Page 1

GB Router

Instruction Manual

F Défonceuse

DOberfräse

I Fresatrice

NL Bovenfrees

E Fresadora

P

Tupia Manual de instruções

DK

Overfr

S

Hand

NHåndoverfres

SF

Yläjyrsin Käyttöohje

GR Ρούτερ Οδηγίες χρήσεως

æser

överfräs

Manuel d’instructions

Betriebsanleitung

Istruzioni per l’uso

Gebruiksaanwijzing

Manual de instrucciones

Brugsanvisning

Bruksanvisning

Bruksanvisning

3620

Page 2

12

34

56

7

2

Page 3

8

910

11 12

13 14

3

Page 4

15 16

17

4

Page 5

ENGLISH

1Tighten

2Loosen

3Hold

4Screw

5 Stopper pole

6Lock lever

7 Depth pointer

8 Adjusting hex bolt

9 Stopper block

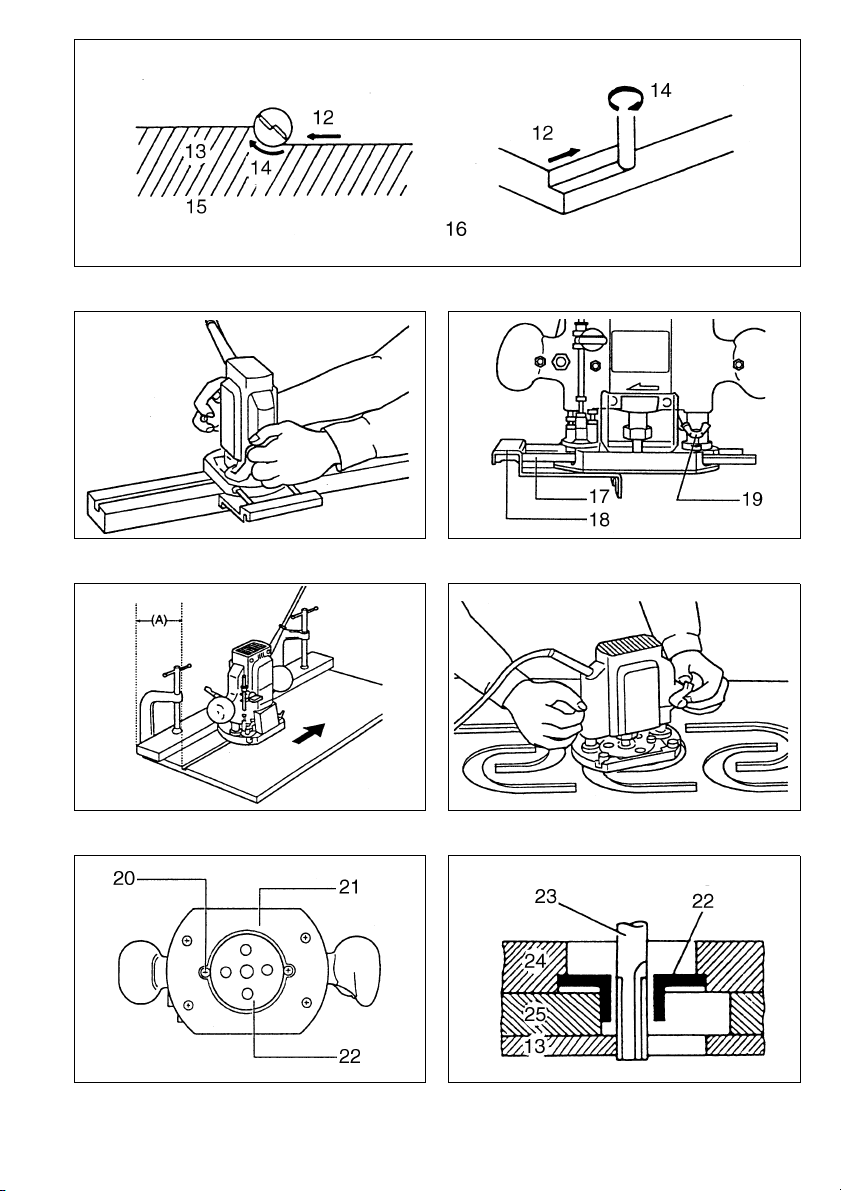

Explanation of general view

10 Hex nut

11 Switch trigger

12 Feed direction

13 Workpiece

14 Bit revolving direction

15 (View from the top of the tool)

16 Correct bit feed direction

17 Guide bar

18 Straight guide

19 Wing bolt

20 Screw

21 Base plate

22 Templet guide

23 Bit

24 Base

25 Templet

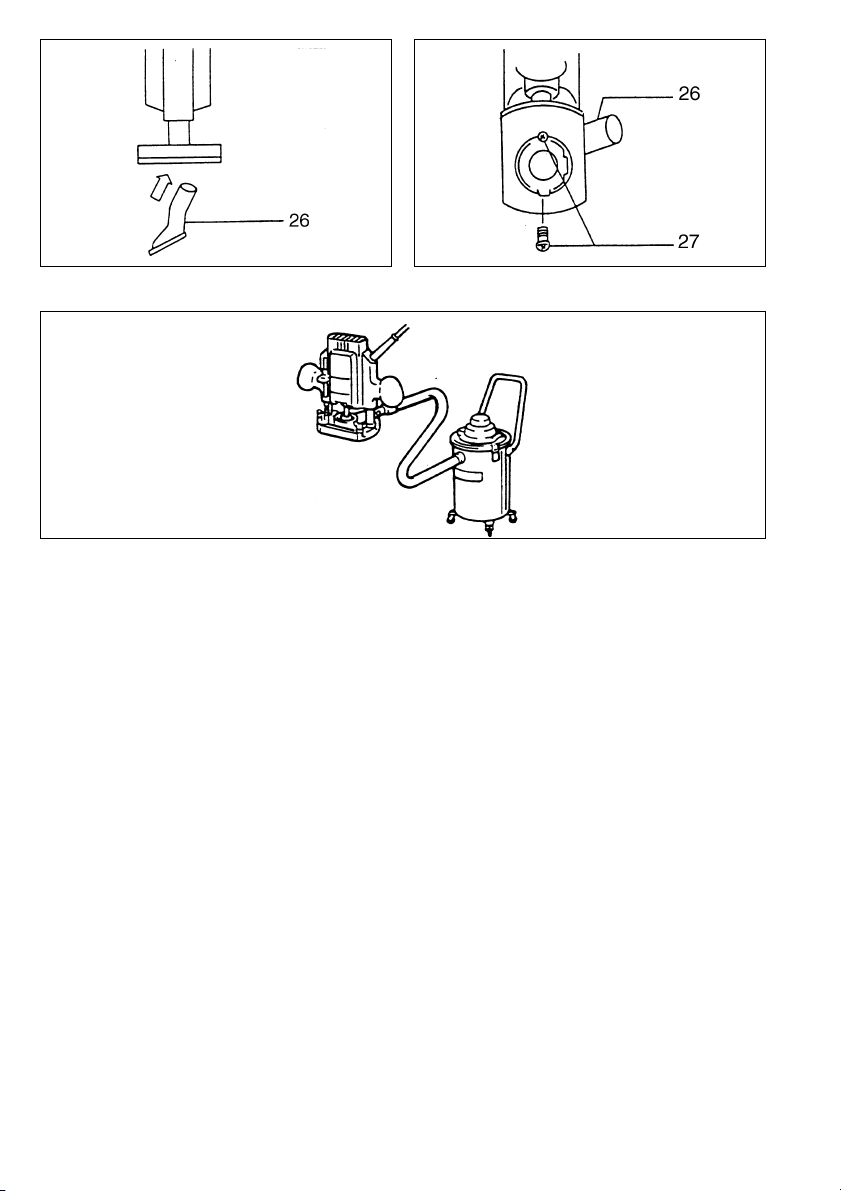

26 Vacuum head

27 Screws

SPECIFICATIONS

Model 3620

Collet capacity ............................................ .8 mm or 3/8”

Plunge capacity ............................................... 0 – 35mm

No load speed (min

Overall height ..................................................... 211 mm

Net weight .............................................................. 2.4 kg

• Due to our continuing program of research and development, the specifications herein are subject to change

without notice.

• Note: Specifications may differ from country to country.

Power supply

The tool should be connected only to a power supply of

the same voltage as indicated on the nameplate, and can

only be operated on single-phase AC supply. They are

double-insulated in accordance with European Standard

and can, therefore, also be used from sockets without

earth wire.

Safety hints

For your own safety, please refer to the enclosed safety

instructions.

-1

) ........................................... 29,000

SPECIFIC SAFETY RULES

GEB018-1

DO NOT let comfort or familiarity with product

(gained from repeated use) replace strict adherence

to router safety rules. If you use this tool unsafely or

incorrectly, you can suffer serious personal injury.

1. Hold power tool by insulated gripping surfaces

when performing an operation where the cutting

tool may contact hidden wiring or its own cord.

Contact with a “live” wire will make exposed

metal parts of the tool “live” and shock the operator.

2. Use clamps or another practical way to secure

and support the workpiece to a stable platform.

Holding the work by hand or against your body

leaves it unstable and may lead to loss of control.

3. Wear hearing protection during extended period

of operation.

4. Handle the bits very carefully.

5. Check the bit carefully for cracks or damage

before operation.

Replace cracked or damaged bit immediately.

6. Avoid cutting nails. Inspect for and remove all

nails from the workpiece before operation.

7. Hold the tool firmly.

8. Keep hands away from rotating parts.

9. Make sure the bit is not contacting the workpiece before the switch is turned on.

10. Before using the tool on an actual workpiece, let

it run for a while.

Watch for vibration or wobbling that could indicate improperly installed bit.

11. Be careful of the bit rotating direction and the

feed direction.

12. Do not leave the tool running. Operate the tool

only when hand-held.

13. Always switch off and wait for the bit to come to

a complete stop before removing the tool from

workpiece.

14. Do not touch the bit immediately after operation;

it may be extremely hot and could burn your

skin.

15. Do not smear the tool base carelessly with thinner, gasoline, oil or the like.

They may cause cracks in the tool base.

16. Draw attention to the need to use cutters of the

correct shank diameter and which are suitable

for the speed of the tool.

17. Some material contains chemicals which may be

toxic. Take caution to prevent dust inhalation

and skin contact. Follow material supplier safety

data.

18. Always use the correct dust mask/respirator for

the material and application you are working

with.

SAVE THESE INSTRUCTIONS.

WARNING:

MISUSE or failure to follow the safety rules stated in

this instruction manual may cause serious personal

injury.

OPERATING INSTRUCTIONS

Installing or removing router bit (Fig.1)

Important:

Always be sure that the tool is switched off and

unplugged before installing or removing the bit.

Insert the bit all the way into the collet cone and tighten

the collet nut securely with the two wrenches.

A 6 mm or 1/4” collet cone is also provided as standard

equipment besides the 8mm or 3/8” collet cone that is

factory installed on the tool. Use the correct size collet

cone for the bit which you intend to use.

To remove the bit, follow the installation procedure in

reverse.

5

Page 6

CAUTION:

Do not tighten the collet nut without inserting a bit, or the

collet cone will break.

Adjusting the depth of cut (Fig. 2, 3 & 4)

Place the tool on a flat surface. Loosen the screw securing the stopper pole.

Loosen the lock lever and lower the tool body until the bit

just touches the flat surface. Tighten the lock lever to lock

the tool body.

Next, lower the stopper pole until it makes contact with

the adjusting hex bolt. Align the depth pointer with the “0”

graduation.

Raise the stopper pole until the desired depth of cut is

obtained. The depth of cut is indicated on the scale

(1 mm or 1/16” per graduation) by the depth pointer.

Then tighten the screw to secure the stopper pole.

Now, your predetermined depth of cut can be obtained by

loosening the lock lever and then lowering the tool body

until the stopper pole makes contact with the adjusting

hex bolt.

CAUTION:

Since excessive cutting may cause overload of the motor

or difficulty in controlling the tool, the depth of cut should

not be more than 15 mm at a pass when cutting grooves

with an 8 mm diameter bit.

[Note: When cutting grooves with a 20 mm diameter bit,

the depth of cut should not be more than 5 mm at a

pass.] When you wish to cut grooves more than 15 mm

deep with an 8 mm diameter bit or more than 5 mm deep

with a 20 mm diameter bit, make several passes with

progressively deeper bit settings.

Stopper block (Fig. 5)

The stopper block has three adjusting hex bolts which

raise or lower 0.8 mm per turn. You can easily obtain

three different depths of cut using these adjusting hex

bolts without readjusting the stopper pole.

Adjust the lowest hex bolt to obtain the deepest depth of

cut, following the method of “Adjusting depth of cut”.

Adjust the two remaining hex bolts to obtain shallower

depths of cut. The differences in height of these hex bolts

are equal to the differences in depths of cut. To adjust the

hex bolts, first loosen the hex nuts on the hex bolts with

the wrench and then turn the hex bolts. After obtaining

the desired position, tighten the hex nuts while holding

the hex bolts in that desired position. The stopper block is

also convenient for making three passes with progressively deeper bit settings when cutting deep grooves.

CAUTION:

When using a bit having total length of 60 mm or more, or

edge length of 35 mm or more, the depth of cut cannot

be adjusted as previously mentioned. To adjust, proceed

as follows:

Loosen the lock lever and carefully adjust bit protrusion

below the tool base to the desired depth of cut by moving

the tool body up or down. Then re-tighten the lock lever

to lock the tool body at that depth of cut. Keep the tool

body locked at this position during use. Since the bit

always protrudes from the tool base, be careful when

handling the tool.

Adjusting the lock lever (Fig. 6)

The locked position of the lock lever is adjustable. To

adjust it, loosen the lock lever 3/4 turn and press the center of the lock lever. The hex nut will come out. Set the

hex nut to the desired position and tighten the lock lever.

Switch action (Fig. 7)

CAUTION:

Before plugging in the tool, always check to see that the

switch trigger actuates properly and returns to the “OFF”

position when released.

To start the tool, simply pull the trigger. Release the trigger to stop.

Operation (Fig. 8)

• Set the tool base on the workpiece to be cut without the

bit making any contact. Then turn the tool on and wait

until the bit attains full speed. Lower the tool body and

move the tool forward over the workpiece surface,

keeping the tool base flush and advancing smoothly

until the cutting is complete.

• When doing edge cutting, the workpiece surface

should be on the left side of the bit in the feed direction.

NOTE:

• Moving the tool forward too fast may cause a poor quality of cut, or damage to the bit or motor. Moving the tool

forward too slowly may burn and mar the cut. The

proper feed rate will depend on the bit size, the kind of

workpiece and depth of cut. Before beginning the cut

on the actual workpiece, it is advisable to make a sample cut on a piece of scrap lumber. This will show

exactly how the cut will look as well as enable you to

check dimensions.

• When using the straight guide, be sure to install it on

the right side in the feed direction. This will help to keep

it flush with the side of the workpiece.

Straight guide (Fig. 9, 10 & 11)

The straight guide is effectively used for straight cuts

when chamfering or grooving.

To install the straight guide, insert the guide bars into the

holes in the tool base. Adjust the distance between the

bit and the straight guide. At the desired distance, tighten

the wing bolts to secure the straight guide in place.

When cutting, move the tool with the straight guide flush

with the side of the workpiece.

If the distance (A) between the side of the workpiece and

the cutting position is too wide for the straight guide, or if

the side of the workpiece is not straight, the straight

guide cannot be used. In this case, firmly clamp a

straight board to the workpiece and use it as a guide

against the router base. Feed the tool in the direction of

the arrow.

Templet guide (optional accessory)

(Fig. 12, 13 & 14)

The templet guide provides a sleeve through which the

bit passes, allowing use of the router with templet patterns.

To install the templet guide, loosen the screws on the tool

base, insert the templet guide and then tighten the

screws.

Secure the templet to the workpiece. Place the tool on

the templet and move the tool with the templet guide sliding along the side of the templet.

6

Page 7

Vacuum head set (optional accessory)

(Fig. 15, 16 & 17)

When you wish to perform clean cutting operation, use

this vacuum head. Install the vacuum head on the router

base using the two screws and connect a vacuum

cleaner to the vacuum head.

MAINTENANCE

CAUTION:

Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

To maintain product safety and reliability, repairs, maintenance or adjustment should be carried out by a Makita

Authorized Service Center.

7

Page 8

NEDERLANDS

1 Vastdraaien

2 Losdraaien

3 Vasthouden

4 Schroef

5Stopas

6 Sluithendel

7 Diepte-indikator

8 Zeskant stelbout

9 Stopblok

10 Zeskantmoer

Verklaring van algemene gegevens

11 Trekschakelaar

12 Machinerichting

13 Werkstuk

14 Freesrichting

15 (van bovenaf gezien)

16 Juiste rotatie- en freesrichting

17 Geleidestaaf

18 Rechte geleider

19 Vleugelbout

20 Schroef

21 Voetplaat

22 Sjabloongeleider

23 Frees

24 Voetstuk

25 Sjabloon

26 Zuigmond

27 Schroef

TECHNISCHE GEGEVENS

Model 3620

Spantang cap. .................. ...........................8 mm of 3/8”

Slag ................................................................ 0 – 35 mm

Toerental onbelast (min

Totale lengte ....................................................... 211 mm

Netto gewicht ......................................................... 2,4 kg

• In verband met ononderbroken research en ontwikkeling behouden wij ons het recht voor bovenstaande

technische gegevens te wijzigen zonder voorafgaande

kennisgeving.

• Opmerking: De technische gegevens kunnen van land

tot land verschillen.

Stroomvoorziening

De machine mag alleen worden aangesloten op een

stroombron van hetzelfde voltage als aangegeven op de

naamplaat, en kan alleen op enkel-fase wisselstroom

worden gebruikt. De machine is dubbel-geïsoleerd volgens de Europese standaard en kan derhalve ook op

een niet-geaard stopcontact worden aangesloten.

Veiligheidswenken

Voor uw veiligheid dient u de bijgevoegde Veiligheidsvoorschriften nauwkeurig op te volgen.

-1

) .................................... 29 000

AANVULLENDE

VEILIGHEIDSVOORSCHRIFTEN

Laat u NIET misleiden door een vals gevoel van comfort en bekendheid met het gereedschap (na veelvuldig gebruik) en neem alle veiligheidsvoorschriften

van de bovenfrees altijd strikt in acht. Bij onveilig of

verkeerd gebruik van het elektrisch gereedschap,

bestaat de kans op ernstig persoonlijk letsel.

1. Houd elektrisch gereedschap vast aan het geïso-

leerde oppervlak van de handgrepen wanneer u

werkt op plaatsen waar het zaaggereedschap

met verborgen bedrading of zijn eigen snoer in

aanraking kan komen. Door contact met onder

spanning staande draden, zullen de niet-geïsoleerde metalen delen van het gereedschap onder

spanning komen te staan zodat de gebruiker een

elektrische schok kan krijgen.

2. Gebruik klemmen of een andere praktische

methode om het werkstuk op een stabiele ondergrond te bevestigen en ondersteunen. Als u het

werkstuk in uw hand of tegen uw lichaam

geklemd houdt, is het onvoldoende stabiel en

kunt u de controle erover verliezen.

3. Gebruik een oorbescherming, wanneer U lange

tijd met dit gereedschap denkt te werken.

4. Wees voorzichtig met het frees.

5. Kontroleer het frees op barsten of beschadiging,

alvorens het gereedschap in te schakelen en vervang onmiddellijk als het frees is gebarsten of

beschadigd.

6. Zorg dat het frees niet in kontakt komt met spijkers enz. Verwijder derhalve alvorens met trimmen te beginnen eventuele spijkers en dergelijke

van het werkstuk.

7. Houd het gereedschap stevig vast.

8. Houd uw handen uit de buurt van de roterende

delen.

9. Zorg dat het frees niet in kontakt is met het werkstuk wanneer u het gereedschap inschakelt.

10. Laat het gereedschap draaien, alvorens het

werkstuk te trimmen.

Kontroleer of er trillingen en/of schommelingen

zijn, die op een verkeerd geinstalleerd frees kunnen wijzen.

11. Zorg dat de rotatierichting overeenkomt met de

trimrichting.

12. Schakel het gereedschap onmiddellijk uit, als u

het niet meer gebruikt. Schakel het gereedschap

allen in, als u het in handen houdt.

13. Schakel het gereedschap uit en wacht tot het

helemaal tot stilstand is gekomen, alvorens het

van het werkstuk te verwijderen.

14. Raak het frees onmiddelijk na het trimmen niet aan;

aangezien het nog gloeiend heet is en derhalve

brandwonden kan veroorzaken.

15. Wees voorzichtig en veeg het voetstuk van het

gereedschap niet af met verfverdunner, benzine,

olie of iets dergelijks, aangezien er anders barsten in kunnen komen.

16. Zorg ervoor dat u uitsluitend frezen gebruikt die

de juiste schachtdiameter hebben en geschikt

zijn voor de snelheid van het gereedschap.

17. Sommige materialen bevatten chemische stoffen

die vergiftig kunnen zijn. Vermijd inademing van

stof en contact met de huid. Volg de veiligheidsinstructies van de leverancier van het materiaal.

18. Gebruik altijd het juiste stofmasker/ademhalingsapparaat voor het materiaal en de toepassing waarmee u werkt.

BEWAAR DEZE VOORSCHRIFTEN.

WAARSCHUWING:

VERKEERD GEBRUIK of het niet naleven van de veiligheidsvoorschriften in deze gebruiksaanwijzing

kan leiden tot ernstige verwondingen.

17

Page 9

BEDIENINGSVOORSCHRIFTEN

Inzetten of verwijderen van de frees (Fig. 1)

Belangrijk:

Controleer altijd of het gereedschap uitgeschakeld is en

het netsnoer van het stopcontact is verwijderd, alvorens

de frees in te zetten of te verwijderen.

Steek de frees helemaal in de spantang en draai de

spantangmoer stevig vast met behulp van de twee sleutels. Behalve de 8 mm of 3/8” spantang die in de fabriek

op het gereedschap is geïnstalleerd, wordt ook nog een

6 mm of 1/4” spantang bijgeleverd als standaard toebehoren. Gebruik dus voor het freesje dat u gebruiken wilt

de passende spantang. Voor het verwijderen van de

frees, volgt u de procedure voor het inzetten in omgekeerde volgorde.

LET OP:

Draai de spantangmoer niet vast als in de spantang geen

frees zit, aangezien anders de spantang kan breken.

Instellen van de freesdiepte (Fig. 2, 3 en 4)

Plaats het gereedschap op een horizontaal vlak. Draai

de schroef die de stopas vastzet, los.

Maak de sluithendel los en laat het motorhuis naar beneden zakken, totdat de frees nog net het horizontaal vlak

aanraakt. Maak vervolgens de sluithendel weer vast om

het motorhuis vast te zetten.

Laat daarna de stopas naar beneden zakken, totdat deze

in kontakt komt met de zeskante afstelbout. Zet de

diepte-indikator in de “0” stand op de schaalverdeling.

Schuif de stopas naar boven totdat de gewenste freesdiepte is bereikt. De freesdiepte kunt u op de schaalverdeling aflezen (1 mm of 1/16” per streepje), met behulp

van de freesdiepte-indikator. Draai vervolgens de schroef

vast om de stopas vast te zetten.

Stel nu het gereedschap in op de aldus verkregen freesdiepte door de sluithendel los te maken en het motorhuis

te laten zakken, totdat de stopas kontakt maakt met de

zeskante afstelbout.

LET OP:

Aangezien de motor overbelast kan raken, wanneer de

freesdiepte te groot is, mag de freesdiepte niet meer dan

15 mm bedragen voor het snijden van groeven met een 8

mm diameter frees.

[Opmerking: Voor het snijden van groeven met een 20

mm diameter frees, mag de freesdiepte telkens niet meer

dan 5 mm bedragen.] Wanneer u derhalve groeven wilt

snijden van meer dan 15 mm diepte met een 8 mm diameter frees, of groeven van meer dan

5 mm diepte met een 20 mm diameter frees, dient u de

bewerking dus de nodige keren te herhalen, en de frees

telkens wat dieper in te stellen.

Stopblok (Fig. 5)

De stopblok is voorzien van drie zeskant stelhouten

waarmee u de frees per draai 0,8 mm naar boven of naar

beneden kunt instellen. Met behulp van de zeskant stelhouten kunt u dus gemakkelijk op drie verschillende

freesdiepten instellen, zonder de stopas opnieuw te moeten instellen.

Stel de onderste zeskant bout zo in dat u de grootste

freesdiepte krijgt. U volgt daarvoor de procedure voor

“Instellen van de freesdiepte”. Stel de overige twee zeskant bouten in voor het verkrijgen van kleinere freesdiepten. De verschillen in hoogte van deze zeskant bouten

zijn gelijk aan de verschillen in freesdiepte. Voor het

instellen van de zeskant bouten, worden de zeskant

moeren op de zeskant bouten met een sleutel losgedraaid en vervolgens de zeskant bouten gedraaid. Draai

de moeren na de gewenste instelling weer vast terwijl u

daarbij de zeskant bouten in de ingestelde positie houdt.

Het stopblok is ook handig voor het geval u diepe groeven moet snijden en de bewerking drie keer moet herhalen met telkens een grotere freesdiepte.

LET OP:

Wanneer de gebruikte frees een totale lengte heeft van

60 mm of meer, of wanneer de uitstekende lengte 35 mm

of meer bedraagt, kan de freesdiepte niet worden ingesteld op de hierboven beschreven manier. U dient dus in

dit geval als volgt te werk te gaan:

Maak de sluithendel los en stel de lengte van de frees die

uit het voetstuk uitsteekt nauwkeurig in op de gewenste

freesdiepte door het motorhuis te lichten of te laten zakken. Vervolgens wordt wanneer de freesdiepte is ingesteld, het motorhuis vastgezet door de sluithendel vast te

maken. Zorg dat tijdens het frezen het motorhuis niet verschoven wordt. Aangezien de frees in dit geval altijd uitsteekt, dient u uitermate voorzichtig te zijn.

Instellen van de sluithendel (Fig. 6)

De vergrendelingspositie van de sluithendel is instelbaar.

Voor het instellen wordt de sluithendel 3/4 draai losgemaakt en vervolgens wordt de sluithendel in het midden

ingedrukt. De zeskant moer komt dan tevoorschijn. Zet

de zeskant moer in de gewenste positie en maak daarna

de sluithendel weer vast.

Trekschakelaar (Fig. 7)

LET OP:

Alvorens het netsnooer op het stopkontakt aan te sluiten,

dient u altijd te kontroleren of de trekschakelaar behoorlijk werkt en bij loslaten onmiddellijk naar de “OFF” positie terugkeert.

Om het gereedschap in te schakelen wordt de trekschakelaar ingedrukt. Laat de schakelaar los om uit te schakelen.

Bediening (Fig. 8)

• Zet het gereedschap op het werkstuk. De frees mag

echter nog niet met het werkstuk in kontakt komen.

Schakel het gereedschap in en wacht tot de frees op

volle toeren draait. Druk vervolgens het motorhuis naar

beneden en schuif het gereedschap over het werkstuk.

Zorg dat het voetstuk volop in kontakt met het werkstuk

blijft en schuif het gereedschap langzaam voorwaarts

totdat het frezen is voltooid.

• Wanneer u de rand moet frezen, dient het werkstuk

t.o.v. van de freesrichting, links te liggen, zoals in de

illustratie.

18

Page 10

OPMERKING:

• Wanneer u het gereedschap te snel naar voren

beweegt, krijgt u slecht gefreesde groeven, of kunnen

de motor en de frees beschadiging oplopen. Wanneer

u daarentegen het gereedschap te langzaam naar

voren beweegt, kunnen brandvlekken ontstaan en krijgt

u ook geen mooie groeven. De juiste freessnelheid

hangt af van de gebruikte freesmaat, het materiaal van

het werkstuk en de freesdiepte. Alvorens het werkstuk

te frezen, verdient het dus aanbeveling eerst een groef

te frezen in een stuk hout van hetzelfde soort. U kunt

dan de snelheid bepalen en het resultaat beoordelen.

• Wanneer u bij het frezen de rechte geleider gebruikt,

dient u de geleider aan de rechterkant (ten opzichte

van de freesrichting) te installeren. U kunt dan de geleider volledig tegen de zijkant van het werkstuk houden.

Rechte geleider (Fig. 9, 10 en 11)

De rechte geleider kunt u met zeer goede resultaten

gebruiken wanneer u rechte groeven moet frezen of recht

moet afschuinen.

Voor het bevestigen van de rechte geleider dienen de

geleidestaven in de gaten in het voetstuk van het gereedschap gestoken te worden. Vervolgens wordt de afstand

tussen de frees en de rechte geleider ingesteld. Daarna

de vleugelmoeren vastdraaien voor het vastzetten van de

rechte geleider.

Tijdens het frezen dient u ervoor te zorgen dat de rechte

geleider steeds tegen de zijkant van het werkstuk aangedrukt blijft.

Wanneer de afstand (A) tussen de zijkant van het werkstuk en de freeslijn te groot is, kan de rechte geleider niet

gebruikt worden. Dit is ook het geval wanneer de zijkant

van het werkstuk niet recht is. Het is dan in dit geval aangeraden een recht stuk plank van de vereiste breedte op

het werkstuk vast te klemmen en de plank te gebruiken

als een geleider. U dient dan tijdens het frezen het voetstuk van het gereedschap tegen de zijkant van de plank

aangedrukt te houden. Ook dient u het gereedschap

voort te bewegen in de richting van de pijl.

Sjabloongeleider (losverkrijgbaar)

(Fig. 12, 13 en 14)

De sjabloongeleider loopt uit op een busje, waardoorheen de frees uitsteekt. Hierdoor kan het gereedschap

precies de patronen van de sjabloon volgen.

Om de sjabloongeleider te bevestigen, maakt u de twee

philipsschroeven onder het voetstuk los, plaats daarna

de sjabloongeleider en zet de geleider met de schroeven

vast.

Plaats de sjabloon op het werkstuk en zet hem vast

zodat hij niet verschuift. Plaats vervolgens het gereedschap op de sjabloon, zodanig dat de sjabloongeleider

de patronen kan volgen.

Zuigmond (losverkrijgbaar) (Fig. 15, 16 en 17)

Wanneer u wilt frezen zonder stof te verspreiden, dient u

de zuigmond te gebruiken. Installeer de zuigmond op het

voetstuk van het gereedschap door middel van de twee

schroeven, en sluit op de zuigmond een stofzuiger aan.

ONDERHOUD

LET OP:

Zorg er altijd voor dat de machine is uitgeschakeld en de

stekker uit het stopcontact is verwijderd alvorens onderhoud aan de machine uit te voeren.

Opdat het gereedschap veilig en betrouwbaar blijft, dienen alle reparaties, onderhoud of afstellingen te worden

uitgevoerd bij een erkend Makita service centrum.

19

Page 11

Straight bit Fraise à rainer Nutfräser Fresa a refilo

Rechte frezen Fresa recta Fresa direita Notfræser

Notfräs Rett bitt Suora terä

DAL1L

20 6

20E 1/4”

8 8 8 (5/16”) 60 (2-3/8”) 25 (63/64”)

86

8E 1/4”

66

6E 1/4”

20

(25/32”)

8

(5/16”)

6

(15/64”)

(Tasoterä)

(1-31/32”)

(1-31/32”)

(1-31/32”)

50

50

50

Ισιο κοπτικ"

15

(19/32”)

18

(45/64”)

18

(45/64”)

mm

2

“U” Grooving bit Fraise à rainurer

en “U”

U-groef frezen Fresa ranuradora

en “U”

U-Nutfräser Fresa a incastro a

“U”

Fresa em forma

U-notfræser

de “U”

Hålkärlsfräs “U”-rille bitt “U” uritusterä Κοπτικ" για

αυλάκωµα “U”

66

6E 1/4”

DA L1L

6

(15/64”)

“V” Grooving bit Fraise à rainurer

en “V”

V-groef frezen Fresa ranuradora

en “V”

60

(2-3/8”)

V-Nutfräser Fresa a incastro a

Fresa em forma

de “V”

2

28

(1-3/32”)

(1/8”)

“V”

V-notfræser

Fasfräs “V”-rille bitt “V” uritusterä Κοπτικ" για

αυλάκωµα “V”

20 6

20E 1/4”

Dovetail bit Fraise à queue

DAL1L

20

(25/32”)

50

(1-31/32”)

Winkelfräser Fresa a incastro o

d’arond

Zwaluwstaart

frezen

Fresa cola de

milano

Fresa de granzepe Sinkefræser

Sinkfräs Svalhaleformet bitt Lohenpyrstö-

uraterä

15S 8

15SE 3/8”

15L 8

15LE 3/8”

12 8

12E 3/8”

DAL1L

14.5

(9/16”)

14.5

(9/16”)

12

(15/32”)

55

(2-5/32”)

55

(2-5/32”)

50

(1-31/32”)

2

15

(19/32”)

coda di rondine

Κοπτικ"

χελιδονοουράς

2

10

(25/64”)

14.5

(9/16”)

9

(23/64”)

R

3

90°

35°

23°

30°

mm

mm

θ

mm

θ

41

Page 12

Drill point flush

trimming bit

Combinatie frezen

(enkel)

88

8E 3/8”

66

6E 1/4”

DAL1L

Fraise à affleurer Bündigfräser Fresa doppio refilo

a punta

Fresa simple para

paneles

Borepunkt

kanttrimmerbitt

Fresa com ponta

piloto para recorte

Porankärkiviimeistelyterä

Kantfræser

Κοπτικ"

κουρέµατος µε

κεφαλή

τρυπανιού

mm

8

(5/16”)

6

(15/64”)

60

(2-3/8”)

60

(2-3/8”)

2

20

(25/32”)

18

(45/64”)

L

3

35

(1-3/8”)

28

(1-3/32”)

Drill point double

flush trimming bit

Combinatie frezen

(dubbel)

88

8E 3/8”

66

6E 1/4

Corner rounding

Fraise à affleurer

combinaison double

Fresa doble para

peneles

Borepunkt dobbel

kanttrimmerbitt

DAL1L

8

(5/16”)80(3-5/32”)55(2-5/32”)20(25/32”)25(63/64”)

6

(15/64”)70(2-3/4”)40(1-37/64”)12(15/32”)14(35/64”)

Doppelbündigfräser Fresa a doppio

Fresa com ponta

piloto dupla para

recorte

Porankärki-kaksoisviimeistelyterä

2

Fraise 1/4 de rond Rundkantenfräser Fresa a raggio

bit

Frezen voor ronde

hoeken

Profilfräs Bitt til abrunding

8R 6

8RE 1/4”

4R 6

4RE 1/4”

Chamfering bit Fraise à chanfrein Winkelkantenfrä-

Profiel frezen Fresa biseladora Fresa para

Fresa para redondeado de cantos

Fresa para aresta

arredondadas

Reunanpyöristys-

av hjøner

DA1A

25

(63/64”)9(23/64”)48(1-57/64”)13(33/64”)5(13/64”)8(5/16”)

20

(25/32”)8(5/16”)45(1-25/32”)10(25/64”)4(5/32”)4(5/32”)

terä

2

L

1

ser

chanfrar

Profilfräs Fasehøvlingsbitt Viisteytysterä

30° 6

30°E 1/4”

45° 6

45°E 1/4”

60° 6

60°E 1/4”

DAL1L

23

(29/32”)46(1-13/16”)11(7/16”)6(15/64”)

20

(25/32”)50(1-31/32”)13(33/64”)5(13/64”)

20

(25/32”)46(1-15/16”)14(35/64”)2(5/64”)

2

refilo

Dobbelt kantfræser

Κοπτικ" διπλού

κουρέµατος µε

κεφαλή τρυπανιού

L

3

Radiusfræser

Κοπτικ" για

στρογγυλές

γωνιές

L

2

Fresa per refilo a

smusso

Fasefræse r

Κοπτικ" για φάσο

L

3

mm

L

4

mm

L

R

3

mm

θ

30°

45°

60°

42

Page 13

Cove beading bit Fraise à profiler

Holle kraal frezen Fresa para

concave

moldurar

Profilfräs Profilbitt Reunakaariterä Κοπτικ"

4R 6

4RE 1/4”

8R 6

8RE 1/4”

DAL1L

(25/32”)

(63/64”)

Rundkantenfräser Fresa a raggio

Fresa para

rebordo côncavo

20

25

43

(1-11/16”)

48

(1-57/64”)

concavo

Hulkehl-fræser

κοιλωµάτων

2

8

(5/16”)

13

(33/64”)

R

4

(5/32”)

8

(5/16”)

mm

Ball bearing flush

trimming bit

Boorfrezen met

kogellager

Kantfräs med

styrlager

10 6

10E 1/4”

Ball bearing corner rounding bit

Frezen voor ronde

hoeken met

kogellager

Profilfräs

med styrlager

16

1E 1/4”

26

2E 1/4”

Ball bearing

chamfering bit

Profiel frezen met

kogellager

Fasfräs

med styrlager

45° 6

45°E 1/4”

60° 6

60°E 1/4”

Fraise à affleurer

avec roulement

Fresa simple para

paneles con

rodamiento

Kanttrimmingbitt

med kulelager

DAL1L

Fraise à arrondir avec

roulement

Fresa para redondeado

de cantos con rodamiento

Bitt med kulelager til

avrunding av hjørner

DA1A

15

(19/32”)8(5/16”)37(1-15/32”)7(9/32”)

21

(53/64”)8(5/16”)40(1-37/64”)10(25/64”)

Fraise à chanfreiner avec roulement

Fresa biseladora

con rodamiento

Faseb itt

med kulelager

DA1A

26

(1-1/32”)8(5/16”)42(1-21/32”)12(15/32”)

20

(25/32”)8(5/16”)41(1-5/8”)11(7/16”)

Bündigfräser mit

Anlaufkugellager

Fresa para recorte

com rolamento de

esferas

Laakeriohjattu

viimeistelyterä

10

(25/64”)

Rundkantenfräser mit

Anlaufkugellager

Fresa para arestas

arredondadas com

rolamento de esferas

Laakeriohjattu

reunanpyöristysterä

L

2

1

Winkelkantenfräser mit

Anlaufkugellager

Fresa para chanfrar com

rolamento de esferas

Laakeriohjattu

viisteytysterä

2

L

1

50

(1-31/32”)

L

2

Fresa a doppio

refilo con cuscinetto

Kantfræser med

kugleleje

Κοπτικ"

κουρέµατος µε

ρουλεµάν

2

20

(25/32”)

Fresa a raggio

con cuscinetto

Radiusfræser

med kugleleje

Κοπτικ" για

στρογγυλές γωνιές

µε ρουλεµάν

L

3.5

(9/64”)3(1/8”)

3.5

(9/64”)6(15/64”)

Fresa per refilo

a smusso

con cuscinetto

Fasefræser med

kugleleje

Κοπτικ" για Φάσο

µε ρουλεµάν

L

2

R

3

θ

45°

60°

mm

mm

mm

43

Page 14

Ball bearing beading bit Fraise à profiler avec

Fresa a raggio convesso con cuscinetto

Profilfräs med styrlager Staffbitt med kulelager Laakeriohjattu

26

2E 1/4”

36

3E 1/4”

roulement

Fresa para moldurar

con rodamiento

DA1A

20

(25/32”)12(15/32”)8(5/16”)40(1-37/64”)10(25/64”)

26

(1-1/32”)12(15/32”)8(5/16”)42(1-21/32”)12(15/32”)

2

Rundkantenfräser mit

Anlaufkugellager

Fresa para rebordo

com rolamento de

esferas

helmilistaterä

A

L

3

Fresa a raggio

convesso

con cuscinetto

Radiusfræser med

kugleleje

Κοπτικ"

τεταρτηµαρίου µε

ρουλεµάν

L

2

L

3

5.5

(7/32”)4(5/32”)

4.5

(11/64”)7(9/32”)

1

mm

R

Ball bearing cove

beading bit

Holle kraal frezen

met kogellager

Fraise à profiler pour cavet

avec roulement

Fresa para moldurar con

rodamiento (concavo)

Staffbitt med kulelager Laakeriohjattu

DA1A

26

2E 1/4”

36

3E 1/4”

Ball bearing roman

ogee bit

Romeinse kraal frezen

met kogellager

Profifräs med styrlager Karnissbitt

26

2E 1/4”

36

3E 1/4”

20

(25/32”)18(45/64”)12(15/32”)8(5/16”)

26

(1-1/32”)22(7/8”)12(15/32”)8(5/16”)

Fraise à profiler pour

doucine avec roulement

Fresa para moldurar

con rodamiento

(convexo)

med kulelager

DA1A

20

(25/32”)8(5/16”)

26

(1-1/32”)8(5/16”)

2

2

Profilfräser mit

Anlaufkugellager

Fresa para rebordo

côncavo com

rolamento de esferas

reunakaariterä

A

A

3

4

Profilfräser mit

Anlaufkugellager

Fresa com gola romana

com rolamento de

esferas

Laakeriohjattu pyörökaari-karniisiterä

L

1

40

(1-37/64”)10(25/64”)

42

(1-21/32”)12(15/32”)

Fresa a raggio concavo con cuscinetto

Profilfræser med

kugleleje

Κοπτικ" κοιλωµάτων

µε ρουλεµάν

L

L

L

1

2

40

(1-37/64”)10(25/64”)

42

(1-21/32”)12(15/32”)5(13/64”)5(13/64”)

L

2

(11/64”)

(11/64”)3(1/8”)6(15/64”)

(7/32”)3(1/8”)

Fresa a raggio convesso con cuscinetto

Profilfræser med

kugleleje

Κοπτικ" ρωµαικού

“ogee” (προφίλ Β) µε

ρουλεµάν

L

R

3

4.5

2.5

(3/32”)

4.5

R

3

5.5

R

1

2

4.5

(11/64”)

mm

mm

44

Page 15

ENGLISH

For European countries only

The typical A-weighted noise levels are

The typical weighted root mean square acceleration

value is not more than 2.5 m/s

These values have been obtained according to

EN60745.

Noise and Vibration

sound pressure level: 92 dB (A)

sound power level: 103 dB (A)

Uncertainty is 3 dB (A).

– Wear ear protection. –

2

.

ENG005-2-V3

ITALIANO

Modello per l’Europa soltanto

I livelli del rumore pesati secondo la curva A sono:

Il valore quadratico medio di accellerazione non supera i

2

2,5 m/s

Questi valori sono stati ottenuti in conformità EN60745.

Rumore e vibrazione

Livello pressione sonora: 92 dB (A)

Livello potenza sonora: 103 dB (A)

L’incertezza è di 3 dB (A).

– Indossare i paraorecchi. –

.

FRANÇAISE

Pour les pays d’Europe uniquement

Les niveaux de bruit ponderes types A sont:

Bruit et vibrations

niveau de pression sonore: 92 dB (A)

niveau de puissance du son: 103 dB (A)

L’incertitude de mesure est de 3 dB (A).

L’accélération pondérée ne dépasse pas 2,5 m/s

– Porter des protecteurs anti-bruit. –

Ces valeurs ont été obtenues selon EN60745.

2

.

DEUTSCH

Nur für europäische Länder

Geräusch- und Vibrationsentwicklung

Die typischen A-bewerteten Geräuschpegel betragen:

Der gewichtete Effektivwert der Beschleunigung beträgt

nicht mehr als 2,5 m/s

Diese Werte wurden gemäß EN60745 erhalten.

Schalldruckpegel: 92 dB (A)

Schalleistungspegel: 103 dB (A)

Die Abweichung beträgt 3 dB (A).

– Gehörschutz tragen. –

2

.

NEDERLANDS

Alleen voor Europese landen

Geluidsniveau en trilling

De typische A-gewogen geluidsniveau’s zijn

geluidsdrukniveau: 92 dB (A)

geluidsenergie-niveau: 103 dB (A)

Onzekerheid is 3 dB (A).

De typische gewogen effectieve versnellingswaarde is

niet meer dan 2,5 m/s

– Draag oorbeschermers. –

2

.

Deze waarden werden verkregen in overeenstemming

met EN60745.

ESPAÑOL

Para países europeos solamente

Los niveles típicos de ruido ponderados A son

El valor ponderado de la aceleración no sobrepasa los

2

.

2,5 m/s

Estos valores han sido obtenidos de acuerdo con

EN60745.

Ruido y vibración

presión sonora: 92 dB (A)

nivel de potencia sonora: 103 dB (A)

Incerteza 3 dB (A).

– Póngase protectores en los oídos. –

45

Page 16

PORTUGUÊS

Só para países Europeus

Os níveis normais de ruído A são

– Utilize protectores para os ouvidos –

O valor médio da aceleração é inferior a 2,5 m/s

Estes valores foram obtidos de acordo com EN60745.

Ruído e vibração

nível de pressão de som: 92 dB (A)

nível do sum: 103 dB (A)

A incerteza é de 3 dB (A).

2

.

ENG005-2-V3

NORSK

Gjelder bare land i Europa

De vanlige A-belastede støynivå er

Den vanlig belastede effektiv-verdi for akselerasjon overskrider ikke 2,5 m/s

Disse verdiene er beregnet eller målt i samsvar med

EN60745.

Støy og vibrasjon

lydtrykksnivå: 92 dB (A)

lydstyrkenivå: 103 dB (A)

Usikkerheten er på 3 dB (A).

– Benytt hørselvern. –

2

.

DANSK

Kun for lande i Europa

Lyd og vibration

De typiske A-vægtede lydniveauer er

lydtryksniveau: 92 dB (A)

lydeffektniveau: 103 dB (A)

Der er en usikkerhed på 3 dB (A).

Den vægtede effektive accelerationsværdi overstiger ikke

2

.

2,5 m/s

– Bær høreværn. –

Disse værdier er beregnet i overensstemmelse med

EN60745.

SVENSKA

Endast för Europa

De typiska A-vägda bullernivåerna är

Det typiskt vägda effektivvärdet för acceleration överstiger inte 2,5 m/s

Dessa värden har erhållits i enlighet med EN60745.

Buller och vibration

ljudtrycksnivå: 92 dB (A)

ljudeffektnivå: 103 dB (A)

Osäkerheten är 3 dB (A).

– Använd hörselskydd –

2

.

SUOMI

Vain Euroopan maat

Melutaso ja tärinä

Tyypilliset A-painotetut melutasot ovat

äänenpainetaso: 92 dB (A)

äänen tehotaso: 103 dB (A)

Epävarmuus on 3 dB (A).

Tyypillinen kiihtyvyyden painotettu tehollisarvo ei ylitä

2,5 m/s

Nämä arvot on mitattu normin EN60745 mukaisesti.

– Käytä kuulosuojaimia. –

2

.

ΕΛΛΗΝΙΚΑ

Μ.νο για χώρες της Ευρώπης

Οι τυπικές A-µετρούµενες εντάσεις ήχου είναι

Η τυπική αξία της µετρούµενης ρίζας του µέσου

τετραγώνου της επιτάχυνσης δεν ξεπερνά τα

2,5 m/s

Αυτές οι τιµές έχουν σηµειωθεί σύµφωνα µε το

EN60745.

Θ.ρυβος και κραδασµ.ς

πίεση ήχου: 92 dB (A)

δύναµη του ήχου: 103 dB (A)

Η Αβεβαι"τητα είναι 3 dB (A).

– Φοράτε ωτοασπίδες. –

2

.

46

Page 17

ENGLISH

EC-DECLARATION OF CONFORMITY

We declare under our sole responsibility that this product

is in compliance with the following standards of standardized documents,

in accordance with Council Directives, 89/336/EEC and

98/37/EC.

EN60745, EN55014, EN61000

ENH101-5

ITALIANO

DICHIARAZIONE DI CONFORMITÀ

CON LE NORME DELLA COMUNITÀ EUROPEA

Dichiariamo sotto la nostra sola responsabilità che

questo prodotto è conforme agli standard di documenti

standardizzati seguenti:

secondo le direttive del Consiglio 89/336/CEE e 98/37/CE.

EN60745, EN55014, EN61000

FRANÇAISE

DÉCLARATION DE CONFORMITÉ CE

Nous déclarons sous notre entière responsabilité que ce

produit est conforme aux normes des documents standardisés suivants,

conformément aux Directives du Conseil, 89/336/CEE et

98/37/EG.

EN60745, EN55014, EN61000

DEUTSCH

CE-KONFORMITÄTSERKLÄRUNG

Hiermit erklärt wir unter unserer alleinigen Verantwortung, daß dieses Produkt gemäß den Ratsdirektiven

89/336/EWG und 98/37/EG mit den folgenden Normen

von Normendokumenten übereinstimmen:

EN60745, EN55014, EN61000.

Yasuhiko Kanzaki

Director Amministratore

Directeur Directeur

Direktor Director

NEDERLANDS

EG-VERKLARING VAN CONFORMITEIT

Wij verklaren hierbij uitsluitend op eigen verantwoordelijkheid dat dit produkt voldoet aan de volgende

normen van genormaliseerde documenten,

in overeenstemming met de richtlijnen van de Raad

89/336/EEC en 98/37/EC.

EN60745, EN55014, EN61000

ESPAÑOL

DECLARACIÓN DE CONFORMIDAD DE LA CE

Declaramos bajo nuestra sola responsabilidad que este

producto cumple con las siguientes normas de documentos normalizados,

de acuerdo con las directivas comunitarias,

89/336/EEC y 98/37/CE.

CE 2005

EN60745, EN55014, EN61000

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

Responsible manufacturer: Produttore responsabile:

Fabricant responsable

Verantwortlicher Hersteller: Fabricante responsable:

Makita Corporation Anjo Aichi Japan

Verantwoordelijke fabrikant:

:

47

Page 18

PORTUGUÊS

DECLARAÇÃO DE CONFORMIDADE DA CE

Declaramos sob inteira responsabilidade que este

produto obedece às seguintes normas de documentos

normalizados,

de acordo com as directivas 89/336/CEE e 98/37/CE do

Conselho.

EN60745, EN55014, EN61000

ENH101-5

NORSK

EUs SAMSVARS-ERKLÆRING

Vi erklærer på eget ansvar at dette produktet er i overensstemmelse med følgende standard i de standardiserte dokumenter:

i samsvar med Råds-direktivene, 89/336/EEC og 98/37/

EC.

EN60745, EN55014, EN61000,

DANSK

EU-DEKLARATION OM KONFORMITET

Vi erklærer hermed på eget ansvar, at dette produkt er i

overensstemmelse med de følgende standarder i de normsættende dokumenter,

i overensstemmelse med Rådets Direktiver 89/336/EEC

og 98/37/EC.

EN60745, EN55014, EN61000

SVENSKA

EG-DEKLARATION OM ÖVERENSSTÄMMELSE

Under eget ansvar deklarerar vi härmed att denna

produkt överensstämmer med följande standardiseringar

för standardiserade dokument,

i enlighet med EG-direktiven 89/336/EEC och 98/37/EC.

EN60745, EN55014, EN61000

Yasuhiko Kanzaki

Director Direktor

Direktør Johtaja

Direktör ∆ιευθυντής

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

Fabricante responsável: Ansvarlig produsent:

Ansvarlig fabrikant: Vastaava valmistaja:

Ansvarig tillverkare: Υπεύθυνος κατασκευαστής:

Makita Corporation Anjo Aichi Japan

SUOMI

VAKUUTUS EC-VASTAAVUUDESTA

Yksinomaisesti vastuullisina ilmoitamme, että tämä tuote

on seuraavien standardoitujen dokumenttien standardien mukainen,

neuvoston direktiivien 89/336/EEC ja 98/37/EC mukaisesti.

EN60745, EN55014, EN61000

ΕΛΛΗΝΙΚΑ

∆ΗΛΩΣΗ ΣΥΜΜΟΡΦΩΣΗΣ ΕΚ

∆ηλώνουµε υπ" την µοναδική µας ευθύνη "τι αυτ"

το προι"ν βρίσκεται σε Συµφωνία µε τα ακ"λουθα

πρ"τυπα τυποποιηµένων εγγράφων,

σύµφωνα µε τις Οδηγίες του Συµβουλίου,

89/336/EEC και 98/37/ΚE.

CE 2005

Sorumlu imalatçı:

EN60745, EN55014, EN61000

Makita Corporation

Anjo, Aichi, Japan

883585D984

Loading...

Loading...