Page 1

400

mm

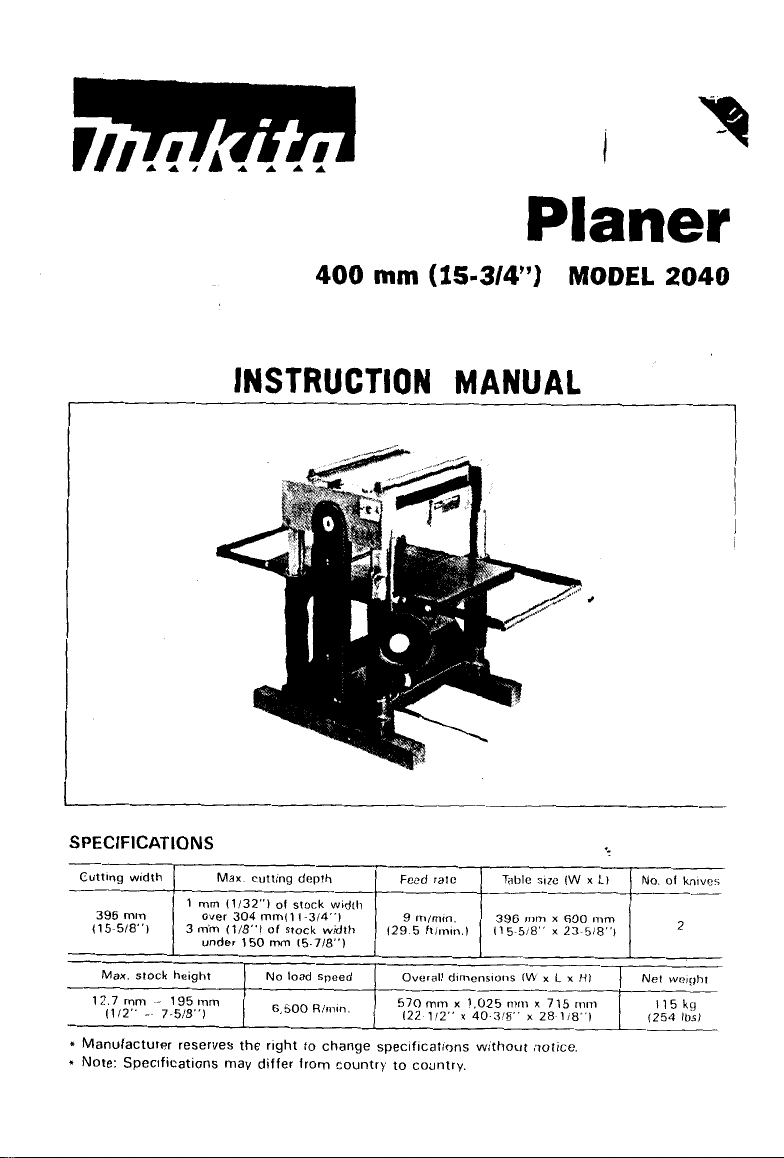

Planer

(15-3/4")

MODEL

2040

SPEC

396

I1

5~518")

Max.

12.7

IF I CAT

mm

srock

mm

1112"

-

-

7-518")

INSTRUCTION

IONS

1

mm

11/32")

of

stock

over

3

mm

under

height

195mm

304

mmll 1-314")

1118"l

of

150

mm

No

stock

load

6,500

wtdth

width

15-718")

speed

,,,,

In,

129

570

MANUAL

9

m/mm

5

ftimin.1

Overall

mm

122

112"

396

115 5/8"

dimenslons

x

1,025

x

40.318''

111111

mm

(W

x

x

x

715

28

x

x

L

600

23

x

rnnl

118"l

nim

5/8"1

HI

Net

115

(254

2

weight

kg

Ibsl

Page 2

For Your Own Safety Read Instruction

Manual Before Operating Planer

GENERAL SAFETY PRECAUTIONS

(For

All

Tools)

1.

KNOW YOUR POWER TOOL. Read the owner's manual carefully. Learn the

tools applications and limitations, as well as the specific potential hazards

peculiar to

2.

KEEP GUARDS IN PLACE and

3.

REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to

see that keys and adjusting wrenches are removed from tool before turning

it

on.

4.

KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

5. DON'T USE IN DANGEROUS ENVIRONMENT. Don't use power tools

or

wet locations, or expose them to rain. Keep work area well lighted.

6.

KEEP CHILDREN AWAY. All visitors should be kept safe distance from work

area.

7.

MAKE WORKSHOP KID

removing starter keys.

8.

DON'T FORCE TOOL.

it

was designed.

9.

USE RIGHT TOOL. Don't force tool or attachment to do a job for which

was not designed.

10.

WEAR PROPER APPAREL. Wear no

bracelets, or other jewelry which may get caught

footwear is recommended. Wear protective hair covering to contain long hair.

11.

ALWAYS USE SAFETY GLASSES. Also use face or dust mask

ation is dusty. Everyday eyeglasses only have impact resistant lenses, they

are NOT safety glasses.

12.

SECURE WORK. Use clamps or a vise to hold work when practical. It's safer

than using your hand and

13.

DON'T OVERREACH. Keep proper footing and balance at all times.

14.

MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and

safest performance. Follow instructions for lubricating and changing accessories.

15. DISCONNECT TOOLS before servicing; when changing accessories such as

blades, bits, cutters, and the like.

it.

in

working order.

in

damp

PROOF

It

will do the job better and safer at the rate for which

it

with padlocks, master switches, or by

loose

clothing, gloves, neckties, rings,

frees both hands to operate tool.

in

moving parts. Nonslip

if

cutting oper-

it

"

Page 3

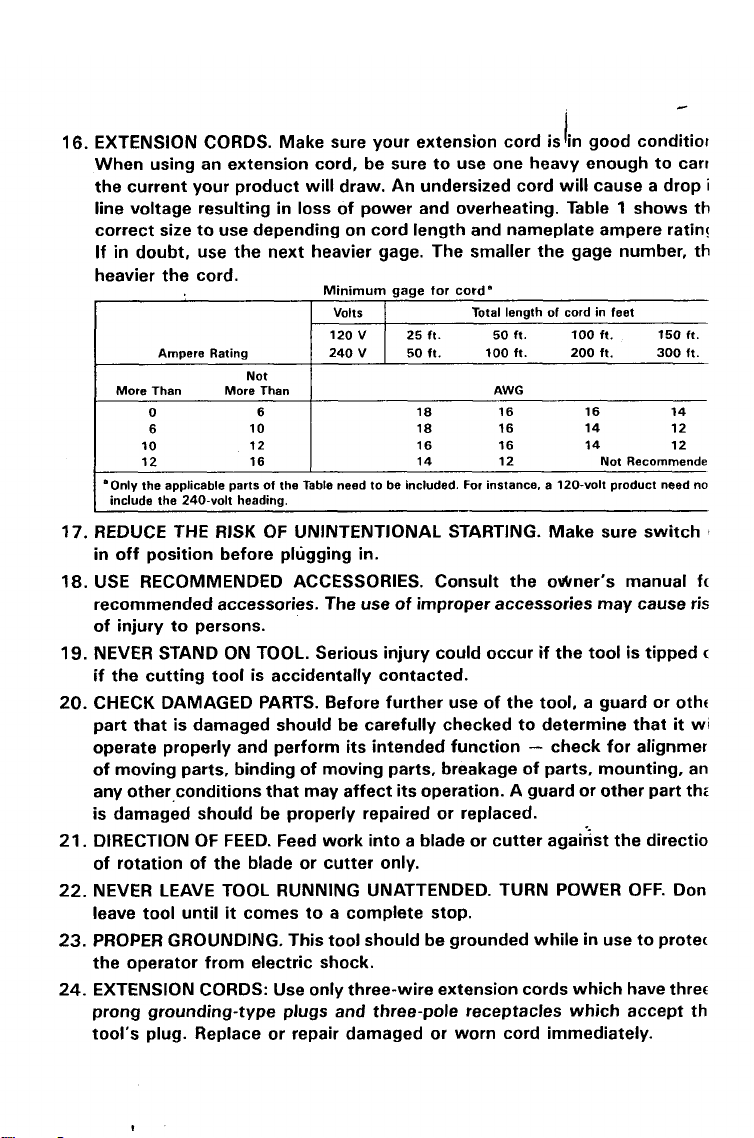

Volts

Ampere Rating

More Than More Than

0

6 10

10 12

12 16

'Only the applicable parts of the Table need to be included. For instance. a 120-volt product need no

I

include the 240-volt headina.

Not

6

12OV 25ft. 50ft. 100ft. 150

240V 5011. 100 ft. 200 ft.

Total length of cord in feet

300

AWG

18 16 16 14

18 16 14 12

16 16 14 12

14 12 Not Recommende

17. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure switch

in

off position before plugging

18.

USE RECOMMENDED ACCESSORIES. Consult the owner's manual fc

in.

recommended accessories. The use of improper accessories may cause ris

of injury to persons.

19.

NEVER STAND ON TOOL. Serious injury could occur

if

the cutting tool is accidentally contacted.

20.

CHECK DAMAGED PARTS. Before further use of the tool, a guard or otht

part that is damaged should be carefully checked to determine that

operate properly and perform its intended function

if

the tool is tipped

-

check for alignmer

it

of moving parts, binding of moving parts, breakage of parts, mounting, an

any other.conditions that may affect its operation. A guard or other part

is damaged should be properly repaired or replaced.

21.

DIRECTION OF FEED. Feed work into a blade or cutter against the directio

of rotation of the blade or cutter only.

22.

NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don

leave tool

23.

PROPER GROUNDING. This tool should be grounded while

until

it

comes to a complete stop.

in

use to protec

the operator from electric shock.

24.

EXTENSION CORDS: Use only three-wire extension cords which have threr

prong grounding-type plugs and three-pole receptacles which accept th

tool's plug. Replace or repair damaged or worn cord immediately.

ft.

ft.

c

wi

thc

I

Page 4

3LTAGE WARNING: Before connecting the tool to a power source (receptacle,

Itlet, etc.) be sure the voltage supplied is the same as that specified on the

meplate of the tool. A power source

)r the tool can result

le tool. If

in

doubt, DO NOT PLUG IN THE TOOL. Using a power source

in

SERIOUS INJURY to the user - as well as damage to

with

voltage greater than that specified

with

oltage less than the nameplate rating is harmful to the motor.

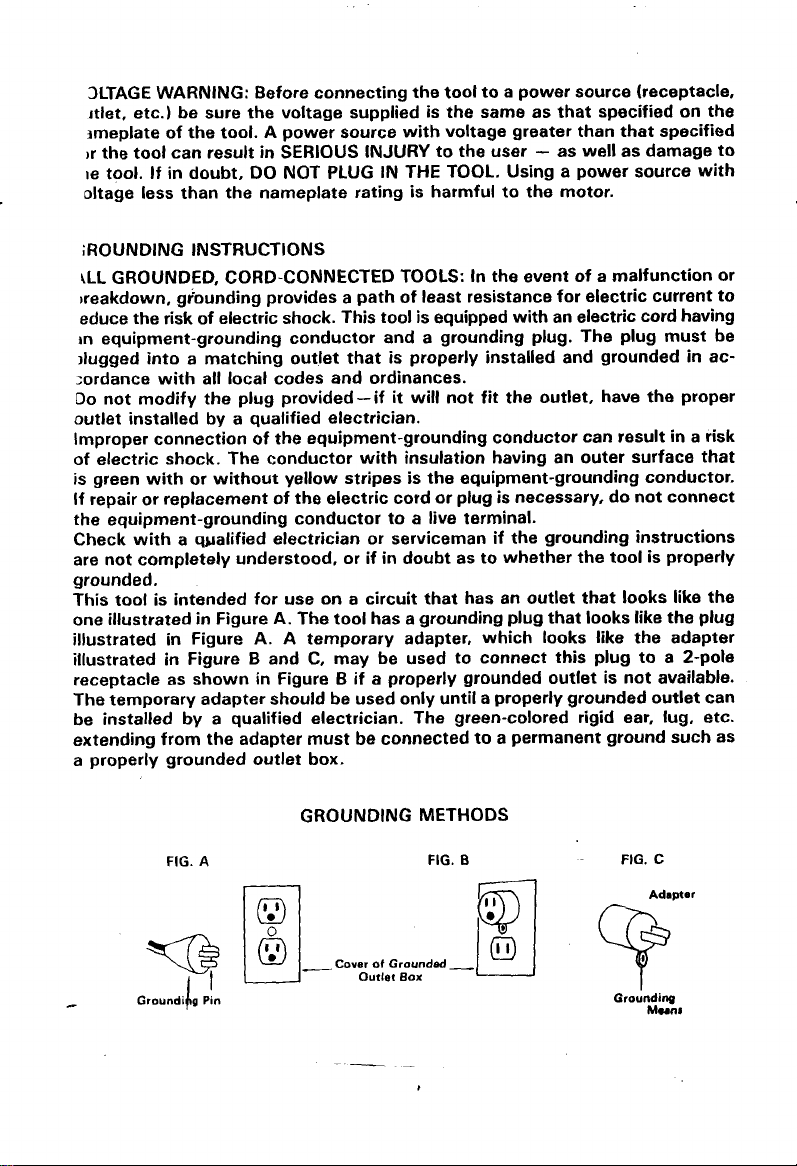

;ROUNDING INSTRUCTIONS

\LL GROUNDED, CORD-CONNECTED

TOOLS:

In

the event of a malfunction or

Breakdown, giounding provides a path of least resistance for electric current to

educe the risk of electric shock. This tool is equipped with an electric cord having

an

equipment-grounding conductor and a grounding plug. The

ilugged into a matching outlet that is properly installed and grounded

plug

must be

in

ac-

zordance with all local codes and ordinances.

Do

not modify the

plug

provided-if

it

will

not fit the outlet, have the proper

outlet installed by a qualified electrician.

in

Improper connection of the equipment-grounding conductor can result

of electric shock. The conductor

is

green with or without yellow stripes is the equipment-grounding conductor.

If

repair or replacement of

the

with

insulation having an outer surface that

electric cord or plug is necessary, do not connect

a risk

the equipment-grounding conductor to a live terminal.

Check with a qualified electrician or serviceman if the grounding instructions

are not completely understood, or if

in

doubt as to whether the tool is properly

grounded.

This tool is intended for use on a circuit that has an outlet that looks like the

one illustrated

illustrated

illustrated

receptacle as shown

The temporary adapter should be used only

be installed by a qualified electrician. The green-colored rigid ear,

in

Figure A. The tool has a grounding

in

Figure A. A temporary adapter, which looks like the adapter

in

Figure B and C, may be used

in

Figure B if a properly grounded outlet is not available.

until

plug

that looks like the

to

connect this

plug

to a 2-pole

a properly grounded outlet can

lug,

plug

etc.

extending from the adapter must be connected to a permanent ground such as

a properly grounded outlet box.

FIG.

Groundibg

A

Pin

GROUNDING METHODS

FIG.

B

--

I

~

FIG.

C

Grounding

Munl

Page 5

ADDITIONAL

1.

Wear eye protection.

2. Never perform planing operation with drive guard removed.

3.

Do not perform planing operations on material shorter than (a dimension

equal to the cutter head length plus 2 inches), narrower than

wider than (the cutter capacity

4.

Don't use the tool

5.

Handle the blades very carefully.

6. Check the blades carefully for cracks or damage before operation. Replace

cracked

7.

Be sure the planer blade installation bolts are securely tightened before

operating.

8.

Sharpen both blades evenly, or replace both blades or both cutterhead covers

at the same time.

9.

Remove nails and clean the workpiece before cutting. Nail, sand or other

matter can cause blade damage.

10.

Make sure

on.

11.

Wait

12.

Keep hands away from rotating parts.

13. Don't back the workpiece toward the infeed table.

14.

Two or more pieces of narrow but similar thickness stock can be passed

through the auto-planer side by side.

However, allow some spacing between the stock to permit the feed rollers

to grip the thinnest piece.

Otherwise, a slightly thinner piece could be kicked back by the cutterhead.

15. Stop operation immediately if you notice anything abnormal.

16. Always switch off and wait for blades to come to a complete stop before

adjusting any parts, cleaning out chips or approaching the blade.

17.

Never stick your finger into

damp wood. Turn off the planer and then clean out chips with a stick.

18. Don't touch blades right after operation, they may be extremely hot and could

burn your skin.

19.

Don't abuse cord. Never yank cord to disconnect from receptacle. Keep cord

from heat,

or

damaged blades immediately.

the

until

the blades attain full speed before cutting.

oil

in

presence of flammable liquids or gases.

blade is not contacting workpiece before

and sharp edges.

SAFETY

RULES

314

in

inches) or thinner than

the

chip chute. Chute may jam when cutting

1/2

inch.

the

switch is turned

inch, or

SAVE THESE INSTRUCTIONS.

Page 6

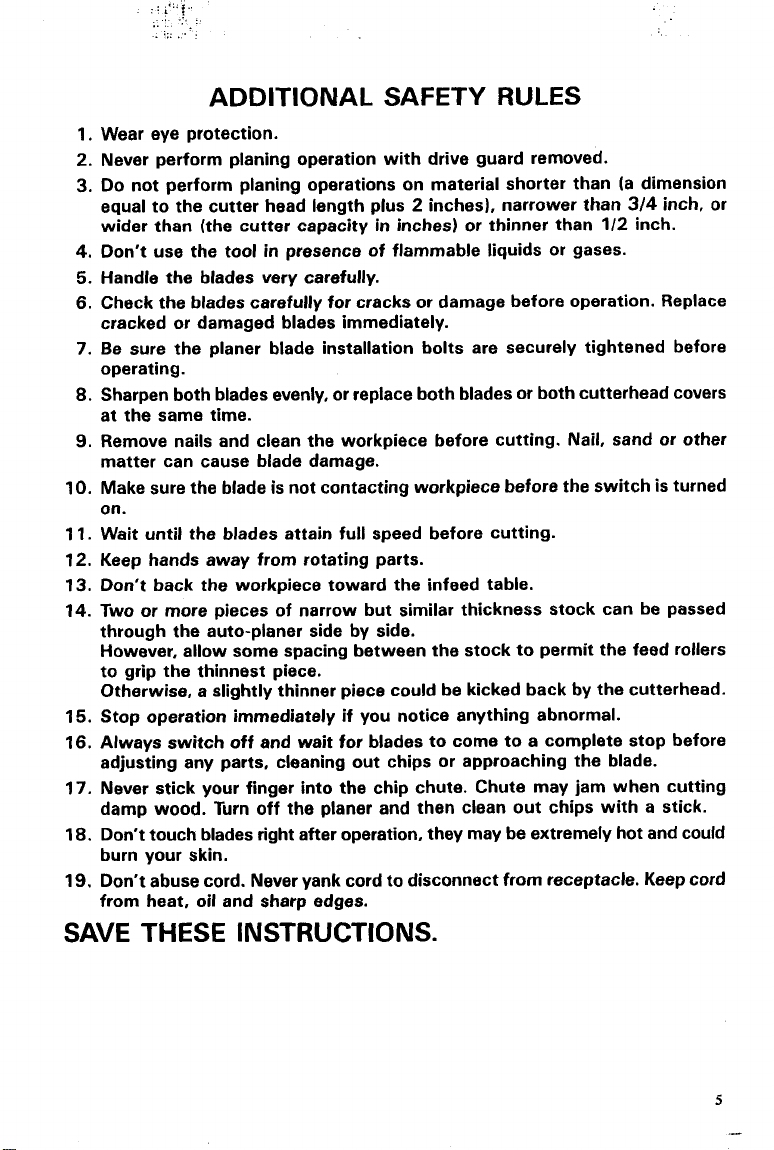

the scale bar graduation for the desired

finished dimension

is

reached. Algin your

workpiece with the top of the table. (One

handle revolution makes for

3

mm

(1/8")

ascent or descent.)

Gauge height shows the amount

of

cut Fig.

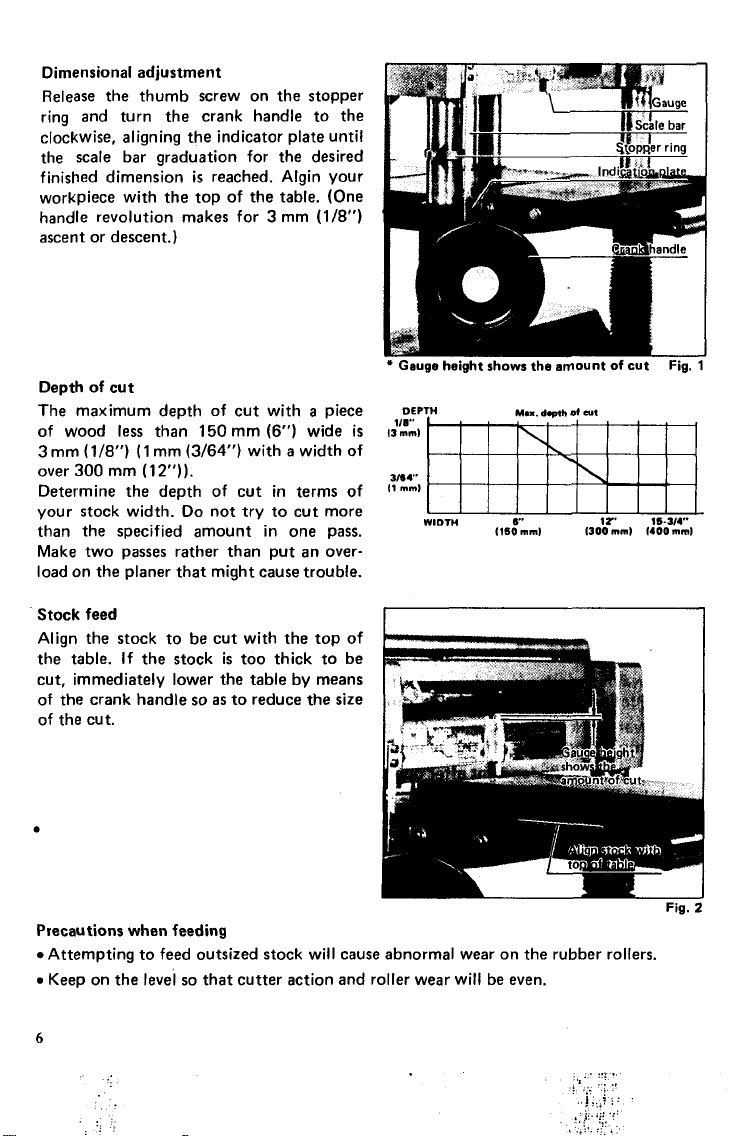

Depth of cut

is

118-

I3

3m4"

11

OEP

mml

mml

WIDTH

1150

c'

mml

1300

1I'

mml

The maximum depth of cut with

of wood

3

mm

over

less

(1/8") (1

300

mm

than

mm

(1

2")).

150

mm

(3/64")

with a width of

(6")

a

piece

wide

Determine the depth of cut in terms of

your stock width.

Do

not try to

cut

more

than the specified amount in one pass.

Make two passes rather than put an overload on the planer that might cause trouble.

Stock feed

Align the stock to be cut with the top

the table. If the stock

is

too thick to be

of

cut, immediately lower the table by means

of

the

crank handle

so

as

to reduce

the

size

of the cut.

Precautions when feeding

*Attempting to feed outsized stock will cause abnormal wear on the rubber rollers.

Keep on the

level

so

that cutter action and roller wear will be even.

16-314"

1400mml

Fig.

1

:

6

Page 7

Return

Returning cut stock back to the front side

is

very easy if you use the convenient re-

turn rollers on

top.

Stopper regulating depth

Numerous workpieces can be planed to the

same thickness very simply just by setting

the stopper ring to the desired dimension.

Do

not crank the handle

so

hard that you

force the stopper ring to move.

-~

~

Return rollers

Fig.

Key

safety

switch

is

This machine can only be switched on after the key

inserted in the switch. The key can

be removed with the switch in the "ON" condition, and the tool may be switched

without the key. When.unattended, the machine should

be

both

"OFF"

and unplugged.

4

off

7

Page 8

a.

Loosen the pan hd. screws on the

set

plates with the

(+)

screwdriver, then swing the

plates.

the

Remove

chip guard, lift the lever and swing

on the belt guard side to align the cutter drum

it

a

full 180 degrees; then use the knob

as

shown in Fig.

6.

Next, release the lever to make the drum stationary.

b.

Remove the 8 hex bolts with the socket wrench provided, then take

cover (cutter retaining plate). Use the end

cutter out slightly.

tion seen in Fig.

Cutter knife Drum cover

Raise

7;

the lever, once more making the drum stationary

then remove the cutter knife.

of

the socket wrench handle to push the

off

the drum

at

set

Fig.

the posi-

Fig.

7

Page 9

CUTTER KNIFE INSTALLATION

HEIGHT ADJUSTMENT

a.

At the position shown in Fig.

so

the knife

those on the drum.

levellers on each

the holes are aligned with

Set

end

of

7,

the wooden

the knife edge

and press down on both ends until the

is

main frame surface

contacted.

The levellers should be pressed down

just above the hex bolt holes on either

end.

at

b. Fix the cutter drum

6,

shown in Fig.

attach the durm cover

the position

and fasten securely the hex bolts.

Tightening

all

bolts fully in order may

cause the knife to move. At first,

tighten bolts gradually and evenly before applying the final tightening torque.

&

insert

c.

Secure the lever

found

it

at

raised, then

at

the position you

when the chip guard was

set

the lever on top

right), pressing down very gently and

turning the cutter drum in the arrow

direction. The leveller should move the

same amount when placed over either

-

(i.e.,

1/4”)).

end of one and the same knife

prox.

5

-

6

mm

(3/16”

adjusting knife height on both knives,

as

replace chip guard

before. Replace

guards after completing adjustments.

Auto-planer guard (chip cover) should

be secured

at

original position.

(see

ap-

After

5-6”

(3/16‘

-

1/4“)

Press

li

Fig.

Fig.

11

12

9

Page 10

notice the adjustment

f

01

I

ows.)

is

off, kindly do

as

Loosen the pan head screw for each roller

under the table. Use

a

screwdriver to rotate

the groove on the roller adjuster within

180

degrees on the four roller

to

the figures for the correct range of

axes.

Refer

adjustment of each roller adjuster. Rotating

the

groove in the ascending direction

causes the bed roller to rise; turning the

groove down causes

NOTE

:

the

bed roller to lower.

The above adjustment procedure should be

Range

of

to

adjust height

groove rotation

of

bed roller

on

roller adjuster

(left).

Range

of

groove

roation on roller adjuster

of

to adjust

bed roller (right).

Caution

Unless the

be twisted

If

the rollers protrude

opposite end. The protrusion from the table surface should be

two

groove positions on the one roller face the same direction, the stock may

to

the left or right.

too

much, notching may result in the surface planed

0.1

thickness). Tighten the small screw when the adjustment has been made.

-

0.3mm

Fig.

11

on

the

(postcard

Page 11

that the roller arm surface

is

at

the

90"

to

the column.

Fig.

11

Adjusting infeed/outfeed rollers

The infeed/outfeed rollers are factory adjusted. If the rollers require adjustment, please

follow this procedure

Place a straight and.lever piece of wood

:

on

the outfeed table top. Turn the crank handle

to raise the table and to bring the piece of wood into contact with the main frame. Then

turn the crank handle a half-turn counterclockwise to lower the table slightly. Insert the

piece

of

wood

so

that

it

adjusting screws

so

Adjust the infeed roller in the same manner

NOTE

:

Turning the height adjusting screw one turn clockwise lowers the roller 3 mm

reaches under the outfeed roller. Adjust the right and left heighi

that

the

outfeed roller contacts the piece of wood evenly.

as

the outfeed roller.

I

(1/8").

Page 12

MAINTENANCE

CAUTION

Always be sure that the tool

inspection or maintenance.

Replacing carbon brushes

3emove and check the carbon brushes

egularly. Replace when they wear down

o

the limit mark. Keep the carbon brushes

:lean and free to slip in

arbon brushes should be replaced

ame time. Use only identical carbon

]rushes.

nsert a minus screwdriver into the holes for carbon brush changeover on the base of the

daner. Remove the brush holder cap and take out the worn carbon brush. Replace with

new carbon brushes, then reinstall the brush holder caps and both holders.

:

is

switched

the

holders. Both

5

off

and unplugged before attempting to perform

at

the

Limit

mark

Fig.

II

eaning

iways brush

atter adhering

.e

that water or

mor.

off

dirt, chips and foreign

to

roller surfaces.

oil

does not enter the

I

Oil

the

portion

Fig.

contact

of the

Fig.

20

21

Page 13

The periodic lubrication should be performed with machine oil. (Oiling should be

done with tool not operating.)

To maintain product SAFETY and RELIABILITY, repairs, any other maintenance or

adjustment should be performed by Makita Authorized or Factory Service Centers,

always using Makita replacement parts.

13

Page 14

ACCESSOR

CAUTION

These accessories or attachments are recommended

manual The use of any other accessories

The accessories

0

Replacement blades

400

mm (15-3/4”1

Part

No.

I

ES

:

or

or

attachments hsould be used only in the proper and intended manner.

731024-2

attachments might present a risk

/

0

Planer stand

Part

No.

122192-3A

for

use with your Makita tool specified in this

Sprocket set

(For Low Speed Feed)

Part

No.

191440-4

;fit

A&

..

of

injury

to

persons.

c

14

Page 15

15

Page 16

MODEL

2040

Jan

-08-'96

Us

c

c

16

Page 17

17

Page 18

7

8

9

10

It

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

,

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

-

2

1

1

1

1

1

2

I

?

2

1

1

2

4

1

4

I

4

I

2

I

I

1

I

1

1

1

I

1

1

1

1

1

1

1

2

I

1

1

1

1

1

1

1

1

1

1

1

1

2

4

4

4

4

1

4

4

1

4

4

4

1

1

1

I

1

1

1

-

Pan

Head

Screw

Spmg

Pm

4 18

Lever 50

Bush

10

ComprFsIlO"

sprmg

Lock

Pin

Pan

Heed

Screw

Bell

cover

Pan

Head

Screw

Pan

Heed

Sciew

Bell

covrr stay

Scale

Bar

Pan

Head

Screw

RlWf

0

5

Name

Plate

Pen

Heid

Screw

Plarrure Plate

Pan Head

Screw

Chip

Bleaker

Pen

Head

Screw M5rlO

Chain Cover

Remnmg

Rtng

Flat

Weshet

12

Tension

Roller

Needle

Bearing

Flat

Washer

12

Tenslo"

Cole

Ratasnmg

Rmg

Sorocket

15

Gear

Housing

Flat

W81her

12

Gear Complete 13

Fla

Waihar

I2

Flat

Washer

14

Helical

Gear

69

Woodrvll

Key

Shaft

Warher

Washer

Washer

Head

nlng

6

Bolt

Arm

Ring

Boll

Washer

Bolt

Washer

Washer

Nut

Not

Wayher

Waihrr

46

Supgorlrr

Shalt

Screw

spmg

50

M6r25

Roller

E

Max25

Plate

M8-25

M6

Screw

MI2

Key

4

14

10

10

9

8

8

I2

4

Diiving

Flat

Flat

Gear Complete

Flat

Hook

Pan

Tenslo"

Te"Sl0"W

Cham Cover Core

SIOP

Ring

Wmg

Extension

Roller

Stop

Hex

Flat

IndiCaIor

Hex

Flat

Table

Spring

Hex

Pan Head

Hex

Spring

Flat

Rmq

Handle

Woodrull

Handle

M5.12

1

I

M5r20

M5x35

M5xIO

M5r14

M5r14

M5.14

S

I2

12 12

S 12

61

11

73

M5r35

8

25 ~395

IWith Washeel

IWith Washcil

6

M6r50

I2

IWith Washerl

IWith Washer1

lWith Warhnrl

IWOlh Washeil

IWith Washerl

lWilh Warheil

With Washer)

IWilh Washer)

IWith Warherl

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

00

01

02

03

04

05

06

07

08

09

IO

11

I2

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

11

12

13

14

15

16

-

1

79

80

61

1

I

I

1

1

1

1

4

4

2

4

4

1

4

1

1

5

1

1

4

8

4

4

2

2

2

2

2

2

2

2

2

4

2

2

2

2

2

2

2

2

I

2

2

4

I

1

I

2

16

4

8

2

1

I

1

I

1

1

4

I

1

I

2

1

1

1

-

GVP 30

Bolt

MI0

Hex

Bolt Max20

WOodrUll

Key

Screw

M24

cap 34

Fell

Rmq 34

88%

Flat

Warher

Her

8011

M10x70

Stable

Base

Snap Ring

Bellow.

50181

Pm

3 25

snap

Rmg

Straight

Bevel

Thrust Needle

Pan

Head

Slraighl

Bevel

Rslalnmg

Ring

COlUm"

Sprmg

Pm 8 60

Felt

Ring

60

Cao

60

Plana

Bcarlng

Roller

32 - 353

Plane

8Fall"g

Adwit

Screw

Mete1 Holder

Pm

10

comprerrmn

Plane

8"

Metal

Cow

Pan

Head

Screw

Roller

85-400

Woodrull

Key

Cwnwersm

Pm

10

Mew

Holder

Ad1u.l

Screw

Sprockst

I5

Retaining

Ring

Cham

35-64

Plans

8earmg

Metal

Cover

Pan

Head

Screw

Cord

Cord Guard

Sllam

Rrlml

Pen

Head

SCTEW

Hex

Flange

Dium

Covet

Pan

Head

Screw

Blade

Holder

Hex

Bolt

M5x45

5pimg

Washer

H~IIc~I

Gear

Ball

8aarmg

Drum

Kcv

5

Countersunk

Besrmg

Retainer

Pall

Bearing 6204LL8

3ea.tng

cover

'an

Head

Screw

d

Pulls"

9

(nob

40

'oly

v

Bell 9 1143

11

55

55

Screw

SOlW

L

Swmg

S

Head

400

4W

15

6204LLB

Head

83

4

Gear

Bearing

M6x3O

Gear

s-

10

10

M27

17

M5r14

4

M27

S-

17

M5x14

M4114

MSx12

5

57

M5x20

I5

12

Bolt

Screw

16

16

14

14

1528

IWith Washer1

lWith Washerl

lWilh Washerl

IWiIh Wa3hcrl

Max30

IWiIh Washer1

M5r16

IWiIh Warherl

IWith Washer)

18

1

,

14

Page 19

MODEL

MACHINE

__

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

I64

165

166

167

2040

ED

1

1

1

2

1

1

I

1

2

2

2

2

1

I

1

1

2

1

2

I

1

DESCRlPTlDN

Hex

Nul

MB

Spring

Washer

Flat

Pm

Trnrlon

Cap

Motor

Rear

Pan

In~~laiion Washri

Cdibon

Brush

Strain

Pan

Pan

P,DleC,Dl

Hex

mye

Stop

FIELD

Ball

8

Warher

8

Herd Screw M6.18 IWllh Washer1

mate

Square

NeLk

Bolt

Screw

Cap

M8.30

E

6200LLB

M5.12

M5x10

M5x30

(With Washer1

15

Max35

IWilh Warherl

IWilh

lWilh Warherl

Housing

Cover

Head

Brush

Holder

Reld

Head Screw

Head Screw

Bolt

PI"

Ring

ASSEMBLY

Bearing

Washell

-

168

169

I70

I71

172

173

174

175

176

177

I78

179

1

900

901

903

904

905

906

908

Jan

-08--'96

US

Dust

Seal

1

2

1

1

1

1

1

1

4

1

1

I

BO

I

1

2

1

I

1

1

2

-

10

Pan

Heed

Screw

Iten>

92

Seal

nearnng

Pin

Head

9

Washer 7

warhsr

spnng

Plate

Plale

Piotector

Cover

M5195

167

168

12

6201~~8

6

Screw

M5r25

-

35

Head

Screw

18

Screw

M5x14 lWilh Warhell

ARMATUAE ASSEMBLY

IWilh

Fan

Dust

BAII

Rubber

8iackeI

Pm

v

PUllSV

Flat

Countorsunk

Flat

Leal

set

Switch

Swtich

Swwh

Kev

Pan Head

IWilh Warherl

LL

170 1731

IWith Washer1

M5r16

lWilh Washer1

19

Page 20

e

MAKnA

LIMITED

ONE YEAR WARRANTY

Warranty Policy

Fvery Makita tool is thorou ly inspected and tested before leaving the factory. It

he

free

of

defects from workanship and materials

orignal purchase. Should 8ny trouble develop during this onc.year period. return the COMPLETE

tool, freight prepaid.

the trouble is caused by defective workmanship

replace) without chargc.

This Warranty does not apply where:

repairs have been made

.

repairs are required because

The tool has been abused, misused

alterations have been made to the

IN NO EVFNT SHALL MAKITA BE LIABLE FOR ANY INDIRECT INCIDENTAL

SEQUENTIAL DAMAGES FROM THE SALE

APPLIES BOTH DURING AND AFTER THE TERM OF THIS WARRANTY.

MAKITA DISCLAIMS LIABILITY FOR ANY IMPLIED WARRANTIES, INCLUDING IMPLIED

WARRANTIES OF "MERCHANTABILITY" AND "FITNESS FOR A SPECIFIC PURPOSE,"

AFTER THE ONE-YEAR TERM

This

Warranty gives you specific legal rights. and you may also have other rights which vary from

stale lo state. Some stales

so

damages,

limitation on how long an implied warranty lasts,

lo

one

of

Mnkitn's Factory

or

attempted by others:

of

do

the above limitation

not allow the exclusion or limitation

normal wear

or

improperly maintained:

1001.

OF

THIS WARRANTY.

or

exclusion may not apply

for

the period

of

ONE YFAR from the date

or

Authorized Service Centers. If inspection shows

or

material. Makitn will repair

and

tear:

OR

USE OF THE PRODkT. THIS DISCLAIMER

of

incidental

lo

so

the above limitation may not apply lo you.

you. Some states do not allow

is

warranted tu

for

at our option.

or

consequential

OR

of

CON-

Makita Corporation

3-11

-8,

Sumiyoshi-cho,

Anjo, Aichi

446

Japan

883106F069

PRINTED

1996

IN

-

JAPAN

2

-

N

Loading...

Loading...