Majectic UVLX18RN, UVLX18MN, UVLX24RN, UVLX24MN, UVLX30RN Installation And Operating Instructions Manual

...

Vent-Free Gas Log Sets*

CERT IFI ED

D

E

S

I

G

N

C

E

R

T

I

F

I

E

D

Models: (Natural Gas) UVLX18RN, UVLX18MN,

UVLX24RN, UVLX24MN, UVLX30RN, UVLX30MN

Models: (Propane) UVLX18RP, UVLX18MP, UVLX24RP,

UVLX24MP, UVLX30RP, UVLX30MP

Installation and Operating Instructions

Decorative Gas Appliances for Installation in

Solid-Fuel Burning Fireplaces.

If the information in this manual is not followed exactly, a fire or explosion may result,

causing property damage, injury, or loss of life.

— Do not store or use gasoline or other flam-

mable vapors and liquids in the vicinity of

this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

INSTALLER PLEASE NOTE:

DO NOT begin installation of this gas logset until all instructions have been read

and understood.

W A R N I N G

Installation and service must be performed

by a qualified agency, individual, firm, corpo

ration, or company, experienced in the instal

lation, repair, and servicing of this type of

gas appliance. Do not modify, alter or tamper

with any part of this heater, control, or logs.

This appliance may be installed in an aftermarket, permanently located, manufactured

(mobile) home, where not prohibited by local

codes.

This appliance is only for use with the type

of gas indicated on the rating plate. This appliance is not convertible for use with other

gases.

*These logsets are not for exterior use.

Tested and listed to ANSI Z21.11.2b-2004,

Unvented Heaters, and Z21.60b-2004;

CSA 2.26b-2004

ATTENTION

-

-

CARBON MONOXIDE POISONING MAY LEAD TO DEATH.

When used without fresh air, vent-free log sets may give off carbon monoxide, an odorless, poisonous gas.

Some people - pregnant women, people with heart or lung disease, anemia, or persons under the influence of alcohol, and

persons at high altitudes are more affected by carbon monoxide than others.

Early signs of carbon monoxide poisoning resemble the flu - headache, dizziness, and/or nausea. If you have these signs,

the heater may not be installed or working properly. GET FRESH AIR AT ONCE!

again.

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

W A R N I N G

Have the heater serviced before using it

20008845 3/08 Rev. 4

General Information

In order to assure a safe and effective installation, only a qualified service person who is

familiar with the building codes and installation

techniques appropriate to your area may install

and service this appliance.

The Logsets have been designed and tested to operate

safely when installed according to the installation instructions

contained in this manual. Read all instructions before starting

the installation.

In the Commonwealth of Massachusetts, all gas fitting

and installation of this heater shall only be done by a

licensed gas fitter or licensed plumber.

• The vent-free gas logset must be installed only in a fire-

place constructed of noncombustible material.

• These logsets are not for exterior use.

• This appliance is for supplemental heating only. It should not

be used as the primary heat source for a dwelling.

• The logset should be inspected before use and at least an-

nually thereafter. More frequent cleaning may be necessary

due to excessive lint from carpeting or bedding material.

• In the United States, the installation and operation must

conform to local codes or, in the absence of local codes, with

the National Fuel Gas Code, ANSI Z223.1/NFPA 54, latest

edition, CSA-B149.1 Installation Code, and with the National

Electrical Code, ANSI/NFPA70 (latest edition). State or local

codes may only allow operation of this appliance in a vented

configuratio. Check your state or local codes. In Canada,

check local province for proper use or CSA-B149. Refer to

pages 7 and 8 for installation details.

• The gas logset and its individual shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of

1/2 p.s.i.g. (3.5 kPa.) The gas logset must be isolated from

the gas supply piping system by closing its individual manual

shutoff valve during any pressure testing of the gas sup

ply piping system at test pressures equal to or less than 1/2

p.s.i.g. (3.5 kPa.)

• Do not, under any circumstances, burn solid fuel (wood,

paper, coal) in the fireplace where you have installed your log

set. Do not use it for cooking. Put nothing on top of the logs.

• The logset must be compatible with its fuel. Natural gas

requires different hardware than propane. Never attempt to

use natural gas with a propane logset or vice versa.

• For a propane burning logset, the supply tank must include

a high to low gas pressure regulator. The tank

doors. Do not, under any circumstances, locate supply tanks

inside any structure.

must be out-

• The fireplace must include a screen made of chain mesh

or a similar material. You must keep the screen closed at all

times during the operation of the logset; it will protect you in

the event of an explosion.

• WARNING: If the fireplace contains glass doors, they must

remain open at all times during the operation of the logset,

allowing combustion air to circulate.

• In order to avoid any possible gas leaks, apply pipe joint

compound to all non-flared, threaded connections involved

in this installation. For propane, the joint compound must be

-

resistant to the corrosive action of propane.

• To check for leaks, always use a soapy water solution or a

sniffer.

Never test by using an open flame.

• The area around the gas logset must be free of all combus-

tible materials, especially gasoline or other highly flammable,

vapor producing liquids.

• Due to high temperatures, locate this logset away from both

high traffic areas and furniture and draperies.

• Children and adults alike should be aware of the high

surface temperatures; to avoid the risk of burns or ignition of

clothing they should stay away.

• Do not touch any part of the logset other than the controls

while it is operating or immediately after you turn it off.

• Supervise young children and pets carefully when they are

in the room where the logset is operating.

• Do not place clothing or other flammable material on or near

the logset.

• Make sure that any safety screen or guard, removed during

servicing, has been replaced before you use the logset.

• Do not, under any circumstances, install the logset in any

bedroom, bathroom, other small, enclosed room, mobile home

or recreational vehicle.

• Do not install the logset in a drafty area or use it with any

after-market blower system that may cause drafting and consequently alter the flame pattern.

• It is imperative that you keep clear all burner areas, control

compartments and passageways for circulating air.

• Do not move the logset in any way that might dislodge the

logs from their fixed positions. If you bump the logset check to

see if you have dislodged anything.

• Provide adequate clearances around air openings into the

combustion chamber and adequate accessibility clearance

for servicing and proper operation. NEVER obstruct the front

opening of the fireplace.

• Avoid propane tank dropping below 25% full. This will help

keep soot from occurring.

WARNING

This appliance is for installation in a solid-fuel

-

burning masonry fireplace with a working flue,

a U.L.-127 Listed manufactured solid-fuel burning fireplace, in any CFM Corporation ventless

firebox or in any listed ventless firebox enclo

sure certified to I.A.S. U.S. requirements 2-97.

NOTICE

This is an unvented gas-fired heater. It uses air

(oxygen) from the room in which it is installed. Provisions for adequate combustion and ventilation air

must be provided. Refer to pages 5 and 6.

This appliance operates as an unvented domestic room

heater when fitted to a masonry or factory-built woodburning fireplace with the flue damper closed, or as

a decorative appliance when the flue damper is fully

open. It must not be used for any other purpose and

must be fitted in a masonry or factory-built fireplace or

ventless firebox enclosure.

-

2

20008845

Installation Requirements

A

B

D

C

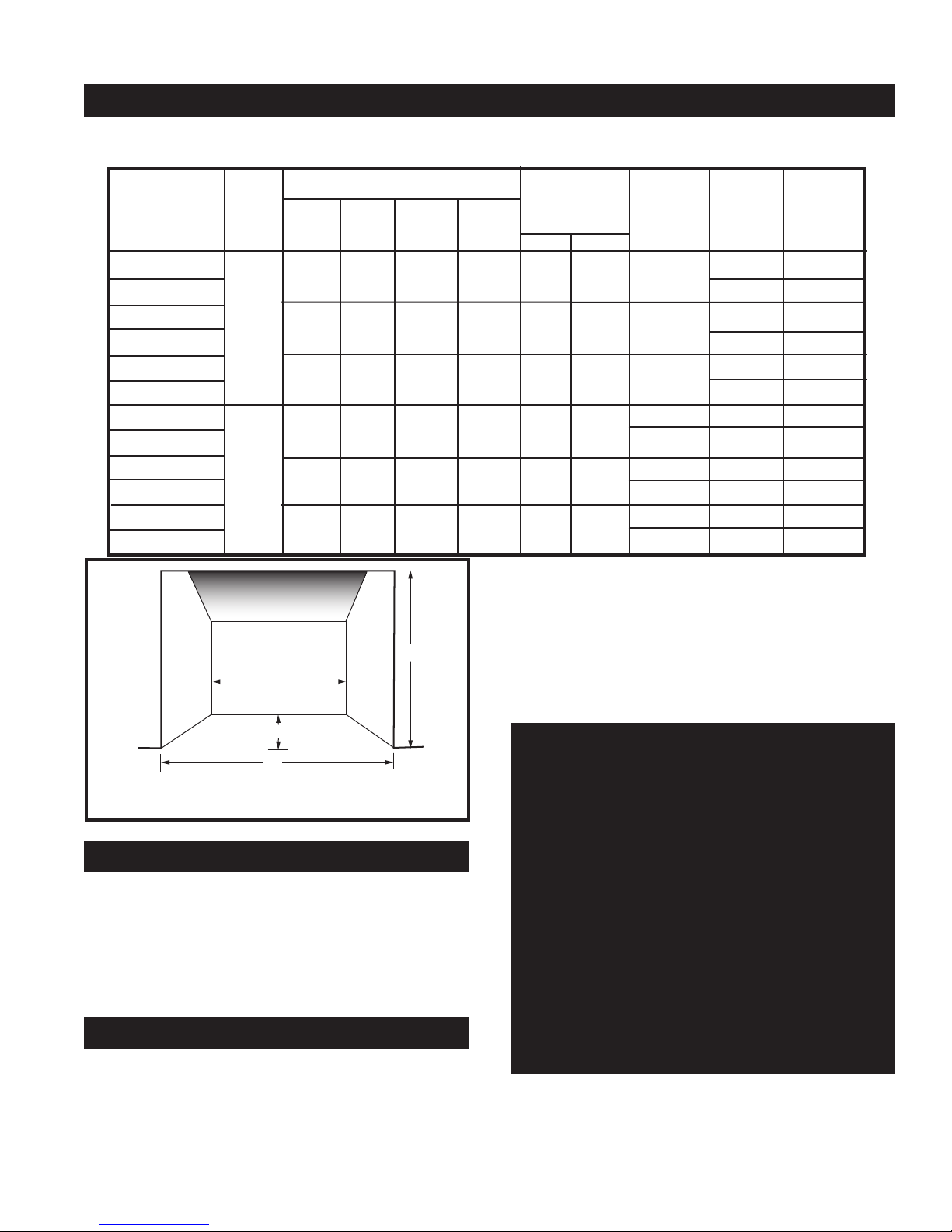

The fireplace must meet the minimum dimensions listed below. (Fig. 1) Do not install the logset if the fireplace does

not meet these minimums.

Min. Fireplace Dimensions

A B C D

Logset Gas Front Rear Overall Overall Pressure (w.c.) Manifold Min. Input Max. Input

Width Width Depth Height Min. Max. Pressure BTU/hr BTU/hr

Inlet Supply

18” UVLX18RN

18” UVLX18MN 15,000 24,000

24” UVLX24RN

24” UVLX24MN 18,000 35,000

30” UVLX30RN

30” UVLX30MN 28,500 39,000

18” UVLX18RP

18” UVLX18MP 10.0” 17,000 24,000

24” UVLX24RP

24” UVLX24MP 10.0” 18,000 35,000

30” UVLX30RP

30” UVLX30MP 10.0” 29,000 39,000

Natural 25¹⁄₂” 18¹⁄₂” 13¹⁄₂” 18” 5.5” 14.0” 3.5”

Propane 25¹⁄₂” 18¹⁄₂” 13¹⁄₂” 18” 11.0” 14.0”

20¹⁄₂” 17” 13¹⁄₂” 18” 5.5” 14.0” 3.5”

25¹⁄₂” 23” 13¹⁄₂” 18” 5.5” 14.0” 3.5”

20¹⁄₂” 17” 13¹⁄₂” 18” 11.0” 14.0”

25¹⁄₂” 23” 13¹⁄₂” 18” 11.0” 14.0”

11.0” 18,000 24,000

11.0” 26,000 35,000

11.0” 29,500 39,000

17,000 24,000

24,500 35,000

25,000 39,000

exist in the immediate area. Cleaning solutions, paint,

solvents, cigarette smoke, candles, adhesives, new

carpet or textiles, etc., all can create fumes. These

fumes may mix with combustion air and can create

odor. Such odors will disappear over time, however,

the condition can be alleviated by opening a window

or otherwise providing additional ventilation to the

area.

A. Front Width B. Rear Width

C. Depth D. Height

Fig. 1 Minimum fireplace dimensions.

FD370-2

Pressure Test Points

UVLX-R Series: The gas control is equipped with a

captured screw-type pressure test point, therefore it is

not necessary to provide a 1/8” test point upstream of

the control.

UVLX-M Series: The gas valve control is equipped with

a captured screw type inlet and manifold pressure test

point on the right side of the valve.

Odor During Operation

Neither natural gas nor propane gas give off an odor

when burned. The nat ure of a vent free combustion

system, however, is such that odors may occasionally

be produced during heater operation when impurities

20008845

High Elevations

Input ratings are shown in BTU per hour and are

certified without deration from elevations up to

4,500 feet (1,370m) above sea level.

Nuisance outages may occur at altitudes above

4,500 feet (1,370m) if dirt, dust, lint and/or cobwebs are allowed to accumulate on burner and/or

ODS pilot. Monthly inspection and cleaning is

recommended for altitudes above 4,500 feet

(1,370m)

For elevations above 4,500 feet (1,370m) in USA,

installations must be in accordance with the

current ANSI Z223.1/NFPA 54 and/or local codes

having jurisdiction.

In Canada, please consult provincial and/or local

authorities having jurisdiction for installations at

elevations above 4,500 feet (1,370m)

3

Planning

Planning the installation is an important first step. It will save

time and money later in the actual installation. In planning the

installation, consider:

• Where the heater will be located.

• All components needed to complete the installation.

• DO NOT use this heater in sleeping quarters, mobile

homes, or in recreational vehicles.

• Installation and repair should be done by a qualified service

person.

• DO NOT use this heater if any part has been under water.

Immediately call a qualified technician to inspect the appliance and replace any part of the control system and any gas

control which has been under water.

• When used as an unvented heater, always ensure there

is adequate ventilation from the room where the appliance is

operating. This appliance is equipped with an ODS (oxygen

depletion sensor) pilot light safety system designed to shut off

the appliance if enough fresh air is not available.

THIS APPLIANCE MUST NOT BE USED WITH GLASS

DOORS IN A CLOSED POSITION .

Keep the burner and control compartment clean. See installation and operating instructions supplied with the heater.

WARNING: During manufacturing, fabricating and ship

ping, various components of this appliance are treated

with certain oils, films or bonding agents. These chemi

cals are not harmful, but may produce annoying smoke

and smells as they are burned off during the initial operation of the appliance, possibly causing headaches or eye

or lung irritation. This is a normal and temporary occurrence. The initial break-in operation should last 2-3 hours

with the burner at its highest setting. Provide maximum

ventilation by opening windows, doors and the chimney

flue to allow odors to dissipate. Any odors remaining

after this initial break-in will be slight and will disappear

with continued use.

This appliance operates as an unvented domestic room

heater when fitted to a masonry or factory-built wood-burn

ing fireplace with the flue damper closed, or as a decorative

appliance when the flue damper is fully open. It must not be

used for any other purpose and must be fitted in a masonry or

factory-built fireplace or ventless firebox enclosure.

State, provincial or local codes may only allow operation of

this appliance in a vented configuration. Check your state or

local codes. If unvented room heaters are not permitted, the

fireplace vent damper must be locked at the minimum vent

area required by local codes or by the National Fuel Gas

Code (ANSI Z223.1/NFPA 54, latest edition).

When installed as a Decorative Gas Appliance for in

stallation in a solid-fuel burning fireplace, a minimum

permanent free opening of 29 square inches must be

maintained with a fixed damper stop provided with the

appliance. Minimum flue size for this appliance is 29

square inches.

-

-

-

-

Proposition 65 Warning: Fuels used in gas, wood-

burning or oil fired appliances, and the products of

combustion of such fuels, contain chemicals known

to the State of California to cause cancer, birth defects and other reproductive harm.

California Health & Safety Code Sec. 25249.6

Installation Precautions

1. This vent-free gas appliance and its components

have been tested and will operate safely when installed

in accordance with this Installation Manual. Read all

instructions before starting the installation, and follow these instructions carefully during installation to

maximize the appliance’s benefit and safety. Failure to

follow them will void your warranty and may present a

fire hazard.

2. After opening the carton, refer to Replacement Parts

on Page 17 and 18, and remove the various parts.

Report to your dealer if any parts were damaged in

shipment.

• CFM Corporation warranty will be voided by,

and CFM Corporation disclaims any responsibility for, the following actions:

• Installation of any damaged appliance.

• Modification of the appliance.

• Installation other than as instructed by

CFM Corporation.

• Improper positioning of the gas logs.

• Installation and/or use of any component

part or accessory not manufactured or

approved by CFM Corporation, not withstanding any independent testing laboratory or

other third-party approval of such component

part or accessory.

Any such action may create a possible fire hazard.

Consult your local building codes.

This heater shall not be installed in a confined

space unless provisions are made for adequate

combustion and ventilation air.

WARNING!

Improper installation, adjustment, alteration,

service or maintenance can cause injury or property damage. Refer to this manual for assistance

or additional information, consult a qualified

installer, service agency or the gas supplier.

4

20008845

Installation Requirements

Fresh Air Requirements for

Combustion and Ventilation

WARNING

This heater must have fresh air for proper operation. If it does not, poor fuel combustion could

result. Read the following instructions to ensure

proper fresh air supply for this and other fuelburning appliances in your home.

Modern construction standards have resulted in

homes that are highly energy-efficient and that allow

little heat loss. Your home needs to breathe, however,

and all fuel-burning appliances need fresh air to function properly and safely. Exhaust fans, clothes dryers,

fireplaces, and other fuel burning appliances all use

the air inside the building. If the available fresh air

supply is insufficient to meet the demands of these appliances, problems can result.

The vent-free logsets have specific fresh air requirements. You must determine that these requirements

will be met within the space where the appliance will be

installed. The following information will help you ensure

that adequate fresh air is available for the heater to

function properly.

Provide for Adequate Ventilation

Any space within a home can be classified in these

categories:

1) Unusually tight construction

2) Confined space

3) Unconfined space.

First, determine which classification defines the intended installation space.

Unusually Tight Construction

You must provide additional fresh air if the space falls

into this classification. Unusually Tight Construction is

defined as construction wherein:

a. Walls and ceilings exposed to the outside atmosphere have a continuous water vapor barrier with a

rating of one perm or less, with openings gasketed or

sealed, and

b. weather stripping has been added on openable windows and doors and

c. caulking or sealants are applied to areas such as

joints around windows and door frames, between sole

plates and floors, between wall and ceiling joints, between wall panels, at penetrations for plumbing, electrical, and gas lines, and at all other openings.

If your home meets all of the above criteria, you must

provide additional fresh air for the appliance as detailed

on Page 6.

If your home does not meet the above criteria, follow

the procedure below.

Determine If You Have a Confined or

Unconfined Space

Use the following formula to determine if you have a

confined or unconfined space.

Space is defined as the room in which you will install

the heater, plus any adjoining rooms with doorless

passageways or ventilation grilles between the rooms.

The National Fuel Gas Code defines a confined space

as a space whose volume is less than 50 cubic feet per

1,000 BTU per hour input rating (4.8m3 per Kw) of the

aggregate (total) input rating of all appliances installed

in that space and an unconfined space as a space

whose volume is not less than 50 cubic feet per 1,000

BTU per hour (4.8m3 per Kw) of the aggregate input

rating of all appliances installed in that space. Rooms

communicating directly with the space in which the appliances are installed, through openings not furnished

with doors, are considered a part of the unconfined

space.

1. Determine the volume of space (length x width x

height). Include adjoining rooms connected by doorless

passageways or ventilating grilles.

Example: A room that is 18’ x 12’ x 8’ has a volume of

1728 cubic feet. An adjoining open kitchen that is 10’

x 12’ x 8’ has a volume of 960 cubic feet. An adjoining

open dining room is 12’ x 12’ x 8’ with a volume of 1152

cubic feet. The total volume is 3840 cubic feet.

2. Divide the volume of space by 50 cubic feet. The

result is the maximum BTU/hour the space can support.

Example: 3840 cubic feet divided by 50 = 76.8 or

76,800 BTU/hour.

3. Add the BTU/hour ratings of all fuel-burning appliances installed in the same space, including the following:

Gas Water Heater Gas Furnace

Gas Fireplace Logs Vent-free Gas Heater

Vented Gas Heater* Other Gas Appliances*

* Do not include Direct-vent appliances as these use

outdoor air for combustion and vent to the outdoors.

20008845

5

Example:

Gas Range 55,000 BTU/hour

Vent-Free LogSet +25,000 BTU/hour

Total 80,000 BTU/hour

4. Compare the maximum BTU/hour rating the space

can support with the total BTU/hour used by the appliances.

Example: 76,800 BTU/hour the space can support

80,000 BTU/hour used by appliances

In this example, the maximum BTU/hour that the space

can support is less than the total used by the appliances.

The space is considered to be Confined Space. Additional air must be provided to meet the requirements

on the vent-free gas log set.

The installation and the provisions for combustion and

ventilation air must conform with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54, or the CSA-B149.1 Installation Code (Series).

A confined space may be ventilated in two ways:

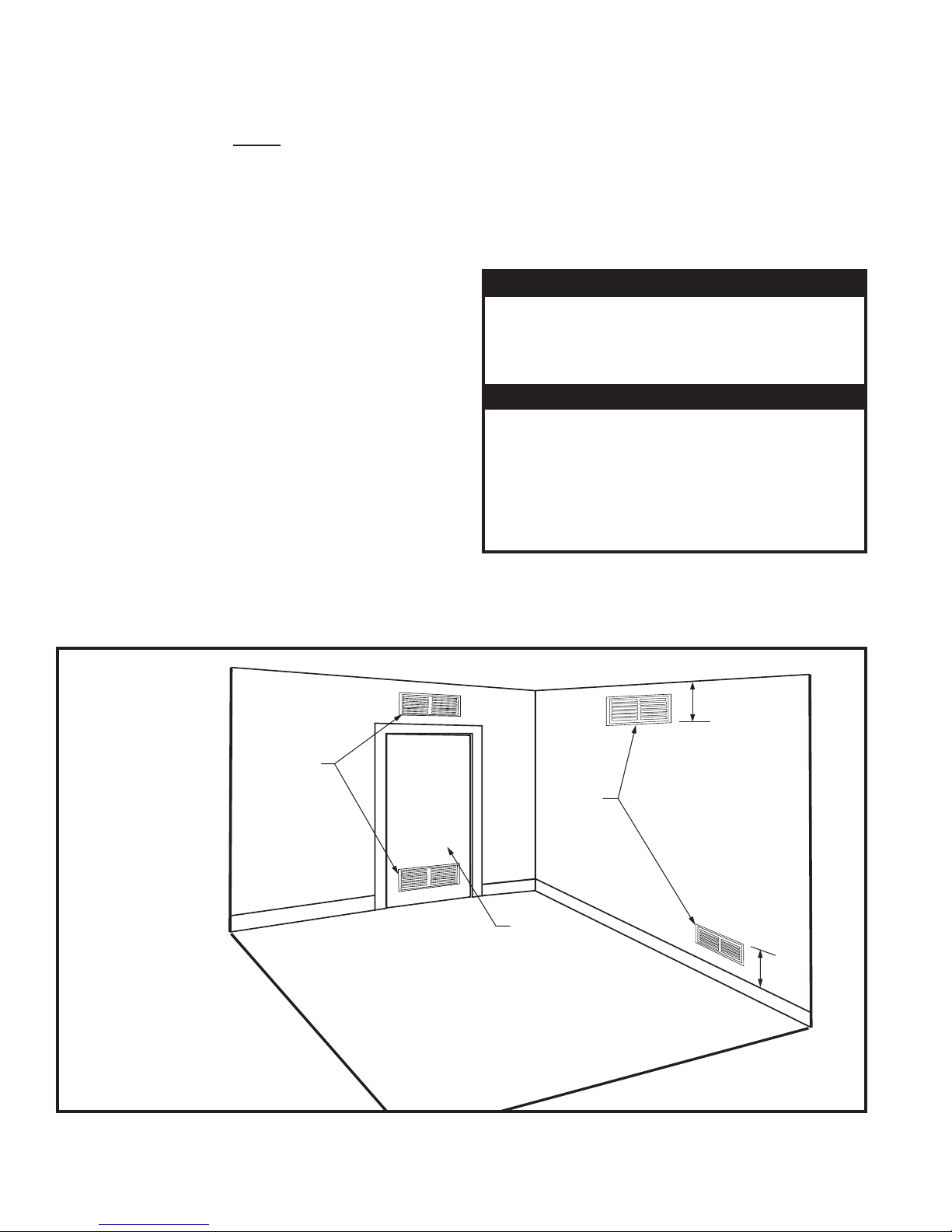

A. Open up or provide at least two ventilating grilles to

an adjoining unconfined space. (Fig. 2)

Each of the two grilles must provide an opening of at

least 50 square inches, with all opening dimensions being at least 3”. One grille must be within 12” of the ceiling; the other within 12” of the floor. (If the total exceeds

100,000 BTU/hour, additional grilles will be needed.)

B. Vent the room directly to the outdoors. (Provide one

square inch of opening for each 4,000 BTU/hr.)

For further information on ventilation guidelines and sizing specifications, follow the National Fuel Gas Code/

NFPA 54/ANSI Z223.1/NFPA 54, Section 5.3.

If the total BTU/hour used by the appliances is less than

the maximum BTU/hr the space can support, the room

meets the Unconfined Space criteria and no further

ventilation is needed.

WARNING

This heater shall not be installed in a confined

space or unusually tight construciton unless

provisions are made for adequate combustion

and ventilation air.

WARNING

If the area in which the heater may be operated

is smaller than that defined as an unconfined

space, or if the building is of unusually tight

construction, provide adequate combustion and

ventilation air by one of the methods described

in the National Fuel Gas Code, ANSI Z223.1/NFPA

54, 1992, Sections 5.3, or applicable codes.

WARNING:

fuel burning fireplace, the chimney flue and firebox

must be cleaned of soot, creosote, and loose paint by a

qualified chimney cleaner.

Before installing the gas log set in a solid-

OPTION 1

- Vents to

Adjoining

Room

Fig. 2 Ventilation options for confined spaces.

12”

OPTION 3

- Vents to Adjoining Room

OPTION 2 Remove Door to

Adjoining Room

12”

VO370-2

6

20008845

Installation Instructions

WARNING

Do not allow fans to blow directly into the fireplace. Avoid any drafts that alter burner flame

patterns.

WARNING: Do not use a blower insert, heat ex

changer insert, or other accessory not approved

for use with this gas logset.

DO NOT burn solid fuels in a fireplace where an

unvented gas room heater or logset is installed.

Any outside air ducts and/or ashdumps in the

fireplace must be permanently closed at time of

appliance installation.

Preparing the Fireplace

Gas Line Preparation

Before connecting the appliance, turn off all gas appliances. Close the main gas valve at the gas meter or

appliances. Close the main gas valve at the gas meter

or LP tank. Make certain there is good ventilation where

the installation will be made. Installation should comply

with all applicable building codes and ANSI Z223.1/

NFPA 54, latest edition, or CSA B-149.1. Use LP gasresistant pipe compound to seal threaded joints.

Installation to Existing Gas Line

There should be a manual ON/OFF valve within easy

reach of the appliance. If not, before installation of the

appliance make certain a valve is installed. There may

be a second valve on the line close to the point where

the fireplace line branches off the main gas supply line.

During installation, make certain this valve is OFF.

Manufactured Fireplace Preparation

Refer to the manufacturer’s fireplace installation manual for the specific method of running the gas line into

the fireplace. The following method is typical of most

manufactured fireplaces.

Insert a 1/2” gas pipe through the gas line tube provided by the manufacturer, from outside the fireplace, as

marked by the manufacturer. An ON/OFF valve should

be placed within easy reach of the appliance. After the

gas supply is installed, reinstall the insulation removed

from the gas line tube, and pack it around the pipe, to

prevent cold air entry and to protect the gas line. (Fig.

3)

NOTE: The gas pipe should not come into contact with

any wood structure until it has reached a point at least

one (1) inch away from the fireplace side. (Fig. 3)

Do not install this appliance in bedrooms or

bathrooms.

WARNING: Any change to this heater or its controls can be dangerous.

Hole in

Outer

Casing

Ceramic Knockout

Gas Access

Holes

Electrical

Access

Outside Air Access

Fig. 3 Gas line installation - factory built fireplace.

1”

Gas Supply Line

Repack

Insulation

760

Masonry Fireplace Installation

Preparation

A 1/2 inch gas supply line must be supplied to the

firebox. In most cases, this will require drilling a gas line

access hole through the masonry wall. The gas

supply line should then be sealed in the access hole with

mortar. The gas supply line should also have a valve

within easy reach of the appliance. Use only 1/2” rigid

pipe or approved 3/8” copper tubing. (Do not use castiron pipe).

Clean the fireplace and chimney (if used) of any ashes,

soot, creosote, or obstruction. This will minimize any

smell from the fireplace. We recommend cleaning by a

chimney sweep.

Flue Damper Preparation

The vented fireplace damper should be fully opened

when operating the appliance as a vented log set. A

damper stop clamp with set screw is provided as a

means to prevent full closure of the fireplace damper

blade. The clamp is designed to prevent accidental clo

sure of the damper when in use. (Fig. 4) (If the damper

stop cannot be installed, the installer should install a

permanent damper stop that will keep the damper open

a minimum of 1¹⁄₂”).

-

20008845

7

Damper Stop Installation

When installing a decorative gas appliance in a fireplace, some local codes require a damper stop be

added so the damper will not close completely. The

CFM Corporation damper stop is designed so the

damper can be locked in the closed position, and still

allow a vent for the pilot gasses.

This damper stop is designed to work on all CFM Corporation BR, BC, SR, SC, TF and TL series fireplaces.

Installation Instructions

1. Open damper. The damper must be open to attach

the damper stop.

2. Locate the damper locking bracket. From inside the

fireplace locate the damper locking bracket on the

left side of the combustion dome. (Fig. 4)

3. Align the two slots on either side of the cutout on the

damper stop with the two small holes on the angled

portion of the damper locking bracket. Attach the

damper stop with the screws provided. (Fig. 5)

NOTE: Some of the early units may not have the holes

in the end of the damper locking bracket. If this is the

case use the damper stop as a template to drill two (2)

1/8” holes in the damper locking bracket to mount the

damper stop.

Damper Locking Bracket

Attachment

Screws (2)

Damper Stop

Fig. 5 Attach damper stop.

DP101

Damper Locking Bracket

Fig. 4 Locate damper locking bracket.

DP100

Damper

Stop

Typical Manufactured

Fireplace

Fig. 6 Damper stop placement.

Damper Stop

Typical Masonry

Fireplace

DP105

8

20008845

7A

Front View

7B

Without Hood

7C

With Hood

3¹⁄₂”

Min.

Top View

11”

3¹⁄₂” Min.

Noncombustible

Facing Material

Mantel Trim

Finished Wall

Material

Firebox

Noncombustible Facing

Material

3¹⁄₂”

42”

762

763

Noncombustible

Material

Stand-off

Front Edge

of Grate

8”

Flat Mantel

Stand-off

38¹⁄₂”

20”

4”

3”

764

4”

Seal with

Noncombustible

Material

Shelf

8”

12”

7¹⁄₂”

4” Hood

765

Fig. 7 Mantel clearances.

Burner Assembly Location

Centrally locate the unit in the fireplace, far enough

back into the firebox to accomplish adequate draft (if

use as a vented appliance is planned). Ensure that the

front grate feet sit inside the front edge of the fireplace

a minimum of 3”. (Fig. 7B)

Clearances

(Refer to Fig. 7, Page 9)

To ensure the safe installation into a masonry or factory-built fireplace, carefully observe the following

instructions:

1. Sidewall Clearances: The clearance from the inside of the front opening of the fireplace to any combustible wall should not be less than 3¹⁄₂” (Fig. 7A)

2. Ceiling Clearances: The ceiling height should not

be less than 42” from the top of the fireplace opening. (Fig.

7A)

3. Mantel Clearances:

When installing an ANSI Z21.11.2 ventless appliance,

the finishing material used for the mantel must be rated

at 250°F or greater. Refer to firebox instructions for any

further information.

Without hood: If no hood is installed, then there must

be non-combustible material from the top front opening

of the fireplace to a height of at least 20 inches and the

full width of the fireplace. A combustible flat mantel shelf

can be no closer than 38¹⁄₂” from the top front of the

fireplace opening (Fig. 7B).

With hood:

If a hood is installed there must be noncombustible material from the top front opening of the

fireplace to a height of 7¹⁄₂” and the full width of the fireplace. A combustible flat mantel shelf may be installed

according to the detail in Figure 7C.

3A. Mantel Depth:

A combustible mantel can be no deeper than 8”, at 12”

above the hood. (Figs. 7B and 7C)

4. Grate Clearance

The minimum clearance between the front legs of the

grate and the front edge of the fireplace is 3” (Fig. 7B).

20008845

9

Gas Line Connection

WARNING

Check the gas type. Use only the gas type indicated on

the appliance rating plate. If the gas listed on the plate

is not the type of gas supplied, DO NOT INSTALL the

logset. Contact your dealer for the proper model.

Always use an external regulator for all LP appliances,

to reduce the supply tank pressure to a maximum of

14” w.c. This is in addition to the regulator fitted to the

heater.

The normal gas connection is made at the right side

(facing the unit). If a left-side connection is desired, the

connecting pipe may be directed under or behind the

rear of the appliance, to terminate at the right-hand side

for connection to the inlet of the appliance.

Connect the appliance to the gas line using fittings and

aluminum tubing provided.

Close the valve knob on the appliance, turn the main

gas supply valve ‘ON’, and carefully check all gas

connections for leaks, with a soapy water solution or a

sniffer. DO NOT TEST FOR LEAKS WITH AN OPEN

FLAME.

Upon completing your gas line connection, a small

amount of air will be in the gas lines. When first lighting

the pilot, it will take a few minutes for the lines to purge

themselves of air. Once the purging is complete, the

pilot and burner will light and operate as indicated in

this manual. Subsequent lightings of the appliance will

not require purging.

Check the inlet pressure to the appliance, to ensure

that it is as shown in the table on page 3. The minimum

is for the purpose of input adjustment.

The pressure is controlled by the regulator and should

be checked at the pressure test point located in the

control valve body. Access to the pressure test point is

obtained by removing all logs. (UVLX-M series only)

The pressure should be checked with the appliance

burning and the control set on ‘HIGH’.

The pressure regulator is preset and locked to avoid

tampering. If the pressure is not as specified, replace

the regulator. Refer to Replacement Parts.

After measuring the pressure, replace the test point

plug. Ensure there are no leaks, then place the logs in

their specified positions.

Connection directly to an unregulated LP tank

can cause an explosion.

During the initial purging and subsequent lightings, never allow the gas valve control knob to

remain depressed in the ‘Pilot’ position without

lighting the pilot with a match or piezo ignitor.

There is a possibility of odor fade in LP. Never install an LP appliance or service line below grade

without a gas detector.

Positioning the Logs

The logs must be positioned on the grate and locating

pins, as shown in Figure 8. Make sure each bottom log

engages the locator pins on the grate, and top logs are

properly positioned in notches on tops of bottom logs.

Gas logs must be properly positioned or the appliance

will not function properly, and may result in soot accumulation on the inside of the firebox and/or on the gas

logs. Make sure there is no yellow flame impinge-

ment on the logs which could result in excessive

carbon monoxide emissions and carboning.

The optional volcanic rock may be applied to the

hearth around the burner assembly.

Never place any other material on the burner.

WARNING

Failure to position the parts in accordance with

these diagrams or failure to use only parts specifically approved for use with this appliance may

result in property damage or personal injury.

10

20008845

PILOT

ON

OFF

L

O

H

I

UVLX18

UVLX24

UVLX30

LG376

Fig. 8 Positioning logs on grate assembly.

Fireplace Screen

The fireplace screen must be in place when the appliance is operating, and unless other provisions for combustion air are made, the screen must have openings

for the introduction of combustion air.

5. Remote wall switch

(RN and RP models only)

1. Thread wire through the electrical knockout located

on either side of the fireplace. Do not cut the wire or

insulation on metal edges. Ensure that the wire is

protected. Run the other end to a conveniently-located

wall receptacle box.

2. Attach the wire to the switch and install the switch

into the receptacle box. Attach the cover plate to the

switch.

3. Connect the wiring to the gas valve. One wire connects to the ‘TP/TH’ terminal; the other attaches to the

‘TH’ terminal. (Fig. 10)

LG378

To Wall Switch

Piezo Ignitor

Control Knob

Hi/Lo Knob

Fig. 9 Connecting a wall switch to the valve terminals.

(UVLX-R Series only)

LG380

751

NOTE: If any of the original wire as supplied with the

appliance must be replaced, it must be replaced with a

wire of at least a 60°C temperature rating.

20008845

11

Operating Instructions

HI

OFF

PILO

T

LO

H

I

L

O

O

F

F

O

N

O

F

F

P

I

L

O

T

O

F

F

E

A

P

I

L

O

T

THTP

TP

TH

PILOT

ON

OFF

L

O

H

I

The First Firing

On completing the gas line connection, a small amount

of air will be trapped in the gas line. When you first light

the unit with the pilot light, it will take a few minutes to

purge the trapped air. Once you have purged the gas

line, the pilot and burner will light and operate normally.

Subsequent lightings of the appliance will not require

purging the gas line.

When lit for the first time, the appliance will emit a slight

odor for an hour or two. This is due to paint and lubri

cants used in the manufacturing process curing under

heat. This is normal. You may wish to have the windows

open to dissipate any odors during the curing process.

Control Knob

-

Red Glow

Fig. 13 UVLX18 proper burner flame appearance.

LG377

HV101a

Piezo Ignitor

Fig. 10 Honeywell control valve.

Fig. 11 EuroSIT control valve.

Fig. 12 SIT control valve.

Hi/Lo Knob

Piezo

Ignitor

FP1395

FP1036

Red Glow

Fig. 14 UVLX24 proper burner flame appearance.

Red Glow

Fig. 15 UVLX30 proper burner flame appearance.

R Series

Thermocouple

Thermopile

M Series

LG379

LG381

Flame Appearance

To obtain proper operation, it is imperative that the

pilot and main burner flame characteristics are steady,

not lifting or floating. Refer to Figure 13 -15 for proper

burner flame appearance. Refer to Figure 16 for proper

pilot flame appearance.

12

Thermopile

Fig. 16 Proper pilot flame.

752

P103

20008845

Lighting and Operating Instructions

PILOT

ON

OFF

ON

P

I

L

O

T

O

F

F

O

F

F

5

4

3

2

1

O

F

F

P

i

l

o

t

3/8" - 1/2"

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING:If you do not follow these instructions exactly, a fire or explosion

may result causing property damage, personal injury or loss of life.

A. This heater has a pilot which must be lit manu

ally. When lighting the pilot follow these

instructions exactly.

B. BEFORE LIGHTING smell all around the heater

area for gas. Be sure to smell next to the floor

because some gas is heavier than air and will

settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any fireplace

• Do not touch any electric switch

• Do not use any phone in your building

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

Lighting Instructions

-

• If you cannot reach your gas supplier, call the

Fire Department

C. Use only your hand to push in or turn the gas

control knob. Never use tools. If the knob will not

push in or turn by hand, do not try to repair it, call a

qualified service technician. Applying force or any

attempted repair may result in a fire or explosion.

D. Do not use this fireplace if any part has been under

water. Immediately call a qualified service technician to inspect the heater and to replace any part of

the control system and any gas control which has

been under water.

1. STOP! Read the safety information above.

2. Turn off all electrical power to the fireplace.

3. For MN/MP/TN/TP appliances ONLY, go on to

Step 4. For RN/RP appliances turn the On/Off

switch to “OFF” position or set thermostat to

lowest level.

4. Open control access panel.

5. Push in gas control knob slightly and turn

clockwise to “OFF”.

Euro SIT SIT NOVA

Honeywell

6. Wait five (5) minutes to clear out any gas. Then

smell for gas, including near the floor. If you

smell gas, STOP! Follow “B” in the safety information above. If you do not smell gas, go to the

next step.

7. Remove glass door before lighting pilot. (See

Glass Frame Removal section).

8. Visibly locate pilot by the main burner.

9. Turn knob on gas control counterclockwise

to “PILOT”.

10. Push the control knob all the way in and hold.

Immediately light the pilot by repeatedly depressing the piezo spark ignitor until a flame appears.

Continue to hold the control knob in for about one

(1) minute after the pilot is lit. Release knob and it

will pop back up. Pilot should remain lit. If it goes

out, repeat steps 5 through 8.

• If knob does not pop up when released, stop

and immediately call your service technician or

gas supplier.

• If after several tries, the pilot will not stay lit,

turn the gas control knob to “OFF” and call your

service technician or gas supplier.

11. Replace glass door.

12. Turn gas control knob to “ON” position.

13. For RN/RP appliances turn the On/Off switch to

“ON” position or set thermostat to desired setting.

14. Turn on all electrical power to the fireplace.

1. Turn the On/Off switch to Off position or set the

thermostat to lowest setting.

2. Turn off all electric power to the fireplace if

service is to be performed.

20008845

To Turn Off Gas To Heater

3. Open control access panel.

4. Push in gas control knob slightly and turn clockwise to “OFF”. Do not force.

5. Close control access panel.

13

START

Troubleshooting

Honeywell Valve (UVLX-R series)

CHECK

Gas supply on

YES

Pilot lights with Piezo

YES

Pilot stays lit

YES

NO

NO

NO

• Supply line hooked up

• Shutoff valve open

• Lockout has engaged. Wait 60 seconds

and try again

• Piezo screws are tight for good ground

• For spark at electrode while depressing

piezo - 1/8” gap to pilot hood needed

• All wiring connections

• Replace piezo ignitor

• For air in the lines

• Thermopile needs a minimum of 325mV

• All wiring connections

• Replace thermopile

• Thermocouple needs a minimum of 14mV

• Defective valve. turn to pilot, meter should

read greater than 100mV. If not, replace the

valve.

Pilot lights main

burner

YES

System OK

14

NO

• Valve turned on

• Wall switch is not turned on

• Thermopile needs a minimum of 325mV

• Plugged burner

20008845

Troubleshooting

SIT 630 Eurosit Valve (‘M’ Series)

With proper installation and maintenance, your new Gas Appliance should provide years of trouble-free service. If you

do experience a problem, this guide will help a CERTIFIED SERVICE PERSON in the diagnosis of problems and the

corrective action to take.

SYMPTOM POSSIBLE CAUSES CORRECTIVE ACTION

1. Pilot will not light with

piezo ignitor or match.

2. Pilot will not stay lit

after carefully following the lighting

instructions.

3. No gas to main burn

er with pilot flame

burning and valve

turned to ‘High-Low’

range.

A. Main shutoff valve closed.

B. Air in the gas line.

C. Pilot orifice plugged, not

letting gas flow.

D. No gas supply to the

fireplace.

A. Defective thermocouple.

B. Thermocouple fitting not

tight in valve.

C. Weak pilot flame.

D. Defective valve.

E. Not enough oxygen in the

room. (Danger!)

-

A. Plugged main burner ori

fice.

B. Defective valve.

-

1. Make sure that the shutoff valve located on the pipe

supplying gas to the fireplace is open.

1. Light a match, turn gas valve knob to ‘PILOT’ position

and depress. Keep match near pilot burner till it lights.

1. Replace the burner assembly.

1. Check plumbing to see if gas fireplace has been hooked

up to the gas supply line.

2. Propane tank is empty.

1. Replace burner assembly.

1. Carefully tighten the fitting.

1. The pilot flame must engulf the thermocouple. Clean

for maximum flame impingement on the thermocouple.

(Fig. 12)

1. Replace the burner assembly.

1. Open the door and get fresh air

1. Replace the burner assembly.

1. Replace the burner assembly.

at once!

20008845

15

Maintenance and Safeguards

Keep the control compartment, logs and burner area

around the logs clean by vacuuming or brushing

at least twice a year. At altitudes above 4,500 feet

(1370m) monthly cleaning is recommended.

THE LOGS CAN GET VERY HOT. HANDLE ONLY

WHEN COOL.

Always turn off gas to the pilot before cleaning. For

relighting, refer to the lighting instructions.

The appliance and venting system (if used) should be

inspected before initial use, and at least annually by a

qualified field service person.

Always keep the appliance area clear and free from

combustible materials, gasoline, and other flammable

vapors and liquids.

Never obstruct the flow of combustion and ventilation

air. Keep the front of the appliance clear of all obstacles

and materials.

Leave clearance of at least 36” from the front of the

fireplace.

Although your gas logs are very realistic in appearance,

the fireplace must not be used for burning any solid

fuels.

To avoid irreparable damage to the appliance or personal injury, matches, paper, garbage, or any other

material must not be placed or thrown on top of the

logs or into the flames.

To avoid personal injury, do not touch hot surfaces

when the appliance is operating. Touch only the valve

control knob. Avoid contact with the grate feet or

prongs, or any other part which may be very hot.

Always ensure that the fireplace screen is closed when

the appliance is operating.

Any safety screen or guard removed for servicing the

appliances must be replaced before operating the appliance.

Close supervision is necessary when the appliance is

being operated near children.

The appliance is intended for use as a gas heater

mounted in a vented or unvented fireplace as described

in the installation section of these instructions. It should

not be used for any other purpose.

Inspecting the Venting System

A vented fireplace venting system is designed and constructed to develop a positive flow adequate to remove

flue gasses to the outside atmosphere. See vented

fireplace installation instructions.

Any foreign objects in the venting system, except those

designed specifically for the venting system, may cause

spillage of the flue gases into the room.

In extreme situations, carbon monoxide poisoning or

suffocation may occur.

Periodic examination and cleaning of the venting

system of the solid-fuel burning fireplace must be done

frequently by the home owner or a qualified agency.

UVLX System Maintenance

The UVLX burner and control system consists of:

• Chassis

• Gas Orifice

• Grate assembly

• UVLX18 - four (4) decorative logs

UVLX24 - five (5) decorative logs

UVLX30 - six (6) decorative logs

• Gas valve assembly

• Pressure regulator (UVLX18M, UVLX24M and

UVLX30M only)

Most of these components require only occasional

check-up and cleaning. Some may require adjustment.

If repair is needed, it should be performed by a qualified

technician.

In order to properly clean the burner and pilot assembly,

turn off the gas to the unit and remove the logs, exposing the burner and pilot assembly. Clean all foreign materials from the top of the burner. Check to make sure

that all burner parts are clean. Visually inspect the pilot.

Brush or blow away any dust or lint accumulations.

NOTE: The burner and pilot assembly should be

checked for any dust or lint at least every six months.

Replacement Parts

Contact the factory for questions about prices and policies covering replacement parts. Parts will be shipped

at prevailing prices. Normally, all parts can be ordered

through your CFM Corporation distributor or dealer.

When ordering replacement parts, always give the following information:

1. The model number of the appliance.

2. The part number

3. The description of the part. (See the Replacement Parts List on Page 17)

4. The installation date of the appliance.

If you need more information, beyond what the dealer

can furnish, contact CFM Corporation, 2695 Meadowvale Blvd, Mississauga, Ontario, Canada L5N 8A3,

Attention: Director of Technical Service

16

20008845

PILOT

ON

OFF

L

O

H

I

3

2

5

12a,b

7

HI

OFF

PILOT

LO

9a,b

Screw

Piezo Ignitor

17

15a,b

19

14a,b

16

11

18a,b

10

13a,b

4

8

20

21a,b

6a,b

c,d

1b

1f

1

1a

1c

1d

1e

UVLX18

UVLX241

1a

1c

1d

1e

UVLX30

1a

1b

1c

1d

1e

22

CFM Corporation reserves the right to make changes in design, materials, specifications, prices and discontinue colors and products at any time,

without notice.

UVLX18/24/30 Premium Vent Free Gas Logs

Ref. Description UVLX18 UVLX24 UVLX30

1. Complete Log Set 20008925 20008786 20008886

1a. Back Log 20008655 20008781 20008876

1b. Right Cross Log -- 20008785 20008880

1c. Left Cross Log 20008653 20008653 20008653

1d. Front Log 20008654 20008783 20008878

1e. Middle Log 20008652 20008782 20008877

1f. Middle Cross Log -- -- 20008879

2a. 3/8” Flare Tubing 7060120 7060120 7060120

2b. 3/8” Flare Tubing (M Series) 20004146 20004146 --

20008845

17

UVLX18/24/30 Premium Vent Free Gas Logs (continued)

Ref. Description UVLX18 UVLX24 UVLX30

3. Volcanic Rock 20000198 20000198 20000198

4. Elbow Fitting 1/2” NPT (F) x 3/8” Flare 7523184 7523184 7523184

5. Damper Stop 7540310 7540310 7540310

or 3030176 3030176 3030176

6a. Burner Supply Assembly - Main Orifice (RP) 20000120 20000124 20001878

6b. Burner Supply Assembly - Main Orifice (RN) 20000119 20000123 20001877

6c. Burner Supply Assembly - Main Orifice (MN) 20000121 20000125 20001875

6d. Burner Supply Assembly - Main Orifice (MP) 20000122 20000126 20001876

7a. Orifice Hood - Front (MP,RP) 20000134 20000133 30000339

7b. Orifice Hood - Front (MN, RN) 20000130 20000132 30000337

8. Front Leg Assembly 3081122 3081122 20001862

9a. Gas Valve - SIT - MN Series 20001354 20001786 20001786

9b. Gas Valve - SIT - MP Series 20001355 20001787 20001787

10. Valve Cover - M Series (includes Piezo & Screw) 51851 51851 51851

11. Piezo Ignitor - M Series & R Series - SIT Valve 52464 52464 52464

12a. Pilot Assembly - MN Series 20001356 20001356 20001356

12b. Pilot Assembly - MP Series 20001357 20001357 20001357

13a. Gas Valve - Honeywell - RP 10000242 10000242 10000242

13b. Gas Valve - Honeywell - RN 10000235 10000235 10000235

14a. Knob Extension (Hi/Lo) - Honeywell Valve 20000006 20000006 20000006

14b. Knob Extension (HI/LO) - SIT Valve 55162 55162 55162

15a. Knob Extension (ON/OFF) - Honeywell Valve 20000007 20000007 20000007

15b. Knob Extension (ON/OFF) - SIT Valve 55163 55163 55163

16. Piezo Ignitor - R Series - Honeywell Valve 20000062 20000062 20000062

17. Piezo Extension (R Series only) 20001427 20001427 20001427

18a. Pilot Assembly - RP 55465 55465 55465

18b. Pilot Assembly - RN 55464 55464 55464

19. Ignitor Cable (M and R Series) 20004419 20004419 20004419

20. Access Panel Assembly 3085109 3081120 20001860

21a. Gas Valve - SIT - RN 55463 55463 55463

21b. Gas Valve - SIT - RP 55462 55462 55462

22. Pilot Tube Assy. (SIT) 10000150 10000150 10000150

18

20008845

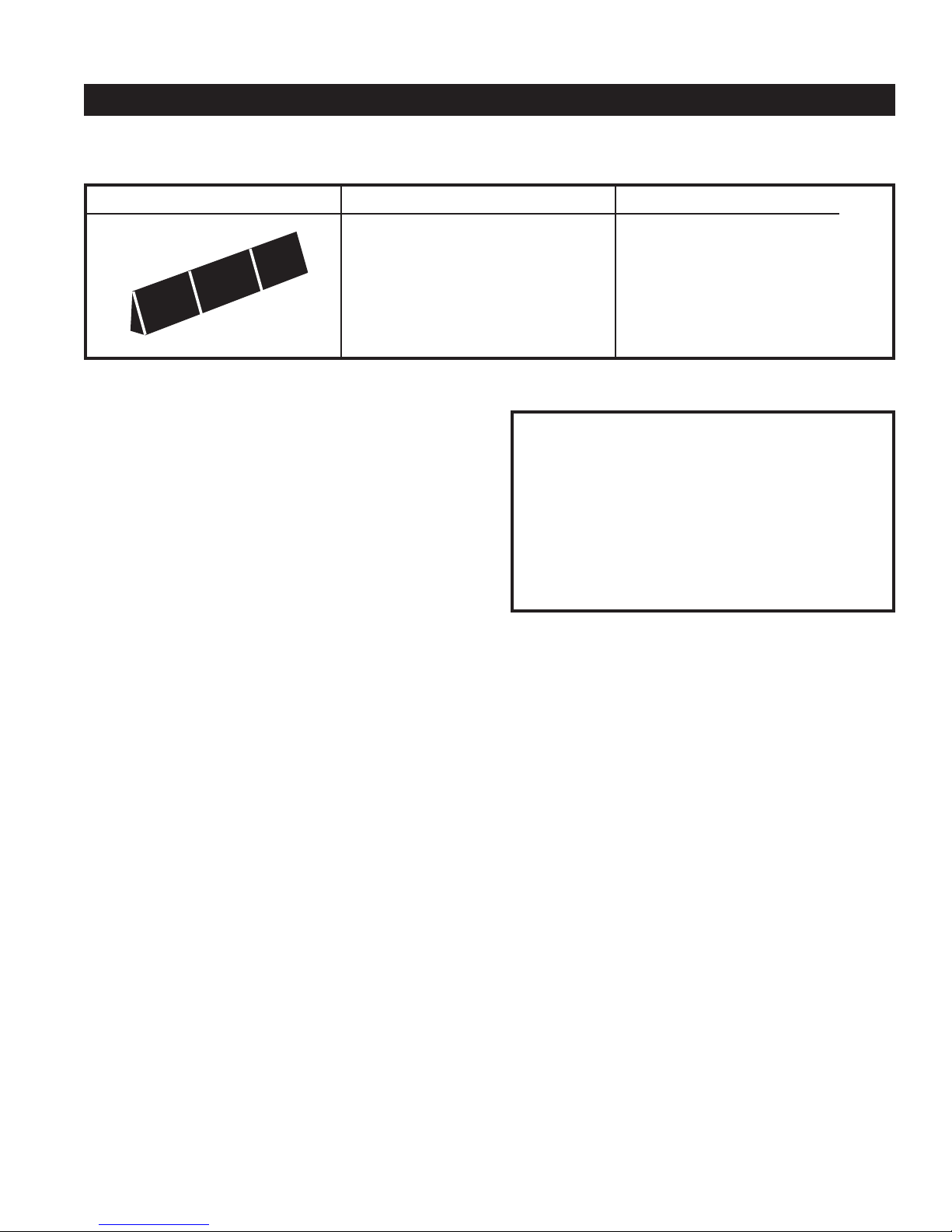

Accessories

The following accessories are available from your Majestic Fireplaces Dealer. If you need additional information beyond what your dealer can supply, contact CFM Corporation, 2695 Meadowvale Blvd, Mississauga, Ontario, Canada

L5N 8A3, Attention: Technical Service.

Accessory Description Model Number

Required to protect wall above

fireplace and/or mantel in certain

applications.

AC100

Contact CFM Corporation with questions concerning

prices and policies covering replacement parts. Parts

may be ordered through your Majestic Fireplaces distributor or dealer.

You will need the following information when ordering

replacement parts:

• The appliance model number.

• The serial number.

• A description of the part.

Should you need additional information beyond what

your dealer can furnish, contact:

CFM Corporation

2695 Meadowvale Blvd.

Mississauga, Ontario

Canada L5N 8A3

AH3244BK (BLACK)

AH3244PB (POLISHED

BRASS)

Model and serial numbers are listed on the rating

plate (located on right side of combustion chamber).

Record your model and serial number here for

future reference.

Model #__________________________________

Serial # __________________________________

20008845

19

LIMITED 2/20 YEAR WARRANTY

For MAJESTIC FIREPLACES® Vent-Free Gas Appliances

CFM Corporation (Company) extends the warranties specified

in paragraphs A and B below with respect to its MAJESTIC

FIREPLACES Decorative Gas Appliances (the “Gas Appliance”), including the CFM Corporation supplied accessories

and components referred to in those paragraphs, subject to the

following conditions and limitations:

(1) These warranties are extended only to the Gas Appliance

installed in the continental United States, including Alaska, and

Canada; only if and so long as the accordance with the installation and operating instructions furnished therewith; and only

if and so long as Gas Appliance is not removed from its original

installation.

(2) These warranties are limited to only the component parts

manufactured and supplied by CFM Corporation. The use of

components manufactured by others with the Gas Appliance

could create serious safety hazard, may result in the denial of

certification by recognized national safety agencies, and could

be in violation of local building codes.

(3) The Gas Appliance must be operated at all times in accor

dance with the operating instruction furnished therewith. The

Gas Appliance is designed to burn either natural or propane gas

only. Burning conventional fireplace fuels such as wood, coal, or

any other solid fuel will cause damage to the Gas Appliance, will

produce excessive temperatures and will result in a fire hazard.

(4) These warranties are limited to repair, replacement or

furnishing a replacement for sale, as specified in Paragraphs

A and B, for a part found to CFM Corporation satisfaction, after

examination, to be defective in materials or workmanship under

normal conditions, use and service.

(5) All obligations with respect to these warranties may be fully

discharged by CFM Corporation refunding the wholesale price

of a defective part.

(6) Except as otherwise expressly specified in Paragr aphs A

and B. NONE OF THESE WARRANTIES COVER, AND CFM

CORPORATION SHALL NOT BE RESPONSIBLE FOR, ANY

CONSTRUCTION, INSTALLATION, LABOR, TRANSPORTA

TION OR OTHER COSTS OR EXPENSES ARISING FROM

A DEFECTIVE PART, ITS REPAIR OR REPLACEMENT OR

OTHERWISE, NOR SHALL CFM CORPORATION IN ANY

EVENT BE RESPONSIBLE FOR ANY INDIRECT, INCIDENTAL

OR CONSEQUENTIAL DAMAGES. EXCEPT TO THE EXTENT PROVIDED BY LAW, THERE ARE NO IMPLIED WAR

RANTIES WITH RESPECT TO THE GAS APPLIANCE, ITS

COMPONENTS AND ACCESSORIES (INCLUDING IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR

A PARTICULAR PURPOSE), ALL OF WHICH ARE HEREBY

-

-

-

EXPRESSLY INCLUDED. IN NO EVENT SHALL ANY IMPLIED

WARRANTY PRESCRIBED BY LAW (NOTWITHSTANDING

THE FOREGOING EXPRESS EXCLUSION) REMAIN IN EFFECT AFTER EXPIRATIONS OF THE WARRANTIES SET

FORTH IN PARAGRAPHS A AND B.

A. Gas Appliances, electrical and manual compon ents,

glass panels, all sealants or adhesives and optional accessories (exclusive of CFM Corporation supplied decorative logs

which are covered by a separate warranty under paragraph B

below):

Within two years from the date of manufacture of the gas appliance, CFM Corporation will repair, or replace (at our option) a

defective part without charge.

B.

CFM Corporation

Within two years from the date of manufacture of the gas appliance, CFM Corporation will replace a defective part without

charge. Within years three through twenty from the date of

manufacture of the gas appliance, CFM Corporation will provide

a replacement for a defective part to the homeowner, but assumes no liability for incurred labor cost.

The foregoing warranties gives you specific legal rights and you

may also have other rights which vary from state to state. Some

states do not allow limitations on how long an implied warranty

may last, so the limitation specified above on the duration of

any implied warranty prescribed by law may not apply to you.

Similarly, some states do not permit the exclusion or limitation of

incidental or consequential damages, so the above exclusion of

such damages may not apply to you.

In order to obtain performance of any of the above warranty

obligations, write to CFM Corporation at this address:

Mississauga, Ontario Canada L5N 8A3

Attention: Director of Warranty Services

Since local building requirements may vary greatly throughout

the country, users of CFM Corporation products should determine in advance whether there are any building code restrictions on the use of a specified product.

CFM CORPORATION MAKES NO REPRESENTATION OR

WARRANTY REGARDING, AND SHALL NOT BE RESPON

SIBLE FOR, ANY BUILDING CODE COMPLIANCE.

The foregoing warranties give you specific legal rights and you may also

have other rights which vary from state to state.

CFM Corporation

2695 Meadowvale Blvd.

cement logs, fiber logs, or firebox liners:

-

2695 Meadowvale Blvd. • Mississauga, Ontario, Canada L5N 8A3

CFM Corporation

800-668-5323 • www.cfmcorp.com

Loading...

Loading...