MakeUp Air Electric Heater, Modular Electric Heater, Electric Heat Module, Electric Insert Maintenance Manual

Page 1

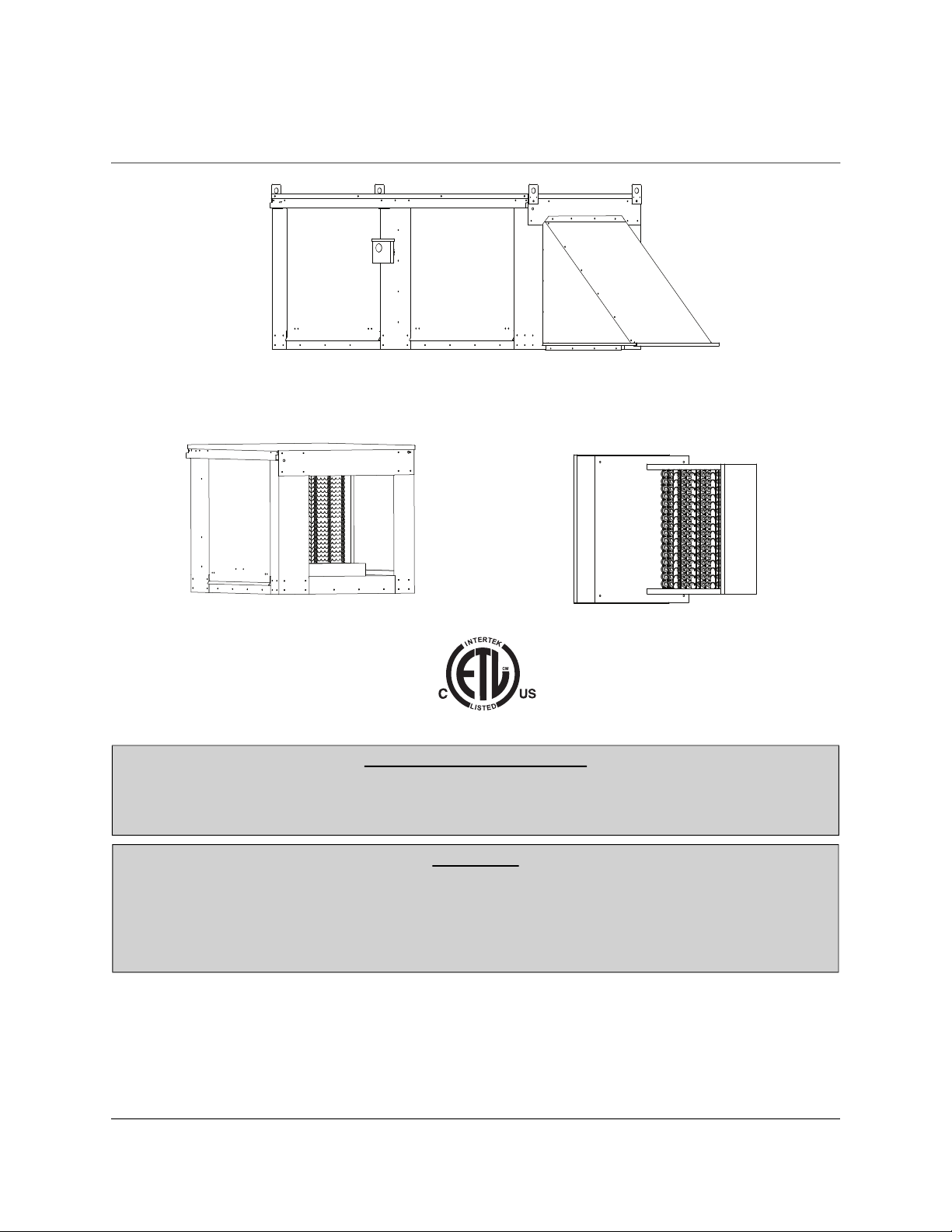

Standard and Modular Electric Heater and Inserts

Installation, Operation, and Maintenance Manual

Modular Electric Heater

Electric Heat Module

RECEIVING AND INSPECTION

Upon receiving unit, check for any interior and exterior damage, and if found, report it

immediately to the carrier. Also check that all accessory items are accounted for and are

damage free.

WARNING!!

Installation of this equipment should only be performed by a qualified professional who has

read and understands these instructions and is familiar with proper safety precautions.

Improper installation poses serious risk of injury due to electric shock and other potential

hazards. Read this manual thoroughly before installing or servicing this equipment. ALWAYS

disconnect power prior to working on equipment.

Save these instructions. This document is the property of the owner of this equipment and is required

for future maintenance. Leave this document with the owner when installation or service is complete.

Electric Insert

A0011031

May 2020 Rev. 24

Page 2

Table of Contents

WARRANTY ............................................................................................................................................................................. 3

INSTALLATION ........................................................................................................................................................................ 4

Mechanical ........................................................................................................................................................................ 4

Service Clearance ..................................................................................................................................................... 4

Common Electric Heater Calculations ....................................................................................................................... 4

Applied vs Rated KW Factors ....................................................................................................................................4

Curb and Ductwork ............................................................................................................................................................ 6

Roof Mount Installation .............................................................................................................................................. 7

Installation with Exhaust Fan ..................................................................................................................................... 7

Duct Mount Installation .............................................................................................................................................. 8

Indoor (Inline) Installation .......................................................................................................................................... 8

Heat Module Add-On Installation ...............................................................................................................................9

ELECTRICAL ..........................................................................................................................................................................10

Fan to Building Wiring Connection .................................................................................................................................. 12

Remote Control Panel ..................................................................................................................................................... 12

Electric Cabinet Heater ............................................................................................................................................13

AC Interlock .............................................................................................................................................................13

Motorized Intake Damper ........................................................................................................................................ 13

Permanent Split Capacitor (PSC) Motor Speed Control ................................................................................................. 13

Electronically Commutated Motor (ECM) Speed Control ................................................................................................ 14

External PWM Signal ...............................................................................................................................................14

Unit Mount Controller ...................................................................................................................................................... 14

Motor Speed Controller (MSC) Installation ...................................................................................................................... 15

MSC Controls Overview .................................................................................................................................................. 16

MSC Menu ...............................................................................................................................................................16

Input Threshold ........................................................................................................................................................18

MSC Menu Tree ...................................................................................................................................................... 19

Heater Controller ..................................................................................................................................................... 20

Variable Frequency Drive (VFD) ..................................................................................................................................... 21

Variable Frequency Drive (VFD) Installation ........................................................................................................... 22

Input AC Power ........................................................................................................................................................ 22

VFD Output Power ................................................................................................................................................... 22

VFD Programming ................................................................................................................................................... 23

ACTECH SMV VFD ................................................................................................................................................. 24

START-UP OPERATION ........................................................................................................................................................25

Start-up Procedure .......................................................................................................................................................... 25

Pulley Adjustment ............................................................................................................................................................ 26

Pulley Alignment/Proper Belt Tension .............................................................................................................................27

Pulley Combination Chart ................................................................................................................................................ 28

Sequence of Operation ................................................................................................................................................... 29

Main Circuit ..............................................................................................................................................................29

Optional Remote Panel Circuit ................................................................................................................................ 30

Silicon Controlled Rectifier (SCR) Electrical Control ....................................................................................................... 31

Modulating Coil Thermostat Settings .............................................................................................................................. 31

Thermostat with Dip Switch Settings ....................................................................................................................... 31

Thermostat without Dip Switch Settings .................................................................................................................. 31

SCR Electrical Circuit Check ...........................................................................................................................................32

Components .................................................................................................................................................................... 33

Remote Panel Option .............................................................................................................................................. 34

Troubleshooting ............................................................................................................................................................... 35

MSC Troubleshooting .............................................................................................................................................. 37

MAINTENANCE ......................................................................................................................................................................38

General Maintenance ...................................................................................................................................................... 38

2 Weeks After Start-up .................................................................................................................................................... 38

Every 3 Months ............................................................................................................................................................... 38

Yearly .............................................................................................................................................................................. 38

Unit Filters ....................................................................................................................................................................... 39

Start-Up and Maintenance Documentation ..................................................................................................................... 40

2

Page 3

WARRANTY

This equipment is warranted to be free from defects in materials and workmanship, under normal use and

service, for a period of 2-years from date of shipment. This warranty shall not apply if:

1. The equipment is not installed by a qualified installer per the MANUFACTURER’S installation instructions shipped with the product.

2. The equipment is not installed in accordance with Federal, State, or Local codes and regulations.

3. The equipment is misused or neglected, or not maintained per the MANUFACTURER’S maintenance instructions.

4. The equipment is not installed and operated within the limitations set forth in this manual.

5. The invoice is not paid within the terms of the sales agreement.

The MANUFACTURER shall not be liable for incidental and consequential losses and damages potentially

attributable to malfunctioning equipment. Should any part of the equipment prove to be defective in

material or workmanship within the 2-year warranty period, upon examination by the MANUFACTURER,

such part will be repaired or replaced by MANUFACTURER at no charge. The BUYER shall pay all labor

costs incurred in connection with such repair or replacement. Equipment shall not be returned without

MANUFACTURER’S prior authorization, and all returned equipment shall be shipped by the BUYER,

freight prepaid to a destination determined by the MANUFACTURER.

NOTE: To receive warranty coverage for this product, copy and print out the “Start-Up and

Maintenance Documentation” on page 40. Fill in all details required. Fax the page to 1-919-516-8710

or call 1-866-784-6900 for email information within thirty (30) days of purchase.

3

Page 4

INSTALLATION

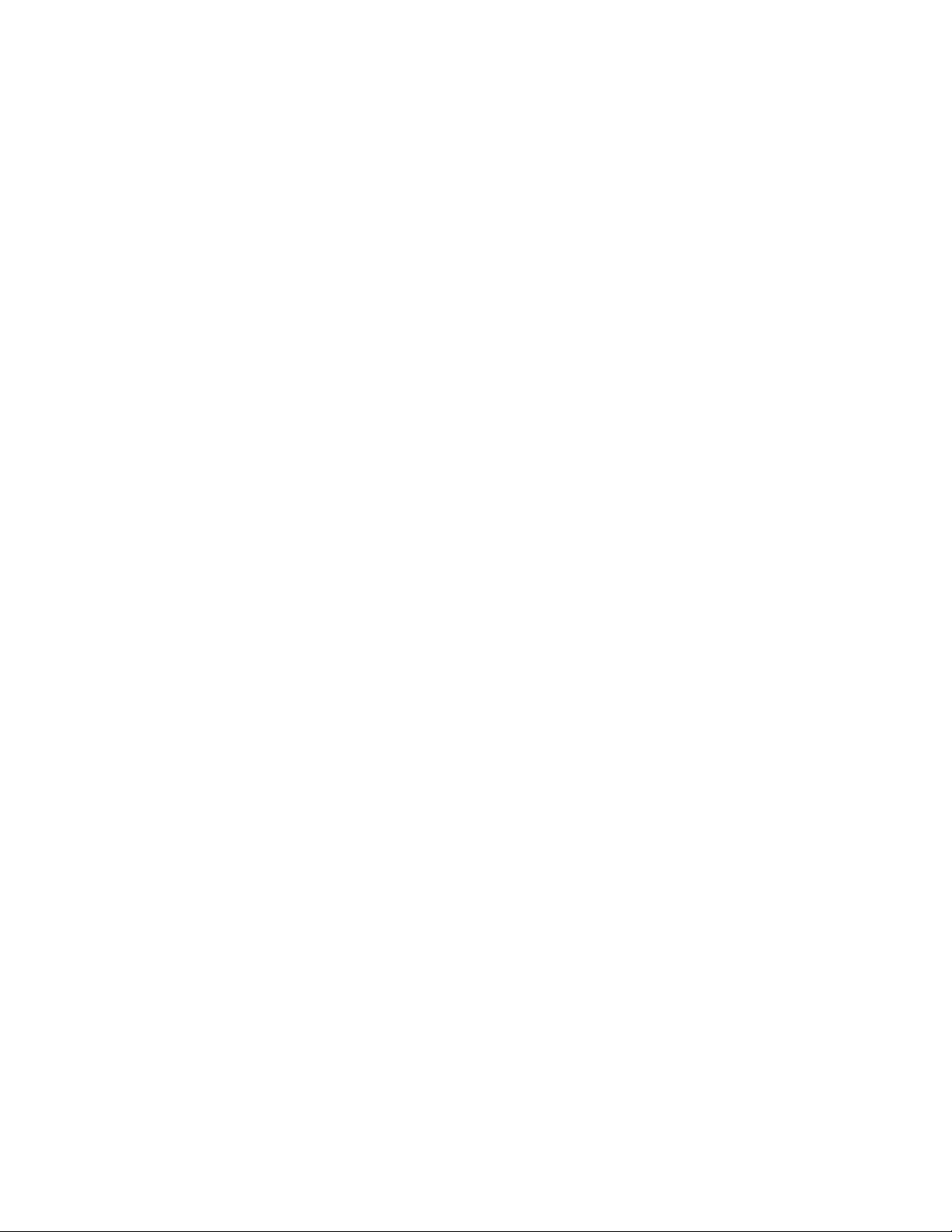

Spreader

Bar

Lifting Lugs

Lifting Lugs

It is imperative that this unit is installed and operated with the designed airflow and electrical supply in

accordance with this manual. If there are any questions about any items, please call the service

department at 1-866-784-6900 for warranty and technical support issues.

Mechanical

WARNING: DO NOT RAISE UNIT BY THE INTAKE HOOD, BLOWER, MOTOR SHAFT, OR

BEARINGS. USE ALL LIFTING LUGS PROVIDED WITH A SPREADER BAR OR SLING UNDER THE

UNIT.

Figure 1 - Spreader Bar

Site Preparation

1. Provide clearance around installation site to safely rig and lift equipment into its final position (Figure 1). Supports must adequately support equipment. Refer to manufacturer’s estimated weights.

2. Locate unit close to the space it will serve to reduce long, twisted duct runs.

3. Consider general service and installation space when locating unit.

4. Do not allow air intake to face prevailing winds. Support

unit above ground or at roof level high enough to prevent

precipitation from being drawn into its inlet. The inlet must

also be located at least 10 feet away from any exhaust

vents. The fan inlet shall be located in accordance with the

applicable building code provisions for ventilation air.

Service Clearance

Refer to Table 1 for unit size clearance specifications. This will

allow for enough clearance in the front, back and sides of the

unit for servicing and maintenance of the unit.

Table 1 - Clearance Chart

Unit Size Clearance

1 24”

2 36”

3 42”

4 48”

5 54”

Common Electric Heater Calculations

Conversion:

1 KW = 3413

Load Requirement:

KW = (CFM x Temperature Rise) / 3160

Line Current (1 Phase):

Amperage = (KW x 1000) / Volts

Applied vs Rated KW Factors

Rated

Voltage

208 .92 1.00 1.12 1.22 1.33 - - -

460 - - - - - .91 1.00 1.09

480 - - - - - .84 .92 1.00

200 208 220 230 240 440 460 480

Applied Voltage

4

Page 5

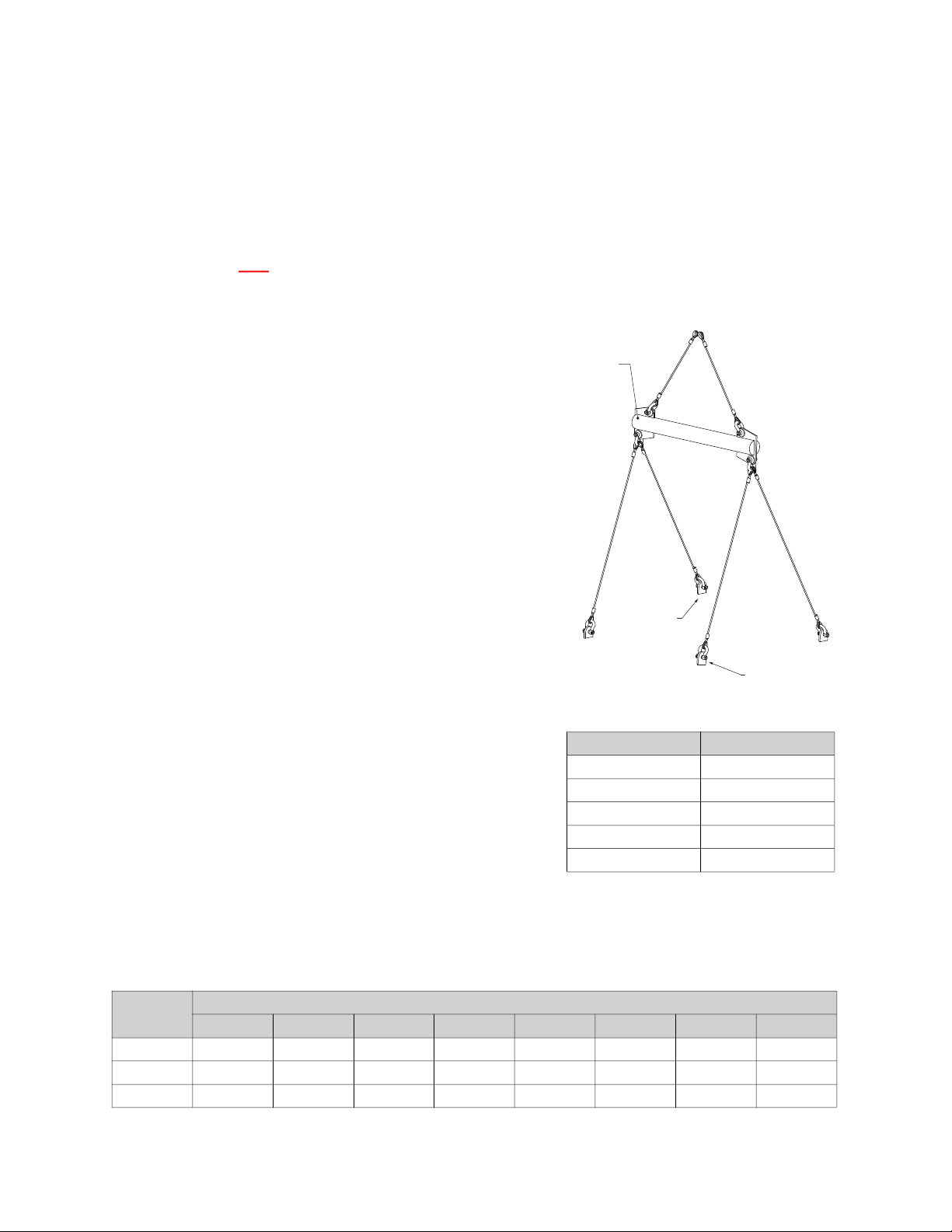

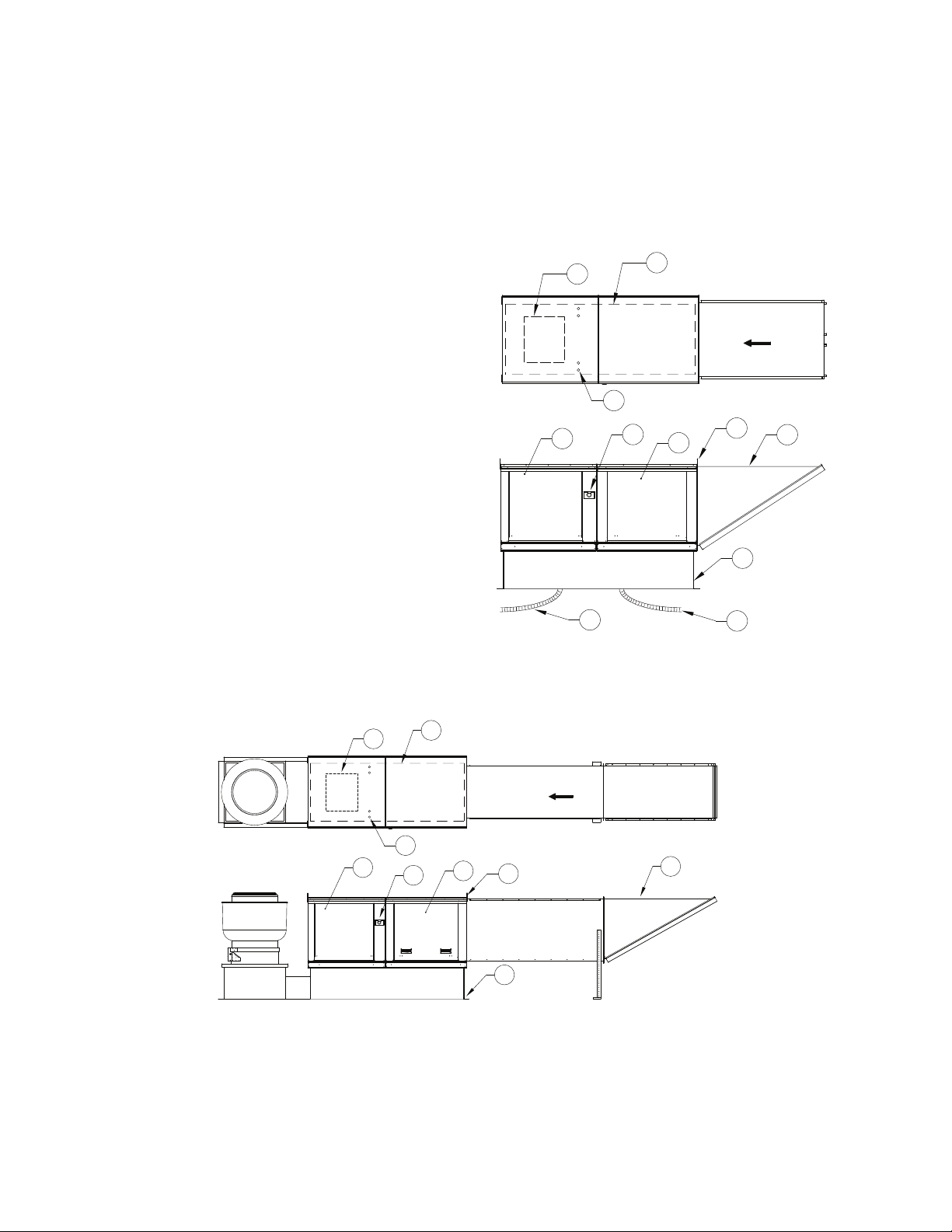

Intake Assembly

1

2

3

4

Intakes and curbs (Figure 2) are shipped on a separate skid. Upon unit arrival, perform the following steps

to assemble the intake to the unit.

1. Apply silicone or weather-proof gasket on the backside of the flanges of the intake hood or V-bank intake.

2. Secure the flanges of the intake hood to the unit with the supplied sheet metal screws.

3. Use caulk on the outside of the screws to prevent water leaks.

4. If the unit is a modular unit with a V-bank or evaporative cooler section, the V-bank or evaporative cooler will bolt to the heater with the bolts provided.

5. Slide the filters down the filter track.

Figure 2 - Intake and Curb Assembly

1. Unit

2. Intake Housing

3. Intake Filter(s)

4. Curb

5

Page 6

Curb and Ductwork

This fan was specified for a specific CFM and static pressure. The ductwork attached to this unit will

significantly affect airflow performance. When using rectangular ductwork, elbows must be radius throat,

radius back with turning vanes. Flexible ductwork and square throat/square back elbows should not be

used. Any transitions and/or turns in the ductwork near the fan outlet will cause system effect. System

effect will drastically increase the static pressure and reduce airflow.

• Table 2 shows the minimum fan outlet duct sizes and straight lengths required for optimal fan

performance.

• Do not use the unit to support ductwork in any way. This may cause damage to the unit.

• Follow SMACNA standards and manufacturer's requirements for the duct runs. Fans designed

for rooftop installation should be installed on a prefabricated or factory-built roof curb.

• Follow curb manufacturer’s instructions for proper curb installation.

• The unit should be installed on a curb and/or rail that meets local code height requirements.

• Make sure the duct connection and fan outlet are properly aligned and sealed.

• Secure fan to curb through vertical portion of the ventilator base assembly flange. Use a minimum of

eight (8) lug screws, anchor bolts, or other suitable fasteners (not furnished). Shims may be required

depending upon curb installation and roofing material.

• Verify all fasteners are secure. Figure 3 through Figure 6 show different mechanical installations.

Table 2 - Required Supply Ductwork

Blower Size (Inches) Discharge Duct Size Straight Duct Length*

10

15D, 16Z, 18Z

12

15

20D, 20Z, 22Z

18

24D, 25Z

20

30D, 28Z

25

36D

Side

Down

Side 20” x 20” 72”

Down 14” x 14” 48”

Side

Down

Side

Down

Side 26” x 26” 108”

Down 20” x 20” 72”

Side

Down

Side 30” x 30” 108”

Down 24” x 24” 86”

Side

Down

Side 32” x 32” 168”

Down 26” x 26” 108”

Side

Down

Side 36” x 36” 189”

Down 32” x 32” 168”

14” x 14” 48”

16” x 16” 54”

20” x 20” 72”

24” x 24” 86”

26” x 26” 108”

32” x 32” 168”

6

Page 7

WARNING: ELECTRIC HEATERS HAVE TWO POWER INPUTS. THE EXTERNAL DISCONNECT

AIRFLOW

1

2

3

4

5

6

8

7

9

10

11

AIRFLOW

1

2

3

4

6

8

7

5

9

INTERRUPTS POWER TO THE MOTOR AND CONTROLS ONLY. THE ELECTRIC COIL POWER IS

INTERRUPTED BY THE DISCONNECT SWITCH ON THE ELECTRIC COIL DOOR.

Roof Mount Installation

Note: Refer to submittal drawings for specific unit dimensions.

Figure 3 - Roof Mount Details

1. Discharge Opening

2. Curb Outer Wall

3. Flex Conduit for Field Wiring

4. Intake Housing

5. Lifting Lugs

6. Electric Heat Module

7. Service Disconnect Switch

8. Blower/Motor Access Door

9. Curb with Support Legs or Rail (20” High)

10. Control Drop

11. Motor Drop

Max. Roof Opening 2” Smaller than Curb

Outside Dimension.

Installation with Exhaust Fan

Note: Refer to submittal drawings for specific unit dimensions.

Figure 4 - Exhaust Fan Details

1. Discharge Opening

2. Curb Outer Wall

3. Flex Conduit for Field Wiring

4. Intake Housing

5. Lifting Lugs

6. Electric Heat Module

7. Service Disconnect Switch

8. Blower/Motor Access Door

9. Curb with Support Legs or Rail (20” High)

7

Page 8

WARNING: ELECTRIC HEATERS HAVE TWO POWER INPUTS. THE EXTERNAL DISCONNECT

AIRFLOW

1

3

2

AIRFLOW

1

2

3

4

5

7

6

INTERRUPTS POWER TO THE MOTOR AND CONTROLS ONLY. THE ELECTRIC COIL POWER IS

INTERRUPTED BY THE DISCONNECT SWITCH ON THE ELECTRIC COIL DOOR.

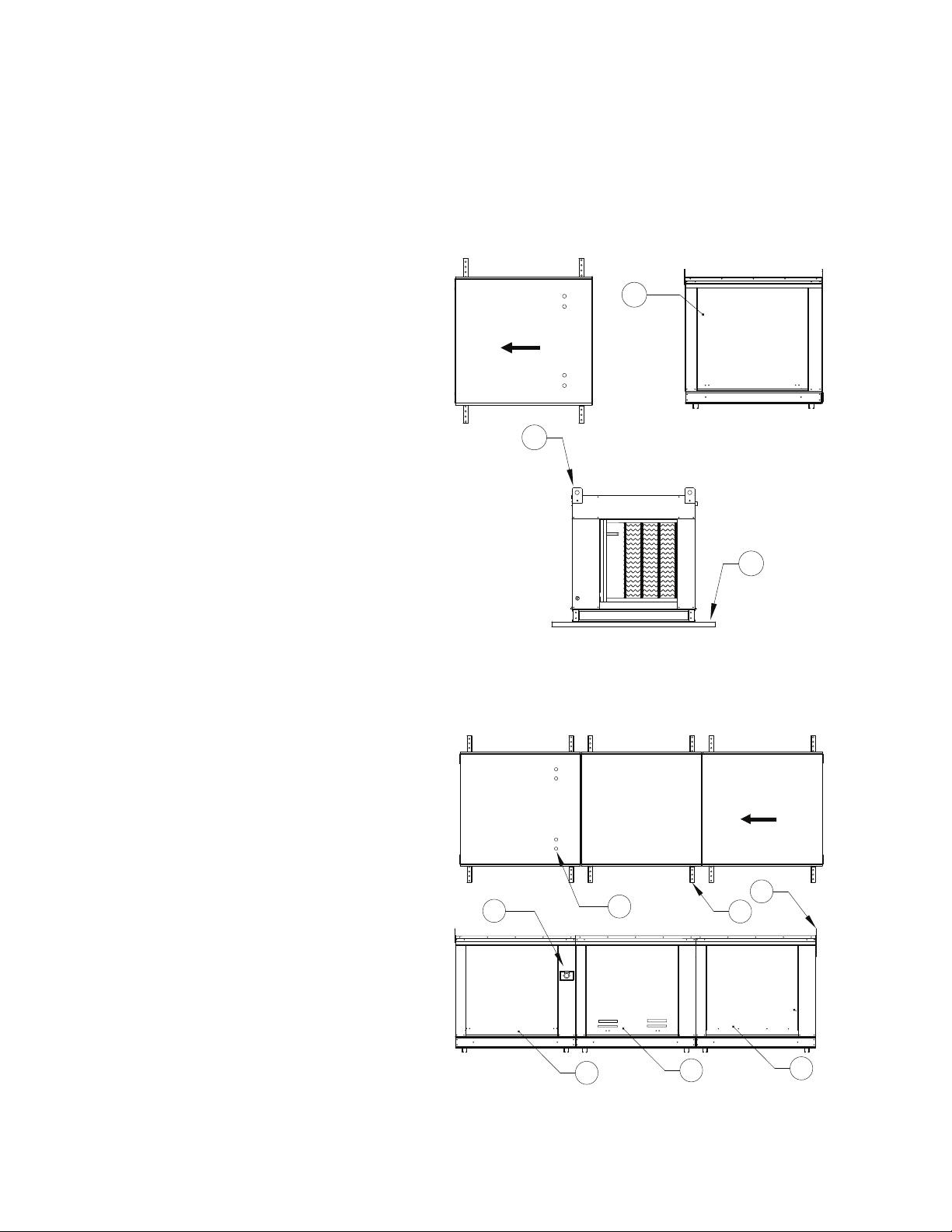

Duct Mount Installation

Note: Refer to submittal drawings for specific unit dimensions.

Figure 5 - Duct Mount Details

1. Control/Coil Access Door

2. Lifting Lugs

3. Optional Uni-Strut Base

Indoor (Inline) Installation

Note: Refer to submittal drawings for specific unit dimensions.

Figure 6 - Indoor Installation Details

1. Flex Conduit for Field Wiring

2. Optional Uni-Strut Base

3. Lifting Lugs

4. Filter Access Door

5. Electric Heat Module

6. Blower/Motor Access Door

7. Service Disconnect Switch

8

Page 9

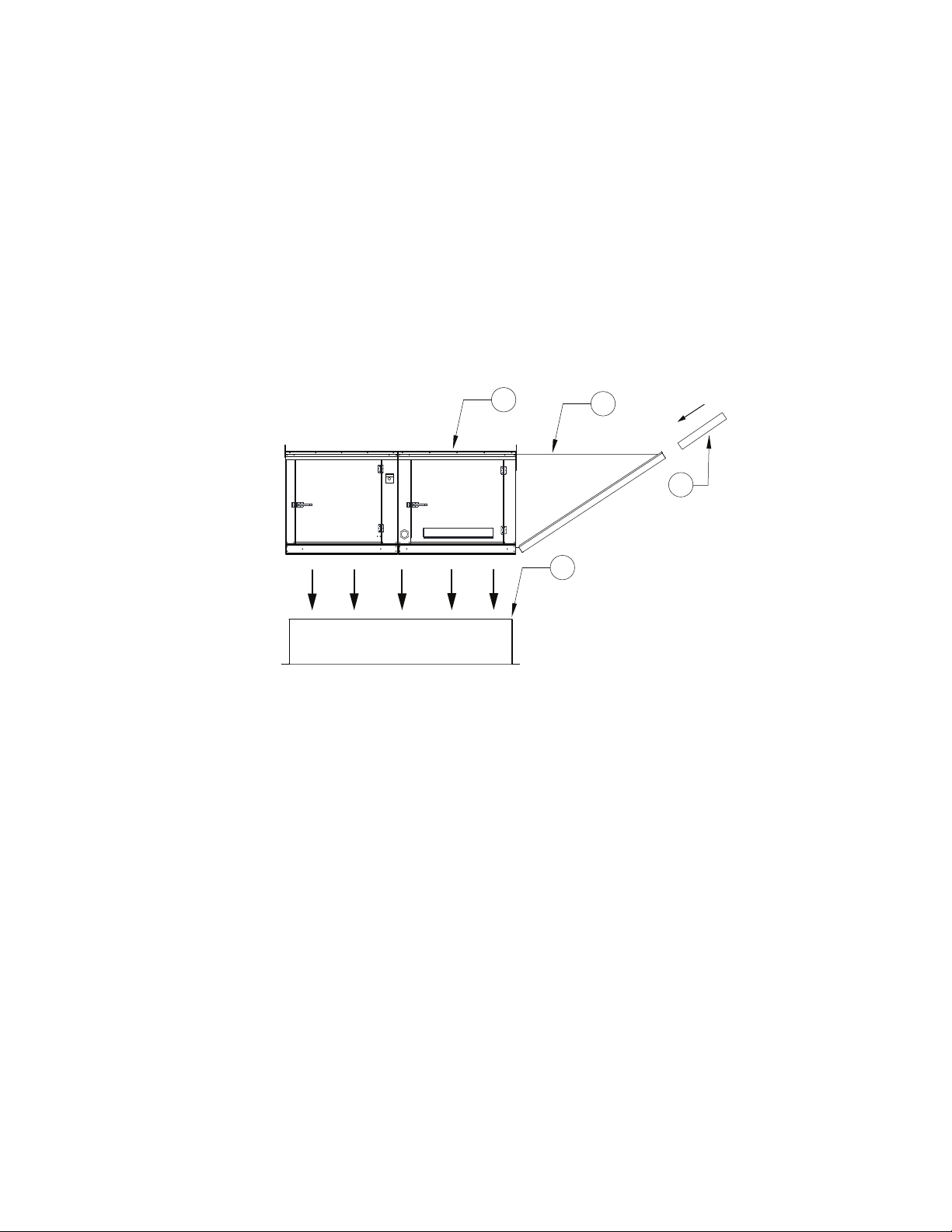

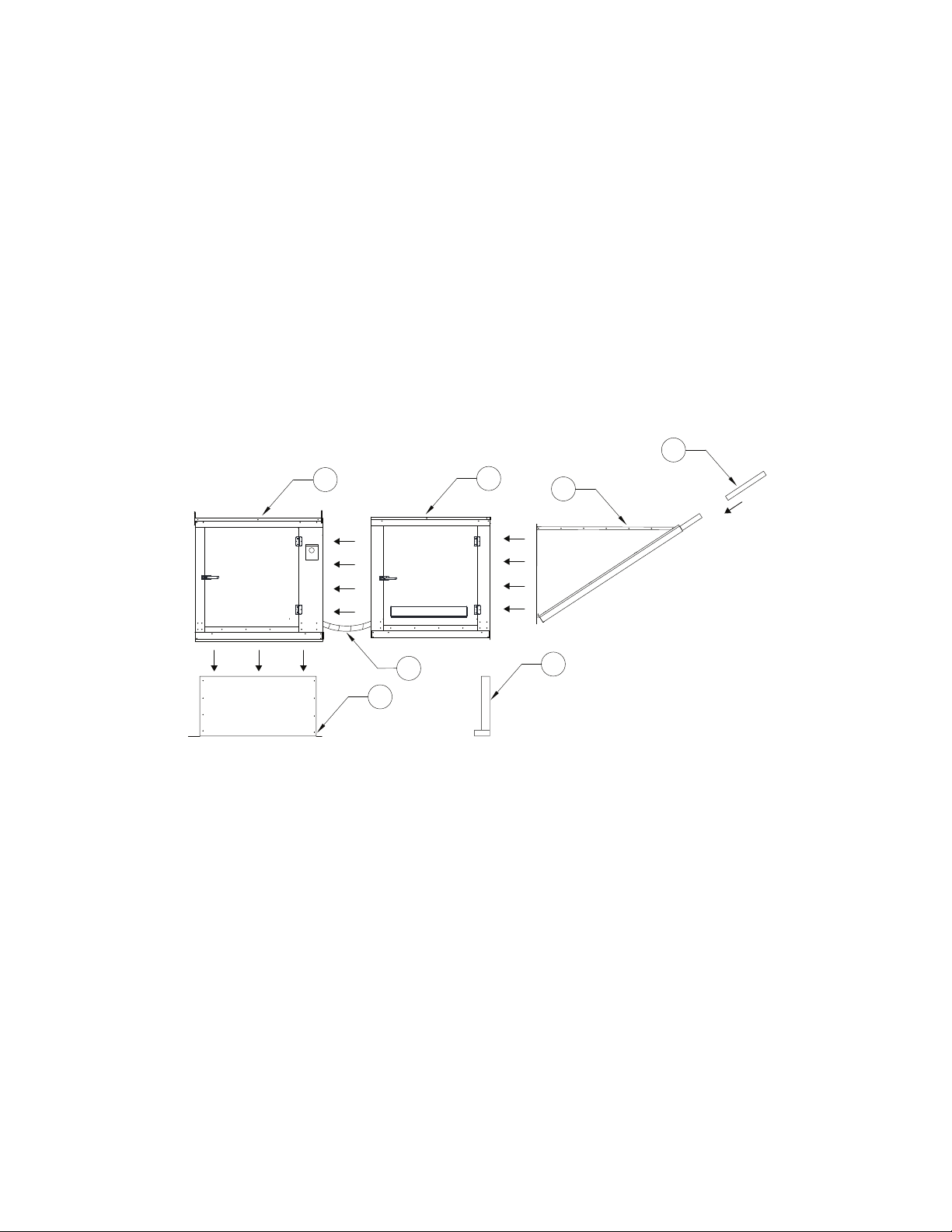

Heat Module Add-On Installation

2

3

4

1

5

7

6

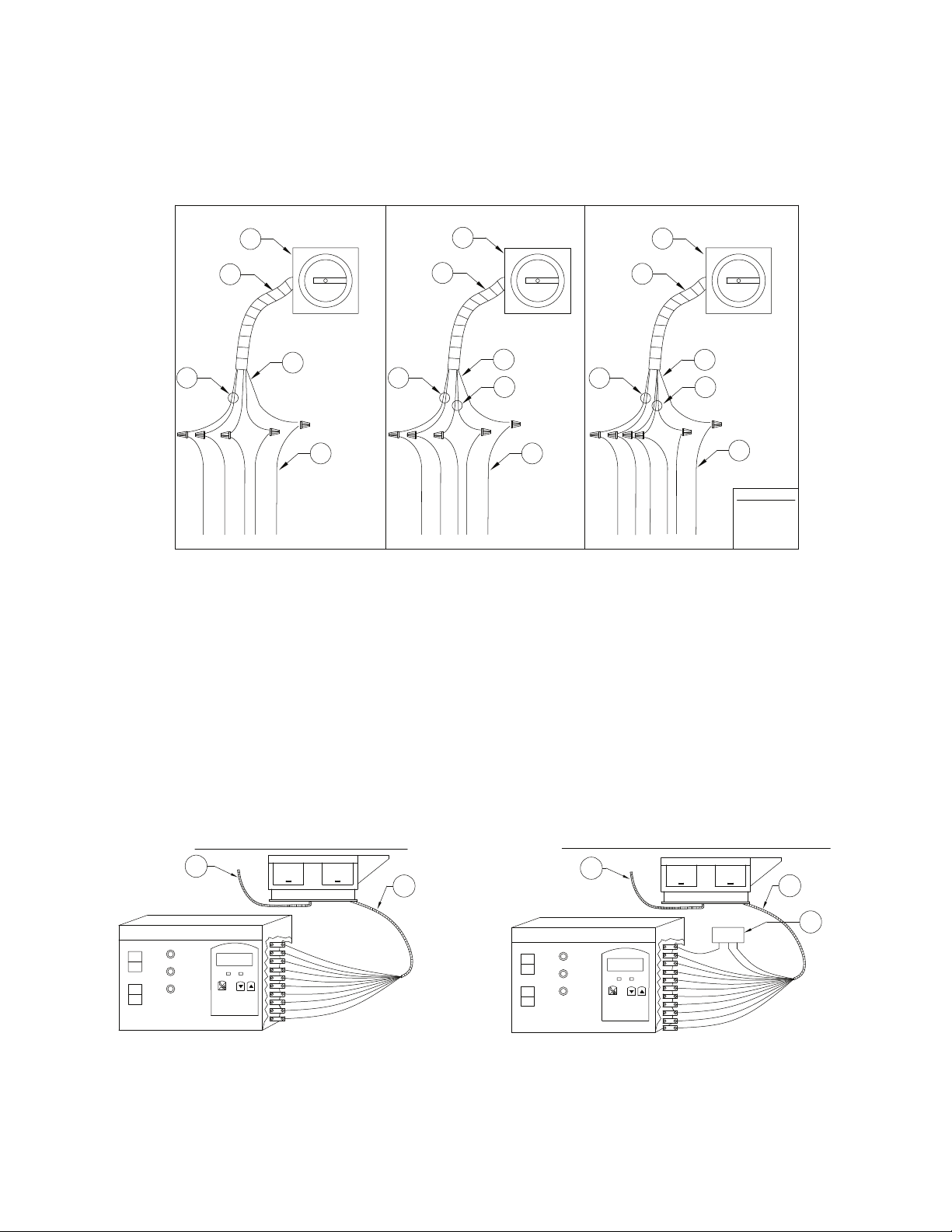

Modular heat units (Figure 7) that are ordered to provide heat onto an existing blower only application

require field mechanical and wiring installation.

1. Remove existing intake housing and lifting lugs from the blower section intake side.

2. Attach heat module to blower intake using the provided sheet metal screws and bolts. Tighten screws and bolts to compress the gasket between the heat module and the blower module.

3. Support and level the end of the heat module (end opposite the blower) with the provided equipment legs/rails.

4. Attach the intake housing to the intake side of the heater module.

5. Drill a hole in the discharge of the blower large enough to insert the discharge control sensor (if provided). Install the sensor through the hole.

6. Wire the sensor and coil as indicated on the supplied wiring schematic. Route all wiring through metal conduit.

7. After the add-on installation is complete, refer to “Start-up Procedure” on page 25.

Figure 7 - Heat Module

1. Blower

2. Electric Heat Module

3. Intake Housing

4. Filters

5. Equipment Legs

6. Conduit

7. Curb

9

Page 10

ELECTRICAL

WARNING!!

Disconnect power before installing or servicing unit. High voltage electrical input is needed for

this equipment. A qualified electrician should perform this work.

Before connecting power to the heater, read and understand the entire section of this document. As-built

wiring diagrams are furnished with each unit by the factory and are attached to the control module’s door

or provided with paperwork packet.

Electrical wiring (Table 3) and connections must be made in accordance with local ordinances and the

National Electric Code, ANSI/NFPA 70. Verify the voltage and phase of the power supply, and the wire

amperage capacity is in accordance with the unit nameplate. For additional safety information, refer to

AMCA publication 410-96, Recommended Safety Practices for Users and Installers of Industrial and

Commercial Fans.

1. Always disconnect power before working on or near this equipment. Lock and tag the disconnect switch and/or breaker to prevent accidental power-up.

2. An electrical drop containing the line voltage power wiring is shipped with every unit. The electrical

drop should be brought through one of the conduit openings located in the base of the unit (Figure 3),

run through the curb, and connected to a junction box inside the building.

3. A dedicated branch circuit should supply the motor circuit with short circuit protection according to the National Electric Code. This dedicated branch should run to the junction box.

4. A separate power source should supply the electric coil power. Power from the building breaker

should be wired directly to the coil disconnect. This should be done using wire of the proper gauge as

indicated in Table 3. A hole must be drilled in the fan enclosure to properly run the electric coil

power.

5. Verify that the power source is compatible with the requirements of your equipment. The nameplate identifies the proper phase and voltage of the equipment.

6. Units shipped with a remote HMI will require a second drop through the base of the unit. It is important to route the motor wires in a separate conduit from the HMI wiring. Refer to Figure 3.

7. Before connecting the unit to the building’s power source, verify that the power source wiring is deenergized.

8. Secure the power cable to prevent contact with sharp objects.

9. Do not kink power cable and never allow the cable to encounter oil, grease, hot surfaces, or chemicals.

10. Before powering up the unit, make sure that the fan rotates freely. Make sure that the interior of the unit is free of loose debris or shipping materials.

11. If any of the original wire supplied with the unit must be replaced, it must be replaced with type THHN wire or equivalent.

WARNING: ELECTRIC HEATERS HAVE TWO POWER INPUTS. THE EXTERNAL DISCONNECT

INTERRUPTS POWER TO THE MOTOR AND CONTROLS ONLY. THE ELECTRIC COIL POWER IS

INTERRUPTED BY THE DISCONNECT SWITCH ON THE ELECTRIC COIL DOOR.

10

Page 11

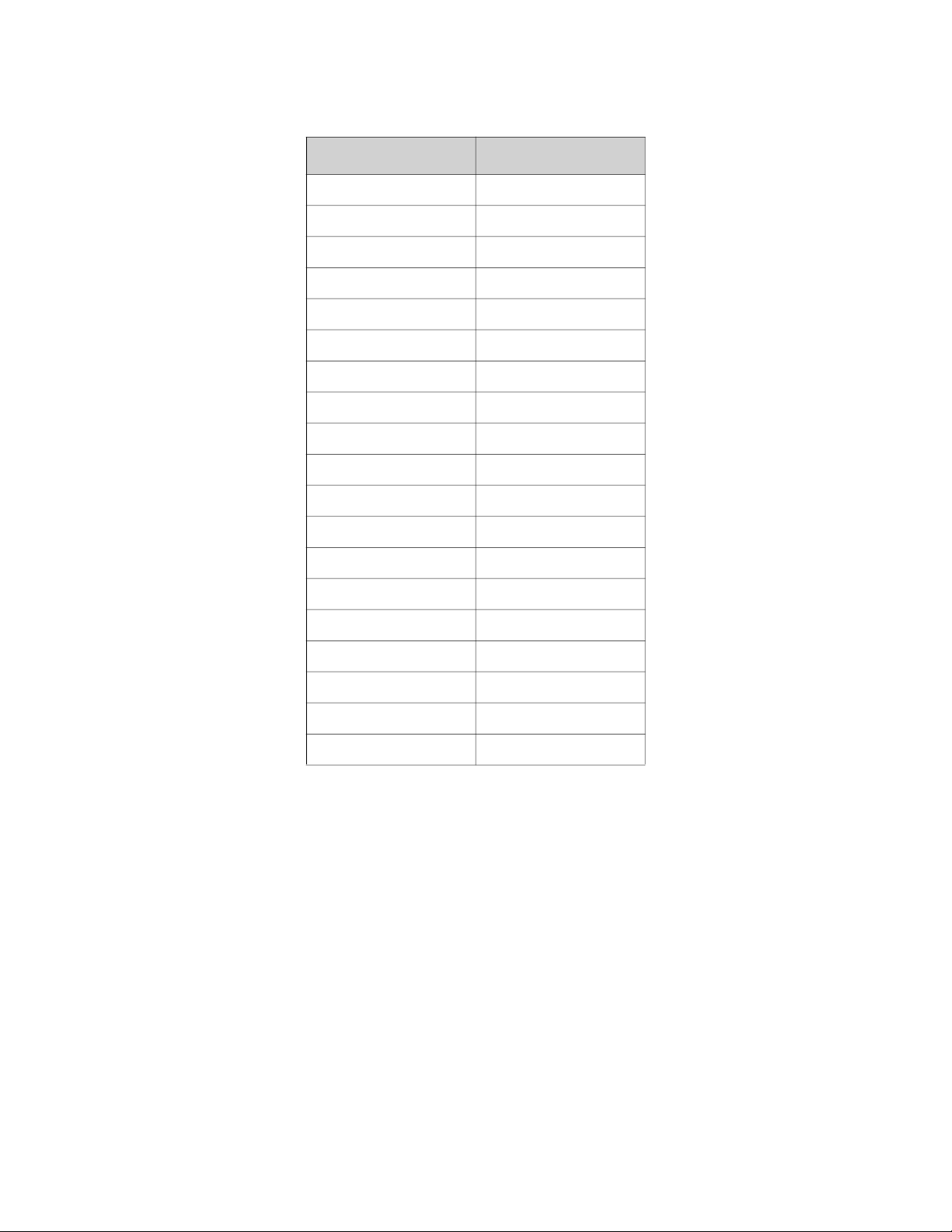

Table 3 - Copper Wire Ampacity

Wire Size AWG Maximum Amps

14 15

12 20

10 30

8 50

6 65

4 85

3 100

2 115

1 130

1/0 150

2/0 175

3/0 200

4/0 230

250 255

300 285

350 310

400 335

500 380

600 420

11

Page 12

Fan to Building Wiring Connection

WHBK

GR

120V 1 PH. 208-240V 1 PH.

208-240/460/600V 3 PH.

1

2

3

4

1

2

1

2

WH - WHITE

RD - RED

WIRE COLOR

BK - BLACK

GR - GREEN

5

BK

GR

3

4

5

6

WH

RD

BK

GR

3

4

5

7

BK

WH

RD

BK

WH

RD

RD

120V Optional

Electric Heater Remote Panel

Blower On

Blower Off

Heat

Vent

Blower On

Power

Heat On

GY

T4

RD

T9

GY

BK

OR

PR

BL

BK

WH

T5

T14

T16

6

1

N

2

Electric Heater Remote Panel

Vent

Heat

Cool

Blower On

Blower Off

Heat On

BL

GY

PR

BL

RD

BK

T9

T4

11

T5

T14

T16

Blower On

Power

WH

GY

BK

OR

N

6

2

1

NO

NC

1

PR

E

BK

C

STANDARD ELECTRIC HEATER REMOTE PANEL

COOLING INTERLOCK AND EXHAUST ON IN FIRE CONTROL

OVERRIDE

OVERRIDE

RD

7

RD

7

1

2

3

1

2

Figure 8 - Wiring Connection Details

1. Disconnect Switch

2. Galflex Conduit (In Unit)

3. Factory Wiring

4. Field Supplied Wiring - From building power or pre-wired control panel.

Remote Control Panel

On units shipped with the optional remote control panel, an electrical drop containing the panel wiring is

provided with the heater. There is a terminal strip inside the remote panel that matches the terminals in the

heater unit. The remote panel should be wired as shown in Figure 9. Wiring may vary by unit, refer to

electrical schematics that were provided with your unit.

Figure 9 - Typical Remote Control Panel Wiring

5. 120V Single Phase Standing Power

6. 208-240 Single Phase

7. Three Phase

1. Motor Connection 2. Control Connection 3. Fire System Micro-switch

12

Page 13

Electric Cabinet Heater

Vari-Speed

HIGH

LOW

OFF

SOLID STATE SPEED CONTROL

On units shipped with an optional electric cabinet heater, ensure that the thermostat is set correctly while

commissioning the unit and that the thermostat sensing bulb is mounted correctly in the control vestibule

where the heater is located. The stat needs to be set to 0 Degrees Fahrenheit

.

AC Interlock

On units shipped with an optional AC interlock relay, 24V AC power from Y1 in the condensing unit or

rooftop unit should be field wired to terminal block 27 in the MUA. 24V AC common from C in the

condensing unit or rooftop unit should be field wired to terminal block 28 in the MUA. When these terminals

are powered, heat will be locked out within the MUA.

Motorized Intake Damper

On units shipped with the optional motorized intake damper, a power transformer is supplied with the unit if

the main incoming voltage is greater than 120V. The damper motor is automatically energized when the

main disconnect switch is in the ON position. No external wiring to the damper motor is required.

Permanent Split Capacitor (PSC) Motor Speed Control

Figure 10 - PSC Motor Speed Control

Some single-phase direct-drive fans contain speed controls that

regulate the amount of voltage going to the motor. Specific PSC

motors must be used in conjunction with speed controls. The

speed control has a knob (Figure 10) with an off position along

with high to low range. At high speed, the speed control allows

all of the line voltage to pass directly to the motor.

A minimum speed adjustment is provided to allow independent

control of the minimum speed setting. Minimum speed

adjustment ensures the motor runs with sufficient torque to

prevent stalling. To adjust this:

1. Motor must be in actual operating conditions to achieve proper speed adjustment. Motor will not slow

2. Turn main control knob to lowest speed position.

3. Locate and adjust minimum speed setting. This can be found under the speed control faceplate. Use a

4. Motor will now operate from this preset minimum speed to full speed.

The lowest minimum voltage that may be applied to these motors is 65V AC. Running lower

voltages to the motor can cause premature failure and overheating problems.

down unless proper load is applied.

small screwdriver to adjust. Rotate clockwise to decrease minimum speed; counter-clockwise to

increase minimum speed.

13

Page 14

Electronically Commutated Motor (ECM) Speed Control

Column 1 Column 2

APPS

SP

LSPD

DN UP

hSPD

tyP

FSC

0-10

20

20

100

nid

TC42

TC48

re

dABl

EnAb

ver

LT RT

1.0

Select the application

Setpoint/Speed of the motor

Set the low speed limit

Set the high speed limit

Select motor type

Enable/Disable remote

View software version number

Fan Speed Control Application

Programmable 0-10V reference

Default Setpoint

Lowest speed motor will operate

Highest speed motor will operate

Nidec/Ziehl Motor

Telco Green TC42 Motor

Telco Green TC48 Motor

Disable remote

Enable remote

An Electrically Commutated Motor (ECM) with speed control allows for an accurate manual adjustment of

the fan’s speed. The benefits of using an EC motor is exceptional efficiency, performance, and motor life.

External PWM Signal

The fan unit will be shipped with power wiring and communication wiring fed to an internal junction box.

The fan is shipped with Shielded Twisted Pair (STP) wire which is used to wire to a remote PWM signal.

Red wire is used to go to the positive PWM signal, black wire is used to go to the negative PWM signal.

Reference schematics for all wiring connections. STP is connected to the communication wiring of the

motor using wire nuts in the junction box. If a preset length of STP is provided, it will be connected to the

junction box from the factory. Run the STP through any available knockout in the fan base.

Unit Mount Controller

The RTC speed controller features a 4 digit LED display with a five button interface. All parameters can be

accessed through the user menu. The percent of run speed can be changed by using the Up and Down

buttons followed by pressing Enter (middle button) to save changes. Every ten seconds the display will

toggle between current percentage of run speed and current RPMs. The flow index has a range of 0-100%

and is typically linear with motor RPM.

If the remote function (re) is enabled, the speed is controlled through a 0-10V input. 0V = 0% and 10V =

100%, unless overridden by the low speed and high speed limits.

The speed controller requires a 24V AC input and can locally turn the motor on and off. The motor RPM

range is fully adjustable between the minimum and maximum setpoints, see LSPD and HSPD on the

programming display. For more information, see the RTC control operating manual.

For all motors except 16Z, 18Z, 20Z, 22Z, 25Z, 28Z: If “oFF” is being displayed, and the speed is set

above 300 RPM, the ECM is not receiving RPM feedback. Check that the ECM is wired correctly. Check

that the motor “tyP” in the settings matches the motor manufacturer. 16Z, 18Z, 20Z, 22Z, 25Z, 28Z do not

send RPM feedback.

NOTE: A Variable Frequency Drive (VFD) is required to adjust the speed control of a nonelectrically commutated 3-phase direct-drive motor.

Figure 11 - RTC Speed Controller and Menu

14

Page 15

Motor Speed Controller (MSC) Installation

INCOUTC

VAC

0-1024

C

J3J2

J8J7

0-10

J-Box

#8-32 x 1/2”

Screw

#8-32 x 1/2”

Screw

Gasket

Micro USB

Programming

Port

The Motor Speed Controller (MSC) is a versatile device able to output various signal types to many

different Electrically Commutated Motors (ECMs). The MSC signal output types can be selected under the

‘Motor Type’ section of the MSC menu. The MSC may be installed in a fan, remotely in a kitchen space, or

in a mechanical room. While this device can be mounted remotely and powered using 24V, it may also be

mounted with the fan where it will be exposed to higher voltages. If installed in the fan, the electrical

installation must be carried out according to the appropriate regulations (e.g., cable cross-sections, circuit

breaker, protective earth [PE] connection). National and local codes must be followed during the

installation process.

The MSC board may be powered through a 120VAC/24VAC CLASS 2 transformer, 120V AC/24V DC

CLASS 2 power supply, or through MODBUS connections.

The MSC contains static sensitive components. Therefore, you must handle with care to avoid damage to

these components. All operations concerning installation, commissioning, and maintenance must be

carried out by qualified, skilled personnel who are familiar with the installation, assembly, commissioning,

and operation of the electronic board and the application for which it is being used.

Ensure proper handling and avoid excessive mechanical stress. Do not bend any components when

handling or installing component. Do not touch any electronic components or contacts.

Precautions must be adhered to during installation, testing, servicing, and repairing of this board.

Component damage may result if proper procedures are not followed.

Do not install the MSC where it is subjected to adverse environmental conditions such as combustibles,

oils, hazardous vapors, corrosive chemicals, excessive dust, moisture, direct sunlight, or extreme

temperatures. When removing or installing the MSC to the j-box, verify the gasket is present. All electrical

connections for the MSC are located on the backside of the controller. Refer to Figure 12 for details on

installation and electrical connections. When the micro USB programming port is not in use, place the

weather-seal plug into the port location.

Figure 12 - Installation/Electrical Connections

Backside - Electrical Connections

15

Page 16

MSC Controls Overview

Menu Up Down Enter

Micro USB

Programming Port

(For Service Use Only)

SPEED%: 0

RPM: 0

Control Type:

LC = Local

MB = Remote Modbus

10V = Remote 0-10V

EXT = External Device

LC

MOTOR SPEED CONTROLLER

MSC

There are four buttons to navigate through the menu screens, refer to Figure 13.

Press the MENU button to access menu settings/parameters, pressing MENU will also back out of the

current menu screen. To scroll through menus, use UP and DOWN buttons. Press the ENTER button to

change setting/parameter selection.

To enter password, press MENU, then press ENTER when “Board Config” is displayed. Use UP and

DOWN to scroll through numbers, press ENTER to advance to the next numerical setting. To save

changes, press MENU until the screen displays “SAVE CHANGES? [ENTER] TO SAVE.” Press the

ENTER button to save changes.

Figure 13 - MSC Front Detail View

MSC Menu

Board Config - Password (default is 0225)

• Motor Type - User may change motor type between Nidec, Telco 42, Telco 48, Ziehl,

0-10V, Other.

• Control Type - This setting adjusts how the fan will be controlled.

• Local - The fan will be controlled by the MSC.

• Remote Modbus - The fan will be controlled by another master board through the MSC. A

connection between the 0-10V Out to 0-10V In must be made for start command.

• Remote 0-10V - The fan will be controlled by an external 0-10V signal.

• Speed Settings - Provides access to speed and voltage settings.

• Low Speed - Adjustable speed from 20% up to high speed setting, or 0-10V. Setting cannot go

above High Speed parameter.

• High Speed - Adjustable speed from 100% down to low speed setting, or 10-0V. Setting cannot go

below Low Speed parameter.

• Set Speed% - Adjustable speed range is dependent on Low Speed and High Speed settings. This

controls the output of the motor.

• Voltage Range - Only available when Motor Type “OTHER” is selected. Default setting is 24V. 5V,

and 10V are also available.

16

Page 17

• Modbus # - Adjustable Modbus ID. Exhaust Fan range 11-18, Supply Fan range 21 or 22. A VFD and

MSC cannot use the same Modbus #.

• Options

• Feedback Fault - If set to ENABLED, the MSC will monitor RPM feedback. If the MSC does not

receive data for 30 seconds or 70% of the expected RPM, this fault will be displayed. Ziehl motors

do not provide feedback.

• 2 Speed - The 0-10V output cannot be used when the 2 Speed or Manual Speed options are On,

or if the “Control Type” is set to Modbus. When the 0-10V OUT and 0-10V IN terminals are not

jumped together, the fan will operate at low speed. When 0-10V OUT and 0-10V IN terminals are

jumped together, the fan will operate at high speed.

• Analog Speed - The user may enable/disable the option, and calibrate a potentiometer for proper

operation that is connected between the 0-10V OUT and 0-10V IN terminals. When enabled, you

must calibrate the potentiometer. Follow the MSC’s on-screen instructions. The speed will be

adjustable between 0V (low speed) to 10V (high speed).

• Input Threshold - When control type is set to Remote 0-10V, an input threshold will be created for

motor control. Refer to Figure 14 on page 18 for threshold examples.

• Zero Operation - The user may select how the motor will operate when the

0-10V input is at 0V. The options will be Off or Low Speed (default).

• Threshold - Increasing the threshold value will allow for the device to hold its voltage/RPM

output while the input is between the 0 - threshold value.

• Restore Settings - Provides access to restore factory settings, and test & balance settings.

• Factory Settings - This will reset all values back to factory settings.

• T & B Settings - This will reset all values back to last saved test & balance settings.

• Change Password - Users may update the password setting to their own. Password 0225 will also be

stored for backup. Both passwords will allow users to enter “Board Config” settings.

Software Version - Displays the current software version installed on the board.

Faults - This provides access to “Fault History,” “Fault Totals,” and “Clear Faults.”

• Fault History - Displays fault history and board reboots in chronological order. Possible displayed

faults are:

• No Faults - There are no active faults with the system.

• Feedback Fault - Only displayed for motors with feedback capabilities.

• Reboot - Any time the fan goes from OFF to ON, this “fault” will be logged. This fault will only

display in “Fault History.”

• Modbus - Issue with Modbus communication between the MSC and master board.

• Variable Device Fault - When “Analog Speed” is selected and a potentiometer is connected, if the

voltage drops below 1V, this fault will be displayed.

• Fault Totals - Displays amount of faults for Modbus, Feedback, Var Device, Reboot, and Total Faults.

• Clear Faults - Users may clear all faults from the board.

Service - This provides access to service settings. Password: 1234

• Save T & B - After the test & balance process has been completed, save adjustments under this

menu.

• IO Status - Provides access to information about the inputs and outputs of the MSC board.

• V In - Displays the incoming voltage (0-10V) to the MSC.

• V Out - Displays the output voltage (0-10V) to the motor.

• RPM - Displays motor RPM feedback. Ziehl motors do not provide feedback.

• PWM V - Displays equivalent voltage reading of the PWM output to the motor.

• Speed% - Displays PWM percentage output value to the motor.

17

Page 18

Input Threshold

OFF

HIGH SPEED

01 423 6785910

OPERATING

BAND

INPUT VOLTS

0-10V OR PWM

OUTPUT SIGNAL

DEPENDANT ON

SETTINGS

0-10V INPUT

Factory Default: Zero operation set to low speed, threshold set to 0V.

LOW

SPEED

DEVICE OUTPUT

HIGH SPEED

01 423 6785910

OPERATING

BAND

INPUT VOLTS

0-10V OR PWM

OUTPUT SIGNAL

DEPENDANT ON

SETTINGS

0-10V INPUT

DEVICE OUTPUT

LOW SPEED

Zero operation set to low speed, threshold set to 2V.

OFF

HIGH SPEED

01 423 6785910

OPERATING

BAND

INPUT VOLTS

0-10V OR PWM

OUTPUT SIGNAL

DEPENDANT ON

SETTINGS

0-10V INPUT

DEVICE OUTPUT

Zero operation set to off, threshold set to 2V.

Figure 14 - Input Threshold Examples

18

Page 19

MSC Menu Tree

RANGE: NIDEC, TELCO 42, TELCO 48 (DEFAULT),

ZIEHL, 0-10V, OTHER

BOARD CONFIG

MOTOR TYPE

RANGE: LOCAL (DEFAULT),

REMOTE MODBUS, REMOTE 0-10V

CONTROL TYPE

SPEED SETTING LOW SPEED

RANGE: 20%-100% or 0-10V

DEFAULT: 20% or 0V

HIGH SPEED

RANGE: 20%-100% or 0-10V

DEFAULT: 100% or 10V

SET SPEED %

RANGE: 20%-100% or 0-10V

DEFAULT: VARIES

VOLTAGE RANGE

RANGE: 5V, 10V, 24V

DEFAULT: 24V

RANGE: 11-18 (EXHAUST FAN) / 21 or 22 (SUPPLY FAN)

DEFAULT: 11

MODBUS #

FEEDBACK FAULT

OPTIONS

FACTORY RESTORE?

[ENTER] TO RESTORE

RESTORE SETTINGS

PASSWORD

0000

CHANGE PASSWORD

PASSWORD OK?

0000

SOFTWARE VERSION

FAULTS

CURRENT SOFTWARE VERSION

DISPLAYED

DISPLAYS FAULTS DAY/HOUR/MINUTE/SECONDS

DISPLAYS BOARD REBOOT

FAULT HISTORY

FAULT TOTALS

FEEDBACK, MODBUS, REBOOT, VARIABLE DEVICE,

and TOTAL FAULT COUNTS ARE SHOWN

2 SPEED

ANALOG SPEED

RANGE: 20%-100% or 0-10V

DEFAULT: VARIES

ENABLED/DISABLED/CALIBRATION

ENABLED/DISABLED

DEFAULT: DISABLED

CLEAR FAULTS

CLEAR FAULTS?

[ENTER] TO CLEAR

IO STATUS

DISPLAYS INCOMING VOLTAGE (0-10V) TO THE MSC.

V IN

V OUT

RPM

DISPLAYS MOTOR RPM FEEDBACK. ZIEHL MOTORS

DO NOT PROVIDE FEEDBACK

PWM V

DISPLAYS EQUIVALENT VOLTAGE READING OF THE

PWM OUTPUT TO THE MOTOR.

SPEED %

DISPLAYS PWM PERCENTAGE OUTPUT VALUE TO

THE MOTOR.

DISPLAYS OUTPUT VOLTAGE (0-10 V) TO THE

MOTOR.

INPUT THRESHOLD

ZERO OPERATION

THRESHOLD

RANGE: OFF - LOW SPEED

DEFAULT: LOW SPEED

RANGE: 0-10V

DEFAULT: 0V

SERVICE

SAVE T & B

T & B SAVE?

[ENTER] TO SAVE

FACTORY SETTINGS

T & B SETTINGS

T & B RESTORE?

[ENTER] TO RESTORE

19

Page 20

Heater Controller

OVERRIDE

1

2

3

Only Factory Service Personnel should make adjustments to the configuration menu settings.

The heat controller features a two-line, eight character display with a three button interface. To adjust heat

settings, use the Up and Down buttons. Other parameters may be accessed in the configuration menu. To

access the configuration menu, press and hold the “Override” button for at least 8 seconds.

Figure 15 - Viconics VT7225 Heat Controller

1. Override Button – Press the “Override” button

to scroll between the available parameters.

2. Up Button – Adjust value up.

3. Down Button – Adjust value down.

Pswrd Set

– This allows the user to set a password to prevent unauthorized access to the configuration

menu. Default value is 0. Range is 0-1000.

MenuScro

– Removes the scrolling display and displays just the room temperature to the user. When set

to on, the scroll feature is active. When set to off, the scroll feature is inactive. Default value is off. On/off

option.

°C/°F

– Sets the temperature unit between Celsius or Fahrenheit. Default is Fahrenheit.

Unocc HT

Heat Max

– Unoccupied heating setpoint. Default value is 62°F (17°C). Range is 0 -180°F (-17° - 82°C).

– Maximum occupied and unoccupied heating setpoint adjustment. Default value is 90°F.

Range is 0 -180°F (-17 - 82°C).

Heat Min

– Minimum occupied and unoccupied cooling setpoint adjustment. Default value is 90°F. Range

is 0 -180°F (-17 - 82°C).

Note: Heat Max has a priority over Heat Min.

Pband

– Adjusts the proportional band used by the room controller. Default is 3°F (1.2°C). Range is 3-

10°F (1.2 - 5.6°C).

Set Type

– Enables temporary setpoint features to any change of occupied or unoccupied setpoints.

Available modes are Permnent/Temporar.

ToccTime

– Temporary occupancy time with occupied mode setpoints when override functions are

enabled. Default value is 2 hours. Range 0-24 hours.

Cal RS

– Offset that can be added/subtracted to the actual displayed room temperature. Default value is

0.0°F/C. Range is +/- 5°F with 1° increments (+/- 2.5°C with 0.5° increments).

20

Page 21

Variable Frequency Drive (VFD)

WARNING!!

- Before installing the VFD drive, ensure the input power supply to the drive is OFF.

- The power supply and motor wiring of the VFD must be completed by a qualified electrician.

- The VFD is factory programmed, only change if replaced or ordered separately.

Consult the VFD manual and all documentation shipped with the unit for proper installation and wiring of

the VFD. The VFD has been programmed by the factory with ordered specific parameters. Use Table 4 as

a guide during installation.

Table 4 - VFD Installation Check List

Check

Off

Description

The installation environment conforms to the VFD manual.

The drive is mounted securely.

Space around the drive meets the drive’s specification for cooling.

The motor and driven equipment are ready to start.

The drive is properly grounded.

The input power voltage matches the drive’s nominal input voltage.

The input power connections at L1, L2, and L3 are connected and tight.

The input power protection is installed.

The motor power connection at U, V, and W are connected and tight.

The input, motor, and control wiring are run in separate conduit runs.

The control wiring is connected and tight.

NO tools or foreign objects (such as drill shavings) are in the drive.

NO alternative power source for the motor (such as a bypass connection) is connected - NO

voltage is applied to the output of the drive.

21

Page 22

Variable Frequency Drive (VFD) Installation

Input AC Power

• Circuit breakers feeding the VFDs are recommended to be thermal-magnetic and fast-acting. They

should be sized based on the VFD amperage and according to Table 5 on page 24. Refer to the

installation schematic for exact breaker sizing.

• Every VFD should receive power from its own breaker. If multiple VFDs are to be combined on the

same breaker, each drive should have its own protection measure (fuses or miniature circuit breaker)

downstream from the breaker.

• Input AC line wires should be routed in conduit from the breaker panel to the drives. AC input power to

multiple VFDs can be run in a single conduit if needed. Do not combine input and output power

cables in the same conduit.

• The VFD should be grounded on the terminal marked PE. A separate insulated ground wire must be

provided to each VFD from the electrical panel. This will reduce the noise being radiated in other

equipment.

ATTENTION: Do not connect incoming AC power to output terminals U, V, W. Severe damage to the

drive will result. Input power must always be wired to the input L terminal connections (L1, L2, L3).

VFD Output Power

• Motor wires from each VFD to its respective motor MUST be routed in a separate steel conduit away

from control wiring and incoming AC power wiring. This is to avoid noise and crosstalk between drives.

An insulated ground must be run from each VFD to its respective motor. Do not run different fan output

power cables in the same conduit.

• VFD mounted in ECP: A load reactor should be used and sized accordingly when the distance

between the VFD and motor is greater than specified below. The load reactor should be installed within

10 feet of the VFD output:

208/230V - Load reactor should be used when distance exceeds 250 feet.

460/480V - Load reactor should be used when distance exceeds 50 feet.

575/600V - Load reactor should be used when distance exceeds 25 feet.

• VFD mounted in fan: The load reactor should be sized accordingly when the VFD is mounted in the

fan.

208/230V - Load reactor is optional but recommended for 15 HP and above motors.

460/480V - Load reactor is optional but recommended for 7.5 HP and above motors.

575/600V - Load reactors are required for all HP motors.

• If the distance between the VFD and the motor is extremely long, up to 1000 FT, a dV/dT filter should

be used, and the VFD should be increased by 1 HP or to the next size VFD. The dV/dT filter should be

sized accordingly and installed within 10 feet of the output of the VFD.

208/230V – dV/dT filter should be used when distance exceeds 400 feet.

460/480V – dV/dT filter should be used when distance exceeds 250 feet.

575/600V – dV/dT filter should be used when distance exceeds 150 feet.

• Do not install a contactor between the drive and the motor. Operating such a device while the drive is

running can potentially cause damage to the power components of the drive.

• When a disconnect switch is installed between the drive and motor, the disconnect should only be

operated when the drive is in a STOP state.

22

Page 23

VFD Programming

AUTO

FWD

REV

RUN

STOP

M

RF

Programming

1. The Drive should be programmed for the proper motor voltage. P107 is set to 0 (Low) if motor voltage

is 120V AC, 208V AC or 400V AC. P107 is set to 1 (High) if the motor voltage is 230V AC, 480V AC, or

575V AC.

2. The Drive should be programmed for the proper motor overload value. P108 is calculated as Motor

FLA x 100 / Drive Output Rating (available in Table 5 on page 24).

To enter the PROGRAM mode to access the parameters:

1. Use the buttons on the VFD screen (Figure 16) to adjust VFD settings. Press the Mode (M) button.

This will activate the password prompt (PASS).

2. Use the Up and Down buttons to scroll to the password value (the factory default password is “0225”)

and press the Mode (M) button. Once the correct password is entered, the display will read “P100”,

which indicates that the PROGRAM mode has been accessed at the beginning of the parameter

menu.

3. Use the Up and Down buttons to scroll to the desired parameter number.

4. Once the desired parameter is found, press the Mode (M) button to display the present parameter

setting. The parameter value will begin blinking, indicating that the present parameter setting is being

displayed. The value of the parameter can be changed by using the Up and Down buttons.

5. Pressing the Mode (M) button will store the new setting and exit the PROGRAM mode. To change

another parameter, press the Mode (M) button again to re-enter the PROGRAM mode. If the Mode

button is pressed within 1 minute of exiting the PROGRAM mode, the password is not required to

access the parameters. After one minute, the password must be re-entered to access the parameters

again.

P500 parameter provides a history of the last 8 faults on the drive. It can be accessed without entering

PROGRAM mode.

Figure 16 - VFD Screen

23

Page 24

ACTECH SMV VFD

Table 5 - Cross Reference

1Ø

HP Part Number Volts

0.5 ESV371N01SXB 120/240V X - 9.2 4.6 2.4 15 15

1 ESV751N01SXB 120/240V X - 16.6 8.3 4.2 25 15

1.5 ESV112N01SXB 120/240V X - 20 10 6 30 20

HP Part Number Volts

0.5 ESV371N02YXB 240V X X 5.1 2.9 2.4 15 15

1 ESV751N02YXB 240V X X 8.8 5 4.2 15 15

1.5 ESV112N02YXB 240V X X 12 6.9 6 20 15

2 ESV152N02YXB 240V X X 13.3 8.1 7 25 15

3 ESV222N02YXB 240V X X 17.1 10.8 9.6 30 20

5 ESV402N02TXB 240V - X - 18.6 16.5 - 30

7.5 ESV552N02TXB 240V - X - 26 23 - 40

10 ESV752N02TXB 240V - X - 33 29 - 50

15 ESV113N02TXB 240V - X - 48 42 - 80

20 ESV153N02TXB 240V - X - 59 54 - 90

1 ESV751N04TXB 480V - X - 2.5 2.1 - 15

1.5 ESV112N04TXB 480V - X - 3.6 3 - 15

2 ESV152N04TXB 480V - X - 4.1 3.5 - 15

3 ESV222N04TXB 480V - X - 5.4 4.8 - 15

5 ESV402N04TXB 480V - X - 9.3 8.2 - 15

7.5 ESV552N04TXB 480V - X - 12.4 11 - 20

10 ESV752N04TXB 480V - X - 15.8 14 - 25

15 ESV113N04TXB 480V - X - 24 21 - 40

20 ESV153N04TXB 480V - X - 31 27 - 50

25 ESV183N04TXB 480V - X - 38 34 - 70

30 ESV223N04TXB 480V - X - 45 40 - 80

40 ESV303N04TXB 480V - X - 59 52 - 100

50 ESV373N04TXB 480V - X - 74 65 - 125

60 ESV453N04TXB 480V - X - 87 77 - 150

Input

1Ø

Input

3Ø

Input

3Ø

Input

Input Amps 1Ø

120V AC

Input Amps 1Ø Input Amps 3Ø

Input Amps 1Ø

240V AC

Output

Amps

Output

Amps

Breaker 1Ø

120V AC

Breaker 1Ø Breaker 3Ø

Breaker 1Ø

240V AC

1 ESV751N06TXB 600V - X - 2 1.7 - 15

2 ESV152N06TXB 600V - X - 3.2 2.7 - 15

3 ESV222N06TXB 600V - X - 4.4 3.9 - 15

5 ESV402N06TXB 600V - X - 6.8 6.1 - 15

7.5 ESV552N06TXB 600V - X - 10.2 9 - 20

10 ESV752N06TXB 600V - X - 12.4 11 - 20

15 ESV113N06TXB 600V - X - 19.7 17 - 30

20 ESV153N06TXB 600V - X - 25 22 - 40

25 ESV183N06TXB 600V - X - 31 27 - 50

30 ESV223N06TXB 600V - X - 36 32 - 60

40 ESV303N06TXB 600V - X - 47 41 - 70

50 ESV373N06TXB 600V - X - 59 52 - 90

60 ESV453N06TXB 600V - X - 71 62 - 110

24

Page 25

START-UP OPERATION

Before starting up or operating the unit, verify all fasteners are secure and tight. Check the set screw in

the, bearings, and the fan sheaves (pulleys). With power OFF to the unit or before connecting the unit to

power, turn the fan wheel by hand. Verify it is not striking the inlet or any obstructions. If necessary, recenter.

Special Tools Required: Standard Hand Tools, AC Voltage Meter, Tachometer

Start-up Procedure

1. Check all electrical connections are secure and tight.

2. Check pulley alignment and belt tension. Refer to “Pulley Alignment/Proper Belt Tension” on

page 27.

3. Inspect the condition of the intake damper and damper linkage, if applicable.

4. Remove intake filters if not already installed, inspect the air stream for obstructions. Install intake

filters.

5. Compare the supplied motor voltage with the fan’s nameplate voltage. If this does not match, correct

the problem. Compare the supplied coil voltage with the coil’s nameplate voltage. If this does not

match, correct the problem. If this does match, turn the coil disconnect to the ON position.

6. Place the external disconnect to the ON position to start the unit. Immediately place the disconnect

switch off. Check the rotation of the fan with the directional arrow on the blower scroll. Reversed

rotation will result in poor air performance, motor overloading and possible burnout. For units equipped

with a single-phase motor, check the motor wiring diagram to change rotation. For 3-phase motors,

any two power leads can be interchanged to reverse motor direction.

7. When the fan is started, observe the operation and check for any unusual noises.

8. Place the external disconnect switch back to the ON position. The system should be in full operation

with all ducts attached. Measure the system airflow. The motor sheave (pulley) is variable pitch and

allows for an increase or decrease of the fan RPM. If an adjustment is needed, refer to “Pulley

Adjustment” on page 26. Refer to “Pulley Combination Chart” on page 28 for adjustment

specifications.

9. Once the proper airflow is achieved, measure and record the fan speed with a reliable tachometer.

Caution - Excessive speed will result in motor overloading or bearing failure. Do not set fan

RPMs higher than specified in the maximum RPM chart. Refer to “Troubleshooting” on page 35

for more information.

10. Measure and record the voltage and amperage to the motor. Compare with the motor’s nameplate to

determine if the motor is operating under safe load conditions.

11. Once the RPM of the ventilator has been properly set, disconnect power. Re-check belt tension and

pulley alignment, refer to “Pulley Alignment/Proper Belt Tension” on page 27.

12. Measure and record the voltage and amperage to the electric coil and compare with the coil

nameplate to determine if the coil is operating under safe load conditions. While the blower is

operating, configure the thermostat for supply temperature control and disconnect one wire from the

discharge air sensor or thermostat. The amp draw and voltage should be measured in the override

condition to verify proper coil operation at max amperage. Reconnect all wires and dip switches to

original stat.

13. Verify that the coil thermostat is operating properly. Turn the thermostat dial to a set-point warmer than

the outside air temperature (if possible). With the blower running, the coil should become energized

and begin to heat the air. Once the thermostat becomes satisfied, the coil should cycle off or reduce

the number of energized heating stages. Turn the set-point below the outside air temperature (if the

climate permits), and the electric coil should cycle off. Set the thermostat set-point to the desired

setting to control either discharge air temperature or space temperature (depending on how the unit

was ordered).

25

Page 26

Pulley Adjustment

Decrease Amperage

and

Blower RPM

The adjustable motor pulley is factory set for the RPM specified (Table 6). Speed can be increased by

closing or decreased by opening the adjustable motor sheave. Two groove variable pitch pulleys must be

adjusted to an equal number of turns open or closed. Any increase in speed represents a substantial

increase in horsepower required by the unit. Motor amperage should always be checked to avoid serious

damage to the motor when the speed is varied. Always torque set screws according to the torque

specifications shown in Figure 17.

Figure 17 - Adjustable Pulley

Setscrew Thread Size Torque (in-lbs)

No. 10 (bushing) 32

1/4” (bushing) 72

5/16” 130

Table 6 - Maximum RPM and HP Chart

Belt Drive

Blower Size Max. RPM Max. HP

10” 1800 2

12” 1500 3

15” 1400 5

18” 1200 5

20” 1000 10

25” 900 20

Direct Drive

Blower Size Max. RPM Max. HP

15D 1800 2

20D 1500 3

24D 1400 5

30D 1200 5

36D 1000 10

16Z 2400 4

18Z 3200 5

20Z 2300 5

22Z 1900 5

25Z 1800 8

28Z 1400 7

26

Page 27

Pulley Alignment/Proper Belt Tension

Correct Incorrect

Incorrect Incorrect

1. Belts tend to stretch and settle into pulleys after an initial start-up sequence. Do not tension belts by

changing the setting of the motor pulley, this will change the fan speed and may damage the motor.

• To re-tension belts, turn OFF power to the fan motor.

• Loosen the fasteners that hold the blower scroll plate to the blower.

• Rotate the motor to the left or right to adjust the belt tension. Belt tension should be adjusted to

allow 1/64” of deflection per inch of belt span. Use extreme care when adjusting V-belts as not to

misalign pulleys. Any misalignment will cause a sharp reduction in belt life and produce squeaky

noises. Over-tightening will cause excessive belt and bearing wear as well as noise. Too little

tension will cause slippage at startup and uneven wear.

• Whenever belts are removed or installed, never force belts over pulleys without loosening

motor first to relieve belt tension. When replacing belts, use the same type as supplied by the

manufacturer. On units shipped with double groove pulleys, matched belts should always be used.

2. All fasteners should be checked for tightness each time maintenance checks are performed before restarting unit.

Belt tension examples:

• Belt span 12” = 3/16” deflection

• Belt span 32” = 1/2” deflection

Figure 18 - Pulley Alignment/Belt Tension

A. Belt Span Length

B. Deflection

C. Center Distance

A

B

C

27

Page 28

Pulley Combination Chart

Motor RPM 1725

1/3 to 1-1/2 HP MOTOR PULLEY Dd1 Dd2 Pd1 Pd2

AX BELTS 1VL34 1.9 2.9 2 3

Open Clos ed

BLOWER PULLEY DATUM DIAMETER PITCH DIAMETER 5 4 1/2 4 3 1/2 3 2 1/2 2 1 1/2 1 1/2 0

AK114 11 11.2 308 323 339 354 37 0 385 400 416 431 447 462

1/3 to 2 HP MOTOR PULLEY Dd1 Dd2 Pd1 Pd2

AX BELTS 1VL40 2.4 3.4 2.6 3.6

Open Clos ed

BLOWER PULLEY DATUM DIAMETER PITCH DIAMETER 5 4 1/2 4 3 1/2 3 2 1/2 2 1 1/2 1 1/2 0

AK114 11 11.2 400 416 431 447 46 2 477 493 508 524 539 554

AK94 9 9.2 4 88 506 525 544 563 5 81 600 619 638 656 67 5

AK79 7.5 7.7 582 605 627 650 672 694 717 739 762 784 806

AK66 6.2 6.4 701 728 755 782 809 836 863 889 916 943 970

AK54 5 5.2 8 63 896 929 962 995 1028 1062 1095 1128 1161 1194

AK46 4.2 4.4 1019 1059 1098 1137 1176 1215 1255 1294 1333 1372 1411

AK39 3.5 3.7 1212 1259 1305 1352 1399 1445 1492 1539 1585 1632 1678

AK32 3 3.2 1402 1455 1509 1563 1617 1671 1725 1779 1833 1887 1941

3 to 5 H P MOTOR PULLEY Dd1 Dd2 Pd1 Pd2

BX BELT S 2VP42 2.9 3.9 3 4

Open Clos ed

BLOWER PULLEY DATUM DIAMETER PITCH DIAMETER 6 5 1/2 5 4 1/2 4 3 1/2 3 2 1/2 2 1 1/2 1 1/2 0

2BK160H 15.4 15.7 330 3 39 348 357 366 375 385 394 403 412 421 430 439

2BK140H 13.4 13.7 378 3 88 399 409 420 430 441 451 462 472 483 493 504

2BK120H 11.4 11.7 442 4 55 467 479 491 504 516 528 541 553 565 577 590

2BK110H 10.4 10.7 484 4 97 511 524 537 551 564 578 591 605 618 631 645

2BK100H 9.4 9.7 534 548 563 578 593 608 622 637 652 667 682 697 711

2BK90H 8 .4 8 .7 595 611 628 644 661 677 694 710 727 744 76 0 777 793

2BK80H 7 .4 7 .7 672 691 709 728 747 765 784 803 821 840 85 9 877 896

2BK70H 6 .4 6 .7 772 794 815 837 858 880 901 923 944 965 987 1008 1030

2BK60H 5 .4 5 .7 908 933 958 984 1009 1034 1059 1084 1110 1135 1160 1185 1211

2BK55H 4 .9 5 .2 995 1023 1050 1078 1106 1133 1161 1189 1 216 1244 1272 1299 1327

2BK50H 4.4 4.7 1101 1132 1162 1193 1223 1254 1285 1315 1346 1376 1407 1438 1468

7-1/2 to 10 HP MOTOR PULLEY Dd1 Dd2 Pd1 Pd 2

BX BELT S 2VP60 4.3 5.5 4.7 5.9

Open Clos ed

BLOWER PULLEY DATUM DIAMETER PITCH DIAMETER 6 5 1/2 5 4 1/2 4 3 1/2 3 2 1/2 2 1 1/2 1 1/2 0

2BK160H 15.4 15.7 516 5 27 538 549 560 571 582 593 604 615 626 637 648

2BK140H 13.4 13.7 592 6 04 617 630 642 655 667 680 693 705 718 730 743

2BK120H 11.4 11.7 693 7 08 722 737 752 767 781 796 811 826 840 855 870

2BK110H 10.4 10.7 758 7 74 790 806 822 838 854 871 887 903 919 935 951

2BK100H 9.4 9.7 836 854 871 889 907 925 943 960 978 996 1014 1031 10 49

2BK90H 8 .4 8 .7 932 952 972 991 1011 1031 1051 1071 1091 1110 1130 1150 1170

2BK80H 7.4 7.7 1053 1075 1098 1120 1143 1165 1187 1210 1232 1255 1277 1299 1322

3 to 5 H P MOTOR PULLEY Dd1 Dd2 Pd1 Pd2

BX BELT S 2VP42 2.9 3.9 3 4

Open Clos ed

BLOWER PULLEY DATUM DIAMETER PITCH DIAMETER 6 5 1/2 5 4 1/2 4 3 1/2 3 2 1/2 2 1 1/2 1 1/2 0

2B5V278 27.8 28.1 184 189 194 200 20 5 210 215 2 20 225 230 235 240 246

2B5V250 25 25.3 205 210 216 222 22 7 233 239 244 250 256 261 267 273

2B5V234 23.4 23.7 218 224 230 237 24 3 249 255 2 61 267 273 279 285 291

2B5V200 20 20.3 255 262 269 276 28 3 290 297 304 312 319 326 333 340

2B5V184 18.4 18.7 277 284 292 300 30 7 315 323 3 31 338 346 354 361 369

2B5V160 16 16.3 317 326 335 344 35 3 362 370 379 388 397 406 414 423

2B5V154 15.4 15.7 330 339 348 357 36 6 375 385 3 94 403 412 421 430 439

2B5V136 12.6 12.9 401 412 423 435 44 6 457 468 4 79 490 501 513 524 535

2B5V124 12.4 12.7 407 419 430 441 45 3 464 475 4 87 498 509 521 532 543

2B5V110 11 11.3 458 471 483 496 50 9 522 534 547 560 572 585 598 611

7-1/2 to 10 HP MOTOR PULLEY Dd1 Dd2 Pd1 Pd 2

BX BELT S 2VP60 4.3 5.5 4.7 5.9

Open Clos ed

BLOWER PULLEY DATUM DIAMETER PITCH DIAMETER 6 5 1/2 5 4 1/2 4 3 1/2 3 2 1/2 2 1 1/2 1 1/2 0

2B5V278 27.8 28.1 289 295 301 307 31 3 319 325 3 31 338 344 350 356 362

2B5V250 25 25.3 320 327 334 341 34 8 355 361 368 375 382 389 395 402

2B5V234 23.4 23.7 342 349 357 364 37 1 378 386 3 93 400 408 415 422 429

2B5V200 20 20.3 399 408 416 425 43 3 442 450 459 467 476 484 493 501

2B5V184 18.4 18.7 434 443 452 461 47 0 480 489 4 98 507 517 526 535 544

2B5V160 16 16.3 497 508 519 529 54 0 550 561 571 582 593 603 614 624

2B5V154 15.4 15.7 516 527 538 549 56 0 571 582 5 93 604 615 626 637 648

2B5V136 12.6 12.9 628 642 655 669 68 2 695 709 7 22 735 749 762 776 789

2B5V124 12.4 12.7 638 652 666 679 69 3 706 720 7 33 747 761 774 788 801

2B5V110 11 11.3 717 733 748 763 77 9 794 809 824 840 855 870 885 901

15 to 20 HP MOTOR PULLEY Dd1 Dd2 Pd1 Pd2

BX BELT S 2VP75 5.8 7 6.2 7.4

Open Clos ed

BLOWER PULLEY DATUM DIAMETER PITCH DIAMETER 6 5 1/2 5 4 1/2 4 3 1/2 3 2 1/2 2 1 1/2 1 1/2 0

2B5V278 27.8 28.1 381 387 393 399 40 5 411 417 4 24 430 436 442 448 454

2B5V250 25 25.3 423 430 436 443 45 0 457 464 470 477 484 491 498 505

2B5V234 23.4 23.7 451 459 466 473 48 0 488 495 5 02 509 517 524 531 539

2B5V200 20 20.3 527 535 544 552 56 1 569 578 586 595 603 612 620 629

2B5V184 18.4 18.7 572 581 590 600 60 9 618 627 6 36 646 655 664 673 683

2B5V160 16 16.3 656 667 677 688 69 8 709 720 730 741 751 762 773 783

2B5V154 15.4 15.7 681 692 703 714 72 5 736 747 7 58 769 780 791 802 813

2B5V136 12.6 12.9 829 842 856 869 88 3 896 909 9 23 936 949 963 976 990

** 2HP Motors on 20 IN Blowe r s use 2V P4 2 Pu l l e ys

10 - 20 IN. BLOWER**

TURNS ON MOT OR PULLEY

25 IN. BLOWER

TURNS ON MOTOR PULLEY

TURNS ON MOTOR PULLEY

TURNS ON MOTOR PULLEY

TURNS ON MOTOR PULLEY

TURNS ON MOT OR PULLEY

TURNS ON MOTOR PULLEY

28

Page 29

Main Power

Supply

External

Disconnect

Switch

On

Off

Nothing

Happens

Freeze-Stat

Powered

Discharge

Temp erature

Blower Shuts Down

After Time Setting

on Freeze-Stat

Passes

Motorized

Damper Actuator

Energized

Colder Then

Freeze-Stat

Set-Point

W armer T hen

Freeze-Stat Set-Point

No Freeze-

Stat

Provided

Damper End

Switch

Damper Opens ,

Nothing Else

Happens

Supply Motor

Contactor is

Energized, M otor

Starts

End Switch

Makes

End Switch

Does N ot

Make

No Damper

Provided

No Fr eeze-Stat

or

Damper Provid ed

Coil Blower

Interlock Relay is

Energized

Coil

Disconnect

Switch

On

Off No Heat

Air flow Switch

Energized

No Heat - Not

Enough Airflow

No

Yes

Yes

Outside Air

Temp erature

No

No Heat

Requirement

Coil Step Controller

is Energized -

Heating Begins

Normal Operation

Cooler Then T hermos tat

Set-Point

Warmer Then

Ther mostat

Set-Point

Blower Interlock

Energized

No

No Heat - No Power to

Blower Interlock Relay -

Follow Flow Chart to Lef t

Thermal Limit

Tripped

Overh eat Situ ation Not Enough Airflow

Yes

Sequence of Operation

The main power supply provides power to both the motor controls and the coil. The blower interlock relay

is the common link between the two circuits, as shown below. Once in normal operation, the coil

modulating stage will energize first and then subsequent power stages as required.

Main Circuit

29

Page 30

Optional Remote Panel Circuit

Power

Supply From

Heater

"Power" LightOnOff

No Power to

Panel

Panel is

Powered

Blower Switch

Nothing Happens

No Power is Sent

to Heat er

Power is Sent to

Heater to Open

Damper (if

provided) and

Star t Blower

"Blower Off"

Position

(3-Position Panels Only)

"Blower On"

Position

"Blower On"

Light

Damper is not

Open or Freeze-

Stat has Detected

Low Temperature

Operation

On

Off

Temperatur e

Control Switch

Blower Operates

Heat D oes not

Oper ate

"Vent"

Position

"Heat"

Position

"Heat On" Light

Turns On

Heat Circuit is

Energized

Blower Operates

Cooling Circuit is

Energized

"Cool"

Position

(if provided)

30

Page 31

Silicon Controlled Rectifier (SCR) Electrical Control

The electric coils on the heater are controlled using Silicon Controlled Rectifier (SCR) controls. SCR is a

time proportioning type controller that modulates the heater and supplies the exact amount of power to

match heating demand of the system.

During modulation (proportional) control of the heater, an electric signal (0-10V DC) from a proportional

thermostat is transmitted to the stage controller. The thermostat, which may be either a duct type for fresh

make-up air or a room sensor thermostat for zone heating. The stage controller activates the modulating

stage(s) of the electric heater. The heater is electronically controlled to provide 0 to 100% of its capacity to

heat the space.

Depending on the space’s thermostat demand, the heater is pulsed in different proportions of ON time and

OFF time to match the heating demand. A modulation control can maintain an accurate room or discharge

temperature without the typical variations of the ON/OFF method.

An example of proportional control would be when the heater element is operating at 10% of its capacity,

10% ON and 90% OFF.

Heaters that use more than one modulating stage use an ON/OFF control for supplemental stages.

Modulating Coil Thermostat Settings

To test and verify all coil circuits during startup, perform the following:

Thermostat with Dip Switch Settings

• Discharge Control: Disconnect one wire from the discharge air sensor to simulate a call for maximum

amperage.

• Space control:

• Set the Thermostat Dip switch to discharge control.

• Once maximum amperage is achieved and tested, configure wiring and Dip switches to their original

state.

Table 7 - Thermostat Dip Switch Settings

Discharge Control

S1 On

S2 Off

S3 On

Space Control

S1 Off

S2 On

S3 On

Thermostat without Dip Switch Settings

• Press the override button for eight seconds to access settings menu. Use the override button to scroll

through the menu to the “Heat Max” setting. Use the up arrow button to change the “Heat Max” setting

to 110°F.

• Press the override button to save changes. Let the controller idle in order to exit the settings menu.

• After the controller has exited the settings menu, change the “Heating” set point to 110°F. This will

simulate a call for maximum amperage.

• Once maximum amperage is achieved and tested, adjust the “Heat Max” setting to 90°F. Change

“Heating” set point to desired temperature.

31

Page 32

SCR Electrical Circuit Check

+

-

0-10VDC INTERLOCK

24V

C

I

-

+

Components and electrical wiring will vary depending on heater model and insert. Refer to schematics

provided with unit for appropriate electrical wiring checks.

• Verify the automatic and manual cutout switches are in their closed position.

• Verify electrical wiring and component connections are secure and tight.

• Check for air flow, and air flow switch operation. If the switch is not closed during operation, verify the

tube is properly installed.

• Verify the control setting is set to 0-10V DC on the stage control board.

• Check for 0-10V DC between (-) to (+) connections.

• When there is a call for heat, verify there is 24V AC between interlock connection “I” and common

connection “C”.

• When the unit is operating at 50% demand, the green LED should blink. If the light is not blinking, there

may be an issue with the stage control board.

• Check for 24V AC at control fuse (labeled CF on heater schematics).

• Check SSR output terminals. There should be 0V DC when the demand is 0% and 24V DC when the

demand is 100%. If the voltage readings are incorrect, there may be an issue with the stage control

board.

• If the heater is equipped with multiple heating stages, verify operation of contacts. When the heating

unit is at 100% demand, there should be 24V AC present at the corresponding contactor coil. The

contacts should be closed.

If any components or wiring are found defective during these checks, repair or replace as required.

Figure 19 - Typical Heater Insert Wiring

32

Page 33

Components

1

15

2

3 4

5

6

8

9

12

10

14

11

13

7

16

The following image and list outlines the common electric heater components and their functions.

Figure 20 - Typical Cabinet

1. Motor Disconnect Switch - Interrupts power to blower motor and controls.

2. Motor Starter - Contactor with overload protection to start and protect motor.

3. Airflow Switch - A safety device insuring proper air flow during coil operation.

4. Automatic Reset Thermal Limit - Safety device that prevents the coil from overheating.

5. Stage Controller - Controls multiple heating stages in a pre-determined sequence. Works in

conjunction with a proportional thermostat (not shown). A sensor is mounted in blower for discharge

control. The set-point is mounted remotely for either space control or discharge control.

6. Coil Termination - Wired connection to heating coil element.

7. Silicon Control Rectifier (SCR) - Modulates power to the electric coil.

8. Fuse Blocks - Provides over-current protection.

9. Control Transformer - 120V primary; 24V secondary control transformer.

10. Coil Contactor - Energizes coil when there is a signal from step controller.

11. Inline Fuse - Provides over-current protection.

12. Terminal Strip - Central location to terminate control wiring.This should be used for troubleshooting.

13. Circuit Breaker - Protects electrical components from high current spikes.

14. Power Transformer - Installed when motor voltage is greater than 120V. Used to provide 120V service to controls.

15. Freeze-Stat Thermostat (Optional) - De-energizes blower motor if the discharge air temperature falls below the set point.