Major MJ2000 Operator's Manual

MAJOR

FLAIL CATCHER

MJ2000

Operator Manual

& Parts List

Head Ofce

Major Equipment Intl. Ltd.

Ballyhaunis,

Co. Mayo,

Ireland.

Tel.: +353 (0) 9496 30572

Fax: +353 (0) 9496 30788

Email: info@major-equipment.com

UK Ofce

Major Equipment Ltd.

Major Industrial Estate,

Middleton Rd.,

Heysham,

Lancs.

LA3 3JJ

Tel.: +44 (0) 1524 850 501

Fax: +44 (0) 1524 850 502

Email: ukinfo@major-equipment.com

NETHERLANDS & GERMANY OFFICE

Major Equipment Intl. Ltd.

Postbus 29,

NL-7700 AA ,

Dedemsvaart,

Nederland.

Tel: +31 (0) 6389 19585

Email: euinfo@major-equipment.com

Web: www.major-equipment.com

Find us on FACEBOOK

MAJOR MACHINERY

View our channel

MAJOREQUIPMENT

Disclaimer

While every effort has been made in the production of this manual to ensure that the information

contained herein is full and correct, Major assumes no responsibility for errors or omissions.

Major reserves the right to modify the machinery and the technical data contained within the

manual without prior notice.

Further to this, Major assumes no liability for any damages which may result from the use of the

information contained within this manual.

Contents

Introduction

Thank you 1

Using Your Operator’s Manual 1

Safety Issues 1

Product Identication

Machine Serial Numbers 1

Product Specications 1

Register Your Product and Warranty Online 1

Safety

Machine Safety Labels 2

Operating Safely 2

Workstation 3

Regulations for use of the transmission 4

PTO Shaft Safety 4

Driving Safely on Public Roads 4

Operating the Machine

Inspections before Use 5

Key to Main Parts 5

Starting Regulations 5

Hitching to the Tractor 6

Operating the Machine 6

Catcher Locking Bar Positions 6

Emptying the Catcher 7

Adjusting the Cutting Height 8

Removing the machine from the tractor 8

Maintenance

PTO Shaft Maintenance 8

Maintenance Schedule 9

Changing the gearbox oil 9

Belt Tension Adjustment 10

Checking and Replacing Blades 10

Storing the machine for long periods of time 11

Disposing of the Machine 11

Trouble Shooting 11

Spare Parts

Chute Assembly 13

Bogey Assembly 14

Flail Assembly 16

Rotor Assembly 17

Catcher Assembly 18

Scarier Assembly 19

Hydraulics 20

EEC certicate of conformity for machines

(conforming to Directive 98/37/EEC)

Company: Major Equipment Ltd.

Address: Coolnaha,

Ballyhaunis,

Co. Mayo,

Ireland.

Tel. +353949630572

Fax +353949630788

declares in sole responsibility that the product:

MJ2000 FLAIL COLLECTOR

When properly installed, maintained and used only for it’s intended purpose, complies with

all the essential Health & Safety requirements of:

• THE SUPPLY OF MACHINERY (SAFETY) REGULATIONS 2008.

• S.I. No. 299 of 2007, Safety, Health and Welfare at Work (General Application)

Regulations 2007 (Ireland).

• Health & Safety at Work, etc. Act 1974 (c.37) (UK).

• EN ISO 14121-1: 2007 ‘Safety of machinery. Principles for risk assessment.

• EN 745 - Agricultural Machinery - Rotary Mowers and Flail Mowers - Safety.

• EN ISO 13857 - Safety of machinery: Safety distances to prevent hazard zones being

reached by upper and lower limbs.

• EN ISO 13857:2008, EN ISO 4413:2010; EN ISO 4254-1:2015

• ISO 11684:2010; ISO 4254-13:2012

I certify on behalf of Major Equipment Int. Ltd., that this machine when properly installed

and operated correctly, complies with all the essential Health & Safety requirements of

all legislation referred to above.

Signature : ______________ Date 11/05/2017

Managing Director

1

www.major-equipment.com

Introduction

Thank you

We appreciate having you as a customer and wish you many years of safe and satised use of your machine.

Using Your Operator’s Manual

This manual is an important part of your machine and should remain with the machine when you buy it.

Reading your operator’s manual will help you and others avoid personal injury or damage to the machine. Information

given in this manual will provide the operator with the safest and most effective use of the machine.

Sections in your operator’s manual are placed in a specic order to help you understand all the safety messages so

you can operate this machine safely. You can also use this manual to answer any specic operating or servicing ques-

tions.

Safety Issues

Your manual contains special messages to bring attention to potential safety concerns, machine damage as well as

helpful operating and servicing information. Please read all the information carefully to avoid injury and machine damage.

Product Identication

Machine Serial Numbers

If you need to contact MAJOR or your MAJOR dealer for information on servicing or spare parts, always provide the

product model and serial numbers.

We suggest that you record your machine details below:

Model No: ____________________________________

Serial No: ____________________________________

Date of Purchase: ____________________________________

Dealer Name: ____________________________________

Dealer Telephone: ____________________________________

Product Specications

Model MJ2000

Overall Width 2.2m

Working Width 2m

Transport Width 2.3m

Power (HP) 50-75

PTO rpm 540

Blade Speed 2006m/min

Cutting Height 12 - 150mm

Weight 1400kg

Collector Capacity 3m³

Register Your Product and Warranty Online

To register your product through the Internet, simply go to the Support section on www.major-equipment.com.

Completing the information, either online or with the product warranty card, will ensure the customer that their product

receives all post sales service and important product information. The MAJOR MJ2000 is warranted for 12 months.

2

www.major-equipment.com

No warranty is given where the machine is being used as a hire machine. Warranty is against faulty workmanship or

parts with the exception of blades, belts and any other consumable parts.

Safety

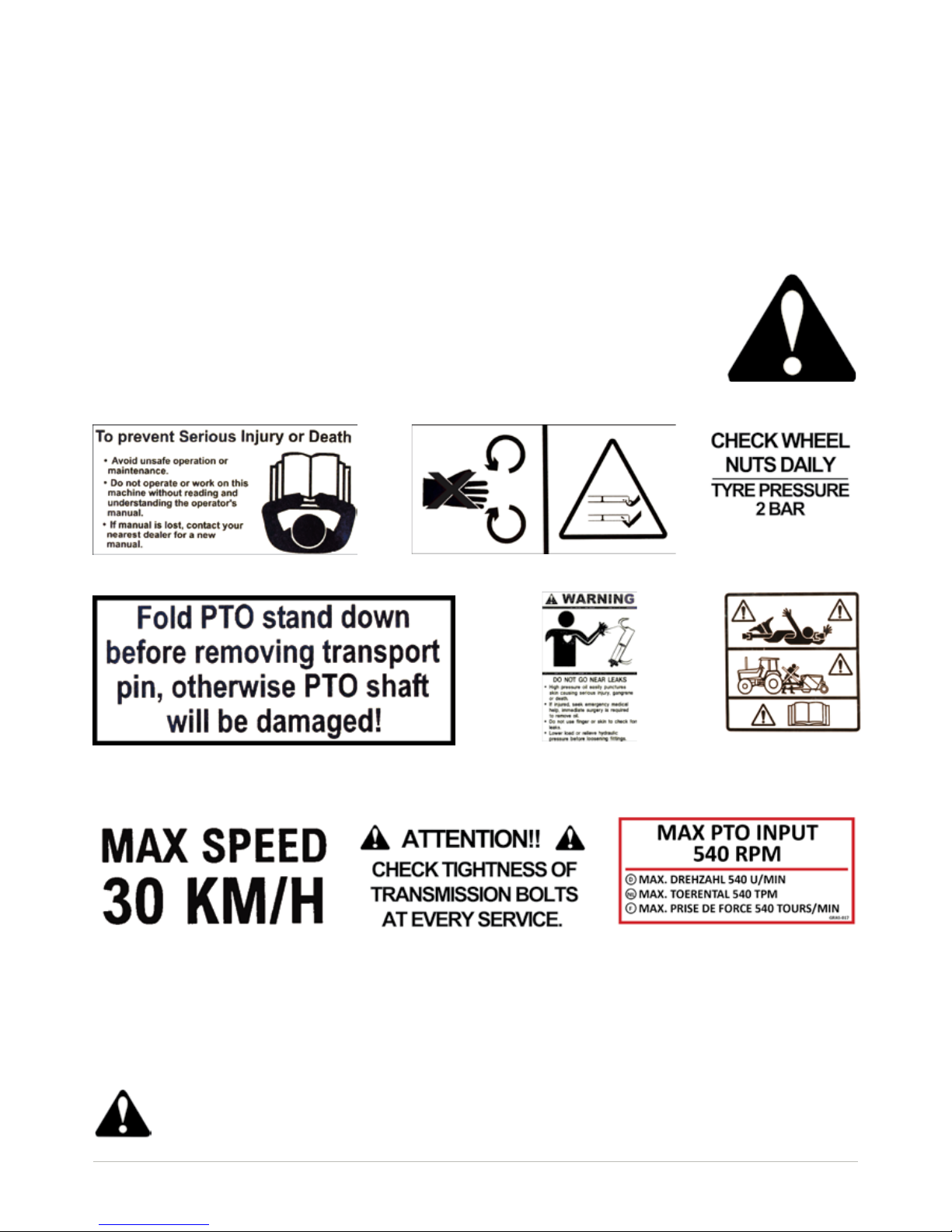

Machine Safety Labels

The machine safety labels shown in this section are placed in important areas on your machine to draw attention to

potential safety hazards.

On your machine safety labels, the words DANGER, WARNING, and CAUTION are used with

this safety-alert symbol. DANGER identies the most serious hazards.

The operator’s manual also explains any potential safety hazards whenever necessary in special

safety messages that are identied with the word, CAUTION, and the safety-alert symbol.

Operating Safely

The MAJOR MJ2000 is designed to operate at 540 RPM. Ensure tractor PTO output is set at 540 RPM.

The MAJOR MJ2000 must only be used for cutting grass. Moreover, it must only be used with a suitable

tractor (see product specications) and driven by an adequate drive-line by the tractor PTO. All other use is

strictly prohibited.

To avoid injury, read the manual

Fold the PTO stand down before removing the

transport pin to avoid PTO shaft damage

Rotating blade hazard

Keep wheel nuts tight.

Check tyre pressure

High oil

pressure hazard

Speed Warning: max. towing

speed for this machine

Keep transmission bolts tight Max. PTO speed for this machine

PTO entanglement

hazard - keep clear

of PTO drives.

3

www.major-equipment.com

Operator:

The machine’s user must be an operator with a suitable technical background to enable him to understand the contents of this manual, including the diagrams found herein.

Mechanical Maintenance Staff:

This must be a qualied technician who is capable of working on all the mechanical parts.

Users should become thoroughly familiar with the contents of this manual before using, servicing and mounting the

implement to the tractor and all other pertinent operations. Never wear jewellery, loose clothing such as ties, scarves,

belts, unbuttoned jackets or dungarees with open zips which could become caught up in moving parts.

Always wear approved garments complying with accident prevention provisions such as non-slip shoes, ear muffs,

goggles and gauntlets. Wear a jacket with reecting stickers if the implement is used near public highways.

Consult your retailer, the Labour Health Service or your nearest equivalent authority for the information about the cur-

rent safety provisions and specic regulations with in order to ensure personal safety.

ALWAYS DISENGAGE PTO, SWITCH OFF THE TRACTOR ENGINE AND ENGAGE THE PARKING

BRAKE BEFORE MAKING ADJUSTMENT TO THE MACHINE.

NEVER PLACE LIMBS UNDER THE MACHINE WHILE ROTORS ARE TURNING. ROTORS CAN REMAIN

TURNING FOR UP TO 1 MINUTE AFTER DISENGAGING PTO.

Noise:

Measurements of the noise issued by the machine indicate that the equivalent noise level is such as to maintain the

daily level to which the operators are exposed within a value of less than 70 dBA. This measurement was made with

a sound level meter set at a distance of about 1.6 m from the machine and at a height of 2 m, operated (no-load) at

a PTO rotation rate of 450 rpm on grassy land. Please also note that the machine is normally used outdoors and that

the position occupied by the operator is seated in the driving seat of the tractor. Also consult the prescriptions listed in

the tractor use and maintenance manual.

Vibrations:

During normal operation, the machine will not transmit appreciable vibrations to the tractor or, thus, to the operator.

These vibrations are less than 2.5 m/sec2. to the operator’s upper limbs and less than 0.5m/sec•’. to the seated part

of the operator’s body. Consult the tractor manual for the vibrations transmitted by the tractor itself.

Disclaimer:

The mower has been built in compliance with the accident prevention instructions in force and therefore the manufacturer cannot be held responsible for damage resulting from:

• use of the machine with faulty or missing guards

• improper use of the machine

• use of the machine by untrained or unauthorised personnel

• incorrect assembly of the mower;

• use of the mower on the wrong tractor;

• lack of maintenance

• unauthorised modications or work carried out on the machine

• use of non-original spare parts or those which are not specic to the machine

• failure to observe all or some of the instructions

• exceptional weather conditions.

Applicable laws and instructions: The machine complies with the relevant standards in force.

Residual Risks

• Risk of severing: The rotating blades may cause serious injury to limbs.

• Risk of ejection of solid objects: The rotating blades may eject solid objects capable of hitting people, animals or

anything else in the vicinity.

• Risk of entanglement: Clothes or limbs may become entangled in the rotating universal shaft causing serious damage or harm to the person involved.

4

www.major-equipment.com

Workstation

The operator must remain seated while working the machine. When the wings need to be raised and lowered the operator must leave the tractor. Always ensure the PTO has been turned off and the parking brake applied before leaving

the tractor cab. The operator must always apply the parking brake, and turn off the engine before leaving machine or

carrying out maintenance.

NEVER OPERATE THE HYDRAULICS WITH THE TRACTOR SWITCHED OFF

Regulations for use of the transmission

The transmission to the gearboxes is protected throughout the machine by both PTO shafts and bolt down covers.

All guarding should be kept efcient and in good condition. If the condition is poor, the guarding should be renewed

before the implement is used.

UNLESS IT IS CORRECTLY PROTECTED THE TRANSMISSION COULD CAUSE DEATH SINCE IT CAN CATCH

ON PARTS OF THE BODY OR CLOTHING

Ensure retaining chains are correctly anchored on all PTO shafts, preventing them form turning. Ensure drive line can

turn easily within the shield. Keep spline grooves clean and greased so that PTO shaft can connect easily. Besides

being described in this manual, the method by which the PTO shaft is connected to the tractor must be checked out

with the instructions in the tractor manufacturer’s manual.

PTO Shaft Safety

MAX PTO INPUT 540 R.P.M. Contact your nearest dealer or a specialised retail outlet if the PTO must be replaced

with a longer one, since this must belong to the same power category and possess the same characteristics. An

unsuitable PTO could easily break.

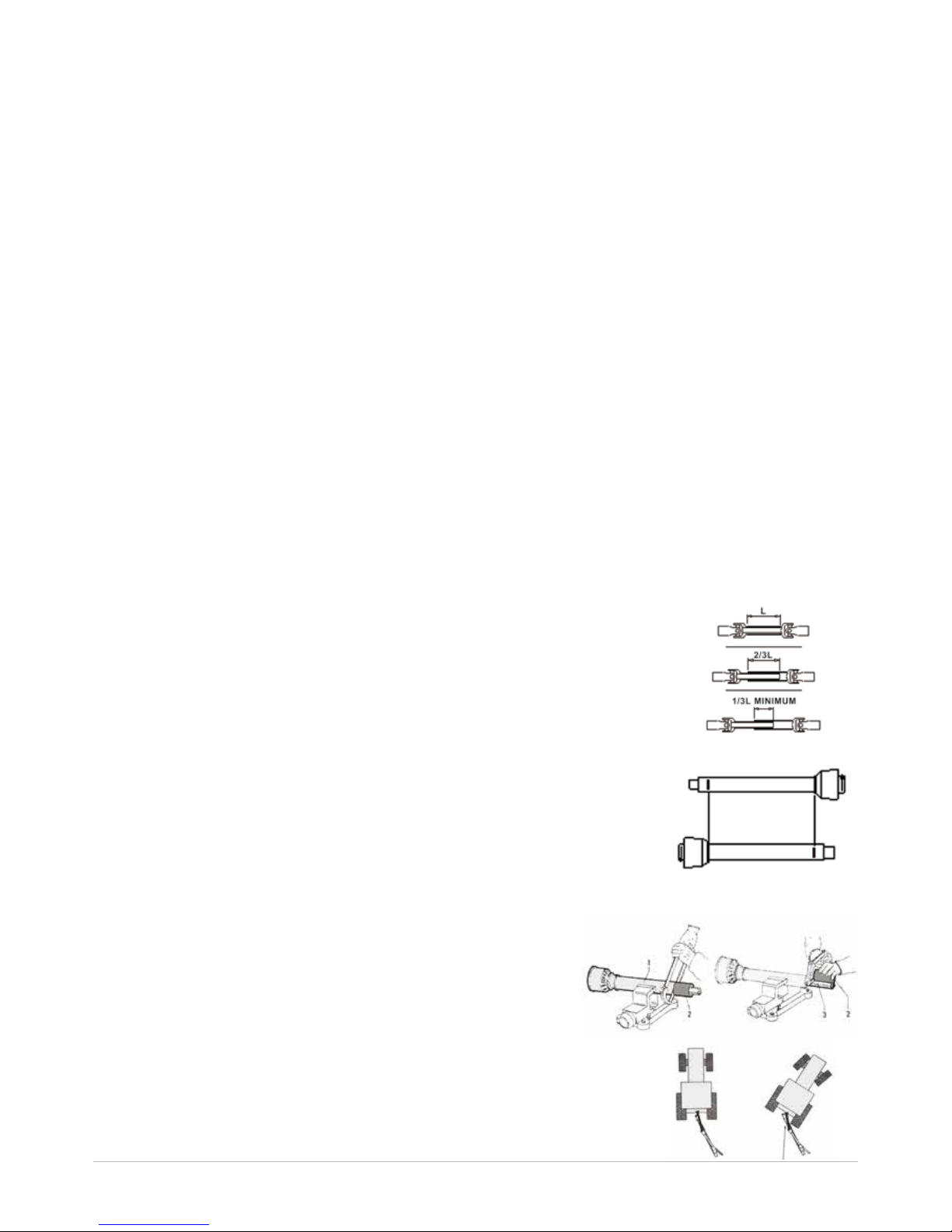

The tractor PTO shaft length may be altered to suit the individual tractor model. When

the machine is in operation, the PTO shaft should have a minimum 1/3 engagement as

shown in the diagrams. After the Rollermower has been hitched to the tractor, it should

be checked in various positions that the drive line is the correct length. If the PTO is too

short and tends to slip out of place, it must be replaced with a longer one.

If the PTO shaft is too long, it should be shortened in the following way:

• Set the machine at a minimum distance from the tractor, then brake the tractor and

switch off the engine.

• Separate the two halves of the PTO. Insert the female part into the tractor PTO and

the male part into the Rollermower PTO, checking that the position is correct by means

of the xing pins.

• Line up the two halves of the PTO together, keeping them parallel.

• Using a felt tip pen, match mark the place where the two halves must be shortened as shown.

• First cut shield “1” and use part “2” as a reference to cut the splined

shaft.

• Proceed in the same way for the second half.

• Trim and chamfer the two cut ends of the PTO and clean off all swarf

and shavings.

• Grease the two proles and join the two halves of the PTO together.

• Mount the PTO shaft and check that its length is correct as before.

The shaft must not reach the end of the tube or project from this. Ensure the PTO

does not bottom when turning

Loading...

Loading...