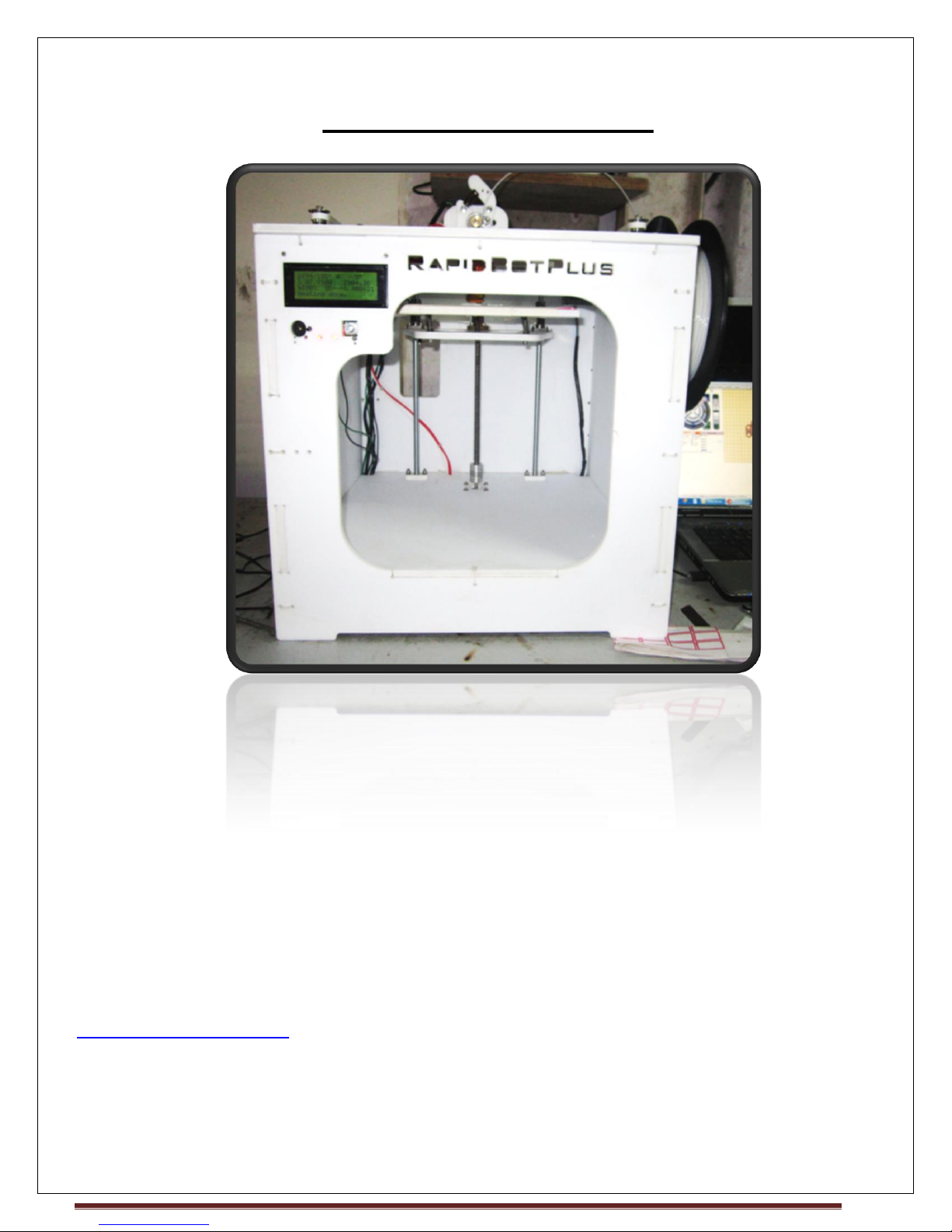

Make Mendel PlusBot User Manual

PlusBot 3D Printer

PlusBot is a latest generation 3D printer, capable of printing 3D objects of PLA/ABS plastic.

PlusBot uses high quality Linear motion guides. So it is very easy to build. Self locking design ensures

rigid frame with easy steps(Without need of any measurements, during building)

Any person can easily build it by following our Manual.

If you have any queries or requests related to RapidBotPlus 3D Printer, Kindly drop a mail at :

support@makemendel.com, Our team will be ready to help you, and to answer your querries.

MAKE MENDEL Page 1

Technical Specification :

• Machine size 400 x 200 x 320 mm

• Build size 220 x 220 x 165 mm

• Nozzle Diameter : 0.4mm

• Layer Thickness : 0.1mm

• Speed : 60 mm/s

• Positioning Precision : 27 microns

• Input Format : STL

• Software : Pronterface (Available on site for free under Download section)

• System Compatibility : Windows 7 and Vista

• Power Supply : ATX, 450W

• Weight (Kg) : 12

Features :

1) XY Core Mechanism.

2) Spring Printbed Adjustment.

3) High quality linear motion guides.

4) Printrboard and Power Supply are adjusted at the bottom to give clean and neat look.

5) Mechanically more Stable Design

6) Very easy to build, just 7-8 hours.

7) High quality Aluminium T2.5 Pulley and belt with Accurate and easy placement.

8) Large build volume with easy accesibility.

9) Uses high quality acrylic from http://www.perspex.co.uk

10) Self locking design ensures rigid frame with easy steps(Without need of any

measurements, during building).

MAKE MENDEL Page 2

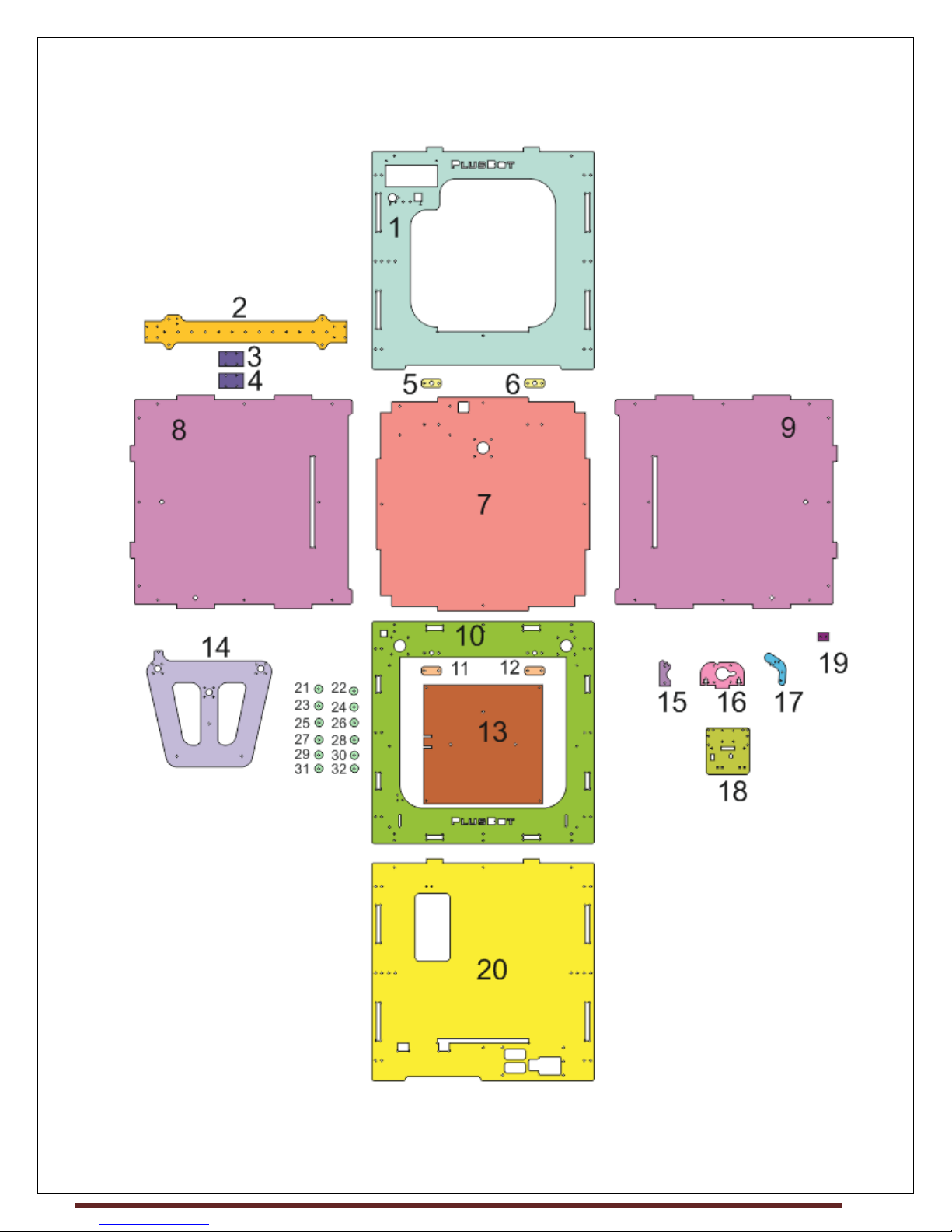

Assembly of PlusBot

MAKE MENDEL Page 3

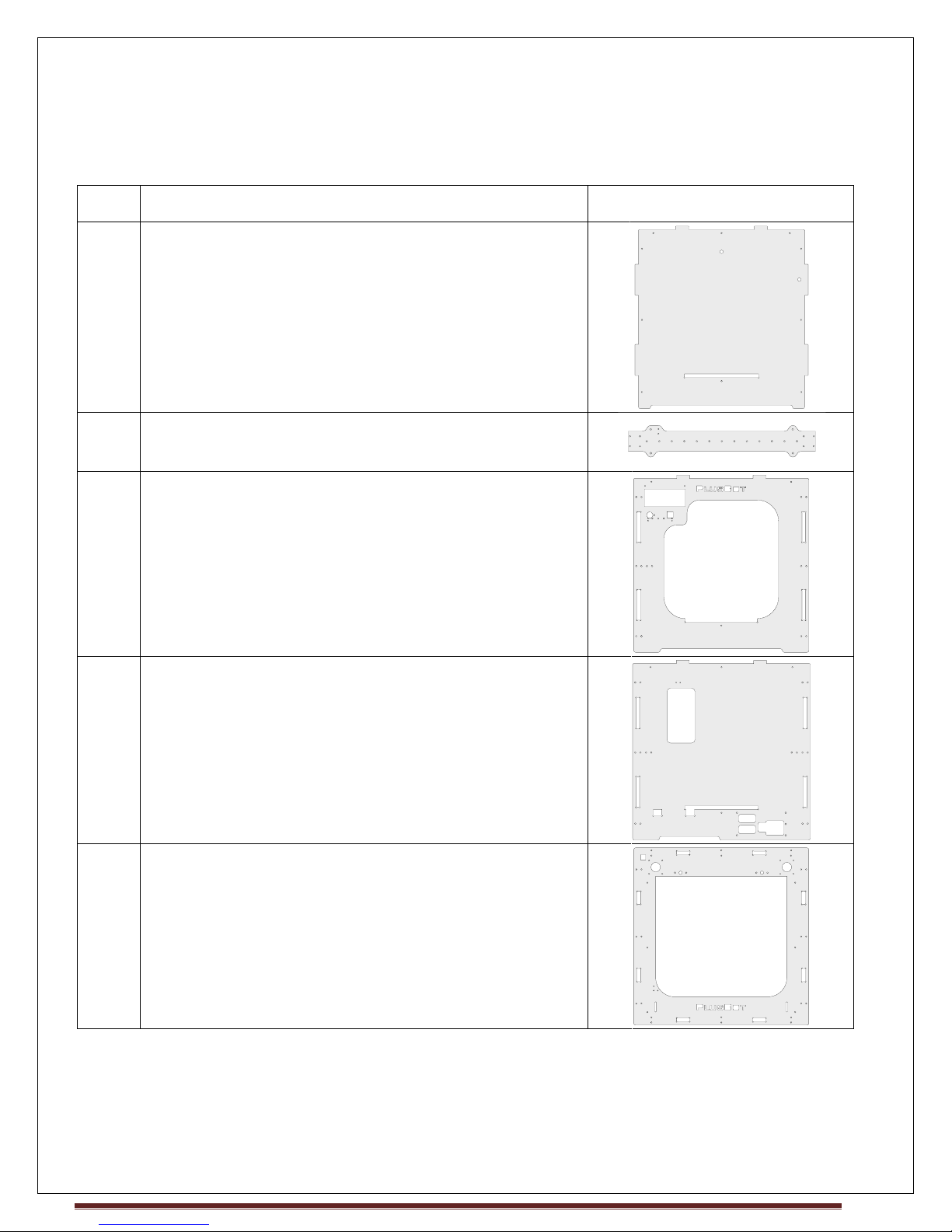

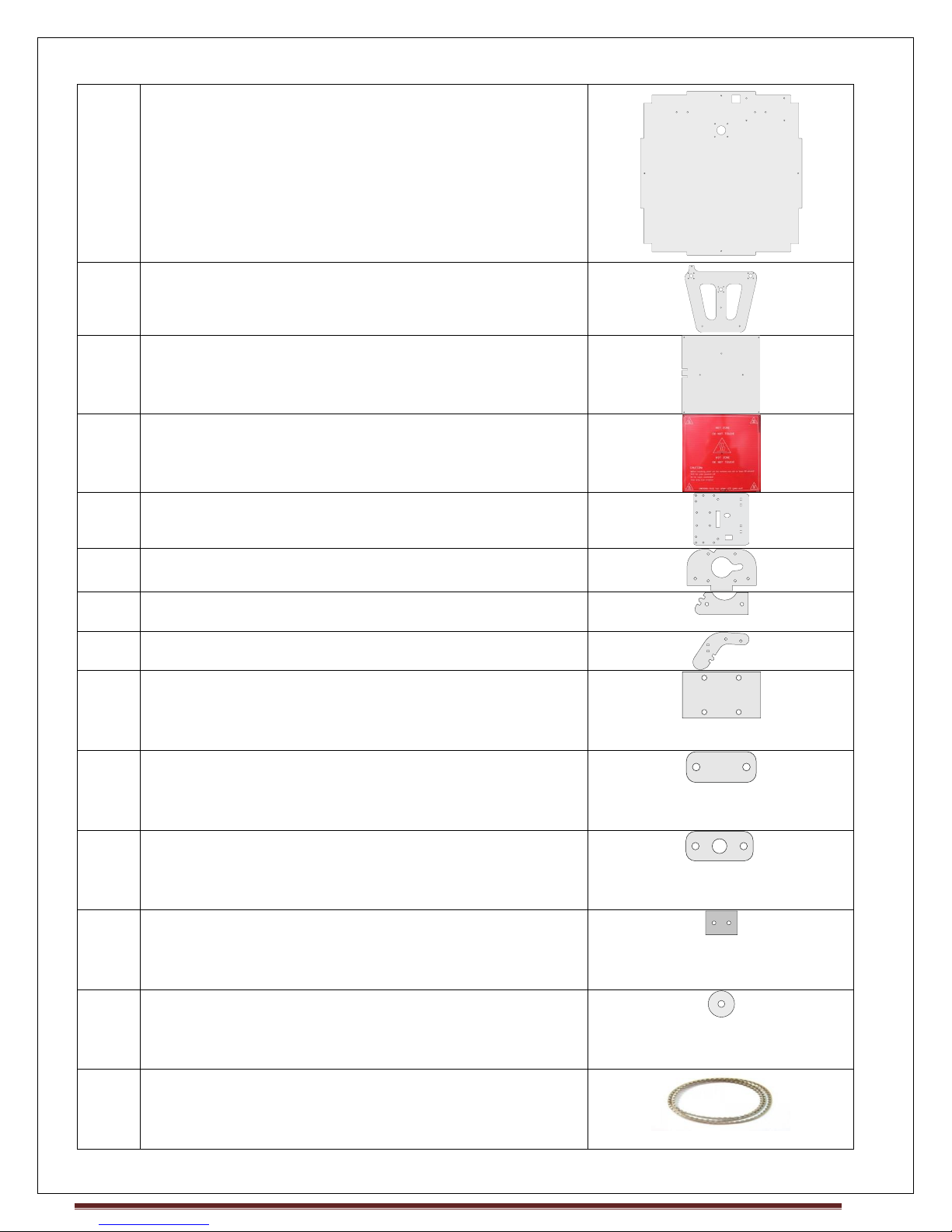

Qty

Part

Drawing

2

Side Plates

1

Middle Plate

1

Front Plate

1

Back Plate

1

Top Plate

Part List For PlusBot-Acrylic Sheets

MAKE MENDEL Page 4

1

BottomPlate

1

PrintrBed-Support Plate

1

AcrylicPrintBed

1

PCB HeatBed

1

Extruder Base

1

Extruder Motor Plate

1

Driven Holder

2

Idler Holder

2

X-Rail Top Plate

2

Smooth Rod Cap

2

Cap screw for smooth rod

1

Acrylic support for Z Mechanical switch

12

BearingSupport in XPlate

2

T2.5 Belt 195cm

MAKE MENDEL Page 5

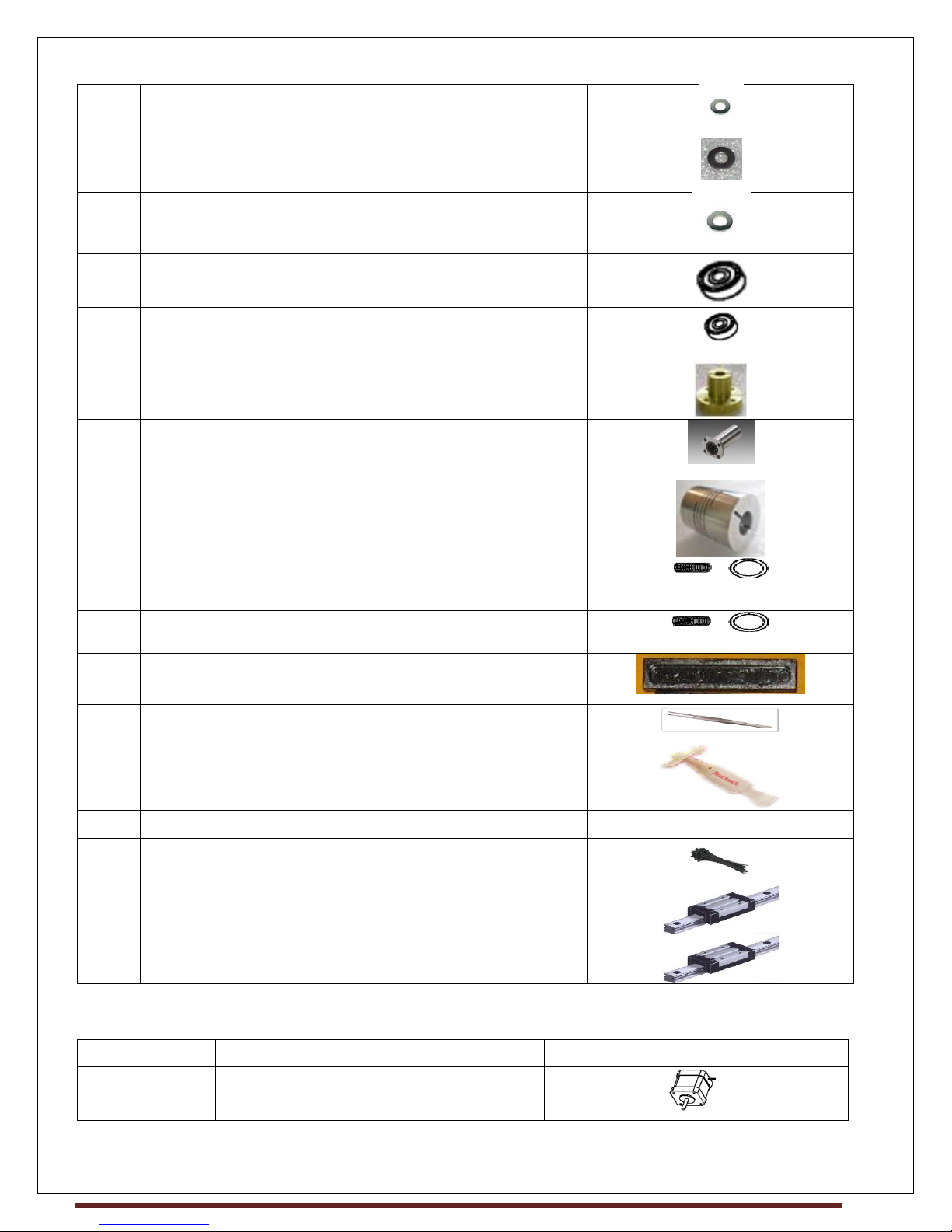

1

MK7 Drive Gear

Qty

Part

Drawing

23

M3 Nylock Nut

8

M4 Nylock Nut

4

M2.5x20 Screw

2

M2.5x25 Screw

6

M2.5 Sada Nut,

13

M3x12 SocketCap Screw

18

M3x15 SocketCap Screw

19

M3x20 SocketCap screw

4

M3x25 CounterSink

2

M4 x20 SocketCap screw

6

M4x25 SocketCap Screw

2

M4x25 Countersink Screw

3

M4x50 Countersink Screw

3

M4x40 SocketCap Screw

4

M4x60 SocketCap

5

SMPS mounting Screw

Hardware

MAKE MENDEL Page 6

M3 Washer

M4 Washer

M4x10 Washer

6

624-Bearing

2

623-Bearing

1

ACME Flange nut

2

Flange bearing

1

Coupling 5 _8

2

Soft Spring

(1Extruder + 1ZSwitch)

3

Hard spring

1

Dummy Rails

1

Forceps

1

FeviQuick

8

M3 x 15 screw

1

Plastic Tie

1

Small Linear Motion Guide

2

Large Linear Motion Guide

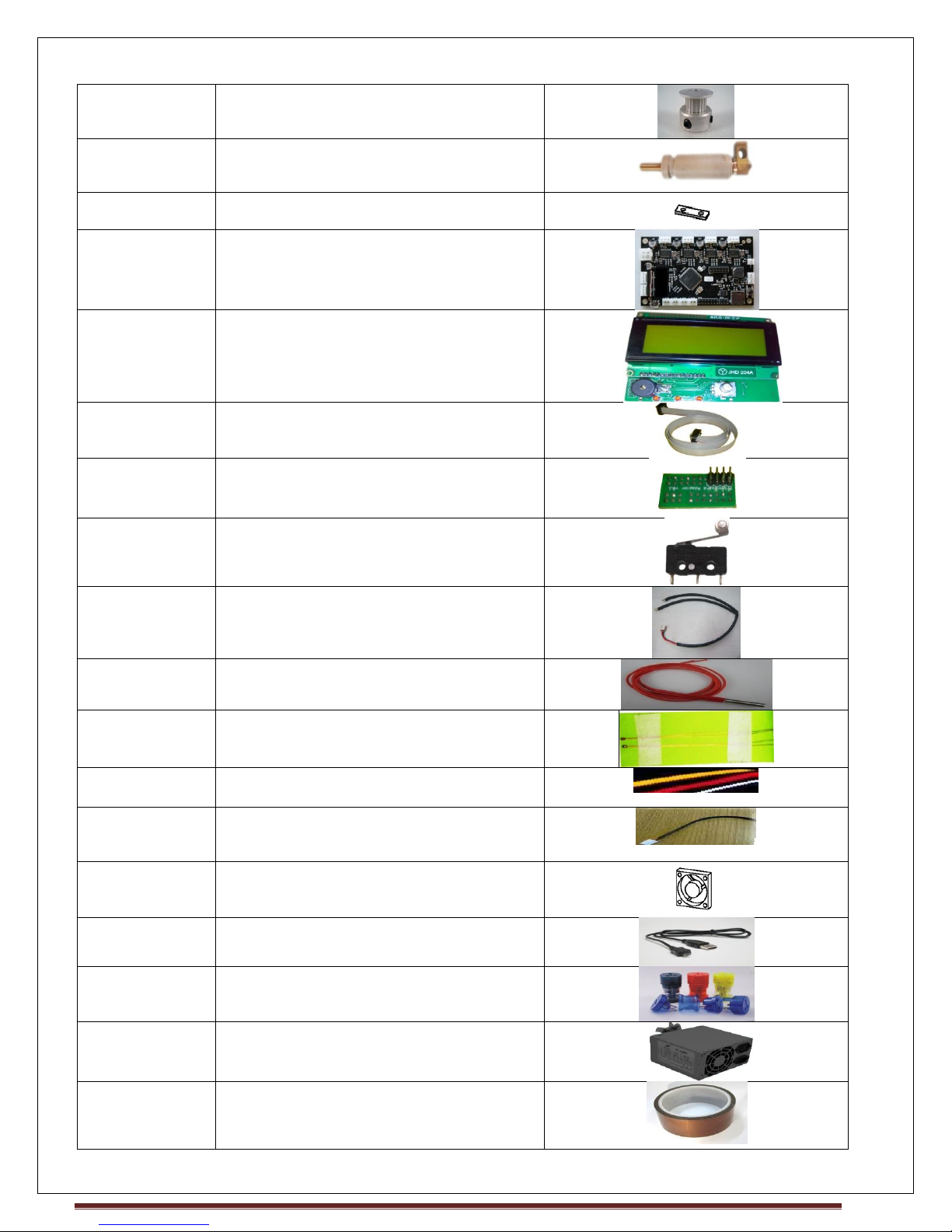

Quantity

Part

Drawing

4

Stepper Motors-NEMA 17

MAKE MENDEL Page 7

Hotend and Electronics

2

T2.5 Timing Pulley_5mmBore (For

X-Y Motor)

1

J HotEnd Extruder

1

PTFE Strain Relief

1

Printrboard REV D Electronics

Board

1

LCD

1

LCD flat cable

1

LCD connection PCB

3

Mechanical switch with 3 pin

Molex Connector

1

Z Prusa Cable

1

Cartridge Heater (12V, 40 Watt)

1

Thermistor G550 EPCOS

2

Teflon sleeve

2

4 pin and 2 pin Teflon Molex

connector

1

Cooling Fan 60 x 60

1

USB Printer cable

1

Universal Travel Adaptor

1

SMPS

2

Kapton Tapes (50mm + 15mm)

MAKE MENDEL Page 8

Loading...

Loading...