Page 1

Circular Saw

Instruction Manual

Handkreissäge

Betribsanleitung

Piła tarczowa

Instrukcja obsługi

Дисковая пила

Инструкция по эксплуатации

190 mm 5704R

190 mm 5704R

190 mm 5704R190 mm 5704R

Page 2

1

1

2

2

3

3

5

7

4

6

5

6

7

4

8

2

Page 3

8

9

10

9

9

12

13

12

14

1 – 5 mm

11

10

15

8

7

11

13

15

16

21

20

16

12

14

16

17

18

19

3

Page 4

17

18

22

23

19

21

24

20

25

4

Page 5

Symbols

The following show the symbols used for the tool. Be sure that you understand their meaning before use.

Symbole

Die folgenden Symbole werden für die Maschine verwendet. Machen Sie sich vor der Benutzung unbedingt

mit ihrer Bedeutung vertraut.

Symbole

Poniższe symbole używane są do opisu piły. Przed użyciem należy upewnić się, że rozumie się ich znaczenie.

Символы

Следующие объяснения показывают символы, используемые для инструмента. Убедитесь перед

использованием, что Вы понимаете их значение.

❏ Read instruction manual.

❏ Bitte Betriebsanleitung lesen.

❏ Przeczytaj instrukcję obsługi.

❏ Прочитайте инструкцию по эксплуатации.

❏ DOUBLE INSULATION

❏ DOPPELT SCHUTZISOLIERT

❏ PODWÓJNA IZOLACJA

❏ ДВОЙНАЯ ИЗОЛЯЦИЯ

5

Page 6

ENGLISH

Explanation of general view

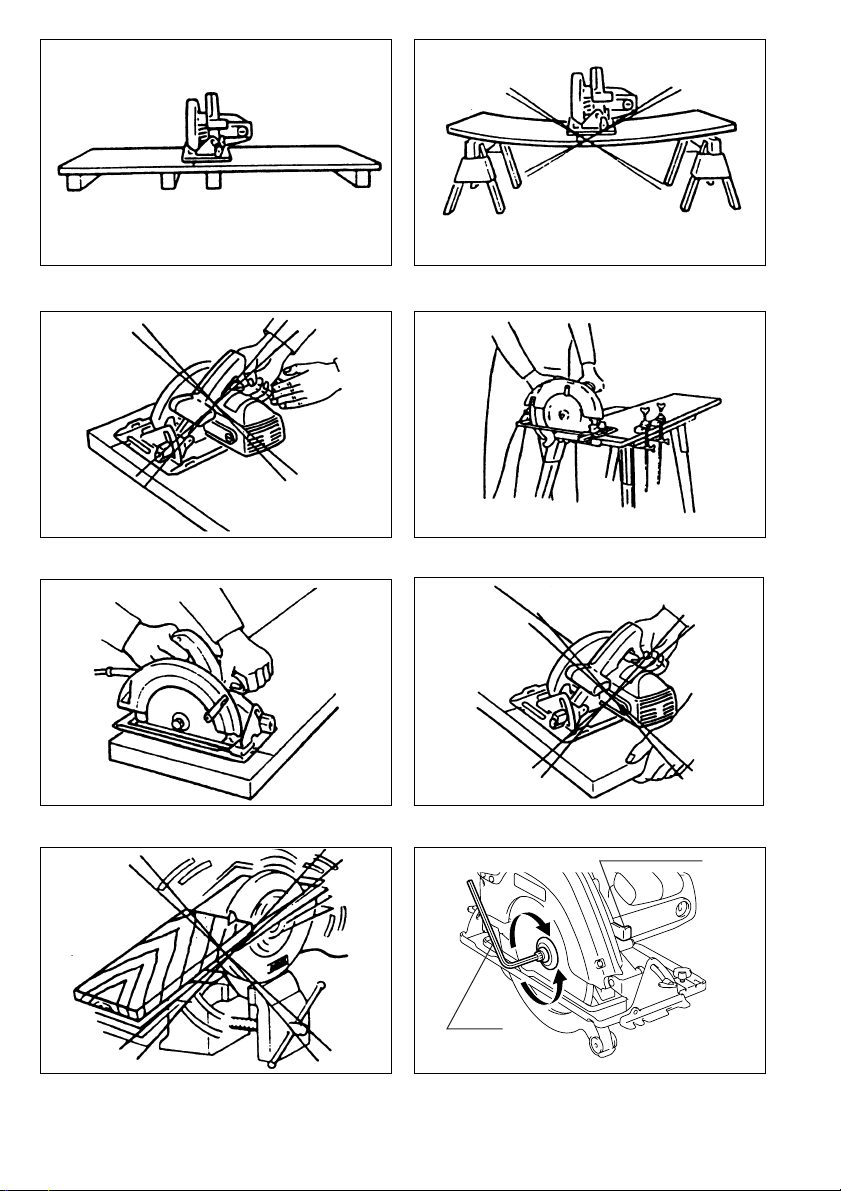

1 To avoid kickback, do support

board or panel near the cut.

2 Don’t support board or panel

away from the cut.

3 A typical illustration of proper

hand support and workpiece

support.

4 Hex wrench

5Shaft lock

6 Tighten

7 Loosen

8 Saw blade

9 Outer flange

10 Inner flange

11 Hex socket head bolt

12 Setting protuberances

13 Hex socket head bolt

(For adjusting riving knife)

14 Cutting depth

15 Lever

16 Thumb screw

17 For 45°°°° bevel cuts

SPECIFICATIONS

Model 5704R

Blade diameter ............................................. 190 mm

Max. cutting depth

At 90° .......................................................... 66 mm

At 45° .......................................................... 46 mm

No load speed (min

Overall length ............................................... 345 mm

Net weight ....................................................... 4.6 kg

• Due to our continuing program of research and

development, the specifications herein are subject

to change without notice.

• Note: Specifications may differ from country to

country.

Intended use

The tool is intended for performing lengthways and

crossways straight cuts and miter cuts with angles to

45° in wood while in firm contact with the workpiece.

Power supply

The tool should be connected only to a power supply

of the same voltage as indicated on the nameplate,

and can only be operated on single-phase AC supply.

They are double-insulated in accordance with European Standard and can, therefore, also be used from

sockets without earth wire.

-1

) ...................................... 4,900

SAFETY INSTRUCTIONS

Warning! When using electric tools, basic safety

precautions should always be followed to reduce

the risk of fire, electric shock and personal injury,

including the following. Read all these instructions before attempting to operate this product

and save these instructions.

For safe operation:

1. Keep work area clean

Cluttered areas and benches invite injuries.

2. Consider work area environment

Don’t expose power tools to rain. Don’t use

power tools in damp or wet locations. Keep work

area well lit. Don’t use power tools in presence of

flammable liquids or gases.

18 For straight cuts

19 Base plate

20 Lock-off button

21 Switch trigger

22 Vacuum cleaner

23 Limit mark

24 Brush holder cap

25 Screwdriver

3. Guard against electric shock

Prevent body contact with grounded surfaces

(e.g. pipes, radiators, ranges, refrigerators).

4. Keep children away

Do not let visitors contact tool or extension cord.

All visitors should be kept away from work area.

5. Store idle tools

When not in use, tools should be stored in dry,

high, or locked-up place, out of the reach of children.

6. Don’t force tool

It will do the job better and safer at the rate for

which it was intended.

7. Use right tool

Don’t force small tools or attachments to do the

job of a heavy duty tool. Don’t use tools for purposes not intended; for example, don’t use circular saw for cutting tree limbs or logs.

8. Dress properly

Do not wear loose clothing or jewelry. They can

be caught in moving parts. Rubber gloves and

non-skid footwear are recommended when working outdoors. Wear protective hair covering to

contain long hair.

9. Use safety glasses and hearing protection

Also use face or dust mask if cutting operation is

dusty.

10. Connect dust extraction equipment

If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used.

11. Don’t abuse cord

Never carry tool by cord or yank it to disconnect it

from receptacle. Keep cord from heat, oil and

sharp edges.

12. Secure work

Use clamps or a vise to hold work. It’s safer than

using your hand and it frees both hands to operate tool.

13. Don’t overreach

Keep proper footing and balance at all times.

6

Page 7

14. Maintain tools with care

Keep tools sharp and clean for better and safer

performance. Follow instructions for lubricating

and changing accessories. Inspect tool cords

periodically and, if damaged, have repaired by

authorized service facility. Inspect extension

cords periodically and replace if damaged. Keep

handles dry, clean and free from oil and grease.

15. Disconnect tools

When not in use, before servicing, and when

changing accessories such as blades, bits and

cutters.

16. Remove adjusting keys and wrenches

Form the habit of checking to see that keys and

adjusting wrenches are removed from tool before

turning it on.

17. Avoid unintentional starting

Don’t carry plugged-in tool with finger on switch.

Be sure switch is off when plugging in.

18. Outdoor use extension cords

When tool is used outdoors, use only extension

cords intended for use outdoors and so marked.

19. Stay alert

Watch what you are doing. Use common sense.

Do not operate tool when you are tired.

20. Check damaged parts

Before further use of the tool, a guard or other

part that is damaged should be carefully checked

to determine that it will operate properly and perform its intended function. Check for alignment of

moving parts, binding of moving parts, breakage

of parts, mounting, and any other conditions that

may affect its operation. A guard or other part

that is damaged should be properly repaired or

replaced by an authorized service center unless

otherwise indicated elsewhere in this instruction

manual. Have defective switches replaced by

and authorized service center. Do not use tool if

switch does not turn it on and off.

21. Warning

The use of any other accessory or attachment

other than recommended in this operating

instruction or the catalog may present a risk of

personal injury.

22. Have your tool repaired by an expert

This electric appliance is in accordance with the

relevant safety rules. Repairing of electric appliances may be carried out only by experts otherwise it may cause considerable danger for the

user.

ADDITIONAL SAFETY RULES

1. Wear hearing protection.

2. Keep Guards In Place and In Working Order.

Never wedge or tie lower guard open. Check

operation of lower guard before each use.

Don’t use if lower guard does not close

briskly over saw blade.

CAUTION: If saw is dropped, lower guard may

be bent, restricting full return.

3. Do not use blades which are deformed or

cracked.

4. Do not use blades of high speed steel.

5. Do not stop the blades by lateral pressure on

the saw blade.

6. Keep Blades Clean and Sharp. Sharp blades

minimize stalling and kickback.

7. DANGER:

Keep Hands Away From Cutting Area. Keep

hands away from blades. Don’t reach underneath work while blade is rotating. Don’t

attempt to remove cut material when blade is

moving.

CAUTION: Blades coast after turn off.

8. Support Large Panels. (Fig. 1 & 2)

Large panels must be supported as shown in

Fig. 1 to minimize the risk of blade pinching

and kickback. When cutting operation

requires the resting of the saw on the workpiece, the saw shall be rested on the larger

portion and the smaller piece cut off.

9. Use Rip Fence.

Always use a fence or straight edge guide

when ripping.

10. Guard Against Kickback. (Fig. 1 & 3)

Kickback occurs when the saw stalls rapidly

and is driven back towards the operator.

Release switch immediately if blade binds or

saw stalls. Keep blades sharp. Support large

panels as shown in Fig.1.

Use fence or straight edge guide when ripping. Don’t force tool. Stay alert – exercise

control. Don’t remove saw from work during a

cut while the blade is moving.

NEVER place your hand or fingers behind the

saw. If kickback occurs, the saw could easily

jump backwards over your hand, possibly

causing severe injury.

11. Lower Guard.

Raise lower guard with the retracting handle.

12. Adjustments.

Before cutting be sure depth and bevel

adjustments are tight.

13. Use Only Correct Blades In Mounting.

Don’t use blades with incorrect size holes.

Never use defective or incorrect blade washers or bolts.

ENB036-2

7

Page 8

14. Avoid Cutting Nails.

Inspect for and remove all nails from lumber

before cutting.

15. When operating the saw, keep the cord away

from the cutting area and position it so that it

will not be caught on the workpiece during

the cutting operation. Operate with proper

hand support, proper workpiece support, and

supply cord routing away from the work area.

WARNING:

It is important to support the workpiece properly and to hold the saw firmly to prevent loss

of control which could cause personal injury.

Fig. 4 illustrates typical hand support of the

saw.

16. Place the wider portion of the saw base on

that part of the workpiece which is solidly

supported, not on the section that will fall off

when the cut is made.

As example, Fig.5 illustrates the RIGHT way

to cut off the end of a board, and Fig.6 the

WRONG way. If the workpiece is short or

small, clamp it down. DON’T TRY TO HOLD

SHORT PIECES BY HAND! (Fig. 6)

17. Never attempt to saw with the circular saw

held upside down in a vise. This is extremely

dangerous and can lead to serious accidents.

(Fig. 7)

18. Before setting the tool down after completing

a cut, be sure that the lower (telescoping)

guard has closed and the blade has come to

a complete stop.

19. Using manufacturer data

• Ensure that the diameter, thickness and

other characteristics of the saw blade are

suitable for the tool.

• Ensure that the saw blade is suitable for the

spindle speed of the tool .

20. Do not use any abrasive wheel.

SAVE THESE INSTRUCTIONS.

OPERATING INSTRUCTIONS

Removing or installing saw blade

The following blade can be used with this tool.

Max.

Min. dia.

dia.

190 mm 170 mm

The thickness of the riving knife is 1.8 mm.

CAUTION:

• Do not use saw blades which do not comply with

the characteristics specified in these instructions.

• Do not use saw blades the disc of which is thicker

or the set of which is smaller than the thickness of

the riving knife.

Hole

dia.

20 mm

30 mm

or

Blade

thick-

ness

Less

than

1.7 mm

Kerf

More

than

1.9 mm

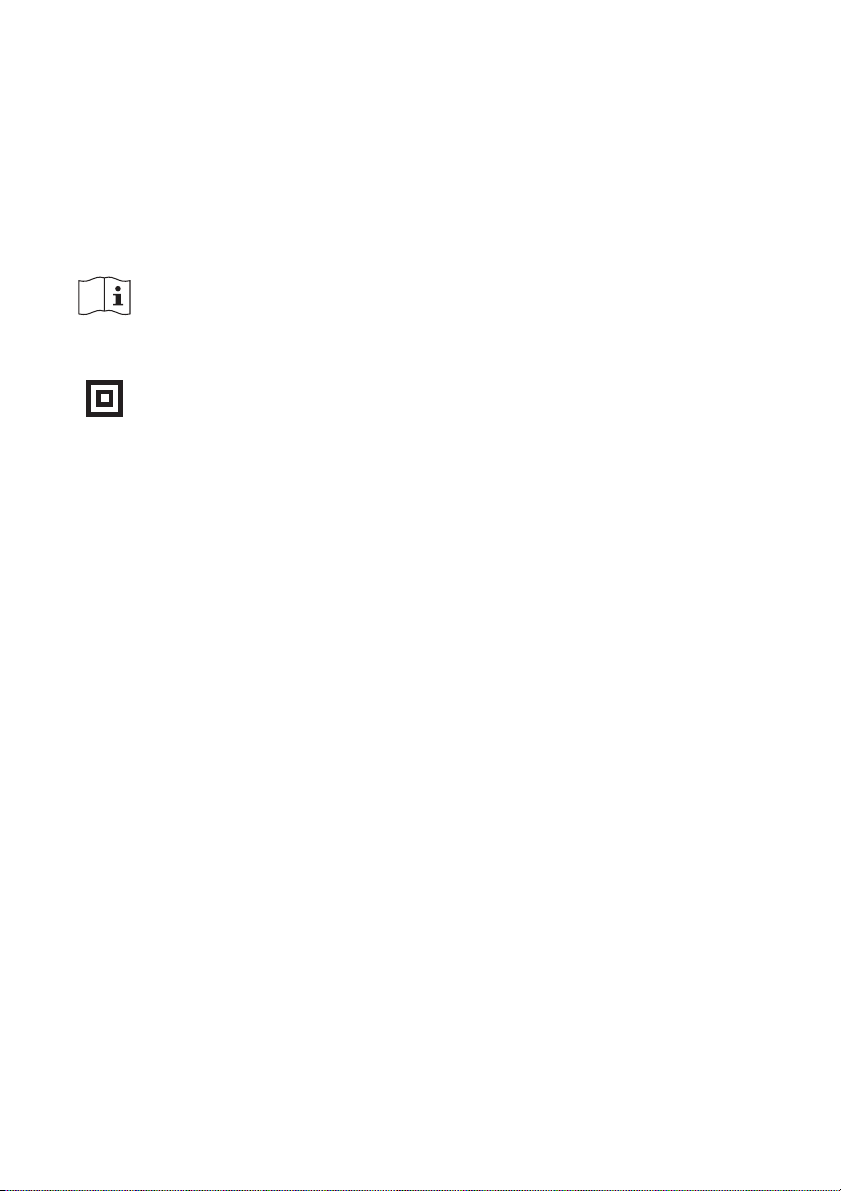

To remove the saw blade, depress the shaft lock fully

to prevent shaft rotation, then use the hex wrench to

loosen the hex socket head bolt. (Fig.8)

Now remove the outer flange, raise the safety cover

as much as possible, and remove the saw blade.

(Fig. 9)

Install the saw blade using the reverse of the removal

procedure. Install the inner flange, saw blade, outer

flange and hex socket head bolt, in that order. Be

sure to secure the hex socket head bolt tightly with

the shaft lock fully depressed. (Fig. 10)

CAUTION:

• Make sure that the blade teeth point forward in the

same direction as the tool rotation (the arrow on the

blade should point in the same direction as the

arrow on the tool).

• The inner flange has a 30 mm diameter on one side

and a 20 mm diameter on the other. The side with

20 mm diameter is marked by “20”. Use the correct

side for the hole diameter of the blade you intend to

use. Mounting the blade on the wrong side can

result in dangerous vibration.

• Use only the Makita hex wrench to remove or install

the blade.

Riving knife adjustment (Fig. 11)

Use the hex wrench to loosen the hex socket head

bolt for the riving knife adjustment, then raise the

safety cover. Move the riving knife up or down over

the two protruberances for settings indicated in the

illustration, so as to obtain the proper clearance

between the riving knife and saw blade.

CAUTION:

Ensure that the riving knife is adjusted such that:

The distance between the riving knife and the

toothed rim of the saw blade is not more than 5mm.

The toothed rim does not extend more than 5mm

beyond the lower edge of the riving knife.

Adjusting depth of cut (Fig. 12)

Loosen the lever on the depth guide and move the

base up or down. At a desired depth of cut, secure

the base by tightening the lever.

CAUTION:

• Use a shallow depth of cut when cutting thin workpiece for cleaner, safer cuts.

• After adjusting the depth of cut, always tighten the

lever securely.

Adjusting for bevel cuts (Fig.13)

Loosen the thumb screws in front and back, and tilt

the tool to the desired angle for bevel cuts (0°–45°).

Secure the thumb screws tightly in front and back

after making the adjustment.

Sighting (Fig.14)

For straight cuts, align the right notch on the front of

the base with your cutting line on the workpiece. For

45° bevel cuts, align the left notch with it.

8

Page 9

Switch action (Fig. 15)

To prevent the switch trigger from being accidentally

pulled, a lock-off button is provided. To start the tool,

depress the lock-off button and pull the switch trigger.

Release the switch trigger to stop.

CAUTION:

Before plugging in the tool, always check to see that

the switch trigger actuates properly and returns to the

“OFF” position when released.

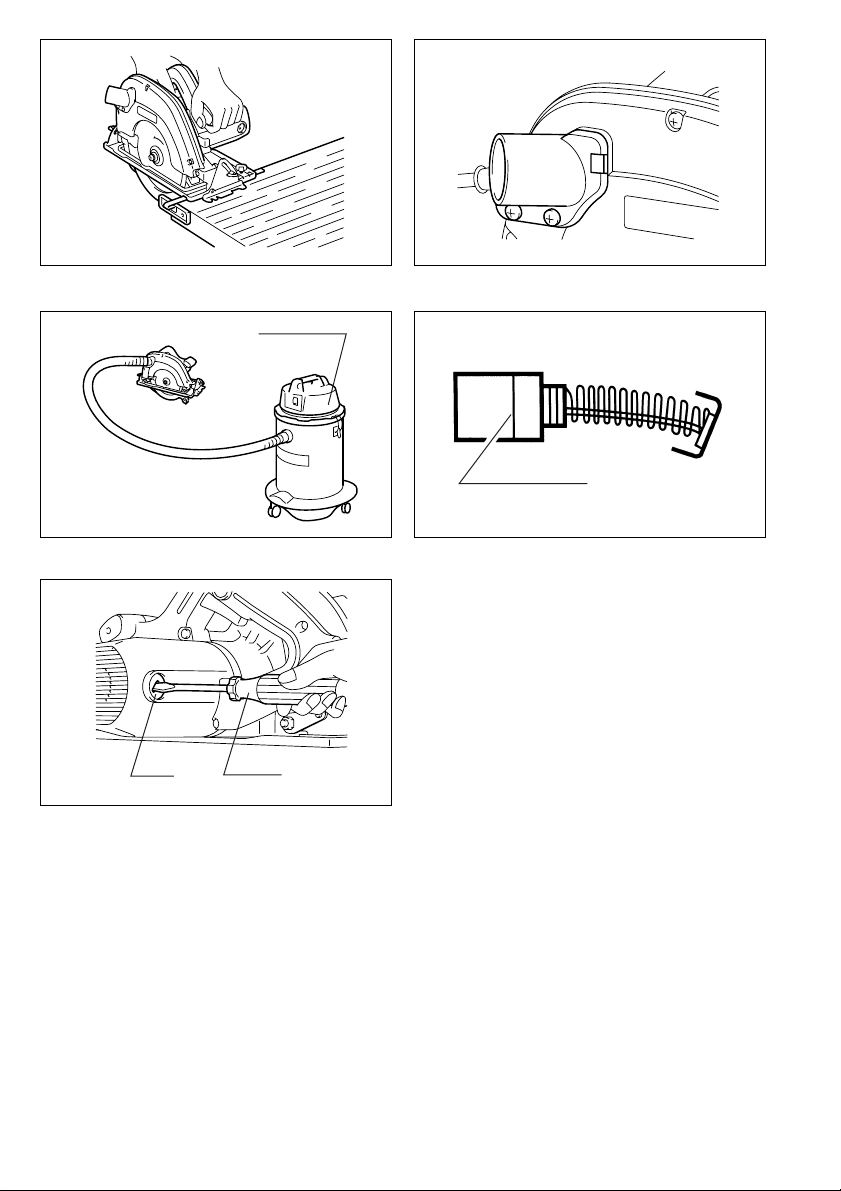

Operation (Fig. 16)

Hold the tool firmly. Set the base plate on the workpiece to be cut without the blade making any contact.

Then turn the tool on and wait until the blade attains

full speed. Now simply move the tool forward over the

workpiece surface, keeping it flat and advancing

smoothly until the sawing is completed. To get clean

cuts, keep your sawing line straight and your speed

of advance uniform.

CAUTION:

• The riving knife should always be used except

when plunging in the middle of the workpiece.

• Do not stop the saw blade by lateral pressure on

the disc.

Guide rule (Fig.17)

The handy guide rule allows you to do extra-accurate

straight cuts. Simply slide the guide rule up snugly

against the side of the workpiece and secure it in

position with the bolt on the front of the base. It also

makes repeated cuts of uniform width possible.

Joint assembly (Fig. 18 &19)

(for connecting a vacuum cleaner)

When you wish to perform clean cutting operation,

connect a vacuum cleaner to your tool. Install the

joint on the tool using the screw. Then connect a

hose of vacuum cleaner to the joint.

MAINTENANCE

CAUTION:

Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Replacement of carbon brushes (Fig. 20 &21)

Replace carbon brushes when they are worn down to

the limit mark. Both identical carbon brushes should

be replaced at the same time.

To maintain product safety and reliability, repairs,

maintenance or adjustment should be carried out by

a Makita Authorized Service Center.

9

Page 10

The typical A-weighted noise levels are

The typical weighted root mean square acceleration value is not more than 2.5 m/s

sound pressure level: 98 dB (A)

sound power level: 111 dB (A)

– Wear ear protection. –

2

.

EC-DECLARATION OF CONFORMITY

We declares that our sole responsibility that this

product is in compliance with the following standards

or standardized documents,

HD400, EN50144, EN55014, EN61000

in accordance with Council Directives, 73/23/EEC,

89/336/EEC and 98/37/EC.

Noise and Vibration

10

Yasuhiko Kanzaki

MAKITA INTERNATIONAL EUROPE LTD

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

CE 2000

Director

.

Page 11

DEUTSCH

Übersicht

1 Anordnung der Werkstückun-

terlagen zur Vermeidung von

Rückschlag.

2Werkstück nicht zu weit von

der Schnittstelle abstützen.

3 Beispiel der richtigen Hand-

haltung und Abstützung

des Werkstücks.

4 Inbusschlüssel

5 Spindelarretierung

6 Anziehen

7Lösen

8Sägeblatt

9Außenflansch

10 Innenflansch

11 Innensechskantschraube

12 Einstellvorsprünge

13 Innensechskantschraube

(zum Einstellen des Spalt-

keils)

14 Schnittiefe

15 Hebel

TECHNISCHE DATEN

Modell 5704R

Sägeblatt ø .................................................... 190 mm

Max. Schnittiefe

90° ................................................................ 66 mm

45° ................................................................ 46 mm

Leerlaufdrehzahl ................................... 4 900 min

Gesamtlänge ................................................ 345 mm

Nettogewicht .................................................... 4,6 kg

• Wir behalten uns vor, Änderungen im Zuge der Ent-

wicklung und des technischen Fortschritts ohne

vorherige Ankündigung vorzunehmen.

• Hinweis: Die technischen Daten können von Land

zu Land abweichen.

Vorgesehene Verwendung

Das Werkzeug ist für Geradschnitte in Längs- und

Querrichtung sowie für Gehrungsschnitte mit Winkeln bis zu 45° in Holz vorgesehen, wobei es in

festem Kontakt mit dem Werkstück bleibt.

Netzanschluß

Die Maschine darf nur an die auf dem Typenschild

angegebene Netzspannung angeschlossen werden

und arbeitet nur mit Einphasen-Wechselspannung.

Sie ist entsprechend den Europäischen Richtlinien

doppelt schutzisoliert und kann daher auch an Steckdosen ohne Erdanschluß betrieben werden.

SICHERHEITSHINWEISE

Achtung! Beim Gebrauch von Elektrowerkzeugen

sind zum Schutz gegen elektrischen Schlag. Verletzungsund Brandgefahr folgende grundsätzlichen Sicherheitsmaßnahmen zu geachten.

Lesen und beachten Sie diese Hinweise, bevor

Sie das Gerät benutzen.

1. Halten Sie Ihren Arbeitsbereich in Ordnung

Unordnung im Arbeitsbereich ergibt Unfallgefahr.

2. Berücksichtigen Sie Umgebungseinflüsse

Setzen sie Elektrowerkzeuge nicht dem Regen

aus. Benützen Sie Elektrowerkzeuge nicht in

feuchter oder nasser Umgebung. Sorgen Sie für

gute Beleuchtung. Benützen Sie Elektrowerkzeuge nicht in Nähe von brennbaren Flüssigkei-

ten oder Gasen.

16 Rändelschraube

17 Für 45°°°°-Schnitte

18 Für gerade Schnitte

19 Gleitschuh

20 Einschaltsperre

21 Ein-Aus-Schalter

22 Staubsauger

23 Verschleißgrenze

24 Bürstenhalterkappe

25 Schraubendreher

3. Schützen Sie sich vor elektrischem Schlag

Vermeiden Sie Körperberührung mit geerdeten

Teilen, zum Beispiel Rohren, Heizkörpern, Her-

den, kühlschränken.

4. Halten Sie Kinder fern!

Lassen Sie andere Personen nicht das Werk-

-1

zeug oder Kabel berühren, halten Sie sie von

Ihrem Arbeitsbereich fern.

5. Bewahren Sie Ihre Werkzeuge sicher auf

Unbenutzte Werkzeuge sollten in trockenem,

verschlossenem Raum und für Kinder nicht

erreichbar aufbewahrt werden.

6. Überlasten Sie Ihr Werkzeug nicht

Sie arbeiten besser und sicherer im angegebenen Leistungsbereich.

7. Benützen Sie das richtige Werkzeug

Verwenden Sie keine zu schwachen Werkzeuge

oder Vorsatzgeräte für schwere Arbeiten.

Benützen Sie Werkzeuge nicht für Zwecke und

Arbeiten, Wofür sie nicht bestimmt sind; zum

Beispiel benützen Sie keine Handkreissäge, um

Bäume zu flällen oder Äste zu schneiden.

8. Tragen Sie geeignete Arbeitskleidung

Tragen Sie keine weite Kleidung oder Schmuck.

Sie können von beweglichen Teilen erfaßt werden. Bei Arbeiten im Freien sind Gummihandschuhe und rutschfestes Schuhwerk

empfehlenswert. Tragen Sie bei langen Haaren

ein Haarnetz.

9. Schutzbrille und Gehörschutz tragen

Verwenden Sie eine Atemmaske bei stauberzeugenden Arbeiten.

10. Schlleßen Sie eine Staubabsaugvorrichtung

an

Wenn Geräte für den Anschluß von Staubabsaug-und-sammelvorrichtungen ausgelegt sind,

sorgen Sie dafür, daß Jiese angeschlossen und

korrekt benutzi werden.

11. Zweckentfremden Sie nicht das Kabel

Tragen Sie das Werkzeug nicht am Kabel, und

benützen Sie es nicht, um den Stecker aus der

Steckdose zu ziehen. Schützen Sie das Kabel

vor Hitze, Öl und scharfen Kanten.

11

Page 12

12. Sichern Sie das Werkstück

Benützen Sie Spannvorrichtungen oder einen

Schraubstock, um das Werkstück festzuhalten.

Es ist damit sicherer gehalten als mit Ihrer Hand

und ermöglicht die Bedienung der Maschine mit

beiden Händen.

13. Überdehnen Sie nicht Ihren Standbereich

Vermeiden Sie abnormale Körperhaltung. Sorgen Sie für sicheren Stand, und halten Sie jederzeit das Gleichgewicht.

14. Pflegen Sie Ihre Werkzeuge mit Sorgtalt

Halten Sie Ihre Werkzeuge scharf und sauber,

um gut und sicher zu arbeiten. Befolgen Sie die

Wartungsvorschriften und die Hinweise für

Werkzeugwechsel. Kontrollieren Sie regelmäßig

den Stecker und das Kabel, und lassen Sie

diese bei Beschädigung von einem anerkannten

Fachmann erneuern.

Kontrollieren Sie Verlängerungskabel regelmä-

ßig und ersetzen Sie beschädigte. Halten Sie

Handgriffe trocken und frei von Öl und Fett.

15. Ziehen Sie den Netzstecker

Bei Nichtgebrauch, vor der Wartung und beim

Werkzeugwechsel, wie zum Beispiel Sägeblatt,

Bohrer und Maschinenwerkzeugen aller Art.

16. Lassen Sie keine Werkzeugschlüssel stecken

Überprüfen Sie vor dem Einschalten, daß die

Schlüssel und Einstellwerkzeuge entfernt sind.

17. Vermeiden Sie unbeabsichtigten Anlauf

Tragen Sie keine an das Stromnetz angeschlossene Werkzeuge mit dem Finger am Schalter.

Vergewissern Sie sich, daß der Schalter beim

Anschluß an das Stromnetz ausgeschaltet ist.

18. Verlängerungskabel im Freien

Verwenden Sie im Freien nur dafür zugelassene

und entsprechend gekennzeichnete Varlänge-

rungskabel.

19. Seien Sie stets aufmerksam

Beobachten Sie Ihre Arbeit. Gehen Sie vernünf-

tig vor. Verwenden Sie das Werkzeug nicht,

wenn Sie unkonzentriert sind.

20. Kontrollieren Sie Ihr Gerät auf Beschädigungen

Vor weiterem Gebrauch des Werkzeugs die

Schutzeinrichtungen oder leicht beschädigte

Teile sorgfältig auf ihre einwandfreie und bestimmungsgemäße Funktion überprüfen. Überprü-

fen Sie, ob die Funktion beweglicher Teile in

Ordnung ist, ob sie nicht klemmen onder ob Teile

beschädigt sind. Sämtliche Teile müssen richtig

montiert sein und alle Bedingungen erfüllen, um

den einwandfreien Betrieb des Gerätes zu

gewährleisten.

Beschädigte Schutzvorrichtungen und Teile sollen sachgemäß durch eine Kundendienstwerkstatt repariert oder ausgewechselt werden,

soweit nichts anderes in den Betriebsanleitungen angegeben ist. Beschädigte Schalter müs-

sen bei einer Kundendienstwerkstatt ersetzt

werden. Benutzen Sie keine Werkzeuge, bei

denen sich der Schalter nicht ein und ausschalten läßt.

21. Achtung!

Zu Ihrer eigenen Sicherheit, benützen Sie nur

Zubehör und Zusatzgeräte, die in der Bedienungsanleitung angegeben oder vom WerkzeugHersteller empfohlen oder angegeben werden.

Der Gebrauch anderer als der in der Bedienungsanleitung oder im Katalog empfohlenen

Einsatzwerkzeuge oder Zubehöre kann eine persönliche Verletzungsgefahr für Sie bedeuten.

22. Reparaturen nur vom Elektrofachmann.

Dieses Elektrowerkzeug entspricht den einschlä-

gigen Sicherheitsbestimmungen. Reparaturen

dürfen nur von einer Elektrofachkraft ausgeführt

werden, andernfalls können Unfälle für den

Betreiber entstehen.

ZUSÄTZLICHE

SICHERHEITSREGELN

1. Tragen Sie während des Betriebs einen

Augen- oder Gesichtsschutz. Ebenfalls dringend empfohlen ist das Tragen von Gehörschutz, Schutzhandschuhen und

Schutzschuhen. Verwenden Sie eine Atemmaske bei stauberzeugenden Arbeiten.

2. Schutzvorrichtungen vor Inbetriebnahme

überprüfen und nicht entfernen. Die bewegliche Schutzhaube niemals im geöffneten

Zustand verkeilen oder festklemmen. Bewegliche Schutzhaube auf Funktion überprüfen.

3. Nur scharfe Sägeblätter in gutem Zustand

verwenden; gesprungene oder verbogene

Sägeblätter sofort ersetzen.

4. Keine Sägeblätter aus hochlegiertem Schnellarbeitsstahl (HSS) verwenden.

5. Das Sägeblatt nicht durch seitlichen Druck

zum Stillstand bringen.

6. Nur scharfe Sägeblätter in gutem Zustand

verwenden; um ein Einklemmen oder einen

Rückschlag möglichst zu vermeiden.

7. ACHTUNG: Niemals die Schneidezähne

berühren (Verletzungsgefahr). Nicht unter

das Werkstück fassen, während das Sägeblatt läuft. VORSICHT: Sägeblatt läuft nach

dem Abschalten nach.

8. Große Werkstücke müssen in der Nähe des

Schnittes abgestützr werden, um ein Einklemmen des Sägeblatts oder einen

Rücksclag möglichst zu vermeiden.

(Abb. 1 u.2).

Werkstücke nicht in zu großer Entfernung

vom Schnitt abstützen.

9. Bei Längsschnitten immer einen Parallelanschlag oder eine Führungsscheine verwenden.

10. Maschine gegen Rückschlag sichern

(Abb. 1 u.3)

Festklemmen bzw. Verkanten des Sägeblatts

kann zu gefährlichem Rückschlag (Kickback)

der Maschine führen! Schalten Sie die

Maschine sofort ab. Um Rückschlag zu vermeiden,

12

Page 13

1) verwenden Sie nur scharfe HM-Sägeblätter.

2) unterstützen Sie das Werkstück mit

entsprechenden Unterlagen

3) verwenden Sie den Parallelanschlag bei

parallelem Schnittverlauf.

4) Führen Sie die Maschine sicher mit kontrolliertem Druck und unter hoher

Aufmerksamkeit.

5) Heben Sie die Maschine bei laufendem

Sägeblatt nicht aus dem Werkstück.

6) überlasten Sie die Maschine nicht.

Während des Schnittvorgangs niemals die

Hand bzw. Finger hinter der Maschine halten.

Bei Rückschlag der Maschine können schwere Verletzungen verursacht werden.

11. Zum Öffnen der Pendelschutzhaube den

Hebel nach hinten ziehen.

12. Überprüfen Sie vor Arbeitsbeginn die Schnittiefen bzw. Winkeleinstellung.

13. Bei der Montage nur auf die Flanschbohrung

abgestimmte Sägeblätter verwenden.

Keine defekten bzw. vom Original abweichende Flansche, Befestigungsschrauben

oder Unterlegscheiben verwenden.

14. Vor Arbeitsbeginn das Werkstück auf Nägel

o. ä. untersuchen und diese ggf. entfernen.

15. Die Netzanschlußleitung vom Schnittbereich

fernhalten. Achten Sie bei der Verlegung darauf, daß die Netzanschlußleitung nicht

beschädigt wird und den Arbeitsablauf nicht

durch Festklemmen behindert.

Warnung:

Maschine, wie in Abb. 4 gezeigt, immer mit

beiden Händen sicher führen und Werkstück

immer ordnungsgemäß abstützen, um Verletzungen durch unkontrollierte Handhabung zu

vermeiden.

16. Maschine, wie in Abb. 5 gezeigt, mit der großen Auflagefläche der Grundplatte auf das

nicht abzuschneidende Material setzen. Abb.

6 zeigt die falsche Anwendung. Kurze bzw.

kleine Werkstücke müssen während des

Schnittvorgangs festgespannt sein – NIEMALS MIT DER HAND HALTEN! (Abb. 6)

17. Die Handkreissäge ist nur für die handgehaltene Verwendung bestimmt. Spannen Sie die

Maschine nie in einen Schraubstock o. ä. ein

– erhöhte Unfallgefahr! (Abb. 7).

18. Nach dem Bearbeitungsvorgang erst Sägeblatt zum Stillstand kommen lassen, Schutzhaube uaf geschlossene Stellung überprüfen

und danach absetzen.

19. Anhand der Herstellerdaten

• sicherstellen, daß Durchmesser, Dicke und

andere Eigenschaften des Sägeblatts für

die Maschine geeignet sind;

• sicherstellen, daß das Sägeblatt für die

Spindeldrehzahl der Maschine geeignet ist.

20. Verwenden Sie keine Schleifscheiben.

BEWAHREN SIE DIESE HINWEISE

SORGFÄLTIG AUF.

BEDIENUNGSHINWEISE

Montage und Demontage des Sägeblatts

Sägeblätter der folgenden Abmessungen können mit

dieser Maschine verwendet werden.

Max.

Durchm.

190 mm 170 mm

Die Dicke des Spaltkeils beträgt 1,8 mm.

VORSICHT:

• Sägeblätter, die nicht den hier angegebenen Spezifikationen entsprechen, dürfen nicht verwendet

werden.

• Verwenden Sie keine Sägeblätter, deren Dicke größer oder deren Schnittbreite kleiner als die Dicke

des Spaltkeils ist.

Zum Demontieren des Sägeblatts blockieren Sie die

Spindel durch Drücken der Spindelarretierung und

lösen dann die Innensechskantschraube mit dem

Inbusschlüssel. (Abb. 8)

Nun den Außenflansch entfernen, die Schutzhaube

so weit wie möglich anheben, und das Sägeblatt

abnehmen. (Abb. 9)

Zum Montieren des Sägeblatts wenden Sie das

Demontageverfahren umgekehrt an. Montieren Sie

Innenflansch, Sägeblatt, Außenflansch und Innen-

sechskantschraube in dieser Reihenfolge. Ziehen Sie

die Innensechskantschraube bei vollständig hineingedrückter Spindelarretierung fest an. (Abb.10)

VORSICHT:

• Das neue Sägeblatt so montieren, daß die Zähne

nach vorn in Drehrichtung des Sägeblatts zeigen.

Der Drehrichtungssinn der Pfeile von Sägeblatt und

Maschine muß übereinstimmen.

• Der Innenflansch hat einen Durchmesser von

30 mm auf der einen, und von 20 mm auf der anderen Seite. Die Seite mit 20 mm Durchmesser ist mit

“20” markiert. Verwenden Sie die für die Bohrung

des zu benutzenden Sägeblatts passende Seite.

Die Montage des Sägeblatts auf der falschen Seite

kann zu gefährlichen Vibrationen führen.

• Verwenden Sie nur den mitgelieferten MakitaInbusschlüssel zum Demontieren oder Montieren

des Sägeblatts.

Min.

Durchm.

Loch-

durch-

messer.

20 mm

oder

30 mm

Säge-

blattdicke

weniger

als

1,7 mm

Schnitt-

breite

mehr als

1,9 mm

13

Page 14

Einstellung des Spaltkeils (Abb. 11)

Lösen Sie die Innensechskantschraube zur Einstellung des Spaltkeils mit dem Inbusschlüssel, und

heben Sie dann die Schutzhaube an. Bewegen Sie

den Spaltkeil über die zwei Vorsprünge nach oben

oder unten, wie in der Abbildung gezeigt, um den

korrekten Abstand zwischen Spaltkeil und Sägeblatt

zu erzielen.

VORSICHT:

Vergewissern Sie sich, daß der Spaltkeil wie folgt

eingestellt ist: Der Abstand des Spaltkeils zum Zahnkranz des Sägeblatts darf nicht größer als 5mm sein.

Der Zahnkranz darf nicht mehr als 5 mm über die

Unterkante des Spaltkeils überstehen.

Einstellung der Schnitttiefe (Abb. 12)

Lösen Sie den Hebel an der Tiefenführung, und verstellen Sie den Gleitschuh nach oben oder unten.

Arretieren Sie den Gleitschuh an der gewünschten

Schnitttiefe durch Festziehen des Hebels.

VORSICHT:

• Verwenden Sie eine geringe Schnitttiefe für dünne

Werkstücke, um Schnitte von größerer Genauigkeit

und Sicherheit auszuführen.

• Ziehen Sie den Hebel nach der Einstellung der

Schnitttiefe stets fest an.

Einstellung für Neigungsschnitte (Abb.13)

Lösen Sie die Rändelschrauben an der Vorder- und

Rückseite, und neigen Sie das Werkzeug auf den

gewünschten Schnittwinkel (0°– 45°). Ziehen Sie die

Rändelschrauben an der Vorder- und Rückseite nach

der Einstellung wieder fest.

Schnittlinie (Abb. 14)

Für gerade Schnitte richten Sie die rechte Kerbe an

der Vorderseite des Gleitschuhs auf die Schnittlinie

am Werkstück aus. Für Neigungsschnitte von 45°

richten Sie die linke Kerbe auf die Schnittlinie aus.

Schalterbedienung (Abb. 15)

Um versehentliche Betätigung des Ein-Aus-Schalters

zu verhüten, ist die Maschine mit einer Einschaltsperre ausgestattet.

Zum Starten der Maschine betätigen Sie den EinAus-Schalter bei gedrückter Einschaltsperre. Zum

Anhalten lassen Sie den Ein-Aus-Schalter los.

VORSICHT:

Vor dem Anschließen der Maschine an das Stromnetz stets überprüfen, ob der EIN-/AUS-Schalter ordnungsgemäß funktioniert und beim Loslassen in die

AUS- Stellung zurückkehrt.

Betrieb (Abb. 16)

Halten Sie die Maschine mit festem Griff. Setzen Sie

den Gleitschuh auf das zu schneidende Werkstück

auf, ohne daß das Sägeblatt mit ihm in Berührung

kommt. Schalten Sie dann die Maschine ein und warten Sie, bis das Sägeblatt die volle Drehzahl erreicht

hat. Schieben Sie nun die Maschine flach und gleichmäßig über die Oberfläche des Werkstücks vor, bis

der Schnitt vollendet ist. Um saubere Schnitte zu

erzielen, halten Sie eine gerade Schnittlinie und eine

gleichmäßige Vorschubgeschwindigkeit ein.

VORSICHT:

• Der Spaltkeil muß, außer bei Tauchschnitten,

immer ordnungsgemäß montiert sein.

• Bremsen Sie die Maschine nicht durch seitlichen

Druck auf das Sägeblatt ab.

Parallelanschlag (Abb.17)

Der Parallelanschlag ermöglicht gerade Schnitte entlang einer Bezugskante. Dazu mit der Befestigungsschraube den Parallelanschlag in der gewünschten

Einstellung sichern.

Montage des Absaugstutzens (Abb. 18 u. 19)

(zum Anschließen eines Staubsaugers)

Für saubere Sägearbeiten kann ein Absauggerät an

die Handkreissäge angeschlossen werden. Den

Absaugstutzen mit der Schraube an der Handkreissäge befestigen, dann den Schlauch des Absauggerätes an den Absaugstutzen anschließen.

WARTUNG

VORSICHT:

Vor Arbeiten an der Maschine vergewissern Sie sich,

daß sich der Schalter in der “AUS-” Position befindet

und der Netzstecker gezogen ist.

Kohlebürsten wechseln (Abb. 20 u.21)

Kohlebürsten ersetzen, wenn sie bis auf die Verschleißgrenze abgenutzt sind. Beide Kohlebürsten

nur paarweise ersetzen.

Um die Sicherheit und Zuverlässigkeit dieses Gerä-

tes zu gewährleisten, sollten Reparatur-, Wartungs-,

und Einstellarbeiten nur von durch Makita autorisierten Werkstätten oder Kundendienstzentren unter

ausschließlicher Verwendung von Makita-Originalersatzteilen ausgeführt werden.

14

Page 15

Geräusch- und Vibrationsentwicklung

Die typischen A-bewerteten Schalldruckpegel betragen:

Schalldruckpegel: 98 dB (A)

Schalleistungspegel: 111dB (A)

– Gehörschutz tragen. –

Der gewichtete Effektivwert der Beschleunigung beträgt nicht

mehr als 2,5 m/s

2

.

CE-KONFORMITÄTSERKLÄRUNG

Hiermit erklären wir unter unserer alleinigen Verantwortung, dass dieses Produkt gemäß den Ratsdirektiven

73/23EWG, 89/336/EWG und 98/37/EG mit den folgenden

Normen bzw. Normendokumenten übereinstimmt:

HD400, EN50144, EN55014, EN61000.

Yasuhiko Kanzaki

CE 2000

Direktor

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

15

Page 16

POLSKI

Wyjaśnienia dotyczące piły i jej użycia

1 Aby uniknąć odbić, deskę lub

panel należy podeprzeć

blisko miejsca cięcia.

2 Nie podpieraj deski lub

panelu z dala od miejsca

cięcia.

3 Poprawne trzymanie piły i

zamocowanie przecinanego

elementu.

4 Klucz inbus

5 Blokada wałka

6Zaciśnij

7Zwolnij

8 Tarcza piły

9 Kołnierz zewnętrzny

10 Kołnierz wewnętrzny

11 Śruba z łbem sześciokątnym

12 Karby do ustawień

13 Śruba z łbem sześciokątnym

(Do regulacji klina

rozsyczepiającego)

14 Głębokość cięcia

DANE TECHNICZNE

Model 5704R

Średnica tarczy .............................................190 mm

Maks. głębokość cięcia

Przy 90° ........................................................66 mm

Przy 45° ........................................................46 mm

Prędkość bez obciążenia (min

Całkowita długość ........................................345 mm

Ciężar netto ......................................................4,6 kg

• Ze względu na prowadzony program udoskonaleń i

badań, podane dane techniczne mogą zostać

zmienione bez uprzedzenia.

• Uwaga: Dane techniczne mogą się różnić w

zależności od kraju.

Przeznaczenie

Urządzenie jest przeznaczone do wykonywania

podłużnego i poprzecznego cięcia prostego oraz

cięcia pod kątem do 45°°°° w drewnie, będąc w

trwałym kontakcie z obrabianym przedmiotem.

Zasilanie

Urządzenie to, powinno być podłączone tylko do

źródła zasilania o takim samym napięciu jak

pokazano na tabliczce znamionowej i może być

używane tylko dla zmiennego prądu jednofazowego.

Zgodnie ze standardami Unii Europejskiej

zastosowano podwójną izolację i dlatego też

możliwe jest zasilanie z gniazda bez uziemienia.

-1

) ...................... 4900

INSTRUKCJE BEZPIECZEŃSTWA

Ostrzeżenie! Używając urządzeń elektrycznych

podstawowe środki ostrożności muszą być

zawsze zachowane, aby zmniejszyć ryzyko

ognia, porażenia prądem i uszkodzenia ciała,

włączając poniższe. Przeczytaj wszystkie podane

instrukcje przed próbą użycia tego produktu i

zachowaj je do wglądu.

15 Dźwignia

16 Śruba skrzydełkowa

17 Dla cięcia ukośnego 45°°°°

18 Dla cięcia prostego

19 Płyta podstawy

20 Przycisk blokady wyłączania

21 Język włącznika

22 Odkurzacz

23 Wskaźnik limitu

24 Nasadka szczotki

25 Śrubokręt

Dla bezpiecznego użycia:

1. Utrzymuj miejsce pracy w czystości

Zabałaganione miejsca i stoły warsztatowe

sprzyjają wypadkom.

2. Zastanów się nad warunkami pracy

Nie wystawiaj urządzeń elektrycznych na

deszcz. Nie używaj urządzeń elektrycznych w

wilgotnych lub mokrych miejscach. Utrzymuj

miejsce pracy dobrze oświetlone. Nie używaj

urządzeń elektrycznych w obecności

łatwopalnych płynów lub gazów.

3. Chroń się przed porażeniem prądu.

Zapobiegaj kontaktom ciała z uziemionymi

powierzchniami (np. rurami, grzejnikami,

kuchenkami, lodówkami).

4. Nie pozwalaj zbliżać się dzieciom

Nie pozwalaj wizytującym osobom dotykać

urządzenia lub przedłużacza. Wszystkie

wizytujące osoby nie powinny zbliżać się do

miejsca pracy.

5. Zachowaj nieczynne urządzenia.

Nieużywane urządzenia powinny być

przechowywane w suchych, wysokich lub

zamykanych miejscach tak, aby były

niedostępne dla dzieci.

6. Nie przeciążaj urządzenia.

Wykona ono pracę lepiej i bezpieczniej, pracując

w sposób, dla którego zostało ono

zaprojektowane.

7. Używaj poprawnego urządzenia.

Nie nadużywaj małych lub dodatkowych

urządzeń do wykonania pracy urządzeń do

dużej pracy. Nie używaj urządzeń do celów, do

których nie zostały przeznaczone; na przykład,

nie używaj piły tarczowej do przecinania gałęzi

lub kłód drzew.

8. Ubierz się odpowiednio

Nie noś luźnych ubrań lub biżuterii. Mogą one

zostać zahaczone o ruchome części. Gumowe

rękawiczki i przeciwpoślizgowe buty są

wskazane przy pracy na dworze. Zaleca się

noszenie ochrony na głowę przytrzymującej

długie włosy.

16

Page 17

9. Użyj okularów ochronnych i ochraniaczy

uszu.

Użyj masek na twarz lub masek

przeciwpyłowych jeżeli czynność cięcia

wytwarza pyły.

10. Podłącz urządzenie usuwające pył.

Jeżeli urządzenia posiadają podłączenia do

urządzeń do usuwania i składowania pyłu,

upewnij się, że są one poprawnie podłączone i

użyte.

11. Uważaj na przewód sieciowy

Nigdy nie noś urządzenia trzymając za przewód i

nie odłączaj go od gniazda przez pociągnięcie

przewodu. Chroń przewód przed ciepłem,

olejem i ostrymi krawędziami.

12. Pewnie mocuj cięte elementy.

Użyj ścisków lub imadła do zamocowania

ciętych elementów. Jest to bezpieczniejsze niż

używanie rąk, a dodatkowo zwalnia obie ręce do

obsługiwania piły.

13. Używając piłę, nie oddalaj jej zbytnio od

siebie.

Cały czas trzymaj dobrze ustawione nogi i

równowagę.

14. Pamiętaj o dobrej konserwacji urządzenia.

Utrzymuj urządzenie ostre i czyste dla jego

lepszego i bezpieczniejszego działania. Wykonaj

podane instrukcje w celu smarowania lub

wymiany elementów wyposażenia. Regularnie

sprawdzaj przewody urządzenia, i jeżeli są

uszkodzone, oddaj je do naprawy do

autoryzowanego serwisu. Regularnie sprawdzaj

przewody przedłużające i wymień je, jeżeli są

uszkodzone. Utrzymuj uchwyty suche, czyste i

nie zabrudzone olejem lub smarem.

15. Odłącz urządzenia

Przed konserwacją urządzenia lub zmianą

wyposażenia takiego jak tarcze, noże do struga i

noże do frezowania, gdy nie jest ono używane.

16. Wyjmij klucze regulacyjne

Nabierz zwyczaju sprawdzania czy klucze

regulacyjne są usunięte z urządzenia przed jego

użyciem.

17. Unikaj przypadkowych uruchomień.

Nie noś podłączonego urządzenia z palcem na

włączniku. Upewnij się, że urządzenie jest

wyłączone, gdy je podłączasz do zasilania.

18. Zastosuj przedłużacz używając urządzenia

na dworze.

Gdy urządzenie używane jest na dworze, stosuj

tylko przedłużacze przeznaczone i oznaczone

do pracy na dworze.

19. Bądź uważny

Patrz co robisz. Bądź rozsądny. Nie używaj

urządzenia, gdy jesteś zmęczony.

20. Sprawdzaj uszkodzone części.

Przed dalszym użyciem urządzenia, osłona lub

inne części, które są uszkodzone, muszą być

uważnie sprawdzone, aby upewnić się, że będą

poprawnie działać i wykonywać przeznaczone

im funkcje. Sprawdzaj ustawienia ruchomych

części, oprawy ruchomych części, pęknięcia

części, zamocowania, i jakiekolwiek inne

warunki, które mogą wpływać na działanie.

Osłona lub inne części, które są uszkodzone,

powinny być naprawione lub wymienione przez

autoryzowany serwis, jeżeli w instrukcji nie

podano inaczej. Uszkodzone przełączniki

powinny być wymienione przez autoryzowany

serwis. Nie używaj urządzenia, jeżeli włącznik

nie może go włączyć lub wyłączyć.

21. Ostrzeżenie

Użycie jakiegokolwiek innego wyposażenia lub

części dodatkowych innych niż zalecane w tej

instrukcji obsługi lub katalogu, może stworzyć

ryzyko uszkodzenia ciała.

22. Naprawy urządzenia powinny być

wykonywane tylko przez specjalistę.

To urządzenie jest wykonane zgodnie z

odpowiednimi zasadami bezpieczeństwa.

Naprawa urządzeń elektrycznych może być

wykonana wyłącznie przez specjalistę, gdyż w

przeciwnym wypadku może ono stanowić

zagrożenie dla użytkownika.

DODATKOWE ZASADY

BEZPIECZEŃSTWA

1. Używaj ochraniaczy uszu.

2. Trzymaj osłony na miejscu i w przeznaczony

do pracy sposób. Nigdy nie klinuj lub

przywiązuj dolnej osłony, tak aby była

otwarta. Sprawdzaj działanie dolnej osłony

przed każdym użyciem. Nie używaj

urządzenia, jeżeli dolna osłona nie zamyka

się szybko na tarczy piły. OSTRZEŻENIE:

Jeżeli piła zostanie upuszczona, dolna osłona

może się skrzywić, uniemożliwiając pełne jej

zamknięcie.

3. Nie używaj tarcz, które są zdeformowane lub

popękane.

4. Nie używaj tarcz szybkotnących ze stali

wysokostopwej.

5. Nie zatrzymuj tarcz przez poprzeczny nacisk

na tarczę piły.

6. Utrzymuj tarcze czyste i ostre. Ostre tarcze,

minimalizują zatrzymania silnika i odbicia

piły.

7. NIEBEZPIECZEŃSTWO:

Trzymaj ręce z dala od miejsca cięcia.

Trzymaj ręce z dala od tarczy piły. Nie sięgaj

rękami pod cięty element w trakcie, gdy

tarcza porusza się. Nie próbuj usunąć

odciętego materiału, gdy tarcza porusza się.

OSTRZEŻENIE: Zaraz po wyłączeniu tarcza

obraca się.

1717

Page 18

8. Podparcie dużych paneli. (Rys.1 i 2)

Duże panele muszą być podparte w sposób

pokazany na rysunku. 1 aby zmniejszyć

ryzyko zaklinowania się tarczy i odbić. Gdy

cięcie wymaga oparcia piły na ciętym

elemencie, piła powinna opierać się na

większej części, zaś mniejsza powinna być

odcinana.

9. Użycie prowadnicy cięcia wzdłużnego

Zawsze używaj prowadnicy cięcia

wzdłużnego lub prowadnicy o prostej

krawędzi do prowadzenia piły, gdy

wykonujesz cięcie wzdłużne.

10. Ochrona przed odbiciami. (Rys.1 i 3)

Odbicia pojawiają się, gdy piła jest nagle

zatrzymana i odbija ją w kierunku operatora.

Natychmiast zwolnij włącznik, gdy tarcza

zakleszczy się lub piła zatrzyma się. Utrzymuj

tarcze ostre. Podpieraj duże panele w sposób

pokazany na rys. 1.

Używaj prowadnicy cięcia wzdłużnego lub

prowadnicy o prostej krawędzi do

prowadzenia piły, gdy wykonujesz cięcie

wzdłużne. Nie przeciążaj urządzenia. Bądź

uważny naucz się opanowania. Nie wyjmuj

piły z ciętego elementu w trakcie cięcia, gdy

tarcza porusza się.

NIGDY nie umieszczaj rąk ani palców poza

piłą. Jeżeli wystąpi odbicie, piła może

skoczyć do tyłu nad twoją ręką, mogąc Cię

poważnie ranić.

11. Dolna osłona.

Podnieś dolną osłonę używając uchwytu

samo- powracającego.

12. Ustawienia.

Przed rozpoczęciem cięcia upewnij się, że

głębokość jak i kąt cięcia ukośnego są

pewnie nastawione.

13. W zamocowaniu instaluj tylko odpowiednie

tarcze.

Nie używaj tarcz z nieodpowiednimi

otworami. Nigdy nie używaj uszkodzonych

lub nieodpowiednich śrub ani podkładek do

tarcz.

14. Unikaj cięcia gwoździ.

Sprawdź i usuń wszystkie gwoździe z drzewa

przed cięciem.

15. Trzymaj przewód z dala od miejsca cięcia i

umieść go tak, aby nie został zahaczony

przez cięty element w trakcie używania piły.

Używaj piły stosując jej odpowiednie

trzymanie, odpowiednie podparcie ciętego

elementu i zapewnij miejsce na przewód z

dala od miejsca pracy.

OSTRZEŻENIE:

Ważne jest, aby poprawnie podeprzeć cięty

element i mocno trzymać piłę, aby nie stracić

nad nią kontroli i nie spowodować

uszkodzenia ciała. Rys. 4 pokazuje typowy

sposób trzymania piły.

16. Umieść szerszą część podstawy piły na

części ciętego elementu, który jest mocno

podparty, a nie na części, która spadnie, gdy

cięcie zostanie wykonane.

Jako przykład, rys. 5 pokazuje POPRAWNY

sposób cięcia końca deski, zaś rys. 6

NIEPOPRAWNY sposób. Jeżeli cięty element

jest krótki lub mały, umocuj go ściskami. NIE

WOLNO TRZYMAĆ RĘKĄ KRÓTKICH

ELEMENTÓW! (Rys. 6)

17. Nigdy nie próbuj ciąć piłą tarczową trzymając

ją w imadle do góry nogami. Jest to bardzo

niebezpieczne i może doprowadzić do

ciężkich wypadków. (Rys. 7)

18. Przed położeniem urządzenia po wykonaniu

cięcia, upewnij się, że dolna (teleskopowa)

osłona zamknęła się i, że tarcza zatrzymała

się zupełnie.

19. Użycie danych producenta

• Upewnij się, że średnica, grubość i inne

charakterystyki tarczy są odpowiednie dla

tego urządzenia.

• Upewnij się, że tarcza jest odpowiednia dla

prędkości obrotowej urządzenia.

20. Nie używaj tarczy ściernych.

ZACHOWAJ TÊ INSTRUKCJÊ.

INSTRUKCJA OBSŁUGI

Wyjmowanie i instalowanie tarczy.

Następujące tarcze mogą być użyte w tym

urządzeniu.

Max.

średn.

190 mm 170 mm

Grubość klina rozszczepiającego wynosi 1,8mm.

OSTRZEŻENIE:

• Nie używaj tarcz, które nie spełniają charakterystyk

określonych w tej instrukcji.

• Nie używaj tarcz, których dysk jest grubszy lub,

których zestaw, jest mniejszy niż grubość klina

rozszczepiającego.

Aby wyjąć tarczę, obniż do końca blokadę wałka,

aby zablokować jego obracanie się, a następnie użyj

klucza inubs, aby poluźnić śrubę z łbem

gniazdowym sześciokątnym. (Rys. 8)

Teraz wyjmij kołnierz zewnętrzny, unieś pokrywę

ochronną na tyle na ile jest to możliwe i wyjmij

tarczę. (Rys. 9)

Zainstaluj tarczę wykonując powyższe czynności w

odwrotnej kolejności. W podanej kolejności

zainstaluj kołnierz wewnętrzny, tarczę, kołnierz

zewnętrzny i śrubę z łbem gniazdowym

sześciokątnym. Upewnij się, ze śruba z łbem

gniazdowym sześciokątnym jest mocno przykręcona

pamiętając o pełnym obniżeniu blokady wałka.

(Rys. 10)

Min.

średn.

Średn.

otworu.

20 mm

lub

30 mm

Grubość

tarczy

Mniej

niż

1,7 mm

Nacięcia

Więcej

niż

1,9 mm

1818

Page 19

OSTRZEŻENIE:

• Upewnij się, że zęby tarczy wskazują ten sam

kierunek do przodu co kierunek obracania się

tarczy (strzałka na tarczy powinna wskazywać ten

sam kierunek co strzałka na urządzeniu).

• Kołnierz wewnętrzny ma na jednej stronie średnicę

30mm, a na drugiej 20mm. Strona o średnicy

20 mm jest oznaczona przez “20” . Użyj

poprawnej strony dla średnicy otworu tarczy, którą

chcesz używać. Zamocowanie tarczy na złej

stronie może spowodować niebezpieczne drgania.

• Używaj tylko klucza inbus Makita do wyjmowania i

instalowania tarczy.

Ustawienie klina rozszczepiającego (Rys. 11)

Użyj klucza unbus do poluźnienia śruby z łbem

gniazdowym sześciokątnym a następnie unieś

pokrywę ochronną. Przesuń klin rozszczepiający do

góry lub do dołu nad dwoma karbami, aby wykonać

ustawienia pokazane na ilustracji tak, aby otrzymać

poprawną odległość pomiędzy klinem

rozszczepiającym a tarczą.

OSTRZEŻENIE:

Upewnij się, że klin rozszczepiający jest ustawiony w

taki sposób, że:

Dystans pomiędzy klinem rozszczepiajacym, a

zębatym obrzeżem piły nie jest większy niż 5 mm.

Zębate obrzeże piły nie powinno wychodzić ponad

dolną krawędź klina rozszczepiającego więcej niż

5 mm.

Ustawienie głębokości cięcia (Rys. 12)

Rozluźnij dźwignię w prowadnicy głębokości i

przesuń podstawę do góry lub do dołu. Na żądanej

głębokości cięcia, zamocuj bazę zaciskając

dźwignię.

OSTRZEŻENIE:

• Użyj płytkiej głębokości cięcia przy przecinaniu

cienkich elementów dla czystszego i

bezpieczniejszego cięcia.

• Po ustawieniu głębokości cięcia, zawsze pewnie

zaciśnij dźwignię.

Ustawienie cięcia skośnego (Rys. 13)

Poluźnij śrubę skrzydełkową na przedzie i na tyle i

skręć urządzenie do żądanego kąta cięcia skośnego.

(0°– 45°). Upewnij się, że śruby skrzydełkowe z

przodu i z tyłu są dobrze zakręcone, po wykonaniu

ustawienia.

Celowanie (Rys.14)

Dla prostych cięć, ustaw prawe wycięcie na przedzie

podstawy z linią cięcia na elemencie. Dla cięć

skośnych 45°, ustaw lewe wycięcie.

Funkcje włącznika (Rys. 15)

Aby zapobiec przypadkowemu wysunięciu się

języka włącznika, zainstalowano przycisk blokady

wyłączania. Aby uruchomić urządzenie, naciśnij

przycisk blokady wyłączania i wciśnij język

włącznika. Zwolnij język włącznika, aby zatrzymać

urządzenie.

OSTRZEŻENIE:

Przed podłączeniem urządzenia, zawsze upewnij

się, że język włącznika poprawnie powraca do

pozycji “OFF” (Wył.), gdy zostanie zwolniony.

Obsługa piły (Rys. 16)

Trzymaj piłę pewnie. Ustaw piłę na elemencie do

cięcia tak, aby tarcza nie dotykała elementu.

Następnie włącz urządzenie i zaczekaj dopóki tarcza

nie osiągnie pełnej prędkości. Teraz, przesuń

urządzenie do przodu po powierzchni elementu,

trzymając je płasko i przesuwając płynnie dopóki

cięcie nie zostanie zakończone. Aby uzyskać czyste

cięcie, trzymaj prostą linię cięcia i jednakową

prędkość przesuwania.

OSTRZEŻENIE:

• Klin rozszczepiający powinien być zawsze

używany, z wyjątkiem, gdy piła wprowadzana jest

w środku ciętego elementu.

• Nie zatrzymuj tarczy przez poprzeczny nacisk na

tarczę piły.

Prowadnica krawędziowa (Rys.17)

Poręczna prowadnica krawędziowa umożliwia

bardzo dokładne proste cięcia. Po prostu przesuń

prowadnicę krawędziową dokładnie do strony

ciętego elementu, a następnie umocuj ją w tej

pozycji przy pomocy śruby na przedzie podstawy.

Umożliwia ona również wielokrotne cięcia o tej

samej grubości.

Montaż złącza (Rys.18 i19)

(dla podłączenia odkurzacza)

Gdy wymagane jest czyste cięcie, podłącz

odkurzacz do urządzenia. Zainstaluj złącze w

urządzeniu używając śrubokrętu. Następnie, podłącz

rurę odkurzacza do złącza.

KONSERWACJA

OSTRZEŻENIE:

Zawsze upewnij się, ze urządzenie jest wyłączone i

odłączone od zasilania przed wykonywaniem

jakichkolwiek prac nad urządzeniem.

Wymiana szczoteczek węglowych (Rys. 20i 21)

Wymień szczoteczki węglowe, gdy są starte do

wskaźnika limitu. Dwie takie same szczoteczki

węglowe powinny być wymienione w tym samym

czasie.

Aby zapewnić bezpieczeństwo i niezawodność

produktu, naprawy i konserwacje lub ustawianie

powinno być wykonywane przez autoryzowany

serwis Makita.

1919

Page 20

Typowe A-ważone poziomy szumów

poziom ciśnienia dźwięku: 98 dB (A).

poziom dźwięku w trakcie pracy: 111 dB (A).

Typowa wartość ważonej średniej kwadratowej

przyspieszenia nie jest większa niż 2,5 m/s

- Noś ochraniacze uszu. -

2

.

UE-DEKLARACJA ZGODNOŚCI

Oświadczamy, biorąc za to wyłączną

odpowiedzialność, że niniejszy wyrób jest

zgodny z następującymi standardami i

standardowymi dokumentami:

HD400, EN50144, EN55014, EN61000,

zgodnie z Zaleceniami Rady: 73/23/EEC,

89/336/EEC i 98/37/EC.

Szumy i drgania

Yasuhiko Kanzaki

Dyrektor

MAKITA INTERNATIONAL EUROPE LTD

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

2020

CE 2000

.

Page 21

РУССКИЙ ЯЗЫК

Объяснения общего плана

1 Во избежание отдачи

закрепите доску или

панель возле резки.

2 Не закрепляйте доску или

панель вдалеке от резки.

3 Типичный рисунок для

правильного упора руки и

крепления рабочего

изделия.

4 Торцовый гаечный ключ

5 Фиксатор оси

6 Завинтите

7 Развинтите

8 Лезвие пилы

9 Внешний фланец

10 Внутренний фланец

11 Болт с шестигранной

головкой

12 Установка выступов

13 Болт с шестигранной

головкой

(Для регулировки

раскалывающего ножа)

14 Глубина резки

ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ

Модель 5704R

Диаметр лезвия ............................................ 190 мм

Макс. глубина резки

При 90° ......................................................... 66 мм

При 45° ......................................................... 46 мм

Скорость в незагруженном

состоянии (мин

Общая длина ................................................ 345мм

Масса нетто .....................................................4,6 кг

• Вследствие нашей продолжающейся программы

поиска и разработок технические

характеристики могут быть изменены без

уведомления.

• Примечание: Технические характеристики могут

различаться в зависимости от страны.

Предназначенное использование

Этот инструмент предназначен для выполнения

продольной и поперечной прямой резки и

наклонной резки под уголом до 45° в дереве при

плотном контакте с рабочим изделием.

Источник питания

Инструмент должен быть подсоединен только к

источнику питания с напряжением, указанным в

табличке номиналов, и может функционировать

только от однофазного источника питания

переменного тока. В соответствии с Европейским

стандартом имеется двойная изоляция,

следовательно, возможно использование с

розетками без провода заземления.

-1

) .............................................4900

15 Рычаг

16 Винт с накатанной

головкой

17 Для 45°°°° наклонной резки

18 Для прямой резки

19 Опорная плита

20 Кнопка фиксации

21 Пусковой механизм

22 Пылесос

23 Ограничительной метки

24 Крышка держателя щеток

25 Отвертка

ИНСТРУКЦИИ ПО МЕРАМ

БЕЗОПАСНОСТИ

Предостережение! При использовании

электрических инструментов следует всегда

соблюдать основные меры безопасности для

уменьшения опасности пожара, поражения

электрическим током и персональных травм,

включая следующие.

Прочитайте эти инструкции перед тем, как

пытаться управлять этим изделием, и

сохраните эти инструкции.

Для безопасного функционирования:

1. Поддерживайте чистоту на рабочем месте

Захламленные места и подставки могут

привести к травмам.

2. Учитывайте рабочую окружающую среду

Не подвергайте инструменты с

электроприводом воздействию дождя. Не

используйте инструменты с электроприводом в

сырых или влажных местах. Поддерживайте

хорошее освещение на рабочем месте. Не

используйте инструменты с электроприводом в

присутствии возгораемых жидкостей или газов.

3. Предохраняйтесь от поражения

электрическим током

Предотвращайте контакт тела с заземленными

поверхностями (например, трубами,

радиаторами, батареями, холодильниками).

4. Держитесь подальше от детей

Не позволяйте посетителям прикасаться к

инструменту или шнуру-удлинителю. Все

посетители должны находиться подальше от

рабочей области.

5. Правильно храните неработающие

инструменты

Если инструменты не используются, они

должны храниться в сухом, высоком или

закрытом месте, вне достижения детей.

6. Не прилагайте усилие к инструменту

Он будет выполнять работу лучше и

безопаснее при скорости, для которой он

предназначен.

212121

Page 22

7. Используйте правильный инструмент

Не пытайтесь прилагать усилие к маленьким

инструментам или присоединениям для

выполнения работы инструмента тяжелого

назначения. Не используйте инструменты

для непредназначенных целей; например, не

используйте дисковую пилу для резки веток

или корней деревьев.

8. Одевайтесь правильно

Не одевайте свисающую одежду или

украшения. Они могут попасть в движущиеся

части. При работе на улице рекомендуется

одевать резиновые перчатки и нескользящую

обувь. Одевайте предохранительный

головной убор для убирания длинных волос.

9. Используйте защитные очки и

предохранительные приборы для слуха.

Если работа по резке является пыльной,

используйте также маску для лица или

пылезащитную маску

10. Подсоедините пылевсасывающее

оборудование

Если имеются подсоединения устройств для

всасывания и сбора пыли, убедитесь в том,

что они подсоединены и используются

правильно.

11. Не прилагайте усилие к шнуру

Никогда не носите инструмент за шнур и не

дергайте за него для отсоединения его из

розетки. Держите шнур подальше от жарких

мест, масла и острых краев.

12. Закрепите рабочее изделие

Используйте зажимы или тиски для

крепления рабочего изделия. Это является

более безопасным, чем использование

Вашей руки, и при этом освобождаются две

руки для управления инструментом.

13. Не заходите слишком далеко

Сохраняйте правильную стойку и баланс все

время.

14. Осторожно обращайтесь с инструментами

Держите инструменты острыми и чистыми для

более лучшей и безопасной работы. Следуйте

инструкциям для смазки и смены

принадлежностей. Периодически проверяйте

шнуры инструмента, и, если они повреждены,

обращайтесь относительно ремонта в

уполномоченный центр по техобслуживанию.

Периодически проверяйте шнуры-удлинители

и заменяйте, если они повреждены. Держите

ручки сухими чистыми и свободными от масла

или смазки.

15. Отсоединяйте инструменты

Если не используются, перед

техобслуживанием, и при смене

принадлежностей, таких, как лезвия, резцы и

резаки.

16. Убирайте регулировочные ключи и

гаечные ключи

Сформируйте привычку проверять, что

регулировочные ключи и гаечные ключи

убраны с инструмента перед его

включением.

17. Избегайте случайных запусков

Не носите подсоединенный к сети инструмент

с пальцем, находящемся на переключателе.

Перед подсоединением инструмента к сети

убедитесь, что переключатель находится в

положении “выкл”.

18. Шнуры-удлинители для использования на

улице

Когда инструмент используется на улице,

используйте только шнуры-удлинители,

предназначенные для использования на

улице с указанием этого.

19. Будьте бдительны

Наблюдайте за тем, что Вы делаете.

Используйте разумный подход. Не

управляйте инструментом, если Вы устали.

20. Проверяйте поврежденные части

Перед дальнейшим использованием

инструмента, предохранитель или другая

часть должны быть тщательно проверены

для определения того, что они будут

функционировать правильно и выполнять

предназначенную функцию. Проверьте на

предмет совмещения движущихся частей,

соединения движущихся частей, поломки

частей, монтажа и других условий, которые

могут повлиять не их функционирование.

Предохранитель или другая часть должны

быть правильно отремонтированы или

заменены в уполномоченном центре по

техобслуживанию, если только не указано

другое в этой инструкции по эксплуатации.

Дефектные переключатели должны быть

заменены в уполномоченном центре по

техобслуживанию. Не используйте

инструмент, если невозможно его включение

и выключение с помощью переключателя.

21. Предостережение

Использование любой другой принадлежности

или присоединения, отличного от

рекомендуемого в этой инструкции по

эксплуатации или каталоге, может привести к

опасности персональной травмы.

22. Используйте для ремонта услуги

специалиста

Это электрическое оборудование

соответствует относящимся к нему правилам

безопасности. Ремонт электрического

оборудования может проводиться только

специалистами, в противном случае, он может

вызвать существенную опасность для

пользователя.

222222

Page 23

ДОПОЛНИТЕЛЬНЫЕ ПРАВИЛА

БЕЗОПАСНОСТИ

1. Одевайте предохранительные приборы

для слуха.

2. Держите предохранители на месте и в

рабочем порядке.

Никогда не закрепляйте и не

привязывайте нижний предохранитель в

открытом состоянии. Проверяйте работу

нижнего предохранителя перед каждым

использованием. Не используйте, если

нижний предохранитель не закрывается

быстро над лезвием пилы.

ПРЕДУПРЕЖДЕНИЕ: Если Вы уронили

пилу, нижний предохранитель может

изогнуться, затрудняя полные повороты.

3. Не используйте лезвия, которые

деформированы или расколоты.

4. Не используйте лезвия из

высокоскоростной стали.

5. Не останавливайте лезвия путем

горизонтального давления на лезвие

пилы.

6. Держите лезвия чистыми и острыми.

Острые лезвия уменьшают застревание и

отдачу.

7. ОПАСНО:

Держите руки подальше от области резки.

Держите руки подальше от лезвий. Не

касайтесь низа изделя во время вращения

лезвия. Не пытайтесь удалять отрезанный

материал во время движения лезвия.

ПРЕДУПРЕЖДЕНИЕ: Лезвия движутся

после выключения.

8. Закрепите большие панели. (Рис. 1 и 2)

Большие панели должны быть

закреплены, как показано на рис. 1 для

уменьшения опасности прищемления

лезвия и отдачи.

Когда операция резки требует, чтобы пила

находилась на рабочем изделии, пила

должна находиться на большем куске, а

меньший кусок срезается.

9. Используйте разборное заграждение.

Всегда используйте заграждение или

предохранитель с прямыми краями при

продольной резке.

10. Предохранитель против отдачи (Рис. 1 и 3)

Отдача происходит, если пила быстро

застревает и перемещается назад по

направлению к оператору. Если лезвие

изгибается, или пила застревает,

немедленно высвободите переключатель.

Держите лезвия острыми. Закрепите

большие панели, как показано на рис. 1.

Используйте заграждение или

предохранитель с прямыми краями при

продольной резке. Не прикладывайте

усилие к инструменту. Будьте бдительны

– контролируйте работу. Не вынимайте

пилу из изделия во время резки, когда

движется лезвие.

НИКОГДА не помещайте Вашу руку или

пальцы позади пилы. Если произойдет

отдача, пила может легко прыгнуть назад

сверху Вашей руки, причинив, возможно,

тяжелую травму.

11. Нижний предохранитель.

Поднимите нижний предохранитель с

помощью выдвигающейся ручки.

12. Регулировки.

Перед выполнением резки убедитесь в

том, что регулировки глубины и наклона

являются точными.

13. При монтаже используйте только

правильные лезвия.

Не используйте лезвия с неправильным

размером отверстий. Никогда не

используйте дефектные или неправильные

шайбы или болты для лезвий.

14. Избегайте резки гвоздей.

Проверьте наличие и удалите все гвозди

из пиломатериалов перед резкой.

15. Во время управления пилой держите

шнур подальше от области резки и

расположите его так, чтобы он не попал

на рабочее изделие во время операции

резки. Управляйте с правильным упором

руки, правильным креплением рабочего

изделия и шнуром питания, проходящим

подальше от рабочей области.

ПРЕДОСТЕРЕЖЕНИЕ:

Важно правильно закрепить рабочее

изделие и плотно держать пилу для

предотвращения потери контроля,

который может привести к персональной

травме. На рис.4 показан типичный упор

руки на пилу.

16. Разместите более широкий участок основы

пилы на части рабочего изделия, которая

сильно закреплена, а не на секции,

которая упадет после выполнения резки.

Например, на рис. 5 показан ПРАВИЛЬНЫЙ

метод обрезания конца доски, а на рис. 6

показан НЕПРАВИЛЬНЫЙ метод. Если

рабочее изделие является коротким или

маленьким, зажмите его. НЕ ПЫТАЙТЕСЬ

ДЕРЖАТЬ КОРОТКИЕ КУСКИ РУКОЙ!

(Рис. 6)

232323

Page 24

17. Никогда не пытайтесь распиливать

дисковой пилой, держа её вверх дном и в

тисках. Это является очень опасным и

может привести к серьезным

происшествиям. (Рис. 7)

18. Перед снятием инструмента по окончании

резки, следует убедиться, что нижний

(телескопический) предохранитель

закрыт, и лезвие полностью остановлено.

19. Используйте данные производителя

• Убедитесь в том, что диаметр, толщина и

другие характеристики лезвия пилы

являются подходящими для

инструмента.

• Убедитесь в том, что лезвие пилы

является подходящим для скорости

вращения инструмента.

20. Не используйте никакие абразивные

диски.

СОХРАНИТЕ ЭТИ ИНСТРУКЦИИ.

ИНСТРУКЦИЯ ПО ЭКСПЛУАТАЦИИ

Удаление или установка лезвия пилы

С этим инструментом возможно использование

следующего лезвия.

Макс.

диаметр

190 мм 170 мм

Толщина раскалывающего ножа 1,8мм.

ПРЕДУПРЕЖДЕНИЕ:

• Не используйте лезвия пилы, которые не

соответствуют характеристикам, заданным в

этой инструкции.

• Не используйте лезвия пилы, диск которых

толще, или развод которых меньше, чем

толщина раскалывающего ножа.

Для удаления лезвия пилы, высвободите

фиксатор оси полностью для предотвращения

вращения оси, затем используйте торцовый

гаечный ключ для развинчивания болта с

шестигранной головкой. (Рис. 8)

Сейчас удалите внешний фланец, поднимите

защитную крышку, как можно выше, и удалите

лезвие пилы. (Рис.9)

Установите лезвие пилы, используя процедуру,

обратную удалению. Установите внутренний

фланец, лезвие пилы, внешний фланец и болт с

шестигранной головкой, в этом порядке. Следует

надежно зафиксировать болт с шестигранной

головкой. (Рис.10)

Мин.

диаметр

Диаметр

отверстия

20 мм

или

30 мм

Толщин

а лезвия

Менее

чем

1,7 мм

Пропил

Более

чем

1,9 мм

ПРЕДУПРЕЖДЕНИЕ:

• Убедитесь в том, что зубья лезвия направлены

в том же направлении, что и вращение

инструмента (стрелка на лезвии должна быть

направлена в том же направлении, что и

стрелка на инструменте.)

• Внутренний фланец имеет диаметр 30 мм с

одной стороны и диаметр 20 мм с другой.

Сторона с диаметром 20 мм промаркирована

как “20”. Используйте правильную сторону для

диаметра отверстия лезвия, которое Вы

намерены использовать. Монтаж лезвия на

неправильной стороне может привести к

опасной вибрации.

• Используйте только торцовый гаечный ключ

Makita для удаления или установки лезвия.

Регулировка раскалывающего ножа (Рис. 11)

Используйте торцовый гаечный ключ для

развинчивания болта с шестигранной головкой

для регулировки раскалывающего ножа, затем

поднимите защитную крышку. Переместите

раскалывающий нож вверх или вниз над двумя

выступами для установок, указанных на рисунке

так, чтобы получить правильное соответствие

между раскалывающим ножом и лезвием пилы.

ПРЕДУПРЕЖДЕНИЕ:

Убедитесь в том, что раскалывающий нож

подрегулирован так, что:

Расстояние между раскалывающим ножом и

зубчатым краем лезвия пилы составляет не

более чем 5 мм. Зубчатый край не простирается

более чем на 5 мм ниже нижнего края

раскалывающего ножа.

Регулировка глубины резки (Рис.12)

Развинтите рычаг на направляющей глубины и

переместите основу вверх или вниз. На

желаемой глубине резки зафиксируйте основу,

завинтив рычаг.

ПРЕДУПРЕЖДЕНИЕ:

• Используйте небольшую глубину резки при

разрезании тонкого рабочего изделия с целью

более чистой безопасной резки.

• После регулировки глубины резки всегда

надежно завинчивайте рычаг.

Регулировка для наклонной резки (Рис. 13)

Развинтите винты с накатанной головкой

спереди и сзади и наклоните инструмент на

желаемый угол для наклонной резки (0°–45°).

После выполнения регулировки надежно

зафиксируйте винты с накатанной головкой

спереди и сзади.

Визирование (Рис.14)

Для прямой резки совместите правую выемку на

передней стороне основы с Вашей линией резки

на рабочем изделии. Для наклонной резки 45°

совместите с ней левую выемку.

242424

Page 25

Действие переключения (Рис.15)

Для предотвращения случайного нажатия

пускового механизма имеется кнопка фиксации.

Для запуска инструмента высвободите кнопку

фиксации и нажмите пусковой механизм.

Высвободите пусковой механизм для остановки.

ПРЕДУПРЕЖДЕНИЕ:

Перед подсоединением инструмента всегда

проверяйте, чтобы видеть, что пусковой

механизм действует правильно и возвращается в

положение “OFF” (выкл.) при высвобождении.

Управление (Рис. 16)

Держите инструмент крепко. Установите

опорную плиту на рабочее изделие для резки без

контакта с лезвием. Затем включите инструмент

и подождите до тех пор, пока лезвие не наберет

полную скорость. Сейчас просто переместите

инструмент над поверхностью рабочего изделия,

сохраняя его в горизонтальном положении и

продвигая плавно до тех пор, пока не завершено

распиливание. Для получения чистых срезов

сохраняйте прямую линию распиливания и

постоянную скорость продвижения.

ПРЕДУПРЕЖДЕНИЕ:

• Всегда должен использоваться

раскалывающий нож, за исключением

погружения в середину рабочего изделия.

• Не останавливайте лезвие пилы путем

горизонтального давления на диск.

Направляющая линейка (Рис. 17)

Удобная направляющая линейка позволяет Вам

выполнять сверхаккуратные прямые срезы.

Просто сдвиньте направляющую линейку,

прижав её к стороне рабочего изделия и

зафиксируйте её в положении с помощью болта

спереди основы. Это также делает возможным

выполнение повторных одинаковых срезов.

Сборка соединения (Рис. 18 и19)

(для подсоединения пылесоса)

Если Вы хотите выполнить чистую операцию

резки, подсоедините пылесос к Вашему

инструменту. Подсоедините соединение к

инструменту, используя винт. Затем

подсоедините шланг пылесоса к соединению.

ОБСЛУЖИВАНИЕ

ПРЕДУПРЕЖДЕНИЕ:

Всегда проверяйте, что инструмент выключен и

отсоединен перед выполнением любой работы с

инструментом.

Замена угольных щеток (Рис. 20 и21)

Заменяйте угольные щетки, когда они износятся

до предельного значка. Обе одинаковые

угольные щетки следует заменять

одновременно.

Для поддержания безопасности и долговечности

изделия, ремонт, уход и регулировка должна

проводиться в уполномоченном центре по

техобслуживанию Makita.

252525

Page 26

Типичные А-взвешенные уровни шума составляют

уровень звукового давления 98 дБ (А).

уровень звуковой мощности 111 дБ (А).

Типичная взвешенное значение квадратного корня

ускорения составляет не более чем 2,5 м/с

– Надевайте защиту для слуха. –

2

.

ЕС ДЕКЛАРАЦИЯ СООТВЕТСТВИЯ

Мы заявляем под свою собственную

ответственность, что этот продукт находится в

соответствии со следующими стандартами или

документами по стандартизации:

HD400, EN50144, EN55014, EN61000,

согласно сборникам директив 73/23EEC,

89/336/EEC и 98/37EC.

Шум и вибрация

262626

Ясухико Канзаки

Директор

MAKITA INTERNATIONAL EUROPE LTD

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

CE 2000

.