Page 1

1

MJ9900

TECHNICAL MANUAL

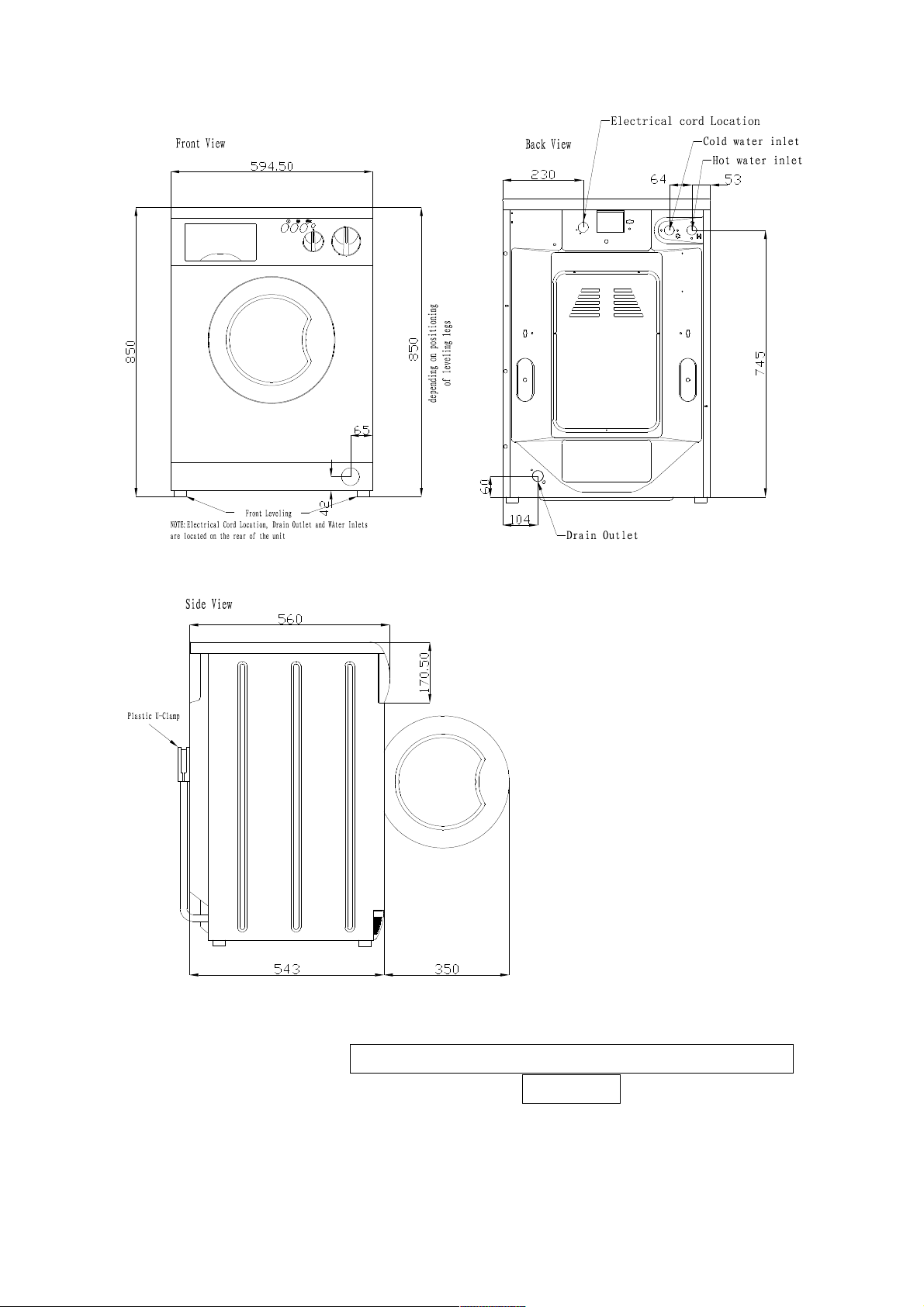

MJ9900 installation dimension

Page 2

2

Your machine, has a solution to every

problem

We have put together here a few questions which may

come to mind when you start using your machine, you will

see for yourself that your new washer dryer can give a

convincing and state of the art reply to all of them.

What to do if

Page 3

3

This machine has been designed to adapt the washing

process to all types of fabric and to treat your washing in

the most delicate way possible. In any case, we would

advise you to take certain basic precaution:

Mend any tears in items before washing them.

Sew back on any buttons that are loose.

Close any zips.

Do not machine wash items without hems.

Empty the pockets of jackets, shirts and trousers and

turn them inside out.

Button up any bag-like items that could hold water

(pillow cases for example).

Large items like sheets and table cloths should be

put in loosely and not folded.

Turn shirts inside out.

Apart from the performance

of the machine, a successful

wash also depends on the quality of the detergent

used. There are numerous excellent brands

on the market. For your machine to work best, we

suggest you use non- foam detergents that are

specifically for automatic washer dryer. If you are

washing synthetics or woollens, you should use

detergents made specially for them.

Above all, avoid using dry cleaning solvents such

as trichloroethylene or similar products.

It depends, In some areas the water is vary hard and it

leaves calcium deposits on both the heating element of

the washer dryer and on the washing itself. Which over

time damage both. In such case, it is a good idea to mix

a water softener, or decalcifier, in with your detergent to

dissolve the calcium.

Your machine, has a solution to every

problem

Every time you have particularly dirty items to wash,

when you think it would help them to have a longer

wash with more detergent.

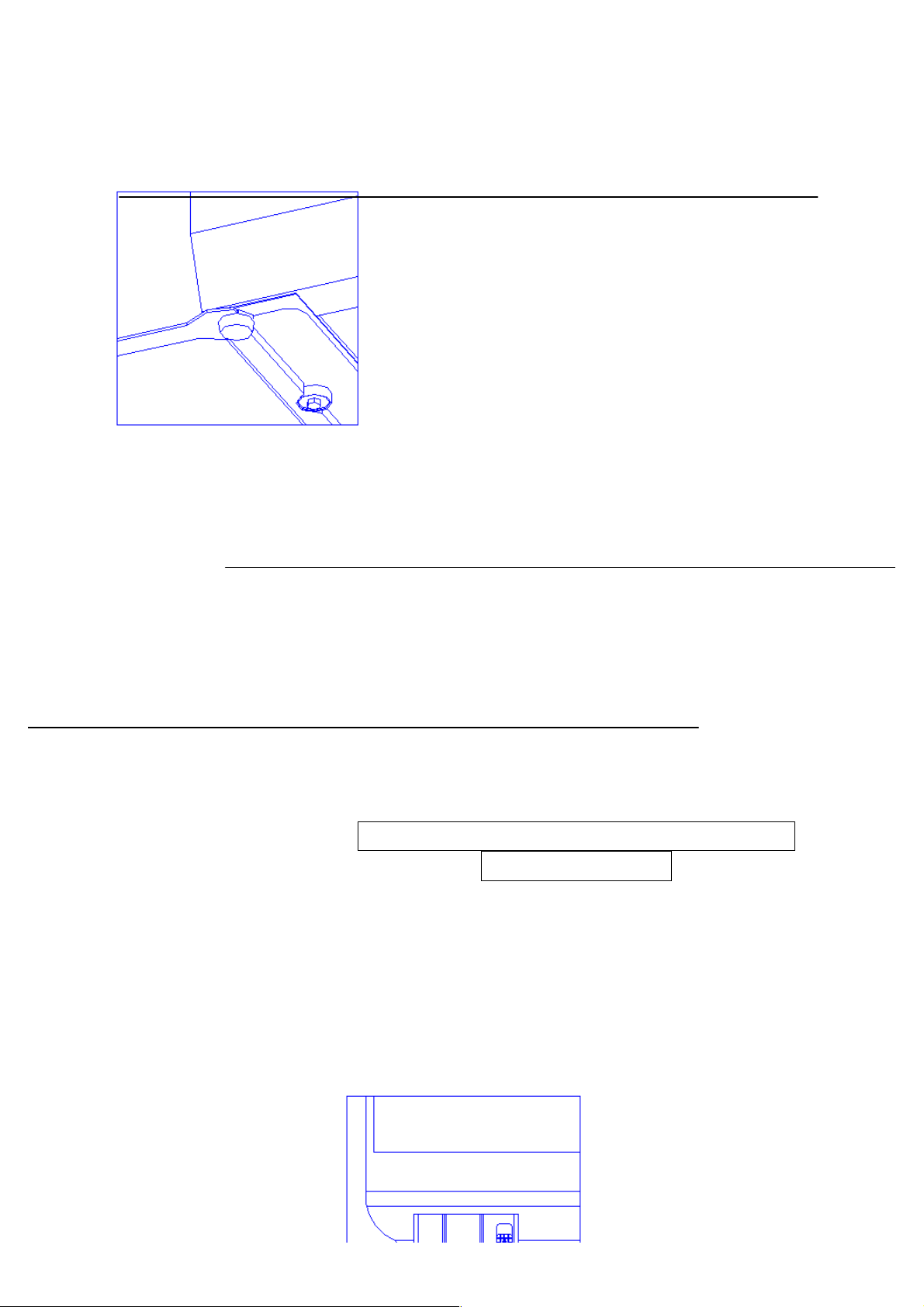

The most important thing is for it to be perfectly level.

This is why it has adjustable feet (fig.1) so as to

eliminate any imperfections in the floor.

1. Can washing

damage my

clothes?

2.What sort of

detergent should

I use?

3.Is it all right if

use a water

softener?

4.When should I

use the prewash?

5.What is the best

position for my

washer-dryer?

Page 4

4

We would also advise you to place your washer-dryer in such a way that there is

some space-even a fraction of an inch-all sides.

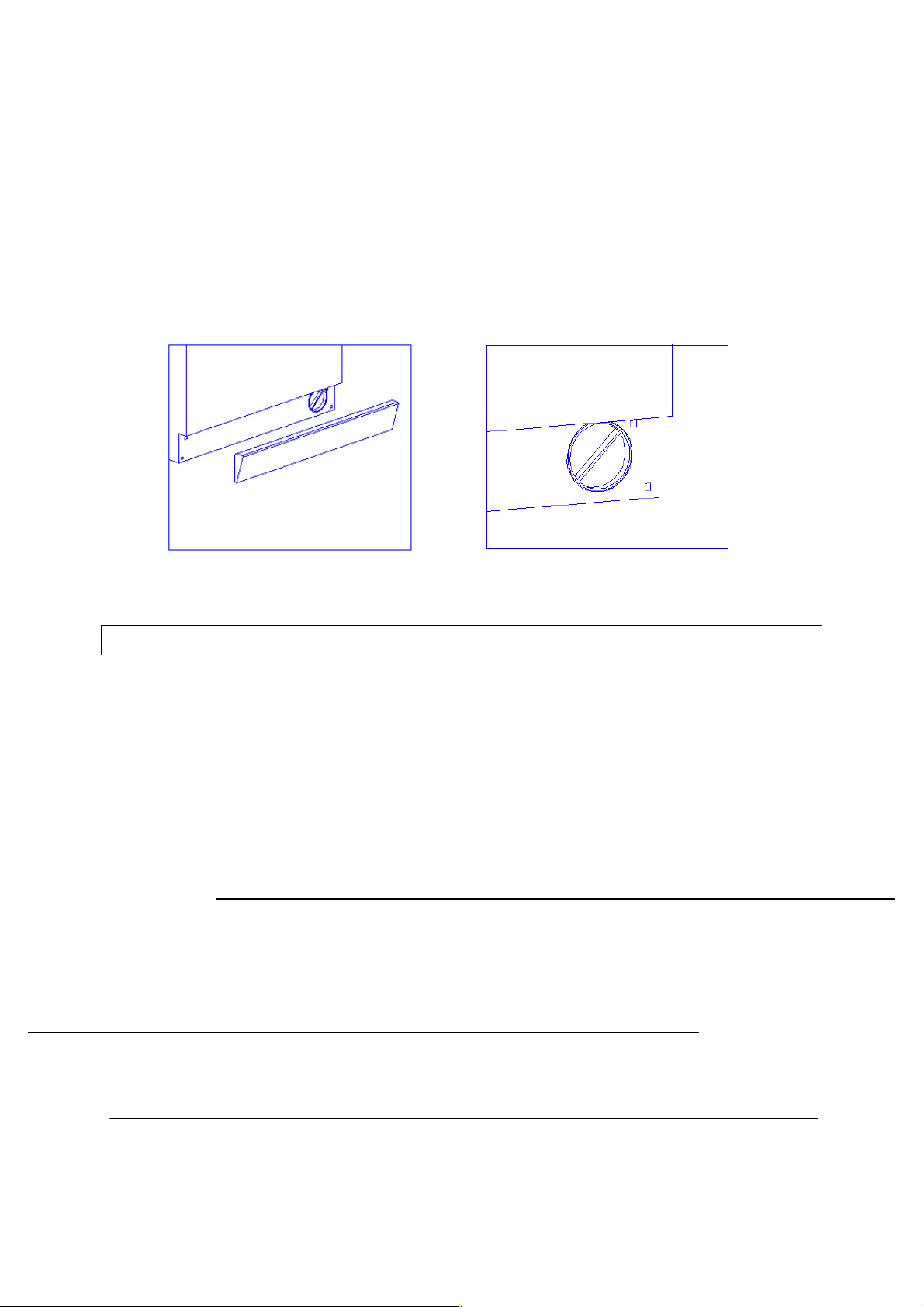

(Fig.1)

First of all, remember to switch off the electricity. Then, to

clean the body and any rubber parts use a damp cloth

and a little soap.

Avoid petrol or other solvents at all costs.

If this means that your washer-dryer is going to stay

unused for a long time, then it would be best before

you go to unplug it, close the water tap and leave the

door ajar so as to avoid any unpleasant odours

remaining inside. In fact, it is advisable to leave the

door open during periods of non-use as well.

If you are moving house, there is one simple but very

important thing you should do: Block the drum to save it

from bumps, To do this, put back the blocking screws

that were removed when it was installed.

Maintenance: Four simple precaution

for this machine

Your machine is a washer-dryer that has been designed to last without complicated

maintenance. All the same, we would ask you to take care of a few small matters. If

you follow these four simple rules, we are sure that the washer-dryer machine will

stay your faithful friend and helper for a long, a long time.

1. Ensure that your machine was installed according to the installation manual that

comes with this booklet.

1. Avoid at all costs using solvents either to clean the machine, or to do the wash.

2. Clean the detergent dispenser every so often. This is very simple and should be

done with water. Your machine has an extractable dispenser to make it even

6.How shoulder I

clean my washerdryer?

7.Do I have to take

any particular

when I go on

holiday?

8.---And if I move

house?

Page 5

5

easier. Just pull it upwards and out, as shown in Fig.2

(Fig.2)

3. Your washer-dryer is equipped with a self-cleaning pump. It is therefore not

necessary to carry out cleaning and maintenance operation. Some objects

however, (such as buttons, coins, etc), may sometimes accidentally drop into the

pimp. Since these cannot be expelled through the drain pipe, they are trapped in a

special “anti-chamber” which can be reached through the front part of pump. Open

the cover of the filter, loose the knob in counter-clockwise rotation, then take out

the filter and clean it with water (see Fig.3 and Fig.4).

(Fig.3) (Fig.4)

Note: Re-assembly the filter carefully after cleaning, ensuring it is fit perfectly

and no water can come inside.

When you do not need a technician----

Even though your washer-dryer has been carefully designed and constructed,

something could still go a miss with your machine. Before rushing to please check

that the operations listed below have been carried out. In many cases you will save

time, money and bother. Our statistics show that many of the calls received by our

service centers could have been avoided with just a little more attention.

Check that:

The plug is pushed right into the main sockets;

The door is closed tight;

The “ON/OFF” button has been pressed.

Check that:

The tap is open and properly connected to the

inlet pipe;

The inlet pipe is not bent.

Check that:

The inlet pipe is placed at least 80cm/32 inches above

ground level.

The washer-dryer

fills and drains

continuously

The washer-dryer

won’t start

The washer-dryer

won’t fill with

water

Page 6

6

Check that:

The inlet pipe is not blocked;

The inlet pipe is not connected at a height more then

1 metre/40 inches above ground level.

Check that:

The detergent being used is meant for

automatic machines and not for washing by

hand;

That the amount used is that shown in this

manual and not more.

Check that:

The transit bolts have been removed (see installation

manual);

The machine is level;

The washing load is according to instructions given in

this booklet.

When you do not need a technician----

Check that:

The plug is fitted firmly into the main socket;

The door is properly closed;

The drying time knob is not in position”0”.

Check that:

The free end of the drain pipe is not under water;

The filter is clean (do not remove the filter while the

washer-dryer is running);

The recommendations for the maximum loads and

drying times have been followed;

The drying time is set at least to 20 minutes;

The water tap is open.

The washer-dryer

will not drain the

water

There is too much

foam in the tub

The washer-dryer

vibrates too much

when spinning

The washer-dryer

is not drying

The washer-dryer

is not drying

efficiently

Page 7

7

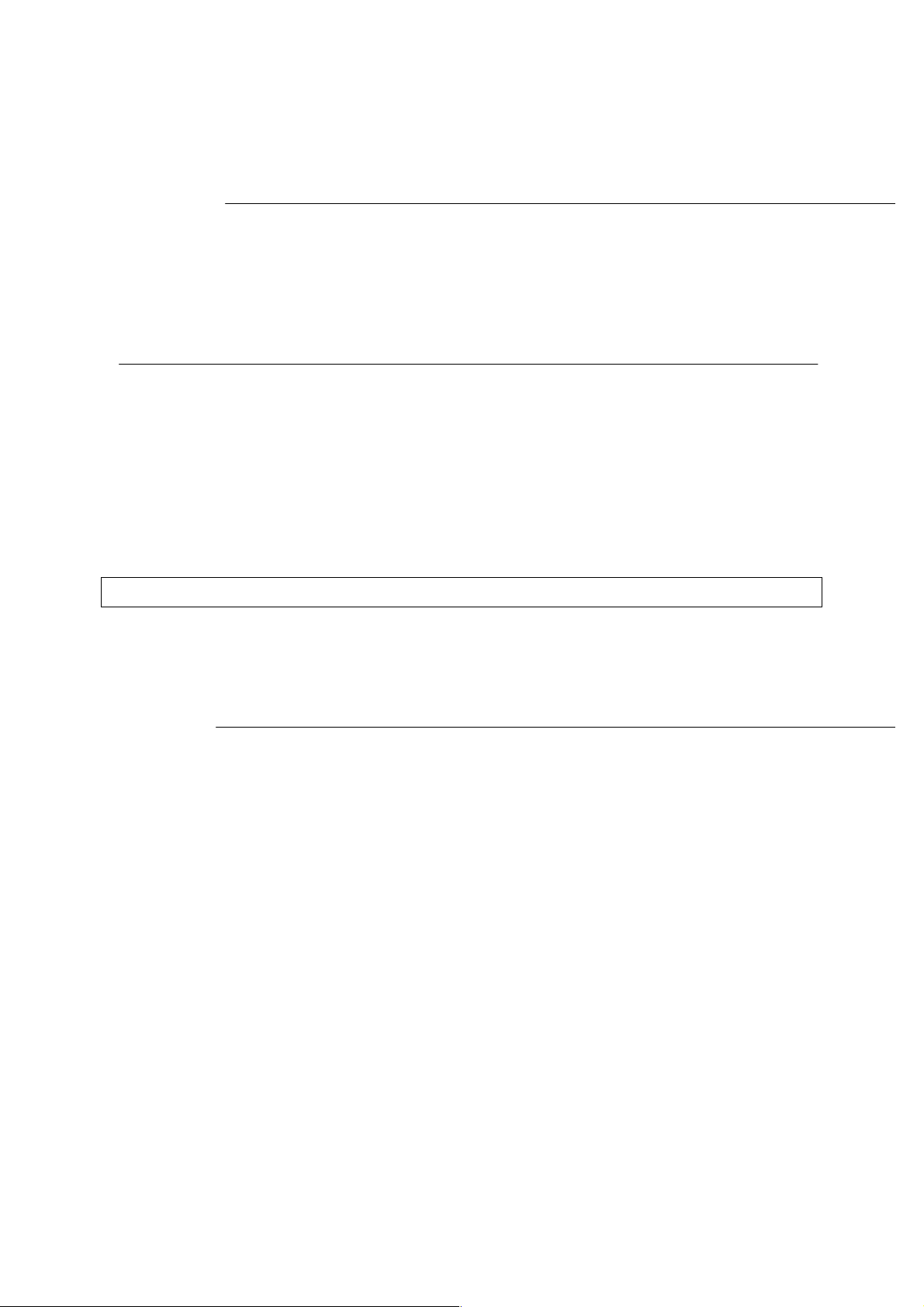

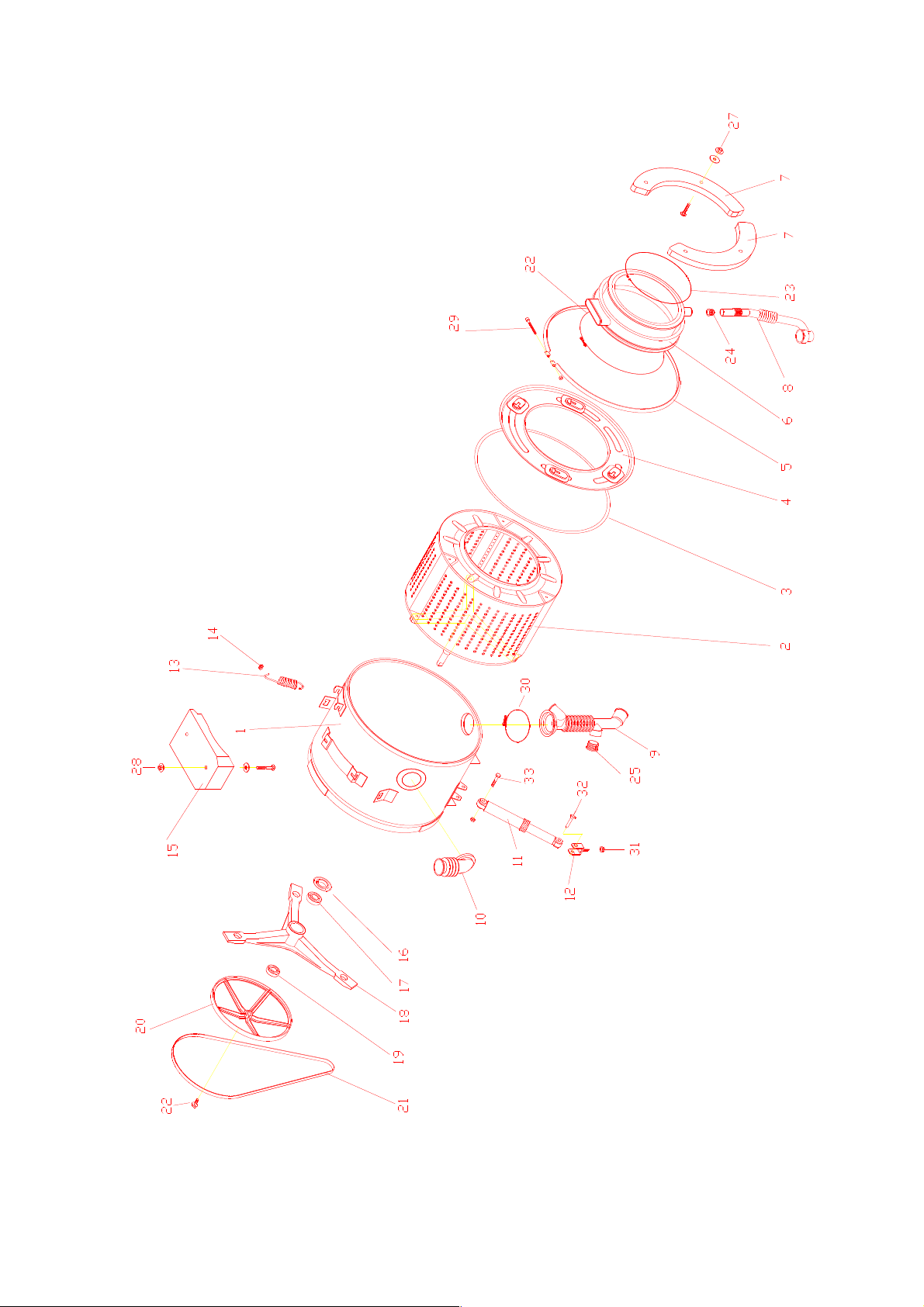

WASHING MACHINES

REF.MODELS MJ9900 DESCRIPTION

Page 8

8

01

Back panel

02

Cabinet assembly

03

Top panel assembly

04

Rest for hose and cable

05

Board panel

06

Switch cover

07

Lamp cover

08

Timer (washing) knob

09

Timer (drying) knob

10

Dispenser handle

11

Micro delaying device

12

Porthole catch

13

Porthole catch pin

14

Porthole catch spring

15

Porthole handle

16

Porthole inner frame

17

Porthole glass

18

Porthole frame

19

Support for porthole hinge

20

Porthole hinge

21

Kick plate cover assembly

22

Feet

23

Under panel

24

Support for capacitor

25

Bracket for capacitor

26

screw

27

Support for speed regulator

Page 9

9

Page 10

10

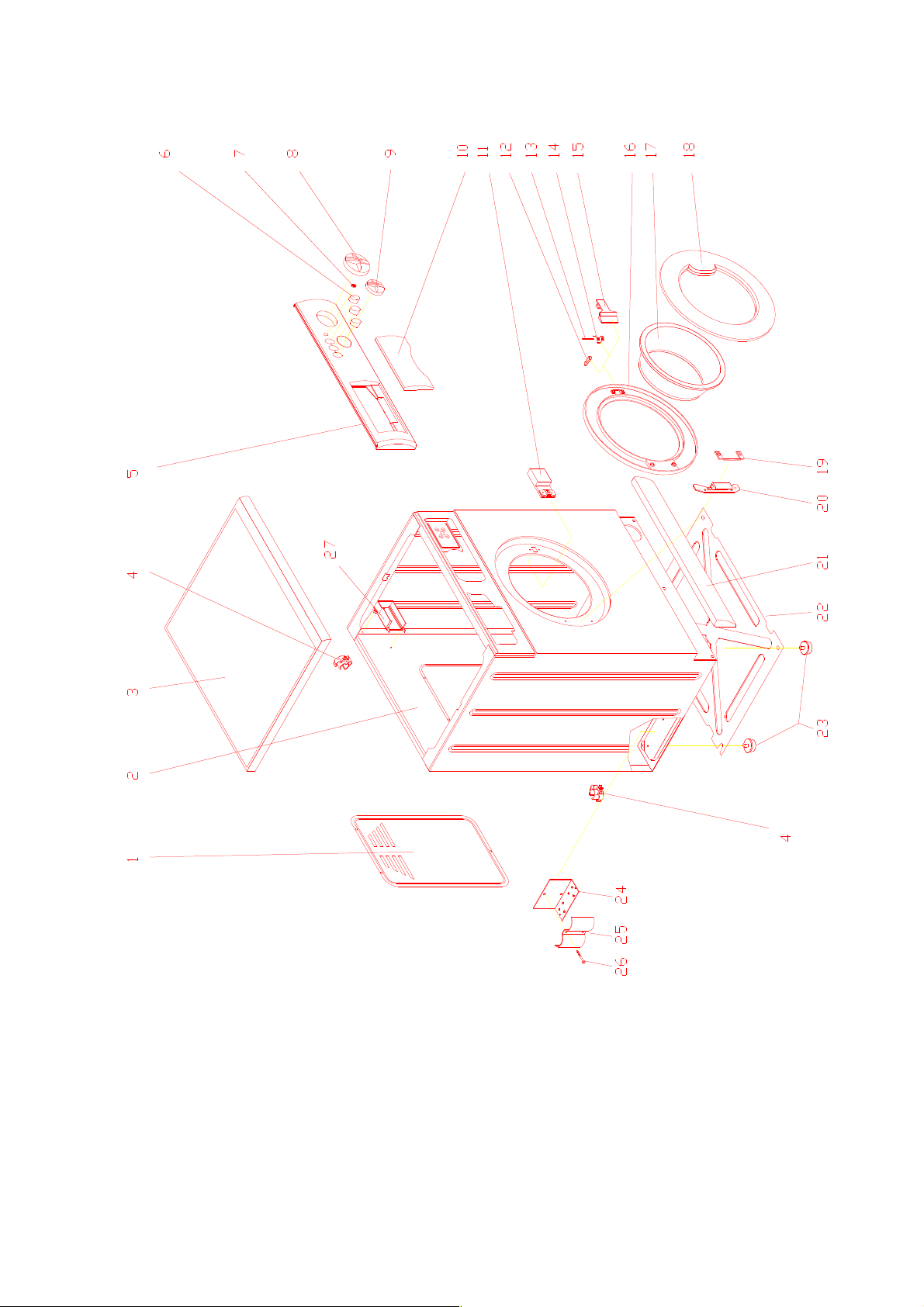

WASHING MACHINES

REF.MODELS MJ9900 DESCRIPTION

01

Tub

02

Drum

03

Tub cover gasket

04

Tub front flange

05

“U” bolt

06

Porthole gasket

07

Front counterweight

08

Detergent recovery hose

09

Hose tub to pump

10

Hose dispenser to tub

11

Shock absorber

12

Shock absorber support

13

Tub suspension spring

14

Spring rest

15

Upper counterweight

16

Retaining ring

17

Bearing 6205

18

Tub spider assembly

19

Bearing 6204

20

Driven pulley

21

Ply V belt

22

Blot. Drum pulley fixing

23

Porthole gasket fixing ring

24

Hose connection to porthole

25

Hose connection

26

Porthole gasket and tub fixing ring

27

Bolt M8X45, washer and nut M8

28

Bolt M8X60, washer and nut M8

29

Screw M6X80 nut M6

30

Fix ring for hose of tube and pump Screw

31

Nut-wash combine M6

32

Plastic pin

33

Bolt M10X40 and nut M10

Page 11

11

Page 12

12

WASHING MACHINES

REF.MODELS MJ9900 DESCRIPTION

01

Dry timer

02-05-45

Pressure switch hose

03

1level Pressure switch with over flow

04

2 level pressure switch

06

Wash timer

07

“Y” coupling

08

Transmission to detergent tray

09

Cam follower

10

Bush to timer cam

11

Timer cam

12

Cable assembly

13

Pump

14-15

Capacitor

16

Motor

17

Nut M6

18

Motor spacer

19

Bush for motor

20

Motor bolt M6X212

21

Support for drain hose

22

Drain hose

23

Wiring assembly

24

Hopper

25

Pipe for solenoid valve

26

“T” coupling

27

Inlet water assembly

28

Detergent tray

29

Cover for detergent tray

30

Lamp

31

Hopper cover

32

Dispenser spring

33

Transmission for dispenser

34

Ejector guide

35

Ejector

36-37-38

Switch_switch_power switch

39

Double head solenoid valve (cool)

40

Solenoid valve (heat)

41

Pressure reducing valve

42

Sponge

43

Air trap

44

Clamp for air trap

46

Speed regulator

47

3 poles terminal board

48

Tube between solenoid valve and condenser

Page 13

13

Page 14

14

WASHING MACHINES

REF.MODELS MJ9900 DESCRIPTION

01

Fan motor

02

The wire with fuse

03

Thermostat 2TT NC 125/85

04-16

Upper body of blower

05

Reflecting screen WDM

06

Heating element

07

Gasket of blower bode WDM

08

Lower body of blower

09

Zipper for porthole gasket and blower

10

Condenser

11

Condenser-tube gasket

12

Hose condenser to tub

13-14

Flux adjusting parts

15

Condenser blower gasket

16,17

Fan group

18

Clips

Page 15

151617

Page 16

Page 17

Timer removal and installation

Removal:

1_ Disconnect power from machine.

2_ Remove the top panel assembly by unfixing the two screws ST3.5x13.

timer for 9900\9000V\9200W

3_ Pull out the timer knob. Round the cam clockwise, let you can see two M5x5 screws,

4_ Unfix two screws size M5x5, and then take out the timer from cam bush.

5_ Pull out all housing of the wiring from the terminals of timer.

6_ Change the new timer as fig above, plug the wire housings to timer terminals, pay

attention to color of housing, the black housing plug to terminal column with a black

point nearby, and then yellow to yellow_green to green and so on.

7_ Plug the time shaft to cam bush, pay attention to the angle and position, be sure that the

section shape is corresponding with the cam bush hole.

8_ Fix time to cabinet using two screw size M5x5, let the wiring at proper position, if the

hole can not be seen, turn cam clockwise an angle to expose the screw hole.

9_ Amount the timer knob, Power on machine, test the machine , insure it can work in

manner indicated in control panel.

10_ Fix the top cover assembly to machine.

11_ Complete.

Motor check and how to change it

1_motor test

Page 18

18

8P socket

M4 ground

connection

Page 19

19

8P connector

Terminal

Description

Resistance

1-2

Auxiliary winding (spin)

5.3-5.8_

1-6

Primary winding (spin)

2.8-3.2_

2-6

Aux and primary winding (spin)

7.7-8.01_

3-5

Common and aux winding((wash)

9.6-9.7_

5-7

Common and primary winding (wash)

9.6-9.7_

3-7

Aux and primary winding(wash)

12.1-12.4_

4-8

Tachometer

23.3-24.1_

2_How to change the motor

1_ Disconnect power and water supply from machine.

2_ Move the machine to an open space for repair.

3_ Remove back panel by removing three size SD3.5x13mm

screws.

4_ Tilt the machine, wrest the two front feet two rounds

anticlockwise.

5_ Tilt the machine forward, unscrew tow back feet, and then take

out under panel.

6_ Fetch the V-belt from the pulley, and Tilt the washing machine

forwards.

7_ Take off 8P plug housing and ground terminal of the wirings from

the motor socket.

8_ Use short handle sleeve spanner unscrews right motor bolt size

M6x217 and nuts M6.then pull out bolt.

9_ Unscrew left motor bolt size M6x217 and nut M6, at the same

time with your left hand support the motor in position. Pull out bolt.

Then take out motor from the button of the machine carefully.

10_ Change a new motor one by one at counter step.

11_ Recover the machine and make a test to insure the machine can

work normally.

12_ Complete.

Page 20

20

Micro delaying device

Housing No: MRL of wiring to L terminal of switch_

Housing No: MRN of wiring to N terminal of switch_

Housing No: MRC of wiring to C terminal of switch.

Housing No: IP_IPX of wiring plug to micro switch

Hose dispenser to tub (9000V\9900)

Speed regulator

1_ picture

Micro switch

Page 21

21

2_removal and connection

1_Disconnect power from machine.

2_Remove the top panel assembly by unfixing the two screws

ST3.5x13.

2_ Unfix two screw size SD3.5X13 from the back of cabinet ,take

off the speed regulator support.

3_pull out all terminals from regulator assembly.

4_take out regulator from regulator support.

5_replace a new speed regulator.

6_connect wiring to speed regulator as follows:

Page 22

22

Plug terminal RV1 of wiring to 1 terminal of regulator

Plug terminal RV2 of wiring to 2 terminal of regulator

Plug terminal RVF of wiring to F terminal of regulator

Plug terminal RV3 of wiring to 3 terminal of regulator

Plug terminal RV4 of wiring to 4 terminal of regulator

Plug terminal RV5 of wiring to 5 terminal of regulator

Plug terminal RV6 of wiring to 6 terminal of regulator

Plug terminal RV7 of wiring to 7 terminal of regulator

7_Plug speed regulator to regulator support until clamp in action.

8_Use two screw SD3.5x13 fix regulator assembly to cabinet.

9_Test the machine to sure the machine can work normal.

10_Recovery the top panel assembly.

11_Complete.

How to change pressure switch

This machine has a 1 level pressure switch and 2 level pressure switch.

2 Level pressure

switch

1 level pressure

switch

Page 23

23

A: 2 level pressure switch

1_ Disconnect power and water supply from machine.

2_ Move the machine to an open space for repair.

3_ Remove back panel by removing three size SD3.5x13mm

screws.

4_ Remove screw SD3.5x13; take out 2 level pressure switch from

cabinet.

5_ Pull out all housing of wiring and hose from switch.

6_ Replace a new switch, connect hose to position, move clamp to

proper position.

7_ Connect housings of wiring to switch as fellow:

Housing No: PV11 to 11 terminal of switch,

Housing No: PV12 to 12 terminal of switch,

Housing No: PV13 to 13 terminal of switch,

Housing No: PV21 to 21 terminal of switch,

Housing No: PV22 to 22 terminal of switch,

Housing No: PV23 to 23 terminal of switch,

8_ Fix screw SD3.5x13, amount the switch to cabinet.

9_ Complete.

B: 1 level pressure switch:

The process is same as above, wiring connect as fellow:

Housing No: PV11 to 1 terminal of switch,

Housing No: PV12 to 2 terminal of switch,

Housing No: PV13 to 3 terminal of switch,

Housing No: PV14 to 4 terminal of switch

How to change drying timer

1_Disconnect power from machine.

2_Remove top panel assembly by removing two size SD3.5x13mm

screws.

3_pull out timer knob from control panel.

4_unscrew two screw size M4x6 from control panel.

5_take out drying timer from control panel.

6_pull out all terminals of wiring.

7_change a new timer and connect terminals as fellow:

Plug terminal No: TAA of wiring to “a” terminal of timer,

Plug terminal No: TAA1 of wiring to “a1” terminal of timer,

Plug terminal No: TAB of wiring to “b” terminal of timer,

Plug terminal No: TAB1 of wiring to “b1” terminal of timer,

Plug terminal No: TAC of wiring to “c1” terminal of timer,

Plug ground terminal (green) of wiring to ground terminal of timer,

8_Use two screws size M4x6 amount timer to control panel .

Page 24

24

9_Test machine.

10_Amount top panel assembly.

11_Complete.

Double head valve (cold water) and solenoid valve (hot water)

1_ picture

2_connect valve to wiring

3_resistance test

resistance of coil R=494_

Page 25

25

Fan motor

Connection: Plug terminal MV of wiring to upper terminal of fan motor.

Plug terminal TF of wiring to lower terminal of fan motor.

Hose dispenser to tub (9000V\9900)

Page 26

26

Pump

1_picture

2_connection to wiring

Capacity

1_picture

2_test

C1=80uF C2=80uF

3_connect to wiring

Connect C1, C1X terminals of wiring to C1.

C1

C2

Page 27

27

Connect C2, C2X terminals of wiring to C2.

Fan

Heat element

Page 28

28

Wire with fuse and Thermostat 2TT NC 125/85

17

Connection of dryer

1,plug MV terminal of wiring to upper terminal of fan motor

2,plug TF terminal of wiring to lower terminal of fan motor

3,plug FEX and FE terminals of wiring to terminals with red point

of thermostats

4,plug FDX and FD terminals of wiring to terminals with black

point of thermostats

5,plug RA terminal to a terminal of heater.

Page 29

29

Loading...

Loading...