Page 1

Table

Saw

210

INSTRUCTION

mm

(8-114")

MANUAL

MODEL

2708

SPEC I F

Manufacturer reserves the right to change specifications of parts and accessories wlthout notice.

Note: Specifications of parts and accessories may differ from country to country.

ICATIONS

Arbor hole

5/8"

No load speed

4,500 R/min.

Blade

diameter

210" 64

I

(8-1/4")

Cutting capacities

9

0"

1

I

1

mm

(2-1/2")

Dimensions

460

mm

(1 8-1/8') x 126") x (1 4-3/4")

x

660

I

(L

mm

x

W

x

4 5"

41

mm

(1-5/8")

x

HI

375

mm

~~

660

1

I

1

Table size

(W x L)

mm

(26")

x

Net weight

17

kg

x

460

(1

8-1/8")

(37.5

mm

Ibs)

Page 2

BEFORE CONNECTING YOUR TOOL

TO A POWER SOURCE

Be sure you have read all

GENERAL

POWER

TOOL

SAFETY

RULES

GENERAL SAFETY PRECAUTIONS

1.

KNOW YOUR POWER TOOL. Read the owner’s manual carefully. Learn the

tools applications and limitations, as well as the specific potential hazards

peculiar to

2. KEEP GUARDS IN PLACE and in working order.

3.

REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see

that keys and adjusting wrenches are removed from tool before turning

4. KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

5.

DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power tools

or wet locations, or expose them to rain. Keep work area well lighted.

6. KEEP CHILDREN AWAY. All visitors should be kept safe distance from work

area.

7.

MAKE WORKSHOP CHILD PROOF with padlocks, master switches, or by

removing starter keys.

8.

DON’T FORCE TOOL.

was designed.

9.

USE RIGHT TOOL. Don’t force tool or attachment to do a job for which

designed. Don’t use tool for purpose not intended; for example, don’t use circular saw for cutting tree limbs or logs.

10. WEAR PROPER APPAREL. No loose clothing, gloves, neckties, rings,

bracelets, or other jewelry to get caught in moving parts. Nonslip footwear

recommended. Wear protective hair covering to contain long hair.

11.

ALWAYS USE SAFETY GLASSES. Also use face or dust mask if cutting operation is dusty. Everyday eyeglasses only have impact resistant lenses, they

are NOT safety glasses.

12. SECURE WORK.

than using your hand and

13. DON’T OVERREACH. Keep proper footing and balance at all times.

14. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and

safest performance. Follow instructions for lubricating and changing acces-

sories.

15. DISCONNECT TOOLS before servicing; when changing accessories such as

blades or adjusting guides.

16. REDUCE THE RISK

position before plugging

17. USE RECOMMENDED ACCESSORIES. Consult the owner’s manual for recommended accessories. The use of improper accessories may cause risk of

injury to persons.

18. NEVER STAND ON TOOL. Serious injury could occur if the tool is tipped or if

the cutting tool is accidentally contacted.

it.

It

will do the job better and safer at the rate for which

Use clamps or a vise to hold work when practical. It’s safer

it

frees both hands to operate tool.

OF

UNINTENTIONAL STARTING. Make sure switch is

in.

in

it

on.

damp

it

was

in

is

off

it

2

Page 3

19.

CHECK DAMAGED PARTS. Before further use

part that is damaged should be carefully checked

ate properly and perform its intended function

of

ing parts, binding

moving parts, breakage of parts, mounting, and any

of

the tool, a guard or other

to

ensure

-

check for alignment

that

it

will

of

opermov-

other conditions that may affect its operation. A guard or other part that is

damaged should be properly repaired or replaced.

20.

DIRECTION

OF

FEED. Feed works into a blade against the direction of rota-

tion of the blade only.

21. NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don’t

leave tool until

22. PROPER GROUNDING.

it

comes to a complete stop.

This tool should be grounded while in use to protect

the operator from electric shock.

23. EXTENSION CORDS. Use only three-wire extension cords which have

three-prong grounding-type plugs and three-pole receptacles which accept

the tool’s plug. Replace or repair damaged or worn cord immediately.

Make sure your extension cord is in good condition. When using an extension cord, be sure to use one heavy enough to carry the current your product

will draw. An undersized cord will cause a drop in line voltage resulting in

loss

of power and overheating. Table 1 shows the correct size to use depending

on cord length and nameplate ampere rating. If in doubt, use the next heavier gauge. The smaller the gauge number, the heavier the cord.

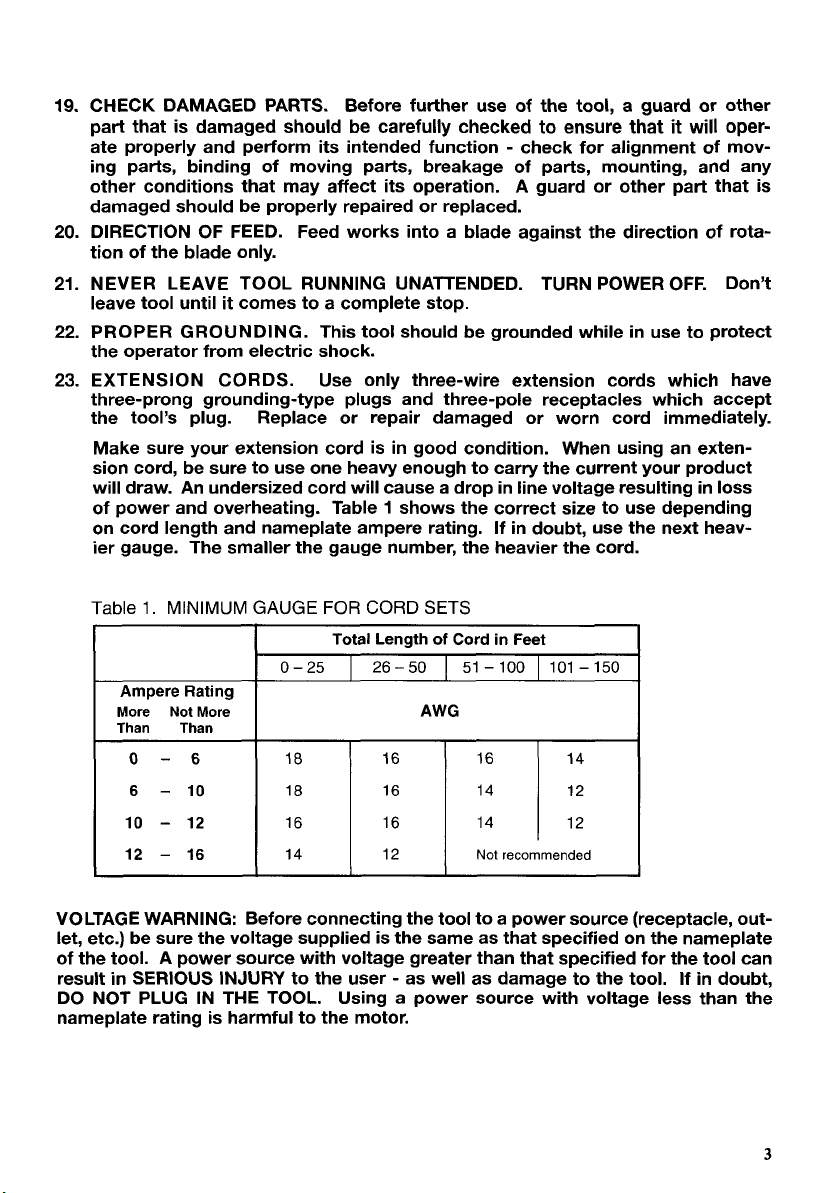

1

rable

1.

MINIMUM

3AUGE

FOR

Total

CORD

Length

SETS

~~

of

Cord in Feet

I

Ampere Rating

More

Not

Than Than

0-6

6

10

12

More

18

-

10

-

12

-

16

18

16

14

16 16 14

16 14 12

16 14 12

Not

12

recommended

VOLTAGE WARNING: Before connecting the tool to a power source (receptacle, outlet, etc.) be sure the voltage supplied is the same as that specified on the nameplate

of the tool. A power source with voltage greater than that specified for the tool can

result in SERIOUS INJURY to the user

-

as well as damage to the tool. If in doubt,

DO NOT PLUG IN THE TOOL. Using a power source with voltage less than the

nameplate rating is harmful to the motor.

3

Page 4

G

RO

U N DING IN STRUCTI 0 NS

ALL GROUNDED, CORD-CONNECTED TOOLS:

In

the event of a malfunction or

breakdown, grounding provides a path of least resistance for electric current to

reduce the risk of electric shock. This tool is equipped with an electric cord having an equipment-grounding conductor and a grounding plug. The plug must be

plugged into a matching outlet that is properly installed and grounded

in

accordance with all local codes and ordinances.

Do not modify the plug provided

-

if

it

will not

fii

the outlet, have the proper outlet

installed by a qualified electrician.

Improper connection of

the

equipment-grounding conductor can result

in

a risk

of electric shock. The conductor with insulation having an outer surface that is

green with or without yellow stripes is

repair or replacement of

the

electric cord or plug is necessary, do not connect

the

equipment-grounding conductor. If

the equipment-grounding conductor to a live terminal.

Check with a qualified electrician or serviceman

not completely understood, or

if

in

doubt as to whether the tool is properly

if

the grounding instructions are

grounded.

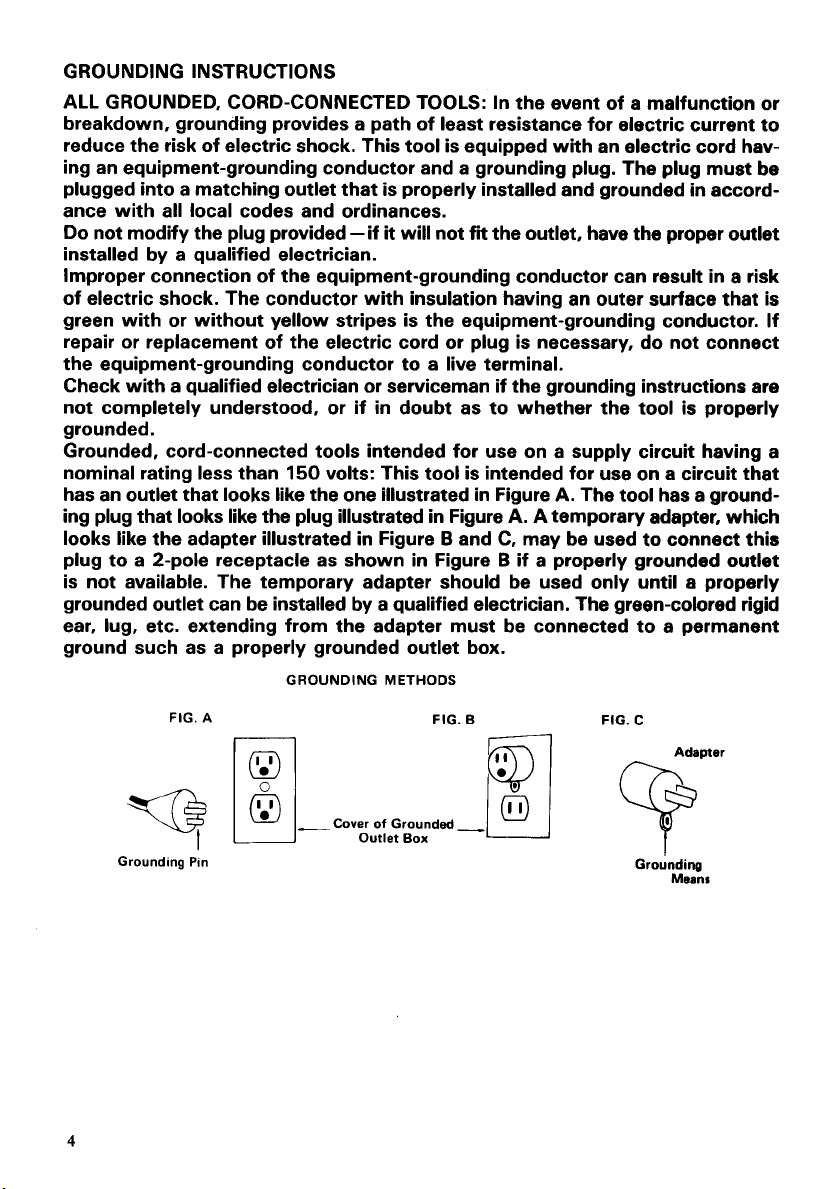

Grounded, cord-connected tools intended for use on a supply circuit having a

nominal rating less than

has an outlet that

looks

ing plug that looks like the plug illustrated

looks like the adapter illustrated

plug to a 2-pole receptacle as shown

is not available. The temporary adapter should be used only

150

volts: This tool is intended for use on a circuit that

like

the

one illustrated

in

Figure B and C, may be used

in

in

Figure A. The tool has a ground-

in

Figure A. A temporary adapter, which

to

connect this

Figure B if a properly grounded outlet

until

a properly

grounded outlet can be installed by a qualified electrician. The green-colored rigid

ear, lug, etc. extending from the adapter must be connected to a permanent

ground such as a properly grounded outlet box.

GROUNDING

METHODS

4

FIG.

Grounding Pin

A

-

Cover

Outlet

of

Grounded

Box

FIG.

-

B

FIG.

C

Grounding

Means

Page 5

ADDITIONAL SAFETY RULES

1.

ALWAYS use guard, spreader and anti-kickback fingers on all "thru-sawing"

operations. Thru-sawing operations are those when the blade cuts complete-

ly

through the work piece as

2.

ALWAYS hold the work firmly against the miter gage or fence.

3.

ALWAYS use a push stick for ripping narrow stock. Refer to ripping applications in instruction manual where push stick is covered

4.

NEVER perform any operation "free-hand" which means using your hands

to support or guide the work piece. Always use either the fence or the miter

gauge to position and guide the work.

5.

NEVER stand or have any part of your body

blade.

6.

NEVER reach behind or over the cutting tool with either hand for any reason.

7.

MOVE the rip fence out of the way when cross cutting.

8.

NEVER use the fence as a cut-off gauge when cross cutting.

9.

NEVER attempt to free a stalled saw blade without first turning the saw

IO.

PROVIDE adequate support to the rear and sides of the saw table for wide

or long workpieces.

11.

AVOID KICKBACKS (work thrown back toward you) by keeping blade sharp,

keeping rip fence parallel to the saw blade, keeping spreader and antikickback fingers and guard in place and operating,

before

that is twisted or warped or does not have a straight edge to guide along

the fence.

12.

AVOID awkward operations and hand positions where a sudden slip could

cause your hand to move into the cutting tool.

13.

Attach this tool with screws either to the optional stand or to a steady stand

or bench with good chip ejection.

14.

Cutting wood with concrete or sand on

dulls the saw blade; the blade may be damaged and even break, causing

a

15.

Keep your hands away from the line of cut. Be especially careful with bevel

cuts.

SAVE

it

is pushed all the way past the saw blade, and

serious injury. Clean all stock of nails and adhering material beforehand.

THESE

INSTRUCTIONS.

in

ripping or cross cutting.

FOR

TABLE

in

line with the path of the saw

it,

or containing old nails, not only

SAW

in

detail.

by

not releasing work

by

not ripping work

OFF.

5

Page 6

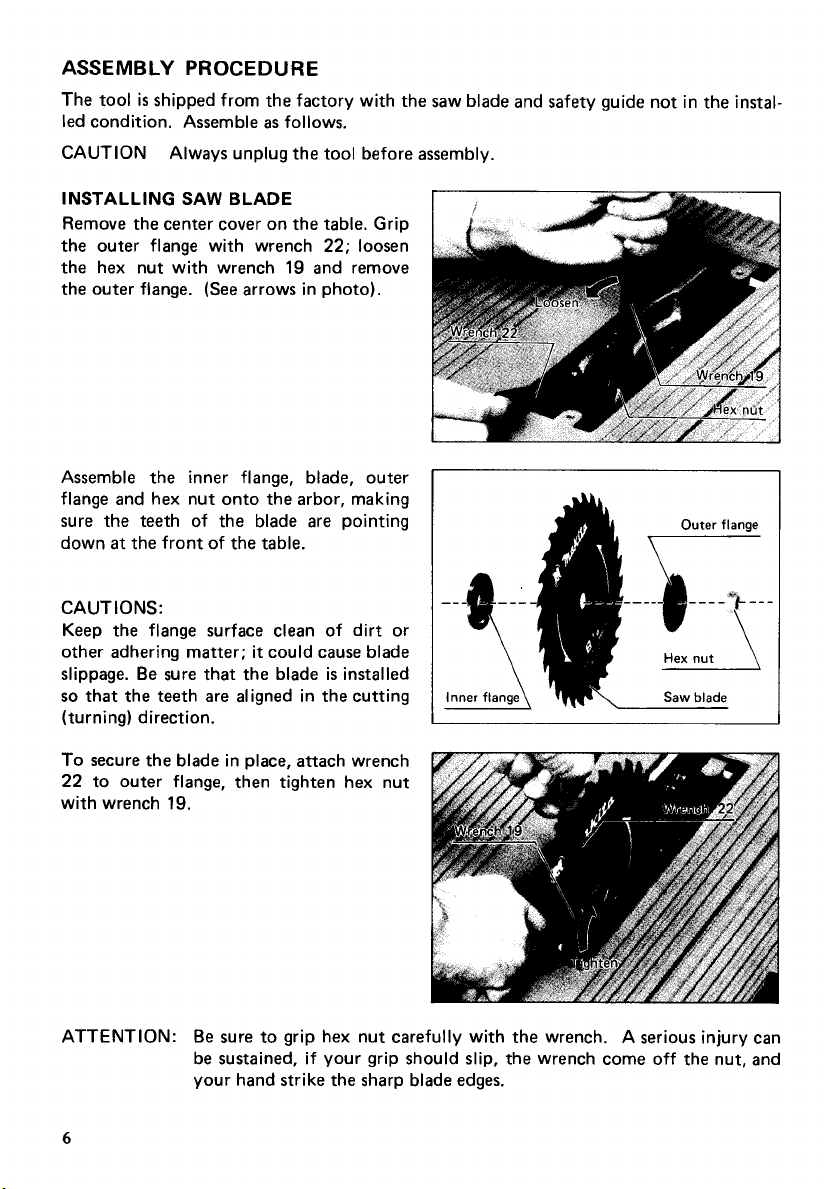

ASSEMBLY PROCEDURE

The tool

led condition. Assemble

CAUTION

INSTALLING SAW BLADE

Remove the center cover on the table. Grip

the outer flange with wrench

the hex nut with wrench

the outer flange.

Assemble the inner flange, blade, outer

flange and hex nut onto the arbor, making

sure the teeth of the blade are pointing

down

CAUTIONS:

Keep the flange surface clean of dirt or

other adhering matter;

slippage. Be sure that the blade

so

(turning) direction.

is

shipped from the factory with the saw blade and safety guide not in the instal-

as

follows.

Always unplug the tool before assembly.

22;

loosen

19

and remove

(See

arrows in photo).

at

the front of the table.

it

could cause blade

is

installed

that the teeth are aligned in the cutting

Outer

flange

____

k---

Hex

nut

--1

Inner

flange Saw

,

..-

,

blade

To secure the blade in place, attach wrench

22

to outer flange, then tighten hex nut

with wrench

ATTENTION:

6

19.

Be sure to grip hex nut carefully with the wrench. A serious injury can

be sustained, if your grip should slip, the wrench come off the nut, and

your hand strike the sharp blade edges.

Page 7

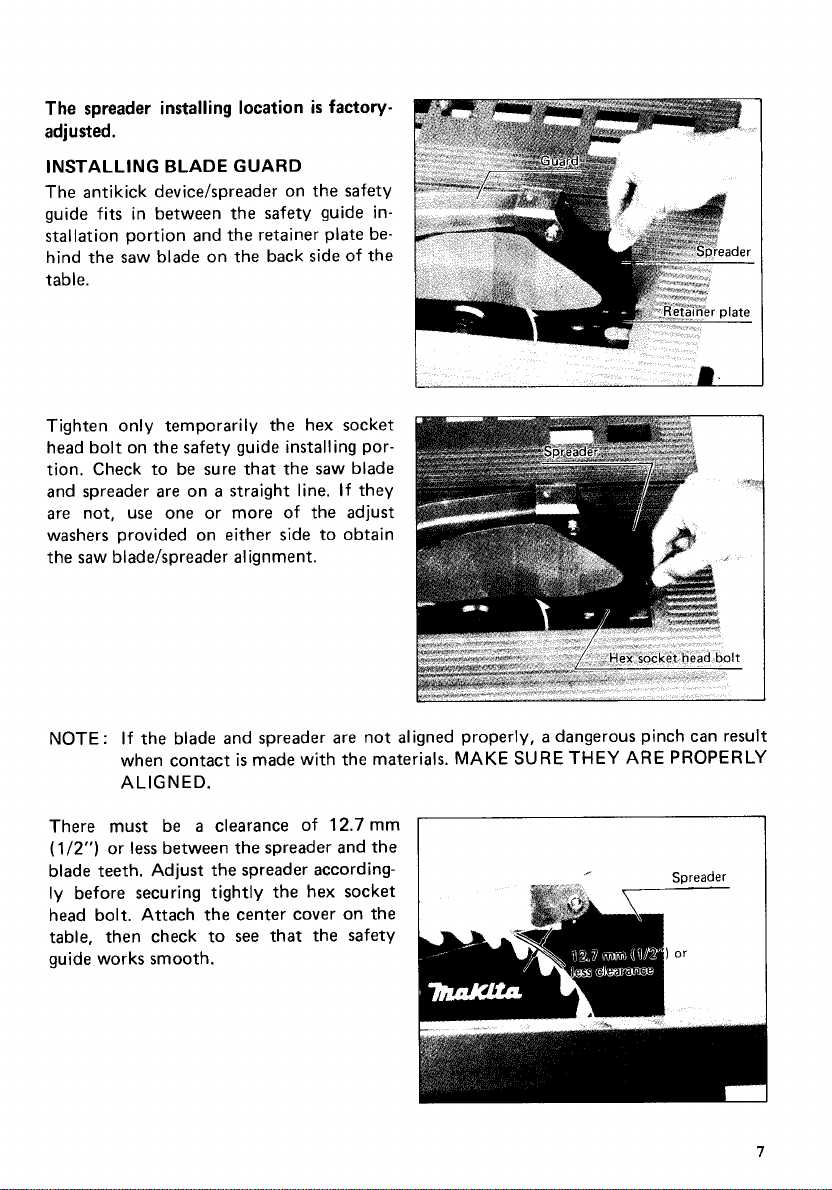

The spreader installing location

is

factory-

adjusted.

INSTALLING BLADE GUARD

The antikick devicehpreader on the safety

guide fits in between the safety guide installation portion and the retainer plate be-

hind the saw blade on the back side of the

table.

Tighten only temporarily the hex socket

head bolt on the safety guide installing por-

tion. Check to be sure that the saw blade

a

and spreader are on

straight line. If they

are not, use one or more of the adjust

washers provided on either side to obtain

the saw bladehpreader alignment.

NOTE

:

If the blade and spreader are not aligned properly, a dangerous pinch can result

when contact

is

made with the materials. MAKE

ALIGNED.

There must be

(1/2") or

less

a

clearance

of

12.7 mm

between the spreader and the

blade teeth. Adjust the spreader according-

ly

before securing tightly the hex socket

head bolt. Attach the center cover on the

table, then check to

see

that the safety

guide works smooth.

SURE

THEY ARE PROPERLY

7

Page 8

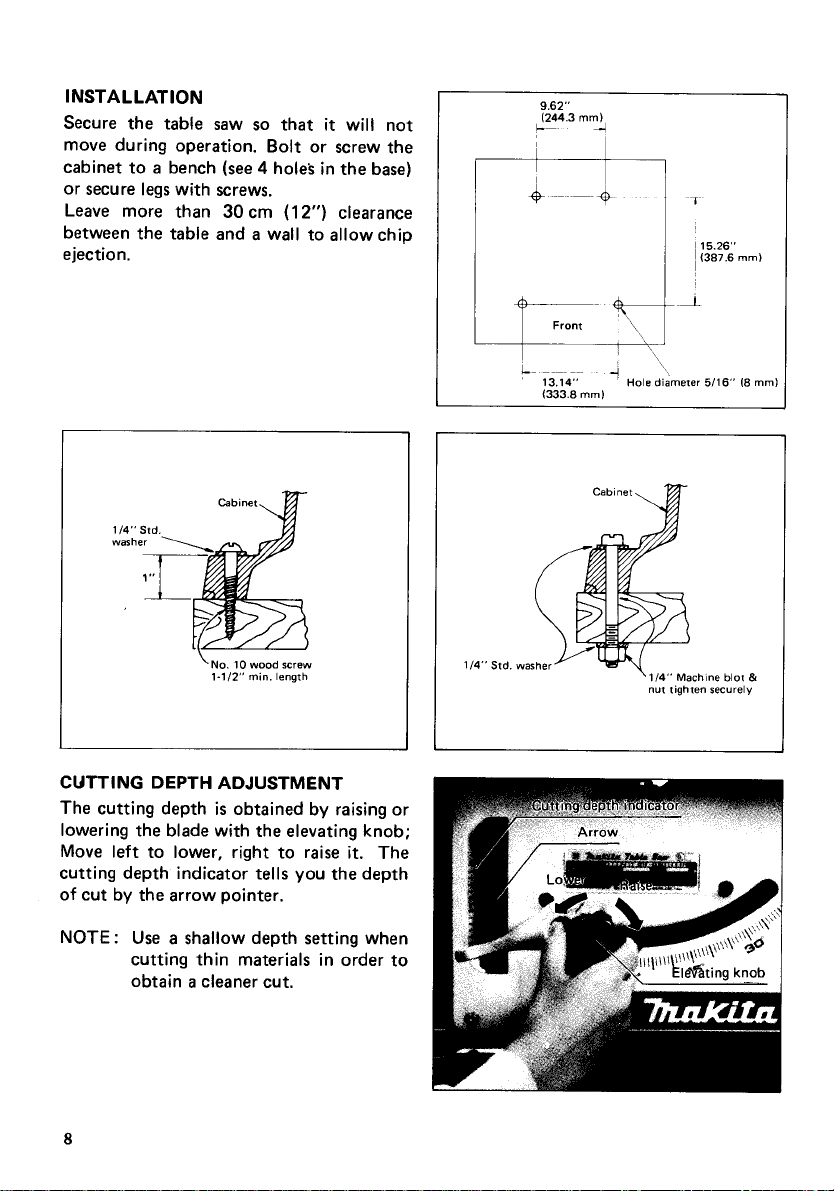

INSTALLATION

Secure the table saw

so

that

it

will not

move during operation. Bolt or screw the

cabinet to

or secure

Leave more than

between the table and

a

bench

legs

with screws.

(see

4

hole's in the base)

30

cm

(1

2")

a

wall to allow chip

clearance

ejection.

9.62"

1244.3

mm)

7

I

15

l(387

26"

6

mm)

11

CUTTING DEPTH ADJUSTMENT

The cutting depth

lowering the blade with the elevating knob;

Move left to lower, right to raise

cutting depth indicator

of

cut by the arrow pointer.

NOTE: Use

cutting thin materials in order to

obtain

is

obtained by raising or

it.

tells

you the depth

a

shallow depth setting when

a

cleaner cut.

The

13.14"

(333.8

mml

Hole diameter

5/16"

18

mml

8

Page 9

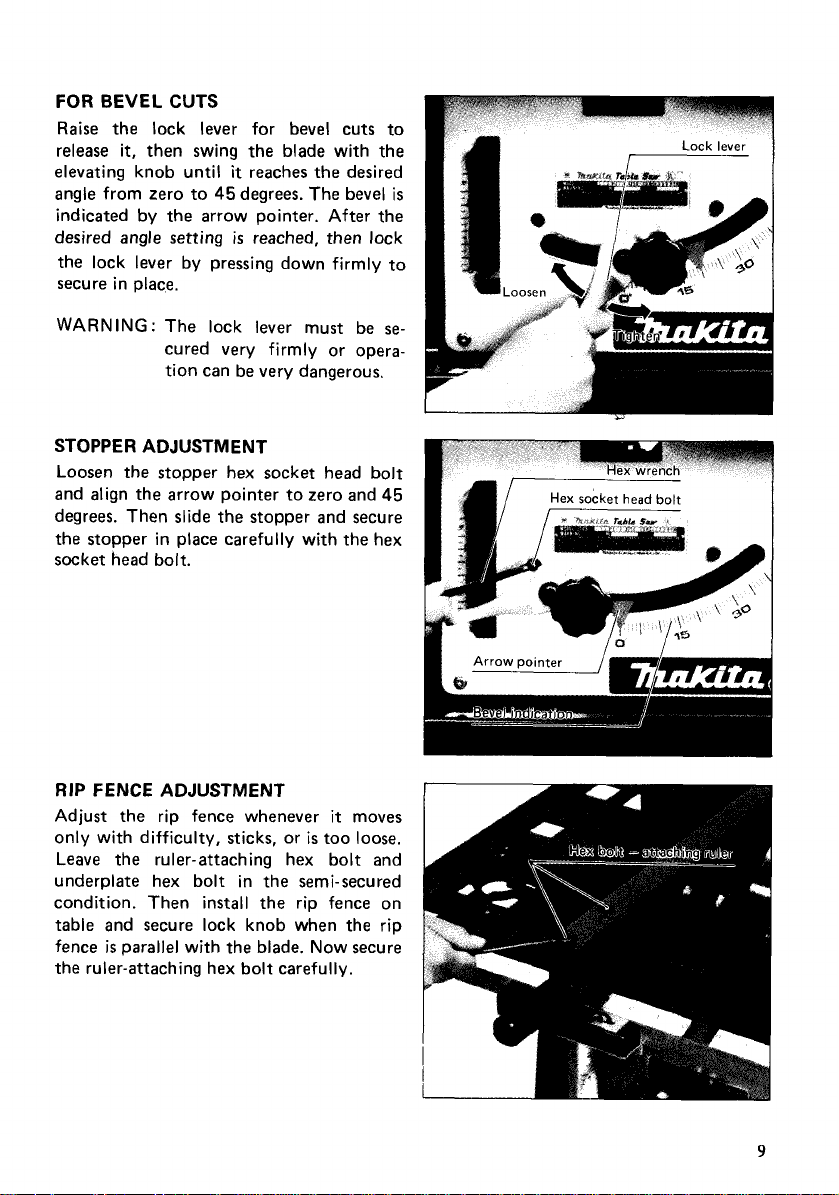

FOR

BEVEL CUTS

Raise

the lock lever for

release

it,

then swing the blade with the

elevating knob until

angle from zero to

45

bevel

cuts to

it

reaches the desired

degrees. The bevel

is

indicated by the arrow pointer. After the

desired angle setting

is

reached, then lock

the lock lever by pressing down firmly to

secure in place.

WARNING: The lock lever must be

se-

cured very firmly or operation can be very dangerous.

STOPPER ADJUSTMENT

Loosen

and align the arrow pointer to zero and

the

stopper hex socket head bolt

45

degrees. Then slide the stopper and secure

the stopper in place carefully with the hex

socket

head

bolt.

RIP FENCE ADJUSTMENT

Adjust the rip fence whenever

only with difficulty, sticks, or

it

moves

is

too loose.

Leave the ruler-attaching hex bolt and

underplate hex bolt in the semi-secured

condition. Then install the rip fence on

table and secure lock knob when the rip

is

fence

parallel with the blade. Now secure

the ruler-attaching hex bolt carefully.

9

Page 10

Bring the ruler underplate flush up against

the rail inside, then fasten the hex bolt

attaching the underplate very securely.

d

Hex bolt -attaching

under

date

I

ADJUSTING FOR

Bring the rip fence up flush against the side

of the blade and loosen the screw. Then

align the arrow with the zero indication on

the table scale before tightening the screw.

ZERO

SETTING

KEY SAFETY SWITCH

Press the ON pushbotton switch to put the

table saw on; press the

it

off.

This machine can only be switched on after

the key

in use, take off the key and the machine

should be both

The key can be removed with the switch

in the "ON" condition, and the tool may

be switched

is

pressed in the switch. When not

"OFF"

off

without the key.

OFF

button to put

and unplugged.

\

Ruler

under

date

I

WARNING:

Be sure that the blade

When switching off, do not attempt to stop the blade by pressing on the side of the blade

with some object.

10

is

not contacting the wood before switching on.

Page 11

CUTTING OPERATIONS

To

assure safe cutting operations, familiarize yourself thoroughly with the following

at

safety rules and the cautions indicated

1. switch on the saw only after making sure that nothing (wood, material, etc.)

tacting the saw blade.

2.

Wait

until the blade attains top speed before feeding the material.

3.

Feed

as

slow

as

possible when cutting hard material.

4. Avoid abrupt, fast feeds.

5.

Do

not bend or twist material while feeding.

6.

Never perform any operation "free-hand" using only your hands to support or guide

the workpiece. Use either the rip fence or the miter gauge to position or guide work

at

all

times.

7.

Always replace the blade guard with spreader after removing them for some reason.

8.

Do

not stand or have any part of your body in line with the path of the saw blade.

9.

Never place your fingers or hand in the path of the sawblade, dado head or other cut-

ting tool.

10. Switch off saw immediately and disconnect if the blade stops or

11.

Do

not reach over or behind the moving blade for any reason.

Do

12.

13.

not remove cut-off material while the saw

Do

not hold, touch or remove free end until blade has stopped.

Do

not attempt to remove scraps or small pieces of wood by hand from between

guard/blade. First, switch off, then use a stick to remove them.

14. Never wear gloves when operating the tool.

the beginning.

is

running.

stalls.

is

con-

WORK

HELPERS

Push sticks, push blocks or auxiliary fence are types of "work helpers."Use them to make

safe, sure cuts without the need for the operator to contact the blade with any part of

the bodv.

Push Stick

A push stick can be easily made from a piece of plywood 3/4" to

(38

mml

1"

thick.

Cut out the hatched area on the stick and smooth edges with a file. H dimension should

less

than 1/2" (12.7 mm)

be

so

as

to be thinner than workpiece.

11

Page 12

Push

Use

Block

a

3/4"

piece of plywood.

W

IC

h

12'

Handle should be in center of plywood piece. Fasten with glue and wood screws

Small piece

(3/8"

x

5/16" x 2")

of wood must always be glued to plywood

as

to

keep saw

shown.

blade from dulling if operator cuts into push block by mistake. (Never use nails in push

block

.

)

Auxiliary

Make auxiliary fence from

plywood pieces.

Wood Facing

A

tions when blade comes close

Fence

3/8"

and

3/4"

(Rip

Fence)

wood facing should be used for opera-

to

fence.

I

Faceledge

parallel

Fasten

with

glue

and

wood

screw.

1-1

/2"

Wood facing for rip fence should be same

size

as

fence.

Make sure bottom of facing

is

flush with

table surface.

12

Page 13

Auxiliary

To prevent a long board from wobbling, fit

the miter gauge with an auxiliary fence

board. Fasten with boltdnuts after drilling

holes, but fasteners must not protrude

from the face board,

Featherboard

The diagram shown illustrates dimensions

for making a typical featherboard. It should

be made from

thats free of knots or cracks.

Wood

Facing (Miter Gauge)

a

straight piece

of

wood

I

24

7

-

Kerf

should

114"

be

apart

about

Miter Gauge

Use the miter gauge for the 4 types of cutting shown below.

I

I

I

CROSS CUTTING MITERING BEVEL CUTTING COMPOUND MITERING (ANGLES)

CAUT

IONS

1.

Remove the rip fence from the table.

2.

Secure the knob on miter gauge carefully.

3.

Avoid creep of workpiece and gauge by firm workholding arrangement, especially

at

when cutting

4.

When cutting long or large workpieces, always use a work support in side.

an angle.

13

Page 14

Use

of

Miter Gauge

Slide the miter gauge into the thick grooves

in the table. Loosen the knob on the gauge

(0

to

60').

and align to desired angle

stock flush up against fence and feed

gently forward into the blade.

Rip

Fence

The rip fence

CAUTIONS

Remove miter gauge from table.

1.

Secure the adjusting knob tightly on the fence.

2.

Always use

3.

come close to the blade.

Use

4.

5.

Fence should be parallel with the blade

6.

Spreader should be parallel with the saw blade.

Is

the anti-kickback device in good working operation?

7.

is

used for ripping, bevel ripping and rabbeting operations.

a

push block or stick when there

a

work support in back whenever cutting long or large workpieces.

Bring

at

all

is

a

danger that your fingers (hand) will

times.

Use

of

Rip

Fence

The rip fence permits repetitive cuts of the

as

same width or parallel cuts,

Loosen the lock knob on the rip fence and

it

insert the rail slot for

align the arrow on the rip fence with the

scale

on the table in terms of the desired

cutting width. Now tighten the lock knob

on the rip fence to hold

14

in the table. Then

it

in place.

desired.

Page 15

Ripping

Ripping

is

the lengthwise cutting of

board.

*When ripping stock over

6”

wide:

Feed the work forward with the hand on

the rip fence side. Use the other hand to

hold the work in position against the rip

fence.

*When ripping stock

Always use

2-1/2”

-

6”

wide:

a

push stick for this type of

workpiece.

a

*When ripping stock

The push stick will strike the guard,

less

than

2-1/2”

wide:

so

auxiliary fence and push block must be

used. Clamp auxiliary fence to rip fence

in two locations.

When workpiece reaches position

side the table, rest push block on

feed through until cut

is

completed.

1”

it

an

in-

and

15

Page 16

Featherboards

A "featherboard" or "fingerboard"

degrees.

a

straight piece with no knots or cracks

A series of parallel cuts

any operation in which workpiece

guard

is

therefore removed.).

as

a

Hold the featherboard

sort of "spring stick" horizontal hold down to press the work

is

a

jig made from a board cut off

is

made part way through the board. Board should be

(see

photo). Featherboards should be used for

is

not sawed

all

the way through (and the saw blade

at

an angle of

firmly against the fence during the pass.

Use

of

featherboard

1. Switch off tool before operation.

2. Set featherboard with clamps

so

as

to

"C

clamps'

hold stock firmly against workpiece. Be

sure of positive attachment.

3.

"Fingers" prevent work from being

thrown back. Perform a trial to be sure

they will stop a kickback.

Do

not use featherboards for non-thrusawing operations with which the miter

gauge

is

employed. Re-install blade guard

whenever the featherboard work

is

finished.

Rabbeting

Rabbeting

done across the end or the entire length of

is

the cutting away of a section from the corner of the workpiece.

the

stock.

The blade guard should be removed to perform rabbet cuts which do not go

through the workpiece.

Feafherboard

It

can be

all

the way

60

How

to perform rabbeting

1. Remove blade guard.

2. Attach auxiliary fence to rip fence for cuts that run the length of the stock. Facing

should be

the workpiece

is

wide. Adjust fence and blade to desired dimen-

as

high

as

sions.

3.

First cut: Hold board flat

4.

Second cut:

Set

workpiece on

on

table

its

as

in ordinary ripping.

edge.

(Use featherboards, push stick, push

block and

so

on, using precautions,

safety rules and guidelines for ripping

or related work.)

5.

For end-type rabbeting, if the work-

piece

is

less

than 10-1/2" wide, rest the

Rabett

wood flat on the table against the miter

gauge (with wood facing). The rip fence

should not be used.

6.

After rabbeting

ately

re-install the blade guard

16

is

completed, immedi-

as

before.

Page 17

MAINTENANCE

CAUTION

Always be sure that the tool

inspection and maintenance.

Replacing carbon brushes

Remove and check the carbon brushes

regularly. Replace when they wear down

to the limit mark. Keep the carbon brushes

clean and free to slip in the holders. Both

carbon brushes should be replaced

same time. Use only Makita carbon brushes.

:

is

switched off and unplugged before attempting to perform

at

the

/

Limit

mark

Lower saw blade

the elevating knob; free lock lever and

secure

screwdriver through window

at

point

Remove the carbon brush and replace with

new one.

as

far

as

possible with

at

which you can insert

of

cutting

Screwdriver

-

17

Page 18

CLEANING

Clean out sawdust and chips from time to time.

Do

not allow them to enter safety guide

or inside where there are moving parts.

LUB

R

ICAT

I

ON

Take keep the table saw in tip-top running condition, and to assure maximum service life,

grease the moving parts and rotating parts from time to time. Lubrication places: and

rotating parts from time to time. Lubrication places:

0

Around elevation screw

0

Frame window and holes

Frame turning shaft

0

Link holes

TOOL STORAGE

POCKET

The table saw comes with a special tool

It

is

a

storage pocket in the base.

con-

venient place to keep the small fittings and

so

on that are standard equipped.

To

maintain product SAFETY and RELIABILITY, repairs, any other maintenance or

adjustment should

be performed by Makita Authorized or Factory Service Centers,

always using Makita replacement parts.

18

Page 19

ACCESSORIES

CAUTION

These accessories or attachments

manual. The use of any other accessories or attachments might present

accessories or attachments should

:

are

recommended for

be

used only in

use

with your Makita

the

proper and intended manner

tool

a

risk

of

specified in this

injury

to

persons.

The

.TABLE

Set

SAW

STAND

(Part

No.

122251-6)

the stays below and assemble the

inside. Secure with cup square neck bolts

and nuts. Then attach rubber caps to

back

of

legs.

NOW

set

the saw on top of the assembled

4

stand and secure with

hex bolts, flat

washers and hex nuts.

Always secure stand with screws to the

floor or surface.

Use

3/8"

screws to secure (same proce-

dure

as

indicated on p.

8).

legs

CAUTION:

This

is

attach or

a

special stand built precisely for this Makita table saw.

set

on other types.

Do

not

19

Page 20

.HOLDER SET COMPONENTS

(Part

No.

191452-7)

Convenient to attach for holding large

materials (either side and/or front and

back).

They are attached by clamps to the back

of the table and secured with panhead

screws.

NOTE:

Never attempt to move the table saw by

gripping these holders. Lift the table

itself.

.SUB-TABLE SET

NOTE

:

A

table saw stand (optional accessory)

Sub-table

Sub-table

(R)

Part

(L)

Part

No.

122405-5

No.

122406-3

20

is

necessary for installing the sub-tables.

Sub table

IL)

Sub

table

R

Page 21

w

Chisel tooth combination saw blade

For rip and cross-cut work.

Most frequently used

general carpentry.

Warbide-tipped saw blade

Fastest, smoothest, longer sawing

without blade sharpening cuts

wood, drywall, plastic,

hardwood,

etc.

for

No.

210-7

Diameter

,~~~~)

diy!2e,

518’’

(15,88mml

tf:k

Part

No.

30

792281-7

792377-4

m

Rip fence

(Part

No.

m

Wrench

(Part

No.

HWrench

(Part

No

122284-

22

781 01

1

-

10-13

781 202-4)

1)

1)

Miter gauge (Angle rule)

(Part

No.

122219-2)

Wrench

(Part

19

No.

781010-3)

-

m

Hex wrench

(Part

No.

783203-8)

21

Page 22

(Part

No.

Dado head

A

dado

into the workpiece. The dado head

sists

cutters and paper washers.

set

is

cutting a rabbet or a wide groove

of

two outside cutters, three inside

191543-4)

set

con-

1/8"

1/16"

1/8"

1

/a

Outside cutters

Inside cutters

Inside cutter

Paper washers

Various combinations of these cutters are used to cut grooves from 118" to 1/2" for use

in making joints, tenoning, grooving,

Dado outer flange

When cutting groove 5/16", 3/8". 7/16"

1/2", use this dado outer flange.

:

6" diameter, 118" thick, 518" arbor hole, 2 pcs.

:

6"

diameter, 118" thick, 5/8" arbor hole, 2 pcs.

:

6" diameter, 1/16" thick, 5/8" arbor hole, 1 pc.

:

(Part

No.

224263-6)

etc.

518" arbor hole, 6 pcs.

or

I

Table insert

When cutting grooves 1/4", 5/16", 318".

7/16", 112" use this table insert instead

the standard table insert.

(Part

No.

342787-1)

of

I

22

Page 23

To

install the dado head

1

Turn the tool off and unplug

2

Remove the blade guard with the spreader.

3

Install the dado head

,4

Use the chart below to select the proper cutters to obtain the various cutting widths.

set,

proceed

set

with the teeth pointing down

as

follows:

it

before installing.

at

the front

of

the table.

CAUTION

I

:

I

1

1

I

I I

The outer flange or the dado outer flange must be used for each cut width.

The hex nut alone must not be used to secure the dado on to the spindle.

23

Page 24

NOTE

:

When widths slightly greater than the above are required, fit the paper washers in between

the inside and outside cutters to adjust the width.

@Arrange the cutters

the inside cutters are positioned

gullets of the outside cutter.

When more than one inside cutter

used, space the tips of the inside cutters

equidistantly in relation to one another.

Poorly spaced cutters may cause vibration and noise.

When ins slling twooutside cutters without any inside cutter, be sure that the

cutter tips do not face each other.

so

that the tips of

at

the

is

@While tightening the hex nut, be careful to maintain the even spacing between the tips

of the inside cutters.

0

Rotate the dado head one turn by hand to make sure that

before operation.

24

it

does not contact anything

Page 25

CAUTION

.Only the Makita dado head

saw Model

.After dadoing, always replace the blade guard with the spreader back in

:

2708.

set

(Part No.

191543-4)

should be used with Makita table

its

original posi-

tion on the table saw.

0

Never attempt bevel cuts when dadoing.

0

Never dado if there

0

Never attempt dados in other than wood.

0

When using a dado head

cutting depth adjustment section.) To know the depth of cut, you must measure

a

ruler.

0

Do

not use the dado

is

vibration (flutter) or a strange noise.

set,

set

for cut-offs.

the depth of cut

is

not indicated by the pointer. (See the

it

Feed work slowly, especially when cutting deep or wide grooves or dados. Fast or

abrupt feeds can be dangerous.

*Use

a

pushstick. When the dado head

is

hidden from view while cutting, your hands

should never be on top of the stock.

*A

very dangerous throwback can result if the wood becomes stuck and you try

remove

to

it

by

pulling toward you. Always stop the tool and wait for dado head to come

a

complete stop. Then simply withdraw the wood.

with

to

25

Page 26

210

mm

TABLE

Model

(8-1/4")

SAW

2708

Jan

~ 26

--'I38

US

26

Page 27

Note: The switch, noise suppressor and other part configurations

may differ from country to country.

21

Page 28

MODEL 2708

'LiM

AtD

DESCRIPTION

'LiM

$ED

DESCRIPTION

Jan.-28'88

US

MACHINE

1

1

Pan

+

Hex.

2

Ball

Bearing

1

1

Motor Housing

1

P~W

Pan

4

Brush Holder Cap

2

2

Carbon Brush

1

InsuIatmn

FIELD ASSEMBLY

1

1

Screw

1

Baffle Plat.

1

Spring Pin 5- 16

1

ARMATURE ASSEMBLY

iWith Item 3. 10. 15.

1

Knob 45

1

Fan 92

1

0"St

1

Ball

1

Gear Housing

Pan Head

4

Hex.

2

1

Pressure

4

Adjust Washer

Blade Guard

1

1

Woodruff Key 5

1

Her. Nut M10

1

Flat Washer

1

Spring Washer 10

1

Her. Nut M10-6

Hex.

1

1

Lwer

Hex.

1

1

Frame

Link

1

1

TBnOlO"

Flat

1

Hex.

1

1

Helical

Retaining

1

1

Needle Bearing 1015

Pin

1

1

Feed

Spring Pin 5-16

1

-

switch and other pan specifications

12

20

Note:

10

11

13

14

15

16

17

18

19

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

43

44

45

2

3

4

5

6

7

8

The

Head

Screw

M4xB

Bolt

M5x65 (With Washer1

62OOLB

a

Head

Screw

M5x40 (With Washed

Washer

Bar

M12

Seal

15

Bearing 6202LLB

Screw

M5x25 iWith Washer1

Socket

Haad

Plate

10

Nut

M10-6

80

Socket

Head

Spring

13

Washer 12

Bolt M10

Gear

45

Ring

5-20

10

Nut

17 - 191

Bolt

M6xl4 With Wsoherl

Boll

MlOx35

may

differ from country

to

MAC

-

46

47

49

50

51

52

53

54

55

56

57

58

59

BO

61

63

64

85

66

67

68

69

-

70

71

72

73

74

75

76

77

78

79

81

82

83

85

88

89

90

91

92

93

94

country.

UE

1

Sleeve

1

1

1

1

1

1

1

1

2

1

1

1

1

2

1

1

2

4

1

1

4

2

4

6

1

1

2

1

1

1

1

2

2

1

2

2

1

2

1

2

2

1

9

Flat

Wahr

9

Flat Washer 40

Ball

Bearing

BZOICLB

Splndle

I"".,

Rat*

810

Pin

8

Gear

Houshg

Pointer

Pan Head

Bhds

Inner

Outer

Hex.

Pan Heed

Table in-n

Table

Pan Head

Pan

Front

Cord

+

Hex. Nu1 M6

cap

Pan Heed Screw

BO60

Strain Relid

Self Tapping Flange Screw PT4rlB

Switch

Cord Guard

Cord

Lock

stopper Plat*

Hex. Socket Head

Name Piate

Flat Washer

Bearing

Pan

Compression Spring 24

Covn

A

Screw

M5xB With Washdrl

Cover

Flange 55

Flange 55

Nut

M12

Screw

M6xl6

Screw

MBxl4 With Washer1

Head

Screw

MBxl4

Plate

Hex.

Bolt

M6x14 With Washer1

20

M8x25

OW

Switch

Button

Pan Head Screw M3x35 Wnh Washarl

6

Box

Head Screw M5rlB With Washdrl

Retainer

Pan

Head

Screw

Flat Washer 9

M5x30

-

Bolt

MBxlO

With

Washdrl

With Warhsrl

28

Page 29

9

MAKITA LIMITED ONE YEAR WARRANTY

Warranty Policy

Every Makita tool is thoroughly inspected and tested before leaving the factory. It is warranted to

be free of defects from workmanship and materials for the period of ONE YEAR from the date

original purchase. Should any trouble develop during this one-year period, return the COMPLETE

tool, freight prepaid, to one of Makita’s Factory or Authorized Service Centers. If inspection shows

the trouble is caused by defective workmanship or material, Makita

replace) without charge.

This Warranty does not apply where:

repairs have been made or attempted by others:

repairs are required because of normal wear and tear:

The tool

has

alterations have been made to the tool.

IN NO EVENT SHALL MAKITA BE LIABLE FOR ANY INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES FROM THE SALE OR USE OF THE PRODUCT. THIS DISCLAIMER

APPLIES BOTH DURING AND AFTER THE TERM OF THIS WARRANTY.

MAKITA DISCLAIMS LIABILITY FOR ANY IMPLIED WARRANTIES, INCLUDING IMPLIED

WARRANTIES OF “MERCHANTABILITY” AND “FITNESS FOR A SPECIFIC PURPOSE,”

AFTER THE ONE-YEAR TERM OF THIS WARRANTY.

This Warranty gives you specific legal rights, and you may also have other rights which vary from

state to state. Some states do not allow the exclusion or limitation of incidental or consequential

damages,

limitation on how long an implied warranty lasts,

been abused, misused or improperly maintained;

so

the above limitation or exclusion may not apply to you. Some states do not allow

so

the above limitation may not apply to you.

will repair (or at our option,

of

MCA - 8/95

Makita Corporation

2650

Buford

Hwy.,

Buford,

883343F065

of

America

GA

30518

PRINTED

IN

U.S.A.

1998-8-CR

Loading...

Loading...