Electronic Router

Equipped with Electric Brake

1/2"

MODEL

INSTRUCTION MANUAL

3612C

DOUBLE

INS

U

L

AT

ION

SPEC

IF

I

CAT

I 0 N

S

Collet chuck

capacity

112"

*

Manufacturer reserves the right to change specifications without notice.

*

Note: Specifications may differ from country

WARNING: For your personal safety, READ and UNDERSTAND before using.

SAVE

THESE INSTRUCTIONS FOR FUTURE REFERENCE.

Main body No load speed Overall Net

stroke (RPM) length weight

I

0 - 60

(0

mm

~ 2-318")

9,000 - 23,000

to

country.

1

324 mm

(12-314")

1

(13.2 lbs)

6.0

kg

I

M

PORTANT

SAFETY

WARNING:

PRECAUTIONS SHOULD ALWAYS

WHEN USING ELECTRIC TOOLS, BASIC SAFETY

INSTRUCTIONS

(For

All

Tools)

BE

FOLLOWED TO REDUCE

THE RISK OF FIRE, ELECTRIC SHOCK, AND PERSONAL

INJURY, INCLUDING THE FOLLOWING:

READ ALL INSTRUCTIONS.

1.

KEEP WORK AREA CLEAN. Cluttered areas and benches invite injuries.

2.

CONSIDER

or wet locations. Keep work area well

Don't use tool in presence of flammable liquids or gases.

3.

KEEP CHILDREN AWAY. All visitors should be kept away from work area.

Don't let visitors contact tool or extension cord.

4.

STORE IDLE TOOLS. When not

or locked-up place

5.

DON'T FORCE TOOL.

it

was intended.

6.

USE RIGHT TOOL. Don't force small tool or attachment to do the job of a

heavy-duty tool. Don't use tool for purpose not intended; for example, don't

use circular saw for cutting tree limbs or logs.

7.

DRESS PROPERLY. Don't wear loose clothing or jewelry. They can be caught

in

moving parts. Rubber gloves and non-skid footwear are recommended

when working outdoors. Wear protective hair covering to contain long hair.

8.

USE SAFETY GLASSES. Also use face or dust mask if cutting operation is

dusty.

9.

DON'T ABUSE CORD. Never carry tool by cord or yank

receptacle. Keep cord from heat, oil, and sharp edges.

IO.

SECURE WORK. Use clamps or a vise to hold work. It's safer than using

your hand and

11.

DON'T OVERREACH. Keep proper footing and balance at all times.

12.

MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for better and

safer performance. Follow instructions for lubricating and changing accessories. Inspect tool cords periodically and

rized service facility. Inspect extension cords periodically and replace if

damaged. Keep handles dry, clean, and free from oil and grease.

13.

DISCONNECT TOOLS. When not in use, before servicing, and when changing accessories, such as blades, bits, cutters.

WORK

AREA ENVIRONMENT. Don't use power tools

lit.

in

use, tools should be stored

-

out of reach of children.

It

will do the job better and safer at the rate for which

it

frees both hands to operate tool.

in

damp

Don't expose power tools to rain.

in

dry, and high

it

to disconnect from

if

damaged, have repaired by autho-

14.

REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to

see that keys and adjusting wrenches are removed from tool before turning

it

on.

15.

AVOID UNINTENTIONAL STARTING. Don't carry tool with finger on switch.

Be sure switch is OFF when plugging in.

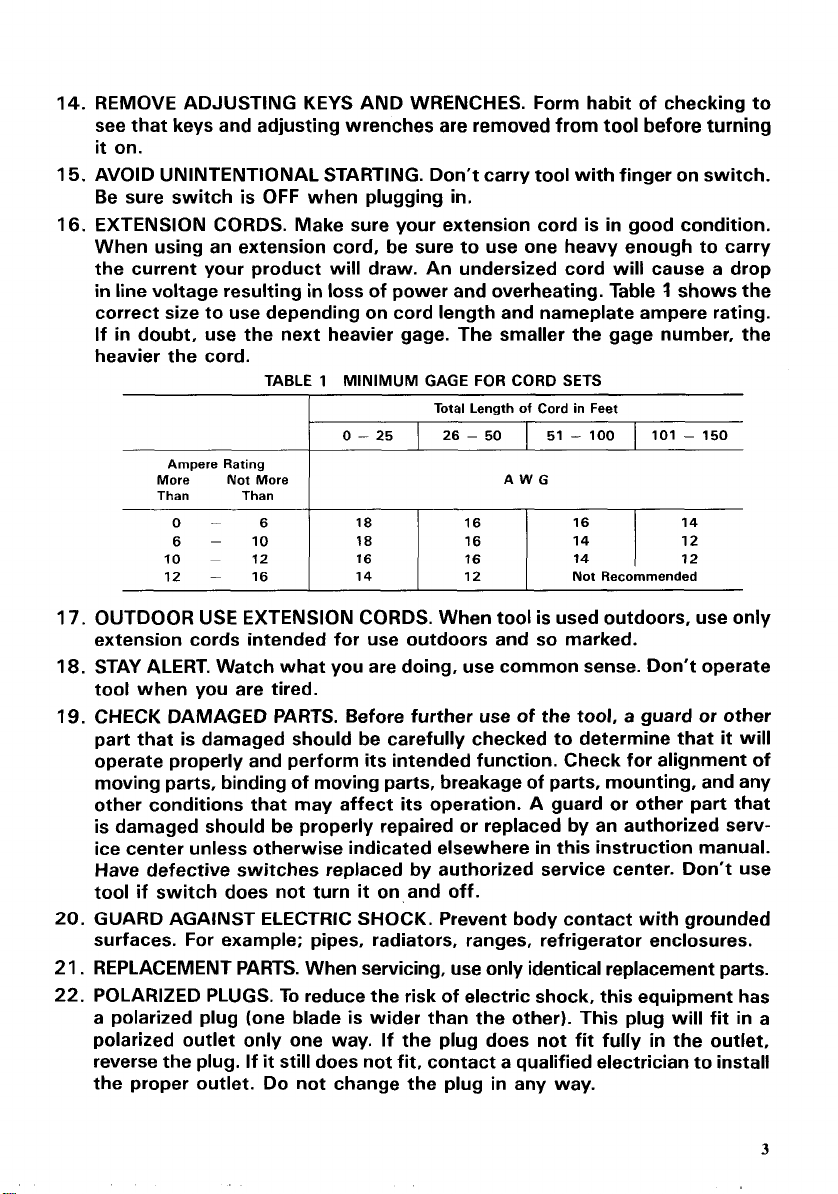

16.

EXTENSION CORDS. Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one heavy enough to carry

the current your product will draw. An undersized cord will cause a drop

in

line voltage resulting

in

loss

of power and overheating. Table shows the

correct size to use depending on cord length and nameplate ampere rating.

If in doubt, use the next heavier gage. The smaller the gage number,

heavier the cord.

TABLE

1

MINIMUM

I

0

-

Ampere Rating

More Not More

Than Than

0-

6

10

12

17.

OUTDOOR

extension cords intended for use outdoors and

18.

STAY ALERT. Watch what you are doing, use common sense. Don't operate

6

-

10

~

12

-

16

18 16

18

16

14 12

USE EXTENSION CORDS. When tool is used outdoors, use only

GAGE

FOR

CORD

SETS

Total Length

25 26 - 50 51 - 100 101 - 150

16

16

of

Cord in Feet

AWG

so

;:

14 12

Not Recommended

1

marked.

14

12

tool when you are tired.

19.

CHECK DAMAGED PARTS. Before further use of the tool, a guard or other

part that is damaged should be carefully checked to determine that

operate properly and perform its intended function. Check for alignment of

moving parts, binding of moving parts, breakage of parts, mounting, and any

other conditions that may affect its operation. A guard or other part that

is damaged should be properly repaired or replaced by an authorized service center unless otherwise indicated elsewhere in this instruction manual.

Have defective switches replaced by authorized service center. Don't use

if

tool

20.

GUARD AGAINST ELECTRIC

switch does not turn

it

on,and off.

SHOCK.

Prevent body contact with grounded

surfaces. For example; pipes, radiators, ranges, refrigerator enclosures.

21

.

REPLACEMENT PARTS. When servicing, use only identical replacement parts.

22.

POLARIZED PLUGS. To reduce the risk of electric shock, this equipment has

a polarized plug (one blade is wider than the other). This plug will fit in a

polarized outlet only one way.

it

reverse the plug. If

still does not fit, contact a qualified electrician to install

If

the plug does not

fit

fully in the outlet,

the proper outlet. Do not change the plug in any way.

it

the

will

3

VOLTAGE WARNING: Before connecting the tool to a power source (receptacle,

outlet, etc.) be sure the voltage supplied is the same as that specified on the

nameplate of the tool. A power source with voltage greater than that specified

for the tool can result in SERIOUS INJURY to the user

the tool.

voltage less than the nameplate rating is harmful to the motor.

If

in doubt,

DO

NOT PLUG

IN

THE

TOOL. Using a power source with

-

as well as damage to

ADDITIONAL SAFETY RULES

1.

Wear hearing protection during extended period of operation.

2.

Handle the bits very carefully.

3.

Check the bit carefully for cracks or damage before operation. Replace

cracked or damaged bit immediately.

4.

Avoid cutting nails. Inspect for and remove all nails from the workpiece

before operation.

5.

Hold the tool firmly

6.

Keep hands away from rotating parts.

7.

Make sure the

on.

8.

Before using the tool on an actual workpiece. let

for vibration or wobbling that could indicate improperly installed bit.

9.

Be careful of the bit rotating direction and the feed direction.

IO.

Do

not leave the tool running. Operate the tool only when hand-held.

11. Always switch off and wait for the bit to come to a complete stop before

removing the tool from workpiece.

12.

Do

not touch the bit immediately after operation;

and could burn your skin.

with

both hands.

bit

is not contacting the workpiece before the switch is turned

it

run for a while. Watch

it

may be extremely hot

SAVE THESE INSTRUCTIONS.

4

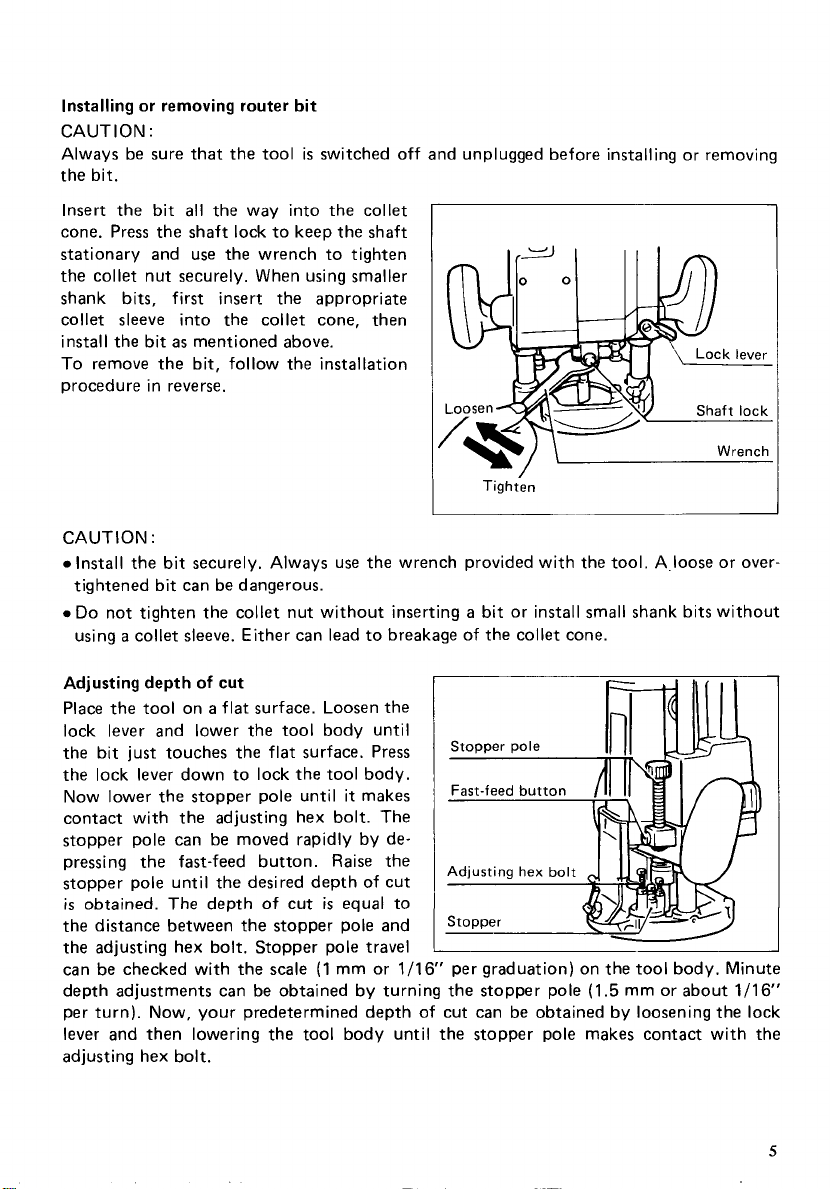

Installing or removing router bit

CAUTION

Always be sure that the tool

the bit.

:

is

switched off and unplugged before installing or removing

Insert the bit

cone. Press the shaft lock to keep the shaft

stationary and use the wrench to tighten

the collet nut securely. When using smaller

shank bits, first insert the appropriate

collet sleeve into the collet cone, then

install the bit

To remove the bit, follow the installation

procedure in reverse.

CAUTION

Install the bit securely. Always use the wrench provided with the tool. A.loose or over-

tightened bit can be dangerous.

0

Do

not tighten the collet nut without inserting a bit or install small shank bits without

a

using

Adjusting depth

Place

the tool on a flat surface. Loosen the

lock lever and lower the tool body until

the bit just touches the flat surface. Press

the lock lever down to lock the tool body.

Now lower the stopper pole until it makes

contact with the adjusting hex bolt. The

stopper pole can be moved rapidly by depressing the fast-feed button. Raise the

stopper pole until the desired depth

is

obtained. The depth of cut

the distance between the stopper pole and

the adjusting hex bolt. Stopper pole travel

can be checked with the scale

depth adjustments can be obtained by turning the stopper pole

per turn). Now, your predetermined depth of cut can be obtained by loosening the lock

lever and then lowering the tool body until the stopper pole makes contact with the

adjusting hex bolt.

all

as

mentioned above.

:

collet

sleeve.

of

the way into the collet

/

Tighten

I

Either can lead to breakage of the collet cone.

cut

of

cut

is

equal

to

(1

mm or

1/16’

per graduation) on the tool body. Minute

(1.5

mm or about

1/16’

5

By

turning the knob, the upper limit of the

be

tool body can

the bit

is

adjusted. When the tip of

retracted more than required in

relation to the base plate surface, turn the

knob to lower the upper limit.

CAUTION

:

.Since excessive cutting may cause overload of the motor or difficulty in controlling the

tool, the depth of cut should not be more than 20 mm (25/32")

at

a

pass when cutting

grooves. When you wish to cut grooves more than 20 mm (25/32") deep, make several

passes with progressively deeper bit settings.

.Do

not lower the knob too low. The bit will protrude dangerously.

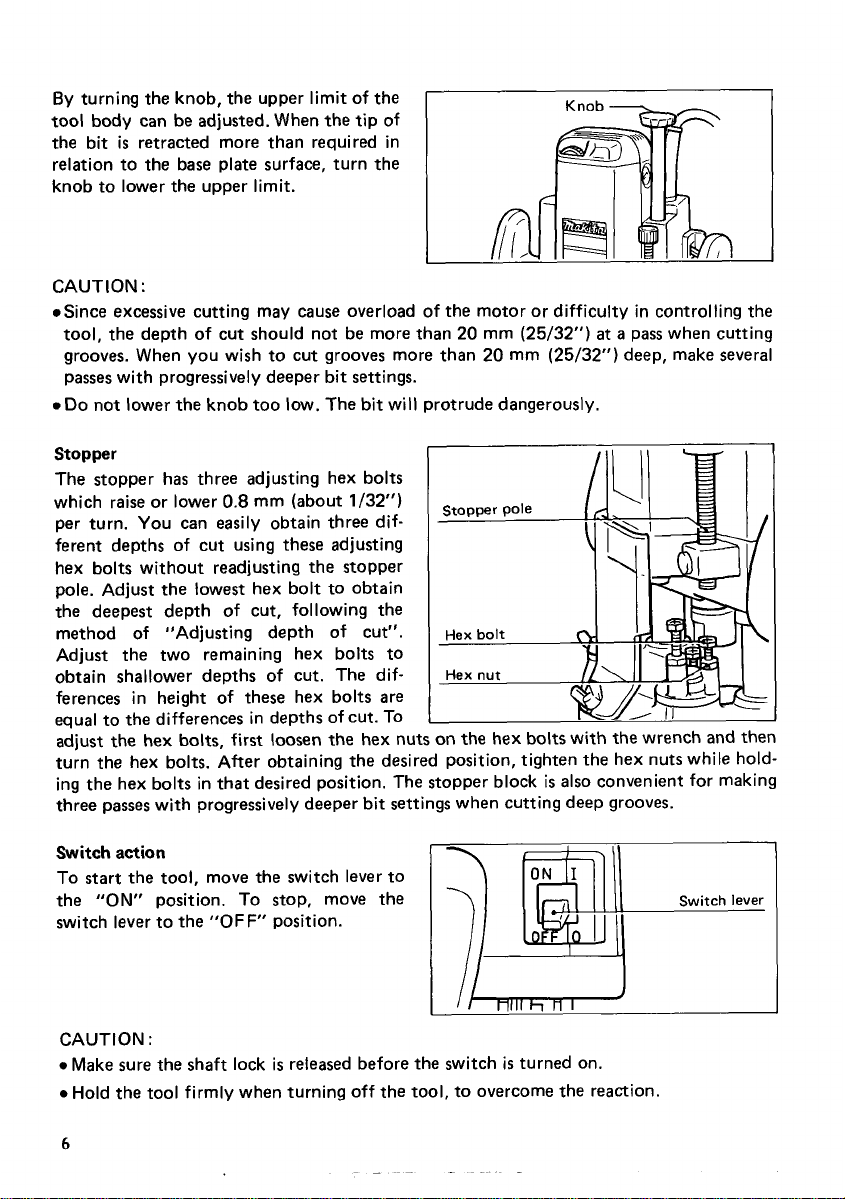

Stopper

The stopper has three adjusting hex bolts

which raise or lower

0.8

mm (about 1/32")

per turn. You can easily obtain three different depths of cut using these adjusting

hex bolts without readjusting the stopper

pole. Adjust the lowest hex bolt to obtain

the deepest depth of cut, following the

method of "Adjusting depth of cut".

Adjust the two remaining hex bolts to

obtain shallower depths of cut. The differences in height of these hex bolts are

equal to the differences in depths of cut. TO

on

adjust the hex bolts, first loosen the hex nuts

the hex bolts with the wrench and then

turn the hex bolts. After obtaining the desired position, tighten the hex nuts while hold-

is

ing the hex bolts in that desired position. The stopper block

also convenient for making

three passes with progressively deeper bit settings when cutting deep grooves.

Switch

action

To start the tool, move the switch lever to

"ON"

the

switch lever to the

position. To stop, move the

"OFF"

position.

Switch

lever

CAUTION

0

Make sure the shaft lock

0

Hold the tool firmly when turning off the tool, to overcome the reaction.

:

is

released before the switch

is

turned on.

6

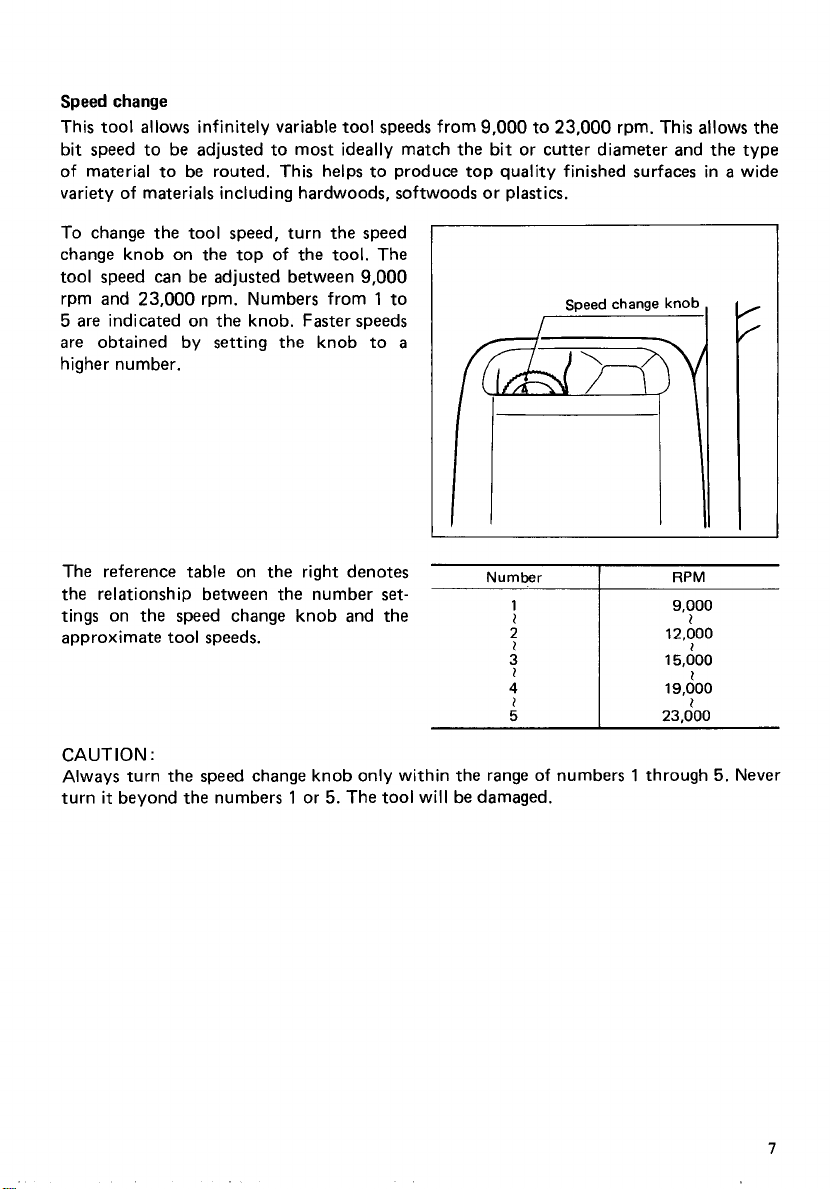

Speed

change

This tool allows infinitely variable tool speeds from

9,000

to

23,000

rpm. This allows the

bit speed to be adjusted to most ideally match the bit or cutter diameter and the type

of

material to be routed. This helps

to

produce top quality finished surfaces in a wide

variety of materials including hardwoods, softwoods or plastics.

To change the tool speed, turn the speed

change knob on the top of the tool. The

tool speed can be adjusted between

rpm and

5

are indicated on the knob. Faster speeds

23,000

rpm. Numbers from 1 to

are obtained by setting the knob to

9,000

a

higher number.

The reference table on the right denotes

the relationship between the number

set-

tings on the speed change knob and the

approximate tool speeds.

CAUTION

:

Number

RPM

9,000

1

12,000

1

15,000

1

19,000

1

23,000

Always turn the speed change knob only within the range of numbers 1 through

it

beyond the numbers 1 or

turn

5.

The tool will be damaged.

5.

Never

7

Operation

CAUTION

0

Before operation, always make sure that the tool body automatically rises to the upper

limit and the bit does not protrude from the tool base when the lock lever

0

Before operation, always make sure that

the chip deflector

0

Set

:

is

loosened.

is

installed properly.

Chip

the tool base on the workpiece to be cut without the bit making any contact. Then

turn the tool on and wait until the bit attains full speed. Lower the tool body and

move the tool forward over the workpiece surface, keeping the tool base flush and

advancing smoothly until the cutting

is

complete.

*When doing edge cutting, the workpiece surface should be on the left side of the bit in

the feed direction.

I

(see

the figure below).

Feed direction

c3

D:+

msi,-.l

'

ving

Bit revolving

direction

I

Bit revolving direction

Bit revolving direction

////////I////

(View from the top

I

NOTE

:

0

Moving the tool forward too fast may cause a poor quality of cut or damage to the bit

or motor. Moving the tool forward too slowly may burn and mar the cut. The proper

feed rate will depend on the bit

beginning the cut on the actual workpiece,

piece of scrap lumber. This will show exactly how the cut will look

to check dimensions.

*When using

in the feed direction. This will help to keep

8

the

straight guide or

of

the tool)

Correct bit feed direction

size,

the kind of workpiece and depth of cut. Before

the

trimmer guide, be sure to

it

is

advisable

it

flush with the side of the workpiece.

to

make a sample cut on

as

well

as

install

it

on

the

enable you

right side

a

The straight guide

is

effectively used for

straight cuts when chamfering or grooving.

Install the straight guide on the guide

(B).

holder with the wing bolt

(B)

wing bolt

only tight enough to hold

Tighten the

the straight guide temporarily. Then insert

the guide holder into the holes in the tool

base and tighten the wing bolts (A). Adjust

the distance between the bit and the

straight guide by turning the fine adjusting

screw (1.5 mm or about 1/16" per turn).

At the desired distance, tighten the wing

(B)

bolt

to secure the straight guide in

place.

When cutting, move the tool with the straight guide flush with the side of the workpiece.

Wider straight guide of desired dimensions

may be made by using the convenient holes

in the guide to bolt on extra pieces of

wood.

When using

a

large diameter bit, attach

pieces of wood to the straight guide which

a

have

(5/8")

thickness

so

that the bit does not strike the

of

more than

15

mm

straight guide.

More than

15

mm

(5/8") Straight guide

/

1

I(

Wood

9

Trimmer

Trimming, curved cuts in veneers for furniture and the like can be done easily with

the trimmer guide. The guide roller rides

the curve and assures a fine cut.

Install the trimmer guide on the guide

holder with the wing bolt

wing bolt

trimmer guide temporarily. Then insert the

guide holder into the holes in the tool base

and tighten the wing bolts (A). Adjust the

distance between the bit and the trimmer

guide by turning the fine adjusting screw

(1.5

desired distance, tighten the wing bolt

to secure the trimmer guide in place. When

adjusting

loosen the wing bolt

it,

guide

(Optional

(6)

only tight enough to hold the

mm

or

about

1

/16’

the

guide roller up on down,

tighten the wing bolt

accessory)

(B).

Tighten the

per turn). At the

(C).

After adjusting

(C)

securely.

(B)

Wing

bolt

Trimmer

(C)

auide

’

/I

When cutting, move the tool with the guide

roller riding the side of the workpiece.

10

Templet guide (Optional accessory)

The templet guide provides a sleeve through

use of

which the bit passes, allowing

router

with templet patterns.

To

install the templet guide, loosen the

the

screws on the tool base, insert the templet

guide and then tighten the screws.

TemDlet auide

Secure the templet to the workpiece.

Place

the tool on the templet and move the tool

with the templet guide sliding along the

side of the templet.

NOTE

:

The workpiece will be cut a slightly different

(X)

tance

between the router bit and the outside

can be calculated by using the following equation:

(X)

Distance

=

Outside diameter of the templet guide - router bit diameter

2

V

Distance (X)

Outside diameter

the templet

size

from

the templet. Allow for the dis-

of

the templet guide. The distance

guide

Screw

Templet guide

/

of

(X)

11

MAINTENANCE

CAUTION

Always be sure that the tool

inspection or maintenance.

Replacing carbon brushes

Remove and check the carbon brushes

regularly. Replace when they wear down to

the limit mark. Keep the carbon brushes

clean and free to slip in the holders. Both

carbon brushes should be replaced

same time. Use

brushes.

Use

holder caps. Take out the worn carbon

brushes, insert the new ones and secure the

brush holder caps.

NOTE:

When replacing carbon brush located on

the same side as the knob, remove the

knob first before unscrewing the brush

holder cap.

:

is

switched off and unplugged before attempting to perform

only

identical carbon

a

screwdriver to remove the brush

at

the

Knob

Limit mark

Brush holder

cap

CAUTION:

Be

sure to re-Install the knob after insert-

ing new carbon brush.

To

maintain product SAFETY and RELIABILITY, repairs, any other maintenance or

by

adjustment should be performed

Makita Authorized or Factory Service Centers,

always using Makita replacement parts.

12

OPTIONAL ACCESSORIES

The accessories listed in this manual are available at an extra cost from your Makita distributor or Makita factory

service center. Service centers are listed on the warranty card packed with your

tool.

CAUTION:

tool

These accessories or attachments are recommended for use with your Makita

of any other accessories or attachments might present a risk of injury

be

should

0

used only in the proper and intended manner.

Templet guide

0

Templet guide

to

persons. The accessories or attachments

specified in this manual. The

25

use

0

Collet

sleeve

Use a sleeve which fits for the

diameter of the

bit

shank.

tr3

Part

NO

I

7638056 3/W'

763803.0

0

Straight guide

Part

No.

342428-9

0

Wrench

24

Part

No.

781210-5

512.

I

1

/.v

Part

No. I Tamplnguide

321812-1 1 25 122.6 157/Wl I 25.4

0

Lock nut

(for templet guide

Part

No.

252627-4

0

Templet guide adapter

(for templet guide

Part

NO

I

321492-3

I

30

l1-3/16'1

0

Trimmer guide

Part

No.

123022-4

0

Guide holder

Part

No.

132306-9

A

I

25)

25)

A

I

8

1

5511.3/8"1

B

11")

Imml

I

c

11 171161

7

C

19132"l

lmml

I

1

0

Wrench

Part

8

No.

781213-9

13

Bits

STRAIGHT -Single Flute

CARBIDE TIPPED

PART

NO.

733002-0A

7330024A 1

HIGH SPEED STEEL

NO.

PART

733232-6A

A B

3/8 1

/2

A

118

1-1 /4 1 -3/8 1

5/16

C

1-1

/2

B

C

1-1/8 1 /4 1.518

D

1

/2

/2

D

E

2-3/4

2-7/8

E

STRAIGHT

STRAIGHT

-

2

Flute

-

2

Flute,

HINGE MORTISING

1/2"

CARBIDE TIPPED

NO.

PART

733003-2A

733003-4A 1 /4

733003-8A

HIGH SPEED STEEL (STRAIGHT

PART

NO.

733233-4A

733234-2A

A

3/16

5/16

A

5/16

1

/2

B

7/16 1 -3/8

3/4 1-3/16 114

1 1-1/8

- 2 Flute)

B

7/8 1-3/16 114 2-118

7/8 1-1/8 1 /4 2-1 /8

Shank

CARBIDE TIPPED

PART NO.

7330054A 1-114

733005-6A 1-1/4 1-7/16

733005-8A 1

733006-4A 3/4 1-1/4 1-1/4

733006-6A 718 1-1/4 1-3/16

733006-8A 1-114 1-3/16 1

/2

1-1/2 1-114

C

C

D

1 /4

114

D

E

2

2

2

E

2-34

2-710

3-110

2-710

/2

2-710

2-710

14

CARBIDE TIPPED

PART

NO.

733006-9A

HIGH SPEED STEEL

PART

NO.

733235-0A 112 1

A

1

I2

A

B

3/4

E

/2

C

1-1/16

C

3/4 1 /4 1-15/16

D

1

/4

0

E

2

E

VEINING

ROUND NOSE

CORE

-Single

BOX

Flute

SOLID

CARBIDE

PART NO. A

733007-8A

CARBIDE TIPPEO

PART NO.

733008-2A 15132

733008-4A 1-114

733008-6A 11/16 1-114 2-3/16

733008-BA 518 11/16 1-114 2.114

733009-0A 3/4 13/16 1-114

3/16

B

7132

C

1-1 /4 114 1-1

1-1

I4 1-718

D

1

/4 2-3/8

E

12

(JpJ

-J

VEE GROOVING

HIGH

SPEED STEEL

PART NO. A

733238-2A

CARBIDE TIPPED

I

PARTNO. A

733009-2A 318 112

733009-4A 5/8 314

114 1 14

B

B

C

1-3/16 114 1-1

C

1-3/16

15/16 1/4

D

D

114

E

/2

E

2

2

el

90"

90"

15

14'

DOVE TAIL

4DC

STAGGER TOOTH

-IDk

~~

PANEL PILOT

CARBIDE TIPPED

PART NO.

733009-6A 1

HIGH SPEED STEEL

I

PARTNO. A

7332394A 1

CARBIDE TIPPED

I

PARTNO. A 8

I

733007-0A 3/8 1-1

CARBIDE TIPPED

I

PARTNO.

7330304A 318 1 1 318 2-1

733030-6A 1

HIGH SPEED STEEL

PART NO. A 8

1

733236-08 114 314 1 114 2-7/16

A

/2

/2

A

12

E

112

E

1

12

12

B

1118 1-1 12 1 12 3-114

C

1-114 114 1-718

C

1 -318 114

C

1-114 112 31

C

C

D

D

D

D

D

E

E

I

2

E

E

12

E

1

CORNER ROUNDING

4DC

16

CARBIDE TIPPED - Ball Bearing Pilot

I

PARTNO. A1 A2 B

1

733120-0A

733120-2A

733120-4A 1-118 1/2 1-114 114 2-1/16 5116

733120-6A 1-1/4

733120-8A 1-1/2 1/2 3/4 1-1/4 1/4 2-1/4 112

733121-0A 1-1/4 1/2

733121-2A 1-112 112 3/4 1-1/2 2-1/2 1/2

HIGH SPEED STEEL

I

PARTNO. A1 A2

733240-2A

733240-6A

:18

ii

i;i

518

5/8

REPLACEMENT BEARING

-

Solid Pilot

11/16 3/16

15/16 3/16

1/2 1 114

5/E

C

D

;:;::

1-114 2-118

1-1/2 1/2 2-3/8 3/8

-

B

ii

NO. 733132-4A

C

D

1 114 1-7/8 3/8

E

1.1;/16

E

1-3/4 114

R

7;:6

318

RI

BEADING

CARBIDE TIPPED - Ball Bearmg Pilot

I

PARTNO. AI A, A2 B C

733121-4A

733121-6A 1

733121-BA

733122-0A

733122-2A

718

112

318 318

112

112

112

318 112

318 112

318

318

1-118

1-114 1/2

1-112

REPLACEMENT BEARING

518

314 1-114

D

1-114 114 1-15/16

1.114 114

1-114

114

1-114

114

114

-

NO. 733132-2A

E

RI

3/16

114

2

2-1/16 5/16

2-118 318

2-114

112

COVE

45'

CHAMFERING

RABBETING

-Pi

CARBIDE TIPPED

733122-BA 1-118 318 112 114 1-314 318

733123-0A 1-318 318

HIGH SPEED STEEL

PARTNO. Ai Ai B

733242-6A 11116

733242-8A 15/16 3/16 314 1 114

CARBIDE TIPPED - Ball Bearing Pilot

I

PARTNO. Ai A?

I

733124-4A 1-3/16 112 112 1-114 114 2-114

-

Ball Bearing Pilot

718 318 318

518

REPLACEMENT BEARING

-

Solid

Pilot

3/16

REPLACEMENT BEARING - NO. 733132-4A

-

112

6

114 1.518 733122-6A

114 1-718 112

NO. 733132-2A

C

D

1

114

C

E

1-314 114

2-1132

D

R

318

E1

I

CARBIDE TIPPED - Ball Bearing Pilot

PARTNO. Ai A2

733124-2A 1-114 112

REPLACEMENT BEARING

6

112

C

1-7/16 114 2-114

-

NO. 733132-4A

D

E

17

ROMAN OGEE

FLUSH TRIMMER -Self Piloting

CARBIDE TIPPED - Ball Bearing Pilot

PARTNO. Ai A2 B C D

733123-2A 1 3/8 15/32 1-1/4 114 2

733123-4A 1-3/B 3/8 21/32 1-1/4 1/4 2-1/8 1/4

REPLACEMENT BEARING

-

NO.

733132-2A

E

R

5/32

m

7"

BEVEL

TRIMMER

2

FLUTE FLUSH TRIMMER

-

SOLID CARBIDE

PART NO. A B C

I

733128-0A 1 /4 1 /4 1-1/16 114 1-9/16

Self-piloting

SOLID CARBIDE

PART NO.

733128-2A

CARBIDE TIPPED

PART

733128-BA

733128-9A

733129-0A 112 1-114

A

3/16 1 I4 1-1/16 1 I4 1-9/16

NO.

318" REPLACEMENT BEARING

1/2" REPLACEMENT BEARING

0

E

I

B

C D E

1-114 2-1/16

1-114 2-1/16

-

-

1 /4 2.518

NO. 733132-2A

NO. 7331324A

18

COMBINATION FLUSH/22" BEVEL TRIMMER

IDC

CARBIDE TIPPED

PART NO. A

733128-6A 7/16 1/2 3/16 1-1/4 1/4 1-3/4

3

FLUTE FLUSH TRIMMER ASSEMBLY

4

DC

SOLID CARBIDE CUTTER

-Self

PART NO. A

733129-2A 518 3/53 1-1 I4 114 2-318

Bi

Piloting

B

REPLACEMENT BEARING

B2 C

C D

-

NO. 733132-6A

D

E

E

L

A

-r

FOR

7/8

FLUSH

733129-4A

SOLID CARBIDE

PART NO.

7331 29-6A 3/8 114

5/8

A

TRIMMER ASSEMBLY

3/8 1-1/4 114 2-318

B

NO.

733129-2A

C

5/B

19

3

FLUTE

22"

BEVEL REPLACEMENT CUTTER

L

A

@

f

114

REPLACEMENT ARBOR

SOLID CARBIDE

PART

NO.

7331 29-EA 318 114 718

FOR

A B

BEVEL TRIMMER ASSEMBLY

NO.

7331294A

C

BALL BEARING PILOT

FA--

@

PART NO. A

733131-2A

FOR

PART

NO.

733132-2A 318 O.D.

7331 324A 112 O.D.

7331 32-6A

518

FLUSH

TRIMMER ASSEMBLY NO. 733129-2A AND NO. 733129-4A

A B

518

O.D.

318

B

C

1-114 1

D

I4

118 I.D.

3/16 I.D.

1.0.

114

E

2-318

20

112"

ELECTRONIC

Model

3612C

ROUTER

Aug

-25-'94

US

Note:

The

switch, noise suppressor and other part configurations

may differ from country to country.

21

MODEL

3612C

ILL,

MACHINE

1 2 Pan Head Screw M5x20 (With Washer)

2

,"

5

; 1 ;

8

1;

11 1 ARMATURE ASSEMBLY

12

13 Bearing Retainer 50

14 1 Ball Bearing 2012DDW

15

16 Motor Bracket

17 1 Compression Spring 10

18 Half Nut

19

20 1

21 Collet cone 12

22

23 1 KnobR

24 1 Torsin Spring 15

25

26 1 Lock Lever

33

34

DESCRIPTION

1 Rear Cover

Controller

1

Tapping Screw4xl8

1 Motor Housing

Name Plate

1

Field

1

Baffle Plate

Ball Bearing 629DDW

1

i

1

Insulation Washer

(Wlth Item 9 12)

1

;

1

Fan83

1

i

1

KnobL

~ Pan Head Screw M5x40 (With Washer)

1

Collel

Nut

1

Pan Head Screw M6x45 (Wlth Washer)

1

1 1 SetBoltMlO

4 Countersunk Head

2 1 Pan Head Screw M5x80 (Wtth Washer)

1

7

Screw

M4~14

",'OM

GFD

MACHINE

35

2

36

2

37 1

381

39

2

40 1

41

1

42

7

43 1

44 1

45

46 1

47 1

48

2

49 1

50 2

51

1

52 1

53 1

54

4

55 2

56

1

57 1

58

1

59 1

60

1

61

1

62

1

63 t

64 1

85 1

66

2

67 1

68 1

69

1

DESCRIPTION

Brush Holder Cap

Carbon Brush

Cord Guard

Strain

Relief

Tapping

Screw

Cord

Bearing

Tapping Screw 4x18

Knob 50

Nut M10 - 15

Terminal Block

Switch

Switch Cover

Tapping Screw 4x18

Pole

Compression Spring 11

Base Assembly

Wing Bolt

Chip Deflectoi

Countersunk

Pan Head Screw M5x10 Wth Washer)

Base Plate

Stopper

Hex Nut M5

Hex Bolt M5x28

Compression Spring 12

Flat

Hex Nul M5

Hex Boll M5x40

Hex Nut M5

Hex Bolt M5x16

Compression

Wing Bolt M5x15

Compresston Spring 12

Flat Washer 10

4x18

Box

Head

Head Screw Ma

Spring

Screw

7

M4x10

Aug

-25-'94

US

22

MAKIIA

LIMED

ONE

YEAR WARRANTY

Warranty Policy

Every Makita

i

be free of defects from workmanship and materials for the period of ONE YEAR from the date of

original purchase. Should any trouble develop during this one-year period, return the COMPLETE

tool,

the trouble is caused by defective workmanship or material, Makita

replace) without charge.

This Warranty does

repairs have been made or attempted by others:

repairs are required because of normal wear and tear:

The

alterations have been made

IN NO EVENT SHALL MAKITA BE LIABLE FOR ANY INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES FROM THE SALE OR USE OF THE PRODUCT. THIS DISCLAIMER

APPLIES BOTH DURING AND AFTER THE TERM OF THIS WARRANTY.

MAKITA DISCLAIMS LIABILITY FOR ANY IMPLIED WARRANTIES, INCLUDING IMPLIED

WARRANTIES OF “MERCHANTABILITY” AND “FITNESS FOR A SPECIFIC PURPOSE,”

AFTER THE ONE-YEAR TERM OF THIS WARRANTY.

This Warranty gives you specific legal rights, and you may also have other rights which vary from

state

damages,

limitation on how long an implied warranty lasts,

tool

is thoroughly inspected and tested before leaving the factory. It is warranted to

freight prepaid, to one of Makita’s Factory or Authorized Service Centers.

not

apply where:

tool

has been abused, misused or improperly maintained;

to

state. Some states do not allow the exclusion or limitation

so

the above limitation or exclusion may not apply

to

the

tool.

so

the above limitation may not apply

‘u

will

repair (or at our option,

of

incidental or consequential

to

you. Some states do not allow

If

inspection shows

to

you.

MCA

-

1/95

Makita

2650

Corporation

Gainesville

Hwy.,

883851

Buford,

-941

of

America

GA 30518

PRINTED

IN

U.S.A.

1995-1 -C

Loading...

Loading...