Makita 5046DWB, 5046D, 15026DWA, 5026D, 5036D User Manual

Cordless Circular

165

mm

(6-112”) MODEL 5026DA, 5026DB

160

mm

(6-114”) MODEL 5036DA, 5036DB

160

mm

(6-114”) MODEL 5046DA, 5046DB

Saw

with Dust Collection

165

mm

(6-112”) MODEL 5026DWA, 5026DWB

With High Capacity Battery Charger

160

mm

(6-114”) MODEL 5036DWA, 5036DWB

With High Capacity Battery Charger

160

mm

(6-114”) MODEL 5046DWA, 5046DWB

With High Capacity Battery Charger

5026D

5036D

5046D

Battery Cartridge 1822

Batterv Cartridqe 1833

165 mm (6-1

160

mm (6-114”)

160

mm

Voltage

V

18

Voltaae

18 V

f6-1/4”) 53

IRPLAI

3111

,.,,

55 mm (2-311

12”)

53

mm

mm

Model DC1801 High Capacity Battery Charger

A

C only

Model DC1801 Hiqh Capacity Battery Charger

I

A.C.

6”)

(2-1116“)

12-1/16’,) 2,400 338 mm

Input output Charging time

50 - 60

lnwt

only

50 ~ 60

2,400 338 mm (13-5116”) 3.8 kg (8.4

2,400 338

Hz

I

Hz

mm

(13-5116”) 3.8 kg (8.4

(13-5/16”)

DC 72V-

D.C. 7.2 V - 18 V 65 min.

18V

Output

3.8

60

I

Charging time

kg

min

18.4

Ibsl

Ibs)

Ibs)

GENERAL SAFETY RULES

(For

All

Battery Operated

Tools)

WARNING!

to

follow all instructions listed below,

Read and understand all instructions.

may

result in electric

Failure

shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

Work Area

Keep your work area clean and well

accidents.

Do not operate power tools

of flammable liquids, gases, or dust. Power tools create sparks which may ignite

the dust or fumes.

Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

A battery operated tool with integral batteries

be recharged only with the specified charger for the battery.

may be suitable for one type of battery may create a risk of fire when used

another battery.

Use battery operated tool only

of any other batteries may create a risk

Personal Safety

Stay alert, watch what you are doing, and use common sense when operating

a power tool. Do not use tool while tired or under the influence of drugs, alcohol,

or

medication. A moment of inattention while operating power

in serious personal injury.

Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep

your hair, clothing, and gloves away from moving parts. Loose clothes, jewelry,

or long hair can be causht in moving parts.

Avoid accidental starting.

inserting battery pack. Carrying tools

the battery pack into a tool with the switch on invites accidents.

Remove adjusting keys or wrenches before turning

a

key

that is left attached to a rotating part of the tool may result

Do not overreach. Keep proper footing and balance at all times. Proper footing

and balance enable better control of the tool in unexpected situations.

Use safety equipment. Always wear eye protection. Dust mask, non-skid safety

shoes, hard hat, or hearing protection must be used for appropriate conditions.

in

Be

lit.

Cluttered benches and dark areas invite

explosive atmospheres, such as

or

a separate battery pack must

with

specifically designated battery pack. Use

of

fire.

sure switch is in the locked or off position before

with

your finger on the switch or inserting

the

in

the presence

A

charger that

tools

may result

tool on. A wrench or

in

personal injury.

with

2

Tool

Use

and

Care

Use clamps or other practical way to secure and support the workpiece to a

stable platform. Holding the work by hand or against your body is unstable and

may lead to

Do

not force tool. Use the correct tool for your application. The correct tool

will do the job better and safer at the rate for which

*Do not use tool

controlled

.Disconnect battery pack from tool

loss

of control.

if

switch does not turn

with

the switch is dangerous and must be repaired.

it

on or off. A tool that cannot be

or

place the switch

it

is designed.

in

the locked or off

position before making any adjustments, changing accessories, or storing the

tool. Such preventive safety measures reduce the risk

of

starting the tool

accidentally.

Store idle tools out of reach of children and other untrained persons.

dangerous

When battery pack is not

in

the hands of untrained users.

in

use, keep

it

away from other metal objects like:

Tools

paper clips, coins, keys, nails, screws, or other small metal objects that can

make a connection from one terminal to another. Shorting the battery terminals

together may cause sparks, burns, or a fire.

Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained

with

tools

sharp cutting edge are less likely to bind and are easier to control.

Check for misalignment or binding of moving parts, breakage of parts, and any

other condition that may affect the tool's operation. If damaged, have the tool

serviced before using. Many accidents are caused

Use only accessories that are recommended

by

poorly maintained tools.

by

the manufacturer for your

model. Accessories that may be suitable for one tool may create a risk of injury

when used on another tool.

Service

Tool

service must be performed only by qualified repair personnel. Service or

by

maintenance performed

unqualified personnel may result

in

a risk of injury.

When servicing a tool, use only identical replacement parts. Follow instructions

in

the Maintenance section

of

this manual. Use

of

unauthorized parts or failure

to follow Maintenance Instructions may create a risk of shock or injury.

are

3

Specific Safety

1.

DANGER! Keep hands away from cutting area and blade. Keep your second

hand on auxiliary handle, or motor housing. If both hands are holding the

saw, they cannot be cut by the blade.

Keep your body positioned to either side of the saw blade, but not

with

the saw blade. KICKBACK could cause the saw to jump backwards. (See

"Causes and Operator Prevention of Kickback")

Do not reach underneath the work. The guard can not protect you from the

blade below the work. Don't attempt to remove cut material when blade is

moving.

CAUTION: Blades coast after turn off.

2.

Check lower guard for proper closing before each use. Do not operate saw

if

lower guard does not move freely and close instantly. Never clamp or tie

the lower guard into the open position. If saw is accidentally dropped, lower

guard may be bent. Raise the lower guard

it

moves freely and does not touch the blade or any other part, in all angles

sure

and depths of cut.

3.

Check the operation and condition of the lower guard spring.

and the spring are not operating properly, they must be serviced before use.

Lower guard may operate sluggishly due to damaged parts gummy deposits,

or a buildup of debris.

4.

Lower guard should be retracted manually only for special cuts such as

"Pocket Cuts" and "Compound Cuts." Raise lower guard by Retracting

Handle. As soon as blade enters the material, lower guard must be released.

For

all

other sawing, the lower guard should operate automatically.

5.

Always observe that the lower guard is covering the blade before placing

saw down on bench or floor. An unprotected, coasting blade

saw to walk backwards, cutting whatever is in its path. Be aware of the time

it

takes for the blade to stop after switch is released.

6.

NEVER hold piece being cut

to support the work properly to minimize body exposure, blade binding, or

loss

of control.

7.

Hold tool by insulated gripping surfaces when performing an operation where

the cutting tool may contact hidden wiring. Contact with a "live" wire

also make exposed metal parts of the tool "live" and shock the operator.

8.

When ripping always use a rip fence or straight edge guide. This improves

the accuracy of cut and reduces the chance for blade binding.

9.

Always use blades

holes. Blades that do not match the mounting hardware of the saw

eccentrically, causing

10.

Never use damaged or incorrect blade washers or bolts. The blade washers

and bolt were specially designed for your saw, for optimum performance and

safety or operation.

with

in

your hands or across your leg.

correct size and shape (diamond vs. round) arbor

loss

of control.

Rules

with

the Retracting Handle and make

If

will

It

is important

the guard

cause the

in

will

line

will

run

4

11.

Causes and Operator Prevention of Kickback:

Kickback is a sudden reaction to a pinched, bound or misaligned saw blade,

causing an uncontrolled saw to lift

up

and out of the workpiece toward the

opera tor.

When the blade is pinched or bound tightly by the kerf closing down, the blade

stalls and the motor reaction drives the unit rapidly back toward the operator.

If the blade becomes twisted or misaligned in the cut, the teeth at the back

edge of the blade can dig into the top surface of the wood causing the blade

to climb out

Kickback is the result

of

the kerf and jump back toward the operator.

of

tool misuse and/or incorrect operating procedures

or conditions and can be avoided by taking proper precautions as given below.

Maintain a firm grip on the saw and position your body and arm in a way

that allows you to resist KICKBACK forces. KICKBACK forces can be

controlled by the operator, if proper precautions are taken.

When blade is binding, or when interrupting a cut for any reason, release

the trigger and hold the saw motionless in the material

until

the blade comes

to a complete stop. Never attempt to remove the saw from the work or pull

the saw backward while the blade is in motion or KICKBACK may occur.

Investigate and take corrective actions to eliminate the cause of blade binding.

When restarting a saw in the workpiece, center the saw blade in the kerf

and check that teeth are not engaged into the material. If 5aw blade is binding,

it

may walk up or KICKBACK from the workpiece as the saw is restarted.

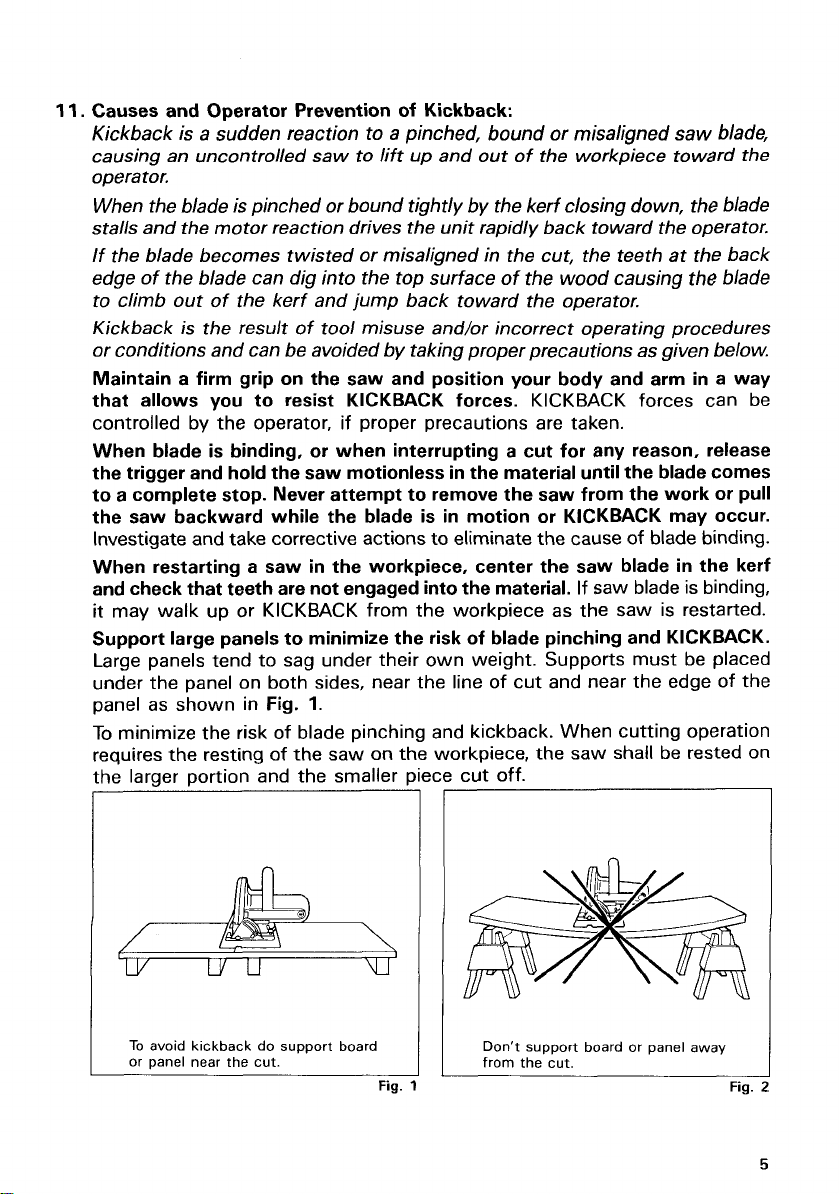

Support large panels to minimize the risk of blade pinching and KICKBACK.

Large panels tend to sag under their own weight. Supports must be placed

under the panel on both sides, near the line of cut and near the edge of the

panel as shown

To

minimize the risk of blade pinching and kickback. When cutting operation

requires the resting

in

Fig.

of

the saw

1.

on

the workpiece, the saw shall be rested on

the larger Dortion and the smaller piece cut off.

To

avoid kickback do support board

or panel near

the

cut.

Fig.

Don't support board or panel away

I

from

the

cut.

1

Fig.

,

5

Do

not use

dull

or damaged blade. Unsharpened or improperly set blades

produce narrow kerf causing excessive friction, blade binding and KICKBACK.

tight

Blade depth and bevel adjusting locking levers must be

If

before making cut.

blade adjustment shifts while cutting,

and secure

it

may cause bind-

ing and KICKBACK.

Use extra caution when making a "Pocket Cut" into existing walls or other

blind areas. The protruding blade may cut objects

that

can cause KICKBACK.

NEVER place your hand or fingers

behind the saw. If kickback occurs,

the saw could easily jump backwards

over your hand, possibly causing

severe injury.

12.

Adjustments. Before cutting be sure depth and bevel adjustments are

13.

Avoid Cutting Nails. Inspect for and remove all nails from lumber before

cutting.

14.

Place the wider portion of the saw base on that part of the workpiece which

is solidly supported, not on the section that will fall off when the cut is made.

4

As examples, Fig.

5

and Fig.

DON'T

the WRONG way.

TRY

TO HOLD SHORT PLACES

illustrates the RIGHT way to cut off the end of a board,

If

the workpiece is short or small, clamp

BY

HAND!

tight.

it

down.

Fig.

6

Fig.

1

Fig.

15.

Never attempt to saw with the

circular saw held upside down

in

a

vise. This is extremely dangerous and

can lead to serious accidents.

16.

Before setting the tool down after completing a cut, be sure that the lower

(telescoping) guard has closed and the blade has come to a complete stop.

Fig.

6

7

Loading...

Loading...