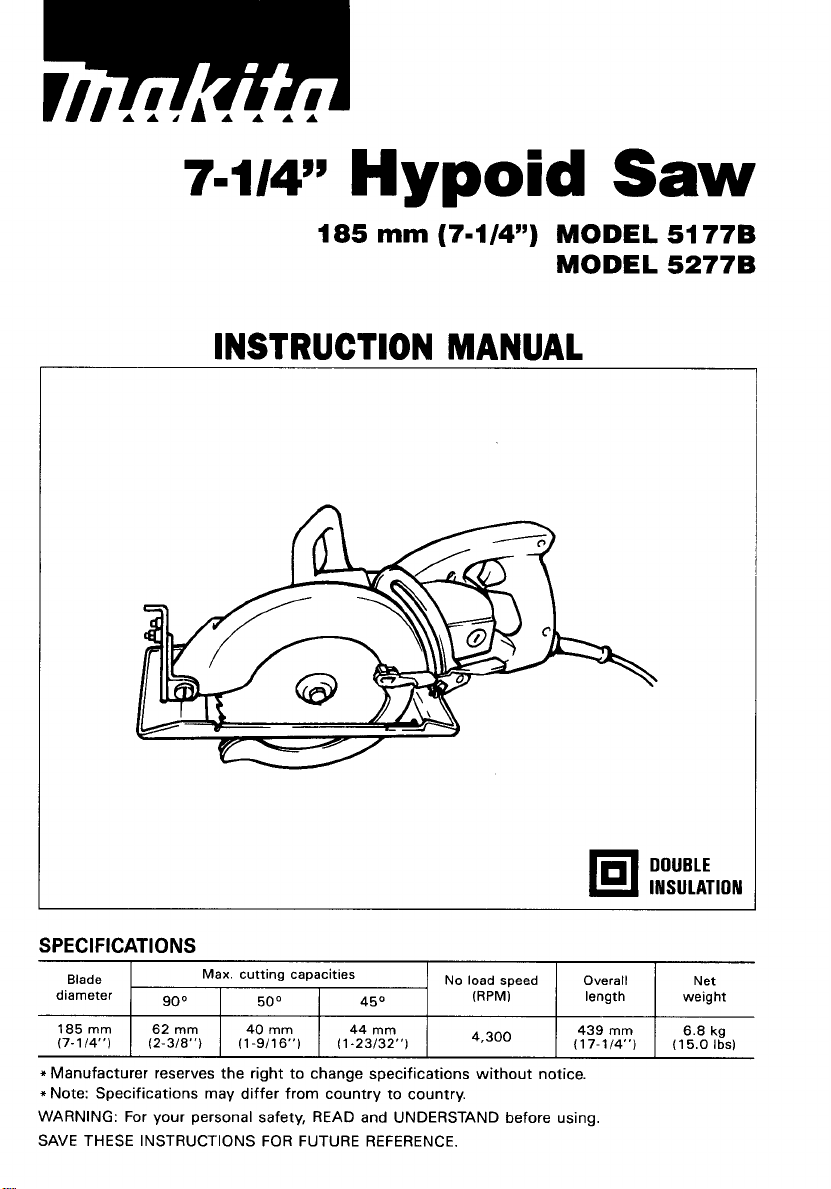

Makita 5177B, 5277B User guide

7-iw

Hypoid

185

mm

(7-1/4”)

INSTRUCTION MANUAL

Saw

MODEL

MODEL

51778

52778

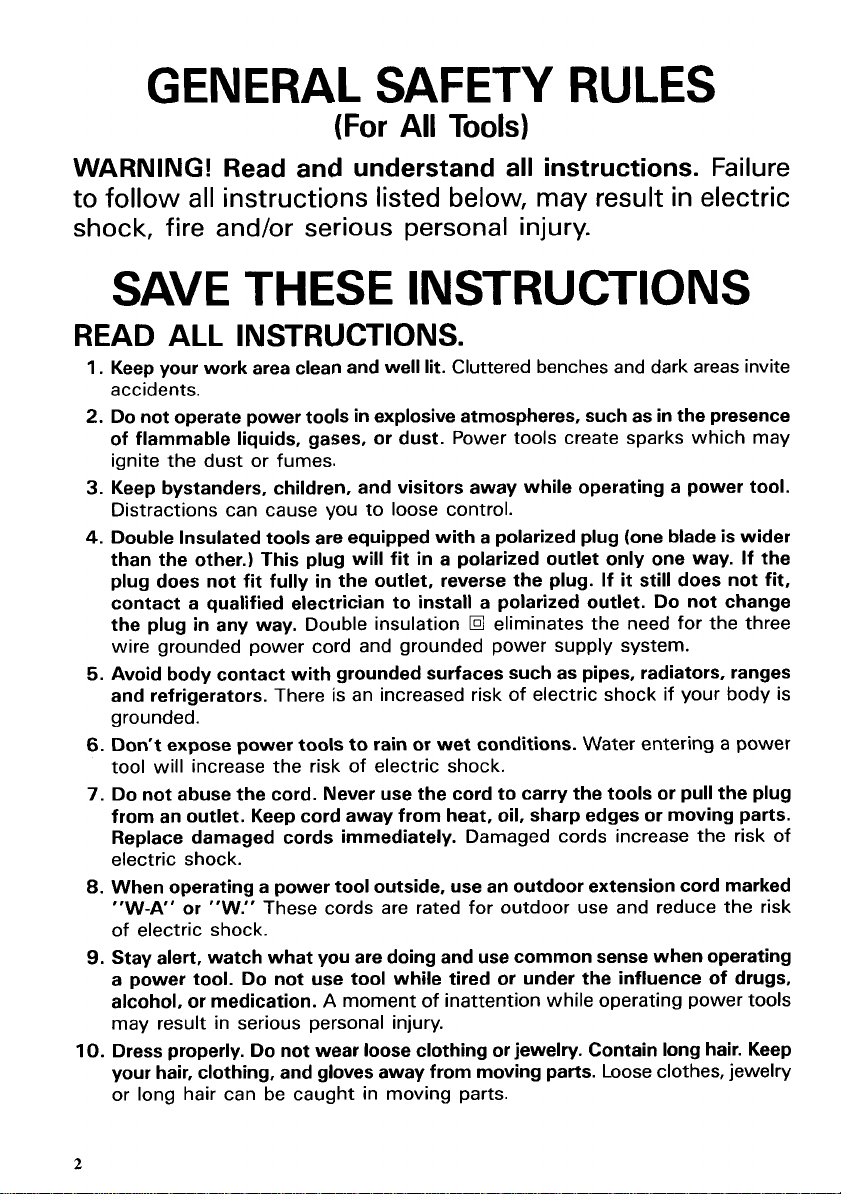

Blade

diameter

185

mm

(7-1/4”)

Max. cutting capacities

I

50’ 450

mm

62

(2-3/8”) (1-9/16”) 11-23/32

40

mm

44

mm,,

No

load speed Overall Net

(RPM)

)

4,300

length weight

439

mm

(17-1/4“) (15.0

6.8

kg

Ibs)

GENERAL

SAFETY

RULES

(For

WARNING! Read and understand

to

follow

all

instructions listed below,

All

Tools)

all

instructions.

may

result

in

electric

shock, fire and/or serious personal injury.

SAVE THESE

READ ALL

1.

Keep your work area clean and well

accidents.

2.

Do not operate power tools

of flammable liquids, gases, or dust. Power tools create sparks which may

ignite the dust or fumes.

3.

Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause

4.

Double Insulated tools are equipped with a polarized plug (one blade is wider

than the other.) This plug will

plug does not

contact a qualified electrician to install a polarized outlet. Do not change

the plug

wire grounded power cord and grounded power supply system.

5.

Avoid body contact with grounded surfaces such as pipes, radiators, ranges

and refrigerators. There

grounded.

6.

Don't expose power tools to rain or wet conditions. Water entering a power

tool

will

7

Do not abuse the cord. Never use the cord to carry the tools or pull the plug

from an outlet. Keep cord away from heat, oil, sharp edges or moving parts.

Replace damaged cords immediately. Damaged cords increase the risk of

electric shock.

8.

When operating a power tool outside, use an outdoor extension cord marked

"W-A'

of electric shock.

9.

Stay alert, watch what you are doing and use common sense when operating

a power tool. Do not use tool while tired or under the influence of drugs,

alcohol, or medication.

may result in serious personal injury.

IO.

Dress properly.

your hair, clothing, and gloves away from moving parts. Loose clothes, jewelry

or long hair can be caught in moving parts.

INSTRUCTIONS.

you

fit

fully in the outlet, reverse the plug. If

in

any way. Double insulation H eliminates the need for the three

is

increase the risk of electric shock.

or "W." These cords are rated for outdoor use and reduce the risk

A

moment of inattention while operating power tools

Do

not wear loose clothing or jewelry. Contain long hair. Keep

INSTRUCTIONS

lit.

Cluttered benches and dark areas invite

in

explosive atmospheres, such as

to loose control.

fit

in a polarized outlet only one way. If the

an increased risk of electric shock if your body is

in

the presence

it

still does not

Failure

fit,

11.

Avoid accidental starting. Be sure switch is off before plugging

tools with your finger on the switch or plugging in tools that have the switch

on invites accidents.

12. Remove adjusting keys or switches before turning the tool on. A wrench or

a key that is left attached to a rotating part of the tool may result in personal

injury.

Do

13.

14.

15. Use clamps or other practical way to secure and support the workpiece to

16. Do not force tool. Use the correct tool for your application. The correct tool

17. Do not use tool if switch does not turn

18.

19.

20.

21.

22.

23.

24.

not overreach. Keep proper footing and balance at all times. Proper footing

and balance enables better control

Use safety equipment. Always wear eye protection. Dust mask, non-skid

safety shoes, hard hat, or hearing protection must be used for appropriate

conditions.

a stable platform. Holding the work by hand or against your body is unstable

loss

and may lead to

will

do the job better and safer at the rate for which

be controlled with the switch is dangerous and must be repaired.

Disconnect the plug from the power source before making any adjustments,

changing accessories, or storing the tool. Such preventive safety measures

reduce the risk of starting the tool accidentally.

Store idle tools out of reach of children and other untrained persons. Tools

are dangerous in the hands of untrained users.

Maintain tools with care. Keep cutting tools sharp and clean. Properly

maintained tools, with sharp cutting edges are less likely to bind and are easier

to control.

Check for misalignment or binding of moving parts, breakage of parts, and

any other condition that may affect the tools operation. If damaged, have

the tool service before using. Many accidents are caused by poorly maintained

tools.

Use only accessories that are recommended by the manufacturer for your

model. Accessories that may be suitable for one tool, may become hazardous

when used on another tool.

Tool

service must be performed only by qualified repair personnel. Service

or maintenance performed by unqualified personnel could result in a risk of

injury.

When servicing a tool, use only identical replacement parts.

tions in the Maintenance section

or failure

injury.

to

follow

of control.

Maintenance Instructions may create a risk

of

the tool in unexpected situations.

it

is

it

on or off. Any tool that cannot

of

this manual.

Use

of

in.

Carrying

designed.

Follow

unauthorized parts

of

electric shock or

instruc-

3

Specific Safety Rules

1.

DANGER! Keep hands away from cutting area and blade. Keep your second

hand on auxiliary handle, or motor housing. If both hands are holding the

saw, they cannot be cut by the blade.

Keep your body positioned to either side of the saw blade, but not

with

the saw blade. KICKBACK could cause the saw to jump backwards. (See

"Causes and Operator Prevention of Kickback")

Do not reach underneath the work while blade is rotating. The guard can

not protect you from the blade below the work. Don't attempt to remove cut

material when blade is moving.

CAUTION: Blades coast after turn off.

2.

Check lower guard for proper closing before each use. Do not operate saw

if lower guard does not move freely and close instantly. Never clamp or tie

the lower guard into the open position. If saw is accidentally dropped, lower

guard may be bent. Raise the lower guard with the Retracting Handle and make

sure

it

moves freely and does not touch the blade or any other part, in all angles

and depths of cut.

3.

Check the operation and condition of the lower guard spring.

and the spring are not operating properly, they must be serviced before use.

Lower guard may operate sluggishly due to damaged parts gummy deposits,

a

buildup of debris.

or

4.

Lower guard should be retracted manually only for special cuts such as

"Pocket Cuts" and "Compound Cuts." Raise lower guard by Retracting

Handle. As soon as blade enters the material, lower guard must be released.

For all other sawing, the lower guard should operate automatically.

5.

Always observe that the lower guard is covering the blade before placing

saw down on bench or floor. An unprotected, coasting blade will cause the

saw to walk backwards, cutting whatever is in its path. Be aware of the time

it takes for the blade to stop after switch is released.

6.

NEVER hold piece being cut

to support the work properly to minimize body exposure, blade binding, or

loss

of control.

7.

Hold tool by insulated gripping surfaces when performing an operation where

the cutting tool may contact hidden

a "live" wire will also make exposed metal parts of the tool "live" and shock

the operator.

8.

When ripping always use a rip fence or straight edge guide. This improves

the accuracy of cut and reduces the chance for blade binding.

9.

Always use blades

holes. Blades that do not match the mounting hardware

eccentrically, causing

IO.

Never use damaged or incorrect blade washers or bolts. The blade washers

and bolt were specially designed for your saw, for optimum performance and

safety or operation.

with

in

your hands or across your leg. It is important

wiring

correct size and shape (diamond vs. round) arbor

or its own cord. Contact with

of

loss

of control.

If

the guard

the saw will run

in

line

4

11.

Causes and Operator Prevention

of

Kickback:

Kickback is a sudden reaction to a pinched, bound or misaligned saw blade,

causing an uncontrolled saw to lift up and

out

of the workpiece toward the

operator.

When the blade is pinched or bound tightly by the kerf closing down, the blade

stalls and the motor reaction drives the unit rapidly back toward the operator.

If the blade becomes twisted or misaligned in the cut, the teeth at the back

edge of the blade can dig into the top surface of the wood causing the blade

to climb out of the kerf and jump back toward operator.

Kickback is the result of tool misuse and/or incorrect operating procedures

or conditions and can be avoided by taking proper precautions as given below.

Maintain a firm grip with both hands on the saw and position your body and

arm to allow you to resist

KICKBACK

forces. KICKBACK forces can be

controlled by the operator, if proper precautions are taken.

When blade is binding, or when interrupting a cut for any reason, release

the trigger and hold the saw motionless in the material until the blade comes

to a complete stop. Never attempt to remove the saw from the work

the saw backward while the blade

is

in motion

or

KICKBACK

may occur.

Investigate and take corrective actions to eliminate the cause of blade binding.

When restarting a saw in the workpiece, center the saw blade

in

and check that saw teeth are not engaged into the material. If saw blade

is binding, it may walk up or KICKBACK from the workpiece as the saw is

restarted.

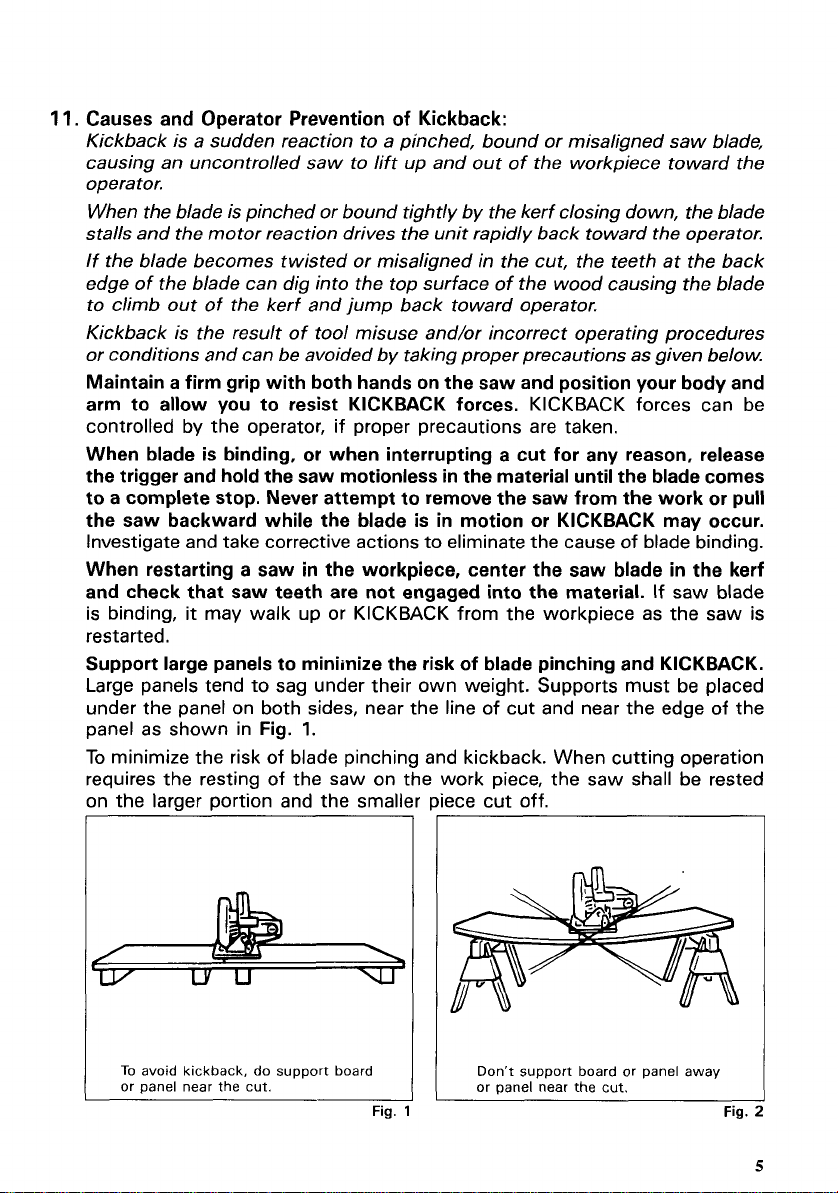

Support large panels to minimize the risk of blade pinching and

Large panels tend to sag under their own weight. Supports must

KICKBACK.

be

under the panel on both sides, near the line of cut and near the edge of the

panel as shown in Fig.

To

minimize the risk of blade pinching and kickback. When cutting operation

1.

requires the resting of the saw on the work piece, the saw shall be rested

on the larger portion and the smaller piece cut off.

or

pull

the kerf

placed

To

avoid kickback, do support board

or panel near the cut.

Fig.

Don’t support board or panel away

or panel near the cut.

1

Fig.

:

5

Loading...

Loading...