dB (A)

Onzekerheid is 3 dB (A).

De typische gewogen effectieve versnellingswaarde is

niet meer dan 2,5 m/s

– Draag oorbeschermers. –

2

.

Deze waarden werden verkregen in overeenstemming

met EN60745.

ESPAÑOL

Para países europeos solamente

Ruido y vibración del modelo 5103R/5143R

Los niveles típicos de ruido ponderados A son

El valor ponderado de la aceleración no sobrepasa los

2,5 m/s

Estos valores han sido obtenidos de acuerdo con

EN60745.

presión sonora: 94 dB (A)

nivel de potencia sonora: 105 dB (A)

Incerteza 3 dB (A).

– Póngase protectores en los oídos. –

2

.

80

Page 24

PORTUGUÊS

Só para países Europeus

Ruído e vibração do modelo 5103R/5143R

Os níveis normais de ruído A são

O valor médio da aceleração é inferior a 2,5 m/s

Estes valores foram obtidos de acordo com EN60745.

nível de pressão de som: 94 dB (A)

nível do sum: 105 dB (A)

A incerteza é de 3 dB (A).

– Utilize protectores para os ouvidos –

2

.

ENG005-2-V3

NORSK

Gjelder bare land i Europa

Støy og vibrasjon fra modell 5103R/5143R

De vanlige A-belastede støynivå er

Den vanlig belastede effektiv-verdi for akselerasjon overskrider ikke 2,5 m/s

Disse verdiene er beregnet eller målt i samsvar med

EN60745.

lydtrykksnivå: 94 dB (A)

lydstyrkenivå: 105 dB (A)

Usikkerheten er på 3 dB (A).

– Benytt hørselvern. –

2

.

DANSK

Kun for lande i Europa

Lyd og vibration fra model 5103R/5143R

De typiske A-vægtede lydniveauer er

lydtryksniveau: 94 dB (A)

lydeffektniveau: 105 dB (A)

Der er en usikkerhed på 3dB (A).

Den vægtede effektive accelerationsværdi overstiger ikke

2

.

2,5 m/s

– Bær høreværn. –

Disse værdier er beregnet i overensstemmelse med

EN60745.

SVENSKA

Endast för Europa

Buller och vibration hos modell 5103R/5143R

De typiska A-vägda bullernivåerna är

Det typiskt vägda effektivvärdet för acceleration översti-

ger inte 2,5 m/s

Dessa värden har erhållits i enlighet med EN60745.

ljudtrycksnivå: 94 dB (A)

ljudeffektnivå: 105 dB (A)

Osäkerheten är 3 dB (A).

– Använd hörselskydd –

2

.

SUOMI

Vain Euroopan maat

Mallin 5103R/5143R melutaso ja tärinä

Tyypilliset A-painotetut melutasot ovat

äänenpainetaso: 94 dB (A)

äänen tehotaso: 105 dB (A)

Epävarmuus on 3 dB (A).

Tyypillinen kiihtyvyyden painotettu tehollisarvo ei ylitä

2,5 m/s

Nämä arvot on mitattu normin EN60745 mukaisesti.

– Käytä kuulosuojaimia. –

2

.

ΕΛΛΗΝΙΚΑ

Μ3νο για χώρες της Ευρώπης

Θ3ρυβος και κραδασµ3ς του µοντέλου 5103R/5143R

Οι τυπικέσ A-µετρούµενεσ εντάσεισ ήχου είναι

πίεση ήχου: 94 dB (A)

δύναµη του ήχου: 105 dB (A)

Η Αβεβαιτητα είναι 3 dB (A).

– Φοράτε ωτοασπίδεσ. –

Η τυπική αξία τησ µετρούµενησ ρίζασ του µέσου

τετραγώνου τησ επιτάχυνσησ δεν ξεπερνά τα

2

.

2,5 m/s

Αυτέσ οι τιµέσ έχουν σηµειωθεί σύµφωνα µε το

EN60745.

TÜRKÇE

Sadece Avrupa ülkeleri için

5103R/5143R

Tipik Aağırlıklı gürültü seviyeleri şöyledir;

Tipik ağırlıklı karekök ortalama ivme 2,5 m/s

değildir.

Bu değerler EN60745 standardına göre elde edilmiştir.

modelin gürültü ve titreşimi

ses basınç seviyesi: 94 dB (A)

ses güç seviyesi: 105 dB (A)

Belirsizlik: 3 dB (A)

– Kulak koruyucusu takın. –

2

’den fazla

81

Page 25

82

Page 26

83

Page 27

Makita Corporation

Anjo, Aichi, Japan

883869F992

Loading...

Loading...