MakeUp Air Electric Heater, Modular Electric Heater, Electric Heat Module, Electric Insert Maintenance Manual

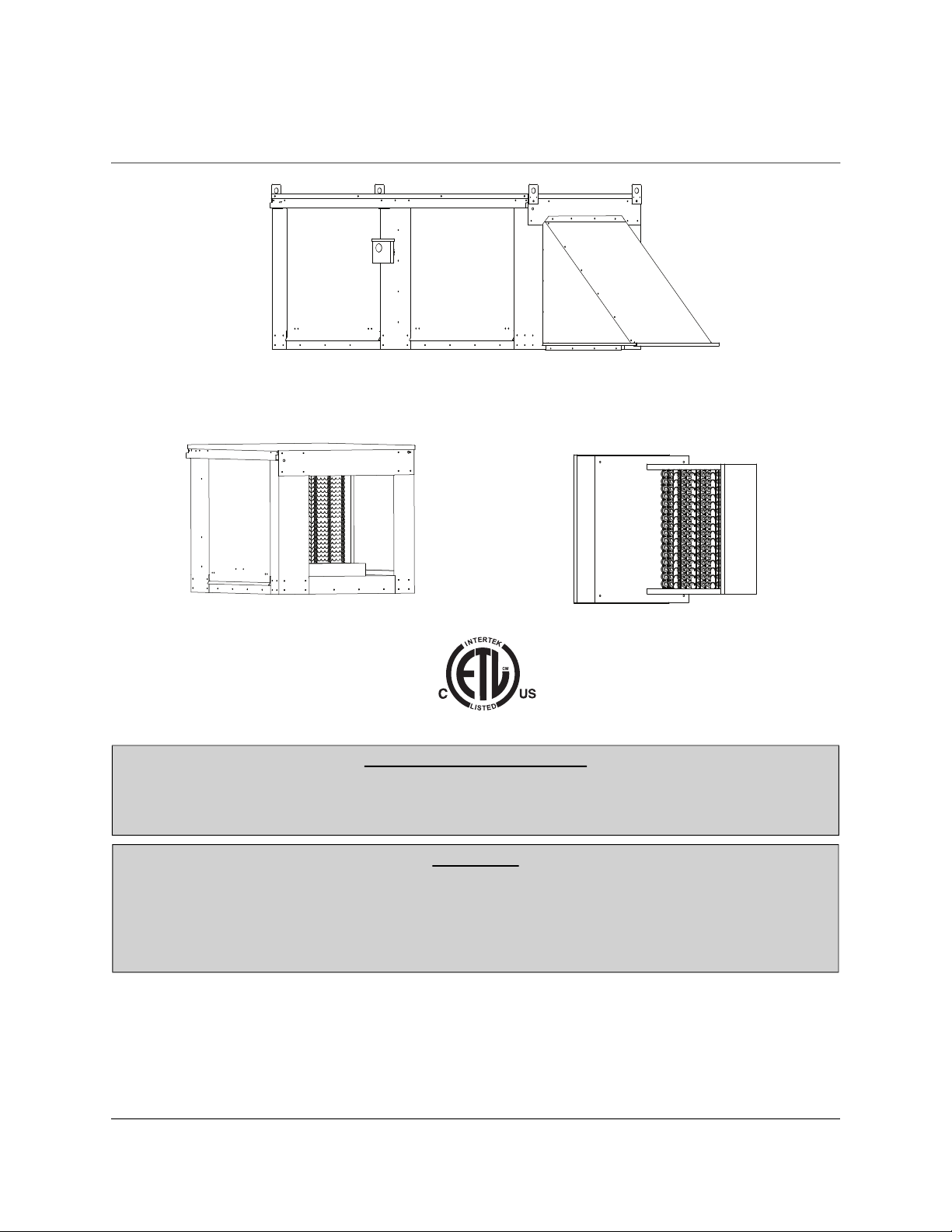

Standard and Modular Electric Heater and Inserts

Installation, Operation, and Maintenance Manual

Modular Electric Heater

Electric Heat Module

RECEIVING AND INSPECTION

Upon receiving unit, check for any interior and exterior damage, and if found, report it

immediately to the carrier. Also check that all accessory items are accounted for and are

damage free.

WARNING!!

Installation of this equipment should only be performed by a qualified professional who has

read and understands these instructions and is familiar with proper safety precautions.

Improper installation poses serious risk of injury due to electric shock and other potential

hazards. Read this manual thoroughly before installing or servicing this equipment. ALWAYS

disconnect power prior to working on equipment.

Save these instructions. This document is the property of the owner of this equipment and is required

for future maintenance. Leave this document with the owner when installation or service is complete.

Electric Insert

A0011031

May 2020 Rev. 24

Table of Contents

WARRANTY ............................................................................................................................................................................. 3

INSTALLATION ........................................................................................................................................................................ 4

Mechanical ........................................................................................................................................................................ 4

Service Clearance ..................................................................................................................................................... 4

Common Electric Heater Calculations ....................................................................................................................... 4

Applied vs Rated KW Factors ....................................................................................................................................4

Curb and Ductwork ............................................................................................................................................................ 6

Roof Mount Installation .............................................................................................................................................. 7

Installation with Exhaust Fan ..................................................................................................................................... 7

Duct Mount Installation .............................................................................................................................................. 8

Indoor (Inline) Installation .......................................................................................................................................... 8

Heat Module Add-On Installation ...............................................................................................................................9

ELECTRICAL ..........................................................................................................................................................................10

Fan to Building Wiring Connection .................................................................................................................................. 12

Remote Control Panel ..................................................................................................................................................... 12

Electric Cabinet Heater ............................................................................................................................................13

AC Interlock .............................................................................................................................................................13

Motorized Intake Damper ........................................................................................................................................ 13

Permanent Split Capacitor (PSC) Motor Speed Control ................................................................................................. 13

Electronically Commutated Motor (ECM) Speed Control ................................................................................................ 14

External PWM Signal ...............................................................................................................................................14

Unit Mount Controller ...................................................................................................................................................... 14

Motor Speed Controller (MSC) Installation ...................................................................................................................... 15

MSC Controls Overview .................................................................................................................................................. 16

MSC Menu ...............................................................................................................................................................16

Input Threshold ........................................................................................................................................................18

MSC Menu Tree ...................................................................................................................................................... 19

Heater Controller ..................................................................................................................................................... 20

Variable Frequency Drive (VFD) ..................................................................................................................................... 21

Variable Frequency Drive (VFD) Installation ........................................................................................................... 22

Input AC Power ........................................................................................................................................................ 22

VFD Output Power ................................................................................................................................................... 22

VFD Programming ................................................................................................................................................... 23

ACTECH SMV VFD ................................................................................................................................................. 24

START-UP OPERATION ........................................................................................................................................................25

Start-up Procedure .......................................................................................................................................................... 25

Pulley Adjustment ............................................................................................................................................................ 26

Pulley Alignment/Proper Belt Tension .............................................................................................................................27

Pulley Combination Chart ................................................................................................................................................ 28

Sequence of Operation ................................................................................................................................................... 29

Main Circuit ..............................................................................................................................................................29

Optional Remote Panel Circuit ................................................................................................................................ 30

Silicon Controlled Rectifier (SCR) Electrical Control ....................................................................................................... 31

Modulating Coil Thermostat Settings .............................................................................................................................. 31

Thermostat with Dip Switch Settings ....................................................................................................................... 31

Thermostat without Dip Switch Settings .................................................................................................................. 31

SCR Electrical Circuit Check ...........................................................................................................................................32

Components .................................................................................................................................................................... 33

Remote Panel Option .............................................................................................................................................. 34

Troubleshooting ............................................................................................................................................................... 35

MSC Troubleshooting .............................................................................................................................................. 37

MAINTENANCE ......................................................................................................................................................................38

General Maintenance ...................................................................................................................................................... 38

2 Weeks After Start-up .................................................................................................................................................... 38

Every 3 Months ............................................................................................................................................................... 38

Yearly .............................................................................................................................................................................. 38

Unit Filters ....................................................................................................................................................................... 39

Start-Up and Maintenance Documentation ..................................................................................................................... 40

2

WARRANTY

This equipment is warranted to be free from defects in materials and workmanship, under normal use and

service, for a period of 2-years from date of shipment. This warranty shall not apply if:

1. The equipment is not installed by a qualified installer per the MANUFACTURER’S installation instructions shipped with the product.

2. The equipment is not installed in accordance with Federal, State, or Local codes and regulations.

3. The equipment is misused or neglected, or not maintained per the MANUFACTURER’S maintenance instructions.

4. The equipment is not installed and operated within the limitations set forth in this manual.

5. The invoice is not paid within the terms of the sales agreement.

The MANUFACTURER shall not be liable for incidental and consequential losses and damages potentially

attributable to malfunctioning equipment. Should any part of the equipment prove to be defective in

material or workmanship within the 2-year warranty period, upon examination by the MANUFACTURER,

such part will be repaired or replaced by MANUFACTURER at no charge. The BUYER shall pay all labor

costs incurred in connection with such repair or replacement. Equipment shall not be returned without

MANUFACTURER’S prior authorization, and all returned equipment shall be shipped by the BUYER,

freight prepaid to a destination determined by the MANUFACTURER.

NOTE: To receive warranty coverage for this product, copy and print out the “Start-Up and

Maintenance Documentation” on page 40. Fill in all details required. Fax the page to 1-919-516-8710

or call 1-866-784-6900 for email information within thirty (30) days of purchase.

3

INSTALLATION

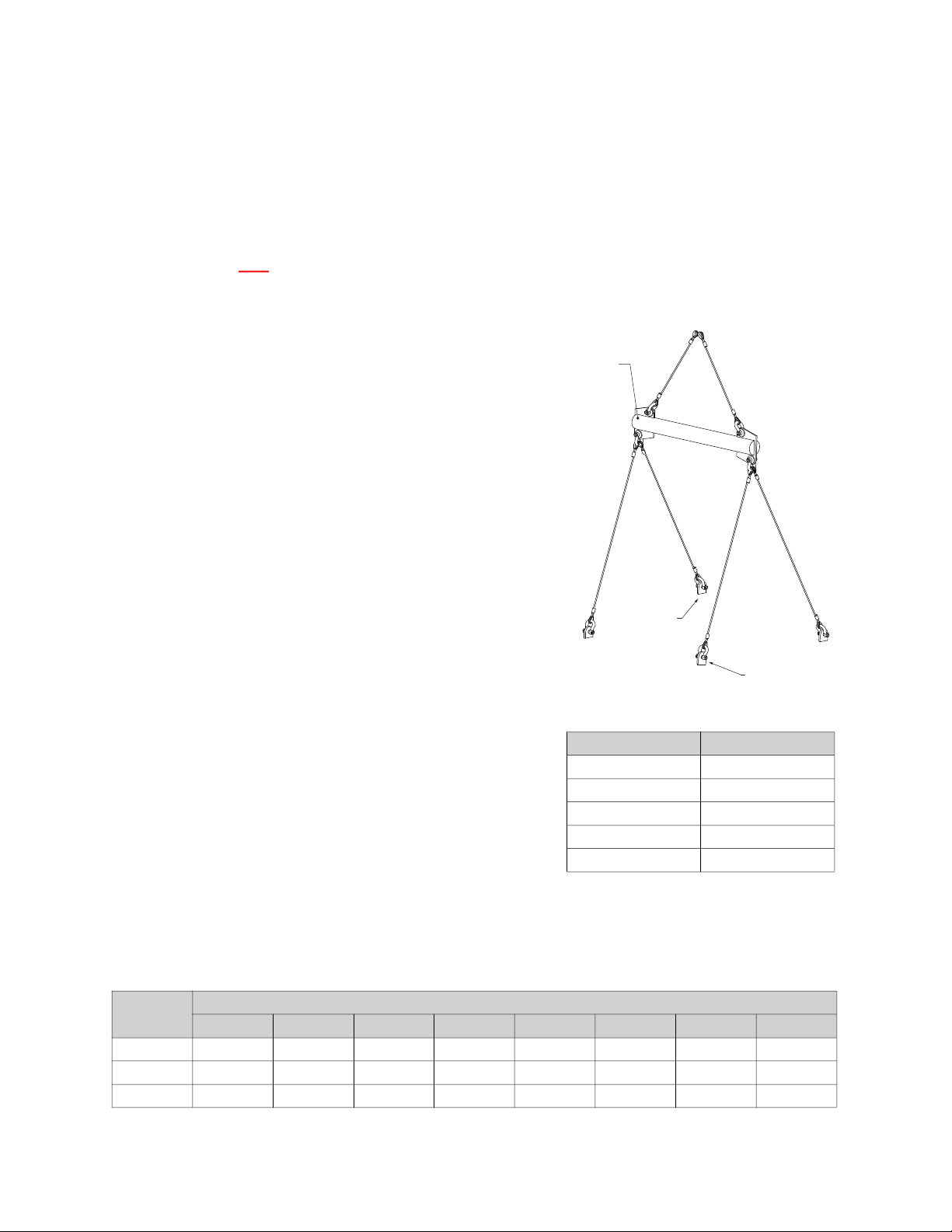

Spreader

Bar

Lifting Lugs

Lifting Lugs

It is imperative that this unit is installed and operated with the designed airflow and electrical supply in

accordance with this manual. If there are any questions about any items, please call the service

department at 1-866-784-6900 for warranty and technical support issues.

Mechanical

WARNING: DO NOT RAISE UNIT BY THE INTAKE HOOD, BLOWER, MOTOR SHAFT, OR

BEARINGS. USE ALL LIFTING LUGS PROVIDED WITH A SPREADER BAR OR SLING UNDER THE

UNIT.

Figure 1 - Spreader Bar

Site Preparation

1. Provide clearance around installation site to safely rig and lift equipment into its final position (Figure 1). Supports must adequately support equipment. Refer to manufacturer’s estimated weights.

2. Locate unit close to the space it will serve to reduce long, twisted duct runs.

3. Consider general service and installation space when locating unit.

4. Do not allow air intake to face prevailing winds. Support

unit above ground or at roof level high enough to prevent

precipitation from being drawn into its inlet. The inlet must

also be located at least 10 feet away from any exhaust

vents. The fan inlet shall be located in accordance with the

applicable building code provisions for ventilation air.

Service Clearance

Refer to Table 1 for unit size clearance specifications. This will

allow for enough clearance in the front, back and sides of the

unit for servicing and maintenance of the unit.

Table 1 - Clearance Chart

Unit Size Clearance

1 24”

2 36”

3 42”

4 48”

5 54”

Common Electric Heater Calculations

Conversion:

1 KW = 3413

Load Requirement:

KW = (CFM x Temperature Rise) / 3160

Line Current (1 Phase):

Amperage = (KW x 1000) / Volts

Applied vs Rated KW Factors

Rated

Voltage

208 .92 1.00 1.12 1.22 1.33 - - -

460 - - - - - .91 1.00 1.09

480 - - - - - .84 .92 1.00

200 208 220 230 240 440 460 480

Applied Voltage

4

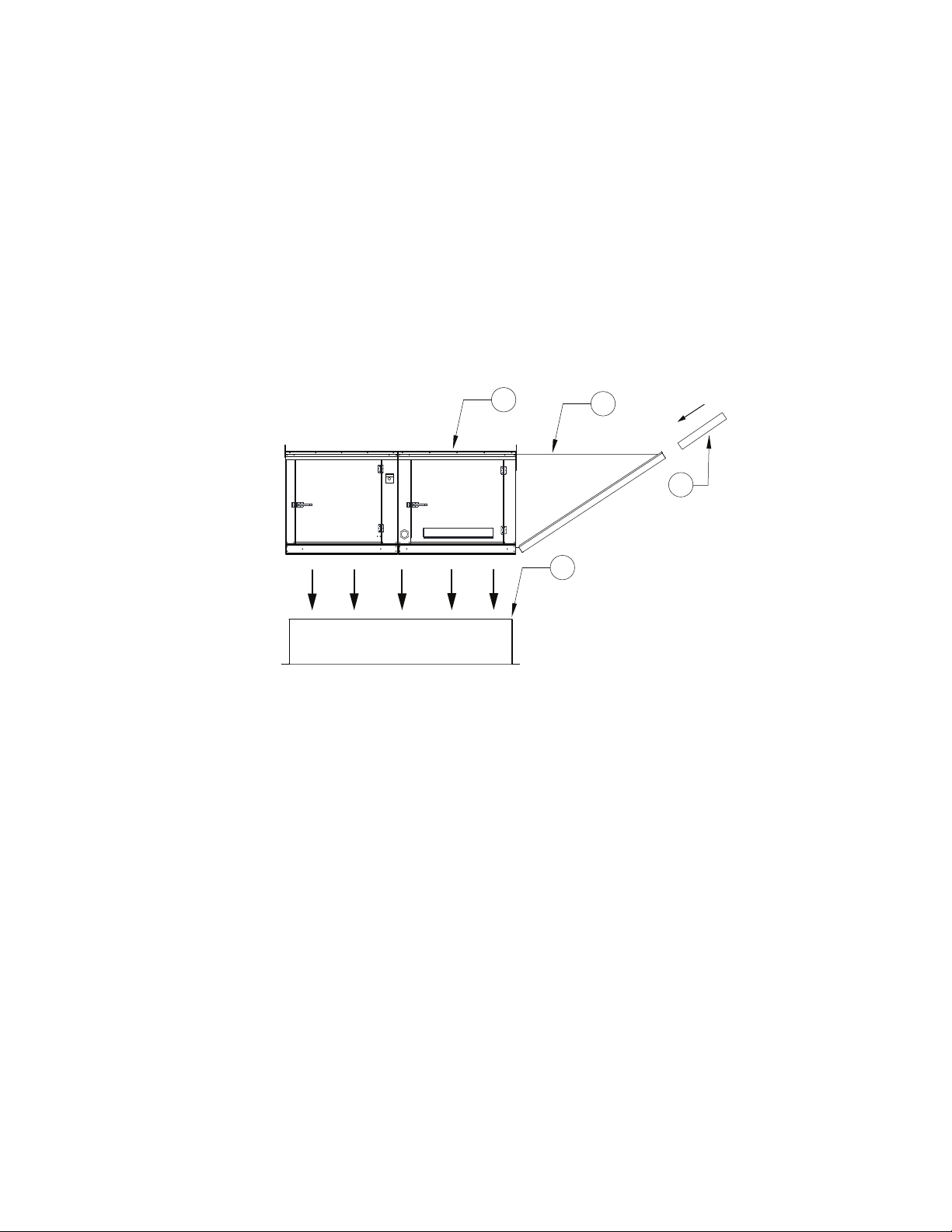

Intake Assembly

1

2

3

4

Intakes and curbs (Figure 2) are shipped on a separate skid. Upon unit arrival, perform the following steps

to assemble the intake to the unit.

1. Apply silicone or weather-proof gasket on the backside of the flanges of the intake hood or V-bank intake.

2. Secure the flanges of the intake hood to the unit with the supplied sheet metal screws.

3. Use caulk on the outside of the screws to prevent water leaks.

4. If the unit is a modular unit with a V-bank or evaporative cooler section, the V-bank or evaporative cooler will bolt to the heater with the bolts provided.

5. Slide the filters down the filter track.

Figure 2 - Intake and Curb Assembly

1. Unit

2. Intake Housing

3. Intake Filter(s)

4. Curb

5

Curb and Ductwork

This fan was specified for a specific CFM and static pressure. The ductwork attached to this unit will

significantly affect airflow performance. When using rectangular ductwork, elbows must be radius throat,

radius back with turning vanes. Flexible ductwork and square throat/square back elbows should not be

used. Any transitions and/or turns in the ductwork near the fan outlet will cause system effect. System

effect will drastically increase the static pressure and reduce airflow.

• Table 2 shows the minimum fan outlet duct sizes and straight lengths required for optimal fan

performance.

• Do not use the unit to support ductwork in any way. This may cause damage to the unit.

• Follow SMACNA standards and manufacturer's requirements for the duct runs. Fans designed

for rooftop installation should be installed on a prefabricated or factory-built roof curb.

• Follow curb manufacturer’s instructions for proper curb installation.

• The unit should be installed on a curb and/or rail that meets local code height requirements.

• Make sure the duct connection and fan outlet are properly aligned and sealed.

• Secure fan to curb through vertical portion of the ventilator base assembly flange. Use a minimum of

eight (8) lug screws, anchor bolts, or other suitable fasteners (not furnished). Shims may be required

depending upon curb installation and roofing material.

• Verify all fasteners are secure. Figure 3 through Figure 6 show different mechanical installations.

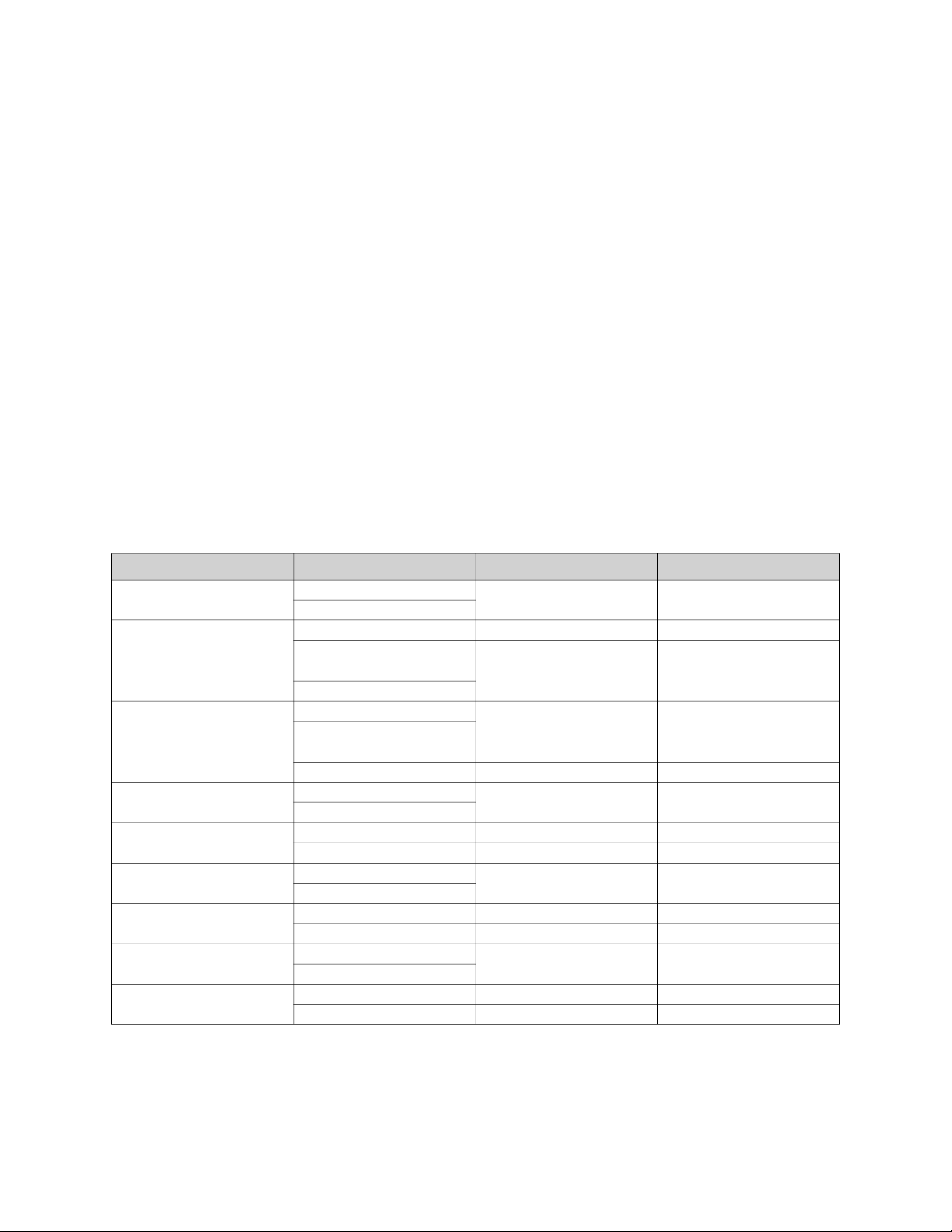

Table 2 - Required Supply Ductwork

Blower Size (Inches) Discharge Duct Size Straight Duct Length*

10

15D, 16Z, 18Z

12

15

20D, 20Z, 22Z

18

24D, 25Z

20

30D, 28Z

25

36D

Side

Down

Side 20” x 20” 72”

Down 14” x 14” 48”

Side

Down

Side

Down

Side 26” x 26” 108”

Down 20” x 20” 72”

Side

Down

Side 30” x 30” 108”

Down 24” x 24” 86”

Side

Down

Side 32” x 32” 168”

Down 26” x 26” 108”

Side

Down

Side 36” x 36” 189”

Down 32” x 32” 168”

14” x 14” 48”

16” x 16” 54”

20” x 20” 72”

24” x 24” 86”

26” x 26” 108”

32” x 32” 168”

6

WARNING: ELECTRIC HEATERS HAVE TWO POWER INPUTS. THE EXTERNAL DISCONNECT

AIRFLOW

1

2

3

4

5

6

8

7

9

10

11

AIRFLOW

1

2

3

4

6

8

7

5

9

INTERRUPTS POWER TO THE MOTOR AND CONTROLS ONLY. THE ELECTRIC COIL POWER IS

INTERRUPTED BY THE DISCONNECT SWITCH ON THE ELECTRIC COIL DOOR.

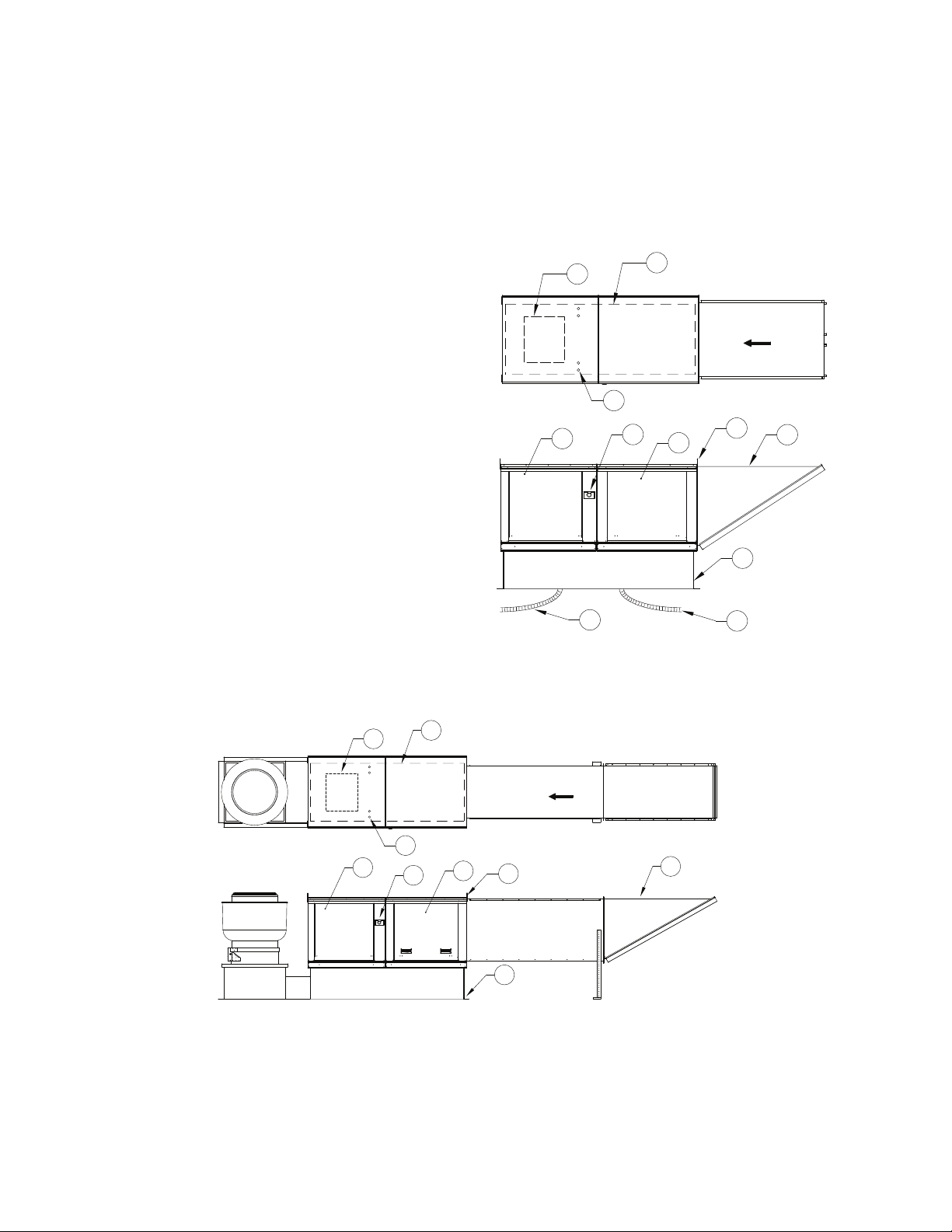

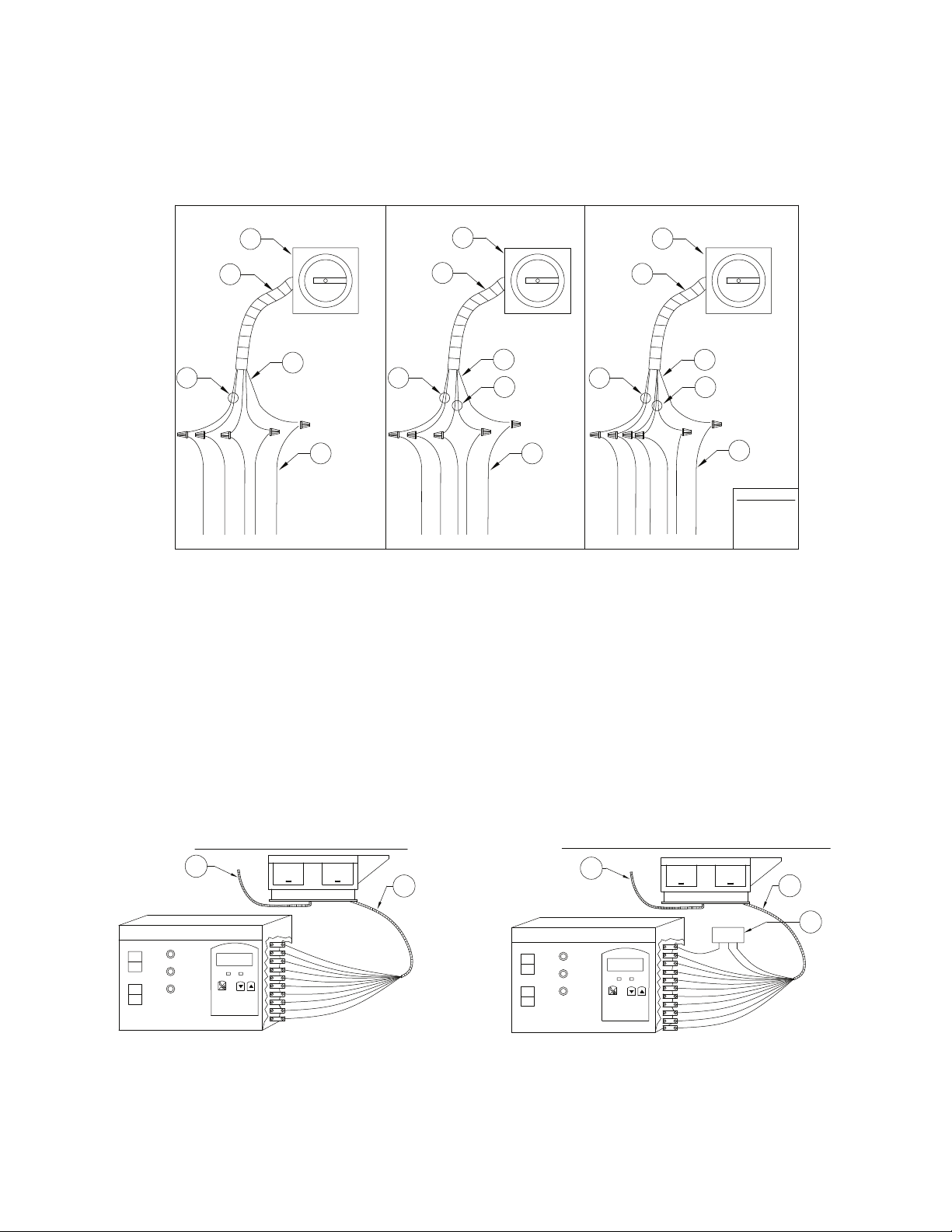

Roof Mount Installation

Note: Refer to submittal drawings for specific unit dimensions.

Figure 3 - Roof Mount Details

1. Discharge Opening

2. Curb Outer Wall

3. Flex Conduit for Field Wiring

4. Intake Housing

5. Lifting Lugs

6. Electric Heat Module

7. Service Disconnect Switch

8. Blower/Motor Access Door

9. Curb with Support Legs or Rail (20” High)

10. Control Drop

11. Motor Drop

Max. Roof Opening 2” Smaller than Curb

Outside Dimension.

Installation with Exhaust Fan

Note: Refer to submittal drawings for specific unit dimensions.

Figure 4 - Exhaust Fan Details

1. Discharge Opening

2. Curb Outer Wall

3. Flex Conduit for Field Wiring

4. Intake Housing

5. Lifting Lugs

6. Electric Heat Module

7. Service Disconnect Switch

8. Blower/Motor Access Door

9. Curb with Support Legs or Rail (20” High)

7

WARNING: ELECTRIC HEATERS HAVE TWO POWER INPUTS. THE EXTERNAL DISCONNECT

AIRFLOW

1

3

2

AIRFLOW

1

2

3

4

5

7

6

INTERRUPTS POWER TO THE MOTOR AND CONTROLS ONLY. THE ELECTRIC COIL POWER IS

INTERRUPTED BY THE DISCONNECT SWITCH ON THE ELECTRIC COIL DOOR.

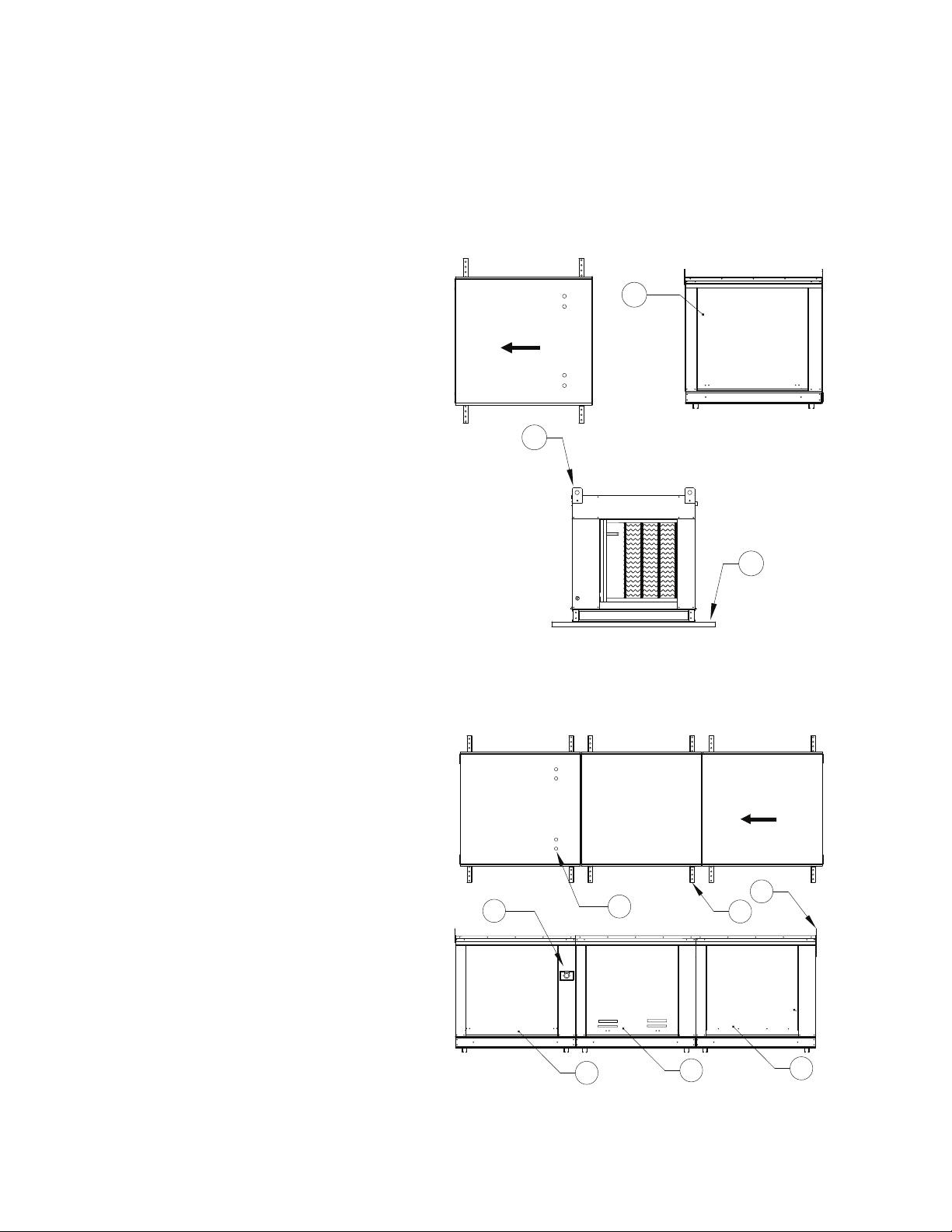

Duct Mount Installation

Note: Refer to submittal drawings for specific unit dimensions.

Figure 5 - Duct Mount Details

1. Control/Coil Access Door

2. Lifting Lugs

3. Optional Uni-Strut Base

Indoor (Inline) Installation

Note: Refer to submittal drawings for specific unit dimensions.

Figure 6 - Indoor Installation Details

1. Flex Conduit for Field Wiring

2. Optional Uni-Strut Base

3. Lifting Lugs

4. Filter Access Door

5. Electric Heat Module

6. Blower/Motor Access Door

7. Service Disconnect Switch

8

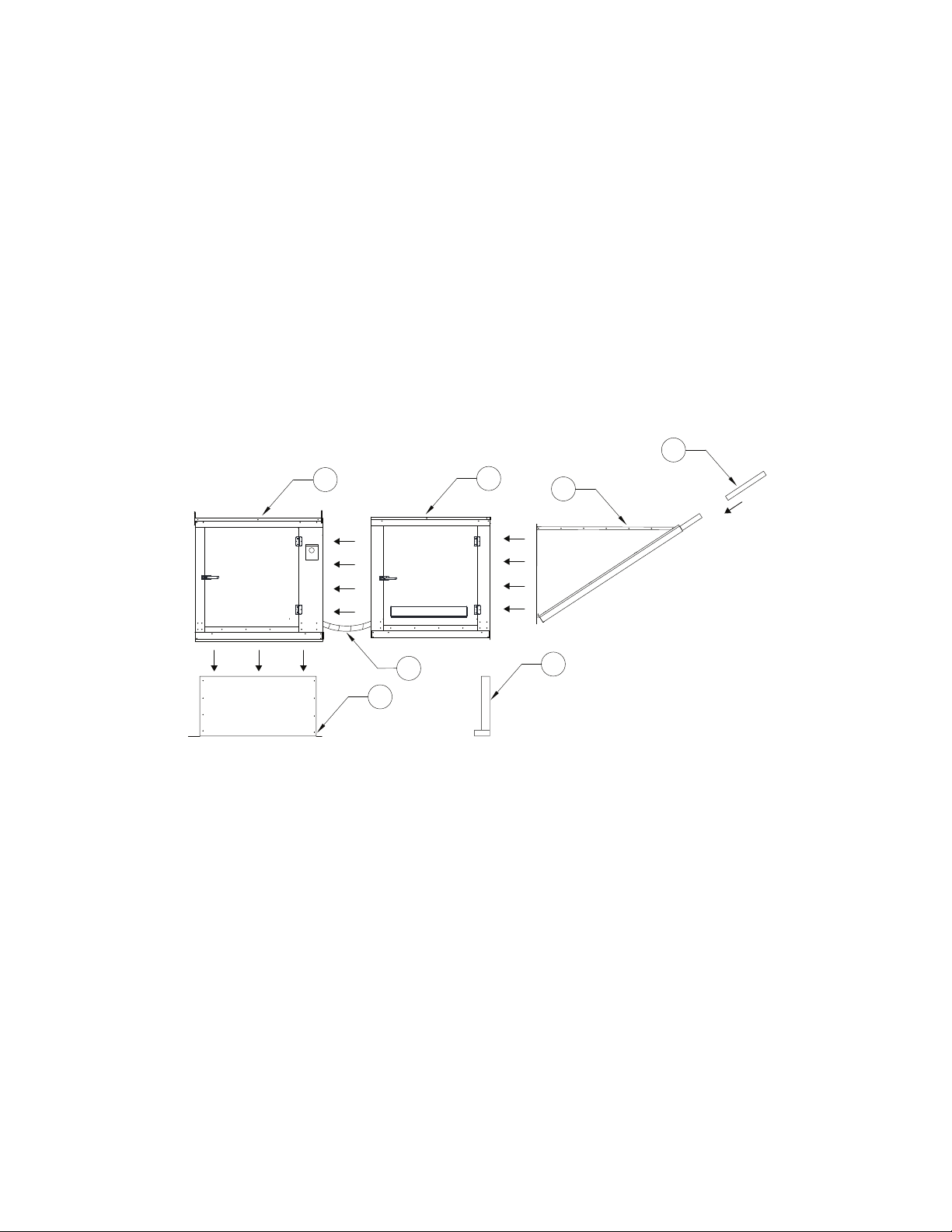

Heat Module Add-On Installation

2

3

4

1

5

7

6

Modular heat units (Figure 7) that are ordered to provide heat onto an existing blower only application

require field mechanical and wiring installation.

1. Remove existing intake housing and lifting lugs from the blower section intake side.

2. Attach heat module to blower intake using the provided sheet metal screws and bolts. Tighten screws and bolts to compress the gasket between the heat module and the blower module.

3. Support and level the end of the heat module (end opposite the blower) with the provided equipment legs/rails.

4. Attach the intake housing to the intake side of the heater module.

5. Drill a hole in the discharge of the blower large enough to insert the discharge control sensor (if provided). Install the sensor through the hole.

6. Wire the sensor and coil as indicated on the supplied wiring schematic. Route all wiring through metal conduit.

7. After the add-on installation is complete, refer to “Start-up Procedure” on page 25.

Figure 7 - Heat Module

1. Blower

2. Electric Heat Module

3. Intake Housing

4. Filters

5. Equipment Legs

6. Conduit

7. Curb

9

ELECTRICAL

WARNING!!

Disconnect power before installing or servicing unit. High voltage electrical input is needed for

this equipment. A qualified electrician should perform this work.

Before connecting power to the heater, read and understand the entire section of this document. As-built

wiring diagrams are furnished with each unit by the factory and are attached to the control module’s door

or provided with paperwork packet.

Electrical wiring (Table 3) and connections must be made in accordance with local ordinances and the

National Electric Code, ANSI/NFPA 70. Verify the voltage and phase of the power supply, and the wire

amperage capacity is in accordance with the unit nameplate. For additional safety information, refer to

AMCA publication 410-96, Recommended Safety Practices for Users and Installers of Industrial and

Commercial Fans.

1. Always disconnect power before working on or near this equipment. Lock and tag the disconnect switch and/or breaker to prevent accidental power-up.

2. An electrical drop containing the line voltage power wiring is shipped with every unit. The electrical

drop should be brought through one of the conduit openings located in the base of the unit (Figure 3),

run through the curb, and connected to a junction box inside the building.

3. A dedicated branch circuit should supply the motor circuit with short circuit protection according to the National Electric Code. This dedicated branch should run to the junction box.

4. A separate power source should supply the electric coil power. Power from the building breaker

should be wired directly to the coil disconnect. This should be done using wire of the proper gauge as

indicated in Table 3. A hole must be drilled in the fan enclosure to properly run the electric coil

power.

5. Verify that the power source is compatible with the requirements of your equipment. The nameplate identifies the proper phase and voltage of the equipment.

6. Units shipped with a remote HMI will require a second drop through the base of the unit. It is important to route the motor wires in a separate conduit from the HMI wiring. Refer to Figure 3.

7. Before connecting the unit to the building’s power source, verify that the power source wiring is deenergized.

8. Secure the power cable to prevent contact with sharp objects.

9. Do not kink power cable and never allow the cable to encounter oil, grease, hot surfaces, or chemicals.

10. Before powering up the unit, make sure that the fan rotates freely. Make sure that the interior of the unit is free of loose debris or shipping materials.

11. If any of the original wire supplied with the unit must be replaced, it must be replaced with type THHN wire or equivalent.

WARNING: ELECTRIC HEATERS HAVE TWO POWER INPUTS. THE EXTERNAL DISCONNECT

INTERRUPTS POWER TO THE MOTOR AND CONTROLS ONLY. THE ELECTRIC COIL POWER IS

INTERRUPTED BY THE DISCONNECT SWITCH ON THE ELECTRIC COIL DOOR.

10

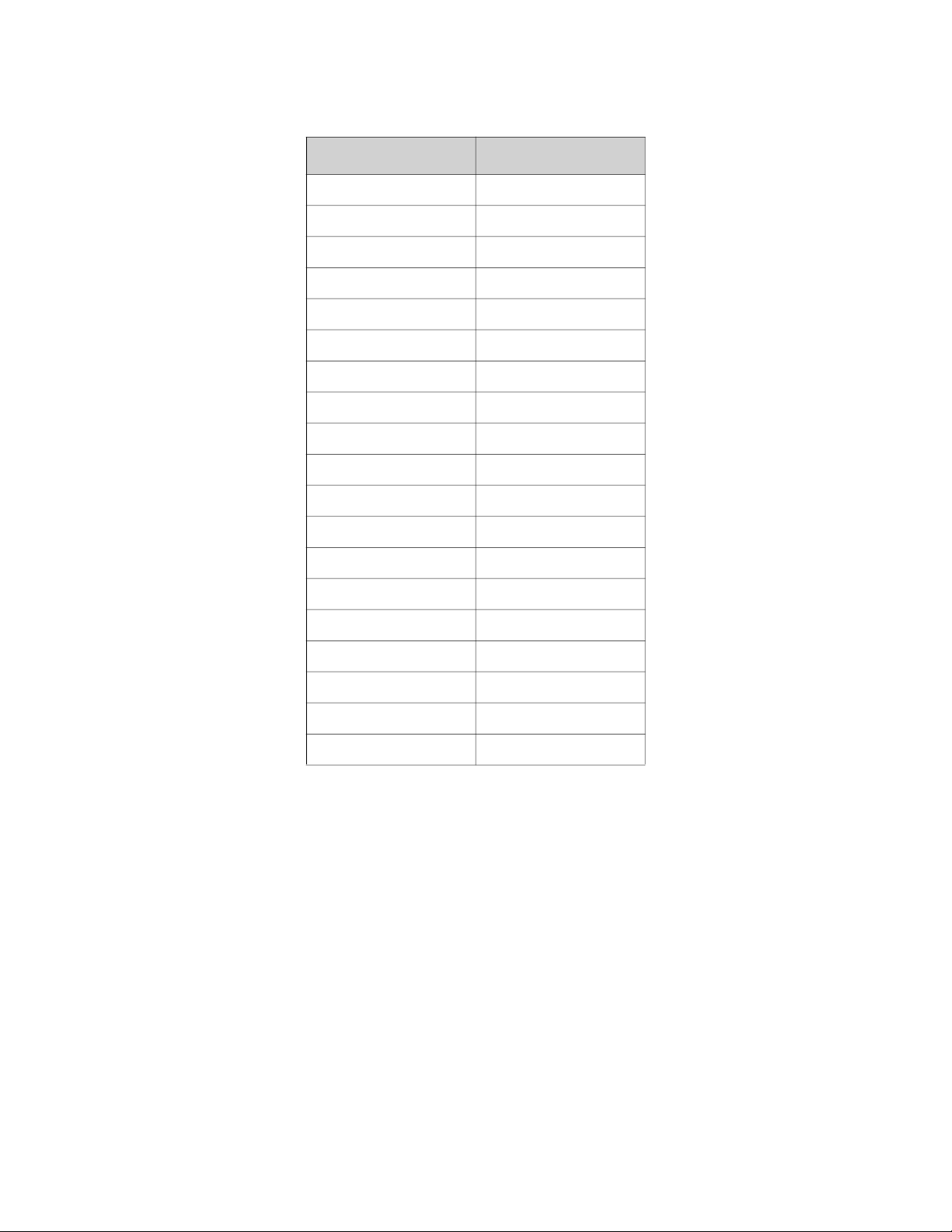

Table 3 - Copper Wire Ampacity

Wire Size AWG Maximum Amps

14 15

12 20

10 30

8 50

6 65

4 85

3 100

2 115

1 130

1/0 150

2/0 175

3/0 200

4/0 230

250 255

300 285

350 310

400 335

500 380

600 420

11

Fan to Building Wiring Connection

WHBK

GR

120V 1 PH. 208-240V 1 PH.

208-240/460/600V 3 PH.

1

2

3

4

1

2

1

2

WH - WHITE

RD - RED

WIRE COLOR

BK - BLACK

GR - GREEN

5

BK

GR

3

4

5

6

WH

RD

BK

GR

3

4

5

7

BK

WH

RD

BK

WH

RD

RD

120V Optional

Electric Heater Remote Panel

Blower On

Blower Off

Heat

Vent

Blower On

Power

Heat On

GY

T4

RD

T9

GY

BK

OR

PR

BL

BK

WH

T5

T14

T16

6

1

N

2

Electric Heater Remote Panel

Vent

Heat

Cool

Blower On

Blower Off

Heat On

BL

GY

PR

BL

RD

BK

T9

T4

11

T5

T14

T16

Blower On

Power

WH

GY

BK

OR

N

6

2

1

NO

NC

1

PR

E

BK

C

STANDARD ELECTRIC HEATER REMOTE PANEL

COOLING INTERLOCK AND EXHAUST ON IN FIRE CONTROL

OVERRIDE

OVERRIDE

RD

7

RD

7

1

2

3

1

2

Figure 8 - Wiring Connection Details

1. Disconnect Switch

2. Galflex Conduit (In Unit)

3. Factory Wiring

4. Field Supplied Wiring - From building power or pre-wired control panel.

Remote Control Panel

On units shipped with the optional remote control panel, an electrical drop containing the panel wiring is

provided with the heater. There is a terminal strip inside the remote panel that matches the terminals in the

heater unit. The remote panel should be wired as shown in Figure 9. Wiring may vary by unit, refer to

electrical schematics that were provided with your unit.

Figure 9 - Typical Remote Control Panel Wiring

5. 120V Single Phase Standing Power

6. 208-240 Single Phase

7. Three Phase

1. Motor Connection 2. Control Connection 3. Fire System Micro-switch

12

Loading...

Loading...