Page 1

INSTRUCTION MANUAL

MANUEL D'INSTRUCTION

MANUAL DE INSTRUCCIONES

Table Saw

Scie de table

Sierra de Banco

2702

2703

2702X1

2703X1

006851

DOUBLE INSULATION

DOUBLE ISOLATION

DOBLE AISLAMIENTO

WARNING:

For your personal safety, READ and UNDERSTAND before using.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

AVERTISSEMENT:

Pour votre propre sécurité, prière de lire attentivement avant l’utilisation.

GARDER CES INSTRUCTIONS POUR RÉFÉRENCE ULTÉRIEURE.

ADVERTENCIA:

Para su seguridad personal, LEA DETENIDAMENTE este manual antes de usar la herramienta.

GUARDE ESTAS INSTRUCCIONES PARA FUTURA REFERENCIA.

Page 2

ENGLISH

SPECIFICATIONS

Model 2702 / 2702X1 2703 / 2703X1

Arbor hole 5/8”

Blade diameter 210 mm (8-1/4”) 255 mm (10”)

Max. cutting capacities

Maximum dado capacity 13 mm (1/2”)

No load speed (RPM) 4,600/min.

Table size (W x L) 686 mm x 560 mm (27” x 22”)

Dimensions (L x W x H) 560 mm x 686 mm x 458 mm (22” x 27” x 18”)

Net weight 18 kg (40 lbs)

• Due to our continuing programme of research and development, the specifications herein are subject to change

without notice.

• Note: Specifications may differ from country to country.

90° 68 mm (2-11/16”) 91 mm (3-9/16”)

45° 47 mm (1-3/4”) 63 mm (2-1/2”)

For Your Own Safety Read Instruction Manual Before Operating Tool

Save it for future reference

GENERAL SAFETY PRECAUTIONS

USA007-2

(For All Tools)

1. KNOW YOUR POWER TOOL. Read the owner’s

manual carefully. Learn the tool’s applications

and limitations, as well as the specific potential

hazards peculiar to it.

2. KEEP GUARDS IN PLACE and in working order.

3. REMOVE ADJUSTING KEYS AND WRENCHES.

Form habit of checking to see that keys and

adjusting wrenches are removed from tool

before turning it on.

4. KEEP WORK AREA CLEAN. Cluttered areas and

benches invite accidents.

5. DON’T USE IN DANGEROUS ENVIRONMENT.

Don’t use power tools in damp or wet locations,

or expose them to rain. Keep work area well

lighted. Don’t use tool in presence of flammable

liquids or gases.

6. KEEP CHILDREN AWAY. All visitors should be

kept safe distance from work area.

7. MAKE WORKSHOP KID PROOF with padlocks,

master switches, or by removing starter keys.

8. DON’T FORCE TOOL. It will do the job better and

safer at the rate for which it was designed.

9. USE RIGHT TOOL. Don’t force tool or attachment

to do a job for which it was not designed.

10. WEAR PROPER APPAREL. Do not wear loose

clothing, gloves, neckties, rings, bracelets, or

other jewelry which may get caught in moving

parts. Nonslip footwear is recommended. Wear

protective hair covering to contain long hair.

11. ALWAYS USE SAFETY GLASSES. Also use face

or dust mask if cutting operation is dusty. Everyday eyeglasses only have impact resistant

lenses, they are NOT safety glasses.

12. SECURE WORK. Use clamps or a vise to hold

work when practical. It’s safer than using your

hand and it frees both hands to operate tool.

13. DON’T OVERREACH. Keep proper footing and

balance at all times.

14. MAINTAIN TOOLS WITH CARE. Keep tools sharp

and clean for best and safest performance. Follow instructions for lubricating and changing

accessories.

15. DISCONNECT TOOLS before servicing; when

changing accessories such as blades, bits, cutters, and the like.

16. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure switch is in off position before

plugging in.

17. USE RECOMMENDED ACCESSORIES. Consult

the owner’s manual for recommended accessories. The use of improper accessories may cause

risk of injury to persons.

18. NEVER STAND ON TOOL. Serious injury could

occur if the tool is tipped or if the cutting tool is

unintentionally contacted.

19. CHECK DAMAGED PARTS. Before further use of

the tool, a guard or other part that is damaged

should be carefully checked to determine that it

2

Page 3

will operate properly and perform its intended

function - check for alignment of moving parts,

binding of moving parts, breakage of parts,

mounting, and any other conditions that may

affect its operation. A guard or other part that is

damaged should be properly repaired or

replaced.

20. DIRECTION OF FEED. Feed work into a blade or

cutter against the direction of rotation of the

blade or cutter only.

21. NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN POWER OFF. Don’t leave tool until it

comes to a complete stop.

22. REPLACEMENT PARTS. When servicing use

only identical replacement parts.

23. POLARIZED PLUGS. To reduce the risk of electric shock, this equipment has a polarized plug

(one blade is wider than the other). This plug will

fit in a polarized outlet only one way. If the plug

does not fit fully in the outlet, reverse the plug. If

it still does not fit, contact a qualified electrician

to install the proper outlet. Do not change the

plug in any way.

VOLTAGE WARNING: Before connecting the tool to a

power source (receptacle, outlet, etc.) be sure the voltage supplied is the same as that specified on the nameplate of the tool. A power source with voltage greater

than that specified for the tool can result in SERIOUS

INJURY to the user – as well as damage to the tool. If in

doubt, DO NOT PLUG IN THE TOOL. Using a power

source with voltage less than the nameplate rating is

harmful to the motor.

USE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to

carry the current your product will draw. An undersized

cord will cause a drop in line voltage resulting in loss of

power and overheating. Table 1 shows the correct size to

use depending on cord length and nameplate ampere

rating. If in doubt, use the next heavier gage. The smaller

the gage number, the heavier the cord.

Table 1. Minimum gage for cord

Ampere Rating

Volts Total length of cord in feet

120 V 25 ft. 50 ft. 100 ft. 150 ft.

More Than Not More Than AWG

0 6 18 16 16 14

6 10 18161412

10 12 16 16 14 12

12 16 14 12 Not Recommended

ADDITIONAL SAFETY RULES

USB059-1

DO NOT let comfort or familiarity with

product (gained from repeated use)

replace strict adherence to table saw

safety rules. If you use this tool unsafely

or incorrectly, you can suffer serious personal injury.

1. Wear eye protection.

2. Don’t use the tool in presence of flammable liquids or gases.

3. NEVER use the tool with an abrasive cut-off

wheel installed.

4. Check the blade carefully for cracks or damage

before operation. Replace cracked or damaged

blade immediately.

5. Clean the spindle, flanges (especially the installing surface) and hex nut before installing the

blade. Poor installation may cause vibration/

wobbling or slippage of the blade.

6. Use saw-blade guard and spreader for every

operation for which it can be used, including all

through sawing operations. Always assemble

and install the blade guard following the step by

step instructions out-lined in this manual.

Through sawing operations are those in which

the blade cuts completely through the workpiece

as in ripping or cross cutting. NEVER use the

tool with a faulty blade guard or secure the blade

guard with a rope, string, etc. Any irregular operation of the blade guard should be corrected

immediately.

7. Immediately reattach the guard and spreader

after completing an operation which requires

removal of the guard.

8. Do not cut metals such as nails and screws.

Inspect for and remove all nails, screws and

other foreign matter from the workpiece before

operation.

9. Remove wrenches, cut-off pieces, etc. from the

table before the switch is turned on.

10. NEVER wear gloves during operation.

11. Keep hands out of the line of the saw blade.

3

Page 4

12. NEVER stand or permit anyone else to stand in

line with the path of the saw blade.

13. Make sure the blade is not contacting the

spreader or workpiece before the switch is

turned on.

14. Before cutting an actual workpiece, let the tool

run for a while. Watch for vibration or wobbling

that could indicate poor installation or a poorly

balanced blade.

15. NEVER make any adjustments while tool is running. Disconnect tool before making any adjustments.

16. Use a push stick when required. Push sticks

MUST be used for ripping narrow workpieces to

keep your hands and fingers well away from the

blade.

17. Pay particular attention to instructions for reducing risk of KICKBACK. KICKBACK is a sudden

reaction to a pinched, bound or misaligned saw

blade. KICKBACK causes the ejection of the

workpiece from the tool back towards the operator. KICKBACKS CAN LEAD TO SERIOUS PERSONAL INJURY. Avoid KICKBACKS by keeping

the blade sharp, by keeping the rip fence parallel

to the blade, by keeping the spreader, antikickback pawls and blade guard in place and operating properly, by not releasing the workpiece until

you have pushed it all the way past the blade,

and by not ripping a workpiece that is twisted or

warped or does not have a straight edge to guide

along the fence.

18. Do not perform any operation freehand. Freehand means using your hands to support or

guide the workpiece, in lieu of a rip fence or

miter gauge.

19. NEVER reach around or over saw blade. NEVER

reach for a workpiece until the saw blade has

completely stopped.

20. Avoid abrupt, fast feeding. Feed as slowly as

possible when cutting hard workpieces. Do not

bend or twist workpiece while feeding. If you

stall or jam the blade in the workpiece, turn the

tool off immediately. Unplug the tool. Then clear

the jam.

21. NEVER remove cut-off pieces near the blade or

touch the blade guard while the blade is running.

22. Knock out any loose knots from workpiece

BEFORE beginning to cut.

23. Don’t abuse cord. Never yank cord to disconnect

from receptacle. Keep cord away from heat, oil,

water and sharp edges.

24. Some material contains chemicals which may be

toxic. Take caution to prevent dust inhalation

and skin contact. Follow material supplier safety

data.

25. The guard can be lifted during workpiece setup

and for ease of cleaning. Always make sure that

guard hood is down and flat against sawtable

before plugging in the tool.

SAVE THESE INSTRUCTIONS

WARNING:

MISUSE or failure to follow the safety

rules stated in this instruction manual

may cause serious personal injury.

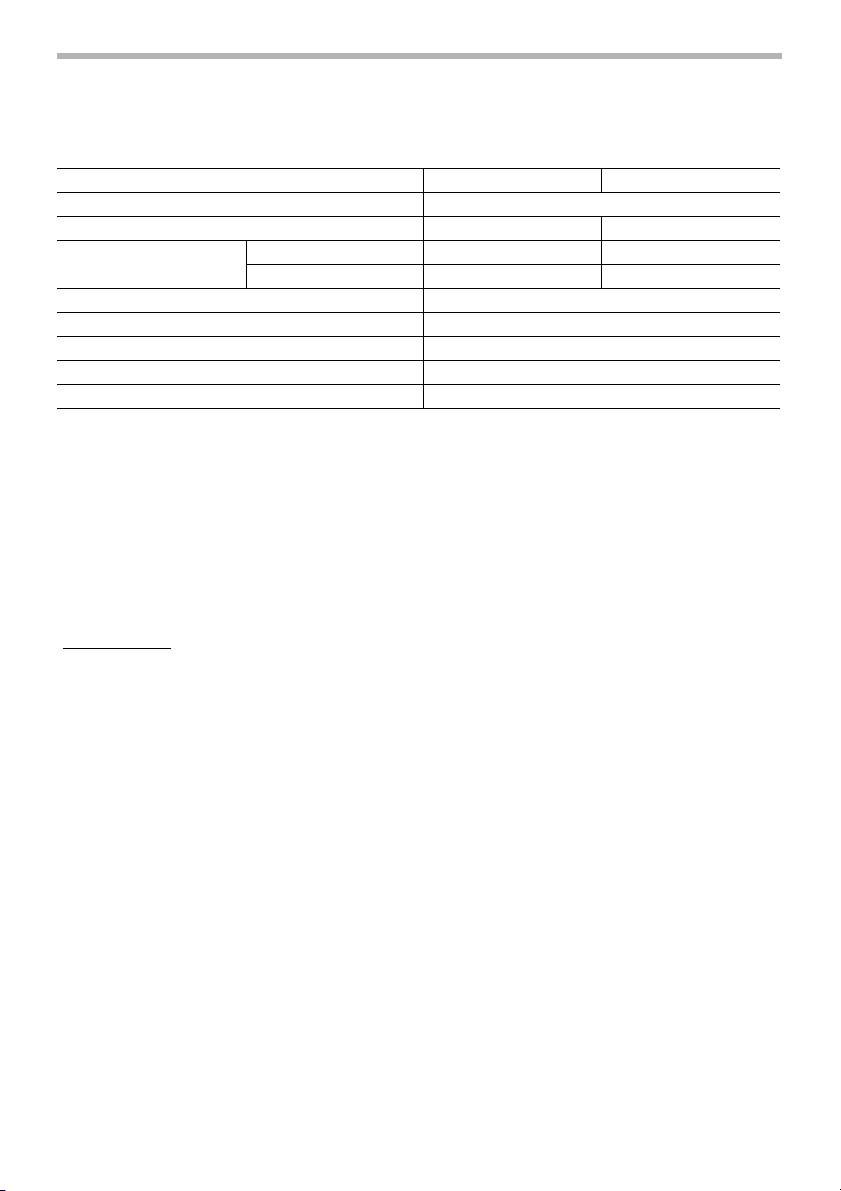

INSTALLATION

Positioning table saw

334 mm

(13-1/8")

1

25 mm

(1")

2

1

Locate the table saw in a well lit and level area where you

can maintain good footing and balance. It should be

installed in an area that leaves enough room to easily

handle the size of your workpieces. The table saw should

be secured with four screws or bolts to the work bench or

table saw stand using the holes provided in the bottom of

the table saw. When securing the table saw on the work

bench, make sure that there is an opening in the top of

the work bench the same size as the opening in the bottom of the table saw so the sawdust can drop through.

4

006875

459 mm

(18-1/16")

1

006146

006148

1. Hole diamter 8

mm (5/16”)

1. 6 mm (1/4”) Std.

washer

2. No.10 wood

screw 40 mm

(1-1/2”) min.

length

1. 6 mm (1/4”) Std.

washer

2. 6 mm (1/4”)

Mounting bolt &

Nut tighten

2

securely

Page 5

If during operation there is any tendency for the table saw

to tip over, slide or move, the work bench or table saw

stand should be secured to the floor.

NOTE:

• Tabl e s aw s t an d

Models 2702X1 and 2703X1 are standardequipped with a table saw stand.

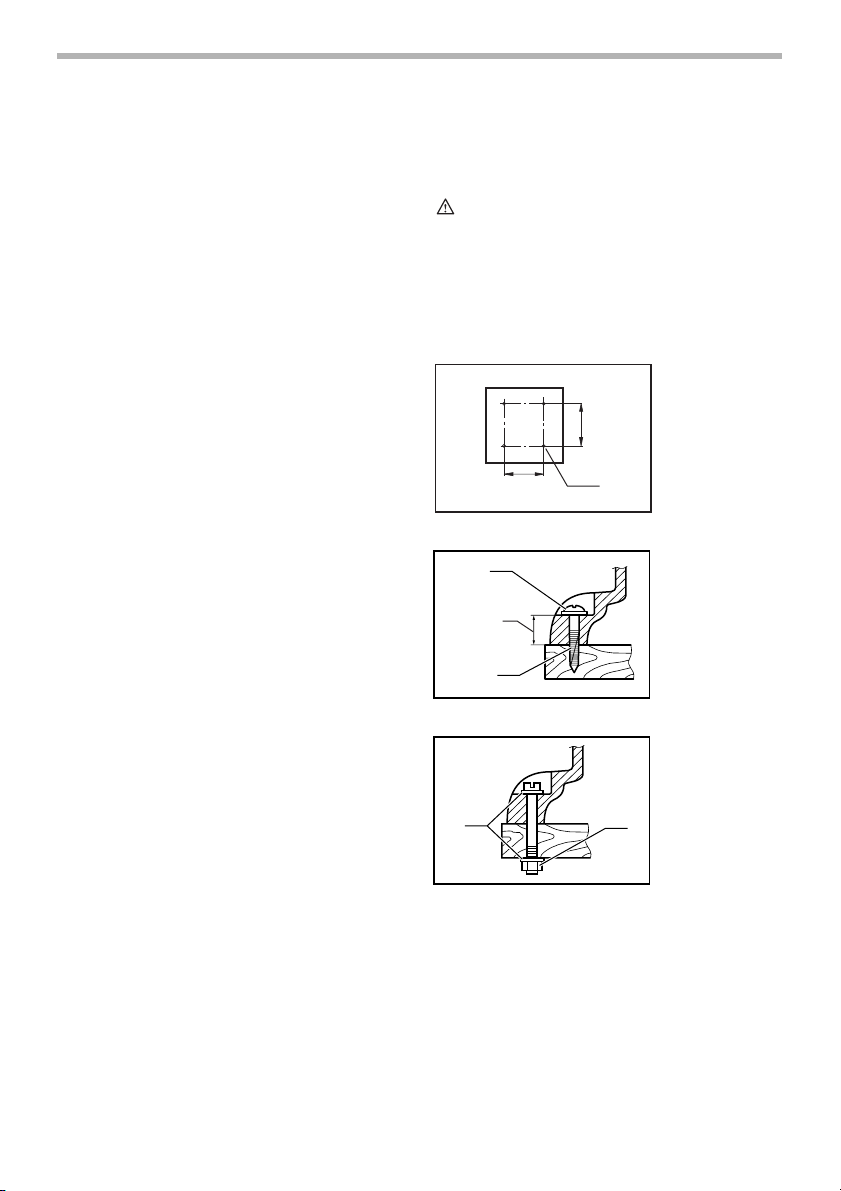

Storing accessories

006858

1. Miter gauge

NOTE:

• Use a shallow depth setting when cutting thin

materials in order to obtain a cleaner cut.

Adjusting the bevel angle

1

006861

1. Lock lever

2. Handwheel

3. Arrow pointer

1

006859

1. Rip fence

1

The miter gauge and wrenches can be stored on the left

side of the base and the rip fence can be stored at the

rear of the base.

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and

unplugged before adjusting or checking function on

the tool.

Adjusting the depth of cut

006860

1. Handle

2

Loosen the lock lever counterclockwise and turn the

handwheel until the desired angle (0° - 45°) is obtained.

3

The bevel angle is indicated by the arrow pointer.

After obtaining the desired angle, tighten the lock lever

clockwise to secure the adjustment.

CAUTION:

• After adjusting the bevel angle, be sure to tighten

the lock lever securely.

Adjusting positive stops

006862

1. 90° adjusting

screw

2. 45° adjusting

screw

2

1

006157

(A)

90

90

45

45

(B)

1

The depth of cut may be adjusted by turning the handle.

Turn the handle clockwise to raise the blade or counterclockwise to lower it.

The tool is equipped with positive stops at 90° and 45° to

the table surface. To check and adjust the positive stops,

proceed as follows:

Move the handwheel as far as possible by turning it.

Place a triangular rule on the table and check to see if

the blade is at 90° or 45° to the table surface. If the blade

is at an angle shown in Fig. A, turn the adjusting screws

clockwise; if it is at an angle shown in Fig. B, turn the

5

Page 6

adjusting screws counterclockwise to adjust the positive

stops.

After adjusting the positive stops, set the blade at 90° to

the table surface. Then adjust the arrow pointer so that

its right edge is aligned to the 0° graduation.

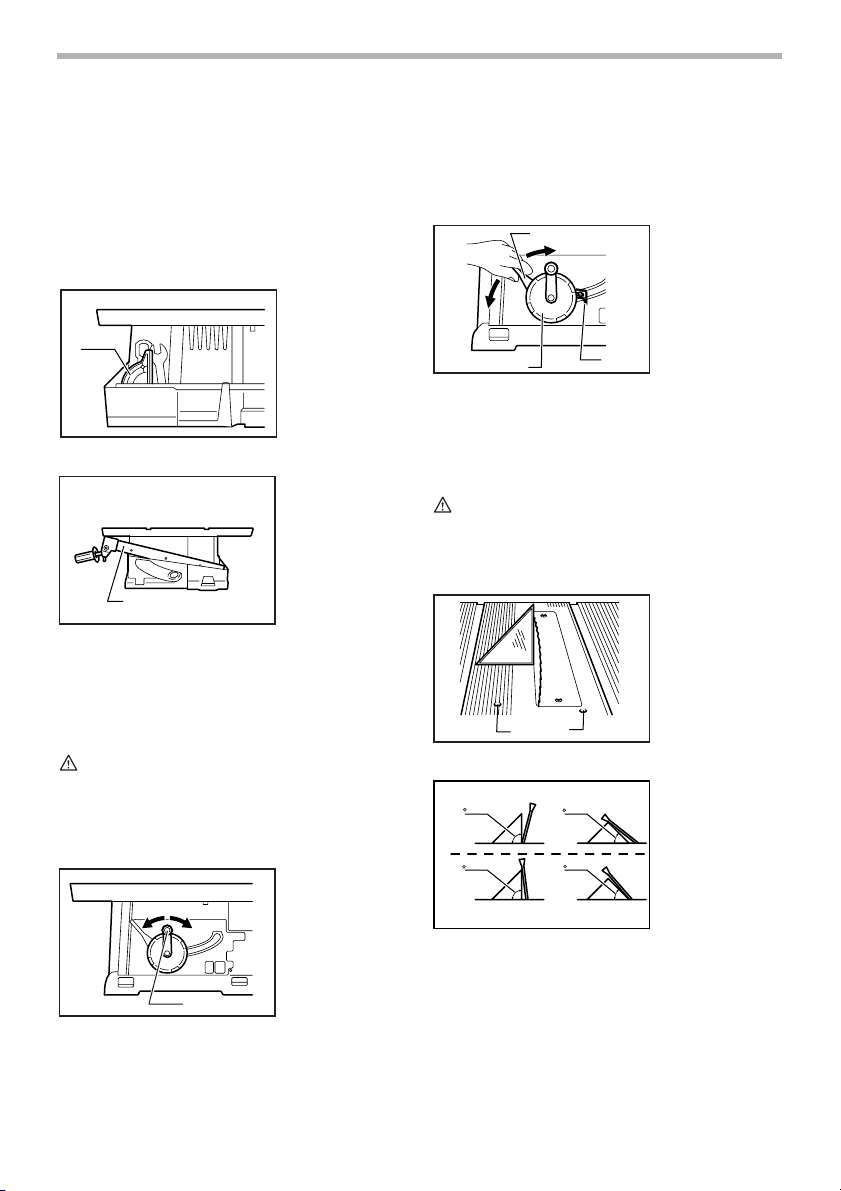

Switch action

1

006864

1

1. Arrow pointer

006868

1. Switch lever

2. Key

2

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

The tool is shipped from the factory with the saw blade

and blade guard not in the installed condition. Assemble

as follows:

Installing or removing saw blade

CAUTION:

• Always be sure that the tool is switched off and

unplugged before installing or removing the blade.

• Use only the Makita socket wrench provided to

install or remove the blade. Failure to do so may

result in overtightening or insufficient tightening of

the hex bolt. This could cause an injury.

006852

1. Wrench

2. Hex nut

3. Offset wrench

CAUTION:

• Before plugging in the tool, always check to see

that the switch lever actuates properly and returns

to the “OFF” position.

This tool is equipped with a special type of switch to prevent unintentional starting. To start the tool, first depress

the switch lever. While keeping it depressed, pull its lower

portion toward you. To stop the tool, press the lower portion of the switch lever.

When operating the switch lever, it is convenient to view it

through the window area in the table.

006869

CAUTION:

• When not using the tool, remove the key and store

it in a secure place. This prevents unauthorized

operation.

• Do not pull the switch lever hard without the key.

This can cause breakage of the switch.

32

1

Remove the table insert on the table. Hold the outer

flange with the offset wrench and loosen the hex nut

counterclockwise with the wrench. Then remove the

outer flange.

Assemble the inner flange, blade, outer flange and hex

nut onto the arbor, making sure that the teeth of the blade

are pointing down at the front of the table. Always install

the hex nut with its recessed side facing the outer flange.

006136

1. Inner flange

12

4

2. Outer flange

3. Saw blade

4. Hex nut

3

CAUTION:

• Keep the flange surface clean of dirt or other

adhering matter; it could cause blade slippage. Be

sure that the blade is installed so that the teeth are

aligned in the cutting (turning) direction.

To secure the blade in place, hold the outer flange with

the offset wrench, then tighten the hex nut clockwise with

the wrench. BE SURE TO TIGHTEN THE HEX NUT

SECURELY.

6

Page 7

006854

1. Wrench

2. Offset wrench

2

1

CAUTION:

• Be sure to hold the hex nut carefully with the

wrench. If your grip should slip, the wrench may

come off the hex nut, and your hand could strike the

sharp blade edges.

Installing blade guard

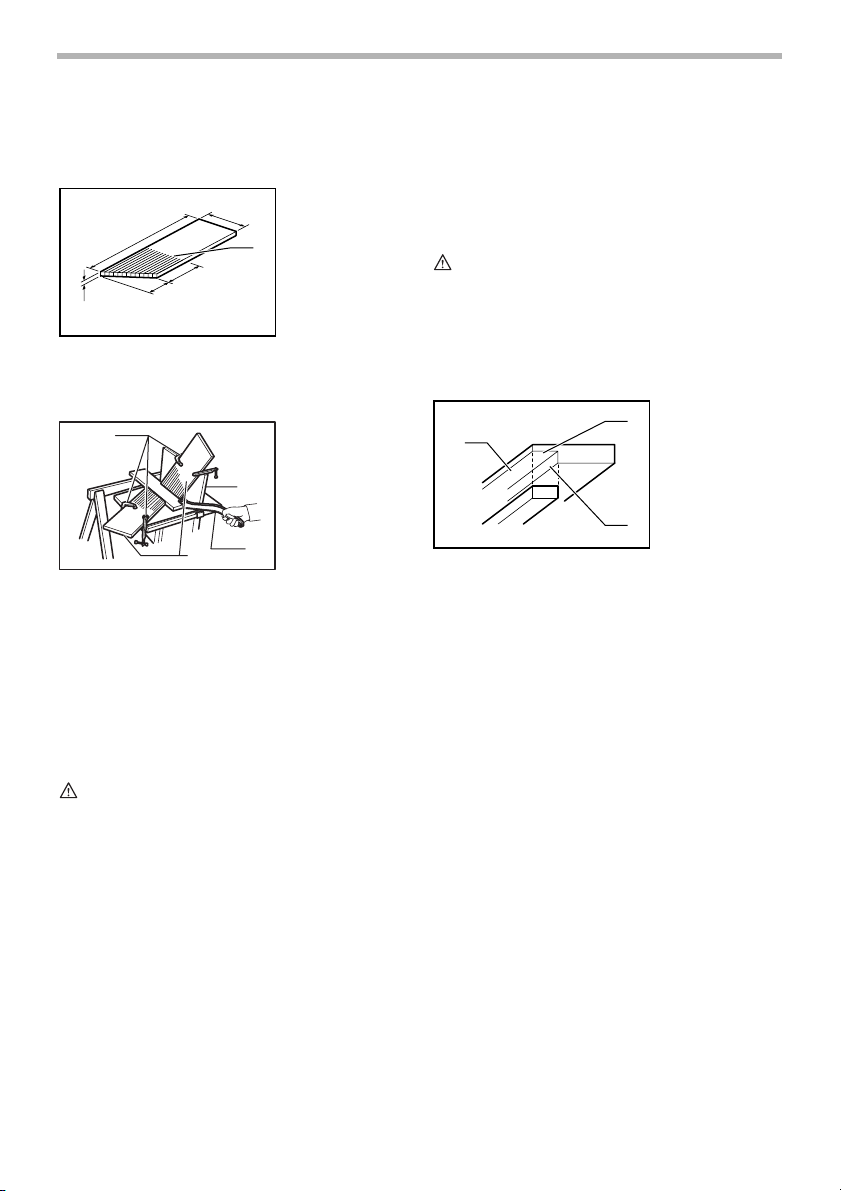

1

006853

1. Blade guard

2

2. Spreader

3. Antikickback

3

4. Pressure plate

4

pawl

CAUTION:

• Before installing the blade guard, adjust the depth

of cut to its maximum elevation. Insert the spreader

between the blade guard mounting portion (stay)

and the pressure plate.

Tighten the hex bolts (A) with the offset wrench. The

spreader installing location is factory-adjusted so that the

blade and spreader will be in a straight line. However, if

they are not in a straight line, loosen the hex bolts (B)

and adjust the blade guard mounting portion (stay) so

that the spreader is aligned directly behind the blade.

Then tighten the hex bolts (B) to secure the stay.

3

1

006856

6

1. These two

clearances

should be equal

2

2. Blade guard

portion

4

5

7

3. Blade

4. Spreader

5. Pressure plate

6. Hex bolts (A)

7. Hex bolts (B)

CAUTION:

• Always grasp the striped portion of the offset

wrench when tightening the hex bolts. If you tighten

the hex bolts while grasping the offset wrench

further than the striped portion, the hex bolts may

be damaged and/or an injury to your hand may

result.

• If the blade and spreader are not aligned properly, a

dangerous pinching condition may result during

operation. Make sure they are properly aligned. You

could suffer serious personal injury while using the

tool without a properly aligned spreader.

• NEVER make any adjustments while tool is

running. Disconnect the tool before making any

adjustments.

There must be a clearance of about 4 - 5 mm (5/32” -13/

64”) between the spreader and the blade teeth.

Adjust the spreader accordingly and tighten the hex bolts

(A) securely. Attach the table insert on the table, then

check to see that the blade guard works smoothly before

cutting.

21

006863

1. Spreader

2. Blade guard

4 - 5 mm

(5/32" - 13/64")

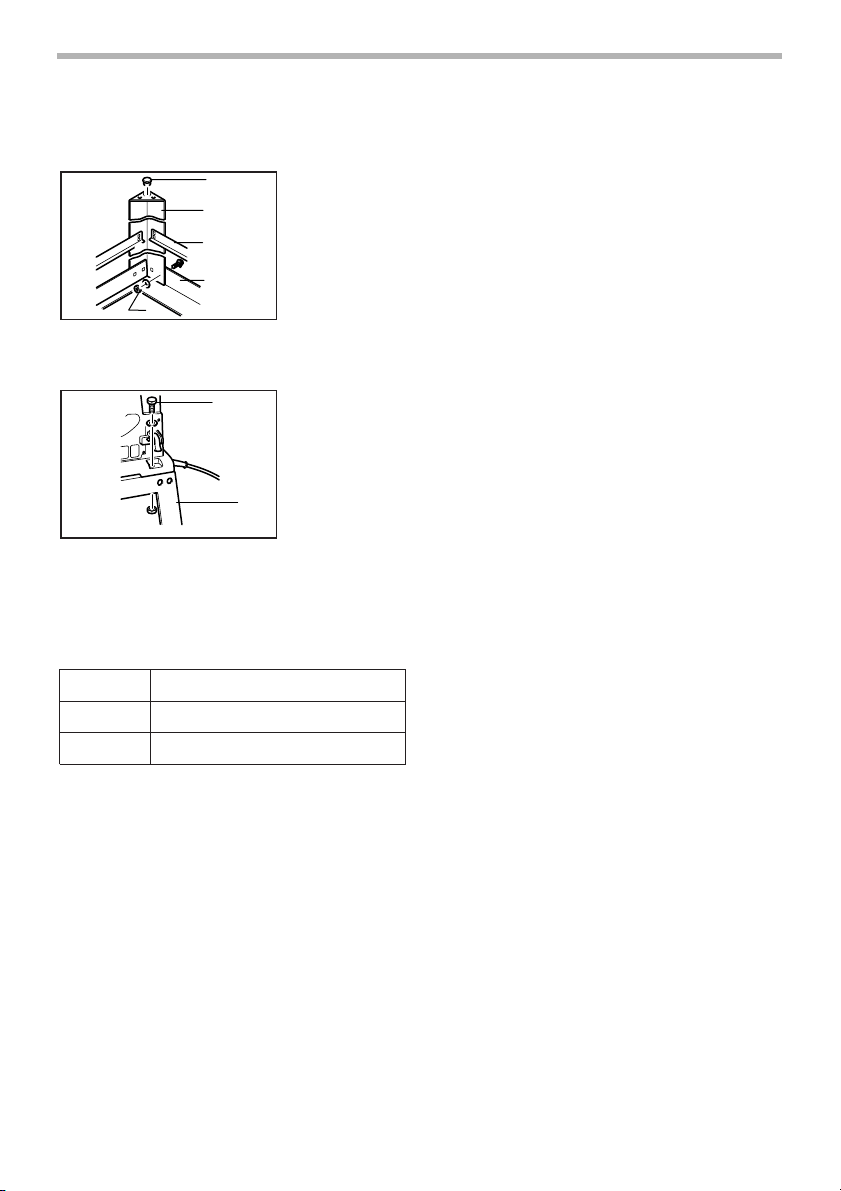

Installing and adjusting rip fence

006865

1. Fence holder

2. Guide rail

3. Grip

1

2

3

Raise the grip of the rip fence. Install the rip fence on the

table so that the fence holder engages with the guide rail.

The rip fence can be secured by lowering the grip.

To check to be sure that the rip fence is parallel with the

blade, secure the rip fence 2 - 3 mm (5/64” - 1/8” ) from

the blade. Raise the blade up to maximum elevation.

Mark one of the blade teeth with a crayon. Measure the

distance (A) and (B) between the rip fence and blade.

Take both measurements using the tooth marked with the

crayon. These two measurements should be identical. If

the rip fence is not parallel with the blade, proceed as follows:

7

Page 8

A

006866

1. Scale

B

CAUTION:

• Be sure to adjust the rip fence so that it is parallel

with the blade, or a dangerous kickback condition

may occur.

Bring the rip fence up flush against the side of the blade.

Make sure that the arrow pointer on the fence holder

points to the 0 graduation. If the arrow pointer does not

1

006881

1

1. Hex bolts

2. Adjusting nut

3. Grip

point to the 0 graduation, loosen the screw on the scale

plate and adjust the scale plate.

1

006882

1. Screw

2. Fence hoder

3. Scale plate

4. Arrow mark

2

3

1. Turn the adjusting nut counterclockwise a couple of

turns.

2. Loosen the two hex bolts on the rip fence with the

wrench provided.

3. Adjust the rip fence until it becomes parallel with

the blade.

4. Lower the grip to secure the rip fence.

5. Tighten the two hex bolts on the rip fence.

006867

CAUTION:

• Always grasp the striped portion of the wrench

when tightening the hex bolts. If you tighten the hex

bolts while grasping the wrench further than the

striped portion, the hex bolts may be damaged and/

or an injury to your hand may result.

6. With the grip of the rip fence lowered, turn the

adjusting nut clockwise to secure the rear end of

the rip fence. Do not turn the adjusting nut clockwise excessively. You may have some difficulty

adjusting the rip fence parallel with the saw blade

when repositioning the rip fence.

2

4

3

OPERATION

CAUTION:

• Always use “work helpers” such as push sticks and

push blocks when there is a danger that your hands

or fingers will come close to the blade.

• Always hold the workpiece firmly with the table and

the rip fence or miter gauge. Do not bend or twist it

while feeding. If the workpiece is bent or twisted,

dangerous kickbacks may occur.

• NEVER withdraw the workpiece while the blade is

running. If you must withdraw the workpiece before

completing a cut, first switch the tool off while

holding the workpiece firmly. Wait until the blade

has come to a complete stop before withdrawing

the workpiece. Failure to do so may cause

dangerous kickbacks.

• NEVER remove cut-off material while the blade is

running.

• NEVER place your hands or fingers in the path of

the saw blade. Be especially careful with bevel cuts.

• Always secure the rip fence firmly, or dangerous

kickbacks may occur.

• Always use “work helpers” such as push sticks and

push blocks when cutting small or narrow

workpieces, or when the dado head is hidden from

view while cutting.

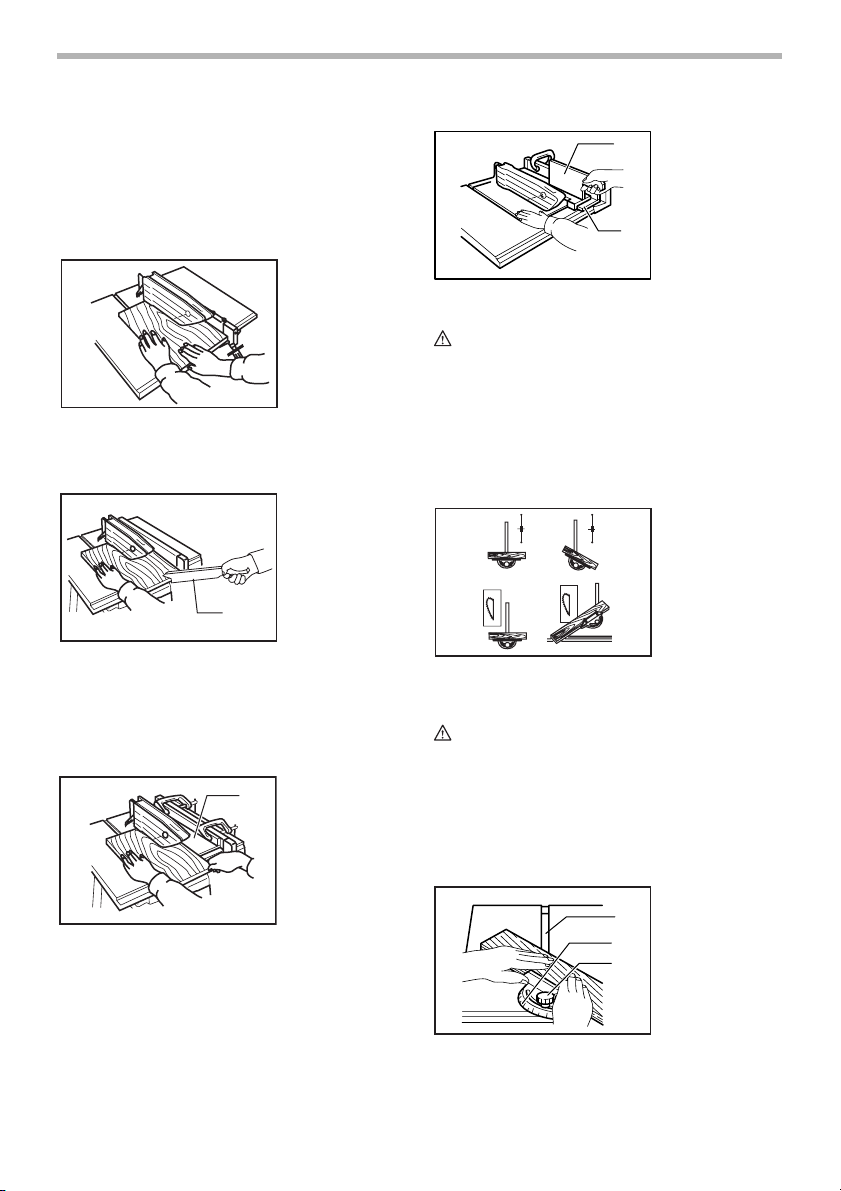

Work helpers

Push sticks, push blocks or auxiliary fence are types of

“work helpers”. Use them to make safe, sure cuts without

the need for the operator to contact the blade with any

part of the body.

8

Page 9

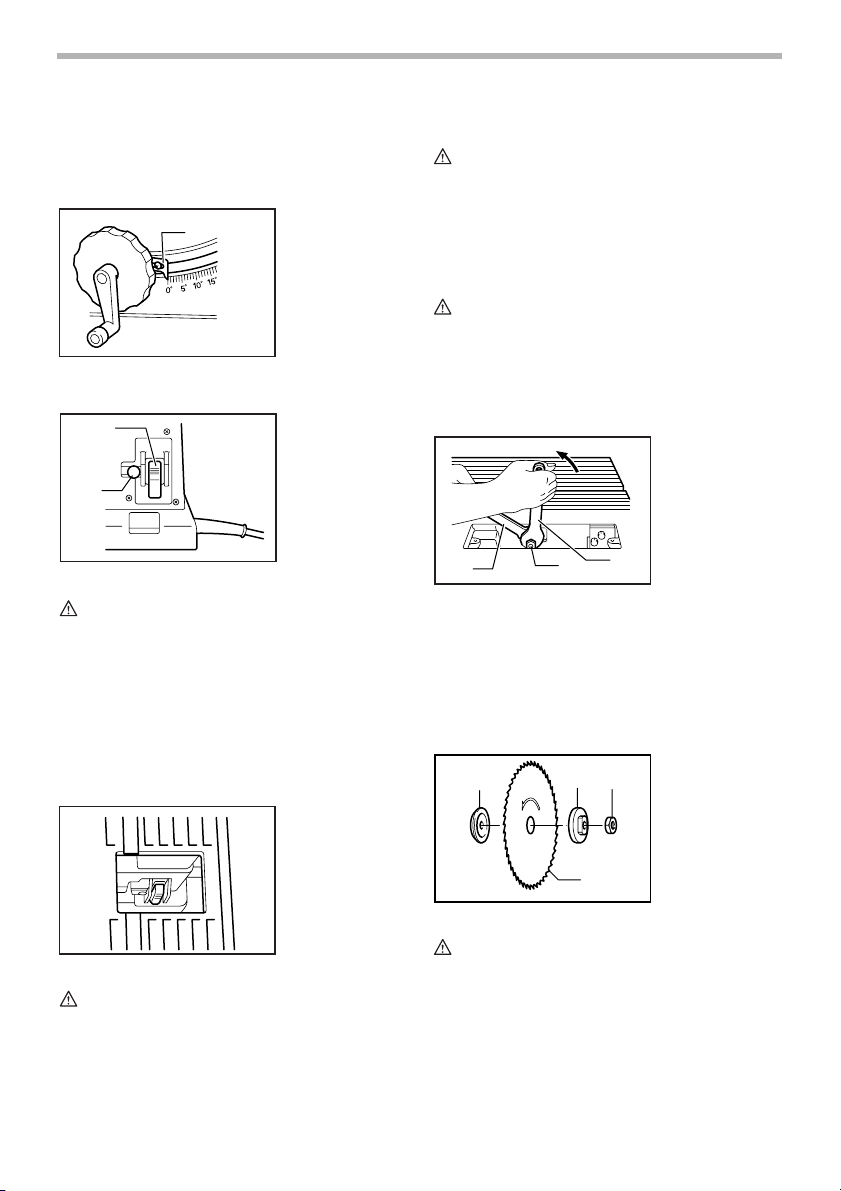

Push stick

(H)

19mm

(3/4")

40mm

(1-1/2")

9.5mm(3/8")

9.5mm(3/8")

380mm(15")

50mm(2")

130mm(5")

75mm(3")

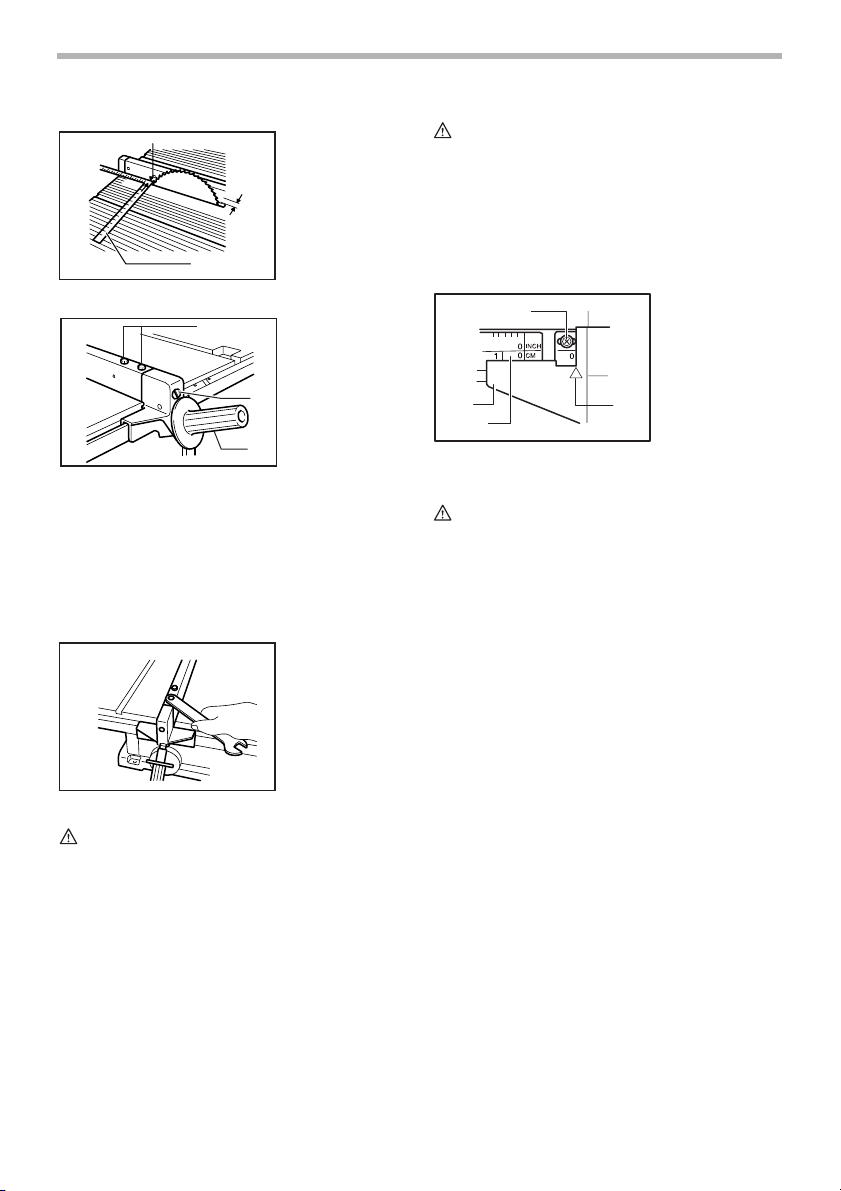

Make auxiliary fence from 9.5 mm (3/8”) and 19 mm (3/

006876

4”) plywood pieces.

Fasten with glue and wood screws.

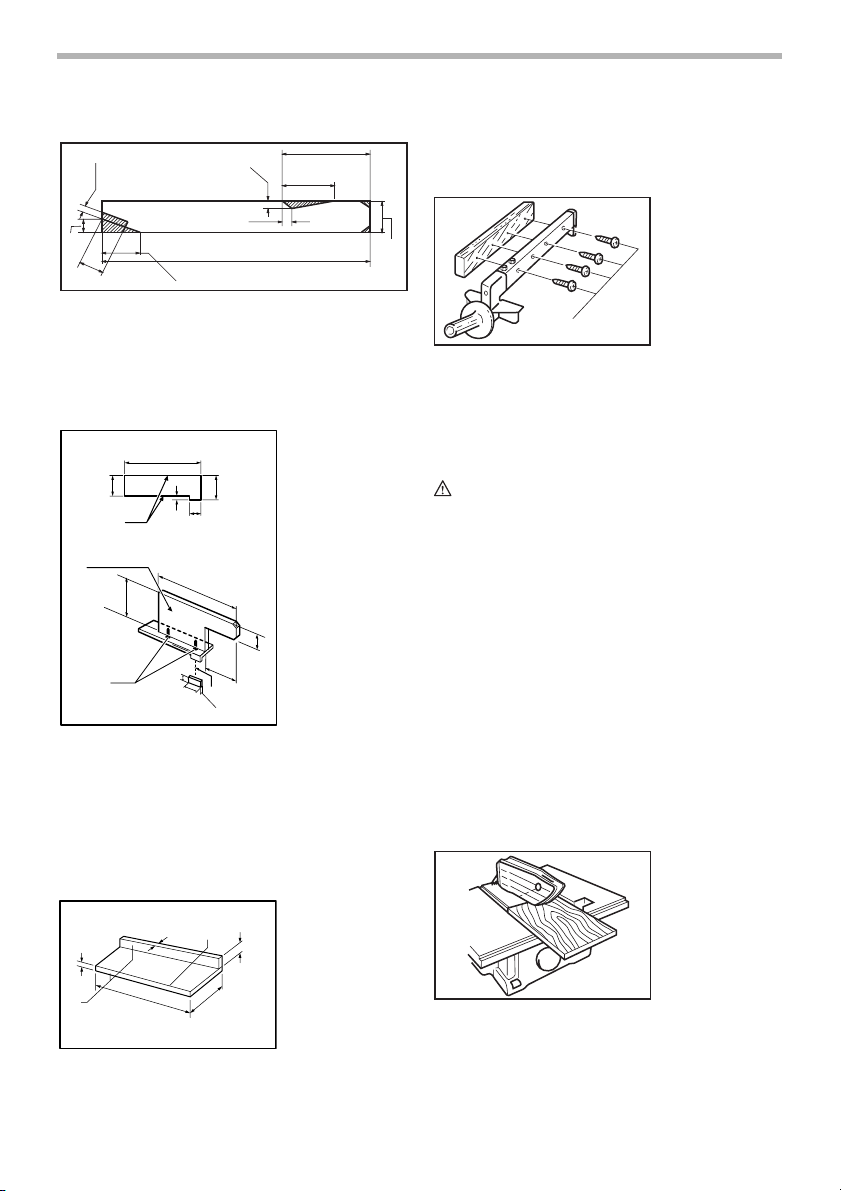

Wood facing (rip fence)

50mm

(2")

006883

1. No.10 wood

screws (long

enough to penetrate halfway

into facing)

A push stick can be easily made from a piece of plywood

19 mm (3/4”) to 25 mm (1”) thick.

Cut out the hatched area on the stick and smooth edges

with a file. (H) dimension should be less than 12.7 mm (1/

2”) so as to be thinner than the workpiece.

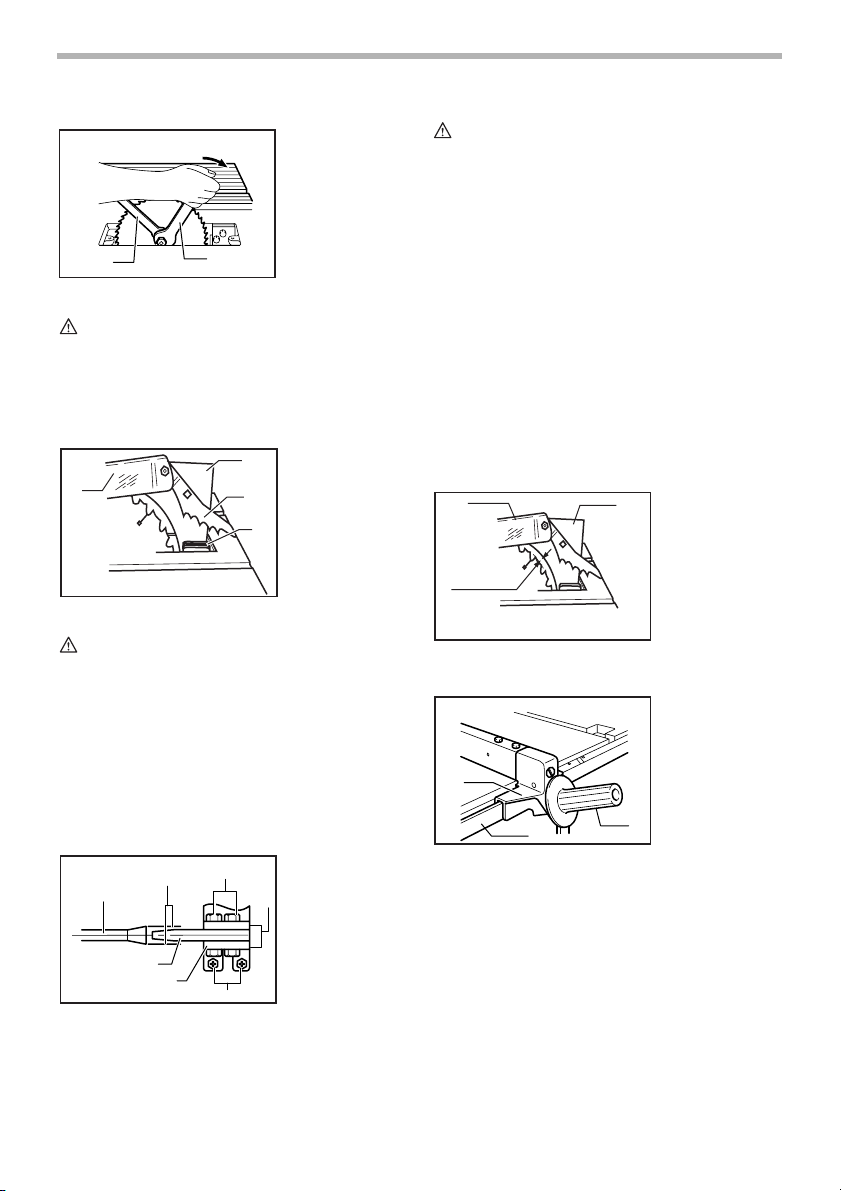

Push block

120mm

(4-3/4")

1

2

130mm

(5")

3

300mm(12")

6mm

(1/4")

9.5mm

(3/8")

50mm

(2")

50mm(2")

300mm(12")

8mm(5/16")

130mm(5")

100mm

4

(4")

006219

1. Face/edge par-

2. Handle

3. Wood screw

4. Glue together

50mm

(2")

allel

Use a 19 mm (3/4”) piece of plywood.

Handle should be in center of plywood piece. Fasten with

glue and wood screws as shown. Small piece 9.5 mm x 8

mm x 50 mm (3/8” x 5/16” x 2”) of wood must always be

glued to plywood to keep the blade from dulling if the

operator cuts into push block by mistake. (Never use

nails in push block.)

Auxiliary fence

9.5mm

(3/8")

1

460mm

(18")

19mm

(3/4")

120mm

(4-3/4")

140mm

(5-1/2")

006211

40mm

(1-1/2")

1. Face/edge parallel

1

A wood facing should be used for operations when the

blade comes close to the rip fence. Wood facing for the

rip fence should be the same size as the rip fence. Make

sure the bottom of facing is flush with the table surface.

Ripping

CAUTION:

• When ripping, remove the miter gauge from the

table.

• When cutting long or large workpieces, always

provide adequate support behind the table. DO

NOT allow a long board to move or shift on the

table. This will cause the blade to bind and increase

the possibility of kickback and personal injury. The

support should be at the same height as the table.

Before operating the table saw, check to be sure that the

antikickback pawls operate properly. Turn the tool off and

unplug it. Feed the workpiece under the blade guard and

along both sides of the blade to simulate cutting. Try to

withdraw the workpiece on each side by pulling it toward

you. The antikickback pawls should grab the workpiece

and prevent it from moving back toward the operator.

Always keep the antikickback pawls sharp so they will

operate properly. Keep them sharp by using a roundshaped file to maintain the original shape of the pawls.

1. Adjust the depth of cut a bit higher than the thick-

ness of the workpiece.

2. Position the rip fence to the desired width of rip and

lock in place by lowering the grip. Before ripping,

make sure the rear end of the rip fence is secured

firmly. If it is not secured enough, follow the proce-

006886

9

Page 10

dures in the section titled “Installing and adjusting

rip fence”.

3. Turn the tool on and gently feed the workpiece into

the blade along with the rip fence.

(1) When the width of rip is 150 mm (6”) and

wider, carefully use your right hand to feed

the workpiece. Use your left hand to hold the

workpiece in position against the rip fence.

006887

(2) When the width of rip is 65 mm - 150 mm (2-

1/2” - 6”) wide, use the push stick to feed the

workpiece.

006888

1. Push stick

1

006874

1. Push block

1

2. Auxiliary fence

2

Cross cutting

CAUTION:

• When making a crosscut, remove the rip fence from

the table.

• When cutting long or large workpieces, always

provide adequate support to the sides of the table.

The support should be at the same height as the

table.

• Always keep hands away from path of blade.

Miter gauge

1

34

2

006884

1. Cross cutting

2. Mitering

3. Bevel cutting

4. Compound

mitering

(angles)

(3) When the width of rip is narrower than 65 mm

(2-1/2”), the push stick cannot be used

because the push stick will strike the blade

guard. Use the auxiliary fence and push

block. Attach the auxiliary fence to the rip

fence with two “C” clamps.

Feed the workpiece by hand until the end is

about 25 mm (1”) from the front edge of the

006889

1. Auxiliary fence

1

table. Continue to feed using the push block

on the top of the auxiliary fence until the cut is

complete.

Use the miter gauge for the 4 types of cutting shown in

the figure.

CAUTION:

• Secure the knob on the miter gauge carefully.

• Avoid creep of workpiece and gauge by firm

workholding arrangement, especially when cutting

at an angle.

• NEVER hold or grasp the intended “cut-off” portion

of the workpiece.

Use of miter gauge

006870

1. Groove

2. Miter gauge

1

3. Knob

2

3

Slide the miter gauge into the thick grooves in the table.

Loosen the knob on the gauge and align to desired angle

10

Page 11

(0° to 60°). Bring stock flush up against fence and feed

gently forward into the blade.

Auxiliary wood facing (miter gauge)

To prevent a long board from wobbling, fit the miter

gauge with an auxiliary fence board. Fasten with bolts/

nuts after drilling holes, but fasteners must not protrude

from the face board.

006885

MAINTENANCE

Both carbon brushes should be replaced at the same

time. Use only identical carbon brushes.

Use a holder cap opener to remove the brush holder

caps. To replace the carbon brush in the side near the

table, lower the blade as far as possible by turning the

handle. Loosen the lock lever, tilt the blade and secure it

at 45°. Then loosen the brush holder cap while viewing it

through the opening of the base. Remove the worn carbon brushes, insert the new ones and secure the brush

holder caps.

After replacing brushes, plug in the tool and break in

brushes by running tool with no load for about 10 minutes. Then check the tool while running and electric

brake operation when releasing the switch trigger. If electric brake is not working well, ask your local Makita service center for repair.

006879

1

1. Holder cap

opener

2. Brush holder

cap

CAUTION:

• Always be sure that the tool is switched off and

unplugged before attempting to perform inspection

or maintenance.

Cleaning

Clean out sawdust and chips from time to time. Carefully

clean the blade guard and moving parts inside the table

saw.

Lubrication

To keep the table saw in tip-top running condition, and to

assure maximum service life, oil or grease the moving

parts and rotating parts from time to time.

Lubrication places:

• Threaded shaft to elevate the blade

• Hinge to rotate the frame

• Elevation guide shafts on motor

• Gear to elevate the blade

Replacing carbon brushes

Remove and check the carbon brushes regularly.

Replace when they wear down to the limit mark. Keep

the carbon brushes clean and free to slip in the holders.

001145

1. Limit mark

1

2

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be performed by Makita Authorized or Factory Service Centers,

always using Makita replacement parts.

ACCESSORIES

CAUTION:

• These accessories or attachments are

recommended for use with your Makita tool

specified in this manual. The use of any other

accessories or attachments might present a risk of

injury to persons. Only use accessory or

attachment for its stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita Service Center.

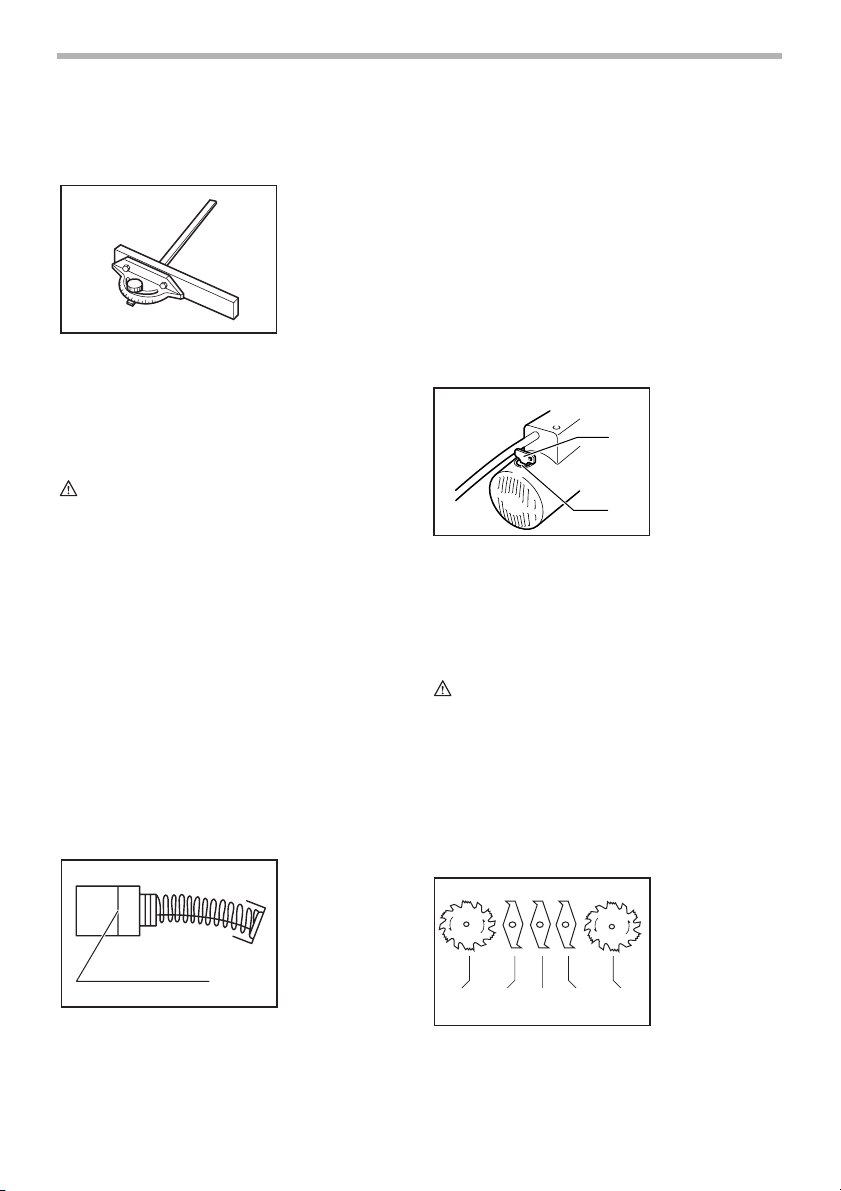

Dado head set (Part No. 191543-4)

1/8" 1/8" 1/8" 1/8"1/16"

A dado is cutting a rabbet or a wide groove into the workpiece. The dado head set consists of two outside cutters,

three inside cutters and paper washers.

11

006890

Page 12

• Outside cutters: 6”diameter, 1/8” thick, 5/8”arbor

hole, 2 pcs.

• Inside cutters: 6”diameter, 1/8”thick, 5/8”arbor hole,

2 pcs.

• Inside cutter: 6”diameter, 1/16”thick, 5/8”arbor hole,

1 pc.

• Paper washers: 5/8”arbor hole, 6 pcs.

Various combinations of these cutters are used to cut

grooves from 1/8” to 1/2” for use in making joints, tenoning, grooving, etc.

Dado flange set (Part No. 192693-8)

006891

1

2

3

4

1. Dado outer flange

When cutting groove 1/4”, 5/16”, 3/8”, 7/16” or 1/2”,

use this dado outer flange.

2. Dado hex nut

When cutting groove 1/4”, 5/16”, 3/8”, 7/16” or 1/2”,

use this dado hex nut.

3. Ring

When cutting groove 1/4”, 5/16”, 3/8”, 7/16” or 1/2”,

use this ring.

4. Washer

When cutting groove 1/4”, 5/16” or 3/8”, use this

washer.

Table insert (Part No. 317061-6)

006892

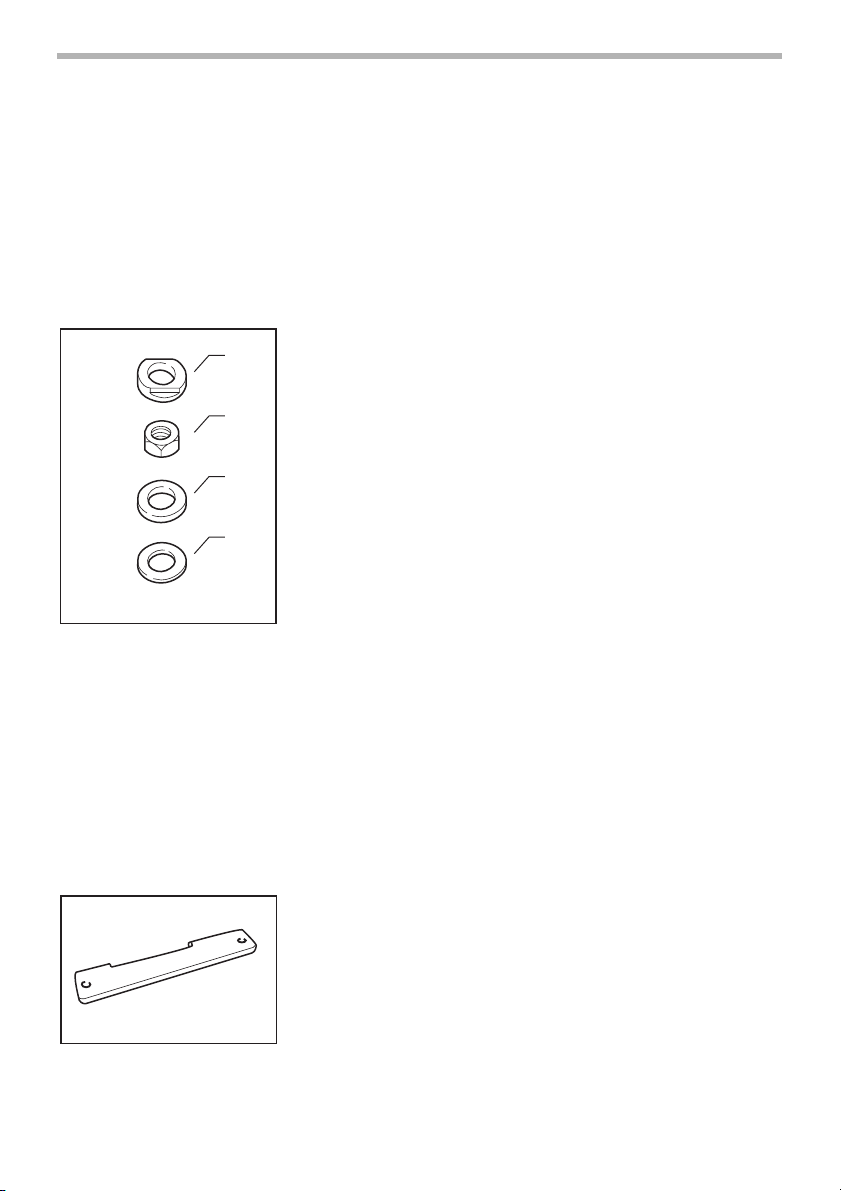

To install the dado head set, proceed as follows:

1. Turn the tool off and unplug it before installing.

2. Remove the blade guard with the spreader.

3. Install the dado head set with the teeth pointing

down at the front of the table.

4. Use the chart below to select the proper cutters to

obtain the various cutting widths.

When cutting grooves 5/16”, 3/8”,7/16” or 1/2” use this

table insert instead of the standard table insert.

12

Page 13

CUT

WIDTH

1/8"

1/4"

5/16"

3/8"

7/16"

1/2"

Spindle

Inner

flange

Ring

Outside

Cutter

1/8"

Inside

cutter

x2

1/16"

Inside

cutter

Outside

cutter

Outer

flange

Washer

Dado

Outer

flange

Hex

nut

006893

Dado

Hex

nut

CAUTION:

• For a 1/8” cut width, the outside cutter is assembled

to the spindle in the same manner as the saw

blade.

• The outer flange or the dado outer flange must be

used for each cut width.

• The hex nut alone must not be used to secure the

dado on to the spindle.

NOTE:

• When widths slightly greater than the above are

required, fit the paper washers in between the

inside and outside cutters to adjust the width.

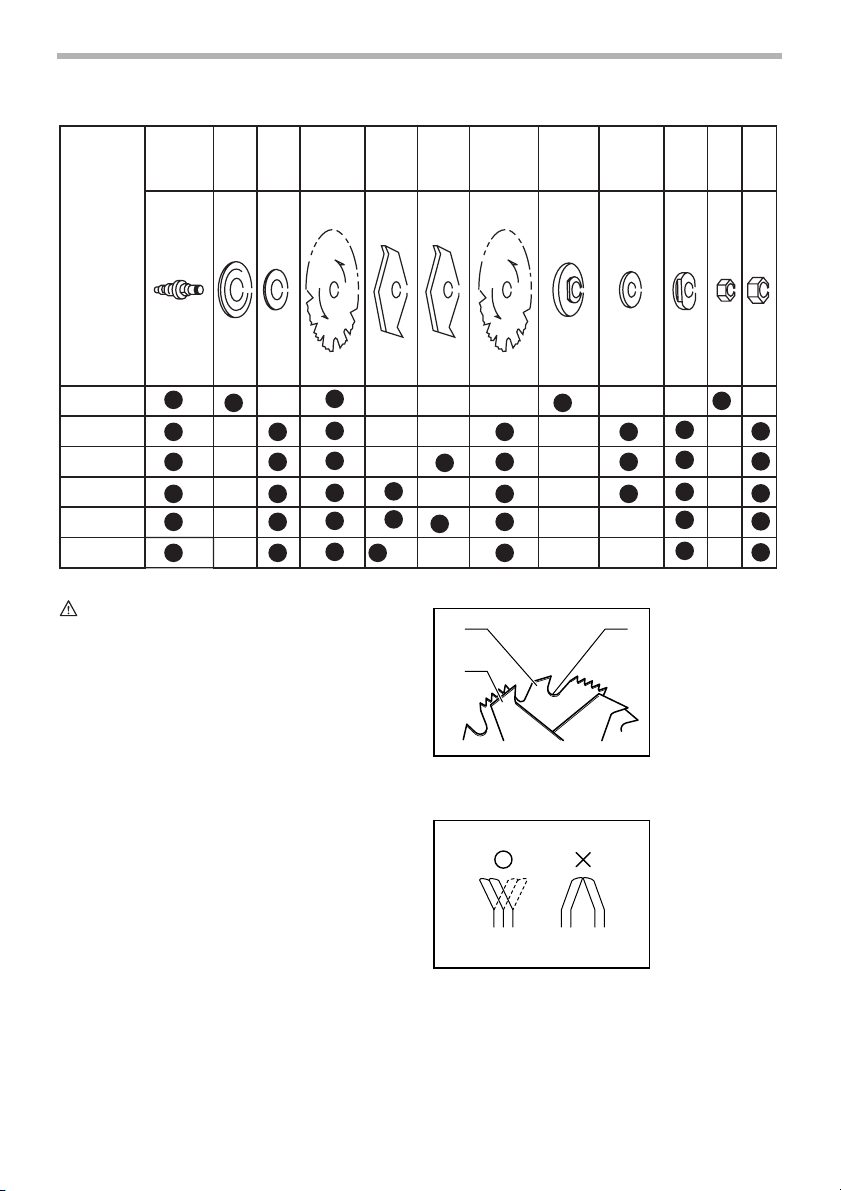

5. Arrange the cutters so that the tips of the inside cut-

ters are positioned at the gullets of the outside cutter. When more than one inside cutter is used,

space the tips of the inside cutters equidistantly in

relation to one another. Poorly spaced cutters may

cause vibration and noise.

006178

1

2

When installing two outside cutters without any inside

cutter, be sure that the cutter tips do not face each other.

6. While tightening the hex nut, be careful to maintain

the even spacing between the tips of the inside cutters.

7. Rotate the dado head one turn by hand to make

sure that it does not contact anything before operation.

3

006179

1. Outside cutter

2. Inside cutter

3. Gullet

13

Page 14

When dadoing, use featherboards. The diagram shown

illustrates dimensions for making a typical featherboard.

It should be made from a straight piece of wood that is

free of knots or cracks.

600 mm

(24")

115 mm

(4-1/2")

(3/4")

19 mm

200 mm

130 mm

006180

(8")

1

(5")

1. Kerf should be

about 6 mm

(1/4”) apart

Featherboards are used to keep the workpiece in contact

with the rip fence and table as shown, and to stop kickbacks.

1

006182

1. C clamps

2. Facing board

3. Push stick

4. Featherboard

2

3

4

To install featherboards, proceed as follows:

1. Turn the tool off and unplug it.

2. Add 8” high flat facing board to the rip fence, the full

length of the rip fence.

3. Mount featherboards to the rip fence and table as

shown, so that the leading edges of the featherboards will support the workpiece until the cut is

completed, and the workpiece has been pushed

completely past the cutter with a push stick.

4. Make sure featherboards are securely attached.

CAUTION:

• Only the Makita dado head set (Part No. 191543-4)

should be used with Makita table saw Model 2702/

Model 2703. Do not use dado combinations wider

than 13 mm (1/2”).

• After dadoing, ALWAYS replace the blade guard

with the spreader back in its original position on the

table saw.

• NEVER attempt bevel cuts when dadoing.

• NEVER dado if there is vibration (flutter) or a

strange noise.

• NEVER attempt dados in other than wood.

• Do not use the dado set for cut-offs.

• Feed work slowly, especially when cutting deep or

wide grooves or dados. If a deep cut is needed,

make several passes through the workpiece rather

than one deep, wide cut. Fast or abrupt feeds can

be dangerous.

• Use a push stick. When the dado head is hidden

from view while cutting, your hands should never be

on top of the stock.

• A very dangerous throwback can result if the wood

becomes stuck and you try to remove it by pulling

toward you. Always stop the tool and wait for dado

head to come to a complete stop. Then simply

withdraw the wood.

WARNI NG:

• Use extra caution when the guard assembly is

removed for any non-through sawing operation

such as dadoing, rabbeting or re-sawing. Replace

guard immediately after non-through sawing is

completed.

How to perform rabbeting

1

006183

2

1. Rabbet

2. Second cut

3. First cut

3

1. Remove blade guard.

2. Attach auxiliary fence to rip fence for cuts that run

the length of the stock. Facing should be as high as

the workpiece is wide. Adjust fence and blade to

desired dimensions.

3. First cut: Hold board flat on table as in ordinary rip-

ping.

4. Second cut: Set workpiece on its edge. (Use feath-

erboards, push stick, push block and so on, using

precautions, safety rules and guidelines for ripping

or related work.)

5. For end-type rabbeting, if the workpiece is less than

10-1/2” wide, rest the wood flat on the table against

the miter gauge (with wood facing). The rip fence

should not be used.

6. After rabbeting is completed, immediately re-install

the blade guard as before.

Table saw stand

NOTE:

• The following is description only for the tools

equipped with a table saw stand. For table saw

stands as optional accessories, refer to the

instruction manuals for table saw stands provided

with them.

14

Page 15

Place the stays on a level location and assemble the legs

inside. Secure with the bolts and nuts, then attach the

rubber caps to the ends of the legs.

006877

1

3

4

1. Rubber cap

2. Nut

3. Leg

4. Under stay

5. stay

5

2

Now set the table saw on top of the assembled stand and

secure with four bolts, washers and nuts.

006878

1

1. Bolt

2. Stand

2

NOTE:

• Models 2702X1 and 2703X1 are standard-

equipped with a table saw stand.

• Steel & Carbide-tipped saw blades

Table/Miter saw

blades

Combination

Fine cross cuts For sand-free cuts cleanly against the grain.

For general purpose cuts for table and miter saws.

General purpose blade for fast and smooth rip,

crosscuts and miters.

006586

MAKITA LIMITED ONE YEAR WARRANTY

EN0006-1

Warranty Policy

Every Makita tool is thoroughly inspected and tested

before leaving the factory. It is warranted to be free of

defects from workmanship and materials for the period of

ONE YEAR from the date of original purchase. Should

any trouble develop during this one year period, return

the COMPLETE tool, freight prepaid, to one of Makita’s

Factory or Authorized Service Centers. If inspection

shows the trouble is caused by defective workmanship or

material, Makita will repair (or at our option, replace)

without charge.

This Warranty does not apply where:

• repairs have been made or attempted by others:

• repairs are required because of normal wear and

tear:

• the tool has been abused, misused or improperly

maintained:

• alterations have been made to the tool.

IN NO EVENT SHALL MAKITA BE LIABLE FOR ANY

INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES FROM THE SALE OR USE OF THE PRODUCT.

THIS DISCLAIMER APPLIES BOTH DURING AND

AFTER THE TERM OF THIS WARRANTY.

MAKITA DISCLAIMS LIABILITY FOR ANY IMPLIED

WARRANTIES, INCLUDING IMPLIED WARRANTIES

OF “MERCHANTABILITY” AND “FITNESS FOR A SPECIFIC PURPOSE,” AFTER THE ONE YEAR TERM OF

THIS WARRANTY.

This Warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not apply to you. Some states do

not allow limitation on how long an implied warranty lasts,

so the above limitation may not apply to you.

• Sub table set (Left / Right)

• Rip fence

• Miter gauge

• Offset wrench 13-22

• Wrench 19

• Key (Switch button)

• Holder cap opener

• Joint ( for connecting to dust collector )

• Stand set

15

Page 16

FRANÇAIS

SPÉCIFICATIONS

Modèle 2702 / 2702X1 2703 / 2703X1

Alésage central 5/8”

Diamètre de la lame 210 mm (8-1/4”) 255 mm (10”)

Capacités de coupe max.

Capacités de lambrissage maximales 13 mm (1/2”)

Vitesse à vide (T/MIN) 4,600/min.

Taille de la table (P X L) 686 mm x 560 mm (27” x 22”)

Dimensions (L x l x H) 560 mm x 686 mm x 458 mm (22” x 27” x 18”)

Poids net 18 kg (40 lbs)

• Le fabricant se réserve le droit de modifier sans avertissement les spécifications.

• Note: Les spécifications peuvent varier selon les pays.

90° 68 mm (2-11/16”) 91 mm (3-9/16”)

45° 47 mm (1-3/4”) 63 mm (2-1/2”)

Pour votre propre sécurité, veuillez

lire le manuel d’instructions avant

d’utiliser l’outil Conservez-le pour

référence ultérieure

CONSIGNES GÉNÉRALES DE

SÉCURITÉ

USA007-2

(Pour TOUS LES OUTILS)

1. VOUS DEVEZ CONNAÎTRE VOTRE OUTIL

ÉLECTRIQUE. Lisez attentivement le manuel

d’instructions. Familiarisez-vous avec les

applications et limites de l’outil, ainsi qu’avec

les risques potentiels qui lui sont spécifiques.

2. MAINTENEZ LES PROTECTEURS EN PLACE et

en bon état de fonctionnement.

3. RETIREZ LES CLÉS DE RÉGLAGE ET LES CLÉS.

Prenez l’habitude de vous assurer que les clés et

clés de réglage ont été retirées de l’outil avant de

le mettre sous tension.

4. MAINTENEZ L’AIRE DE TRAVAIL PROPRE. Les

aires de travail et les établis encombrés ouvrent

la porte aux accidents.

5. ÉVITEZ L’UTILISATION DANS UN

ENVIRONNEMENT DANGEREUX. N’utilisez pas

les outils électriques dans les endroits humides

ou mouillés, et ne les exposez pas à la pluie.

Maintenez un éclairage adéquat dans l’aire de

travail. N’utilisez pas l’outil en présence de

liquides ou gaz inflammables.

6. MAINTENEZ LES ENFANTS À L’ÉCART. Toute

autre personne que l’utilisateur de l’outil doit se

tenir à une distance sûre de l’aire de travail.

7. FAITES EN SORTE QUE L’ATELIER SOIT SANS

DANGER POUR LES ENFANTS, en y posant des

cadenas, un interrupteur principal, ou en retirant

des équipements leurs clés de démarrage.

8. NE FORCEZ PAS L’OUTIL. Il effectuera un travail

de meilleure qualité et plus sûr s’il est utilisé au

régime pour lequel il a été conçu.

9. UTILISEZ LE BON OUTIL. Ne forcez pas un outil

ou accessoire à effectuer un travail pour lequel il

n’a pas été conçu.

10. PORTEZ DES VÊTEMENTS ADÉQUATS. Ne

portez ni vêtements ni gants amples, ni cravate,

anneaux, bracelets ou autres bijoux

susceptibles d’être happés par les pièces

mobiles de l’outil. Le port de chaussures

antidérapantes est recommandé. Portez un filet

de protection pour envelopper les cheveux

longs.

11. PORTEZ TOUJOURS DES LUNETTES DE

PROTECTION. Si le travail de coupe dégage de la

poussière, portez également un écran facial ou

un masque antipoussières. Les lunettes

ordinaires ne sont munies que de lentilles

résistances aux chocs ; elles ne constituent PAS

des lunettes de protection.

12. FIXEZ BIEN LA PIÈCE. Lorsque cela est

possible, fixez la pièce à travailler à l’aide de

dispositifs de serrage ou d’un étau. Cela est plus

sécuritaire que l’utilisation de la main et libère

les deux mains pour le maniement de l’outil.

13. MAINTENEZ UNE BONNE POSITION. Assurezvous d’une bonne prise au sol et d’une bonne

position d’équilibre en tout temps.

16

Page 17

14. PRENEZ SOIN DES OUTILS. Maintenez les outils

bien aiguisés et propres pour assurer une

performance sécuritaire et optimale. Suivez les

instructions de lubrification et de changement

des accessoires.

15. DÉBRANCHEZ LES OUTILS avant tout travail de

réparation ou avant de changer les accessoires

tels que lames, embouts/forets/fraises et

couteaux.

16. RÉDUISEZ LES RISQUES DE MISE EN MARCHE

ACCIDENTELLE. Assurez-vous que

l’interrupteur est en position d’arrêt avant de

brancher l’outil.

17. UTILISEZ LES ACCESSOIRES RECOMMANDÉS.

Consultez le manuel de l’utilisateur pour savoir

quels sont les accessoires recommandés.

L’utilisation d’accessoires non adéquats peut

comporter un risque de blessure.

18. NE VOUS APPUYEZ JAMAIS SUR L’OUTIL. Une

blessure grave peut survenir si l’outil bascule ou

si vous touchez accidentellement l’outil

tranchant.

19. VÉRIFIEZ S’IL Y A DES PIÈCES

ENDOMMAGÉES. Avant d’utiliser l’outil, tout

protecteur ou dispositif endommagé doit être

vérifié soigneusement afin de s’assurer qu’il

fonctionne adéquatement et peut remplir la

fonction pour laquelle il est conçu. Vérifiez si les

pièces mobiles sont bien alignées et bien fixées,

vérifiez la présence de pièces brisées, vérifiez

que l’outil est bien monté et assurez-vous que

rien ne peut entraver son bon fonctionnement.

Un protecteur ou tout autre dispositif

endommagé doit être adéquatement réparé ou

remplacé.

20. SENS D’ALIMENTATION. N’alimentez la lame ou

l’outil tranchant avec la pièce à travailler que

dans le sens opposé à celui de la progression de

la lame ou de l’outil tranchant.

21. NE LAISSEZ JAMAIS SANS SURVEILLANCE UN

OUTIL EN MARCHE. COUPEZ LE CONTACT.

Attendez que l’outil se soit complètement arrêté

avant de le quitter.

22. PIÈCES DE RECHANGE. Seules des pièces de

rechange identiques doivent être utilisées lors

des réparations.

23. FICHES POLARISÉES. Pour réduire les risques

de choc électrique, cet appareil est muni d’une

fiche polarisée (une des broches est plus large

que l’autre). Cette fiche ne peut être insérée

dans une prise polarisée que dans un seul sens.

Si la fiche ne s’insère pas à fond dans la prise,

insérez-la en sens inverse. Si elle ne s’insère

toujours pas à fond, contactez un technicien

qualifié pour faire installer une prise appropriée.

N’apportez aucune modification à la fiche.

MISE EN GARDE RELATIVE À LA TENSION: Avant de

brancher l’outil sur une source d’alimentation (prise ou

autre dispositif), assurez-vous que la tension du circuit

correspond à celle qui est spécifiée sur la plaque

signalétique de l’outil. L’utilisation d’une source

d’alimentation dont la tension est supérieure à celle

spécifiée pour l’outil peut entraîner l’utilisateur à une

GRAVE BLESSURE et endommager l’outil. En cas de

doute, NE BRANCHEZ PAS L’OUTIL. L’utilisation d’une

source d’alimentation dont la tension est inférieure à la

valeur indiquée sur la plaque signalétique endommagera

le moteur.

UTLISEZ UN CORDON PROLONGATEUR ADÉQUAT.

Assurez-vous que le cordon prolongateur est en bon

état. Lors de l’utilisation d’un cordon prolongateur,

utilisez sans faute un cordon assez gros pour conduire le

courant que le produit nécessite. Un cordon trop petit

provoquera une baisse de tension de secteur, résultant

en une perte de puissance et une surchauffe. Le Tableau

1 indique la dimension appropriée de cordon selon sa

longueur et selon l’intensité nominale indiquée sur la

plaque signalétique. En cas de doute sur un cordon

donné, utilisez le cordon suivant (plus gros). Plus le

numéro de gabarit indiqué est petit, plus le cordon est

gros.

Tableau 1. Gabarit minimum du cordon

Intensité nominale

Volts Longueur totale du cordon en pieds

120 V 25 ft. 50 ft. 100 ft. 150 ft.

Plus de Pas plus de Calibre américain des fils

0 6 18 16 16 14

6 10 18161412

10 12 16 16 14 12

12 16 14 12 Non recommandé

17

Page 18

CONSIGNES DE SÉCURITÉ

ADDITIONNELLES

USB059-1

NE vous laissez PAS tromper (au fil d’une

utilisation répétée) par un sentiment

d’aisance et de familiarité avec le

produit, en négligeant le respect

rigoureux des consignes de sécurité qui

accompagnent la scie circulaire à table.

Si cet outil n’est pas utilisé de façon sûre

et adéquate, il y a risque de blessure

grave.

1. Portez une protection oculaire.

2. Ne vous servez pas de votre outil en présence de

gaz ou liquides inflammables.

3. N’utilisez JAMAIS l’outil sans y avoir installé une

meule à tronçonner abrasive.

4. Avant l’utilisation, assurez-vous que la lame ne

comporte aucune fissure et qu’elle n’est pas

endommagée. Remplacez immédiatement toute

lame fissurée ou endommagée.

5. Avant d’installer la lame, nettoyez l’axe, les

flasques (tout particulièrement leur surface

d’installation) et l’écrou hexagonal. La lame

risque de vibrer, d’osciller ou de glisser si elle

n’est pas correctement installée.

6. Utilisez le protecteur de lame et l’extenseur

chaque fois que cela est possible, y compris lors

des coupes sur toute la pièce. Pour monter et

installer le protecteur de lame, suivez toujours

étape par étape les instructions de ce manuel.

Les "coupes sur toute la pièce" sont celles où la

lame traverse complètement la pièce, comme

lors du sciage en long et des coupes en travers.

NE JAMAIS utiliser l’outil si son protecteur de

lame est déficient, ni fixer le protecteur de lame

avec une corde, une ficelle, etc. Tout

fonctionnement irrégulier du protecteur de lame

doit être corrigé immédiatement.

7. Après un travail qui nécessite le retrait du

protecteur, remettez immédiatement en place ce

dernier et l’extenseur.

8. Évitez de couper des pièces de métal telles que

les clous et vis. Avant de procéder à la coupe,

vérifiez la pièce pour en retirer les clous, vis et

autres corps étrangers.

9. Avant de mettre le contact, retirez de la table les

clés, bouts de pièce sciés et autres objets.

10. Ne portez JAMAIS de gants pendant l’utilisation

de cet outil.

11. Gardez les mains à l’écart de la trajectoire de la

lame.

12. Ne vous placez JAMAIS dans la trajectoire de la

lame et assurez-vous que personne ne s’y

trouve.

13. Assurez-vous que la lame ne touche pas

l’extenseur ou la pièce à scier avant de mettre le

contact.

14. Avant de scier la pièce elle-même, faites tourner

l’outil un instant à vide. Assurez-vous que la

lame ne vibre ou ne tremble pas, ceci pouvant

indiquer qu’elle est mal installée ou mal

équilibrée.

15. N’effectuez JAMAIS de réglages pendant que

l’outil tourne. Débranchez l’outil avant

d’effectuer les réglages.

16. Lorsque nécessaire, utilisez un bâton-poussoir.

Vous DEVEZ utiliser un bâton-poussoir pour

scier en long des pièces minces, de sorte que

vous mains et doigts demeurent à l’écart de la

lame.

17. Prêtez une attention particulière aux instructions

relatives à la réduction des risques de CHOC EN

RETOUR. Le choc en retour est une réaction

soudaine de l’outil provoquée par le coincement,

le pincement ou le désalignement de la lame.

Lors d’un CHOC EN RETOUR la pièce se trouve

projetée vers l’utilisateur par l’outil. LES CHOCS

EN RETOUR COMPORTENT UN RISQUE DE

BLESSURE GRAVE. Évitez les CHOCS EN

RETOUR en maintenant la lame bien affûtée, le

garde parallèle en position parallèle à la lame,

l’extenseur, les cliquets de prévention des chocs

en retour et le protecteur de lame bien en place

et en bon état de fonctionnement, en évitant de

relâcher la pièce avant de l’avoir fait progresser

complètement derrière la lame, et en évitant de

scier en long dans une pièce tordue, déformée

ou dont les bords inégaux ne permettent pas

l’utilisation du guide.

18. Ne sciez jamais à la volée. Le sciage à la volée

consiste à utiliser les mains au lieu d’un garde

parallèle ou d’un guide d’onglet pour soutenir ou

guider la pièce.

19. NE JAMAIS passer la main près ou au-dessus de

la lame. NE JAMAIS passer la main près de la

lame pour saisir une pièce à scier avant que la

lame ne soit complètement arrêtée.

20. Évitez de faire avancer l’outil de manière

brusque ou rapide. Faites-le avancer le plus

lentement possible lorsque vous sciez des

pièces dures. Évitez de plier ou tordre la pièce

pendant la progression de l’outil. Coupez

immédiatement le contact de l’outil si la lame se

bloque ou se coince dans la pièce. Débranchez

l’outil. Dégagez la lame.

21. NE JAMAIS retirer les bouts de pièce coupés ni

toucher le protecteur de lame pendant que la

lame tourne.

18

Page 19

22. AVANT de commencer la coupe, arrachez tous

les nœuds lâches non adhérents de la pièce.

23. Ne maltraitez pas le cordon. Ne tirez jamais

directement sur le cordon pour le débrancher de

la prise de courant. Maintenez le cordon à l’écart

de la chaleur, de l’eau, de l’huile et des objets à

bords tranchants.

24. Certains matériaux contiennent des produits

chimiques qui peuvent être toxiques. Prenez les

précautions nécessaires pour ne pas inhaler les

poussières qu’ils dégagent et pour éviter tout

contact avec la peau. Respectez les consignes

de sécurité fournies par le fabricant des

matériaux utilisés.

25. Vous pouvez soulever le protecteur pendant la

mise en place de la pièce à travailler et pour

faciliter le nettoyage. Assurez-vous toujours que

le capot du protecteur est abaissé et se trouve à

plat contre la table avant de brancher l’outil.

CONSERVEZ CES

INSTRUCTIONS

AVERTISSEMENT:

LA MAUVAISE UTILISATION de l’outil ou

l’ignorance des consignes de sécurité du

présent manuel d’instructions comporte un

risque de blessure grave.

Pose

Placement de la scie circulaire à table

006875

459 mm

(18-1/16")

1. Diamètre

d’orifice 8 mm

(5/16 po)

006148

1. Rondelle

ordinaire de 6

mm (1/4” )

2. Boulon et écrou

1

Placez la scie circulaire à table dans un emplacement

bien éclairé et de niveau, où vous pourrez maintenir une

position stable et équilibrée. Elle doit être installée dans

un emplacement fournissant l’espace nécessaire à la

facilité des manipulations, suivant la taille des pièces à

travailler. La scie circulaire à table doit être fixée à l’établi

ou au support de scie circulaire à table au moyen de

quatre vis ou boulons, en utilisant les orifices prévus à

cet effet au bas de la scie circulaire à table. Si vous

installez la scie circulaire à table sur un établi, assurezvous que ce dernier comporte une ouverture sur le

dessus et que cette ouverture est de taille identique à

celle se trouvant sur la face inférieure de la scie circulaire

à table, de sorte que la sciure de bois puisse s’y

échapper.

Il faudra fixer l’établi ou le support de scie circulaire à

table au plancher si, pendant la coupe, la scie circulaire à

table a tendance à basculer, glisser ou bouger.

NOTE:

• Support de scie circulaire

Les modèles 2702X1 et 2703X1 sont équipés en

standard d’un support de scie circulaire.

Rangement des accessoires

1

2

006858

1. Guide d’onglet

de montage de

6 mm (1/4” ) –

Serrer

fermement

1

25 mm

(1")

2

334 mm

(13-1/8")

1

006146

1. Rondelle

ordinaire de 6

mm (1/4” )

2. Vis à bois no 10,

longueur min.

40 mm (1-1/2

po)

006859

1. Garde parallèle

1

Le guide d’onglet et les clés se rangent du côté gauche

de la base, et le garde parallèle du côté droit de la base.

19

Page 20

DESCRIPTION DU

FONCTIONNEMENT

ATTENTION:

• Assurez-vous toujours que l’outil est hors tension et

débranché avant de l’ajuster ou de vérifier son

fonctionnement.

Réglage de la profondeur de coupe

006860

1. Poignée

Réglage des butées fixes

2

1

(A)

90

45

006862

1. Vis de réglage

90°

2. Vis de réglage

45°

006157

1

Le réglage de la profondeur de coupe s’effectue en

tournant la poignée. Tournez la poignée dans le sens des

aiguilles d’une montre pour élever la lame, et en sens

inverse pour l’abaisser.

NOTE:

• Réglez-la sur une faible profondeur lorsque vous

coupez des matériaux minces, afin d’obtenir une

coupe plus nette.

Réglage de l’angle de coupe en biseau

1

2

Desserrez le levier de verrouillage en le tournant dans le

sens inverse des aiguilles d’une montre et tournez le

volant de commande jusqu’à l’angle désiré (0° à 45°).

L’angle de coupe en biseau est indiqué par le pointeur

flèche.

Une fois l’angle désiré obtenu, serrez le levier de

verrouillage en le tournant dans le sens des aiguilles

d’une montre pour conserver ce réglage.

ATTENTION:

• Une fois l’angle de coupe en biseau réglé, n’oubliez

pas de serrer fermement le levier de verrouillage.

006861

3

1. Levier de

verrouillage

2. Volant de

commande

3. Pointeur flèche

90

(B)

L’outil est équipé de butées fixes sur les positions

correspondant à 90° et 45° sur la surface de la table.

Pour vérifier et régler les butées fixes, procédez comme

suit :

Déplacez le volant de commande le plus loin possible en

le tournant. Placez une règle triangulaire sur la table et

vérifiez que la lame se trouve à un angle de 90° ou 45°

par rapport à la surface de la table. Si la lame se trouve

sur un angle indiqué sur la Fig. A, tournez les vis de

réglage dans le sens des aiguilles d’une montre ; si elle

se trouve sur un angle indiqué sur la Fig. B, tournez-les

dans le sens inverse pour ajuster les butées fixes.

Une fois les butées fixées réglées, réglez la lame sur un

angle de 90° par rapport à la surface de la table. Ajustez

ensuite la pointe de la flèche de sorte que son bord de

droite soit aligné sur la valeur de graduation 0°.

45

006864

1

1. Pointeur flèche

20

Page 21

Interrupteur

1

006868

1. Levier de

I’interrupteur

2. Clé

2

ATTENTION:

• Avant de brancher l’outil, assurez-vous toujours

que le levier de l’interrupteur fonctionne

correctement et retourne en position d’arrêt.

Cet outil est doté d’un interrupteur spécial qui prévient le

démarrage accidentel. Pour faire démarrer l’outil,

enfoncez d’abord le levier de l’interrupteur. Tout en le

maintenant enfoncé, tirez sa partie inférieure vers vous.

Pour arrêter l’outil, appuyez sur la partie inférieure du

levier de l’interrupteur.

Lors de l’utilisation du levier de l’interrupteur, il est

pratique de le regarder par la fenêtre de la table.

ATTENTION:

• Lorsque vous avez terminé d’utiliser l’outil, retirez la

clé et rangez-la dans un endroit sûr. Cela évitera

l’utilisation de l’outil sans autorisation.

• Ne tirez pas fort sur le levier de l’interrupteur sans

la clé. Vous risqueriez de casser l’interrupteur.

006869

ASSEMBLAGE

ATTENTION:

• Avant d’effectuer toute intervention sur l’outil,

assurez-vous toujours qu’il est hors tension et

débranché.

À sa sortie d’usine, la lame et le protecteur de lame ne

sont pas installés sur l’outil. Procédez comme suit pour

l’assemblage :

Pose et retrait de la lame de scie

ATTENTION:

• Assurez-vous toujours que l’outil est hors tension et

débranché avant de poser ou de retirer la lame.

• Utilisez exclusivement la clé à douille Makita

fournie pour poser ou retirer la lame. Sinon, le

boulon hexagonal risque d’être trop ou pas assez

serré. Cela peut entraîner une blessure.

32

Retirez la fiche de la table. Immobilisez le flasque

extérieur au moyen de la clé coudée et desserrez l’écrou

hexagonal avec la clé en tournant dans le sens inverse

des aiguilles d’une montre. Retirez ensuite le flasque

extérieur.

Montez le flasque intérieur, la lame, le flasque extérieur

et l’écrou hexagonal sur l’arbre, en vous assurant que les

dents de la lame pointent vers le bas à l’avant de la table.

Posez toujours l’écrou hexagonal en orientant sa face

enfoncée vers le flasque extérieur.

12

ATTENTION:

• Gardez la surface du flasque propre en essuyant

les saletés ou autres matières adhérentes ; cela

peut causer le glissement de la lame. Assurez-vous

que la lame est installée de sorte que les dents

soient alignées dans le sens de la coupe (rotation).

Pour installer fermement la lame en place, immobilisez le

flasque extérieur à l’aide de la clé coudée, puis serrez

l’écrou hexagonal en le tournant dans le sens des

aiguilles d’une montre avec la clé. VOUS DEVEZ

SERRER L’ÉCROU HEXAGONAL FERMEMENT.

006852

1. Clé

2. Écrou

hexagonal

3. Clé coudée

1

006136

1. Flasque

4

3

intérieur

2. Flasque

extérieur

3. Lame

4. Écrou

hexagonal

21

Page 22

006854

1. Clé

2. Clé coudée

2

1

ATTENTION:

• Vous devez tenir l’écrou hexagonal avec précaution

à l’aide de la clé. Si vous perdIez prise la clé

risquerait de s’écarter de l’écrou hexagonal et votre

main pourrait frapper contre le tranchant de la

lame.

Installation du protecteur de lame

1

006853

2

3

4

1. Protecteur de

lame

2. Extenseur

3. Cliquet de

prévention des

chocs en retour

4. Plaque de

pression

ATTENTION:

• Avant d’installer le protecteur de lame, réglez la

profondeur de coupe sur l’élévation maximale.

Insérez l’extenseur entre la pièce de montage du

protecteur de lame (l’étai) et la plaque de pression.

Serrez les boulons hexagonaux (A) à l’aide de la clé

coudée. Le point d’installation de l’extenseur est ajusté

en usine de sorte que la lame et l’extenseur se trouvent

en ligne droite. S’ils ne sont pas en ligne droite,

desserrez les boulons hexagonaux (B) et ajustez la pièce

de montage du protecteur de lame (l’étai) de sorte que

l’extenseur se trouve dans l’alignement direct de la lame

derrière celle-ci. Serrez ensuite les boulons hexagonaux

(B) pour immobiliser l’étai.

006856

6

3

1

4

5

7

1. Ces deux

espaces doivent

être égaux.

2

2. Partie du

protecteur de

lame

3. Lame

4. Extenseur

5. Plaque de

pression

6. Boulons

hexagonaux (A)

7. Boulons

hexagonaux (B)

ATTENTION:

• Tenez toujours la clé coudée par sa partie rayée

pour visser les boulons hexagonaux. Si vous serrez

le boulons hexagonaux en tenant la clé coudée

plus loin que sur sa partie rayée, vous risquez

d’endommager les boulons et/ou de vous blesser à

la main.

• Si la lame et l’extenseur ne sont pas bien alignés, la

lame risque de se coincer dangereusement

pendant la coupe. Assurez-vous qu’ils sont bien

alignés. Vous risquez une grave blessure si vous

utilisez l’outil alors que l’extenseur n’est pas bien

aligné.

• N’effectuez JAMAIS de réglages pendant que l’outil

tourne. Débranchez l’outil avant d’effectuer les

réglages.

Il doit y avoir un espace libre d’environ 4 à 5 mm (5/32 po

à 3/64 po) entre l’extenseur et les dents de la lame.

Réglez l’extenseur en conséquence et serrez les boulons

hexagonaux (A) fermement. Fixez la fiche sur la table,

puis assurez-vous que le protecteur de lame se déplace

de manière fluide avant de procéder à la coupe.

21

4 - 5 mm

(5/32" - 13/64")

006863

1. Extenseur

2. Protecteur de

lame

22

Page 23

Installation et réglage du garde parallèle

006865

1. Support du

garde

2. Rail-guide

3. Poignée

1

006867

2

Soulevez la poignée du garde parallèle. Installez le garde

parallèle sur la table de sorte que le support du garde

3

s’engage dans le rail de guidage. Abaissez la poignée

pour serrer le garde parallèle.

Pour vous assurer que le garde parallèle est parallèle à

la lame, fixez-le à 2 ou 3 mm (5/64 po à 1/8 po) de la

lame. Soulevez la lame jusqu’à l’élévation maximale.

Marquez une des dents de la lame avec un crayon.

Mesurez la distance (A) et la distance (B) entre le garde

parallèle et la lame. Effectuez ces deux mesures avec la

dent marquée au crayon. Ces deux mesures doivent être

identiques. Si le garde parallèle n’est pas parallèle à la

lame, procédez comme suit :

A

006866

1. Échelle

B

1

006881

1

1. Boulons

hexagonaux

2. Écrou de

réglage

3. Poignée

2

3

ATTENTION:

• Tenez toujours la clé par sa partie rayée pour visser

les boulons hexagonaux. Si vous serrez le boulons

hexagonaux en tenant la clé plus loin que sur sa

partie rayée, vous risquez d’endommager les

boulons et/ou de vous blesser à la main.

6. Avec la poignée du garde parallèle abaissée,

tournez l’écrou de réglage dans le sens des

aiguilles d’une montre pour immobiliser la partie

arrière du garde parallèle. Ne tournez pas trop

l’écrou de réglage dans le sens des aiguilles d’une

montre. Vous risqueriez d’avoir du mal à placer le

garde parallèle parallèlement à la lame lorsque

vous modifiez la position de ce dernier.

ATTENTION:

• Vous devez régler le garde parallèle de sorte qu’il

soit parallèle à la lame, autrement il y a risque de

dangereux choc en retour.

Amenez le garde parallèle parfaitement contre le côté de

la lame. Assurez-vous que le pointeur flèche du support

du garde indique la graduation 0. Si le pointeur flèche

n’indique pas la graduation 0, desserrez la vis du secteur

angulaire et ajustez ce dernier.

1

006882

1. Vis

2. Support du

garde

3. Secteur

angulaire

2

4. Flèche

4

3

1. Tournez l’écrou de réglage dans le sens inverse

des aiguilles d’une montre, de quelques tours.

2. Desserrez les deux boulons hexagonaux du garde

parallèle à l’aide de la clé fournie.

3. Ajustez le garde parallèle jusqu’à ce qu’il soit

parallèle à la lame.

4. Abaissez la poignée pour immobiliser le garde

parallèle.

5. Serrez les deux boulons hexagonaux du garde

parallèle.

UTILISATION

ATTENTION:

• Utilisez toujours des dispositifs tels que bâtons-

poussoirs et blocs-poussoirs lorsque vos mains ou

doigts courent le risque de se trouver près de la

lame pendant le sciage.

• Tenez toujours la pièce fermement avec la table et

le garde parallèle ou le guide d’onglet. Évitez de la

plier ou de la tordre pendant la progression de

l’outil. Si la pièce se plie ou se tort, il y a risque de

choc en retour dangereux.

23

Page 24

• NE JAMAIS retirer la pièce pendant que la lame

tourne. Si vous devez retirer la pièce avant d’avoir

terminé la coupe, coupez d’abord le contact de

l’outil sans cesser de tenir la pièce fermement.

Attendez que la lame se soit complètement arrêtée

avant de retirer la pièce. Autrement il y a risque de

choc en retour dangereux.

• NE JAMAIS retirer le matériau coupé pendant que

la lame tourne.

• NE JAMAIS placer les doigts ou la main dans la

trajectoire de la lame. Soyez tout particulièrement

prudent lors des coupes en biseau.

• Immobilisez toujours le garde parallèle fermement,

autrement il y a risque de choc en retour

dangereux.

• Utilisez toujours des “dispositifs d’aide” tels que

bâtons-poussoirs et blocs-poussoirs lorsque vous

coupez des pièces petites ou étroites, ou lorsque le

Dado n’est pas visible pendant la coupe.

Dispositifs d’aide

Les bâtons-poussoirs, les blocs-poussoirs et le garde

auxiliaire sont autant de types de “dispositif d’aide”.

Utilisez-les pour effectuer vos coupes de manière sûre et

en toute sécurité, sans avoir à toucher la pièce avec une

partie quelconque du corps.

Bâton-poussoir

130mm(5")

75mm(3")

19mm

(3/4")

40mm

(1-1/2")

(H)

9.5mm(3/8")

9.5mm(3/8")

380mm(15")

50mm(2")

Il est facile de fabriquer un bâton-poussoir à partir d’une

pièce de contre-plaqué de 19 mm (3/4 po) à 25 mm (1

po) d’épaisseur.

Détachez la partie hachurée du bâton et adoucissez les

bords à l’aide d’une lime. La hauteur (H) doit être

inférieure à 12.7 mm (1/2 po), c’est-à-dire inférieure à

celle de la pièce.

006876

50mm

(2")

Bloc-poussoir

120mm

(4-3/4")

1

2

130mm

(5")

3

300mm(12")

6mm

(1/4")

9.5mm

(3/8")

50mm

(2")

50mm(2")

300mm(12")

8mm(5/16")

130mm(5")

100mm

4

(4")

006219

1. Face/bord

2. Poignée

3. Vis à bois

4. Coller ensemble

50mm

(2")

parallèle

Utilisez une pièce de contreplaqué de 19 mm (3/4 po).

La poignée doit se trouver au centre de la pièce de

contreplaqué. Collez avec de la colle et des vis à bois, tel

qu’illustré. Il faut toujours coller des petites pièces de

bois de 9.5 mm x 8 mm x 50 mm (3/8 po x 5/16 po x 2

po) sur la pièce pour éviter que la lame ne s’émousse si

vous coupez par erreur dans le bloc-poussoir. (Le blocpoussoir doit toujours être exempt de clous.)

Garde auxiliaire

9.5mm

(3/8")

1

Utilisez des pièces de contreplaqué de 9.5 mm (3/8 po)

et 19 mm (3/4 po) pour fabriquer votre garde auxiliaire.

19mm

(3/4")

460mm

(18")

120mm

(4-3/4")

140mm

(5-1/2")

006211

40mm

(1-1/2")

1. Face/bord

parallèle

Collez-le avec de la colle et des vis à bois.

Parement de bois (garde parallèle)

006883

1. Vis à bois no 10

(assez longues

pour pénétrer

jusqu’à la moitié

du parement)

1

Un parement de bois doit être utilisé pour les coupes au

cours desquelles la lame se rend près du garde parallèle.

24

Page 25

Le parement de bois utilisé avec le garde parallèle doit

être de la même dimension que ce dernier. Assurez-vous

que la face inférieure du parement est bien à plat sur la

surface de la table.

Sciage en long

ATTENTION:

• Pour le sciage en long, retirez le guide d’onglet de

la table.

• Lorsque vous coupez des pièces longues ou

larges, installez toujours des dispositifs de soutien

adéquats sous la table. NE PAS laisser un long

panneau se déplacer ou bouger librement sur la

table. La lame se coincerait et les risques de choc

en retour et de blessure augmenteraient. Le

dispositif de soutien doit être de la même hauteur

que la table.

Avant d’utiliser la scie circulaire à table, assurez-vous

que les cliquets de prévention des chocs en retour

fonctionnent bien. Arrêtez l’outil et débranchez-le.

Introduisez la pièce à couper sous le protecteur de lame

et le long des deux côtés de la lame pour simuler une

coupe. Essayez de retirer la pièce par chacun des côtés

en la tirant vers vous. Les cliquets de prévention des

chocs en retour doivent saisir la pièce et l’empêcher de

reculer vers vous. Maintenez toujours les cliquets de

prévention des chocs en retour bien aiguisés pour qu’ils

fonctionnent correctement. Pour les affûter et maintenir

leur forme originale, utilisez une lime ronde.

1. Réglez la profondeur de coupe un peu plus haut

que l’épaisseur de la pièce.

006886

006887

(2) Si la largeur de coupe est de 65 mm à 150

mm (2-1/2 po à 6 po) utilisez le bâton-

poussoir pour faire avancer la pièce.

006888

1. Bâton-poussoir

1

(3) Si la largeur de coupe est inférieure à 65 mm

(2-1/2 po), il n’est pas possible d’utiliser le

bâton-poussoir puisqu’il frappera contre le

protecteur de lame. Utilisez le garde auxiliaire

et le bloc-poussoir. Fixez le garde auxiliaire

au garde parallèle avec deux dispositifs de

serrage “C”.

006889

1. Garde auxiliaire

1

2. Placez le garde parallèle sur la largeur de coupe

longitudinale désirée et verrouillez-le en place en

abaissant la poignée. Avant de procéder au sciage

en long, assurez-vous que l’extrémité arrière du

garde parallèle est fermement immobilisée. Si elle

ne l’est pas, suivez la procédure décrite à la section

intitulée “ Installation et réglage du garde parallèle”.

3. Mettez le contact et faites avancer doucement la

pièce vers la lame le long du garde parallèle.

(1) Si la coupe est d’une largeur de 150 mm (6

po) ou plus, utilisez prudemment votre main

droite pour faire progresser la pièce. Utilisez

la main gauche pour maintenir la pièce

appuyée contre le garde parallèle.

25

Faites avancer la pièce avec la main jusqu’à

ce que le bout se trouve à environ 25 mm (1

po) du bord avant de la table. Continuez de la

faire avancer avec le bloc-poussoir sur la

partie supérieure du garde auxiliaire jusqu’à

ce que la coupe soit terminée.

006874

1. Bloc-poussoir

1

2. Garde auxiliaire

2

Page 26

Coupe en travers

ATTENTION:

• Pour effectuer une coupe en travers, retirez le

garde parallèle de la table.

• Pour couper des pièces longues ou larges, installez

toujours des dispositifs de soutien adéquats des

deux côtés de la table. Le dispositif de soutien doit

être de la même hauteur que la table.

• Maintenez toujours les mains à l’écart de la

trajectoire de la lame.

Guide d’onglet

1

34