MAKITA 3612, 3612C User Manual

INSTRUCTION MANUAL

MANUEL D'INSTRUCTION

MANUAL DE INSTRUCCIONES

Router

Défonceuse

Rebajadora

3612

3612C

003647

DOUBLE INSULATION

DOUBLE ISOLATION

DOBLE AISLAMIENTO

WARNING:

For your personal safety, READ and UNDERSTAND before using.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

AVERTISSEMENT:

Pour votre propre sécurité, prière de lire attentivement avant l’utilisation.

GARDER CES INSTRUCTIONS POUR RÉFÉRENCE ULTÉRIEURE.

ADVERTENCIA:

Para su seguridad personal, LEA DETENIDAMENTE este manual antes de usar la herramienta.

GUARDE ESTAS INSTRUCCIONES PARA FUTURA REFERENCIA.

ENGLISH

SPECIFICATIONS

Model 3612 3612C

Collet chuck capacity 1/2”

Plunge capacity 0 - 60 mm (0 - 2-3/8”)

No load speed (RPM) 22,000/min. 9,000 - 23,000/min.

Overall length 324 mm (12-3/4”)

Net weight 6.0 kg (13.2 lbs)

• Due to our continuing programme of research and development, the specifications herein are subject to change

without notice.

• Note: Specifications may differ from country to country.

GENERAL SAFETY RULES

GEA001-3

WARNING:

Read all instructions. Failure to follow all

instructions listed below may result in electric shock, fire and/or serious injury. The

term “power tool” in all of the warnings listed

below refers to your mains-operated

(corded) power tool or battery-operated

(cordless) power tool.

SAVE THESE INSTRUCTIONS

Work area safety

1. Keep work area clean and well lit. Cluttered and

dark areas invite accidents.

2. Do not operate power tools in explosive atmo-

spheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

3. Keep children and bystanders away while oper-

ating a power tool. Distractions can cause you to

lose control.

Electrical safety

4. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodified plugs and matching outlets will

reduce risk of electric shock.

5. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

6. Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the

risk of electric shock.

7. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords

increase the risk of electric shock.

8. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of

electric shock.

Personal safety

9. Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the influence of drugs, alcohol or medication. A

moment of inattention while operating power tools

may result in serious personal injury.

10. Use safety equipment. Always wear eye protection. Safety equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used

for appropriate conditions will reduce personal injuries.

11. Avoid accidental starting. Ensure the switch is in

the off-position before plugging in. Carrying

power tools with your finger on the switch or plugging in power tools that have the switch on invites

accidents.

12. Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

13. Do not overreach. Keep proper footing and balance at all times. This enables better control of the

power tool in unexpected situations.

14. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing, and gloves

2

away from moving parts. Loose clothes, jewellery

or long hair can be caught in moving parts.

15. If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

these devices can reduce dust-related hazards.

Power tool use and care

16. Do not force the power tool. Use the correct

power tool for your application. The correct power

tool will do the job better and safer at the rate for

which it was designed.

17. Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be

repaired.

18. Disconnect the plug from the power source and/

or the battery pack from the power tool before

making any adjustments, changing accessories,

or storing power tools. Such preventive safety

measures reduce the risk of starting the power tool

accidentally.

19. Store idle power tools out of the reach of children and do not allow persons unfamiliar with

the power tool or these instructions to operate

the power tool. Power tools are dangerous in the

hands of untrained users.

20. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the power

tools operation. If damaged, have the power tool

repaired before use. Many accidents are caused by

poorly maintained power tools.

21. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

22. Use the power tool, accessories and tool bits

etc. in accordance with these instructions and in

the manner intended for the particular type of

power tool, taking into account the working conditions and the work to be performed. Use of the

power tool for operations different from those

intended could result in a hazardous situation.

Service

23. Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

24. Follow instruction for lubricating and changing

accessories.

25. Keep handles dry, clean and free from oil and

grease.

GEB018-1

SPECIFIC SAFETY RULES

DO NOT let comfort or familiarity with product

(gained from repeated use) replace strict adherence

to router safety rules. If you use this tool unsafely or

incorrectly, you can suffer serious personal injury.

1. Hold power tools by insulated gripping surfaces

when performing an operation where the cutting tool may contact hidden wiring or its own

cord. Contact with a “live” wire will make exposed

metal parts of the tool “live” and shock the operator.

2. Use clamps or another practical way to secure

and support the workpiece to a stable platform.

Holding the work by hand or against your body

leaves it unstable and may lead to loss of control.

3. Wear hearing protection during extended period

of operation.

4. Handle the bits very carefully.

5. Check the bit carefully for cracks or damage

before operation. Replace cracked or damaged

bit immediately.

6. Avoid cutting nails. Inspect for and remove all

nails from the workpiece before operation.

7. Hold the tool firmly with both hands.

8. Keep hands away from rotating parts.

9. Make sure the bit is not contacting the workpiece before the switch is turned on.

10. Before using the tool on an actual workpiece,

let it run for a while. Watch for vibration or wobbling that could indicate improperly installed

bit.

11. Be careful of the bit rotating direction and the

feed direction.

12. Do not leave the tool running. Operate the tool

only when hand-held.

13. Always switch off and wait for the bit to come to

a complete stop before removing the tool from

workpiece.

14. Do not touch the bit immediately after operation; it may be extremely hot and could burn

your skin.

15. Do not smear the tool base carelessly with thinner, gasoline, oil or the like. They may cause

cracks in the tool base.

16. Draw attention to the need to use cutters of the

correct shank diameter and which are suitable

for the speed of the tool.

17. Some material contains chemicals which may

be toxic. Take caution to prevent dust inhalation

and skin contact. Follow material supplier

safety data.

18. Always use the correct dust mask/respirator for

the material and application you are working

with.

3

SAVE THESE INSTRUCTIONS.

WARNING:

MISUSE or failure to follow the safety rules

stated in this instruction manual may cause

serious personal injury.

SYMBOLS

USD201-2

The followings show the symbols used for tool.

V............................volts

A ...........................amperes

Hz..........................hertz

....................alternating current

.......................no load speed

.......................Class II Construction

.../min....................revolutions or reciprocation per

minute

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and

unplugged before adjusting or checking function on

the tool.

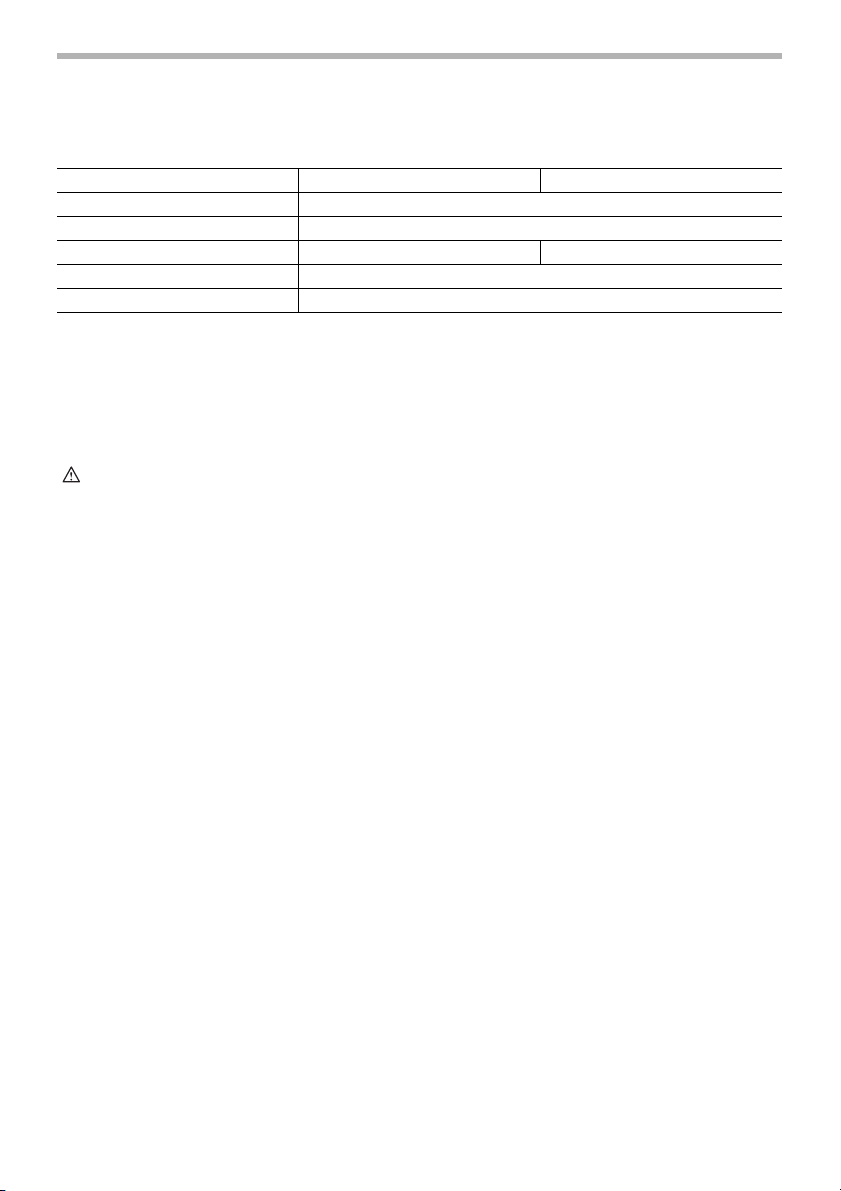

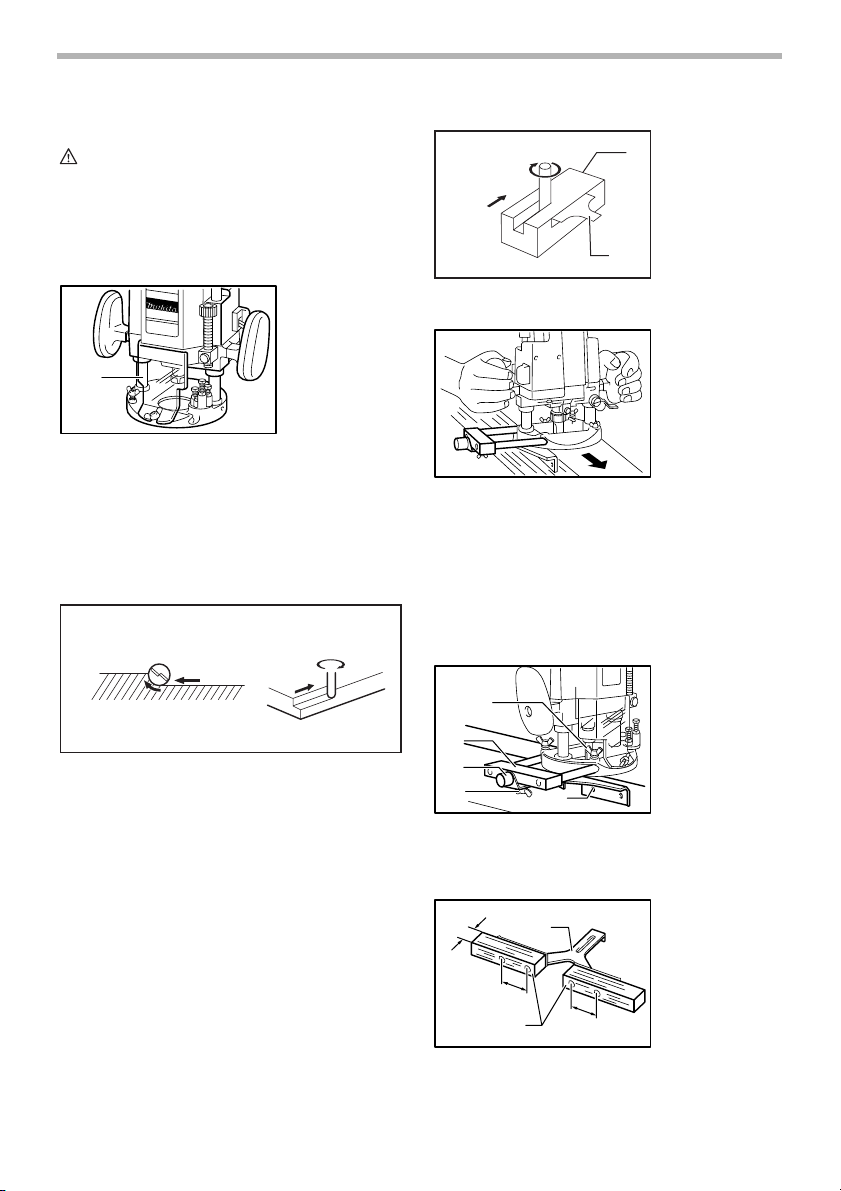

Adjusting the depth of cut

1

2

3

4

Place the tool on a flat surface. Loosen the lock lever and

lower the tool body until the bit just touches the flat surface. Press the lock lever down to lock the tool body.

Now lower the stopper pole until it makes contact with the

adjusting hex bolt. The stopper pole can be moved rapidly by depressing the fast-feed button. While pressing

the fast-feed button, raise the stopper pole until the

desired depth of cut is obtained. The depth of cut is equal

to the distance between the stopper pole and the adjusting hex bolt. Stopper pole travel can be checked with the

scale (1 mm or 1/16” per graduation) on the tool body.

Minute depth adjustments can be obtained by turning the

stopper pole (1.5 mm or about 1/16” per turn).

003652

1. Stopper pole

2. Fast-feed button

3. Adjusting hex

bolt

4. Stopper block

Now, your predetermined depth of cut can be obtained by

loosening the lock lever and then lowering the tool body

until the stopper pole makes contact with the adjusting

hex bolt.

By turning the knob, the upper limit of the tool body can

be adjusted. When the tip of the bit is retracted more than

required in relation to the base plate surface, turn the

knob to lower the upper limit.

CAUTION:

• Since excessive cutting may cause overload of the

motor or difficulty in controlling the tool, the depth of

cut should not be more than 20 mm (13/16”) at a

pass when cutting grooves. When you wish to cut

grooves more than 20 mm (13/16”) deep, make

several passes with progressively deeper bit settings.

• Do not lower the knob too low. The bit will protrude

dangerously.

Stopper block

1

4

The stopper block has three adjusting hex bolts which

raise or lower 0.8 mm (1/32”) per turn. You can easily

obtain three different depths of cut using these adjusting

hex bolts without readjusting the stopper pole.

Adjust the lowest hex bolt to obtain the deepest depth of

cut, following the method of “Adjusting depth of cut”.

Adjust the two remaining hex bolts to obtain shallower

depths of cut. The differences in height of these hex bolts

are equal to the differences in depths of cut.

To adjust the hex bolts, first loosen the hex nuts on the

hex bolts with the wrench and then turn the hex bolts.

After obtaining the desired position, tighten the hex nuts

while holding the hex bolts in that desired position. The

stopper block is also convenient for making three passes

with progressively deeper bit settings when cutting deep

grooves.

003655

1

003657

2

3

1. Knob

1. Stopper pole

2. Hex bolt

3. Hex nut

4. Stopper block

4

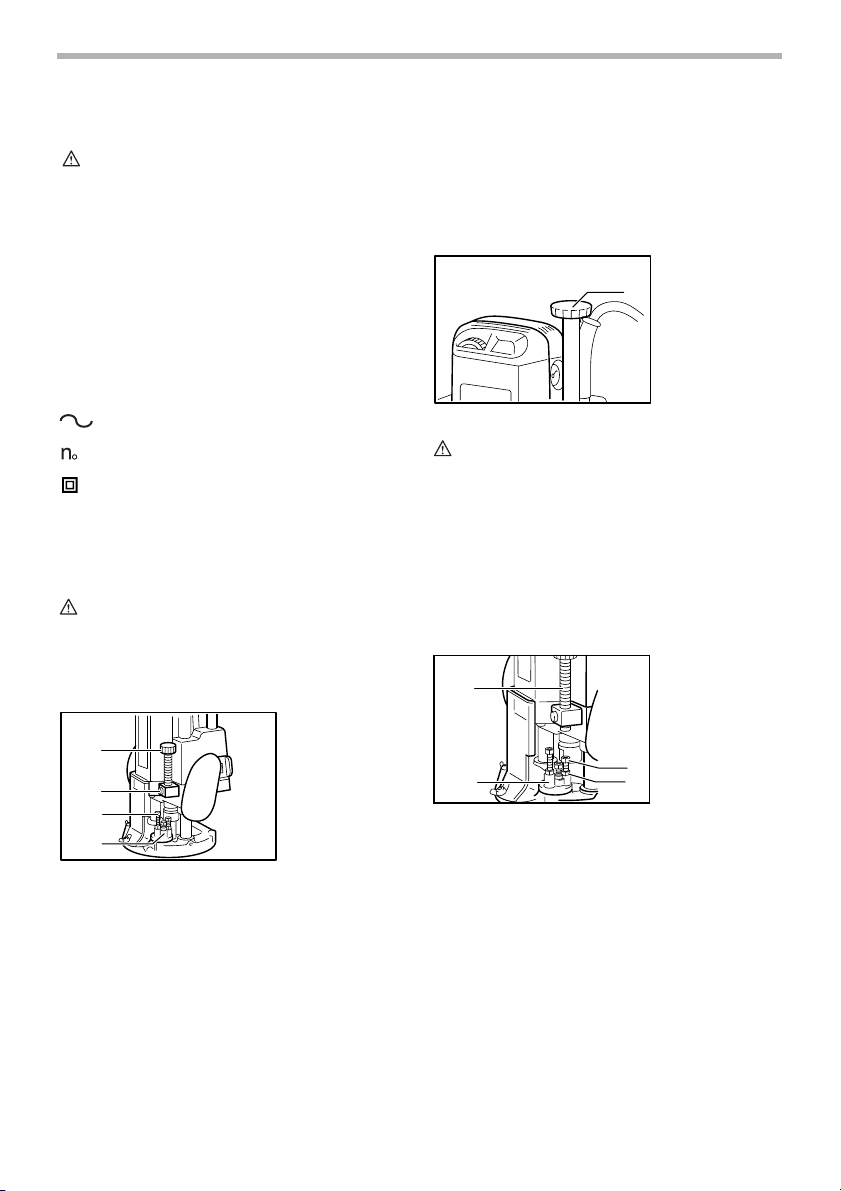

Switch action

CAUTION:

• Before plugging in the tool, always check to see

that the tool is switched off.

• Switch can be locked in “ON” position for ease of

operator comfort during extended use. Apply caution when locking tool in “ON” position and maintain

firm grasp on tool.

• Make sure that the shaft lock is released before the

switch is turned on.

• Hold the tool firmly when turning off the tool, to

overcome the reaction.

To start the tool, move the switch lever to the I (ON) position. To stop the tool, move the switch lever to the O

(OFF) position.

003660

1. Switch lever

1

Electric brake

This tool is equipped with an electric brake. If the tool

consistently fails to quickly stop after switch lever moving

to the O (OFF) position, have tool serviced at a Makita

service center.

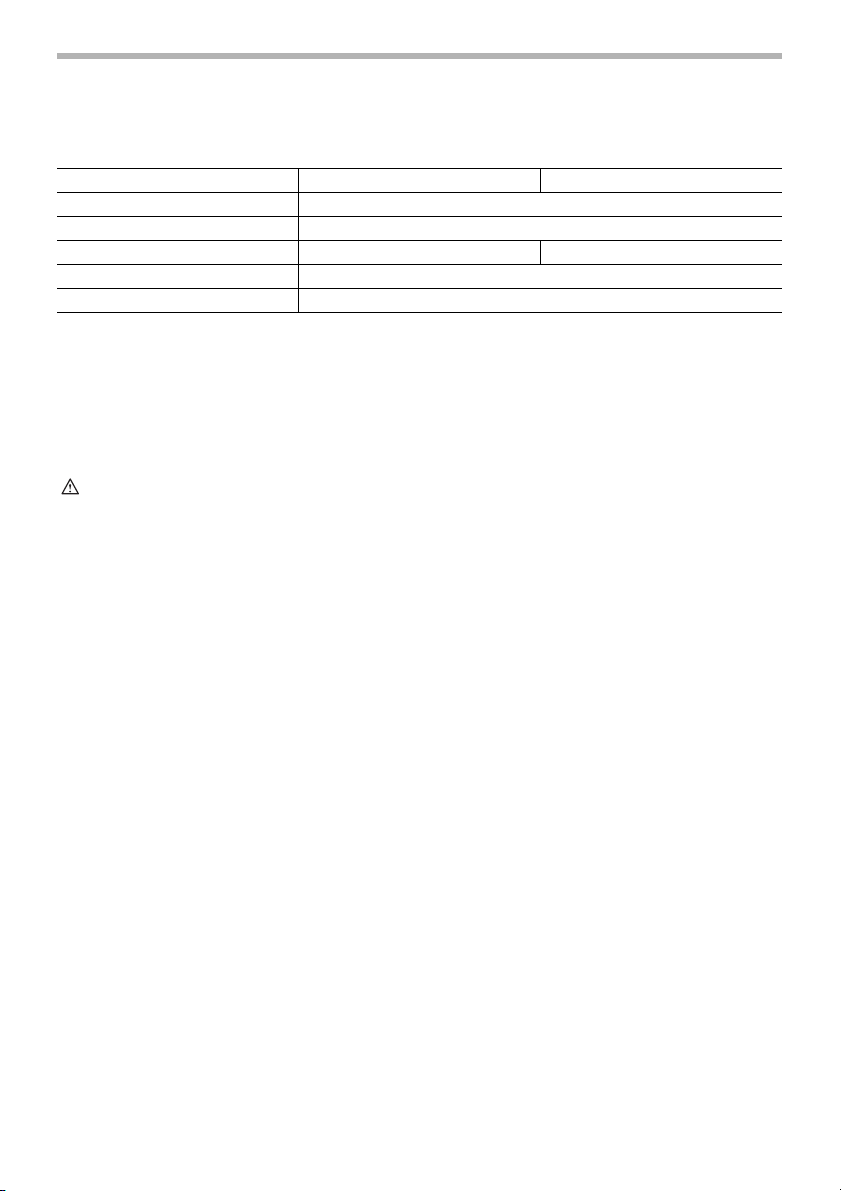

Speed adjusting dial

For model 3612C only

1

003802

1. Speed adjusting dial

Number

1

2

3

4

5

CAUTION:

• If the tool is operated continuously at low speeds for

a long time, the motor will get overloaded, resulting

in tool malfunction.

• The speed adjusting dial can be turned only as far

as 5 and back to 1. Do not force it past 5 or 1, or the

speed adjusting function may no longer work.

003667

RPM

9,000

12,000

15,000

19,000

23,000

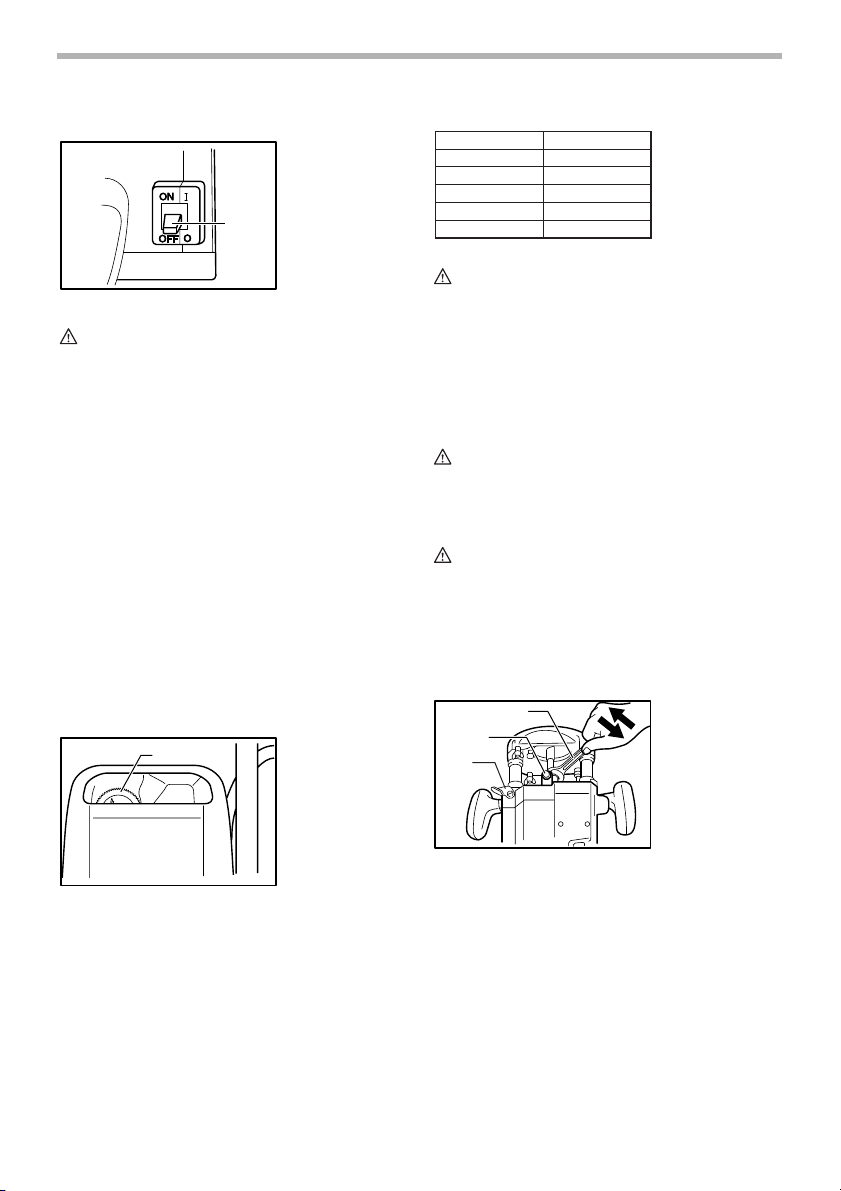

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Installing or removing the bit

CAUTION:

• Install the bit securely. Always use only the wrench

provided with the tool. A loose or overtightened bit

can be dangerous.

• Do not tighten the collet nut without inserting a bit

or install small shank bits without using a collet

sleeve. Either can lead to breakage of the collet

cone.

1

2

3

003670

1. Wrench

2. Shaft lock

3. Lock lever

The tool speed can be changed by turning the speed

adjusting dial to a given number setting from 1 to 5.

Higher speed is obtained when the dial is turned in the

direction of number 5. And lower speed is obtained when

it is turned in the direction of number 1.

This allows the ideal speed to be selected for optimum

material processing, i.e. the speed can be correctly

adjusted to suit the material and bit diameter.

Refer to the table for the relationship between the number settings on the dial and the approximate tool speed.

Insert the bit all the way into the collet cone. Press the

shaft lock to keep the shaft stationary and use the

wrench to tighten the collet nut securely. When using

router bits with smaller shank diameter, first insert the

appropriate collet sleeve into the collet cone, then install

the bit as described above.

To remove the bit, follow the installation procedure in

reverse.

5

OPERATION

CAUTION:

• Before operation, always make sure that the tool

body automatically rises to the upper limit and the

bit does not protrude from the tool base when the

lock lever is loosened.

• Before operation, always make sure that the chip

deflector is installed properly.

1

Set the tool base on the workpiece to be cut without the

bit making any contact. Then turn the tool on and wait

until the bit attains full speed. Lower the tool body and

move the tool forward over the workpiece surface, keeping the tool base flush and advancing smoothly until the

cutting is complete.

When doing edge cutting, the workpiece surface should

be on the left side of the bit in the feed direction.

1

2

3

1. Workpiece 2. Bit revolving direction

3. View from the top of the

tool

003803

4

4. Feed direction

1. Chip deflector

001984

2

4

001985

2

1. Feed direction

3

2. Bit revolving

direction

3. Workpiece

1

4. Straight guide

4

Straight guide (optional accessory)

003677

The straight guide is effectively used for straight cuts

when chamfering or grooving.

Install the straight guide on the guide holder with the

wing bolt (B). Insert the guide holder into the holes in the

tool base and tighten the wing bolt (A). To adjust the distance between the bit and the straight guide, loosen the

wing bolt (B) and turn the fine adjusting screw (1.5 mm or

about 1/16” per turn). At the desired distance, tighten the

wing bolt (B) to secure the straight guide in place.

003683

1. Wing bolt (A)

1

2

3

4

5

2. Guide holder

3. Fine adjusting

screw

4. Wing bolt (B)

5. Straight guide

NOTE:

• Moving the tool forward too fast may cause a poor

quality of cut, or damage to the bit or motor. Moving

the tool forward too slowly may burn and mar the

cut. The proper feed rate will depend on the bit size,

the kind of workpiece and depth of cut. Before

beginning the cut on the actual workpiece, it is

advisable to make a sample cut on a piece of scrap

lumber. This will show exactly how the cut will look

as well as enable you to check dimensions.

• When using the straight guide or the trimmer guide,

be sure to install it on the right side in the feed

direction. This will help to keep it flush with the side

of the workpiece.

Wider straight guide of desired dimensions may be made

by using the convenient holes in the guide to bolt on extra

pieces of wood.

1

2

003684

1. More than

15mm (5/8”)

2. Straight guide

3. Wood

55 mm

( 2-3/16” )

55 mm

3

( 2-3/16” )

6

When using a large diameter bit, attach pieces of wood

to the straight guide which have a thickness of more than

15 mm (5/8”) to prevent the bit from striking the straight

guide.

When cutting, move the tool with the straight guide flush

with the side of the workpiece.

Templet guide (optional accessory)

003688

The templet guide provides a sleeve through which the

bit passes, allowing use of the tool with templet patterns.

To install the templet guide, loosen the screws on the tool

base, insert the templet guide and then tighten the

screws.

3

003692

1

1. Templet guide

2. Screw

3. Base plate

2

Secure the templet to the workpiece. Place the tool on

the templet and move the tool with the templet guide sliding along the side of the templet.

1

2

003695

7

1. Bit

2. Base

3. Templet

4. Workpiece

3

4

5

6

5. Distance (X)

6. Outside diameter of the templet guide

7. Templet guide

Trimmer guide (optional accessory)

Trimming, curved cuts in veneers for furniture and the like

can be done easily with the trimmer guide. The guide

003698

roller rides the curve and assures a fine cut.

Install the trimmer guide on the guide holder with the

wing bolt (B). Insert the guide holder into the holes in the

tool base and tighten the wing bolt (A). To adjust the distance between the bit and the trimmer guide, loosen the

wing bolt (B) and turn the fine adjusting screw (1.5 mm or

1/16” per turn). When adjusting the guide roller up or

down, loosen the wing bolt (C). After adjusting, tighten all

the wing bolts securely.

1

2

3

4

5

003700

1. Wing bolt (A)

2. Guide holder

3. Fine adjusting

screw

4. Wing bolt (B)

5. Wing bolt (C)

6. Trimmer guide

7

6

7. Guide roller

When cutting, move the tool with the guide roller riding

the side of the workpiece.

3

003701

1

1. Bit

2. Guide roller

3. Workpiece

2

MAINTENANCE

NOTE:

• The workpiece will be cut a slightly different size

from the templet. Allow for the distance (X) between

the bit and the outside of the templet guide. The

distance (X) can be calculated by using the following equation:

Distance (X) = (outside diameter of the templet

guide - bit diameter) / 2

CAUTION:

• Always be sure that the tool is switched off and

unplugged before attempting to perform inspection

or maintenance.

7

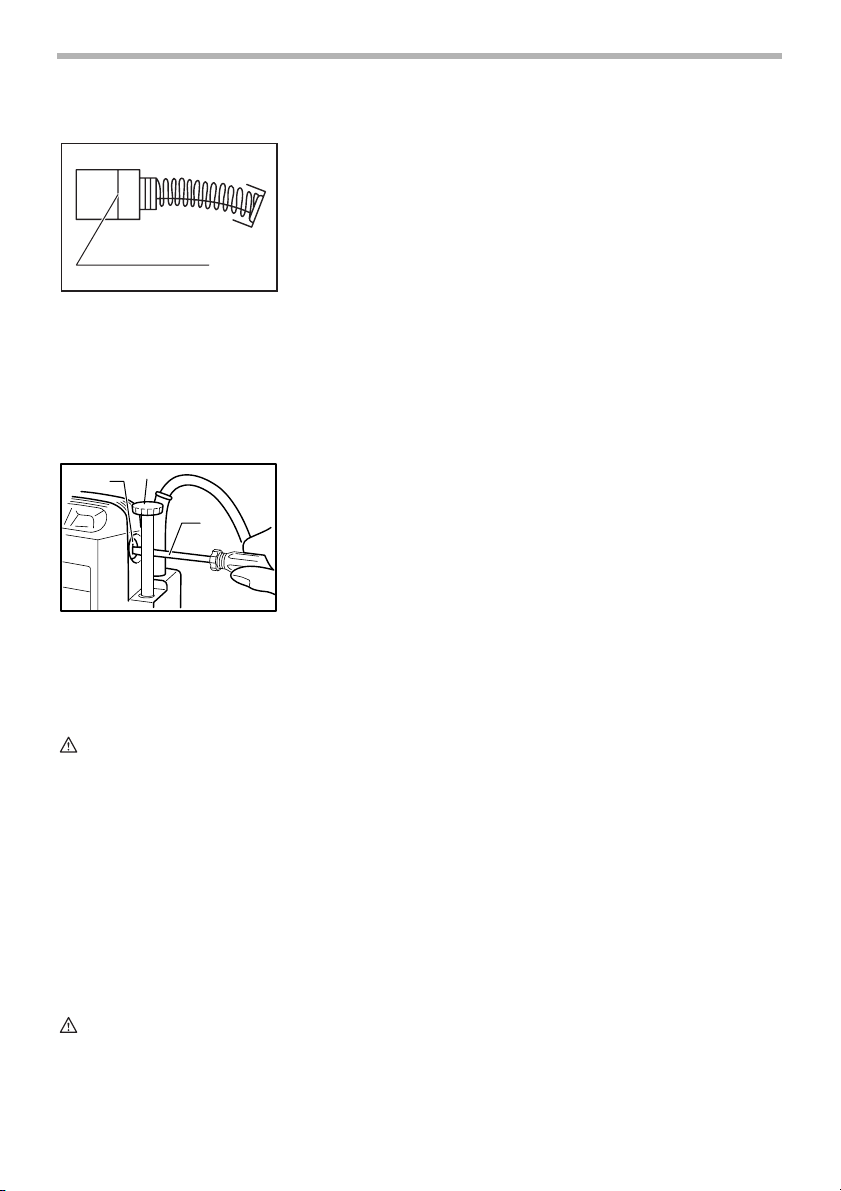

Replacing carbon brushes

Remove and check the carbon brushes regularly.

Replace when they wear down to the limit mark. Keep

the carbon brushes clean and free to slip in the holders.

Both carbon brushes should be replaced at the same

time. Use only identical carbon brushes.

Use a screwdriver to remove the brush holder caps. Take

out the worn carbon brushes, insert the new ones and

secure the brush holder caps.

2

1

NOTE:

• When replacing carbon brush located on the same

side as the knob, remove the knob first before

unscrewing the brush holder cap.

CAUTION:

• Be sure to re-install the knob after inserting new

carbon brush.

After replacing brushes, plug in the tool and break in

brushes by running tool with no load for about 10 minutes. Then check the tool while running and electric

brake operation when releasing the switch trigger. If electric brake is not working well, ask your local Makita service center for repair.

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be performed by Makita Authorized or Factory Service Centers,

always using Makita replacement parts.

001145

1. Limit mark

1

003702

1. Brush holder

cap

3

2. Knob

3. Screwdriver

ACCESSORIES

CAUTION:

• These accessories or attachments are recom-

mended for use with your Makita tool specified in

this manual. The use of any other accessories or

attachments might present a risk of injury to persons. Only use accessory or attachment for its

stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita Service Center.

• Straight & groove forming bits

• Edge forming bits

• Laminate trimming bits

• Straight guide

• Trimmer guide

• Guide holder

• Temp l e t gu i d es

• Templet guide adapter

• Lock nut

• Collet sleeve 3/8”, 1/4”

• Wrench 8

• Wrench 24

EN0006-1

MAKITA LIMITED ONE YEAR WARRANTY

Warranty Policy

Every Makita tool is thoroughly inspected and tested

before leaving the factory. It is warranted to be free of

defects from workmanship and materials for the period of

ONE YEAR from the date of original purchase. Should

any trouble develop during this one year period, return

the COMPLETE tool, freight prepaid, to one of Makita’s

Factory or Authorized Service Centers. If inspection

shows the trouble is caused by defective workmanship or

material, Makita will repair (or at our option, replace)

without charge.

This Warranty does not apply where:

• repairs have been made or attempted by others:

• repairs are required because of normal wear and

tear:

• the tool has been abused, misused or improperly

maintained:

• alterations have been made to the tool.

IN NO EVENT SHALL MAKITA BE LIABLE FOR ANY

INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES FROM THE SALE OR USE OF THE PRODUCT.

THIS DISCLAIMER APPLIES BOTH DURING AND

AFTER THE TERM OF THIS WARRANTY.

MAKITA DISCLAIMS LIABILITY FOR ANY IMPLIED

WARRANTIES, INCLUDING IMPLIED WARRANTIES

OF “MERCHANTABILITY” AND “FITNESS FOR A SPECIFIC PURPOSE,” AFTER THE ONE YEAR TERM OF

THIS WARRANTY.

This Warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not apply to you. Some states do

not allow limitation on how long an implied warranty lasts,

so the above limitation may not apply to you.

8

FRANÇAIS

SPÉCIFICATIONS

Modèle 3612 3612C

Capacité du mandrin 1/2”

Capacité d’insertion 0 - 60 mm (0 - 2-3/8”)

Vitesse à vide (T/MIN) 22,000/min. 9,000 - 23,000/min.

Longueur totale 324 mm (12-3/4”)

Poids net 6.0 kg (13.2 lbs)

• Le fabricant se réserve le droit de modifier sans avertissement les spécifications.

• Note: Les spécifications peuvent varier selon les pays.

CONSIGNES DE SÉCURITÉ

GÉNÉRALES

GEA001-3

AVERTISSEMENT:

Veuillez lire l’ensemble des présentes

instructions. Il y a risque de choc

électrique, d’incendie et/ou de blessure

grave si toutes les instructions énumérées

ci-dessous ne sont pas respectées. Dans

tous les avertissements ci-dessous, le terme

“outil électrique” fait référence aux outils

électriques qui fonctionnent sur le secteur

(avec un cordon d’alimentation) et aux outils

électriques alimentés par batterie (sans

cordon d’alimentation).

CONSERVEZ CES

INSTRUCTIONS

Sécurité de la zone de travail

1. Maintenez la zone de travail propre et bien

éclairée. Les zones de travail encombrées et

sombres ouvrent grande la porte aux accidents.

2. N’utilisez pas les outils électriques dans des

atmosphères explosives, telles qu’en présence

de liquides, de gaz ou de poussières

inflammables. Les outils électriques produisent des

étincelles au contact desquelles la poussière ou les

vapeurs risqueraient de s’enflammer.

3. Assurez-vous qu’aucun enfant ou passant ne

s’approche pendant que vous utilisez un outil

électrique. Vous risquez de perdre la maîtrise de

l’outil si votre attention est détournée.

Sécurité en matière d’électricité

4. La fiche des outils électriques doit être conçue

pour la prise de courant utilisée. Ne modifiez

jamais la fiche de quelque façon que ce soit.

N’utilisez aucun adaptateur de fiche sur les

outils électriques avec mise à la terre. En ne

modifiant pas les fiches et en les insérant dans des

prises de courant pour lesquelles elles ont été

conçues vous réduirez les risques de choc

électrique.

5. Évitez tout contact corporel avec les surfaces

mises à la terre, telles que les tuyaux, radiateurs,

cuisinières et réfrigérateurs. Le risque de choc

électrique augmentera si votre corps se trouve mis à

la terre.

6. N’exposez pas les outils électriques à la pluie et

évitez qu’ils ne soient mouillés. Les risques de

choc électrique augmentent lorsque de l’eau

pénètre dans un outil électrique.

7. Ne maltraitez pas le cordon. N’utilisez jamais le

cordon pour transporter l’outil électrique, pour

tirer dessus ou pour le débrancher. Maintenez le

cordon à l’écart des sources de chaleur, de

l’huile, des objets à bords tranchants et des

pièces en mouvement. Le risque de choc

électrique augmente lorsque les cordons sont

endommagés ou enchevêtrés.

8. Lorsque vous utilisez un outil électrique à

l’extérieur, utilisez un cordon prolongateur prévu

à cette fin. Les risques de choc électrique

diminuent lorsqu’un cordon conçu pour l’extérieur

est utilisé.

Sécurité personnelle

9. Restez alerte, attentif à vos mouvements et

faites preuve de bon sens lorsque vous utilisez

un outil électrique. Évitez d’utiliser un outil

électrique si vous êtes fatigué ou si vous avez

pris une drogue, de l’alcool ou un médicament.

Un moment d’inattention pendant l’utilisation d’un

outil électrique peut entraîner une grave blessure.

9

Loading...

Loading...