Major MR150, MR180, MR235 Operator's Manual And Parts List

Operator Manual

and Parts List

MAJOR

FINISHING MOWERS

MR150, MR180 and MR235

Head Ofce

Major Equipment Intl Ltd

Ballyhaunis,

Co. Mayo,

Ireland

Tel.: 09496 30572

Fax: 09496 30788

UK Ofce

Major Equipment Ltd.

Major Industrial Estate.

Middleton Rd

Heysham

Lancs.

LA3 3JJ

Tel.: 01524 850 501

Fax: 01524 850 502

NL & GERMANY OFFICE

Major Equipment Intl Ltd

Postbus 29

NL-7700 AA

Dedemsvaart

Nederland

Tel: + 31 (0) 6389 19585

Web: www.major-equipment.com

We suggest that you record your machine details along with your dealers address & telephone

number for your convenience

MODEL: ______________ SERIAL NO: __________________

DEALER: ________________________________________________________

ADDRESS: ________________________________________________________

________________________________________________________

________________________________________________________

TEL NO: ________________________________________________________

Disclaimer

While every effort has been made in the production of this manual to ensure that the information contained herein is full and

correct, Major assumes no responsibility for errors or omissions.

Major reserves the right to modify the machinery and the technical data contained within the manual without prior notice.

Further to this, Major assumes no liability for any damages which may result from the use of the information contained within this

manual.

Contents

Introduction

Identication Data 2

Main Parts 2

Safety Regulations

General Safety regulations 3

Regulations for use of the driveline 3

Starting regulations 4

Warning and danger plates and stickers 5

Key to safety devices 6

Delivery of the mower 7

Hitching to the tractor

Preliminary instructions on use of the machine 8

Coupling the machine to the tractor 11

Shortening the driveline 12

Use of the Machine

Preparing the implement for work 13

Use of the machine 14

Demounting the implement from the tractor 15

Maintenance

Technician specications 15

Inspections before use 16

Periodical inspections 16

Storage of machine 19

Spare Parts

Spare parts list 20

Trouble shooting 28

Warranty procedure 30

EEC certicate of conformity for machines

(conforming to Directive 98/37/EEC)

Company: Major Equipment Ltd.

Address: Coolnaha,

Ballyhaunis,

Co. Mayo,

Ireland.

Tel. +353949630572

Fax +353949630788

declares in sole responsibility that the product:

FINISHING MOWER

When properly installed, maintained and used only for it’s intended purpose, complies with

all the essential Health & Safety requirements of:

• THE SUPPLY OF MACHINERY (SAFETY) REGULATIONS 2008.

• S.I. No. 299 of 2007, Safety, Health and Welfare at Work (General Application)

Regulations 2007 (Ireland).

• Health & Safety at Work, etc. Act 1974 (c.37) (UK).

• EN ISO 12100:2010, ISO 11684:1995.

• EN ISO 13857:2009, EN 349:2009, EN ISO 4413:2011.

• EN ISO 4254-12:2012, EN ISO 4254-1:2010

I certify on behalf of Major Equipment Int. Ltd., that this machine when properly installed

and operated correctly, complies with all the essential Health & Safety requirements of

all legislation referred to above.

Signature : ______________ Date 11/01/2013

Managing Director

INTRODUCTION

Thank you for purchasing this Major Finishing Mower. Please carefully read this operation manual and strictly

observe these instructions for the safety of you and the personnel around you. In this manner, you will enjoy

long and satisfactory use of this product.

The user of the mower (also called "Implement" or "Machine" in the text) is personally responsible for his own

safety and that of any other people in the vicinity of the machine.

It is therefore essential for the user to possess detailed knowledge about how to use, service and correctly

mount the mower on the tractor. The machine's user must be an operator with a suitable technical background to

enable him to understand the contents of this manual, including the diagrams found herein. The figures and

descriptions in this handbook give both users and maintenance staff all the basic instructions to comply with

when using and servicing the mower.

The user is responsible for ensuring that connection to the tractor and use of the mower complies with the

current provisions in merit. The machine may only be used and serviced by persons who have be come fully

familiar with the contents of this manual, which should always be kept ready to hand. Users should become

particularly familiar with chapter 2 concerning safety precautions.

Always comply with the given instructions. Consult the Major After-Sales Service Centre or your nearest dealer

in case of doubt. In the event of faults or problems which require the assistance of a qualified technician, contact

the manufacturer directly or your nearest dealer.

This machine is consigned according to the warranty conditions valid at the moment of purchase. The user must

not tamper with the machine or make modifications to its parts since such action shall void the guarantee.

The manufacturer reserves the right to modify the machine specifications and performances without advance

warning and declines all responsibility for any errors caused by incorrect installation or improper use of the

equipment.

Contact MAJOR or your nearest dealer if there are substantial differences between the implement and the

indications in this handbook. The standards that govern the guarantee are cited in the "Certificate of Guarantee"

which is supplied to the user with this manual.

This symbol is used in the manual to call the reader's attention to various levels of danger that if not

avoided will result in death or serious injury.

Important: References to this manual to the right side and left side of the machine mean to the right and left

side of the operator seated in the tractors driving seat.

IMPORTANT NOTICE

BEFORE OPERATING THIS MACHINE, BE SURE TO CHECK THE

FOLLOWING CHECK-POINTS (HAVING FIRST STOPPED THE TRACTOR

ENGINE, DISENGAGED THE PTO AND CAREFULLY READ AND

UNDERSTOODF THE OWNER’S MANUAL):

1. Check oil levels (if necessary and SAE 90 EP oil)

2. Grease the driveline spiders

3. Grease all marked points on the machine

4. Check to be sure the nuts/bolts are snug on those parts which are under

the most stress (tines, blades, front linkage bolts, gear box bolts etc)

1

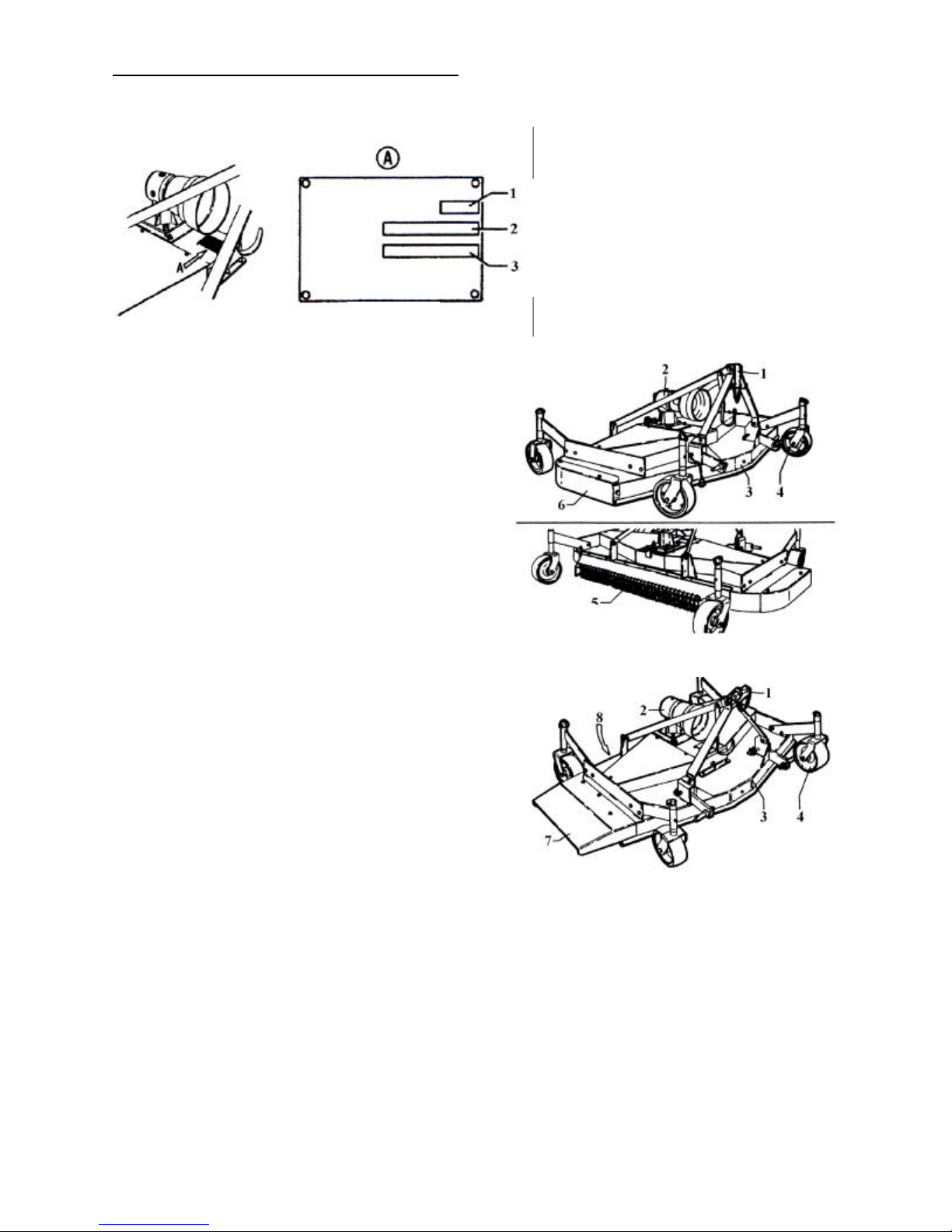

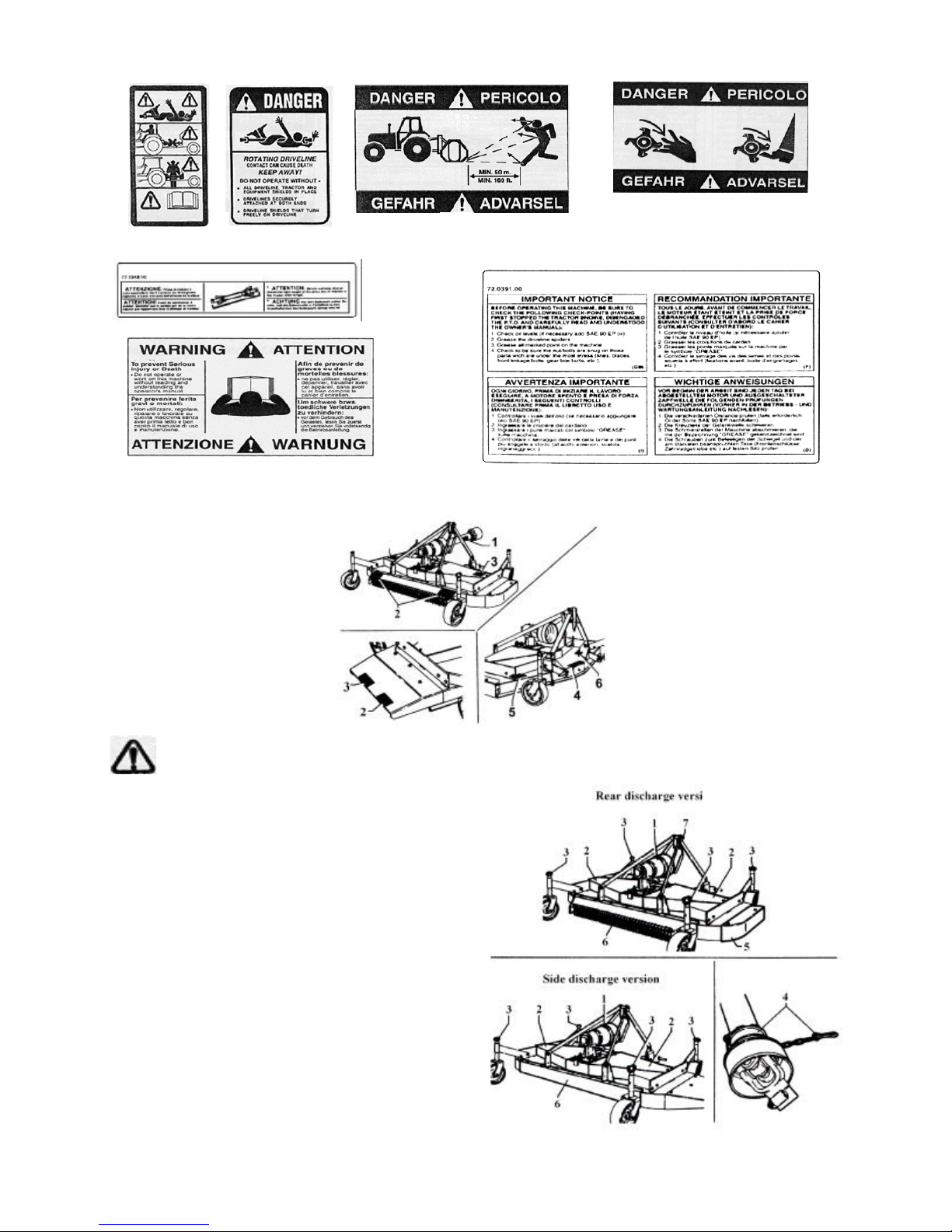

IDENTIFICATION DATA & GUIDE TO MAIN PARTS

Key to the main parts

Fig 2.1

Fig 2.2

The data plate indications must not be altered for any reason. We suggest that you write the data pertaining to

your mower in the spaces below (Fig. 2.1)

1. Year of Manufacture

2. Machine type or model

3. Serial Number

1. Three-point linkage used to couple the

implement to the tractor.

2. Gearbox: Increases the rotation speed

of the tractor PTO.

3. Chassis: This is the bearing structure of

the implement.

4. Pivoting wheels: The machine is

supported by pivoting wheels which can

also be used to adjust the cutting height.

5. Rear discharge conveyor.

6. Side closing part.

7. Side discharge conveyor. (MR150 &

MR180 only)

8. Rear closing part.

(Fig. 2.2)

Side Discharge Mower

The main feature of this machine is its versatility, since the user (if in possession of the transformation kit) can

modify the machine from the rear discharge version to the side discharge version and vice versa. The essential parts

of the machine are as follows: a

1. Kiln-lacquered, electro-welded steel frame;

2. A gearbox unit to be connected to the tractor's power takeoff with a PTO shaft.

3. Four pivoting wheels to support the machine on the ground while it is in use.

4. Three blades with a milled cutting edge.

5. Conveying and discharging set, positioned on the side or the rear of the machine.

2

GENERAL SAFETY & SAFETY REGULATIONS

Fig. 3.1

Fig.

3.2 Fig.

3.3 Fig.

3.4

The mower must only be used with a suitable tractor and driven by an adequate driveline driven from the

tractor PTO. All other use is strictly prohibited. Users should become thoroughly familiar with the contents of this

manual before using, servicing or mounting the implement on the tractor and all other pertinent operations.

Never wear jewellery, loose clothing such as ties, scarves, belts, unbuttoned jackets or dungarees with

open zips which could become caught up in moving parts. Always wear approved garments complying with

accident prevention provisions such as: non-slip shoes, ear muffs, goggles and gauntlets.

Consult your dealer, the "Labour Health Service" or your nearest equivalent authority for information about

the current safety provisions and specific regulations to comply with in order to ensure personal safety. If the

machine is used in the evening, follow the relevant instructions.

REGUALTIONS FOR THE USE OF THE DRIVELINE

The machine maybe supplied with a driveline; the driveline is complete with shields able to ensure the operator's

safety (see Figure 3.6 page 8)

Keep the non-rotation shields efficient and in a good condition. If their condition is poor, they should be changed

before the implement is used. Unless it is correctly protected, the driveline could even cause the user's death

since it can catch on parts of the body or clothing. Always check that the shields are installed and perfectly

efficient before using the machine. Check that they are well fixed and correctly inserted into their housings.

Check that the retaining chains are correctly fixed to the tractor or mower in order to prevent the shields from

turning together with the driveline.

Check that the driveline is free to turn within the shield. Take great care to prevent the shields from being

damaged when the implement is coupled and released from the tractor. Keep the grooved parts perfectly clean

and greased so that they are able to correctly slide.

Besides being described in this manual, the method by which the driveline is coupled must also be checked out

with the instructions in the tractor manufacturer's manual. The correct rotation speed of the tractor PTO is

indicated on the PTO shaft guards of each machine.

This rate is usually 540 or 1000 rpm. Always comply with the indicated speed. The following items are applied to

the driveline (if delivered with the machine):

• A danger sticker on the shaft guard (Fig. 3.1)

• A danger sticker on the driveline which becomes visible if the shield is damaged or missing (Fig. 3.2)

Strictly comply with the instructions on the sticker.

3

STARTING REGULATIONS

1. Always check that any imminently dangerous condition has been appropriately eliminated before using

the implement. Check that all guards and safety shields are installed, efficient and correctly mounted in

place.

2. Never allow inadequately trained personnel to use the implement.

3. Before starting, always check that there are no persons, particularly children and animals, within the

operative range of the implement. Examine the work area in order to become familiar with the type of

soil in question. Check that there are no obstructions or objects in the area that could be caught up by

the implement and thrown up at a distance. Clean all such objects from the area.

4. Never work near roads, paths, housing areas or places potentially frequented by people, vehicles,

animals, etc. If such action is inevitable, check that these areas are deserted be-fore beginning work and

while on the job.

5. Never start the tractor before being correctly seated in the driving position. Never start a faulty

implement, even when such a condition is only suspected. Contact your nearest dealer, or the person in

charge, and ask for the implement to be inspected.

GENERAL OPERATION

1. Never ever use the mower under influence of alcohol or the effect of medicines such as tranquillisers,

sedatives, stimulants, drugs or any other substance as could slow or alter the reflexes or sight.

2. Never ever work when there are persons on the implement .No one must ride on the tractor apart from

the driver unless this is explicitly allowed by the tractor manufacturer. The tractor must be equipped with

a roll-bar and/or all other safety devices prescribed by the current laws in force. To ensure his personal

safety, the operator must use these devices correctly. Consult and strictly comply with the instructions in

the tractor use and maintenance manual.

3. The operator should never allow himself to be distracted when working. He should pay great attention

and concentrate on what he is doing. Constantly keep the vehicle under control and always remember

how to quickly stop and switch off both the tractor and implement.

4. Always check that children, adults and animals keep at an adequate safety distance from the mower

when it is in use.

5. Take great care when working on sloping surfaces. It is preferable to work upwards or downwards rather

than crosswise in order to avoid the risk of over-turning. Always check and comply with the tractor

manufacturer's instructions, particularly in relation to the maximum gradient on which it is possible to

work. When working on slopes, it is advisable to reduce the work speed, gradually varying the speed

and direction of the vehicle during manoeuvres. Never repeatedly stop and start the machine.

6. Never operate on wet, slippery grass or soil or where the tyre grip is precarious. If such action is

inevitable, always work at low speed to ensure the operator's safety. Pay great attention to any

obstructions, stones or other objects which could hit the knives. The tractor engine must always be

turned off, and the ignition key must be removed from the dashboard when intervening on the machine.

For example, when it is necessary to detach the machine from the tractor or if grass or other objects that

might have become tangled up in it must be removed.

7. Before dismounting from the tractor, always disengage the power takeoff (P. T.O.), turn off the engine,

remove the ignition key from the dashboard, insert the brake, and do not approach the machine before

the tools have come to a complete stop.

8. After having hit an obstacle, simultaneously stop the tractor and machine tool, turn off the engine,

remove the ignition key from the dashboard, insert the brake, and check for any possible damage. If the

machine has been damaged, all repairs must be carried out before continuing the working process.

Always carry out any required repairs before continuing work. When the knives are turning, always keep

the limbs well away from moving parts and those which heat during operation such as the over gear unit.

Never ever attempt to check or adjust the belt tension while the implement is operating. Always stop it

before this operation. Never ever lubricate the machine while it is operating, or when the PTO is

engaged.

9. Never smoke while refuelling. Never refuel near smouldering, sparking material or open flames.

10. Always check whether the soil around the tractor is slippery. Clean all mud from the soles of the shoes

before mounting the tractor. Keep the steps, bearing surfaces, handrails, shackles and tractor pedals

(brake, clutch and accelerator) clean and free from all foreign bodies such as oil, grease, mud or snow in

order to prevent all possibility of slipping or tripping.

11. Keep the operator support areas on the tractor free from mud or any thing else that could cause the

operator to slip when the implement is mounted or demounted from the tractor. Never jump on or off the

tractor. Always keep both hands and one foot well anchored. Never use the control levers or hose pipes

as holds. These are mobile parts and do not offer a safe grip. Involuntary activation of a control could

also cause the tractor or implement to accidentally move. Before the machine is released from the

tractor, it should be rested on the ground in a stable position using the support foot where installed.

4

Always check that the machine is balanced and stable, then release it from the tractor, checking again to

ensure that it is firmly positioned.

TRANSIT ON PUBLIC HIGHWAYS

1. When driving on public roads, always comply with the Highway Code provisions in force in the country

where the machine is being used. Pay particular attention near crossroads, underpasses, and level

crossings, when meeting other vehicles, overtaking stationary or slower vehicles. Drive near the edge of

the road and try not to hold up the traffic.

2. Never park the tractor and/or mower near crossroads, bends, level crossings or where the equipment

could be a danger or obstruction to pedestrian traffic.

3. Never drive on public highways when the implement or tractor is particularly dirty since soil, grass and

other items could drop on to the road and obstruct the normal road traffic. Disengage the PTO and

disconnect the driveline when transporting the implement.

INSTRUCTIONS FOR MAINTENANCE TECHNICIANS

1. The implement must be stationary and the tractor PTO disengaged before any work is carried out on the

implement.

2. Routine and extraordinary maintenance operations must be carried out in a specially prepared place

using correct and efficient tools. This place must always be kept clean and dry. There must be sufficient

space around the implement to allow work to be easily carried out. Only trained and specialised

personnel must be allowed to service the implement. Contact your nearest dealer when maintenance

work is required.

3. Comply with the indicated bans and procedures when servicing the implement. Never ever use gasoline,

solvents or other inflammable fluids as detergents. Use the non-flammable and non-toxic commercially

available solvents authorised by the competent authorities. Never use compressed air or highly

pressurised water to clean the implement. When this is absolutely inevitable, protect the eyes using

goggles with side guards and use the lowest possible pressure.

4. At the end of the job, check and inspect the implement while it is still disconnected from the tractor.

Check the cutting blades for wear. Never carry out welding operations without the manufacturer's

permission and instructions. Before welding, always detach the implement from the tractor in order to

prevent damage to the battery. Always wear a protective mask, goggles and gauntlets when welding,

lapping or grinding, hammering or drilling. The implement should be lubricated as described the

maintenance section (page 15).

5. Correctly remount all guards and shields that were removed during the maintenance and repair

operations.

TEST REGULATIONS

1. Always operate the machine outdoors. If the machine connected to the tractor must inevitably be started

in a closed room, e.g. during tests after maintenance, always ensure that there is adequate ventilation to

prevent harmful exhaust gas from accumulating.

2. Carry out various manoeuvres assisted by specialized personnel in order to simulate the different work

conditions and acquire the necessary familiarity with the implement. Before starting, always check that

there are no foreign bodies such as stones, soil or other, clinging to the rotors. When the rotor turns,

such items could detach and be violently thrown notable distances. Always operate within a protective

cage, or at least near a solid wall.

3. Always check that no one is too near or in a potentially dangerous position if the implement is to be

operated raised from the ground, when testing for example.

4. Always disengage the PTO before driving the tractor to transport the implement from one place to the

other.

WARNING DANGER PLATES AND STICKERS

1. Comply with the warnings on the stickers. (See picture for locations & details of warning stickers on the

machine) Failure to comply with the given instructions could cause death or serious personal injury.

2. Check that the stickers are always installed and legible. If this is not the case, contact your nearest

dealer or "MAJOR" in order to obtain replacements (state the code number printed on the left hand side

of each sticker when ordering).

5

STICKER NUMBERS & LOCATIONS

1 2 3

5

6

Fig.

3.5

4

MR150 &

KEY TO SAFETY DEVICES

1. PTO shaft guard.

A cowling where the driveline couples with the

shredder over-drive protects the rotating end

of the driveline itself.

2. Drive belt guard.

Prevents access to the drive belts and

pulleys.

3. Snap Pin.

Prevents the wheel with the fork slipping off

accidentally.

4 Driveline shield.

The driveline is supplied with adequate plastic

shields and relative fixing chains.

5. Guards (only on the rear discharge

version)

Prevents the product leaking out of the side of

the machine

6. Rear Guards

Prevent any solid objects there may be in the

earth from being ejected great distances.

7. Safety Pin

Prevents the pin in the attachment point 3

slipping out accidentally. Fig. 3.5

6

MR180 only

NOISE

Measurements of the noise issued by the machine indicate that the equivalent noise level is such as to maintain

the daily level to which the operators are exposed within a value of less than 70 dBA. This measurement was

made with a sound level meter set at a distance of about 1.6 m from the machine and at a height of 2 m,

operated (no-load) at a PTO rotation rate of 450 rpm on grassy land. Please also note that the machine is

normally used outdoors and that the position occupied by the operator is seated in the driving seat of the tractor.

Also consult the prescriptions listed in the tractor use and maintenance manual.

VIBRATIONS

During normal operation, the machine will not transmit appreciable vibrations to the tractor or, thus, to the

operator. These vibrations are less than 2.5 m/sec2. to the operator's upper limbs and less than 0.5m/sec•'. to

the seated part of the operator's body. Consult the tractor manual for the vibrations transmitted by the tractor

itself.

DISCLAMER

The mower has been built in compliance with the accident prevention regulations in force and therefore the

manufacturer cannot be held responsible for damage resulting from:

• Use of the machine with faulty or missing guards

• Improper use of the machine

• Use of the machine by untrained or unauthorised personnel

• Incorrect assembly of the mower;

• Use of the mower on the wrong tractor;

• Lack of maintenance

• Unauthorised modifications or work carried out on the machine

• Use of non-original spare parts or those which are not specific to the machine

• Failure to observe all or some of the instructions & exceptional weather conditions.

DELIVERY OF THE MOWER

All mowers are tested in our plants to ensure that all moving parts operate correctly. All items are thoroughly

checked before dispatch or delivery. When the implement is received, always check that it has not been

damaged during transport. Contact your dealer if such damage is discovered.

The machine is usually delivered partially disassembled and wrapped in a heat-sealed film. The disassembled

parts are contained inside the packing, attached firmly to the machine

Hoisting & Handling the Packed Machine

Do not place the packed machines on top of each other as the packing is not designed to be piled up.

• Hoisting with a Forklift

Open the forks as wide as possible, hoist the machine using a lift truck, with an adequate carrying capacity to lift

the machine, checking its weight in the table on page 15. Check that the load is stable and well positioned on

the truck forks.

Keep the load as low as possible when moving the implement. This will ensure greater stability and visibility.

• Hoisting with a Crane or Bridge Crane

There is a small eyelet in the upper part of the machine to facilitate its hoisting. When hoisting the machine, only

hook up to this eyelet, not any other part. Take care to avoid swinging the load as this could be hazardous for

the operator and the machine could be damaged. Use chains, cables and hooks whose capacity is greater than

the load to be hoisted. Take particular care to use chains or cables that are intact and show no signs of fraying

or wear, which could put the user's safety at risk.

7

Loading...

Loading...