Page 1

INSTRUCTION MANUAL

MANUEL D'INSTRUCTION

MANUAL DE INSTRUCCIONES

Circular Saw

Scie circulaire

Sierra circular

5007N

5007NF

5007NFA

008671

DOUBLE INSULATION

DOUBLE ISOLATION

WARNING:

For your personal safety, READ and UNDERSTAND before using.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

AVERTISSEMENT:

Pour votre propre sécurité, prière de lire attentivement avant l'utilisation.

GARDER CES INSTRUCTIONS POUR RÉFÉRENCE ULTÉRIEURE.

ADVERTENCIA:

Para su seguridad personal, LEA DETENIDAMENTE este manual antes de usar la

herramienta.

GUARDE ESTAS INSTRUCCIONES PARA FUTURA REFERENCIA.

DOBLE AISLAMIENTO

1

Page 2

ENGLISH

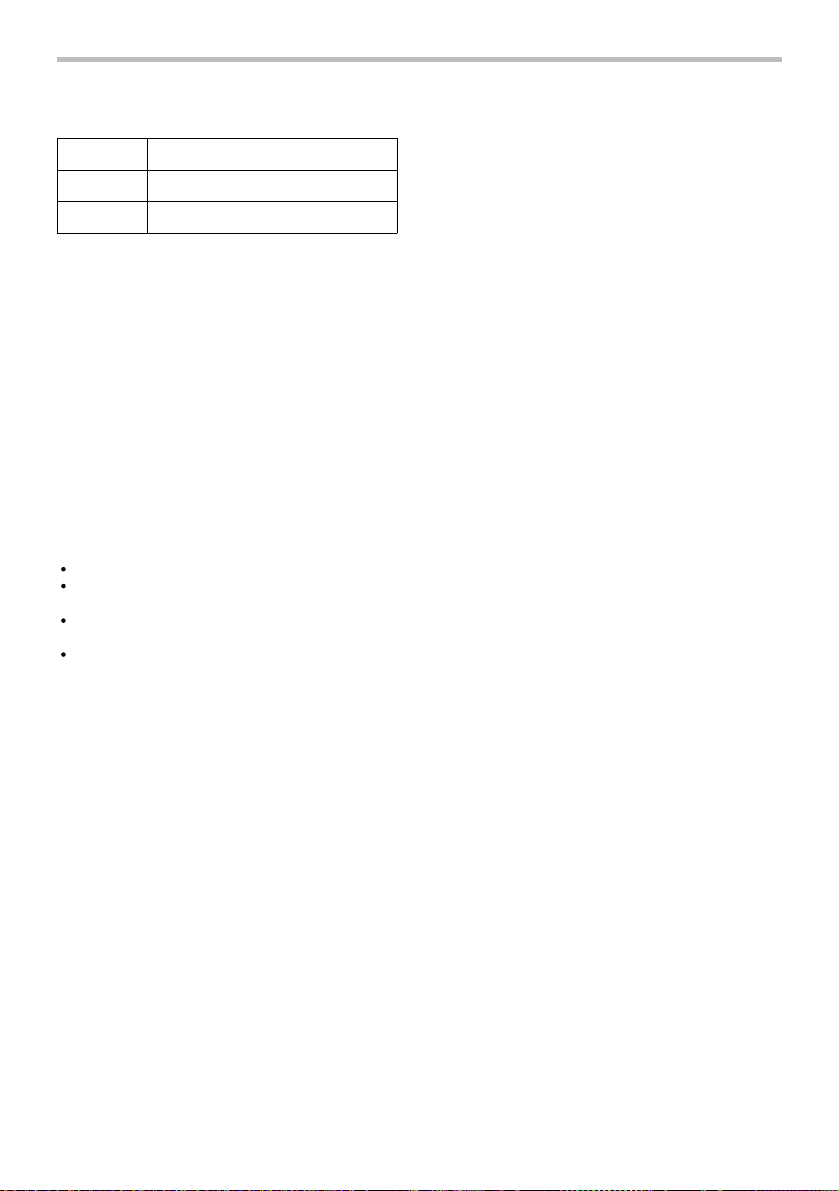

SPECIFICATIONS

Model 5007N/5007NF/5007NFA

Blade diameter 185 mm (7-1/4")

Max. Cutting depth

No load speed (RPM) 5,800/min.

Overall length 317 mm (12-1/2")

• Due to our continuing programme of research and development, the specifications herein are subject to change without notice.

• Note: Specifications may differ from country to country.

Net weight 5.0 kg (11 lbs)

General Power Tool Safety

Warnings

WARNING Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or

serious injury.

Save all warnings and

instructions for future reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

Work area safety

1. Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

2. Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

3. Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

Electrical Safety

4. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodified plugs and matching outlets will

reduce risk of electric shock.

5. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of

electric shock if your body is earthed or grounded.

6. Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

7. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

at 0° 63.5 mm (2-1/2")

at 45° 45 mm (1-3/4")

at 56° 35 mm (1-3/8")

GEA008-1

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords

increase the risk of electric shock.

8. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electric shock.

9. If operating a power tool in a damp location is

unavoidable, use a ground fault circuit

interrupter (GFCI) protected supply. Use of an

GFCI reduces the risk of electric shock.

Personal Safety

10. Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the influence of drugs, alcohol or

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

11. Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions

will reduce personal injuries.

12. Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or battery pack, picking

up or carrying the tool. . Carrying power tools

with your finger on the switch or energising power

tools that have the switch on invites accidents.

13. Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

14. Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

15. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing, and gloves

away from moving parts. Loose clothes,

2

Page 3

jewellery or long hair can be caught in moving

parts.

16. If devices are provided for the connection of

dust extraction and collection facilities,

ensure these are connected and properly used.

Use of dust collection can reduce dust-related

hazards.

Power tool use and care

17. Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

18. Do not use the power tool if the switch does

not turn it on and off. Any power tool that cannot

be controlled with the switch is dangerous and

must be repaired.

19. Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

20. Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

21. Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tool’s operation. If damaged, have the

power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

22. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

23. Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the power

tool for operations different from those intended

could result in a hazardous situation.

SERVICE

24. Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

25. Follow instruction for lubricating and

changing accessories.

26. Keep handles dry, clean and free from oil and

grease.

USE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to

carry the current your product will draw. An undersized

cord will cause a drop in line voltage resulting in loss of

power and overheating. Table 1 shows the correct size

to use depending on cord length and nameplate ampere

rating. If in doubt, use the next heavier gage. The

smaller the gage number, the heavier the cord.

Table 1: Minimum gage for cord

Ampere Rating

Volts Total length of cord in feet

120 V 25 ft. 50 ft. 100 ft. 150 ft.

More Than Not More Than AWG

0 6 18 16 16 14

18 16 14 12610

10 12 16 16 14 12

000173

SPECIFIC SAFETY RULES

DO NOT let comfort or familiarity with product

(gained from repeated use) replace strict adherence

to circular saw safety rules. If you use this tool

unsafely or incorrectly, you can suffer serious

personal injury.

Danger:

1. Keep hands away from cutting area and the

12 16 14 12

GEB013-1

blade. Keep your second hand on auxiliary

handle, or motor housing. If both hands are

holding the saw, they cannot be cut by the blade.

2. Do not reach underneath the workpiece. The

guard cannot protect you from the blade below the

workpiece. Do not attempt to remove cut material

when blade is moving.

CAUTION: Blades coast after turn off. Wait until

blade stops before grasping cut material.

3. Adjust the cutting depth to the thickness of

the workpiece. Less than a full tooth of the blade

teeth should be visible below the workpiece.

4. Never hold piece being cut in your hands or

across your leg. Secure the workpiece to

3

Not Recommended

Page 4

stable platform. It is important to support the

work properly to minimize body exposure, blade

binding, or loss of control.

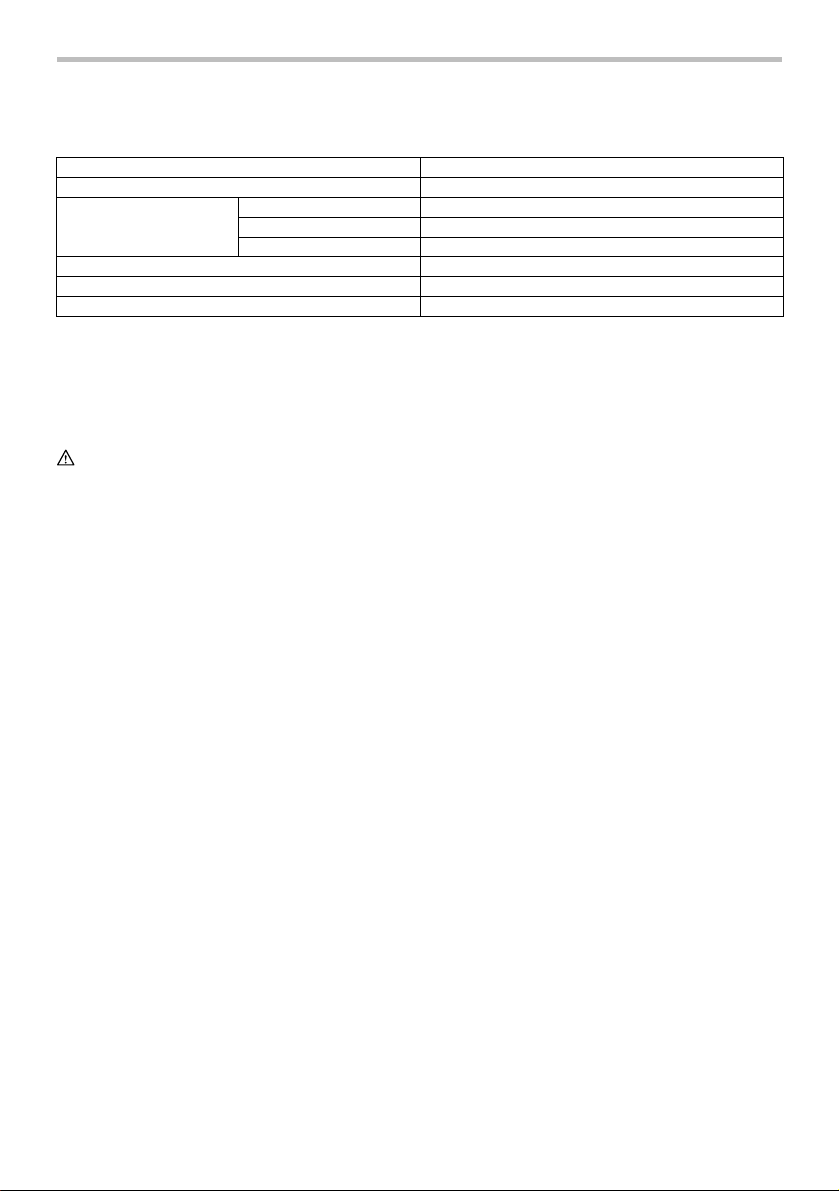

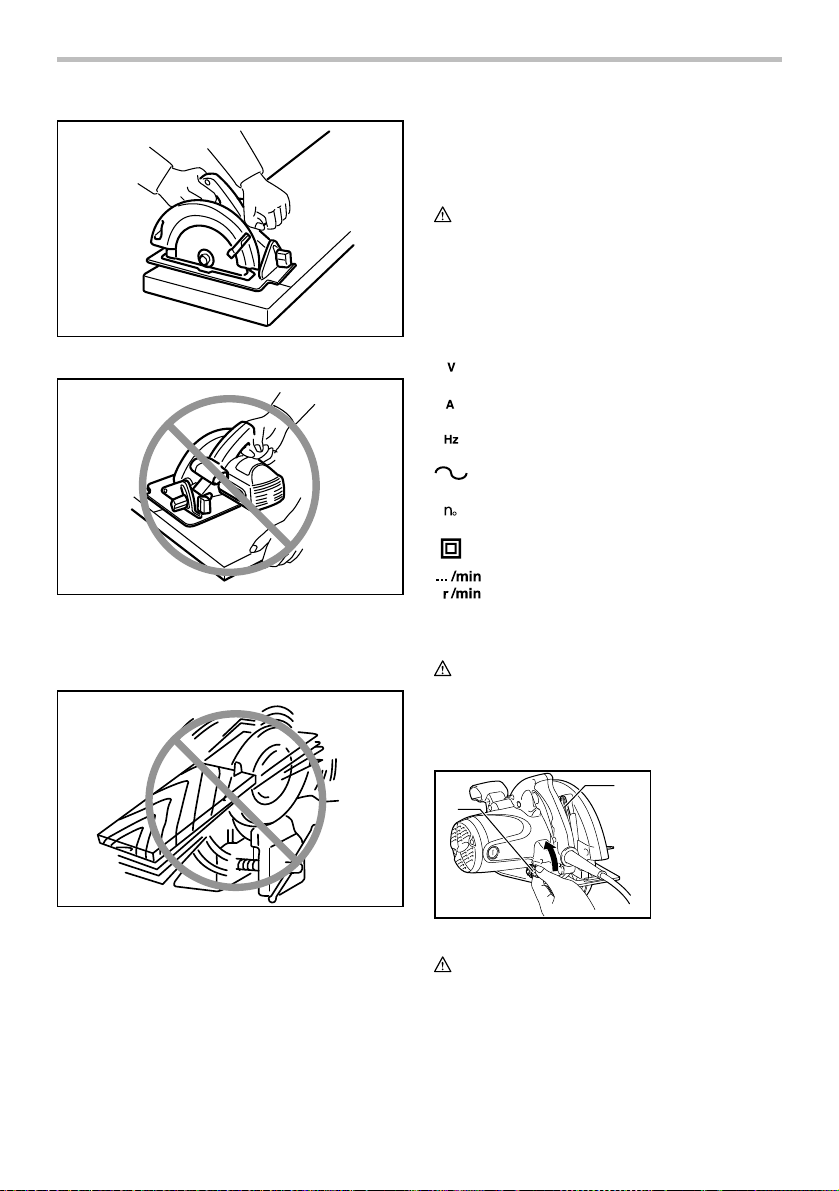

A typical illustration of proper hand support, workpiece

support, and supply cord routing (if applicable).

000157

5. Hold power tool by insulated gripping

surfaces when performing an operation where

the cutting tool may contact hidden wiring or

its own cord. Contact with a "live" wire will also

make exposed metal parts of the power tool "live"

and shock the operator.

6. When ripping always use a rip fence or

straight edge guide. This improves the accuracy

cut and reduces the chance of blade binding.

7. Always use blades with correct size and shape

(diamond versus round) of arbour holes.

Blades that do not match the mounting hardware

of the saw will run eccentrically, causing loss of

control.

8. Never use damaged or incorrect blade

washers or bolt. The blade washers and bolt

were specially designed for your saw, for optimum

performance and safety of operation.

9. Causes and Operator Prevention of Kickback:

− kickback is a sudden reaction to a pinched,

bound or misaligned saw blade, causing an

uncontrolled saw to lift up and out of the

workpiece toward the operator;

− when the blade is pinched or bound tightly by

the kerf closing down, the blade stalls and the

motor reaction drives the unit rapidly back

toward the operator;

− if the blade becomes twisted or misaligned in

the cut, the teeth at the back edge of the

blade can dig into the top surface of the wood

causing the blade to climb out of the kerf and

jump back toward the operator.

Kickback is the result of saw misuse and/or

incorrect operating procedures or conditions and

can be avoided by taking proper precautions as

given below.

• Maintain a firm grip with both hands on the

saw and position your arms to resist

kickback forces. Position your body to

either side of the blade, but not in line with

the blade. Kickback could cause the saw to

jump backwards, but kickback forces can be

controlled by the operator, if proper

precautions are taken.

• When blade is binding, or when

interrupting a cut for any reason, release

the trigger and hold the saw motionless in

the material until the blade comes to a

complete stop. Never attempt to remove

the saw from the work or pull the saw

backward while the blade is in motion or

kickback may occur. Investigate and take

corrective actions to eliminate the cause of

blade binding.

• When restarting a saw in the workpiece,

centre the saw blade in the kerf and check

that saw teeth are not engaged into the

material. If saw blade is binding, it may walk

up or kickback from the workpiece as the saw

is restarted.

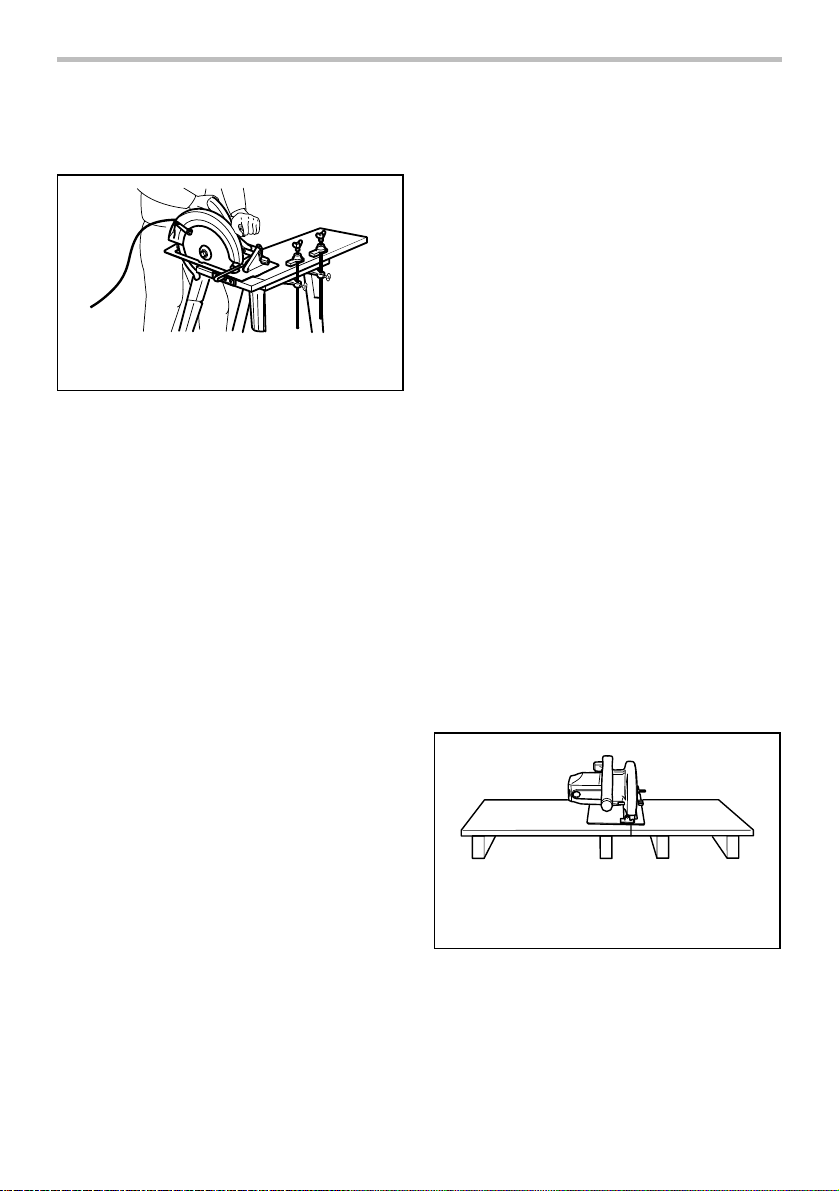

• Support large panels to minimise the risk

of blade pinching and kickback. Large

panels tend to sag under their own weight.

Supports must be placed under the panel on

both sides, near the line of cut and near the

edge of the panel.

To minimize the risk of blade pinching and kickback.

When cutting operation requires the resting of the

saw on the workpiece, the saw should be rested on

the larger portion and the smaller piece cut off.

To avoid kickback, do support

board or panel near the cut.

000154

4

Page 5

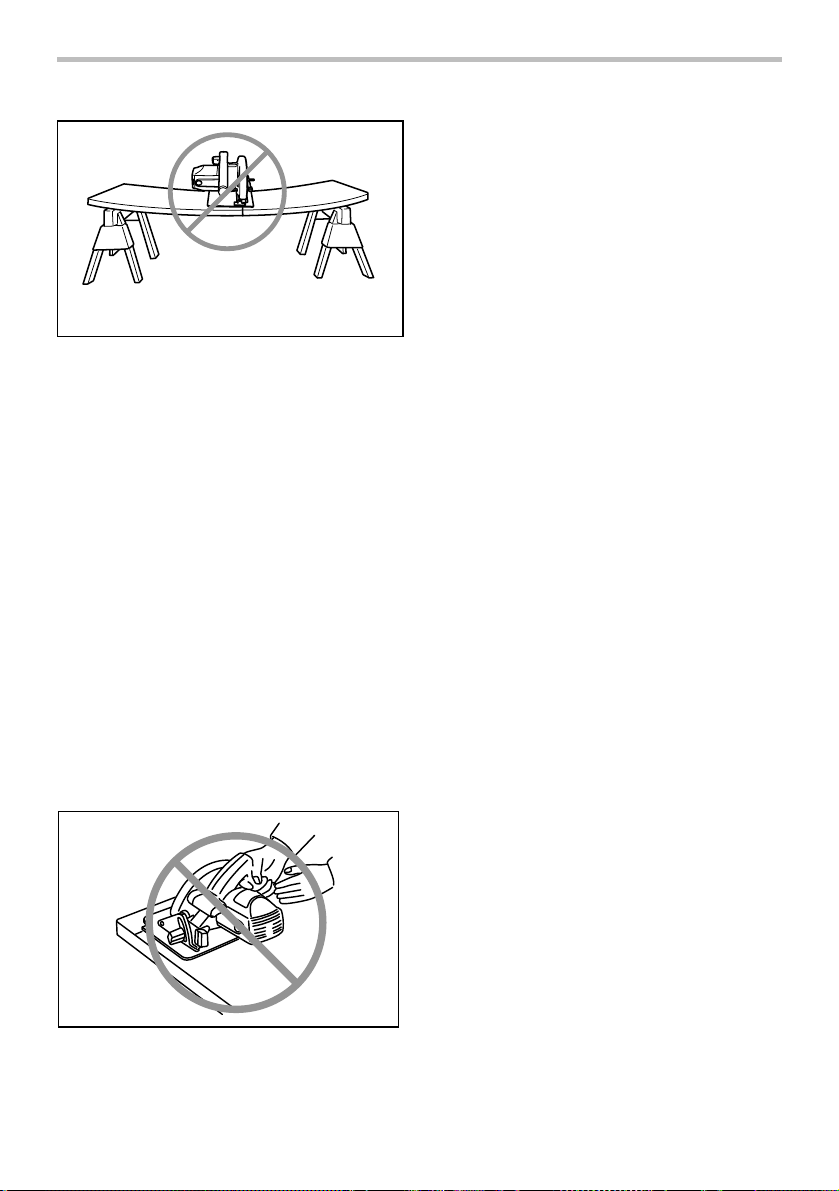

Do not support board or

panel away from the cut.

000156

• Do not use dull or damaged blades.

Unsharpened or improperly set blades

produce narrow kerf causing excessive friction,

blade binding and kickback. Keep blade sharp

and clean. Gum and wood pitch hardened on

blades slows saw and increases potential for

kickback. Keep blade clean by first removing it

from tool, then cleaning it with gum and pitch

remover, hot water or kerosene. Never use

gasoline.

• Blade depth and bevel adjusting locking

levers must be tight and secure before

making cut. If blade adjustment shifts while

cutting, it may cause binding and kickback.

• Use extra caution when making a "plunge

cut" into existing walls or other blind areas.

The protruding blade may cut objects that can

cause kickback. For plunge cuts, retract lower

guard using retracting handle.

• ALWAYS hold the tool firmly with both

hands. NEVER place your hand or fingers

behind the saw. If kickback occurs, the saw

could easily jump backwards over your hand,

leading to serious personal injury.

000194

• Never force the saw. Forcing the saw can

cause uneven cuts, loss of accuracy, and

possible kickback. Push the saw forward at

a speed so that the blade cuts without slowing.

10. Check lower guard for proper closing before

each use. Do not operate the saw if lower

guard does not move freely and close instantly.

Never clamp or tie the lower guard into the

open position. If saw is accidentally dropped,

lower guard may be bent. Raise the lower guard

with the retracting handle and make sure it moves

freely and does not touch the blade or any other

part, in all angles and depths of cut.

To check lower guard, open lower guard by hand,

then release and watch guard closure. Also check

to see that retracting handle does not touch tool

housing. Leaving blade exposed is VERY

DANGEROUS and can lead to serious personal

injury.

11. Check the operation of the lower guard spring.

If the guard and the spring are not operating

properly, they must be serviced before use.

Lower guard may operate sluggishly due to

damaged parts, gummy deposits, or a build-up of

debris.

12. Lower guard should be retracted manually

only for special cuts such as "plunge cuts"

and "compound cuts." Raise lower guard by

retracting handle and as soon as blade enters

the material, the lower guard must be released.

For all other sawing, the lower guard should

operate automatically.

13. Always observe that the lower guard is

covering the blade before placing saw down

on bench or floor. An unprotected, coasting

blade will cause the saw to walk backwards,

cutting whatever is in its path. Be aware of the

time it takes for the blade to stop after switch is

released. Before setting the tool down after

completing a cut, be sure that the lower guard has

closed and the blade has come to a complete

stop.

14. Use extra caution when cutting damp wood,

pressure treated lumber, or wood containing

knots. Adjust speed of cut to maintain smooth

advancement of tool without decrease in blade

speed.

15. Avoid Cutting Nails. Inspect for and remove all

nails from lumber before cutting.

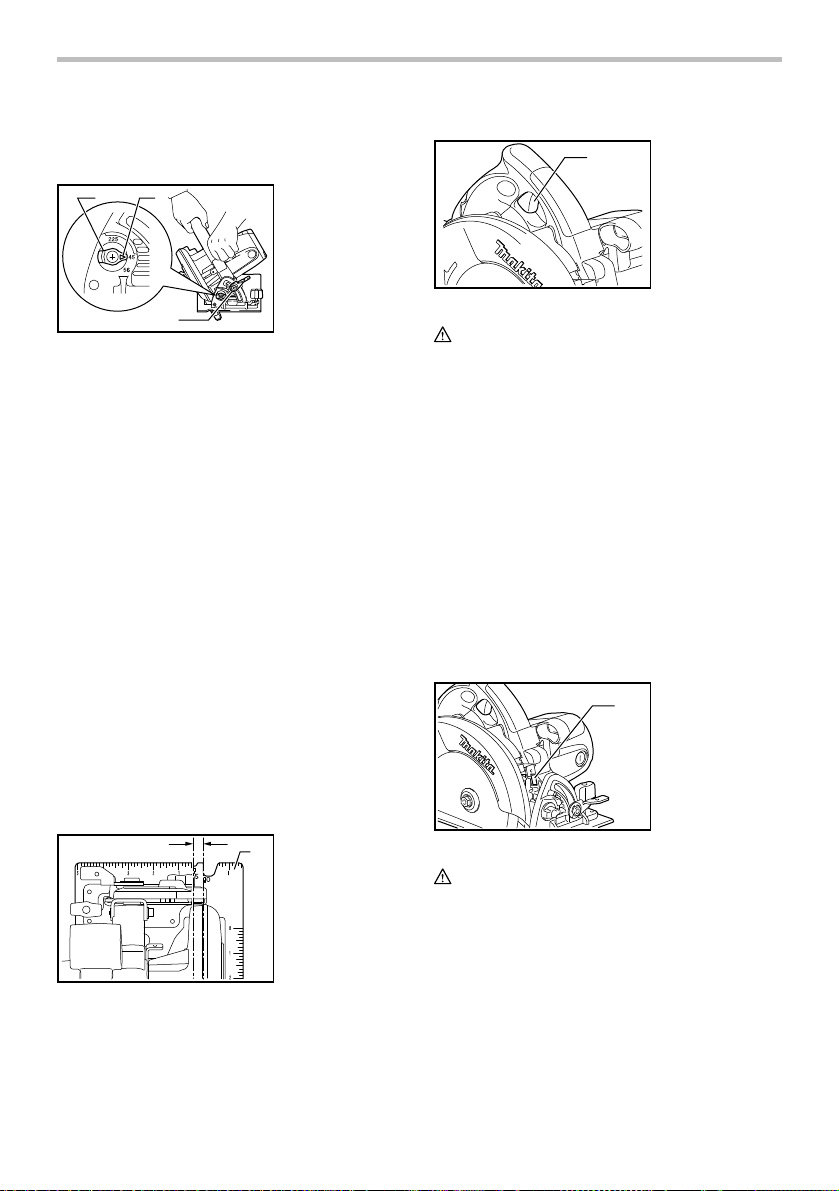

16. Place the wider portion of the saw base on that

part of the workpiece which is solidly

supported, not on the section that will fall off

when the cut is made. As examples, Fig. 1

illustrates the RIGHT way to cut off the end of

a board, and Fig. 2 the WRONG way. If the

workpiece is short or small, clamp it down. DO

NOT TRY TO HOLD SHORT PIECES BY HAND!

5

Page 6

Fig. 1

000147

Fig. 2

000150

17. Never attempt to saw with the circular saw

held upside down in a vise. This is extremely

dangerous and can lead to serious accidents.

21. Wear a dust mask and hearing protection

when use the tool.

SAVE THESE INSTRUCTIONS.

WARNING:

MISUSE or failure to follow the safety rules stated in

this instruction manual may cause serious personal

injury.

Symbols

The followings show the symbols used for tool.

・ volts

・ amperes

・ hertz

・ alternating current

・ no load speed

・ Class II Construction

・ revolutions or reciprocation per minute

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and

unplugged before adjusting or checking function on

the tool.

Adjusting depth of cut

1. Lever

2

1

2. Depth guide

USD201-2

000029

18. Some material contains chemicals which may

be toxic. Take caution to prevent dust

inhalation and skin contact. Follow material

supplier safety data.

19. Do not stop the blades by lateral pressure on

the saw blade.

20. Always use blades recommended in this

manual. Do not use any abrasive wheels.

008672

CAUTION:

• After adjusting the depth of cut, always tighten the

lever securely.

Loosen the lever on the depth guide and move the base

up or down. At the desired depth of cut, secure the base

by tightening the lever.

For cleaner, safer cuts, set cut depth so that no more

than one blade tooth projects below workpiece. Using

6

Page 7

proper cut depth helps to reduce potential for dangerous

KICKBACKS which can cause personal injury.

Bevel cutting

2

3

1. Lever

2. Positive stopper

3. Arrow on

positive stopper

Switch action

1

1. Switch trigger

008673

1

Positive stopper

Turn the positive stopper so that the arrow on it points

one of three positions (22.5°,45°,56°). Then, tilt the tool

base until it stops and secure the base with the lever. At

this time, the same angle as the one that the arrow

points is obtained.

Setting bevel angle

Loosen the lever and tentatively set the tool base at the

0°bevel angle, then tighten the lever securely.

Turn the positive stopper so that the arrow on it points

one of three positions (22.5°,45°,56°) that is equal to or

greater than the desired bevel angle.

Loosen the lever again and then tilt and secure the tool

base at the desired angle securely.

NOTE:

• When changing the positive stopper's position,

loosening the lever and tilting the bevel angle to

less than the desired stopper position number

allows to change it.

• When the arrow on the positive stopper points 22.5,

the bevel angle can be adjusted 0 - 22.5°;when the

arrow points 45, it can be adjusted 0 - 45°; when

the arrow points 56, it can be adjusted 0 - 56°.

Sighting

AB

1. Base

1

008674

For straight cuts, align the A position on the front of the

base with your cutting line. For 45° bevel cuts, align the

B position with it.

008675

CAUTION:

• Before plugging in the tool, always check to see

that the switch trigger actuates properly and

returns to the "OFF" position when released.

To start the tool, simply pull the switch trigger. Release

the switch trigger to stop.

Electric brake

For model 5007NFA only

This tool is equipped with an electric blade brake. If the

tool consistently fails to quickly stop blade after switch

trigger release, have tool serviced at a Makita service

center.

The blade brake system is not a substitute for lower

guard. NEVER USE TOOL WITHOUT A FUNCTIONING

LOWER GUARD. SERIOUS PERSONAL INJURY CAN

RESULT.

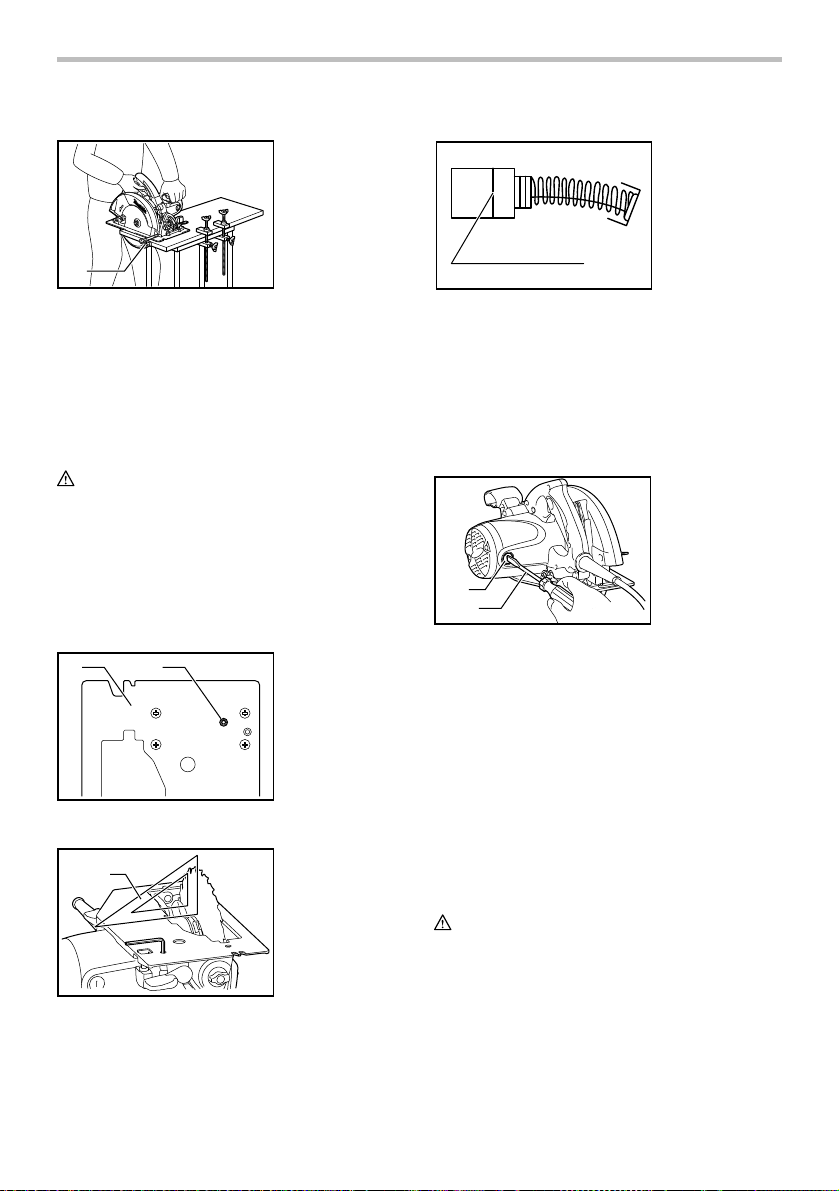

Lighting the lamp (For models

5007NF,5007NFA)

1. Lamp

1

008676

CAUTION:

• Do not apply impact to the lamp, which may cause

damage or shorted service time to it.

• Do not look in the light or see the source of light

directly.

The lamp lights up when the tool is plugged. The lamp

keeps on lighting until the tool is unplugged.

If the lamp does not light up, the mains cord may be

defective. The lamp is lit but the tool does not start even

if the tool is switched on, the carbon brushes may be

worn out, the motor or the ON/OFF switch may be

defective.

7

Page 8

NOTE:

• Use a dry cloth to wipe the dirt off the lens of lamp.

Be careful not to scratch the lens of lamp, or it may

lower the illumination.

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and

unplugged before carrying out any work on the

tool.

Hex wrench storage

1. Hex wrench

2. Protrusion

1

2

008677

Hex wrench is stored on the tool. To remove hex wrench,

rotate it toward yourself and pull it out.

To install hex wrench, place it on the handle and turn it

until it comes into contact with the protrusion on the

handle.

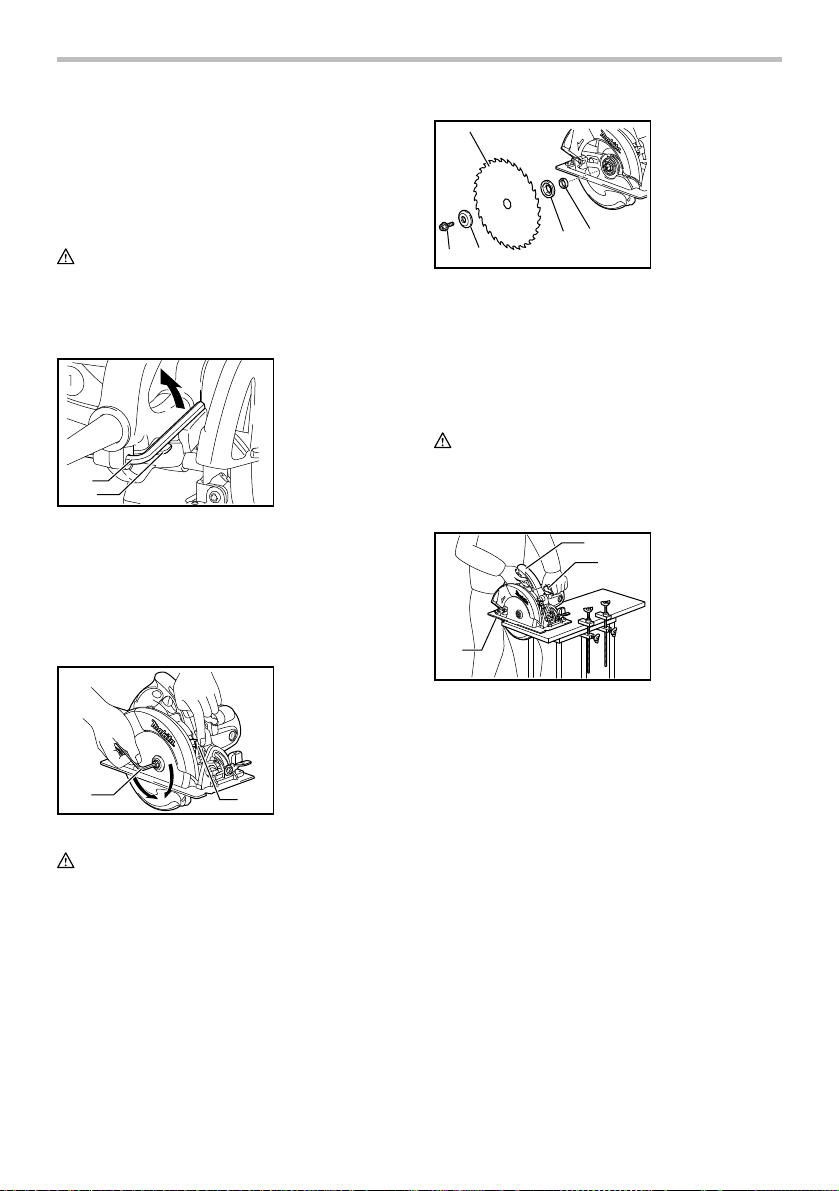

Removing or installing saw blade

1

008678

CAUTION:

• Be sure the blade is installed with teeth pointing up

at the front of the tool.

• Use only the Makita wrench to install or remove the

blade.

To remove the blade, press the shaft lock so that the

blade cannot revolve and use the hex wrench to loosen

the hex bolt counterclockwise. Then remove the hex bolt,

outer flange and blade.

To install the blade, follow the removal procedure in

reverse. BE SURE TO TIGHTEN THE HEX BOLT

CLOCKWISE SECURELY.

1. Hex wrench

2. Shaft lock

2

3

12

008679

5

4

1. Hex bolt

2. Outer flange

3. Saw blade

4. Inner flange

5. Ring

When changing blade, make sure to also clean upper

and lower blade guards of accumulated sawdust. Such

efforts do not, however, replace the need to check lower

guard operation before each use.

OPERATION

CAUTION:

• Be sure to move the tool forward in a straight line

gently. Forcing or twisting the tool will result in

overheating the motor and dangerous kickback,

possibly causing severe injury.

2

1

008680

Hold the tool firmly. The tool is provided with both a front

grip and rear handle. Use both to best grasp the tool. If

both hands are holding saw, they cannot be cut by the

blade. Set the base on the workpiece to be cut without

the blade making any contact. Then turn the tool on and

wait until the blade attains full speed. Now simply move

the tool forward over the workpiece surface, keeping it

flat and advancing smoothly until the sawing is

completed.

To get clean cuts, keep your sawing line straight and

your speed of advance uniform. If the cut fails to properly

follow your intended cut line, do not attempt to turn or

force the tool back to the cut line. Doing so may bind the

blade and lead to dangerous kickback and possible

serious injury. Release switch, wait for blade to stop and

then withdraw tool. Realign tool on new cut line, and

start cut again. Attempt to avoid positioning which

exposes operator to chips and wood dust being ejected

from saw. Use eye protection to help avoid injury.

8

1. Base

2. Rear handle

3

3. Front grip

Page 9

Rip fence (Guide rule)

1. Rip fence (Guide

rule)

Replacing carbon brushes

1. Limit mark

1

008681

The handy rip fence allows you to do extra-accurate

straight cuts. Simply slide the rip fence up snugly against

the side of the workpiece and secure it in position with

the screw on the front of the base. It also makes

repeated cuts of uniform width possible.

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and

unplugged before attempting to perform inspection

or maintenance.

Adjusting for accuracy of 90° cut (vertical cut)

This adjustment has been made at the factory. But if it is

off, adjust the adjusting screw with a hex wrench while

squaring the blade with the base using a triangular rule,

try square, etc.

1

008682

008683

2

1

1. Base

2. Adjusting screw

1. Triangular rule

1

001145

Remove and check the carbon brushes regularly.

Replace when they wear down to the limit mark. Keep

the carbon brushes clean and free to slip in the holders.

Both carbon brushes should be replaced at the same

time. Use only identical carbon brushes.

Use a screwdriver to remove the brush holder caps.

Take out the worn carbon brushes, insert the new ones

and secure the brush holder caps.

1

2

008684

For model 5007NFA only

After replacing brushes, plug in the tool and break in

brushes by running tool with no load for about 10

minutes. Then check the tool while running and electric

brake operation when releasing the switch trigger. If

electric brake is not working well, ask your local Makita

service center for repair.

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be

performed by Makita Authorized or Factory Service

Centers, always using Makita replacement parts.

1. Brush holder

cap

2. Screwdriver

ACCESSORIES

CAUTION:

• These accessories or attachments are

recommended for use with your Makita tool

specified in this manual. The use of any other

accessories or attachments might present a risk of

injury to persons. Only use accessory or

attachment for its stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita Service Center.

9

Page 10

• Steel & Carbide-tipped saw blades

Combination

Pressure treated/

Wet lumber

Fine cross cuts

006549

General purpose blade for fast and smooth rip,

crosscuts and miters.

Designed for fast cutting of pressure treated and

wet lumber.

For sand-free cuts cleanly against the grain.

• Rip fence (Guide rule)

• Hex wrench

MAKITA LIMITED ONE YEAR WARRANTY

Warranty Policy

Every Makita tool is thoroughly inspected and tested

before leaving the factory. It is warranted to be free of

defects from workmanship and materials for the period

of ONE YEAR from the date of original purchase.

Should any trouble develop during this one year period,

return the COMPLETE tool, freight prepaid, to one of

Makita’s Factory or Authorized Service Centers. If

inspection shows the trouble is caused by defective

workmanship or material, Makita will repair (or at our

option, replace) without charge.

This Warranty does not apply where:

repairs have been made or attempted by others:

repairs are required because of normal wear and

tear:

the tool has been abused, misused or improperly

maintained:

alterations have been made to the tool.

IN NO EVENT SHALL MAKITA BE LIABLE FOR ANY

INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES FROM THE SALE OR USE OF THE

PRODUCT. THIS DISCLAIMER APPLIES BOTH

DURING AND AFTER THE TERM OF THIS

WARRANTY.

MAKITA DISCLAIMS LIABILITY FOR ANY IMPLIED

WARRANTIES, INCLUDING IMPLIED WARRANTIES

OF "MERCHANTABILITY" AND "FITNESS FOR A

SPECIFIC PURPOSE," AFTER THE ONE YEAR TERM

OF THIS WARRANTY.

This Warranty gives you specific legal rights, and you

may also have other rights which vary from state to

state. Some states do not allow the exclusion or

limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you.

Some states do not allow limitation on how long an

implied warranty lasts, so the above limitation may not

apply to you.

EN0006-1

10

Page 11

FRANÇAIS

SPÉCIFICATIONS

Modèle 5007N/5007NF/5007NFA

Diamètre de la lame 185 mm (7-1/4")

Profondeur de coupe max.

Vitesse à vide (T/MIN) 5,800/min

Longueur totale 317 mm (12-1/2")

Poids net 5,0 kg (11 lbs)

• Étant donné l'évolution constante de notre programme de recherche et de développement, les spécifications contenues dans ce

manuel sont sujettes à modification sans préavis.

• Note : Les spécifications peuvent varier suivant les pays.

Consignes de sécurité générales

pour outils électriques

MISE EN GARDE Veuillez lire toutes les mises en

garde de sécurité et toutes les instructions.

L'ignorance des mises en garde et des instructions

comporte un risque de choc électrique, d'incendie et/ou

de blessure grave.

Conservez toutes les mises en

garde et instructions pour

référence future.

Le terme ≪ outil électrique ≫ qui figure dans les

avertissements fait référence à un outil électrique

branché sur une prise de courant (par un cordon

d'alimentation) ou alimenté par batterie (sans fil).

Sécurité de la zone de travail

1. Maintenez la zone de travail propre et bien

éclairée. Les zones de travail encombrées ou

sombres ouvrent grande la porte aux accidents.

2. N'utilisez pas les outils électriques dans les

atmosphères explosives, par exemple en

présence de liquides, gaz ou poussières

inflammables. Les outils électriques produisent

des étincelles au contact desquelles la poussière

ou les vapeurs peuvent s'enflammer.

3. Assurez-vous qu'aucun enfant ou curieux ne

s'approche pendant que vous utilisez un outil

électrique. Vous risquez de perdre la maîtrise de

l'outil si votre attention est détournée.

Sécurité en matière d'électricité

4. Les fiches d'outil électrique sont conçues

pour s'adapter parfaitement aux prises de

courant. Ne modifiez jamais la fiche de

quelque façon que ce soit. N'utilisez aucun

adaptateur de fiche sur les outils électriques

avec mise à la terre. En ne modifiant pas les

à 0° 63.5 mm (2-1/2")

à 45° 45 mm (1-3/4")

à 56° 35 mm (1-3/8")

GEA008-1

11

fiches et en les insérant dans des prises de

courant pour lesquelles elles ont été conçues

vous réduirez les risques de choc électrique.

5. Évitez tout contact corporel avec les surfaces

mises à la terre, telles que les tuyaux,

radiateurs, cuisinières et réfrigérateurs. Le

risque de choc électrique est plus élevé si votre

corps se trouve mis à la terre.

6. N'exposez pas les outils électriques à la pluie

ou à l'eau. La présence d'eau dans un outil

électrique augmente le risque de choc électrique.

7. Ne maltraitez pas le cordon. N'utilisez jamais

le cordon pour transporter, tirer ou débrancher

l'outil électrique. Maintenez le cordon à l'écart

des sources de chaleur, de l'huile, des objets à

bords tranchants et des pièces en mouvement.

Le risque de choc électrique est plus élevé

lorsque les cordons sont endommagés ou

enchevêtrés.

8. Lorsque vous utilisez un outil électrique à

l'extérieur, utilisez un cordon prolongateur

prévu à cette fin. Les risques de choc électrique

sont moindres lorsqu'un cordon conçu pour

l'extérieur est utilisé.

9. Si vous devez utiliser un outil électrique dans

un endroit humide, utilisez une source

d'alimentation protégée par un disjoncteur de

fuite à la terre. L'utilisation d'un disjoncteur de

fuite à la terre réduit le risque de choc électrique.

Sécurité personnelle

10. Restez alerte, attentif à vos mouvements et

faites preuve de bon sens lorsque vous

utilisez un outil électrique. Évitez d'utiliser un

outil électrique si vous êtes fatigué ou si vous

avez pris une drogue, de l'alcool ou un

médicament. Un moment d'inattention pendant

l'utilisation d'un outil électrique peut entraîner une

grave blessure.

Page 12

11. Portez des dispositifs de protection

personnelle. Portez toujours un protecteur

pour la vue. Les risques de blessure seront

moins élevés si vous utilisez des dispositifs de

protection tels qu'un masque antipoussières, des

chaussures à semelle antidérapante, une coiffure

résistante ou une protection d'oreilles.

12. Évitez les démarrages accidentels.

Assurez-vous que l'interrupteur est en

position d'arrêt avant de brancher l'outil et/ou

d'insérer la batterie, ainsi qu'avant de saisir ou

de transporter l'outil. . Vous ouvrez la porte aux

accidents si vous transportez les outils électriques

avec le doigt sur l'interrupteur ou laissez

l'interrupteur en position de marche avant de

mettre l'outil sous tension.

13. Retirez toute clé de réglage ou de serrage

avant de mettre l'outil sous tension. Toute clé

laissée en place sur une pièce rotative de l'outil

électrique peut entraîner une blessure.

14. Maintenez une bonne position. Assurez-vous

d'une bonne prise au sol et d'une bonne

position d'équilibre en tout temps. Cela vous

permettra d'avoir une meilleure maîtrise de l'outil

dans les situations imprévues.

15. Portez des vêtements adéquats. Ne portez ni

vêtements amples ni bijoux. Vous devez

maintenir cheveux, vêtements et gants à

l'écart des pièces en mouvement. Les pièces

en mouvement peuvent happer les vêtements

amples, les bijoux et les cheveux longs.

16. Si des accessoires sont fournis pour

raccorder un appareil d'aspiration et de

collecte de la poussière, assurez-vous qu'ils

sont correctement raccordés et qu'ils sont

utilisés de manière adéquate. L'utilisation d'un

appareil d'aspiration permet de réduire les risques

liés à la présence de poussière dans l'air.

Utilisation et entretien des outils électriques

17. Ne forcez pas l'outil électrique. Utilisez l'outil

électrique adéquat suivant le type de travail à

effectuer. Si vous utilisez l'outil électrique

adéquat et respectez le régime pour lequel il a été

conçu, il effectuera un travail de meilleure qualité

et de façon plus sécuritaire.

18. N'utilisez pas l'outil électrique s'il n'est pas

possible de mettre sa gâchette en position de

marche et d'arrêt. Un outil électrique dont

l'interrupteur est défectueux représente un danger

et doit être réparé.

19. Débranchez la fiche de la source

d'alimentation et/ou retirez le bloc-piles de

l'outil électrique avant d'effectuer tout réglage,

de changer un accessoire ou de ranger l'outil

électrique. De telles mesures préventives

réduisent les risques de démarrage accidentel de

l'outil électrique.

20. Après l'utilisation d'un outil électrique,

rangez-le hors de portée des enfants et ne

laissez aucune personne l'utiliser si elle n'est

pas familiarisée avec l'outil électrique ou les

présentes instructions d'utilisation. Les outils

électriques représentent un danger entre les

mains de personnes qui n'en connaissent pas le

mode d'utilisation.

21. Veillez à l’entretien des outils électriques.

Assurez-vous que les pièces mobiles ne sont

pas désalignées ou coincées, qu’aucune pièce

n’est cassée et que l’outil électrique n’a subi

aucun dommage affectant son bon

fonctionnement. Le cas échéant, faites réparer

l'outil électrique avant de l'utiliser. De

nombreux accidents sont causés par des outils

électriques mal entretenus.

22. Maintenez les outils tranchants bien aiguisés

et propres. Un outil tranchant dont l'entretien est

effectué correctement et dont les bords sont bien

aiguisés risquera moins de se coincer et sera plus

facile à maîtriser.

23. Utilisez l'outil électrique, ses accessoires, ses

embouts, etc., en respectant les présentes

instructions, en tenant compte des conditions

de travail et du type de travail à effectuer.

L'utilisation d'un outil électrique à des fins autres

que celles prévues peut entraîner une situation

dangereuse.

SERVICE

24. Faites réparer votre outil électrique par un

réparateur qualifié qui utilise des pièces de

rechange identiques aux pièces d'origine. Le

maintien de la sûreté de l'outil électrique sera

ainsi assuré.

25. Suivez les instructions de lubrification et de

changement des accessoires.

26. Maintenez les poignées de l'outil sèches,

propres et exemptes d'huile ou de graisse.

UTILISEZ UN CORDON PROLONGATEUR

APPROPRIÉ. Assurez-vous que votre cordon

prolongateur est en bonne condition. Lorsque vous

utilisez un cordon prolongateur, assurez-vous qu'il est

assez robuste pour transporter le courant exigé par le

produit. Un cordon qui est trop petit entraînera une

baisse dans la tension composée, ce qui causera une

perte d'énergie et un surchauffage. Le tableau 1 indique

la dimension de cordon à utiliser, en fonction de la

longueur du cordon et de l'intensité nominale figurant

sur la plaque signalétique. En cas de doute, utilisez un

cordon plus robuste. Plus le numéro de calibre est bas,

plus le cordon est robuste.

12

Page 13

Tableau 1. Gabarit minimum du cordon

Intensit

é nominale

Volts Longueur totale du cordon en pieds

120 V 25 pi 50 pi 100 pi 150 pi

Plus de Pas plus de Calibre am

0 6 18 16 16 14

10 12 16 16 14 12

000173

12 16 14 12

GEB013-1

RÈGLES DE SÉCURITÉ

PARTICULIÈRES

NE vous laissez PAS tromper (au fil d'une utilisation

répétée) par un sentiment d'aisance ou de familiarité

avec le produit, au point de négliger le respect

rigoureux des consignes de sécurité qui

accompagnent la scie circulaire. Si vous n'utilisez

pas cet outil électrique de façon sécuritaire et

adéquate, vous courez un risque de blessure grave.

DANGER :

1. Gardez les mains à l'écart de la zone de coupe

et de la lame. Gardez la deuxième main sur la

poignée auxiliaire ou sur le boîtier du moteur.

Vous ne risquerez pas de coupure aux mains si

vous saisissez la scie à deux mains.

2. N'étendez pas la main sous la pièce. Le

protecteur ne peut pas vous protéger contre la

lame sous la pièce. N'essayez pas de retirer le

matériau coupé pendant que la lame tourne.

ATTENTION : La lame continue de tourner après

la mise hors tension de l'outil. Attendez l'arrêt

complet de la lame avant de saisir le matériau

coupé.

3. Ajustez la profondeur de coupe en fonction de

l'épaisseur de la pièce. La partie de la lame

visible sous la pièce doit être inférieure à une dent

de lame complète.

4. Ne tenez jamais la pièce à couper dans vos

mains ou appuyée contre une jambe.

Immobilisez la pièce contre une surface de

travail stable. Il est important que la pièce à

couper soit soutenue pour minimiser l'exposition

du corps, le pincement de la lame ou la perte de

maîtrise.

000157

5. Saisissez l'outil électrique par ses surfaces de

6. Pour effectuer un sciage en long utilisez

7. Employez toujours une lame de diamètre

8. N'utilisez jamais de rondelles ou boulons

9. Causes des reculs et mesures préventives à

éricain des fils

18 16 14 12610

Non recommand

Illustration de la façon typique et correcte de tenir la scie,

de soutenir la pièce et de placer le cordon.

é

prise isolées pour effectuer un travail au cours

duquel l'outil tranchant risque d'entrer en

contact avec des fils cachés ou avec le cordon

de l'outil. Le contact avec un fil sous tension

mettra également les parties métalliques

exposées de l'outil électrique sous tension,

causant ainsi un choc électrique chez l'utilisateur.

toujours un garde parallèle ou un guide de

coupe rectiligne. Cela permet une plus grande

précision de coupe et réduit les risques de

pincement de la lame.

approprié et dont le trou central est de forme

correcte (angulaire ou ronde). Une lame dont le

trou ne correspond pas à la forme du moyeu de

fixation de la scie risque de tourner de façon

excentrique et de vous faire perdre la maîtrise de

l'outil.

endommagés ou inadéquats pour fixer la lame.

Les rondelles et le boulon ont été conçus

spécialement pour votre scie, afin d'assurer un

fonctionnement optimal et un travail sécuritaire.

prendre :

13

Page 14

− le recul est une réaction soudaine survenant

lorsque la lame, coincée, pincée ou mal

alignée devient incontrôlable, se soulève

hors de la pièce et se dirige vers l'utilisateur ;

− Lorsque la lame se trouve coincée ou pincée

par le trait de scie qui se referme sur elle, elle

se bloque et une réaction du moteur entraîne

alors l'outil rapidement vers l'utilisateur ;

− Si la lame se tord ou se désaligne par rapport

à la ligne de coupe, les dents arrière risquent

de s'enfoncer dans la surface du bois et la

lame de quitter le trait de scie en reculant

brusquement vers l'utilisateur.

Le recul est le résultat d'une utilisation inadéquate

de la scie et/ou de procédures ou conditions

d'utilisation incorrectes ; on peut l'éviter en prenant

des précautions adéquates, indiquées ci-dessous.

• Maintenez une prise ferme à deux mains

sur la scie, et placez vos bras de manière à

pouvoir résister à la force exercée lors des

reculs. Posez votre corps d'un côté ou de

l'autre de la lame, jamais dans sa ligne de

coupe. Un recul peut faire sauter la scie vers

l'arrière, mais l'utilisateur pourra maîtriser la

force exercée par ce recul s'il prend les

précautions nécessaires.

• Lorsque la lame se coince ou lorsque vous

interrompez la coupe pour une raison

quelconque, libérez la gâchette et gardez la

scie immobile dans le matériau jusqu'à ce

que la lame s'arrête parfaitement.

N'essayez jamais de retirer la scie de la

pièce ou de faire reculer la scie pendant

que la lame tourne, autrement il y a risque

de choc recul. Identifiez la cause du

coincement de la lame et prenez les mesures

correctives pour éliminer le problème.

• Avant de faire redémarrer la scie dans la

pièce, centrez la lame dans le trait de scie

et assurez-vous que les dents de la lame ne

mordent pas déjà dans le matériau. Si la

lame est coincée, elle risque de remonter

dans le trait de scie ou de causer un recul au

moment du redémarrage de la scie.

• Les grands panneaux doivent être

soutenus pour minimiser les risques de

recul causé par le coincement de la lame.

Les grands panneaux ont tendance à

s'affaisser sous leur propre poids. Des

supports doivent être installés sous le

panneau, des deux côtés, près de la ligne de

coupe et près du bord du panneau.

Pour minimiser les risques de coincement de la

lame et les chocs en retour. Lorsqu'il est

nécessaire que la scie soit déposée sur la pièce

pendant la coupe, elle doit l'être sur la partie la plus

grande de la pièce, non sur la plus petite, qui se

détachera.

Pour éviter la rétroaction, supporter la planche

ou le panneau près de la ligne de coupe.

000154

Ne pas supporter la planche ou le panneau

de façon éloignée de la ligne de coupe.

000156

• N'utilisez pas les lames émoussées ou

endommagées. Les lames mal affûtées ou

mal posées produisent un trait de scie étroit,

ce qui entraîne une friction excessive, des

pincements de lame et des reculs. Maintenez

la lame bien affûtée et propre. La colle et les

copeaux de bois qui se solidifient sur les

lames ralentissent la scie et accroissent les

risques de choc et retour. Pour nettoyer la

lame, retirez-la d'abord de l'outil, puis utilisez

un décapant, de l'eau chaude ou du kérosène

pour retirer la colle et les copeaux. N'utilisez

jamais d'essence.

• Avant d'effectuer la coupe, les leviers de

verrouillage de la profondeur de coupe et

de la coupe en biseau doivent être

fermement serrés. Il y a risque de pincement

et de recul si les réglages de la lame se

modifient pendant coupe.

• Faites preuve d'une grande prudence

lorsque vous effectuez une ≪ coupe en

plongée ≫ dans un mur ou toute autre

surface ≪ aveugle ≫. La lame peut accrocher

14

Page 15

des objets cachés en dépassant de l'autre

côté de la surface, entraînant un recul. Pour

les coupes en plongée, rétractez le protecteur

inférieur à l'aide de la poignée de rappel.

• Tenez TOUJOURS l'outil fermement à deux

mains. Ne placez JAMAIS vos mains ou

vos doigts derrière la scie. En cas de choc

en retour, la scie pourrait alors bondir vers

votre main et causer une blessure grave.

000194

• Ne forcez jamais la scie. Cela pourrait

provoquer des coupes inégales ou une

perte de précision, voire un choc en retour.

Ne forcez jamais la scie. Cela pourrait

provoquer des coupes inégales ou une perte

de précision, voire un recul.

10. Avant chaque utilisation, assurez-vous que le

protecteur inférieur se ferme bien. N'utilisez

pas la scie si le protecteur inférieur ne se

déplace pas librement et ne se ferme pas de

manière instantanée. Ne jamais fixer ou attacher

le protecteur inférieur en position ouverte. Le

protecteur inférieur risque de plier si la scie est

échappée par accident. Soulevez le protecteur

inférieur à l'aide de la poignée de rappel et

assurez-vous qu'il se déplace librement et n'entre

pas en contact avec la lame ou toute autre partie

de la scie, quel que soit l'angle ou la profondeur

de coupe.

Pour vérifier le bon fonctionnement du protecteur

inférieur, ouvrez-le manuellement et libérez-le

pour voir s'il se referme. Assurez-vous aussi que

la poignée de rappel ne touche pas le carter de

l'outil. Une lame exposée est TRÈS

DANGEREUSE et peut causer des blessures

graves.

11. Vérifiez le fonctionnement du ressort du

protecteur inférieur. Le protecteur et le ressort

doivent être réparés avant l'utilisation s'ils ne

fonctionnent pas correctement. Le

fonctionnement du protecteur inférieur peut être

ralenti par des pièces endommagées, des dépôts

collants ou l'accumulation de débris.

12. Le protecteur inférieur doit être rétracté de

manière manuelle uniquement lors des

coupes spéciales, telles que les coupes en

plongée et les coupes composées. Soulevez le

protecteur inférieur à l'aide de la poignée de

rappel et libérez-le dès que la lame entre en

contact avec le matériau. Pour tout autre type de

coupe, il faut laisser le protecteur inférieur

fonctionner de lui-même.

13. Avant de déposer la scie sur l'établi ou le

plancher, assurez-vous que le protecteur

inférieur recouvre la lame. Sans protection et en

roue libre, la scie reculera en coupant tout sur son

passage. N'oubliez pas qu'il faut un certain temps

avant que la lame ne cesse de tourner une fois

l'interrupteur relâché. Avant de déposer l'outil une

fois la coupe terminée, assurez-vous que le

protecteur inférieur recouvre la lame et que

celle-ci a complètement cessé de tourner.

14. Redoublez de prudence lorsque vous coupez

du bois humide, du bois traité sous pression

ou du bois qui contient des nœuds. Ajustez la

vitesse de coupe de telle sorte que l'outil continue

d'avancer en douceur, sans que la vitesse de la

lame ne diminue.

15. Prenez garde aux clous lors de la coupe. Avant

la coupe, vérifiez la présence de clous dans le

bois et retirez-les le cas échéant.

16. Placez la base de la scie sur la partie de la

pièce qui est solidement soutenue, non sur

celle qui tombera une fois la coupe terminée.

À titre d'exemples, la Fig. 1 illustre la BONNE

façon de couper l'extrémité d'une planche,

tandis que la Fig. 2 illustre la MAUVAISE façon

de procéder. Si la pièce est courte ou petite,

installez-la dans un dispositif de serrage.

N'ESSAYEZ PAS DE TENIR LES COURTES

PIÈCES UNIQUEMENT AVEC LA MAIN !

Fig. 1

000147

15

Page 16

Fig. 2

000150

17. Ne tentez jamais de scier en plaçant la scie la

tête en bas dans un étau. Cela est très

dangereux et peut entraîner de graves

accidents.

000029

18. Certains matériaux contiennent des produits

chimiques qui peuvent être toxiques. Prenez

les précautions nécessaires pour éviter

l'inhalation de ces poussières ou leur contact

avec la peau. Conformez-vous aux consignes

de sécurité du fournisseur du matériau.

19. N'appliquez jamais une pression latérale sur la

lame pour l'arrêter.

20. Utilisez toujours les lames recommandées

dans ce manuel. N'utilisez aucune meule

abrasive.

21. Portez un masque antipoussières et des

protections d'oreilles lorsque vous utilisez

l'outil.

CONSERVEZ CE MODE

D'EMPLOI.

AVERTISSEMENT:

Une MAUVAISE UTILISATION de l'outil ou

l'ignorance des consignes de sécurité du présent

manuel d'instructions peuvent entraîner une grave

blessure.

USD201-2

Symboles

Les symboles utilisés pour l'outil sont indiqués

ci-dessous.

・ volts

・ ampères

・ hertz

・ courant alternatif

・ vitesse à vide

・ construction, catégorie II

・ tours ou alternances par minute

DESCRIPTION DU

FONCTIONNEMENT

ATT EN TI ON :

• Assurez-vous toujours que l'outil est hors tension

et débranché avant de l'ajuster ou de vérifier son

fonctionnement.

Réglage de la profondeur de coupe

1. Levier

2

1

008672

ATT EN TI ON :

• Après avoir ajusté la profondeur de coupe, serrez

toujours fermement le levier.

Desserrez le levier du guide de profondeur puis

déplacez la base vers le haut ou le bas. À la profondeur

de coupe désirée, fixez la base en serrant le levier.

Pour obtenir des coupes plus propres et sans danger,

réglez la profondeur de coupe de sorte que pas plus

d'une dent de lame ne dépasse sous la pièce.

L'utilisation d'une profondeur de coupe adéquate aide à

réduire les risques de chocs en retour dangereux qui

peuvent causer des blessures.

2. Guide de

profondeur

16

Page 17

Coupe en biseau

2

3

1. Levier

2. Butoir positif

3. Flèche du butoir

positif

Interrupteur

1

1. Gâchette

008673

1

Butoir positif

Tournez le butoir positif de sorte que sa flèche pointe

vers l’une ou l’autre des trois positions (22.5°, 45°, 56°).

Ensuite, inclinez la base de l’outil jusqu’à ce qu’elle

s’arrête et fixez-la à l’aide du levier. Vous obtenez alors

un angle identique à celui vers lequel la flèche pointe.

Régler l'angle de coupe en biseau

Desserrez le levier et réglez provisoirement la base de

l'outil sur un angle de coupe en biseau de 0°, puis serrez

fermement le levier.

Tournez le butoir positif de sorte que sa flèche pointe sur

l’une des trois positions (22.5°, 45°, 56°) égale ou

supérieure à l’angle de coupe en biseau désiré.

Desserrez à nouveau le levier puis inclinez et serrez

fermement la base de l'outil sur l'angle désiré.

NOTE:

• Vous pouvez changer la position du butoir positif

en desserrant le levier et en inclinant l'angle de

coupe en biseau sur une valeur inférieure au

numéro de la position de butoir désirée.

• Lorsque la flèche du butoir positif pointe sur 22.5,

l’angle de coupe en biseau est réglable sur une

plage de 0 à 22.5° ; lorsqu’elle pointe sur 45, il est

réglable sur une plage de 0 à 45° ; et lorsqu’elle

pointe sur 56, elle est réglable sur une plage de 0 à

56°.

Visée

AB

1. Base

1

008674

Pour les coupes rectilignes, alignez sur la ligne de

coupe la position A à l'avant de la base. Pour les coupes

en biseau de 45°, alignez la position B sur la ligne de

coupe.

008675

ATT EN TI ON :

• Avant de brancher l'outil, assurez-vous toujours

que la gâchette fonctionne correctement et revient

en position d'arrêt une fois relâchée.

Pour faire démarrer l'outil, appuyez simplement sur la

gâchette. Pour l'arrêter, relâchez la gâchette.

Frein électrique

Pour le modèle 5007NFA uniquement

Cet outil est équipé d'un frein à lame électrique. Si à

plusieurs reprises l'outil ne s'arrête pas rapidement

après le relâchement de la gâchette, faites-le réparer

dans un centre de service après-vente Makita.

Le mécanisme de frein à lame ne doit pas être utilisé en

remplacement du garde inférieur. N'UTILISEZ JAMAIS

L'OUTIL LORSQUE LE GARDE INFÉRIEUR NE

FONCTIONNE PAS. CELA COMPORTE DES

RISQUES DE BLESSURE GRAVE.

Allumer la lampe (pour les modèles 5007NF et

5007NFA)

1. Lampe

1

008676

ATT EN TI ON :

• Évitez de faire subir des chocs à la lampe. Cela

risquerait de l'endommager ou de réduire sa durée

de service.

• Evitez de regarder directement le faisceau

lumineux ou sa source.

La lampe s'allume lorsque vous branchez l'outil. La

lampe demeure allumée jusqu'à ce que vous

débranchiez l'outil.

Si la lampe ne s’allume pas, il se peut que le cordon

d’alimentation soit défectueux. Si la lampe s’allume mais

17

Page 18

que l’outil ne démarre pas même s’il est sous tension, il

se peut que les charbons soient usés, ou bien que le

moteur ou l’interrupteur d’alimentation soit défectueux.

NOTE:

• Utilisez un chiffon sec pour essuyer la saleté qui

recouvre la lentille de la lampe. Prenez garde de

rayer la lentille de la lampe, pour éviter une

diminution de l'éclairage.

ASSEMBLAGE

ATT EN TI ON :

• Avant d'effectuer toute intervention sur l'outil,

assurez-vous toujours qu'il est hors tension et

débranché.

Rangement de la clé hexagonale

1. Clé hexagonale

2. Saillie

1

2

008677

La clé hexagonale est rangée sur l'outil. Pour retirer la

clé hexagonale, tournez-la vers vous-même et tirez.

Pour installer la clé hexagonale, placez-la sur la poignée

et tournez-la jusqu'à ce qu'elle entre en contact avec la

partie saillante de la poignée.

Retrait ou pose de la lame

1

008678

ATT EN TI ON :

• Assurez-vous que la lame est installée avec les

dents orientées vers le haut à l'avant de l'outil.

• Utilisez exclusivement une clé Makita pour installer

ou retirer la lame.

Pour retirer la lame, appuyez sur le blocage de l'arbre de

sorte que la lame ne puisse pas tourner, et utilisez la clé

hexagonale pour desserrer le boulon hexagonal en

tournant dans le sens contraire des aiguilles d'une

1. Clé hexagonale

2. Verrouillage de

l'arbre

2

montre. Retirez ensuite le boulon hexagonal, le flasque

extérieur et la lame.

Pour poser la lame, suivez la procédure de retrait en

sens inverse. ASSUREZ-VOUS D'AVOIR FERMEMENT

SERRÉ LE BOULON HEXAGONAL, DANS LE SENS

DES AIGUILLES D'UNE MONTRE.

3

12

008679

5

4

1. Boulon

hexagonal

2. Bague externe

3. Lame

4. Bague interne

5. Bague

Lorsque vous changez la lame, assurez-vous de retirer

la sciure de bois accumulée sur les gardes supérieur et

inférieur. Même après ce nettoyage, vous devez quand

même vérifier le bon fonctionnement du garde inférieur

avant chaque utilisation.

UTILISATION

ATT EN TI ON :

• Assurez-vous de déplacer l'outil doucement vers

l'avant, en ligne droite. Le fait de forcer ou de

tordre l'outil entraînera une surchauffe du moteur

et un dangereux choc en retour, risquant de

provoquer une blessure grave.

2

1

008680

Tenez l'outil fermement. L'outil est équipé d'une poignée

avant et d'une poignée arrière. Utilisez les deux

poignées pour assurer la meilleure prise possible sur

l'outil. De plus, lorsque la scie est saisie à deux mains,

celles-ci ne risquent pas d'être coupées par la lame.

Placez la base de l'outil sur la pièce à couper de sorte

que la lame n'entre pas en contact avec quoi que ce soit.

Mettez ensuite l'outil sous tension et attendez que la

lame ait atteint sa pleine vitesse. Faites alors

simplement avancer l'outil sur la surface de la pièce, en

le maintenant de niveau et en le faisant avancer

doucement jusqu'à ce que la coupe soit terminée.

Pour obtenir des coupes nettes, maintenez votre ligne

18

1. Base

2. Poignée arrière

3

3. Poignée avant

Page 19

de coupe bien droite et la vitesse de progression

uniforme. Si la lame dévie de la ligne de coupe prévue,

ne tentez pas de modifier la course de l'outil pour le

forcer à revenir sur la ligne de coupe. Vous risqueriez de

plier la lame et de provoquer un dangereux choc en

retour pouvant causer une blessure grave. Relâchez la

gâchette, attendez jusqu'à l'arrêt complet de la lame,

puis retirez l'outil. Réalignez l'outil sur une nouvelle ligne

de coupe, puis poursuivez la coupe. Évitez toute

position vous exposant aux copeaux et sciures de bois

éjectés par la scie. Portez des lunettes de protection

pour réduire les risques de blessure.

Garde parallèle (règle de guidage)

1. Garde parallèle

(règle de

guidage)

1

008682

2

1. Base

2. Vis de réglage

1. Règle

1

triangulaire

1

008681

Un garde parallèle pratique vous permet d'effectuer des

coupes droites d'une extrême précision. Faites

simplement glisser le garde parallèle le long du côté de

la pièce en le maintenant en position à l'aide de la vis de

serrage située à l'avant de la base. Cela permet

également d'effectuer plusieurs coupes d'une largeur

uniforme.

ENTRETIEN

ATT EN TI ON :

• Assurez-vous toujours que l'outil est hors tension

et débranché avant d'y effectuer tout travail

d'inspection ou d'entretien.

Réglage de précision pour les coupes de 90°

(coupes à angle droit)

Ce réglage est effectué en usine. S'il est désactivé,

ajustez la vis de réglage au moyen d'une clé hexagonale,

en plaçant la lame sur un angle droit par rapport à la

base avec une règle triangulaire, une équerre de

menuisier, etc.

008683

Remplacement des charbons

1. Trait de limite

d'usure

1

001145

Retirez et vérifiez régulièrement les charbons.

Remplacez-les lorsqu'ils sont usés jusqu'au trait de

limite d'usure. Maintenez les charbons propres et en état

de glisser aisément dans les porte-charbon. Les deux

charbons doivent être remplacés en même temps.

N'utilisez que des charbons identiques.

Utilisez un tournevis pour retirer les bouchons de

porte-charbon. Enlevez les charbons usés, insérez-en

de nouveaux et revissez solidement les bouchons de

porte-charbon.

1

2

008684

1. Bouchon de

porte-charbon

2. Tournevis

19

Page 20

Pour le modèle 5007NFA uniquement

A

À

A

Après avoir remplacé les charbons, branchez l'outil et

rodez les brosses en faisant fonctionner l'outil à vide

pendant environ 10 minutes. Vérifiez ensuite le bon

fonctionnement de l'outil, ainsi que l'activation du frein

électrique lors du relâchement de la gâchette. Si le frein

électrique ne fonctionne pas bien, faites une demande

de réparation auprès du centre de service après-vente

Makita le plus près.

Pour maintenir la SÉCURITÉ et la FIABILITÉ du produit,

les réparations, tout autre travail d'entretien ou de

réglage doivent être effectués dans un centre de service

Makita agréé ou un centre de service de l'usine Makita,

exclusivement avec des pièces de rechange Makita.

ACCESSOIRES

ATT EN TI ON :

• Ces accessoires ou pièces complémentaires sont

recommandés pour l'utilisation avec l'outil Makita

spécifié dans ce mode d'emploi. L'utilisation de

tout autre accessoire ou pièce complémentaire

peut comporter un risque de blessure. N'utilisez les

accessoires ou pièces qu'aux fins auxquelles ils

ont été conçus.

Si vous désirez obtenir plus de détails concernant ces

accessoires, veuillez contacter le centre de service

après-vente Makita le plus près.

• Lames à dents d'acier et de carbure de tungstène

Combinaison

Bois traité sous pression

et bois humide

Coupes en travers

de précision

006549

• Garde parallèle (règle de guidage)

• Clé hexagonale

Lame d'usage général pour effectuer rapidement et en douceur des

coupes longitudinales, des coupes en travers et des coupes d'onglet.

Conçues pour la coupe rapide du bois traité sous

pression et du bois humide.

Pour des coupes propres et sans ponçage dans le

sens opposé au grain.

GARANTIE LIMITÉE D’UN AN MAKITA

Politique de garantie

Chaque outil Makita est inspecté rigoureusement et

testé avant sa sortie d’usine. Nous garantissons qu’il

sera exempt de défaut de fabrication et de vice de

matériau pour une période d’UN AN à partir de la date

de son achat initial. Si un problème quelconque devait

survenir au cours de cette période d’un an, veuillez

retourner l’outil COMPLET, port payé, à une usine ou à

un centre de service après-vente Makita. Makita

réparera l’outil gratuitement (ou le remplacera, à sa

discrétion) si un défaut de fabrication ou un vice de

matériau est découvert lors de l’inspection.

Cette garantie ne s’applique pas dans les cas où:

des réparations ont été effectuées ou tentées par

un tiers:

des réparations s’imposent suite à une usure

normale:

l’outil a été malmené, mal utilisé ou mal entretenu:

l’outil a subi des modifications.

MAKITA DÉCLINE TOUTE RESPONSABILITÉ POUR

TOUT DOMMAGE ACCESSOIRE OU INDIRECT LIÉ À

LA VENTE OU À L’UTILISATION DU PRODUIT. CET

VIS DE NON-RESPONSABILITÉ S’APPLIQUE À LA

FOIS PENDANT ET APRÈS LA PÉRIODE COUVERTE

PAR CETTE GARANTIE.

MAKITA DÉCLINE TOUTE RESPONSABILITÉ QUANT

TOUTE GARANTIE TACITE, INCLUANT LES

GARANTIES TACITES DE “QUALITÉ MARCHANDE”

ET “ADÉQUATION À UN USAGE PARTICULIER”

PRÈS LA PÉRIODE D’UN AN COUVERTE PAR

CETTE GARANTIE.

Cette garantie vous donne des droits spécifiques

reconnus par la loi, et possiblement d’autres droits, qui

varient d’un État à l’autre. Certains États ne permettant

pas l’exclusion ou la limitation des dommages

accessoires ou indirects, il se peut que la limitation ou

exclusion ci-dessus ne s’applique pas à vous. Certains

États ne permettant pas la limitation de la durée

d’application d’une garantie tacite, il se peut que la

limitation ci-dessus ne s’applique pas à vous.

EN0006-1

20

Page 21

ESPAÑOL

ESPECIFICACIONES

Especificaciones eléctricas en México 120 V 15 A 50/60 Hz

Profundidad de corte máxima

Revoluciones por minuto (r.p.m.) 5 800 r/min

• Debido a nuestro programa continuo de investigación y desarrollo, las especificaciones aquí dadas están sujetas a cambios sin

previo aviso.

• Nota: Las especificaciones pueden ser diferentes de país a país.

Advertencias de seguridad

generales para herramientas

eléctricas

ADVERTENCIA: lea todas las advertencias de

seguridad e instrucciones. Si no sigue todas las

advertencias e instrucciones indicadas a continuación,

podrá ocasionar una descarga eléctrica, un incendio y/o

lesiones graves.

Guarde todas las advertencias e

instrucciones para su futura

referencia.

El término “herramienta eléctrica” se refiere, en todas

las advertencias que aparecen a continuación, a su

herramienta eléctrica de funcionamiento con conexión a

la red eléctrica (con cableado eléctrico) o herramienta

eléctrica de funcionamiento a batería (inalámbrica).

Seguridad en el área de trabajo

1. Mantenga el área de trabajo limpia y bien

iluminada. Las áreas oscuras o desordenadas

son propensas a accidentes.

2. No utilice las herramientas eléctricas en

atmósferas explosivas, tal como en la

presencia de líquidos, gases o polvo

inflamables. Las herramientas eléctricas crean

chispas que pueden prender fuego al polvo o los

humos.

3. Mantenga a los niños y curiosos alejados

mientras utiliza una herramienta eléctrica. Las

distracciones le pueden hacer perder el control.

Seguridad eléctrica

4. Las clavijas de conexión de las herramientas

eléctricas deberán encajar perfectamente en la

toma de corriente. No modifique nunca la

Modelo 5007N/5007NF/5007NFA

Diámetro del disco 185 mm (7-1/4")

Longitud total 317 mm (12-1/2")

Peso neto 5,0 kg (11 lbs)

a 0° 63,5 mm (2-1/2")

a 45° 45 mm (1-3/4")

a 56° 35 mm (1-3/8")

GEA008-1

clavija de conexión de ninguna forma. No

utilice ninguna clavija adaptadora con

herramientas eléctricas que tengan conexión a

tierra (puesta a tierra). La utilización de clavijas

no modificadas y que encajen perfectamente en

la toma de corriente reducirá el riesgo de que se

produzca una descarga eléctrica.

5. Evite tocar con el cuerpo superficies

conectadas a tierra o puestas a tierra tales

como tubos, radiadores, cocinas y

refrigeradores. Si su cuerpo es puesto a tierra o

conectado a tierra existirá un mayor riesgo de que

sufra una descarga eléctrica.

6. No exponga las herramientas eléctricas a la

lluvia ni a condiciones húmedas. La entrada de

agua en una herramienta eléctrica aumentará el

riesgo de que se produzca una descarga

eléctrica.

7. No jale el cable. Nunca utilice el cable para

transportar, jalar o desconectar la herramienta

eléctrica. Mantenga el cable alejado del calor,

aceite, objetos cortantes o piezas móviles. Los

cables dañados o atrapados aumentan el riesgo

de sufrir una descarga eléctrica.

8. Cuando utilice una herramienta eléctrica en

exteriores, utilice un cable de extensión

apropiado para uso en exteriores. La utilización

de un cable apropiado para uso en exteriores

reducirá el riesgo de que se produzca una

descarga eléctrica.

9. Si no es posible evitar usar una herramienta

eléctrica en condiciones húmedas, utilice un

alimentador protegido con interruptor de

circuito de falla en tierra (ICFT). El uso de un

ICFT reduce el riesgo de descarga eléctrica.

21

Page 22

Seguridad personal

10. Manténgase alerta, preste atención a lo que

está haciendo y utilice su sentido común

cuando opere una herramienta eléctrica. No

utilice la herramienta eléctrica cuando esté

cansado o bajo la influencia de drogas,

alcohol o medicamentos. Un momento de

distracción mientras opera la máquina puede dar

como resultado heridas personales graves.

11. Use equipo de protección personal. Póngase

siempre protección para los ojos. El equipo

protector tal como máscara contra el polvo,

zapatos de seguridad antiderrapantes, casco

rígido y protección para oídos utilizado en las

condiciones apropiadas reducirá las heridas

personales.

12. Impida el encendido accidental. Asegúrese de

que el interruptor esté en la posición de

apagado antes de conectar a la alimentación

eléctrica y/o de colocar el cartucho de la

batería, así como al levantar o cargar la

herramienta. Cargar las herramientas eléctricas

con su dedo en el interruptor o enchufarlas con el

interruptor encendido hace que los accidentes

sean propensos.

13. Retire cualquier llave de ajuste o llave de

apriete antes de encender la herramienta. Una

llave de ajuste o llave de apriete que haya sido

dejada puesta en una parte giratoria de la

herramienta eléctrica podrá resultar en heridas

personales.

14. No utilice la herramienta donde no alcance.

Mantenga los pies sobre suelo firme y el

equilibrio en todo momento. Esto permite un

mejor control de la herramienta eléctrica en

situaciones inesperadas.

15. Use vestimenta apropiada. No use ropas

sueltas ni joyas. Mantenga el cabello, la ropa y

los guantes alejados de las partes móviles, ya

que pueden ser atrapadas por estas partes en

movimiento.

16. Si dispone de dispositivos para la conexión de

equipos de extracción y recolección de polvo,

asegúrese de conectarlos y utilizarlos

debidamente. La utilización de estos dispositivos

reduce los riesgos relacionados con el polvo.

Mantenimiento y uso de la herramienta eléctrica

17. No fuerce la herramienta eléctrica. Utilice la

herramienta eléctrica correcta para su

aplicación. La herramienta eléctrica adecuada

hará un trabajo mejor a la velocidad para la que

ha sido fabricada.

18. No utilice la herramienta eléctrica si el

interruptor no la enciende y apaga. Cualquier

herramienta eléctrica que no pueda ser

controlada con el interruptor es peligrosa y debe

ser reemplazada.

19. Desconecte la clavija de la fuente de energía

y/o la batería de la herramienta eléctrica antes

de realizar ajustes, cambiar accesorios o

guardar las herramientas eléctricas. Dichas

medidas de seguridad preventivas reducen el

riesgo de que la herramienta se inicie

accidentalmente.

20. Guarde la herramienta eléctrica que no use

fuera del alcance de los niños y no permita

que las personas que no están familiarizadas

con ella o con las instrucciones la operen. Las

herramientas eléctricas son peligrosas en manos

de personas que no saben operarlas

21. Realice el mantenimiento a las herramientas

eléctricas. Compruebe que no haya partes

móviles desalineadas o estancadas, piezas

rotas y cualquier otra condición que pueda

afectar al funcionamiento de la herramienta

eléctrica. Si la herramienta eléctrica está

dañada, haga que se la reparen antes de

utilizarla. Muchos accidentes son ocasionados

por herramientas eléctricas con un mal

mantenimiento.

22. Mantenga las herramientas de corte limpias y

filosas. Si recibe un mantenimiento adecuado y

tiene los bordes afilados, es probable que la

herramienta se atasque menos y sea más fácil

controlarla.

23. Utilice la herramienta eléctrica, así como

accesorios, piezas, brocas, etc. de acuerdo

con estas instrucciones y de la manera

establecida para cada tipo de unidad en

particular; tenga en cuenta las condiciones

laborales y el trabajo a realizar. Si utiliza la

herramienta eléctrica para realizar operaciones

distintas de las indicadas, podrá presentarse una

situación peligrosa.

SERVICIO DE MANTENIMIENTO

24. Haga que una persona calificada repare la

herramienta utilizando sólo piezas de repuesto

idénticas. Esto asegura que se mantenga la

seguridad de la herramienta eléctrica.

25. Siga las instrucciones para la lubricación y

cambio de accesorios.

26. Mantenga las agarraderas secas, limpias y sin

aceite o grasa.

UTILICE CABLES DE EXTENSIÓN APROPIADOS.

Asegúrese de que su cable de extensión esté en

buenas condiciones. Cuando utilice un cable de

extensión, asegúrese de utilizar uno del calibre

suficiente para conducir la corriente que demande el

producto. Un cable de calibre inferior ocasionará una

caída en la tensión de línea y a su vez en una pérdida

22

Page 23

de potencia y sobrecalentamiento. La Tabla 1 muestra la

medida correcta a utilizar dependiendo de la longitud del

cable y el amperaje nominal indicado en la placa de

características. Si no está seguro, utilice el siguiente

calibre más alto. Mientrás más pequeño sea el nú mero

de calibre del cable, mayor corriente podrá conducir

éste.

Tabla 1. Calibre mínimo para el cable

Amperaje nominal

Voltios Longitud total del cable en metros

120 V~

7,6 m (25 ft) 15,2 m (50 ft) 30,4 m (100 ft) 45,7 m (150 ft)

Más de No más de Calibre del cable (AWG)

0 A 6 A 18161614

18 16 14 126 A 10 A

10 A 12 A 16 16 14 12

000173

12 A 16 A 14 12

GEB013-1

NORMAS ESPECÍFICAS DE

SEGURIDAD

NO deje que la comodidad o familiaridad con el

producto (a base de utilizarlo repetidamente)

sustituya la estricta observancia de las normas de

seguridad para la sierra circular. Si utiliza esta

herramienta de forma no segura o incorrecta, podrá

sufrir graves heridas personales.

PELIGRO:

1. Mantenga las manos alejadas del área de corte

y del disco. Mantenga su segunda mano sobre

el mango auxiliar o sobre el alojamiento del

motor. Si ambas manos sujetan la sierra no

pueden sufrir cortes del disco.

2. Nunca meta la mano por debajo de la pieza de

trabajo. El protector no puede protegerle de la

sierra debajo de la pieza de trabajo. No intente

retirar material cortado cuando el disco se está

moviendo.

PRECAUCIÓN: Los discos siguen girando por

inercia después de apagar la herramienta. Espere

hasta que el disco se detenga antes de recoger el

material cortado.

3. Ajuste la profundidad de corte al grosor de la

pieza de trabajo. Debe verse menos de un diente

completo por debajo de la pieza de trabajo.

4. Nunca sujete la pieza que se está cortando

con las manos ni entre las piernas. Fije la

pieza de trabajo a una plataforma estable. Es

importante sujetar la pieza de trabajo

correctamente para minimizar la exposición del

cuerpo, el estancamiento del disco o la pérdida de

control.

Una ilustración típica del correcto apoyo de las manos, apoyo

de la pieza de trabajo, y tendido del cable de alimentación.

000157

5. Sujete la herramienta eléctrica por las

superficies de agarre aisladas al realizar una

operación en la que la herramienta de corte

pueda entrar en contacto con cables ocultos o

con su propio cable. Si entra en contacto con un

cable con corriente, las piezas metálicas

expuestas de la herramienta eléctrica se cargarán

también de corriente y el operario puede recibir

una descarga.

6. Cuando corte longitudinalmente, utilice

siempre un tope lateral o una guía de borde

recto. Esto mejora la precisión del corte y reduce

la posibilidad de que el disco se atasque.

7. Utilice siempre discos con orificios de husillo

del tamaño y la forma (poligonal o redonda)

correctos. Los discos que no encajen con las

piezas de montaje de la sierra girarán

excéntricamente y producirán una pérdida de

control.

8. Nunca utilice arandelas o pernos de disco

dañados o incorrectos. El perno y las arandelas

del disco se han diseñado específicamente para

el mismo, para una seguridad y un rendimiento

No se recomienda

23

Page 24

óptimos.