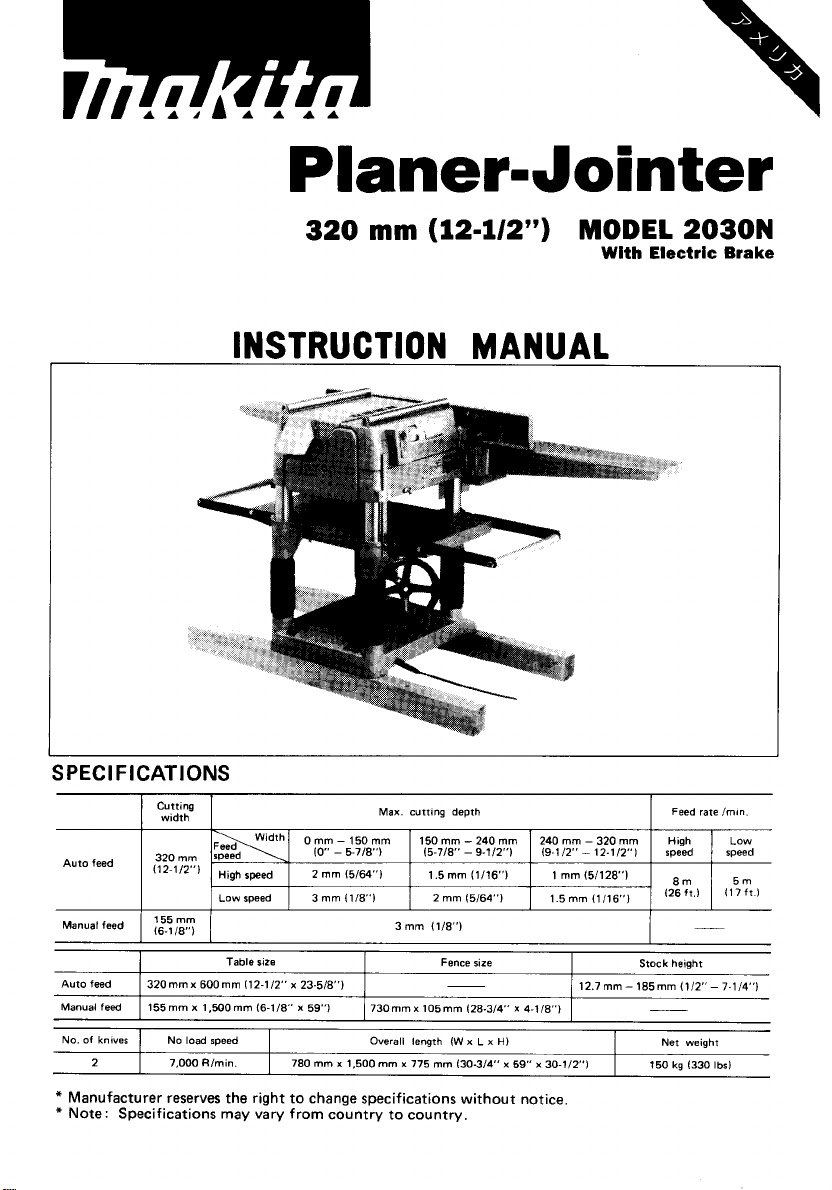

Specifications and Main Features

- Model: 2030N

- Max Cutter Spindle Rotation Speed 0 mm-150 mm, 150 mm to 240mm, 240mm to 320mm

- Rate of feed: High feed speed from 2mm (5/64") to 1.5mm (1/16") decreasing to 1 mm (5/128") | Low feed speed starting from 3 mm (1/8") to 2 mm (5/64") and decreasing to 1.5mm (1/16")

- Auto feed unit length: 12-1/2 inches

- Operator feed length: 6-1/8 inches by 59 inches

- Table Size Inventory feed auto unit length by width: 12-1/2 by 23-5/8 inches

Auto feed table size 320 mm x 600 mm

- Fence size:28-3/4 x 4-1/8 inch..

- Stock Height Range: 7-1/4 inches narrowing down to 1/2 inch

- Number of Knives: 2

- No load freespeed: R/min of 7000

- Length Dimension: 780 mm x 1,500 mm and Height: 775 mm (30-3/4" x 59" x 30-1/2")

- Net weight: 150 kg (330 lbs)

Frequently Asked Questions

- Is the specified maximum cutting depth of the planer-jointer uniform?

There are three varying planes of cutting depath maximum which are 0 mm to 150 mm, 150 mm to 240 mm and lastly 240 mm to 320 mm.

- What are the feed rates for this device?

High speed options are 2 mm ( 5/64″), 1.5 mm ( 1/16″) and 1 mm ( 5/128″) while the Low speed options are 3 mm ( 1/8″), 2 mm ( 5/64″) and 1.5 mm ( 1/16″) respectively.

- What is the size of the auto feed table?

The table measures 320 mm by 600 mm, or 12 and 1 half inches by 23 and 5 eighths inches.

- How heavy is the planner-jointer?

The net weight for this device is 150 kgs or 330 lbs.

- What is the no load speed of the device?

As for the no load speed, it is 7,000 R/min.

User Manual

Page 1

Planer-

Jointer

SPECIFICATIONS

I

Cutting

I

width

Feed

mm

.weed

Auto feed

Manual feed

320

112~1'2"'

High speed 2

Low speed 3

320

mm

(1242")

MODEL

With Electric

INSTRUCTION MANUAL

Max. cutting depth

Width

0

mm

-

150

mm

150

mm - 240

mm

240

mm

-

320

IO'

-

5-7/87 l5-7/8" - 9.1/2"1 (9-112" - 12.1/2"1 speed speed

mm

15/64") 1.5mm11/16"l

mm

I1

18")

3mm

2

mm

(1/8")

15/64")

1

1.5mm11/16,,) 126ft.l (17ftI

mm

mm15/128'1

2030N

I

Feed rate

High Low

8m

__

Brake

/man

5m

Auto feed

Manual feed

No.

of

knives

2

Table

SIZE

320mmx

600mm

112.112" x 23-518")

155" x 1,MOmm l6-1/8' x 59")

No

load speed Overall length IW x L

7,000

R/min.

780

730mmx 105" 128-3/4"

mm

x

1,500

mm

Fence

x

775

mm

size

~

x

4-1/8"1

x

HI

1303/4' x 59" x 30-1

/2"l

12.7

mm

-

Stock

185

~

150

height

mm

(1

Net

weight

kg 1330 Ibs)

12"

-

7-1 14")

Page 2

BEFORE CONNECTING YOUR TOOL

TO A POWER SOURCE

you

Be sure

have read all

GENERAL POWER TOOL SAFETY RULES

GENERAL SAFETY PRECAUTIONS

(For

All

Tools)

1.

KNOW YOUR POWER TOOL. Read the owner's manual carefully. Learn the

tools applications and limitations, as well as the specific potential hazards

peculiar to

2.

KEEP GUARDS IN PLACE and

3.

REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to

see that keys and adjusting wrenches are removed from tool before turning

it

4.

KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

5.

DON'T USE IN DANGEROUS ENVIRONMENT. Don't use power tools

damp or wet locations, or expose them to rain. Keep work area well lighted.

6.

KEEP CHILDREN AWAY. All visitors should be kept safe distance from work

area.

7.

MAKE WORKSHOP KID PROOF with padlocks, master switches, or by

removing starter keys.

8.

DON'T FORCE TOOL.

it

was designed.

9.

USE RIGHT TOOL. Don't force tool or attachment to do a job for which

it

was not designed.

IO.

WEAR PROPER APPAREL. Wear no loose clothing, gloves, neckties, rings,

bracelets, or other jewelry

footwear is recommended. Wear protective hair covering to contain long hair.

11.

ALWAYS USE SAFETY GLASSES. Also use face or dust mask if cutting operation is dusty. Everyday eyeglasses only have impact resistant lenses, they

are NOT safety glasses.

12.

SECURE WORK. Use clamps or a vise to hold work when practical. It's safer

than using your hand and

13.

DON'T OVERREACH. Keep proper footing and balance at all times.

14.

MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and

safest performance. Follow instructions for lubricating and changing accessories.

15.

DISCONNECT TOOLS before servicing; when changing accessories such

as blades, bits, cutters, and the like.

on.

it.

in

working order.

It

will do the job better and safer at the rate for which

which

may get caught

it

frees both hands to operate tool.

in

moving parts. Nonslip

in

2

Page 3

16.

REDUCE THE

in off position before plugging

17.

USE RECOMMENDED ACCESSORIES. Consult the owner's manual for

recommended accessories. The use of improper accessories may cause risk

of injury to persons.

NEVER STAND ON TOOL. Serious injury could occur

18.

or if the cutting tool is accidentally contacted.

CHECK DAMAGED PARTS. Before further use of the tool, a guard or other

19.

part that is damaged should be carefully checked to determine that

operate properly and perform its intended function

of moving parts, binding of moving parts, breakage of parts, mounting, and

any other conditions that may affect its operation.

that is damaged should be properly repaired or replaced.

20.

DIRECTION OF FEED. Feed work into a blade or cutter against the direction

of rotation of the blade or cutter only.

21.

NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don't

leave tool

22.

PROPER GROUNDING. This tool should be grounded while in use to protect the operator from electric shock.

EXTENSION CORDS: Use only three-wire extension cords which have three-

23.

prong grounding-type plugs and three-pole receptacles which accept the

tool's plug. Replace or repair damaged or worn cord immediately.

VOLTAGE WARNING: Before connecting the tool to a power source (receptacle,

outlet, etc.) be sure the voltage supplied is the same as that specified on the

nameplate of the tool. A power source with voltage greater than that specified

for the tool can result

the tool. If

voltage less than the nameplate rating is harmful to the motor.

in

until

doubt,

RISK

OF

UNINTENTIONAL STARTING. Make sure switch

in.

if

the

tool

-

check for alignment

A

guard or other part

it

comes to a complete stop.

in

SERIOUS INJURY to the user - as well as damage to

DO

NOT PLUG IN THE TOOL. Using a power source

is

tipped

it

with

is

will

3

Page 4

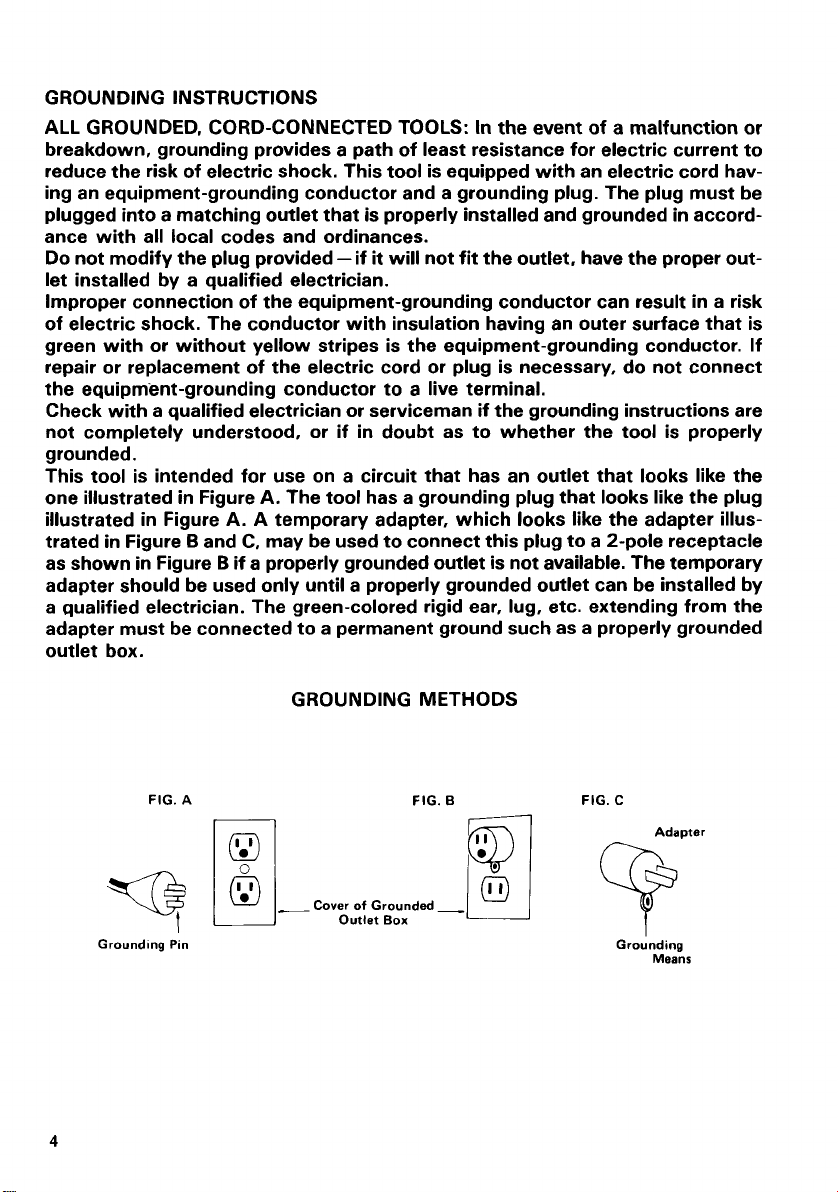

GROUNDING INSTRUCTIONS

In

ALL GROUNDED, CORD-CONNECTED TOOLS:

the event of a malfunction or

breakdown, grounding provides a path of least resistance for electric current to

reduce the risk of electric shock. This tool is equipped

with

an electric cord having an equipment-grounding conductor and a grounding plug. The plug must be

plugged into a matching outlet that is properly installed and grounded

in

accordance with all local codes and ordinances.

Do not modify the

plug

provided

-if

it

will

not

fit

the outlet, have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor can result

in

a risk

of electric shock. The conductor with insulation having an outer surface that is

with

or

green

without yellow stripes is the equipment-grounding conductor. If

repair or replacement of the electric cord or plug is necessary, do not connect

the equipment-grounding conductor to a live terminal.

Check with a qualified electrician or serviceman

not completely understood, or

if

in

doubt as to whether the tool is properly

if

the grounding instructions are

grounded.

This tool is intended for use on a circuit that has an outlet that looks like the

one illustrated

illustrated

trated

in

as shown

adapter should be used only

in

Figure A. The tool has a grounding plug that looks like the plug

in

Figure A. A temporary adapter, which looks like the adapter illus-

Figure B and C, may be used to connect this plug to a 2-pole receptacle

in

Figure

B

if

a properly grounded outlet is not available. The temporary

until

a properly grounded outlet can be installed

by

a qualified electrician. The green-colored rigid ear, lug, etc. extending from the

adapter must be connected to a permanent ground such as a properly grounded

outlet box.

4

FIG.

t

Grounding Pin

GROUNDING METHODS

A

-Cover

Outlet

of

Grounded

Box

FIG.

-

B

FIG. C

Grounding

Means

Page 5

ADDITIONAL SAFETY RULES

Don't use the tool in presence of flammable liquids or gases.

1.

2.

Handle the blades very carefully.

Check the blades carefully for cracks or damage before operation. Replace

3.

cracked or damaged blades immediately.

Be sure the planer blade installation bolts are securely tightened before

4.

operating.

Sharpen both blades evenly, or replace both blades or both cutterhead covers

5.

at the same time.

Never make jointing or planing cut deeper than

6.

Remove nails and clean the workpiece before cutting. Nail, sand or other

7.

matter can cause blade damage.

Make sure the blade is not contacting workpiece before the switch is turned

8.

on.

Wait until the blades attain

9.

Keep hands away from rotating parts.

IO.

Stop operation immediately

11.

Always switch off and wait for blades to come to a complete stop before

12.

adjusting any parts, cleaning out chips or approaching the blade.

Never stick your finger into the chip chute. Chute may jam when cutting

13.

damp wood. Turn off the planer-jointer and then clean out chips with a stick.

Do

14.

15.

16.

not touch blades right after operation, they may be extremely hot and

could burn your skin.

Don't abuse cord. Never yank cord to disconnect from receptacle. Keep cord

from heat, oil and sharp edges.

Do not use auto-planer and jointer at the same time. Overloading of the

motor can occur.

full

speed before cutting.

if

you notice anything abnormal.

3.2

mm

(1/8

inch).

5

Page 6

ADDITIONAL SAFETY RULES FOR JOINTER

1. Maintain the proper relationships of infeed and outfeed table surfaces and cutterhead blade path.

2.

Do

not perform jointing operations on material shorter than

inches), narrower than

3.

Do

not perform planing operations on material shorter than

inches), narrower than

or thinner than 12.7 mm (1/2 inch).

4.

Support the workpiece adequately at all times during operation.

Do

not back the work toward the infeed table.

5.

6. Always use hold-downlpush blocks for jointing material narrower than 76.2

mm

(3

inches), or planing material thinner than 76.2 mm

19

mm (3/4 inch), or less than 12.7 mm (112 inch) thick.

19

mm (314 inch), wider than 155 mm (6-118 inches)

140

140

(3

inches).

mm (5-112

mm (5-1/2

SAVE THESE INSTRUCTIONS.

ADDITIONAL SAFETY RULES FOR AUTO-PLANER

1.

Two or more pieces of narrow

through the auto-planer side by side.

However, allow some spacing between the stock to permit the feed rollers

to grip the thinnest piece.

Otherwise, a slightly thinner piece could be kicked back by the cutterhead.

but

similar thickness stock can be passed

WARNING

For Your Own Safety, Read Instruction Manual Before Operating Jointer

1.

Wear eye protection.

2.

Never perform jointing or planing operation with cutter head or drive guard

removed.

3.

Never make jointing or planing cut deeper than

4.

Always use hold-downlpush blocks for jointing material narrower than 76.2

(3

mm

5.

Do

and the use of adequate hold-down1push blocks, jigs, fixtures, stops, etc.

inches), or planing material thinner than 76.2 mm

not attempt to perform an abnormal or little-used operation without study

3.2

mm

(1/8 inch).

(3

inches).

SAVE THESE INSTRUCTIONS.

6

Page 7

HOW

TO

USE

AUTO-PLANER

1.

Adjusting depth

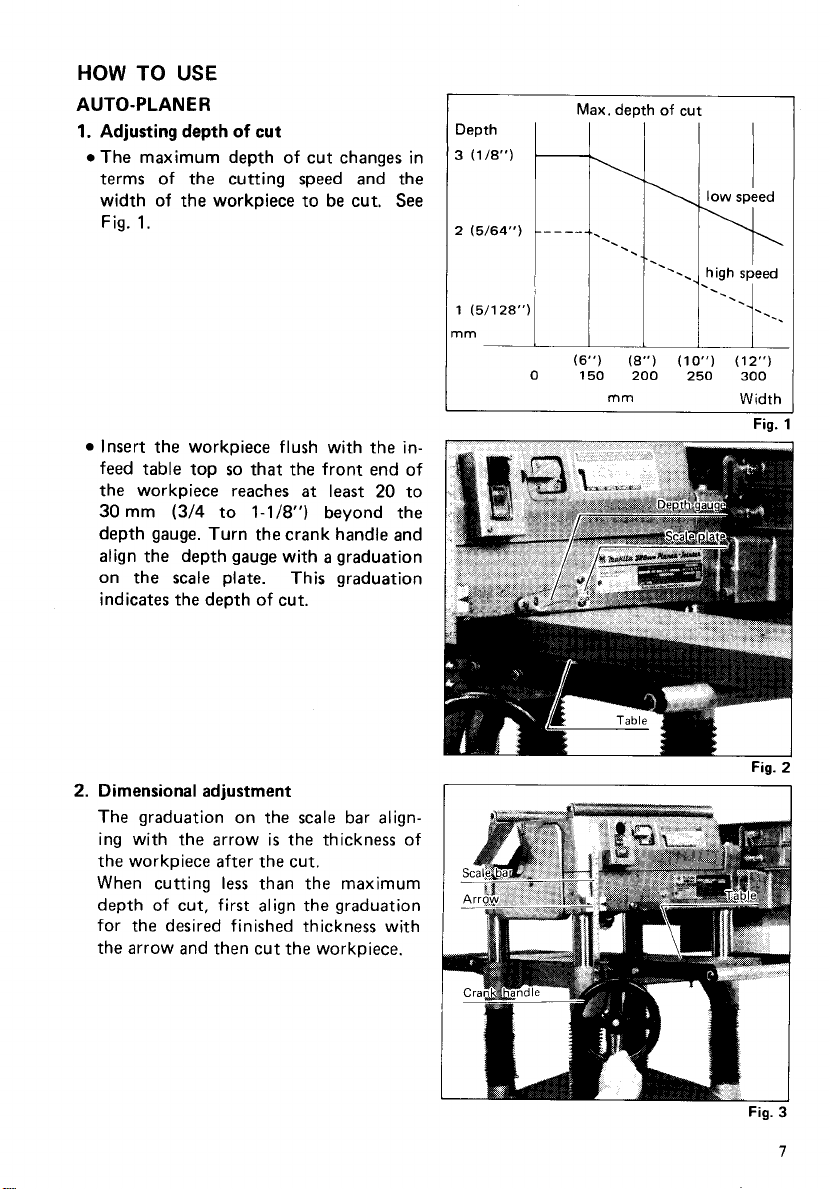

The maximum depth of cut changes in

terms of the cutting speed and the

width of the workpiece to

Fig.

1.

Insert the workpiece flush with the infeed table top

the workpiece reaches

30

mm

(3/4

depth gauge. Turn the crank handle and

align the depth gauge with

on the scale plate. This graduation

indicates the depth of cut.

of

cut

be

so

that the front end of

at

least

to

1-1/8")

beyond the

a

graduation

cut.

20

See

to

2

(5/64")

1

(5/128")

nrn

Max.

depth

of

----

1

I=-..

(6") (8") (10") (12")

0

150

_1

200

mm

cut

250

low

speed

300

Width

Fig.

1

2.

Dimensional adjustment

The graduation on the scale bar align-

is

ing with the arrow

the workpiece after the cut.

When cutting

depth of cut, first align the graduation

for the desired finished thickness with

the arrow and then cut the workpiece.

less

the thickness of

than the maximum

c

Fig.

Fig.

2

I

3

7

Page 8

3.

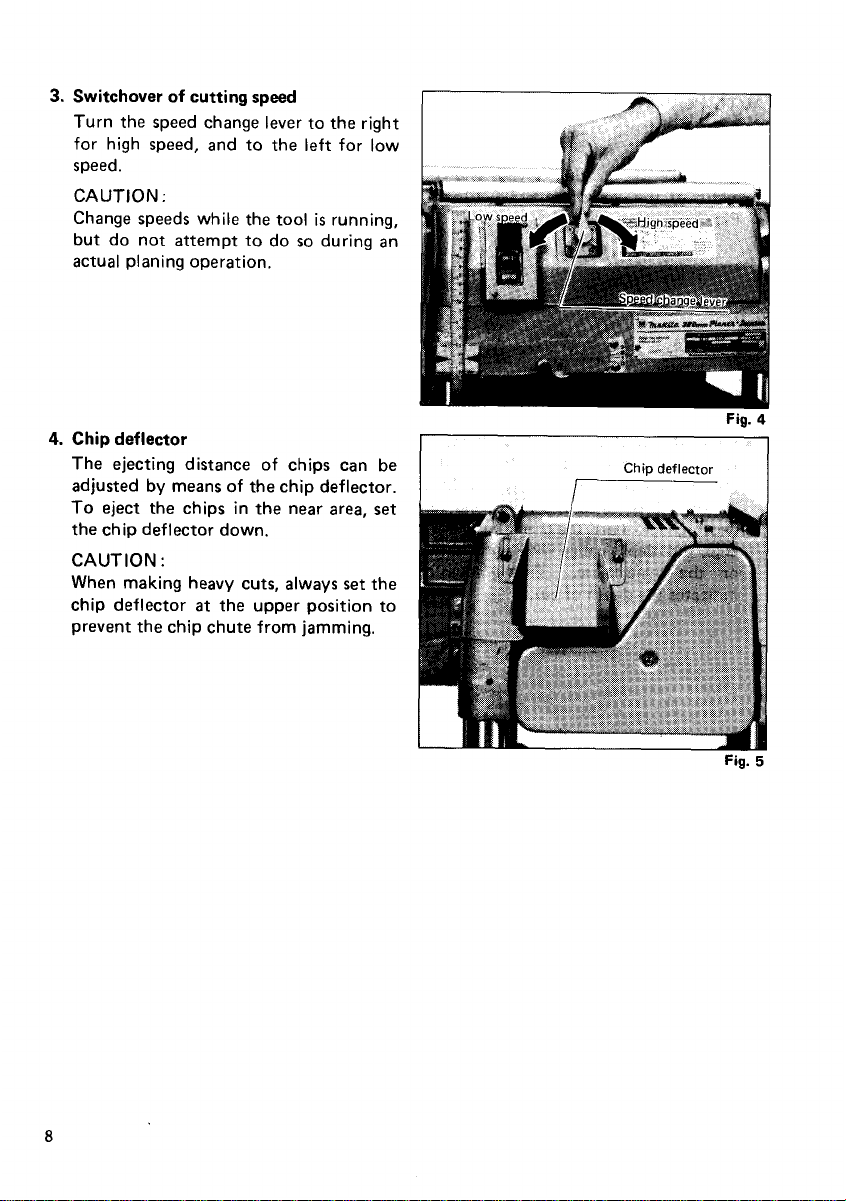

Switchover

of

cutting speed

Turn the speed change lever to the right

for high speed, and to the left for low

speed.

CAUTION.

Change speeds while the tool

but do not attempt to do

is

running,

so

during an

actual planing operation.

4.

Chip deflector

The ejecting distance of chips can be

adjusted

by

means of the chip deflector.

To eject the chips in the near area,

the chip deflector down.

CAUTION

:

When making heavy cuts, always

at

chip deflector

the upper position to

prevent the chip chute from jamming.

set

set

the

Fig.

4

Chip

I

deflector

Fig.

5

8

Page 9

JOINTER

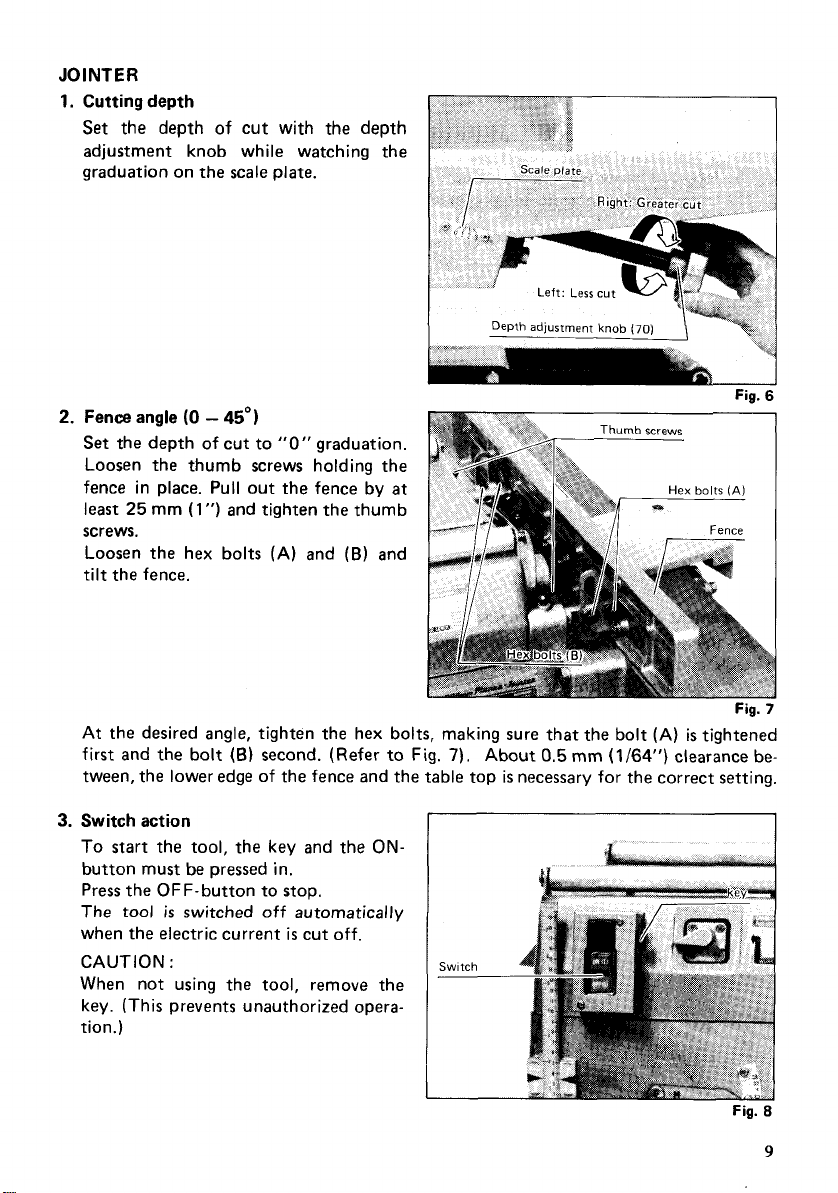

1.

Cutting depth

Set

the depth of cut with

the

adjustment knob while watching the

graduation on the

2.

Fence angle

Set

the depth of cut to

(0

-

scale

45')

plate.

"0"

graduation.

Loosen the thumb screws holding the

fence in place. Pull out the fence by at

least

25

mm

(1")

and tighten the thumb

screws.

Loosen the hex bolts

tilt

the fence.

(A)

and

(B)

depth

and

Fig.

6

At the desired angle, tighten the hex bolts, making sure that the bolt

(BI

first and the bolt

tween, the lower edge

3.

Switch action

second. (Refer to

of

the fence and the table top

To start the tool, the key and the

ON-

Fig.

7).

About

0.5

mm

is

necessary for the correct setting.

button must be pressed in.

Press the OFF-button to stop.

The

tool

is

switched off automatically

when the electric current

CAUTION

:

is

cut

off.

When not using the tool, remove the

key. (This prevents unauthorized operation.)

(A)

(1/64")

Fig.

7

is

tightened

clearance be-

Fig.

8

9

Page 10

OPE

RATION

1.

Auto-Planer

Determine the depth of cut and the cutting speed in terms of the width of the workpiece you intend to cut. Insert the workpiece flush with the table top. When cutting

at

the long and heavy workpiece, lift up the end of the workpiece slightly

at

the end of cutting to avoid gouging or sniping

the extreme ends of the workpiece.

the start and

Two rollers are provided on top of the

chip cover to enable quick, efficient

return of the workpiece to the infeed

table side. This

with two operators.

CAUTION

Stop the tool when the workpiece

stalled. Keeping the tool running with

stalled workpiece causes the abnormal

wearing of the feed rollers.

2.

Jointer

Placement of hands during feeding

At the start of the cut, the left hand holds the workpiece firmly against the infeed

table and fence, while the right hand pushes the workpiece toward the blade. After the

cut

is

under way, the new surface rests firmly on the outfeed table. The left hand

should press down on this part,

fence. The right hand presses the workpiece forward and before the right hand passes

over the cutterhead

is

especially convenient

:

is

a

at

the same time maintaining flat contact with the

it

should be moved to

the

workpiece on the outfeed table.

Return (for another pass)

Fig.

I

9

10

Page 11

Jointing edge

Set the fence square with the table.

Hold the best face of the workpiece

firmly against the fence throughout the

feed. (Fig.

CAUTION

10)

:

Cover the cutterhead with the safety

cover when the fence

11).

However, never touch the safety

cover when the jointer

is

pulled out. (Fig.

is

running.

Jointing warped workpieces

If

the workpiece

is

dished or warped,

press down when the workpiece moves

over the outfeed table to obtain

smooth surface. (Fig.

10)

Fig.

10

a

Using hold-downlpush blocks

For safety reasons, use hold-downlpush

Push

blocks

Fig.

12

11

Page 12

Direction

Avoid feeding workpiece into the Jointer

against the grain

The result will be chipped and splintered

edges. Feed with the grain

Fig.

of

grain

as

shown in Fig.13.

14,

to

obtain a smooth surface.

as

shown in

Wor kpiece

Outfeed table

Cutterhead

Wrong feed -against the grain.

lnfeed table

Fig.

1:

12

I-

Correct feed - with the grain

V-

Fig.

14

Page 13

CHANGING PLANER BLADES

1.

Removing

a

1

Remove the screw

of the chip cover.

blades

on the outfeed side

Then open the chip

cover.

Loosen the hex bolt with the wrench and lift

off

Set the depth of cut for Jointer to maximum graduation.

the safety guard assembly.

Fig.

1

*Push the lock plate in the direction

the arrow and raise

knob to lock the drum. (Fig.

The drum can be locked

shown in Fig.

Bolt Drum cover

17

it

slightly. Turn the

at

or

Fig.

18.

16)

the position

of

Fig.

Blade Drum

cover

1(

Fig.

17

Fig.

1E

13

Page 14

0

Lock the drum

at

the position shown in

Fig.

17

and loosen the hex bolts with the

socket wrench. Remove the hex bolts and the drum cover.

When removina the blade from the Auto-Planer, lock the drum

in

Fig.

I

18

and push the blade

out with

the screwdriver.

.When removing the blade from the

Jointer, release the drum lock and turn

at

the knob to the position

which the

blade can be pushed out with the screwdriver.

at

the position shown

Fig.

19

2.

Installing blades

0

Lock the drum

0

Insert the blade between the drum and

the blade holder.

it

will protrude by 2 mm

3

mm

(1/8")

at

the position shown in

Set

the blade

(5/64")

from the drum. The holes

of the blade should be aligned with the

holes of the drum.

14

so

that

to

Fig.

18.

2mm

Blade

-

3mm

Blade

Fig.

holder

20

Page 15

.On the Auto-Planer, press down on

both ends

of

the blades with wooden

levelers.

*On the Jointer,

outfeed table and slide

blade edge. The edge

just contact underside

Lock the drum

Fig.

17.

set

the leveler on the

it

out over the

of

blade should

of

leveler.

at

the position shown in

Mount the drum cover and tighten the

hex bolts evenly and alternately.

Fig.

Fig.

~

22

23

*After unlocking the drum, press down

the wooden leveler on the blades slight-

ly

and turn the knob slowly in the direc-

of

tion

the arrow.

(See

Fig.

24).

The wooden leveler should slide about

3

mm

(1/8")

blade setting

to 5 mm

is

perfect.

(3/16")

when the

Fig.

24

15

Page 16

VARIOUS ADJUSTMENTS

1.

Adjusting infeed/outfeed rollers (Auto-planer)

NOTE

:

The planer infeed and outfeed rollers are factory adjusted. If you notice the adjust-

is

ment

off, kindly do

as

follows.

Use the wrench to loosen the installation nuts slightly. Turn the adjusting screw to

obtain

a

level

of from

It

is

relatively simple to make the setting

0.1

to

0.3

mm above the table surface.

so

that a postcard can slip in and out between the roller and the leveler. After adjusting rollers, be sure to tighten installation

nuts securely.

A roller that protrudes too much will cause gouging or shiping in the workpiece and

rough surfaces.

Roller

shaft

Roller

3

mm

2.

Extension roller adjustment

Gently loosen the hex bolts,

or

yardstick on the table surface and ad-

just

so

that roller arm

set

is

slightly higher

than the table. Tighten the hex bolts

securely

at

16

so

90"

to the column.

that the roller arm surface

a

rule

is

Fig.

21

Page 17

MAINTENANCE

CAUTION

Always be sure that the tool

inspection and maintenance.

Replacing carbon brushes

.Remove and check the carbon brushes

regularly. Replace when they wear down

to about

brushes clean and free to slip in the

holders. Both brushes should be changed

at

brushes.

:

is

switched off and unplugged before attempting to perform

6

mm

(1/4")

or

less.

Keep the

the same time. Use only Makita carbon

U

6mm

(1/4")

Remove the screws that hold the chip

cover and the switch cover. Set the speed

change lever in the neutral position and

remove the switch cover. Open the chip

cover.

a

.Use

screwdriver to remove the brush

holder cap

as

shown on the figure.

I

Fig.

Fig.

2Z

29

Fig.

30

17

Page 18

.Take out the worn brush, insert the new

one and secure the brush holder cap.

Cleaning

Always brush off dirt, chips and foreign

matter adhering to roller surfaces, motor

vents. Make sure that water or oil does not

enter the motor.

Fig.

31

Lubrication (periodic)

Oil

the chain (after removing the chain

cover), the column moving parts (contact

areas) and the crank handle. This periodic

lubrication should be performed with

machine oil. (Oiling should be done with

tool turned off and unplugged.)

18

I

Remove

chain

guard

Fig.

3:

to

011

Fig.

I

33

Page 19

Sharpening planer blades

(In case of blade width 155 mm (6-1/8”))

1. Remove the two wing nuts on the

holder.

2.

Set the blade A and blade B on the

holder

so

that the heel of the blade will

be flush against

C

and D surface of the

holder respectively.

3.

Tighten the wing nuts to hold the blades

in the holder.

4.

Sharpen with the dressing stone keeping

both blades contacting the dressing stone

surface

at

the same time.

Immerse dressing stone in water for 2 or

3

minutes before sharpening. Hold the

holder

so

that blades both contact the

dressing stone for simultaneous sharpening

at

the same angle. Stock removal

possible up to

7.5

mm (5/16”). Blades

may be used down to 24.5mm (1”)

width.

is

1

Wing

nut

Blade

B

\

Dsurface\

I

Fig.

Fig.

31

3!

Fig.

36

To

maintain product SAFETY and RELIABILITY, repairs, any other maintenance and

adjustment should be performed by Makita Authorized or Factory Service Centers,

always using Makita replacement parts.

19

Page 20

ACCESSORIES

CAUTION

These accessories or attachments are recommended for use with your Makita tool specified in this

manual. The use of any other accessories or attachments might present a risk of injury to persons. The

accessories or attachments should be used only in the proper and intended manner.

0

Sharpening Holder

(Part No. 123006-2)

0

Triangular Rule

(Part

:

No.

762001-3)

0

Socket Wrench

(Part

No.

782213-2)

0

Wooden Levelers

(Part No. 441021 -7)

(13)

*Push Block

(Part

0

(+I

Screwdriver

(Part

0

Replacement Blades

Width (mm)

155 16-118")

- - . - . -

155 (6;1/8")

320

320

Material

-

No.

155508-0)

No.

783002-8)

.

(12-1/2")

(12-1/2") I 731211-3

. .

.

Tungsten-carbide

1

Part

I

731021-8

[

731206-6

I

731035-7

No.

Hex Wrench

(Part

No.

783202-0)

0

Hex Flange Hd. Bolt M8x

(Part

No.

251690-4)

Sprocket Set

No.

(Part

191605-8)

30

20

Page 21

Dressing Stone

(Part

No.

741801-4)

180-1200

Key

(Part

No.

411447-7)

Leveler

(Part

No.

41 1908-71

Wrench

(Part

No.

781202-4)

21

Page 22

320

mm

(12-1/2")

PLANER-JOINTER

Model

2030N

Seo

-19-'84

US

22

Page 23

23

Page 24

24

Note: The switch and other part configurations

may differ from country to country.

Page 25

MODEL

MACHINE

~

1

2

3

4

5

6

7

8

9

10

I1

16

17

IS

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

2030N

AiD

3

1

I

2

2

2

3

2

2

2

1

1

2

1

1

1

1

1

4

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

1

2

2

2

1

6

12

2

4

1

1

2

2

4

1

1

1

1

1

1

1

1

1

1

4

1

1

1

1

1

1

1

4

1

1

1

1

-

DESCRIPTION

Pan

Head

S~rew

Chip Cover

Chip

Pan

Plane

Rod

Pan

Roller

Plane

Stop Ring

Switch

Switch

Stop

Retaining Ring

Spllny

Rod

0

Ring

Lever 40

Countersunk

supportsr

Ball

Flat

Gear

Flat

Ball

Flat

Compression

Helical

Gear

Helical

Compression Spring 21

Flat Washer 12

Brush

Carbon Brush

Motor

Insulation Washer

Countersunk

Pan

Retainer

Chip Breaker

Compresrlon

Guide

Rivet

Name Plate

Retainer

Countersunk

Pan

Pan

v

Pulley

Brackel

Ball

Dust

Fan

ARMATURE ASSEMBLY

[With

Dust

Ball Bearing

FIELD ASSEMBLY

Gear

Pan

Flat Washer 14

Helical

Woodruff Key 4

Driving Shaft

Woodruff Key 4

Flat Washer 14

Gear

Pan

Cham Cover

Chain 35-74

Reiain8ng Ring

Sorocket 15

M5x12 !Wilh Washer]

Blast

Head

Screw

M5xl2 IWith Washer)

Bearing

10

10-400

Head

Screw

M5x12 IWith Washer]

26-375

Bearing

10

E-9

Cover

Ring E 9

S

P,n

4-18

1

Head

Bearing 609LLB

Warher

10

Complete 11 - 16

Washer

10

Bearing

620311B

Washer 18

Spring

Gear

68

Complete 13

Gear

63

Holder

Cap

Housing

Head

Head

Screw

M5x16

L

Spring

Bar

2

5

R

Head

Head

Screw

M5x16 [With Washer)

Head

Screw

M5x30 IWtth Washerl

9-3M

Bearmg

6201110

Seal

12

92

Item

55

-

601

Seal

10

6200LlB

Housing

Head

Screw

M5xBO !With Washer)

Gear 79

Housing

Cover

Head

Screw

M5x45 1WiIh Washer]

S-

9

Screw

Screw

Screw

12

M4x10 !With Washeri

71

21

M5x14 [With Washerl

[With Washer)

4

M5x14 IWith Washerl

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

I00

I01

102

I03

I04

105

I06

107

IO8

I09

110

I11

112

113

I14

115

116

117

118

119

I20

121

122

123

124

I25

I26

I27

I28

129

130

131

132

133

I34

135

I36

137

I38

I39

I40

141

142

I43

44

45

I46

847

-

AtD

DESCRIPTION

2

Pan

1

Rerasnmy

1

Sprocket 10

Chain Cover Stay

1

Reraining Ring S-12

1

1

Flat Washer

1

Needle Bearing 1212

1

Flat Washer

1

Bearing

1

Pan

1

Strain

2

Pan

1

Lock

1

Spring

1

Sleeve

1

Flat Washer

1

Pan

1

Spring

Torsion Sprfng 12

1

1

Pan

1

Strain

6

Countersunk Head

Main

1

4

Spring

Tension

1

4

Pan

1

Tension

1

Sleeve

Torsion

1

Flat Washer

1

1

Pan

Sprocket 15

1

Retaining Ring

1

Pan

1

4

Pan

Metal

2

2

Plane

2

Woodruff

2

Roller45 310

2

Plane

2

Compression Spring

2

Metal Cover A

4

Pan

8

Pan

Blade

2

1

Key

Urethane

1

1

Poly V Bell 9 453

1

V

Hex

1

1

Ball

Ball

1

Main Drum

1

Planer

1

Drum Cover

4

Hex

12

Compression Spring 13

2

Retaining

1

Drum Cover

1

1

Ruler

1

Spring

2

Pan

1

Torsion Spring 14

1

Hex

1

Adpsi

1

Scale

Pan

2

2

Pan

1

Ruler

1

Chip Guide

2

Her

1

Safety cover

-

Head

Screw

M5x12 IWilh Washerl

Ring

S-

12

12

12

BOX

Head

Screw

M5il2 !With Washerl

Relief

Head

Screw

M5x95 !With Washerl

Plate

Pin

4 18

5

6

Head

Screw

M5x25 [With Washer]

Pin

4-24

Head

Screw

M5x12 IWifh Warherl

Relief

Pin

8-70

Core

Screw

Roller

5

Spring 13

Screw

Screw

Screw

Cover

Bearing

Key

Bearing

Screw

Screw

Holder

Sleeve

9-70

Blade

6

B

300

Head

320

300

Screw

M5x20 lWiIh Washer)

M5x20 [With Washer]

S

-

12

M5x12 1WiIh Washer)

M5x16 IWith Washerl

14

4

14

13

M5x16

M5x12 lWiIh Washer1

IO

Bolt

Frame

Head

Head

Head

Head

Head

Head

5

Pulley

Socket

Bearing 6303LLB

Bearing 6303LLB

Flange Head Bolt MBx3O

Ring S 12

Pin 4-24

Head

Screw

M5x16 !With Washerl

Bolt M6x12

Bed

Plate

Head Screw

M4x10 !With Washer)

Head

Screw

M5x12 lWith Washerl

Holder

L

Bolt M6x12 [With Washer)

Sep 19-84

M6x20 lWnh Washerl

lWith Washerl

M5x16

US

25

Page 26

MODEL 2030N

'itM

$tD

DESCRIPTION

Sep.-19-84

';,'d"

$ZD

DESCRIPTION

US

MACHINE

~

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

166

169

170

171

172

173

174

175

176

177

178

179

180

181

182

183

184

185

186

187

180

109

190

191

192

193

194

195

196

197

198

199

200

201

202

203

204

205

206

207

208

209

210

211

212

Note'

The

4

4

-

switch

1

Ruler

Hex

2

Pan

2

Ruler

1

Fix

Bed

1

Spring

1

Knob

Hex Bolt

1

Be"

1

Ball

1

Sub

1

Ball Bearing 6203LLB

1

Pan

1

Belt

1

Key

1

Planer Blade

Blade Holder

2

2

Drum

4

Hex

4

Lesi

Hex Flange Head

8

4

Sleeve

4

Pan

1

Hex

1

Coupling

Spring

2

Spring

4

4

Hex Bolt

Pan

2

1

Scale Plate

1

sprmg

1

+

Binding Head

1

Depth

4

Countersunk

2

P0l"t

1

Spring

2

Indication

Hex Bolt Max38

2

Her

2

2

Tension

1

pressure

1

Ruler

4

Hex

Wing Bolt

2

1

Flat

1

Bar

Hex

2

1

Flat

1

Spring

1

Adjust

Knob

1

1

Spring

1

Indication

1

Rod

2

Stop

Roller

2

2

Plane

2

Roller

Rod

2

2

Plane Besrlng

2

Stop

4

Cap

Roller

2

Felt

4

8

Hex

and

Holder

R

Flange

Head

Head Screw

Bar L

Pin

4-32

40

Max25

cover

Bearing

6203LL8

Drum

Head

Screw

Cover

5

155

155

Cover 155

Bolt

M10x35

Spring

10

Head Screw

Socket

Head

Pin

10-60

Washer

M12x50

Head

Screw

PI"

4- 12

Gauge

Head

Plate

Pin

5-24

Label

Bolt

MBx30

Spring

Plate

Supporter

Bolt

Max30

M6x15

Washer

14

Holder

Bolt Max30

Washer

14

Pin

6-24

Pole

70

Pin

5-28

Label

12-125

Ring

E-9

Arm

Bearing

26-315

10-340

Ring

E-9

60

Arm

Ring

60

Bolt

M8x20

other

part SpeCifiCatiOns

Bolt

M5x16

lWith Washer)

M5x35

Bolt

M5x12

Bolt

12

M5x14

Screw

Screw

6

IWith Washer)

lWith Warher)

10

10

lWnh Washer)

M8xZO

[With Washer)

[With Washer1

MBx30

IWith Washer1

M5x18

lWith Washer)

M8

M5x12

may

IWith Washer)

differ

from country

MACHINE

213

214

215

216

217

218

219

220

221

222

223

224

225

226

227

228

229

230

231

232

233

234

235

236

237

238

239

240

241

243

244

245

246

247

248

249

250

251

252

253

254

255

2

56

257

258

259

260

261

262

263

264

265

266

268

269

270

271

272

273

274

275

276

277

278

to

country.

1

4

4

1

1

1

1

1

5

1

1

1

1

4

4

4

4

2

2

4

1

2

2

1

1

1

1

2

1

2

2

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

1

2

1

2

2

2

2

1

1

2

1

1

1

1

1

1

1

4

-

Table

~BX

Nu1 M6

"an Head

Screw

lex

NulM12

Spring

Washer

:la1

Washer

3D"g

53

Handle

Supporter

Hex

Bolt

M6x35

Thrust Needle

Straight

Bevel

Screw

TM25

Stable

Bare

3olumn

Snap

Ring

3ellows

Snap

Ring

Hex

Nut

M10

'la1

Washer

Spring

Pin

Stable

Bars

Ut

Washer

Hex

Bolt

M10x140

Pan

Head

Screw

Strain

Relief

CORD

ASSEMBLY

Usembled

Cord

Guard

Pan

Head

Screw

Strain

Relief

Hex

BDII

~10x100

Flat

Washer

-

Bolt

M10

Base

Grip

30

Flat

Washer

Flat

Washer

Hex

Nut

M10

Handle

175

Woodruff

Key

Split Pin

3

Hex

Bolt

MBx20

Compression

Flat

Washer

Handle

Shaft

Straight

Bevel

Retaining

Ring

Woodruff

Key

Pen

Head

Screw

Scale

Bar

Plane

Bearing

Roller

26-265

Plane

BBarlng

Rod

10-315

Pan

Head

Screw

Key

Pan

Head

Screw

Hex Nut

M10-17

Pan Head

Screw

set

Plate

Pan Head

Screw

Knob

20

Pan

Head

Screw

Spring

Pin

Flat

Washer

12

55

55

10

8-70

11

Cord

11

10

10

0-25

16

4-18

8

Bearing

Gear

4

Spring

Gear

S

4

10

10

M6x50

12

IWith Washer)

1520

28

M5x12

Plug

&

M5x12

16

14

-

12

M5x14

M5x12

M4x10

M5x12

M5x10

M5x12

[With Weshe0

Item

2391

lWith Washer)

IWith Washer)

IWith Washer)

lWith Washerl

lWith Washer)

lWith Washer)

Page 27

.

.

. .

. . . . .

. . . . . . . . . . . .

. . .

. . . . . . . . . . . . . .

. . . . . . . . . . -. . -. . . . . . . .

MAKITA LIMITED ONE YEAR WARRANTY

Warranty

Every Makita tool is thoroughly inspected and tested before leaving the factory. It is warranted to

be free of defects from workmanship and materials for the period of ONE YEAR from the date of

original purchase. Should any trouble develop during this one-year period, return the COMPLETE

tool, freight prepaid, to one of Makita’s Factory or Authorized Service Centers. If inspection shows

the trouble is caused by defective workmanship or material, Makita will repair (or at our option,

replace) without charge.

This Warranty does not apply where:

repairs have been made or attempted by others:

repairs are required because of

The tool has been abused, misused or improperly maintained;

alterations have been made to the tool.

IN NO EVENT SHALL MAKITA BE LIABLE FOR ANY INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES FROM THE SALE OR USE OF THE PRODUCT. THIS DISCLAIMER

APPLIES BOTH DURING AND AFTER THE TERM OF THIS WARRANTY.

MAKITA DISCLAIMS LIABILITY FOR ANY IMPLIED WARRANTIES, INCLUDING IMPLIED

WARRANTIES

AFTER THE ONE-YEAR TERM OF THIS WARRANTY.

This Warranty gives you specific legal rights, and you may also have other rights which vary from

state to state. Some states do not allow the exclusion or Limitation of incidental or consequential

damages,

limitation on how long an implied warranty lasts,

OF

“MERCHANTABILITY” AND “FITNESS FOR A SPECIFIC PURPOSE,”

so

the above limitation or exclusion may not apply to you. Some states do not allow

normal

wear and tear:

Policy

so

the above limitation may not apply to you.

Makita Corporation

3-11

-8,

Sumiyoshi-cho,

Anjo, Aichi

446

883441

Japan

-

065

PRINTED IN JAPAN

1991 - 8

-

N

Loading...

Loading...