Page 1

able Of Contents

T

SUBJECT PAGE NO.

1.1 Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Side Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

NOTE

This section provides information unique to the FXDP police model motorcycle. Any information not presented in this supplement can be found in the Dyna Models Service Manual.

MAINTENANCE 1

Page 2

Page 3

HOME

4

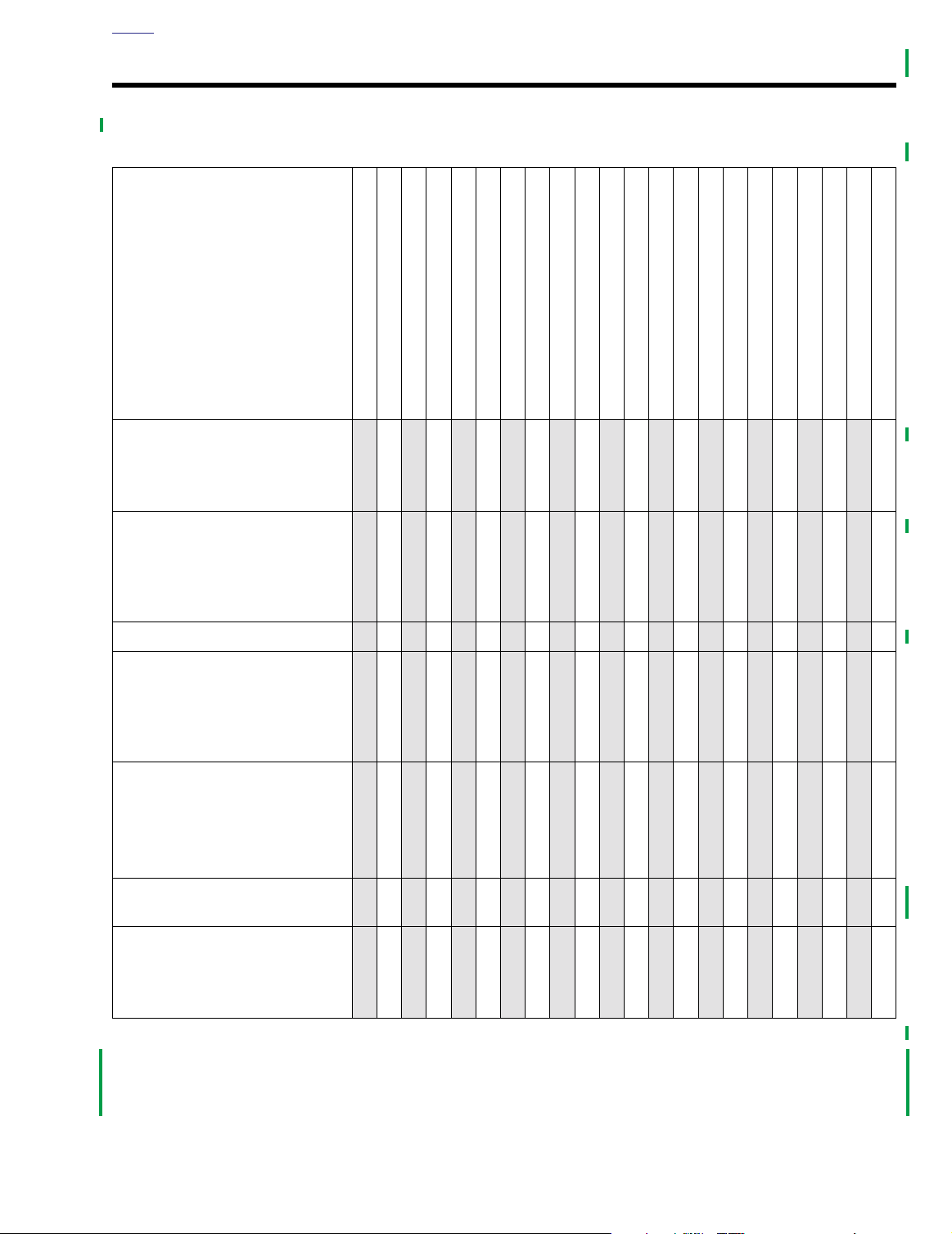

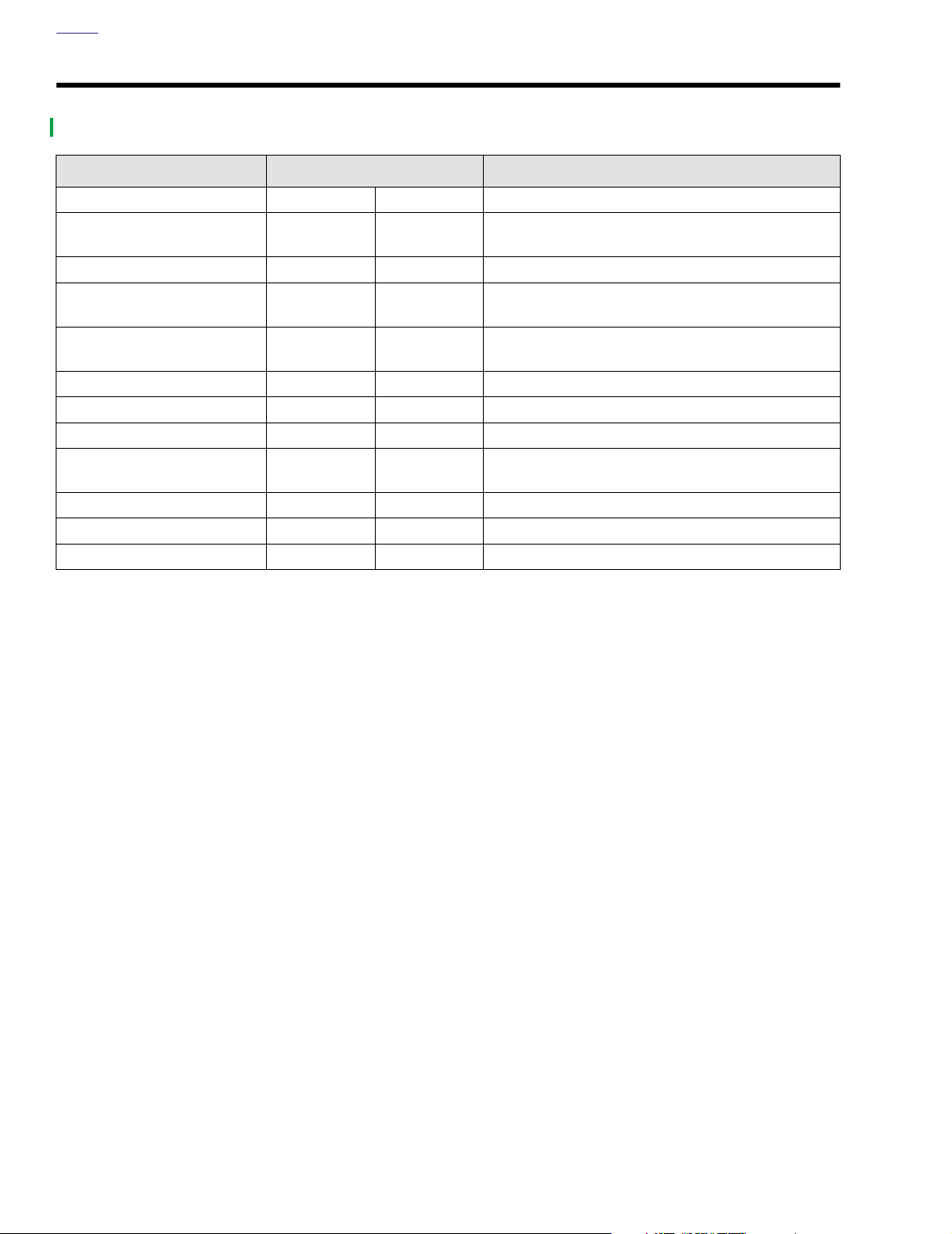

MAINTENANCE SCHEDULE 1.1

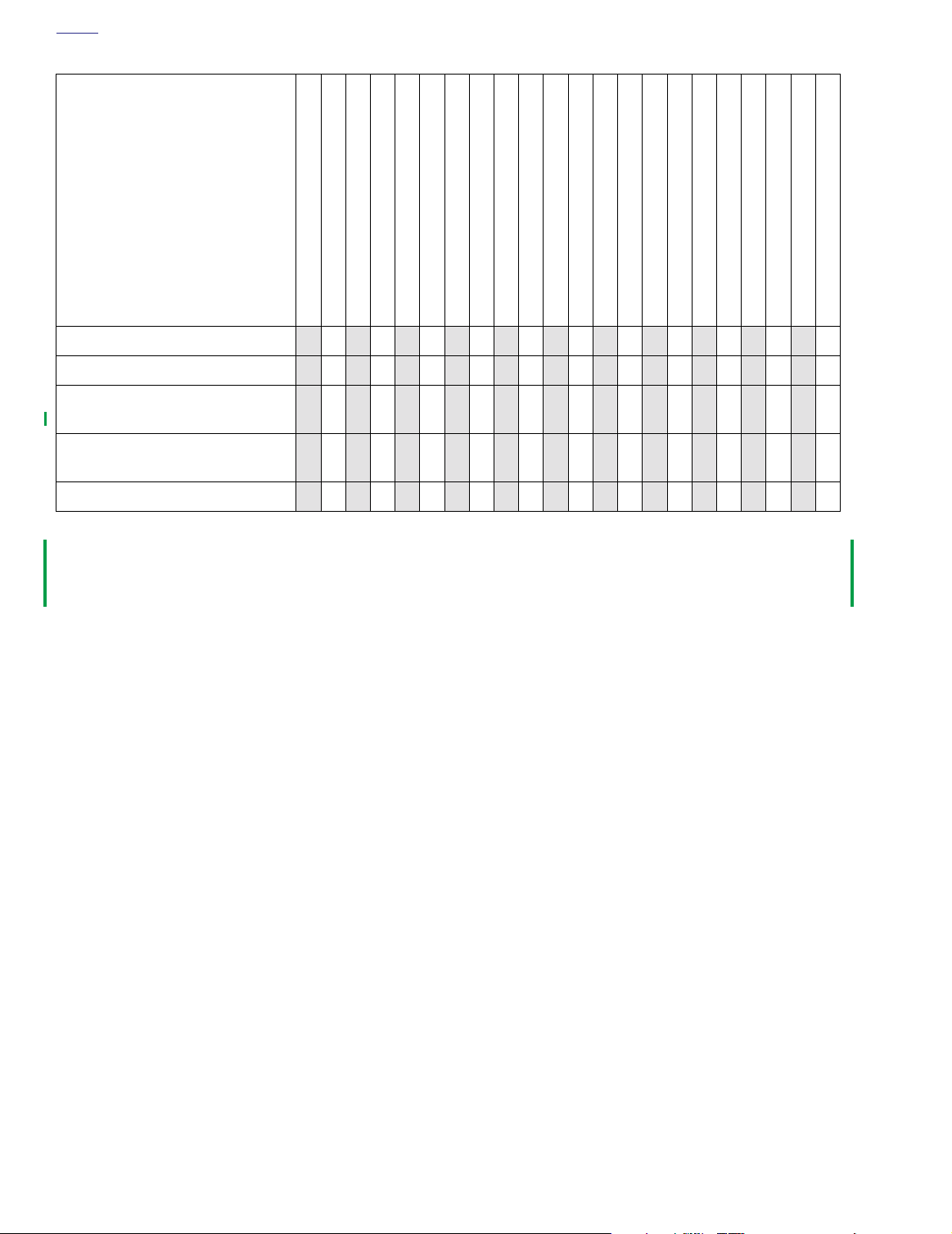

Table 1-1. Maintenance Schedule

1

1

1

1

2

2

2

2

3

3

3

3

4

4

4

4

5

7

0

5

0

0

0

0

0

M

M

I

I

I

7

8

6

0

0

0

0

0

0

0

K

K

M

M

MAINTENANCE TASK

AND SERVICE DATA

Engine oil (*)

Oil level:

Dipstick level depends on vehicle

temperature

Engine oil filter (*)

Filter tightening:

Hand tighten oil filter 1/2 to 3/4 turn

after gasket surface contacts filter

mounting surface.

1

2

5

7

0

2

5

7

0

2

5

7

0

2

5

7

0

5

0

5

0

5

0

5

0

5

0

5

0

5

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

M

M

M

M

M

M

M

M

I

I

I

I

I

I

P

R

1

E

R

D

E

4

6

0

0

0

I

0

0

K

K

M

M

IR

RRRRRRRRRRRRRRRRRRRR

R

RRRRRRRRRRRRRRRRRRRR

1

1

8

2

0

0

0

0

0

0

K

K

M

M

2

6

0

0

0

0

0

0

0

K

K

M

K

M

M

M

I

I

2

2

4

0

0

0

3

8

2

0

0

0

0

0

0

K

K

M

M

0

M

M

I

I

3

4

6

0

0

0

0

0

0

0

K

K

M

M

0

0

0

M

M

I

I

4

4

4

8

0

0

0

0

0

0

K

K

M

M

0

0

0

0

0

M

M

I

I

5

5

2

6

0

0

0

0

0

0

K

K

M

M

0

5

0

0

0

0

0

M

M

I

I

I

6

6

0

4

0

0

0

0

0

0

K

K

M

M

2

5

5

0

0

0

0

0

M

M

I

6

7

8

2

0

0

0

0

0

0

K

K

M

M

Battery (*)

Brake fluid level and condition

Brake fluid type:

D.O.T. 5 SILICONE BRAKE FLUID

Part No. 99902-77 (12 oz.) or

99901-77 (gallon)

Brake pads and discs for wear

Minimum pad thickness:

0.04 in. (1.02 mm)

II

Maximum brake disc lateral runout:

0.008 in. (0.2 mm)

Tire pressure and inspect tires for

wear/damage (*)

II

Primary chain adjustment

Deflection:

Cold: 5/8-7/8 in. (15.9-22.2 mm)

Hot: 3/8-5/8 in. (9.5-15.9 mm)

Tab le Code:

A

- Adjust.

I

- Inspect, and if necessary, correct, adjust, clean or replace.

L

- Lubricate with specified lubricant.

R

- Replace or change.

I

IIIIIIIIIIIIIIIIIIII

I

I

I I I I I I I I I I

IIIIIIIIIIIIIIIIIIII

IIIIIIIIIIIIIIIIIIII

I I I I I I I I I I

T

- Tighten to proper torque.

X

-Perform.

D

- Disassemble, lubricate and inspect.

(*)- Also perform prior to storage or annually.

2003 Dyna Police: Maintenance 1-1

Page 4

HOME

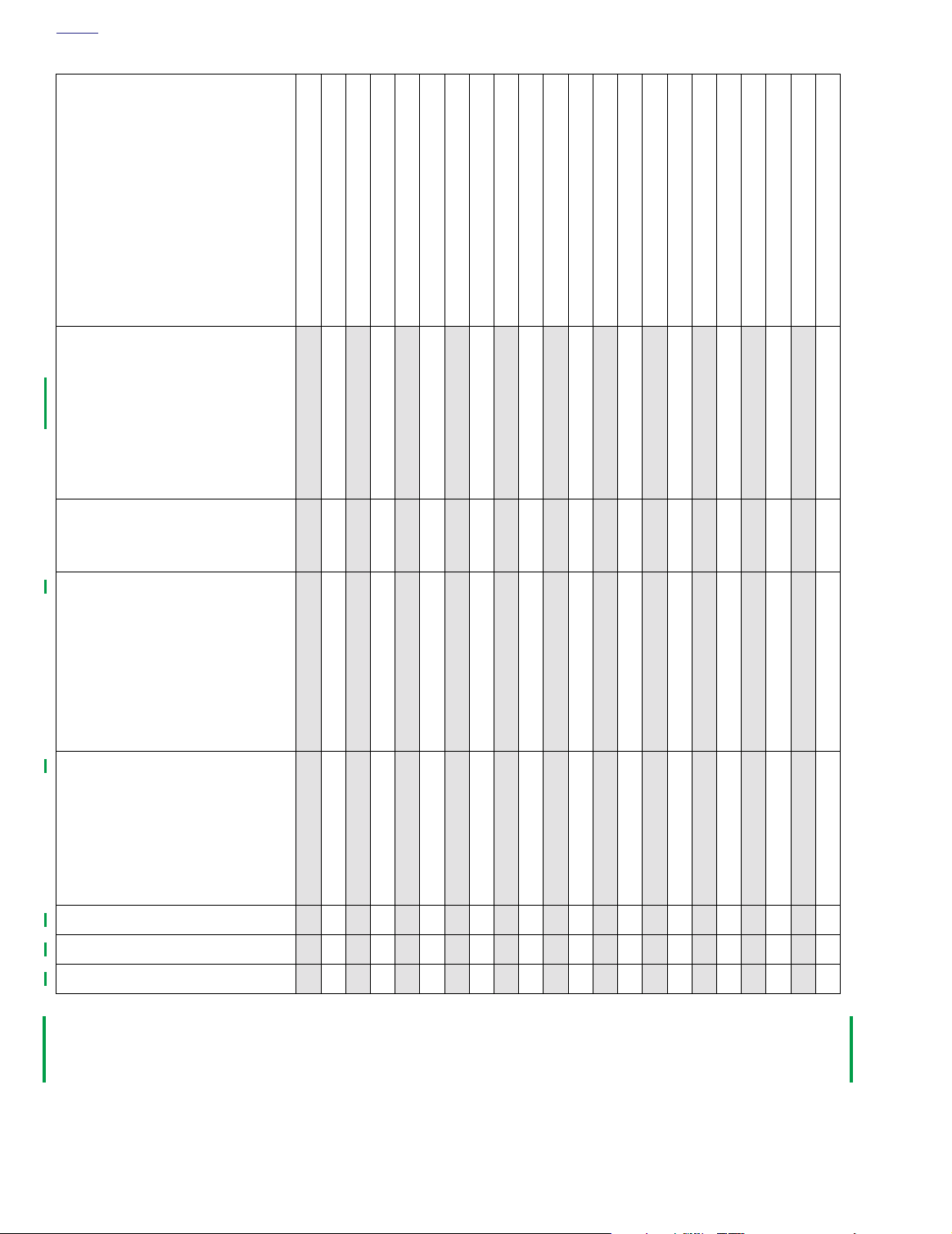

MAINTENANCE TASK

AND SERVICE DATA

Primary chain lubricant

Lubricant level:

Visible between clutch and chaincase inner wall with vehicle upright,

26 oz (768.8 ml).

Lubricant type:

Part No. 99887-84 (quart) or

99886-84 (gallon)

Table 1-1. Maintenance Schedule

1

1

1

1

2

2

1

2

5

7

0

2

5

7

0

5

0

5

0

0

0

0

0

0

M

M

I

P

R

1

4

E

6

0

R

0

0

I

0

0

D

K

K

E

M

M

R

RRRRRRRRRRRRRRRRRRRR

0

0

0

M

M

I

I

1

8

2

0

0

0

0

0

0

K

K

M

M

5

0

0

0

0

M

M

I

M

I

I

1

2

6

0

0

0

0

0

0

0

K

K

K

M

M

M

0

0

5

0

0

0

0

0

0

0

M

M

I

I

2

2

3

4

8

2

0

0

0

0

0

0

0

0

0

K

K

M

M

2

2

5

5

0

0

0

0

0

M

M

I

I

I

3

4

6

0

0

0

0

0

0

0

K

K

M

M

2

3

3

3

3

4

4

4

4

7

0

2

5

7

0

2

5

0

5

0

5

0

0

0

M

4

4

0

0

0

K

M

0

0

0

M

M

I

K

M

M

I

I

4

5

8

2

0

0

0

0

0

0

K

K

M

M

0

0

0

0

0

0

0

M

M

I

I

5

6

6

6

0

4

0

0

0

0

0

0

0

0

0

K

K

M

M

5

5

0

0

0

0

0

M

M

I

I

6

7

8

2

0

0

0

0

0

0

K

K

M

M

5

7

0

5

0

0

0

0

0

M

M

I

I

I

7

8

6

0

0

0

0

0

0

0

K

K

M

M

Clutch adjustment

Hand lever free play:

1/16-1/8 in. (1.6-3.2 mm)

Transmission lubricant (*)

Lubricant level:

Bottom edge of FULL mark on dipstick with vehicle upright.

Lubricant type:

Part No. 99892-84 (quart)

Drain plug:

14-21 ft-lbs (19.0-28.5 Nm)

Rear belt deflection inspection (*)

Deflection:

5/16-3/8 in. (7.9-9.5 mm)

Bottom strand with 10 lb. (4.5kg)

upward force.

Specialty tool:

Part No. HD-35381

Rear belt and sprocket (*)

Steering head bearing

Front fork oil

X

R

II

I

A

X X X X X X X X X X

IRIRIRIRIRIRIRIRIRIR

IIIIIIIIIIIIIIIIIIII

I I I I I I I I I I

A A D A A

R

R

Tab le Code:

A

- Adjust.

I

- Inspect, and if necessary, correct, adjust, clean or replace.

L

- Lubricate with specified lubricant.

R

- Replace or change.

1-2 2003 Dyna Police: Maintenance

T

- Tighten to proper torque.

X

-Perform.

D

- Disassemble, lubricate and inspect.

(*)- Also perform prior to storage or annually.

Page 5

HOME

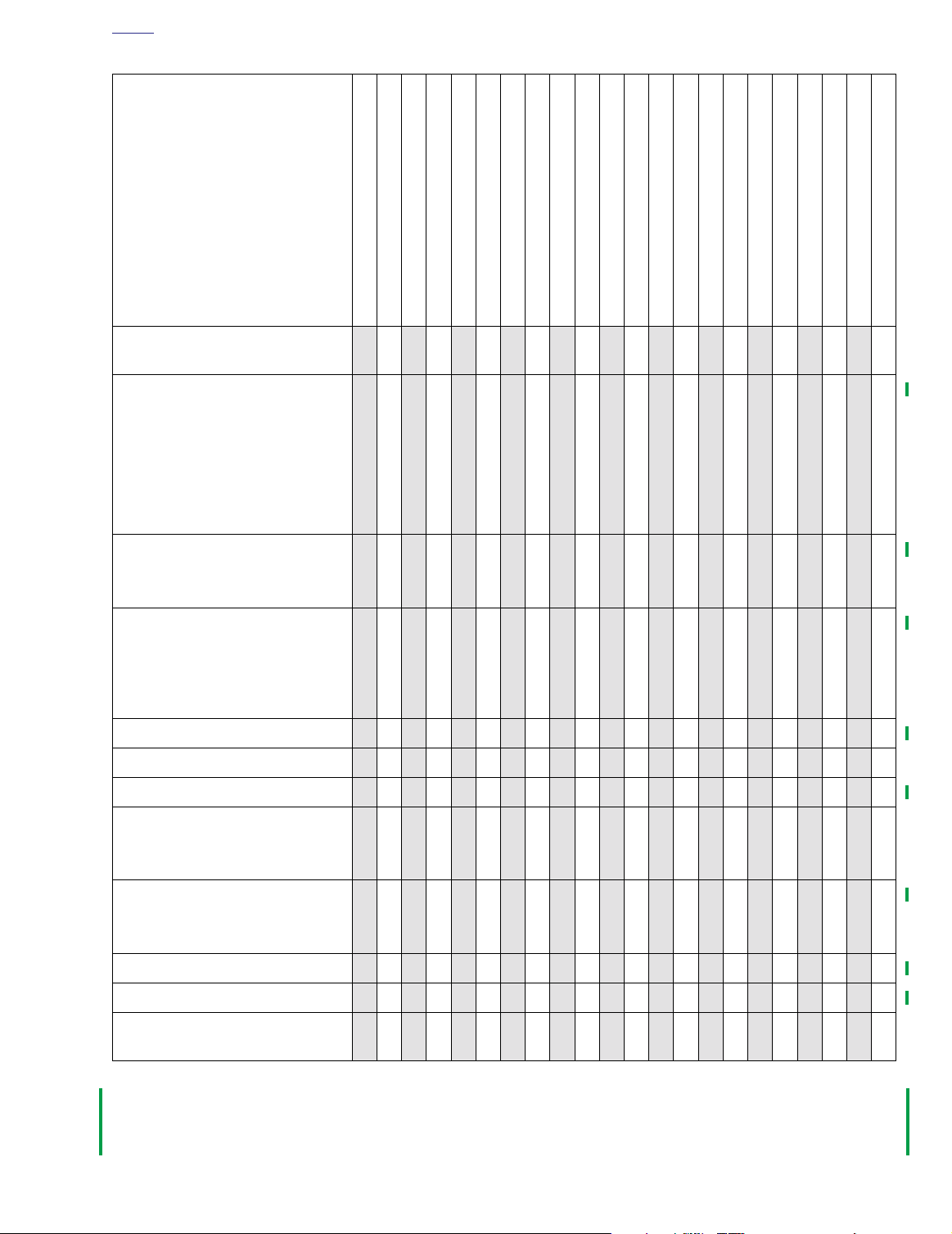

MAINTENANCE TASK

AND SERVICE DATA

Table 1-1. Maintenance Schedule

1

1

1

1

2

2

1

2

5

7

0

2

5

7

0

5

0

5

0

5

0

0

0

0

0

0

M

P

R

1

E

6

R

0

I

0

D

K

E

M

0

M

M

I

I

4

8

0

0

0

0

0

0

K

K

M

M

0

0

0

M

M

I

I

1

1

2

6

0

0

0

0

0

0

K

K

M

M

0

0

0

0

0

M

M

I

I

2

2

0

4

0

0

0

0

0

0

K

K

M

M

0

5

0

0

0

0

0

M

M

I

I

2

3

8

2

0

0

0

0

0

0

K

K

M

M

2

2

5

5

0

0

0

0

0

M

M

I

I

I

3

4

6

0

0

0

0

0

0

0

K

K

M

M

2

3

3

3

3

4

4

4

4

7

0

2

5

7

0

2

5

0

5

0

5

0

0

0

0

0

M

M

I

4

4

4

8

0

0

0

0

0

0

K

K

M

M

0

0

0

M

M

I

I

5

5

2

6

0

0

0

0

0

0

K

K

M

M

0

0

0

0

0

M

M

I

I

6

6

0

4

0

0

0

0

0

0

K

K

M

M

5

5

0

0

0

0

0

M

M

I

I

6

7

8

2

0

0

0

0

0

0

K

K

M

M

5

7

0

5

0

0

0

0

0

M

M

I

I

I

7

8

6

0

0

0

0

0

0

0

K

K

M

M

Check air suspension - pressure,

operation and leakage

Spark plugs (*)

Plug type:

No. 6R12

Plug gap:

0.038-0.043 (0.97-1.09 mm)

Plug torque:

11-18 ft-lbs (14.9-24.4 Nm)

Air cleaner filter (*)

Cover screw torque:

36-60

in-lbs

(4.1-6.8 Nm)

Lubricate controls (*)

Front brake hand lever, clutch hand

lever, throttle control cables, clutch

control cable, rear brake pedal and

jiffy stand

Shift Lever

Operation of throttle controls

Enrichener operation

I

I

I

L

L

I

I

I I I I I I I I I I

I R I R I R I R I R

IIIIIIIIIIIIIIIIIIII

L L L L L L L L L L

L L L L L L L L L L

IIIIIIIIIIIIIIIIIIII

IIIIIIIIIIIIIIIIIIII

Engine idle speed

Idle speed:

950-1050 RPM

Fuel supply valve filter screen

Filter hex fitting torque:

15-20 ft-lbs (20.3-27.1 Nm)

Fuel system lines and fittings (*)

Repack rear fork bearings

Hinges, latches - saddlebags,

fuel door

Tab le Code:

A

- Adjust.

I

- Inspect, and if necessary, correct, adjust, clean or replace.

L

- Lubricate with specified lubricant.

R

- Replace or change.

I

I

L

I I I I I I I I I I

X

IIIIIIIIIIIIIIIIIIII

X

L L L L L L L L L L

T

- Tighten to proper torque.

X

-Perform.

D

- Disassemble, lubricate and inspect.

(*)- Also perform prior to storage or annually.

X

X

2003 Dyna Police: Maintenance 1-3

Page 6

HOME

MAINTENANCE TASK

AND SERVICE DATA

Check oil and brake lines for leaks

Table 1-1. Maintenance Schedule

1

1

1

1

2

2

1

2

5

7

0

2

5

7

0

5

0

5

0

0

0

0

0

0

M

M

I

P

R

1

4

E

6

0

R

0

0

I

0

0

D

K

K

E

M

M

I

0

0

0

M

M

I

I

1

8

2

0

0

0

0

0

0

K

K

M

M

IIIIIIIIIIIIIIIIIIII

5

0

0

0

0

M

M

I

M

I

I

1

2

6

0

0

0

0

0

0

0

K

K

K

M

M

M

0

0

5

0

0

0

0

0

0

0

M

M

I

I

2

2

3

4

8

2

0

0

0

0

0

0

0

0

0

K

K

M

M

2

2

5

5

0

0

0

0

0

M

M

I

I

I

3

4

6

0

0

0

0

0

0

0

K

K

M

M

2

3

3

3

3

4

4

4

4

7

0

2

5

7

0

2

5

0

5

0

5

0

0

0

M

4

4

0

0

0

K

M

0

0

0

M

M

I

K

M

M

I

I

4

5

8

2

0

0

0

0

0

0

K

K

M

M

0

0

0

0

0

0

0

M

M

I

I

5

6

6

6

0

4

0

0

0

0

0

0

0

0

0

K

K

M

M

5

5

0

0

0

0

0

M

M

I

I

6

7

8

2

0

0

0

0

0

0

K

K

M

M

5

7

0

5

0

0

0

0

0

M

M

I

I

I

7

8

6

0

0

0

0

0

0

0

K

K

M

M

Engine mounts

Operation of all electrical equipment and switches (*)

All critical fasteners except engine

head bolts

Road test

Tab le Code:

A

- Adjust.

I

- Inspect, and if necessary, correct, adjust, clean or replace.

L

- Lubricate with specified lubricant.

R

- Replace or change.

I

I

IIIIIIIIIIIIIIIIIIII

T

X

XXXXXXXXXXXXXXXXXXXX

T T T T T

I I I I

T

- Tighten to proper torque.

X

-Perform.

D

- Disassemble, lubricate and inspect.

(*)- Also perform prior to storage or annually.

1-4 2003 Dyna Police: Maintenance

Page 7

HOME

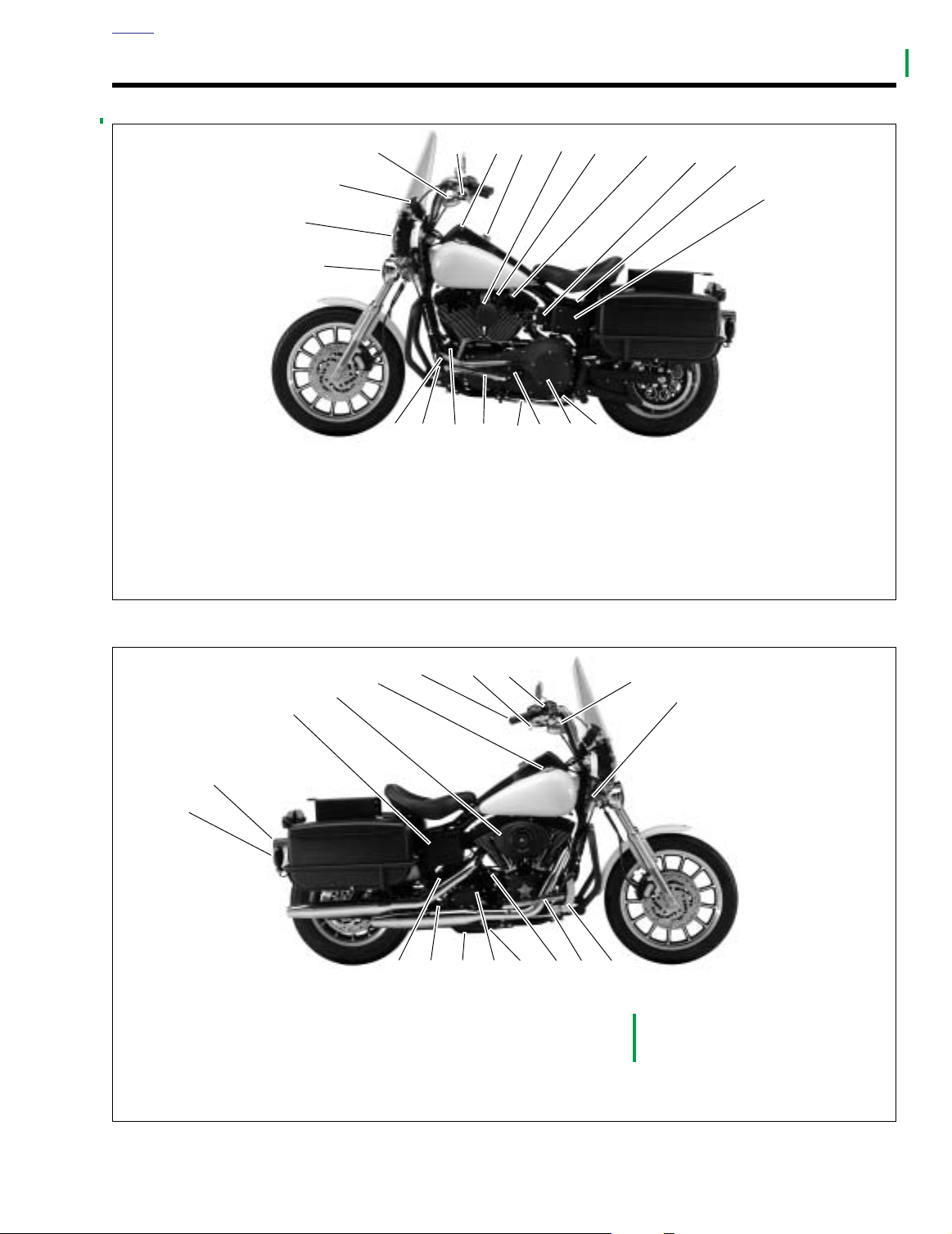

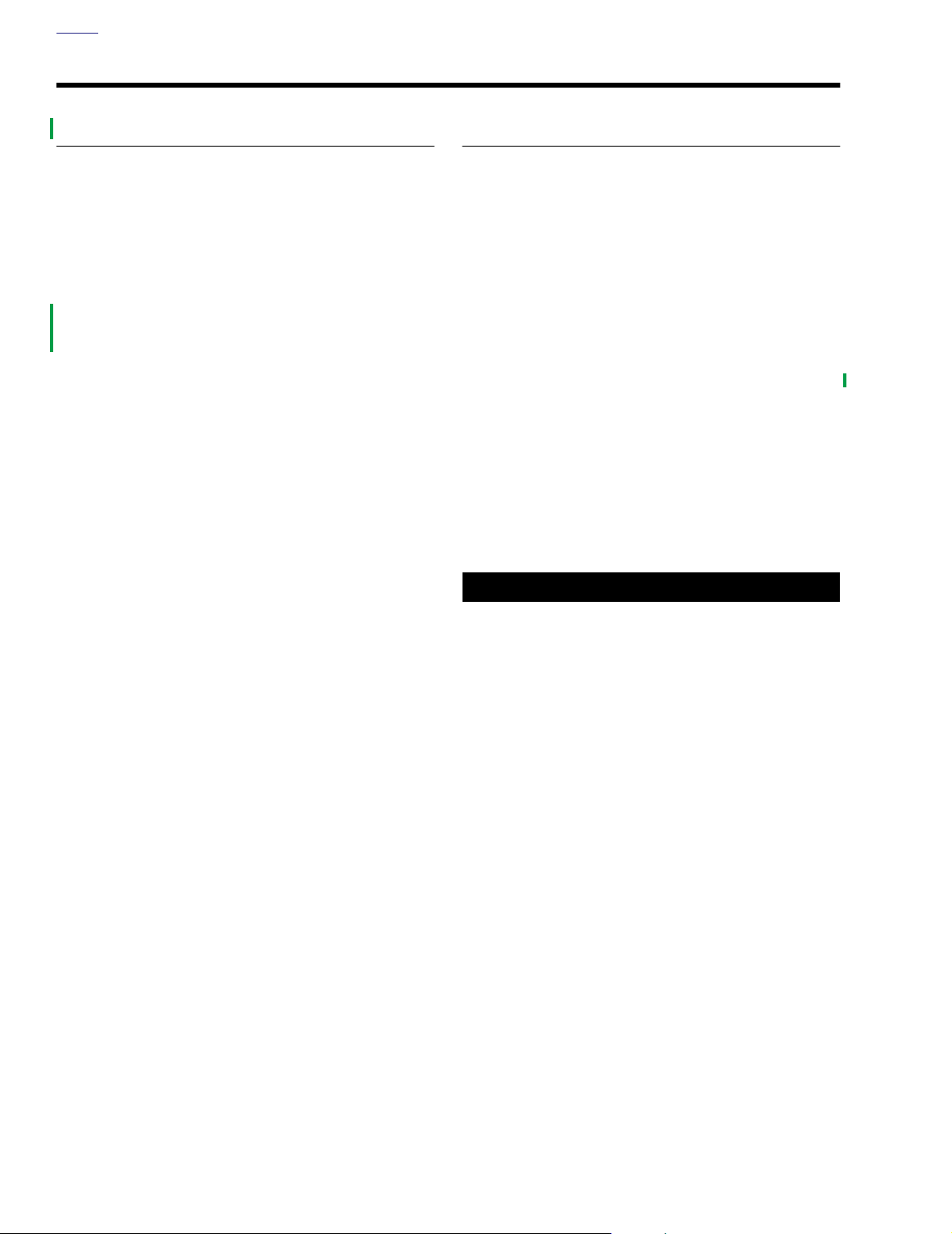

9845

1. Rear turn signal lamp

2. Tail/stop lamp

3. Battery

4. Air cleaner

5. Fuel filler cap

6. Throttle control grip

7. Front brake hand lever

8. Front brake

master cylinder/reservoir

9. Front turn signal/running lamp

10. Fork Lock

11. Rear brake pedal

12. Footrest

13. Engine oil fill plug/dipstick

14. Engine oil pan drain

15. Transmission fill plug

16. Transmission drain plug

17. Rear brake

master cylinder/reservoir

18. Electric starter motor

10

11121314

15161718

7

9

6

5

4

3

2

1

8

SIDE VIEWS 1.2

9844

3

2

1

1. Pursuit lamp

2. Headlamp

3. Speedometer/tachometer

4. Front turn signal/running lamp

5. Clutch hand lever

6. Fuel gauge

7. Ignition/light key switch

8. Horn

17

76

16

4

21

9. Enrichener

10. Fuel supply valve

11. Ignition coil

12. Accessory connector

13. Main 30 amp circuit breaker,

5

20

(under seat)

system fuses/relays (under

electrical panel cover)

19

18

8

15

14

9

10

11

12

13

14. Primary drain plug

15. Clutch inspection cover

16. Primary chain inspection cover

17. Jiffy stand

18. Footrest

19. Engine oil filter

20. Voltage regulator

21. Gear shifter lever

Figure 1-1. FXDP (Left Side View)

Figure 1-2. FXDP (Right Side View)

2003 Dyna Police: Maintenance 1-5

Page 8

HOME

NOTES

1-6 2003 Dyna Police: Maintenance

Page 9

T

able Of Contents

CHASSIS 2

SUBJECT PAGE NO.

2.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Torque Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.3 Vehicle Identification Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.4 Seat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.5 Saddlebags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.6 Windshield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.7 Pursuit Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.8 Footboards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.9 Radio Mounting Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

NOTE

This section provides information unique to the FXDP police model motorcycle. Any information not presented in this supplement can be found in the Dyna Models Service Manual.

Page 10

Page 11

2

HOME

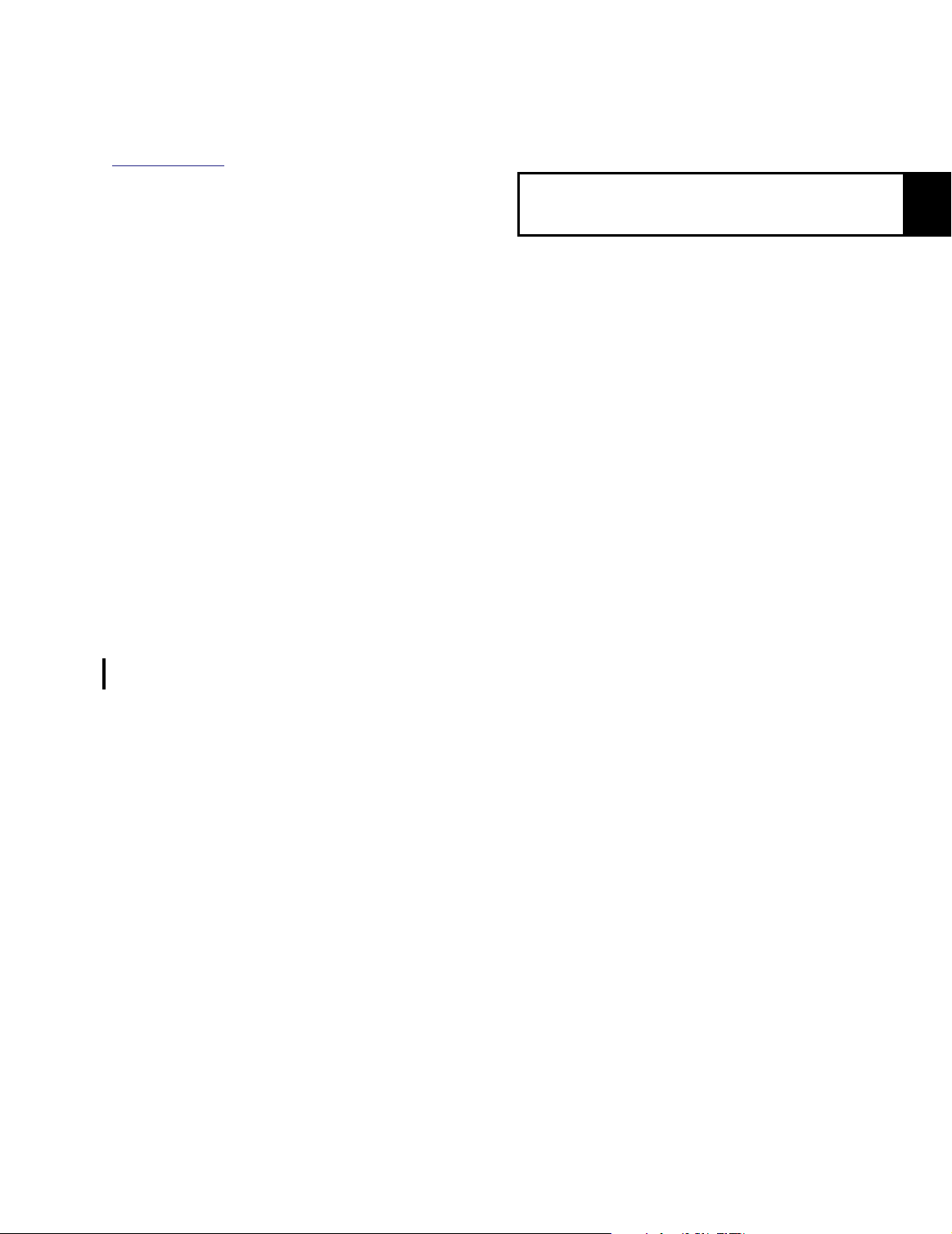

SPECIFICATIONS 2.1

Table 2-1. Capacities

FUEL TANK

TOTAL

gal. liter gal. liter qt. liter oz. liter oz. liter oz. liter

5.2 19.68 1.1 4.16 3.0 2.84 24 0.71 26 0.77 11.5 0.34

FUEL TANK

RESERVE

OIL TANK

W/FILTER

TRANSMISSION

(APPROX.)

PRIMARY

CHAINCASE

FRONT

FORKS

Table 2-2. Dimensions

WHEELBASE

in. mm in. mm in. mm in. mm in. mm in. mm in. mm

63.5 1612.9 91.6 2326.6 33.5 850.9 5.5 139.7 47.5 1206.5 31.0 787.4 28.0 711.2

OVERALL

LENGTH

OVERALL

WIDTH

ROAD

CLEARANCE

OVERALL

HEIGHT

SADDLE HEIGHT

Solo Seat

Frame Mount

Seat

Table 2-3. Weight

DRY WEIGHT

lb. kg lb. kg lb. kg lb. kg

697.4 316.3 1200.0 544.3 460.0 208.6 740.0 335.7

NOTE

Gross vehicle weight rating (GVWR) (maximum allowable

loaded vehicle weight) and corresponding gross axle weight

rating (GAWR) are given on a label located on the frame

steering head.

GVWR GAWR FRONT GAWR REAR

Table 2-4. Tire Data

TIRE LOCATION SIZE

Front MT9019 Dunlop D402F PT 30 psi (206 kPa)

Rear MT90B16 Dunlop D402 PT 36 psi (248 kPa)

MANUFACTURER’S

DESIGNATION

TIRE PRESSURE (Cold)

2003 Dyna Police: Chassis 2-1

Page 12

HOME

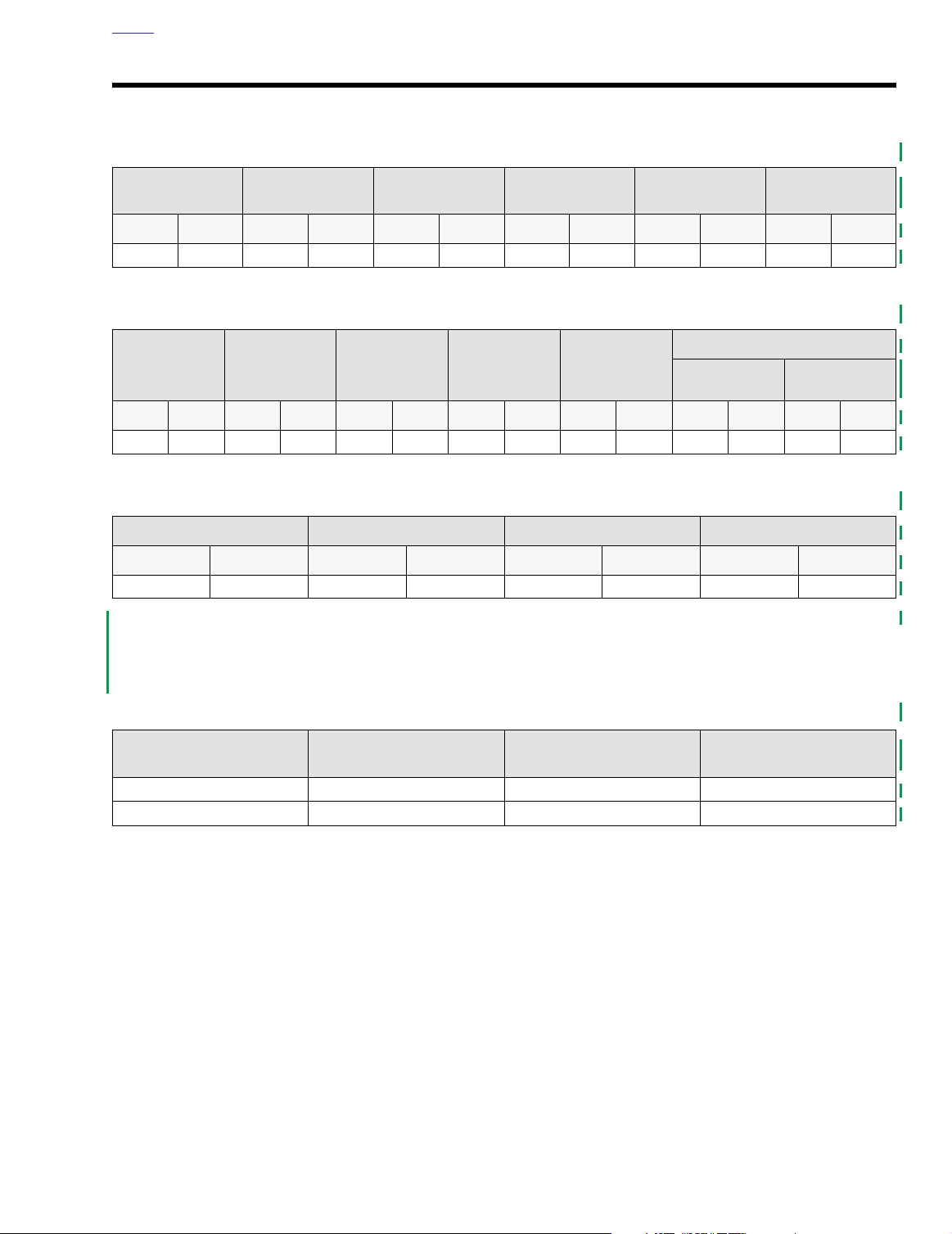

TORQUE VALUES 2.2

ITEM

Footboard mounting nuts 84-108

Footboard support mounting

bolts

Front seat mounting nut 120-216

Lower engine guard mounting

nuts

Pursuit lamp mounting bracket

screw

Radio mounting bracket screws 12-18 ft-lbs 16.3-24.4 Nm page 2-14

Rear seat mounting nuts 12-18 ft-lbs 16.3-24.4 Nm page 2-4

Saddlebag guard mounting nut 25-30 ft-lbs 33.9-40.7 Nm page 2-6

Saddlebag guard mounting

screw

Saddlebag mounting acorn nut 96-120

Shock mount stud nut 25-30 ft-lbs 33.9-40.7 Nm page 2-6

Tu rn signal mounting nut 12-15 ft-lbs 16.3-20.3 Nm page 2-6

25-35 ft-lbs 33.9-47.5 Nm page 2-12

18-22 ft-lbs 24.4-29.8 Nm page 2-12

30-35 ft-lbs 40.7-47.5 Nm page 2-10

12-18 ft-lbs 16.3-24.4 Nm page 2-6

TORQUE NOTES

in-lbs

in-lbs

in-lbs

9.5-12.2 Nm page 2-12

13.6-24.4 Nm page 2-4

10.8-13.6 Nm page 2-6

2-2 2003 Dyna Police: Chassis

Page 13

HOME

VEHICLE IDENTIFICATION NUMBER 2.3

GENERAL

See Figure 2-1. A 17-digit serial number, or Vehicle Identification Number (V.I.N.), is stamped on the top of the right front

frame downtube.

A label bearing the V.I.N. number is affixed to the right front

frame downtube.

Market Designation

Manufacturer and Make

Motorcycle Type

Model Designation

Engine

Harley-Davidson

V= Twin Cam 88TM (Carbureted)

An abbreviated V.I.N. is stamped on the left side crankcase at

the base of the cylinders.

NOTE

Always give the complete 17 digit V.I.N. when ordering parts

or making inquiries about your motorcycle.

1=Domestic

5=International

1=Heavyweight

GK = FXDP

Varies: 1-8

Model Year

K=Manufactured in Kansas City, MO

3=2003

Sequential Number

1HD1GK V 1* 3 K 100000

*Varies - can be 0-9 or X

Sample V.I.N. as it appears on the steering head - 1HD1GKV103K100000

Sample abbreviated V.I.N. as it appears on the left side crankcase - GKV3100000

Figure 2-1. Vehicle Identification Number (V.I.N.)

2003 Dyna Police: Chassis 2-3

Page 14

HOME

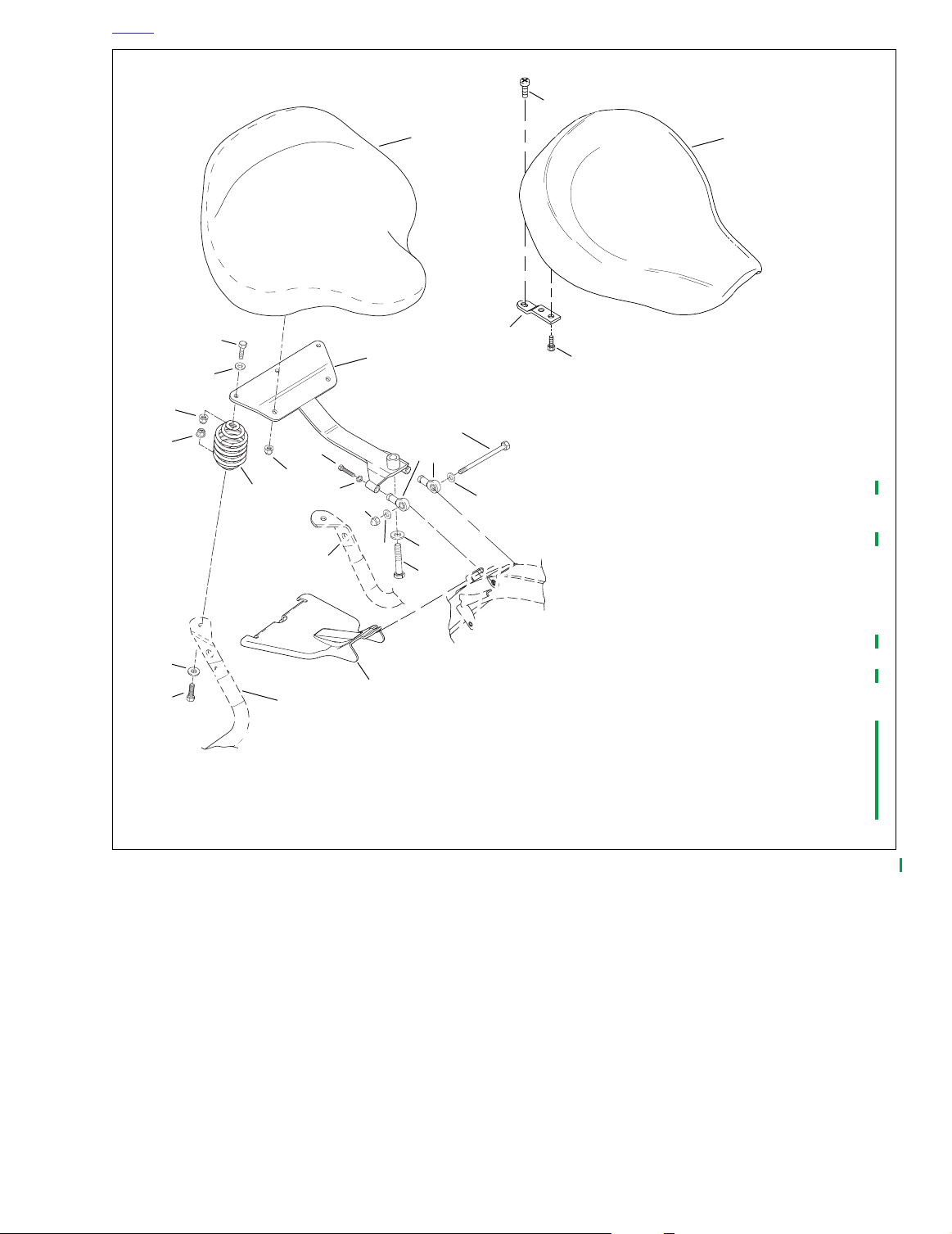

SEAT 2.4

REMOVAL

Solo Seat

1. See Figure 2-2. Remove screws (1), washers (2) and

nuts (5) from right and left side saddlebag guards.

2. Remove acorn nut (17) and washer (16).

3. Remove fuel tank screw (11) and washer (13) from rod

end (12), fuel tank mounting tabs, and frame backbone.

NOTE

If switching from solo seat to frame mounted seat, be sure to

remove seat cover (26).

Frame Mount Seat

1. See Figure 2-2. Remove screw (23) to detach seat from

fender.

2. Slide seat rearward to remove from frame.

INSTALLATION

Solo Seat

1. See Figure 2-2. Place rod ends (12) over rear fuel tank

mounting tabs.

2. Insert screw (11) with washer (13) through rod ends (12),

fuel tank mounting tabs, and frame backbone.

3. Loosely install acorn nut (17) and washer (16) on screw

(11).

4. Install screws (1), washers (2) and nuts (5) on right and

left side saddlebag guards. Tighten nuts to 12-18 ft-lbs

(16.3-24.4 Nm).

5. Tighten acorn nut (17) to 120-216

in-lbs

(13.6-24.4 Nm).

Frame Mount Seat

1. See Figure 2-2. Ver ify that seat bracket (24) is securely

fastened to bottom of seat. Position seat on frame with

bracket at rear.

2. Slide seat forward until tongue on front of seat bottom

engages bracket on frame.

3. Install screw (23) to fasten seat bracket to top of rear

fender. Tighten mounting bracket screw.

11WARNING1WARNING

After installing seat, pull upward on front of seat to be

sure it is locked in position. if seat is loose, it could shift

during vehicle operation and startle the rider, causing

loss of control and death or serious injury.

4. Pull up on seat to verify that it is locked in place.

2-4 2003 Dyna Police: Chassis

Page 15

HOME

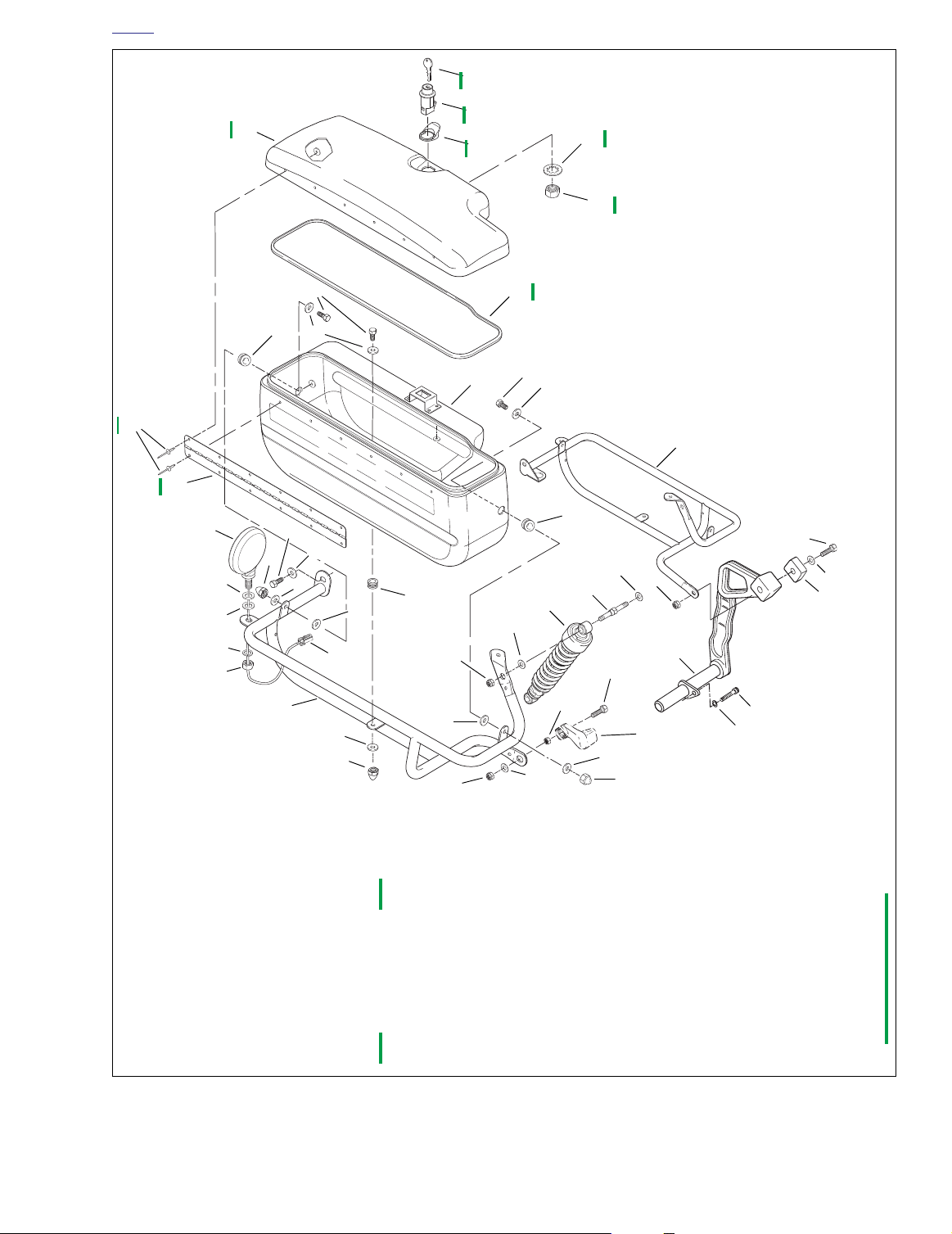

p0080a2x

23

9

8

10

24

25

22

7

6

11

5

20

12

21

19

18

17

16

13

14

15

4

2

1

3

26

1. Screw (2)

2. Washer (2)

3. Right saddlebag guard

4. Spring (2)

5. Nut (2)

6. Nut (2) @12-18 ft-lbs (16.3-24.4 Nm)

7. Washer (2)

8. Screw (2)

9. Seat, solo

10. Seat support bracket

11. Fuel tank screw

12. Rod end (2)

13. Washer

14. Washer

15. Screw @ 18-22 ft-lbs (24.4-29.8 Nm)

16. Washer

17. Acorn nut @ 120-216 in-lbs (13.6-24.4 Nm)

18. Lockwasher (2)

19. Left saddlebag guard

20. Screw (2) @ 18-22 ft-lbs (24.4-29.8 Nm)

21. Nut (2) @ 96-120 in-lbs (10.8-13.6 Nm)

22. Seat, frame mount

23. Screw, frame mount

24. Bracket, seat - frame mount

25. Screw, frame mount (2)

26. Cover seat, plastic - spring mount

Figure 2-2. Seat

2003 Dyna Police: Chassis 2-5

Page 16

HOME

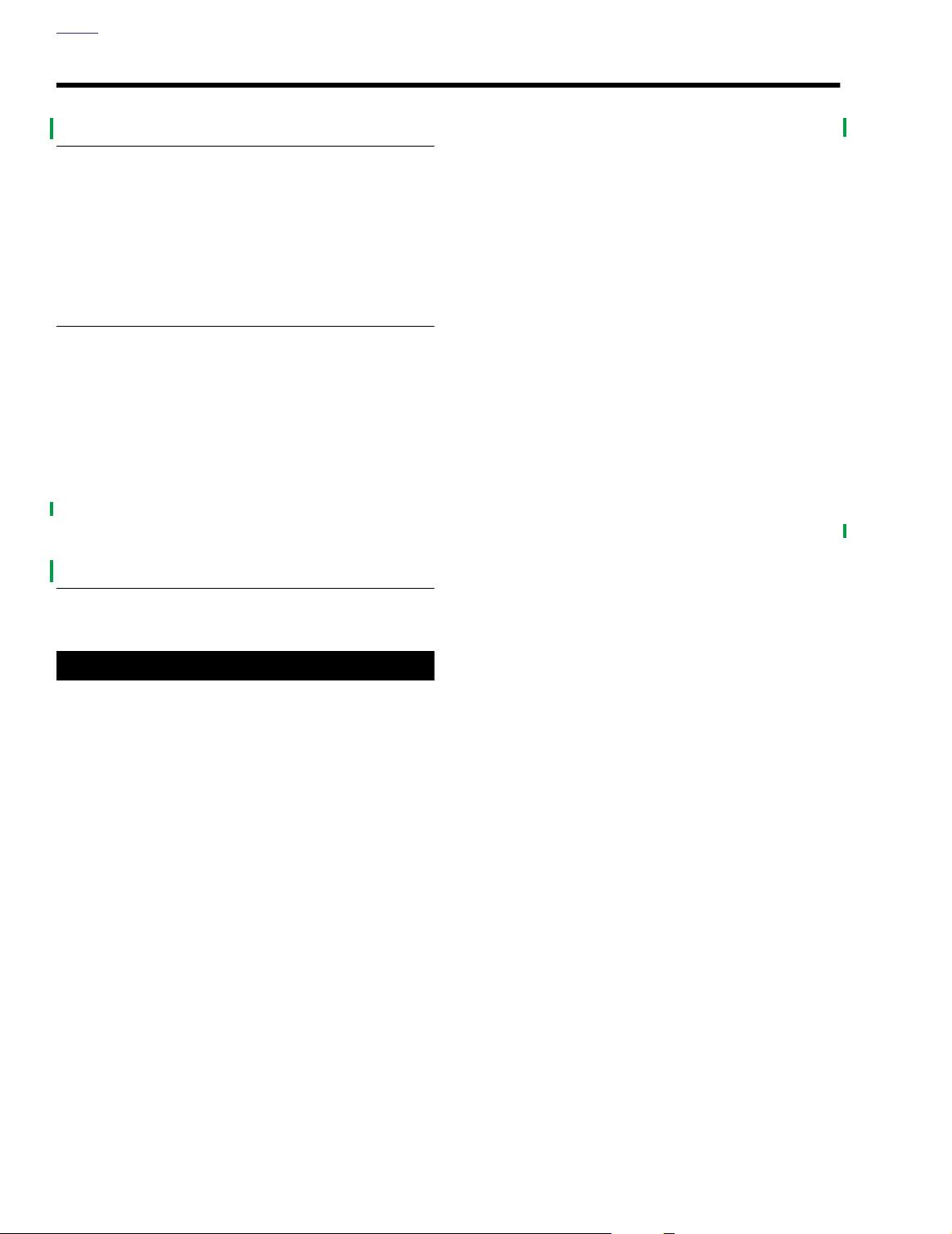

SADDLEBAGS 2.5

REMOVAL

1. See Figure 2-3. Remove acorn nuts (1) and washers (2)

from front, middle and rear of saddlebag (16).

2. Remove screws (15) and washers (14) from inside of

saddlebag. Note position of washers (7) between saddlebag and saddlebag guard (3, 17).

3. Remove saddlebag.

INSTALLATION

1. See Figure 2-3. Place saddlebag (16) into position inside

saddlebag guards (3, 17).

NOTE

In next step, be sure washers (7) are installed in between

saddlebag and saddlebag guard.

2. Insert screws (15) and washers (14) through saddlebag

grommets (8) and saddlebag guards.

3. Install acorn nuts (1) and washers (2) at front, middle

and rear of saddlebag (16). Tighten nuts to 96-120

(10.8-13.6 Nm).

in-lbs

SADDLEBAG GUARDS

Installation

1. See Figure 2-3. Place saddlebag mount into position on

shock mount stud (25).

2. Loosely install washer (11) screw (12), and saddlebag

mount to fender.

3. On left side, insert screw (18) and washer (19) thru left

saddlebag guard (17) and upright bracket (22). Install nut

(23) and tighten securely.

4. On right side, install washer (31) and nut (32) on screw

(27). Tighten to 25-30 ft-lbs (33.9-40.7 Nm).

5. Install nut (30) on shock mount stud (25). Tighten to 2530 ft-lbs (33.9-40.7 Nm).

6. Tighten screw (12) to 12-18 ft-lbs (16.3-24.4 Nm).

7. Install washer (10) and rubber washer (9) over threads

on turn signal (13).

8. Install turn signal thru mounting tab on saddlebag guard.

9. Install lockwasher (5) and nut (4) on turn signal. Tighten

nut to 12-15 ft-lbs (16.3-20.3 Nm).

10. Insert wire terminals into connector (6).

11. Connect turn signal connector.

12. Install pole lamp. See 8.5 POLE LAMP.

13. Install saddlebags (16).

14. Connect negative battery cable.

Removal

11WARNING1WARNING

To protect against shock and accidental start-up of vehicle, disconnect the negative battery cable before proceeding. Inadequate safety precautions could result in

death or serious injury.

1. Disconnect negative battery cable.

2. Remove saddlebag (16).

3. See 8.5 POLE LAMP. Remove pole lamp.

4. See Figure 2-3. Disconnect turn signal connector (6) [18,

19].

5. Remove wire terminals from turn signal connector.

6. Remove nut (4) and washer (5) from turn signal (13).

7. Remove turn signal (13), washer (10) and rubber washer

(9) from saddlebag guard (3, 17).

8. Remove nut (30) from shock mount stud (25).

9. On left side, remove screw (18) washer (19) and nut (23)

from upright bracket (22).

10. On right side, remove nut (32) and washer (31) from

screw (27).

11. Remove screw (12) and washer (11) from rear fender.

12. Remove saddlebag mount.

2-6 2003 Dyna Police: Chassis

Page 17

HOME

p0081a2x

35

39

38

13

1

10

9

5

4

1. Acorn nut (6)

2. Washer (6)

3. Right saddlebag guard

4. Nut (2)

5. Lockwasher (2)

6. Connector (2) [18, 19]

7. Washer (4)

8. Grommet (6)

9. Rubber washer (2)

10. Washer (2)

11. Washer (2)

12. Screw (2)

13. Turn signal (2)

14. Washer (6)

15. Screw (6)

42

41

40

36

37

16

34

15

14

15

8

14

17

8

12

18

11

24

2

7

8

25

26

23

19

33

29

6

3

2

1

16. Saddlebag (2)

17. Left saddlebag guard

18. Screw

19. Washer

20. Screw @ 25-30 ft-lbs

21. Washer

22. Upright bracket

23. Nut

24. Washer (2)

25. Shock mount stud (2)

26. Shock absorber (2)

27. Screw

28. Nut @ 25-30 ft-lbs

30

7

32

(33.9-40.7 Nm)

(33.9-40.7 Nm)

27

28

2

31

22

Motorcycle

frame

20

21

1

29. Washer (2)

30. Nut (2)

31. Washer

32. Nut

33. Spacer

34. Gasket (2)

35. Saddlebag lid (2)

36. Lockwasher, internal (2)

37. Nut (2)

38. Hinge (2)

39. Rivet, blind (32)

40. Tab pull, latch (2)

41. Lock mechanism

42. Key

Figure 2-3. Saddlebags and Saddlebag Guards

2003 Dyna Police: Chassis 2-7

Page 18

HOME

WINDSHIELD 2.6

REMOVAL

1. Cover the front fender with suitable material to protect

the fender paint.

2. See Figure 2-4. Loosen, but do not remove, four screws

(2) securing mounting brackets (1) to windshield clamps

(6).

3. Carefully pull windshield straight forward and up slightly,

so that mounting bracket slots (5) clear screws. Remove

windshield.

INSTALLATION

1. See Figure 2-4. Lower windshield into position, so that

right and left windshield brackets (1) are on the outboard

side of windshield clamps (6).

11WARNING1WARNING

Do not replace the screws and washers with ordinary

hardware. The screws and washers are designed to maintain a specific clamping force which other hardware does

not provide. Use of other hardware may allow the windshield to detach during riding, which can startle the rider

and cause loss of vehicle control, which could result in

death or serious injury.

2. Slide mounting brackets rearward so screws (2) on windshield clamps fit in slots in brackets. Make sure that

mounting bracket slots are positioned between flat washers (4) and windshield clamps.

NOTE

In the next step, position windshield so that it does not contact headlamp bracket, gauges, pursuit lamp brackets, handlebars, or any other part of vehicle.

3. Adjust windshield to desired angle and position. Using a

crosswise pattern, tighten all four mounting screws.

4. Turn the front forks to the full left and full right positions to

verify that movement is unrestricted.

8857

3

1

2

5

6

1. Windshield mounting bracket (2)

2. Screw (4)

3. Lockwasher (4)

4. Flat washer (4)

5. Adjustment slot

6. Windshield clamp (4)

Figure 2-4. FXDP Windshield Mounting Bracket

4

CARE

CAUTION

Do not clean Lexan® polycarbonate in hot sun or high

temperature. Powdered, abrasive or alkaline cleanser will

damage the windshield. Never scrape the windshield

with a razor blade or other sharp instruments because

permanent damage will result. Sunlight reflections off of

the inside curvature of a windshield can, at certain times

of the day, cause extreme heat build-up on motorcycle

instruments. Exercise care in parking. Park facing the

sun, place an opaque object over the instruments, or

adjust the windshield to avoid reflections. Harley-Davidson windshields are made of Lexan®, a more durable

and distortion-resistant material than other types of

motorcycle windshield material, But Lexan® still requires

attention and care to maintain.

Do not use liquid windshield “protectors” on your

●

windshield. Although they may work well on automobile safety glass, Harley-Davidson cannot ensure the

results when used on Lexan® Harley-Davidson windshields.

Do not use benzene, paint thinner, gasoline, or other

●

types of harsh cleaning agents on windshield. They

will damage the windshield surface.

Do not use benzene, paint thinner, gasoline, lubri-

●

cants or other cleaning agents on the rubber bushings. They will damage the bushing surfaces.

2-8 2003 Dyna Police: Chassis

Page 19

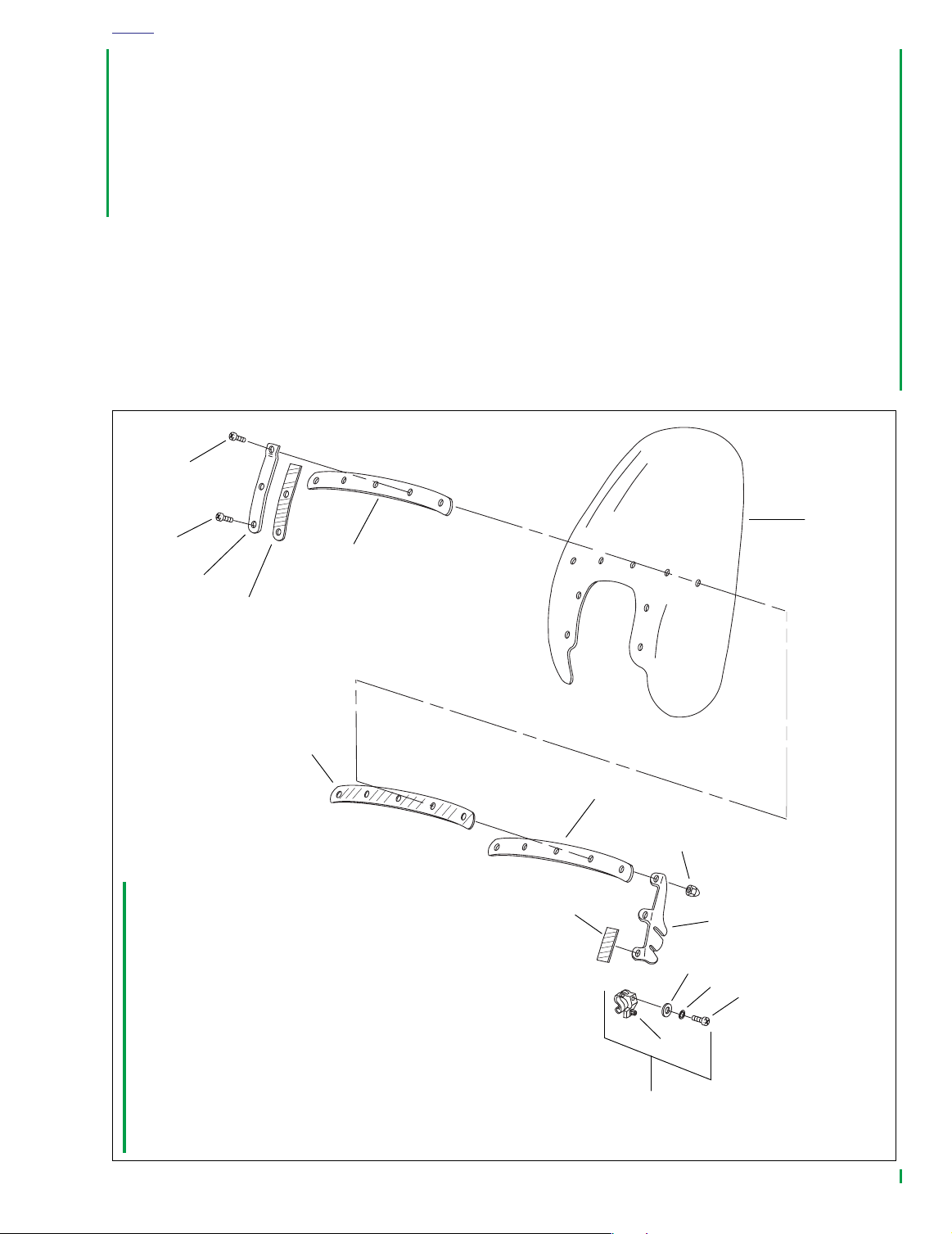

1. Shoulder screw (7)

2. Shoulder screw (2)

3. Vertical brace (2)

4. Cushion tape (vertical) (2)

5. Outer horizontal brace

6. Windshield

7. Cushion tape (inner horizontal)

8. Inner horizontal brace

9. Mounting bracket (2)

10. Cushion tape (cut to length)

11. Acorn nut (9)

12. Screw (4)

13. Lockwasher (4)

14. Flat washer (4)

15. Screw (4)

16. Windshield clamp (complete) (4)

1

2

3

4

5

6

7

8

9

10

11

12

15

16

13

14

p0114a2x

HOME

Notes

To remove minor surface scratches, use NOVUS® No. 2

●

SCRATCH REMOVER (Part No. 99836-94).

●

If you wish to use a windshield protectant on your windshield, use Harley® Glaze Polish and Sealant (Part No.

99701-84).

●

Covering the windshield with a clean, wet cloth for

approximately 15-20 minutes before washing will make

dried bug removal easier.

1. Use mild soap and warm water to wash the windshield.

2. Wipe dry with a soft, clean towel.

Figure 2-5. Windshield and Brackets

2003 Dyna Police: Chassis 2-9

Page 20

HOME

PURSUIT LAMPS 2.7

MOUNTING BRACKET REPLACEMENT

Removal

11WARNING1WARNING

To protect against shock and accidental start-up of vehicle, disconnect the negative battery cable before proceeding. Inadequate safety precautions could result in

death or serious injury.

1. Disconnect negative battery cable.

2. Remove fuel tank outer console assembly.

a. Remove the two screws securing the console above

the ignition switch.

b. Remove screw ahead of seat.

c. See Figure 2-6. Lift outer console assembly (1),

removing wiring harnesses (3) from slot (2) in front

of outer console.

3. See Figure 2-7. Disconnect pursuit lamp connector [73]

(5).

NOTE

Right pursuit lamp is connected to pin 1 of connector [73],

and left pursuit lamp is connected to pin 3.

4. Remove wire terminals from pursuit lamp connector shell

[73B] using appropriate pick tool (Snap-On TT600-3)

according to instructions in the AMP Multilock Electrical

Connector section of Appendix B in the Dyna Models

Service Manual.

5. Cut any cable straps holding pursuit lamp wiring harness

to vehicle, noting position(s) of cable strap(s) and wire

harness routing for replacement.

6. See Figure 2-8. Remove screw (7) and lamp mounting

bracket (8) with pursuit lamp assembly (1-6).

7. Repeat steps 5-6 for opposite side.

4. Install fuel tank outer console assembly.

a. See Figure 2-6. While lowering outer console

assembly (1) onto fuel tank console, push wiring

harnesses (3) into outer console slot (2).

b. Install the two screws above ignition switch and one

ahead of seat. Tighten screws securely.

5. Connect negative battery cable.

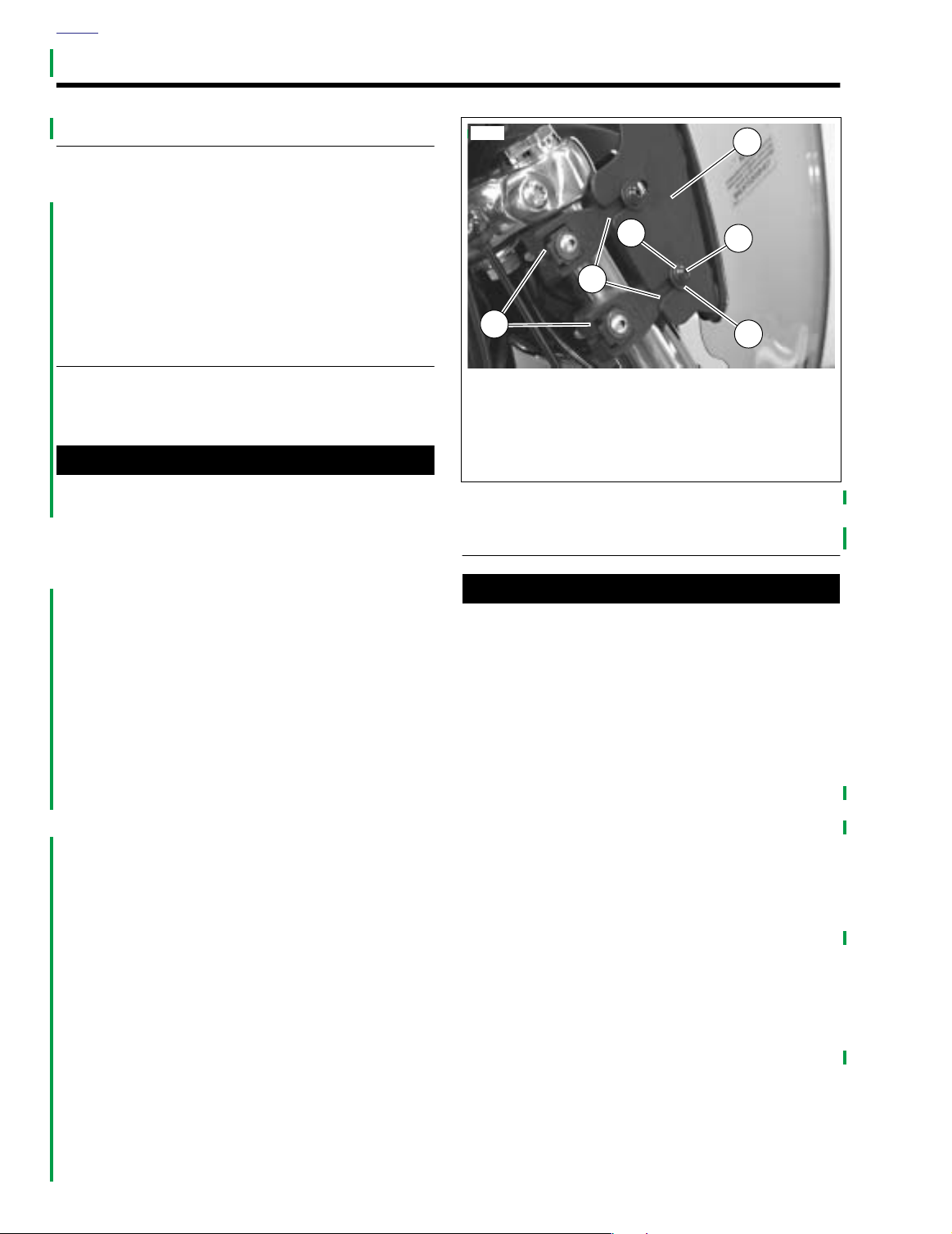

8855

3

1

1. Outer console assembly

2. Slot

3. Wiring harnesses

Figure 2-6. FXDP Console Wiring Harnesses

8856

2

1

2

3

4

Installation

1. See Figure 2-8. Mount pursuit lamp mounting bracket (8)

to lower triple clamp with screw (7). Tighten to 30-35 ftlbs (40.7-47.5 Nm). Repeat for opposite side.

2. See Figure 2-7. Route pursuit lamp wiring harnesses up

to fuel tank console. Install wire terminals into connector

[73] (5).

a. Install wire terminal from right pursuit lamp into pin 1

hole in connector shell.

b. Install wire terminal from left pursuit lamp into pin 3

hole in connector shell.

3. Connect pursuit lamp connector [73]. Secure cable with

cable straps.

2-10 2003 Dyna Police: Chassis

5

1. Right handlebar control connector [22]

2. Pursuit lamp flasher connector [69]

3. Left handlebar control connector [24]

4. Ignition switch connector [33]

5. Pursuit lamp connector [73]

Figure 2-7. FXDP Console Connectors

Page 21

HOME

11WARNING1WARNING

p0083b2x

10

7

8

1

2

5

1. Pursuit lamp shell

2. Mounting ring

3. Pursuit lamp bulb

(right side - blue, left side - red)

4. Bezel ring

5. Screw (2)

6. Nut (2)

7. Screw (2)

8. Lamp mounting bracket (2)

9. Nut (2)

10. Socket housing

Figure 2-8. FXDP Pursuit Lamp Assembly

HOUSING REPLACEMENT

To protect against shock and accidental start-up of vehicle, disconnect the negative battery cable before proceeding. Inadequate safety precautions could result in

death or serious injury.

1. Disconnect negative battery cable.

2. See Removal under 2.7 PURSUIT LAMPS, MOUNTING

BRACKET REPLACEMENT. Follow instructions and

remove pursuit lamp and mounting bracket.

9

3

4

6

3. See Figure 2-8. Remove nut (6), screw (5) and bezel ring

(4).

4. Loosen screws and disconnect two wire terminals from

back of pursuit lamp bulb (3).

5. Pull GY/BK wire through plastic conduit and pursuit lamp

housing (1).

6. Remove nut (9) securing pursuit lamp housing to mounting bracket (8).

7. Install new pursuit lamp housing onto mounting bracket

and secure with nut.

8. Temporarily mount pursuit lamp housing and mounting

bracket on lower triple clamp and check that housing

points straight ahead when vehicle is upright with front

fork pointing straight. If housing is not straight, loosen nut

and readjust housing, then retighten nut.

9. Push GY/BK wire through pursuit lamp housing, mounting bracket and plastic conduit.

10. See Installation under 2.7 PURSUIT LAMPS, MOUNT-

ING BRACKET REPLACEMENT. Follow instructions

and install pursuit lamp and mounting bracket.

11. Connect two wire terminals to pursuit lamp bulb.

12. Install pursuit lamp bulb in pursuit lamp housing. Make

certain to install mounting ring (2) between bulb and

housing. Install bezel ring. Secure with nut and screw.

13. Connect negative battery cable.

BULB REPLACEMENT

11WARNING1WARNING

To protect against shock and accidental start-up of vehicle, disconnect the negative battery cable before proceeding. Inadequate safety precautions could result in

death or serious injury.

1. Disconnect negative battery cable.

2. See Figure 2-8. Remove nut (6), screw (5) and bezel ring

(4).

3. Loosen screws and disconnect two wire terminals from

back of pursuit lamp bulb (3).

4. Connect two wire terminals to new pursuit lamp bulb.

5. Install pursuit lamp bulb in pursuit lamp housing (1).

Make certain to install mounting ring (2) between bulb

and housing. Install bezel ring. Secure with nut and

screw.

6. Connect negative battery cable.

2003 Dyna Police: Chassis 2-11

Page 22

HOME

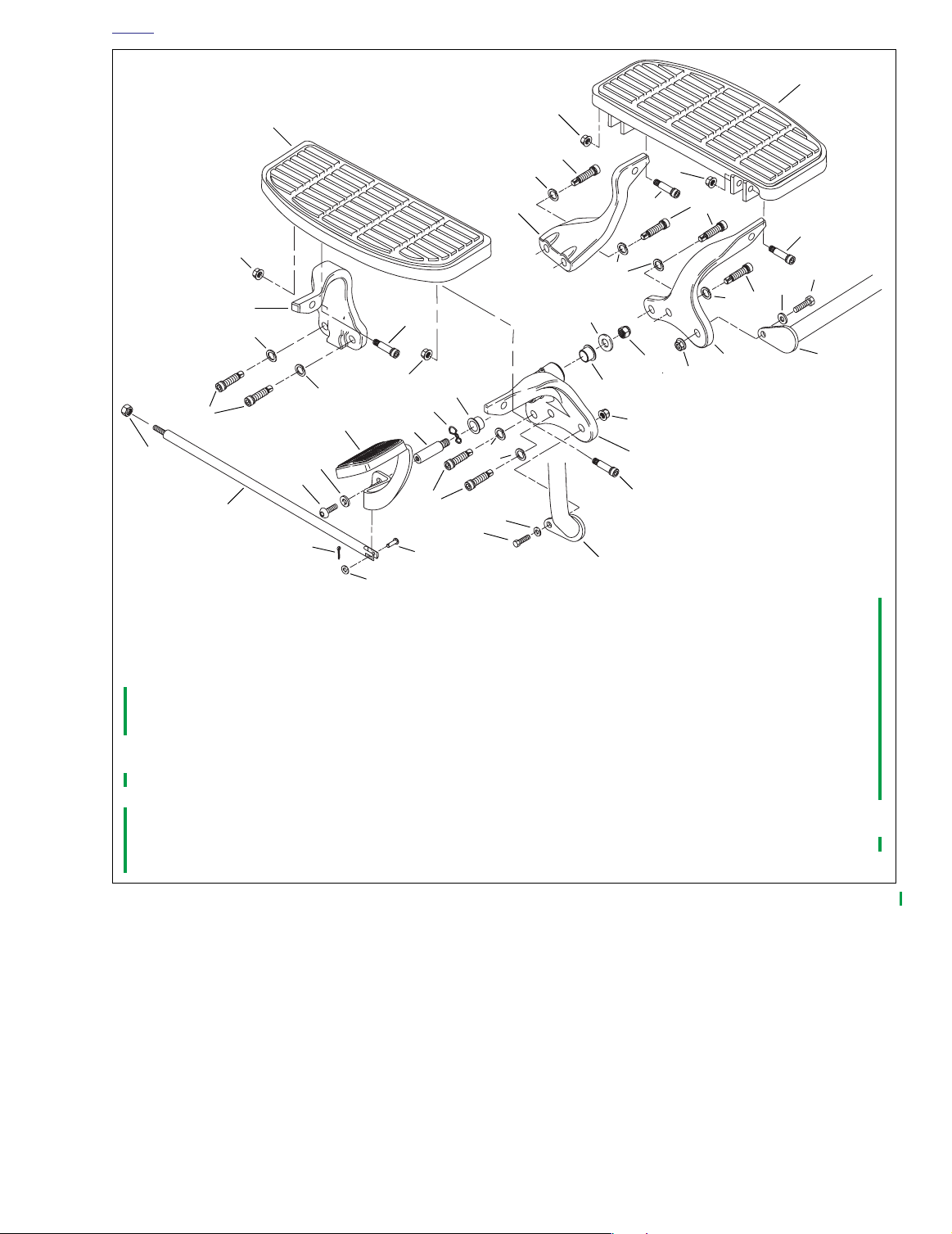

FOOTBOARDS 2.8

REMOVAL

Left Side, Footboard Only

1. See Figure 2-9. Remove two screws (8) and nuts (11)

securing footboard (14) to footboard support brackets

(13 and 18).

2. Remove footboard from brackets.

Right Side, Footboard Only

1. See Figure 2-9. Remove two screws (8) and nuts (11)

securing footboard (12) to footboard support brackets

(10 and 23).

2. Remove footboard from brackets.

Left Side Footboard Assembly

1. See Figure 2-9. Remove screw (15), washer (16) and nut

(19) securing left engine guard mount (17) to left front

footboard support (18).

2. Remove bolts (6) and lockwashers (7) securing left front

footboard support (18) and left rear footboard support

(13) to frame.

Right Side Footboard Assembly

1. See Figure 2-9. Remove cotter pin (3) and washer (2)

from clevis pin (1).

2. Remove clevis pin from push rod (5).

3. Remove screw (29), washer (30) and nut (31) securing

right engine guard mount (24) to right front footboard

support (23).

4. Remove bolts (6) and lockwashers (7) securing right

front footboard support (23) and right rear footboard support (10) to frame.

INSTALLATION

Left Side, Footboard Only

1. See Figure 2-9. Mount footboard (14) to footboard support brackets (13 and 18) with two screws (8) and nuts

(11).

2. Tighten nuts to 84-108 in-lbs (9.5-12.2 Nm).

Right Side, Footboard Only

1. See Figure 2-9. Mount footboard (12) to footboard support brackets (10 and 23) with two screws (8) and nuts

(11).

2. Tighten nuts to 84-108 in-lbs (9.5-12.2 Nm).

Left Side Footboard Assembly

1. See Figure 2-9. Secure left rear footboard support (13)

and left front footboard support (18) to frame.

a. Install bolts (6) and lockwashers (7).

b. Tighten bolts to 25-35 ft-lbs (33.9-47.5 Nm).

2. Secure left engine guard mount (17) to left front footboard support.

a. Install screw (15), washer (16), and nut (19).

b. Tighten nut to 18-22 ft-lbs (24.4-29.8 Nm).

Right Side Footboard Assembly

1. See Figure 2-9. Secure right rear footboard support (10)

and right front footboard support (23) to frame.

a. Install bolts (6) and lockwashers (7).

b. Tighten bolts to 25-35 ft-lbs (33.9-47.5 Nm).

2. Secure right engine guard mount (24) to right front footboard support (23).

a. Install screw (29), washer (30), and nut (31).

b. Tighten nut to 18-22 ft-lbs (24.4-29.8 Nm).

3. Install push rod (5) over mounting hole in brake pedal

(4).

4. Push clevis pin (1) through push rod and brake pedal.

5. Install washer (2) and cotter pin (3).

2-12 2003 Dyna Police: Chassis

Page 23

HOME

p0101a2x

14

12

11

10

7

7

6

9

4

27

28

5

3

2

1. Clevis pin

2. Washer

3. Cotter pin

4. Brake pedal

5. Push rod

6. Bolt (8) @ 25-35 ft-lbs (33.9-47.5 Nm)

7. Lockwasher (8)

8. Screw (4)

9. Nut

10. Right rear footboard support

11. Nut (4)@ 84-108 in-lbs (9.5-12.2 Nm)

12. Right footboard

13. Left rear footboard support

14. Left footboard

15. Screw

16. Washer

11

26

11

6

7

13

11

8

6

8

7

7

8

20

21

19

25

22

22

6

18

15

16

17

31

7

6

30

29

1

17. Left engine guard mount

18. Left front footboard support

19. Nut @ 18-22 ft-lbs (24.4-29.8 Nm)

20. Washer

21. Nut @ 30-35 ft-lbs (40.7-47.5 Nm)

22. Bushing

23. Right front footboard support

24. Right engine guard mount

25. Wave washer

26. Pivot shaft

27. Washer

28. Screw @ 30-35 ft-lbs (40-7-47.5 Nm)

29. Screw

30. Washer

31. Nut @ 18-22 ft-lbs (24.4-29.8 Nm)

23

8

24

Figure 2-9. Footboards

2003 Dyna Police: Chassis 2-13

Page 24

HOME

RADIO MOUNTING BRACKET 2.9

REMOVAL

1. Remove pole lamp. See 8.5 POLE LAMP.

2. See Figure 2-10. Remove screws (2), washers (3) and

nuts (4) securing radio mounting bracket (1) to fender.

INSTALLATION

1. Place radio mounting bracket (1) in place over fender

rails (5).

2. Install screws (2), washers (3) and nuts (4). Tighten

screws to 12-18 ft-lbs (16.3-24.4 Nm).

3. Install pole lamp. See 8.5 POLE LAMP.

p0102x2x

1

2

5

1. Radio mounting bracket

2. Screw @ 12-18 ft-lbs (16.3-24.4 Nm)

3. Washer

4. Nut

5. Fender rails

3

5

4

Figure 2-10. Radio Mounting Bracket

2-14 2003 Dyna Police: Chassis

Page 25

ENGINE 3

able Of Contents

T

NOTE

All service information in the Dyna Models Service Manual applies to the FXDP police model

motorcycle.

Page 26

Page 27

able Of Contents

T

FUEL SYSTEM 4

SUBJECT PAGE NO.

4.1 Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

NOTE

This section provides information unique to the FXDP police model motorcycles. Any information not presented in this supplement can be found in the Dyna Models Service Manual.

Page 28

Page 29

HOME

8856

1. Right handlebar control connector [22]

2. Pursuit lamp flasher connector [69]

3. Left handlebar control connector [24]

4. Ignition switch connector [33]

5. Pursuit lamp connector [73]

3

4

1

5

2

FUEL TANK 4.1

REMOVAL

1WARNING1WARNING

Gasoline is extremely flammable and highly explosive.

Always stop the engine when refueling or servicing the

fuel system. Do not smoke or allow open flame or sparks

near the work site. Inadequate safety precautions could

result in death or serious injury.

p0117x4x

4

1

2

NOTE

For instructions on properly draining fuel from the fuel supply

valve filter, refer to the Dyna Models Service Manual.

8. Drain fuel into adequately sized, approved gasoline container.

9. See Figure 4-3. Disconnect crossover hose (16) from

one end only.

10. Disconnect continuous venting vent line (17) from fitting

on fuel tank.

11. Remove front mounting bolt (14), acorn nut (32) and flat

washers (13).

12. Remove rear mounting bolt (11), acorn nut (32) and flat

washers (13).

NOTE

For instructions on properly disconnecting and connecting

the fuel gauge, see 8.15 FUEL GAUGE.

13. Disconnect fuel gauge connector [117] located under left

side of fuel tank (12).

14. Remove fuel tank from motorcycle.

H

a

3

1. Console outer assembly

2. Console

3. Fuel tank

4. Screw (3)

Figure 4-1. FXDP Console Assembly

1. If necessary, remove microphone from jack connection

on console.

2. See Figure 4-1. Remove console outer assembly (1).

a. Remove the two screws (4) on the console above

the ignition switch.

b. Remove screw (4) ahead of seat.

For instructions on properly removing and installing Deutsch

electrical connector wire terminals, refer to the Dyna Models

Service Manual.

3. See Figure 4-2. Disconnect wire harness connectors (1,

2, 3, 4 and 5).

4. Remove windshield. See 2.6 WINDSHIELD.

5. See Figure 4-3. Verify fuel supply valve (24) is in OFF

position.

6. Remove fuel line hose (22) from the fuel supply valve.

7. Remove vacuum hose (28) from fuel supply valve.

r

l

e

y

-

D

NOTE

a

v

i

d

s

o

n

Figure 4-2. FXDP Console Connectors

2003 Dyna Police: Fuel System 4-1

Page 30

HOME

p0103a4x

32

213 4

6

4

4

8

10

7

5

9

11

12

33

13

13

14

13

31

30

29

1. Screw (4)

2. Ignition switch

3. Nameplate

4. Screw (4)

5. Washer

6. Console outer assembly

7. Gasket

8. Console assembly

9. Clip flasher

10. Rivet

11. Bolt

12. Fuel tank

13. Washer (4)

14. Bolt

15. Clamp (4)

16. Hose

15

16

H

a

r

l

e

y

-

D

a

v

i

d

s

o

n

27

32

13

17

18

26

25

19

28

15

21

20

24

23

22

17. Vent line

18. Vapor valve

19. Vapor valve clip

°

20. 90 Elbow

21. Vent line connector

22. Hose (valve to carb.)

23. Insulator

24. Fuel supply valve

25. Fuel filter gasket

26. Nut

27. Filter

28. Hose (vacuum carb.)

29. Decal (2)

30. Filler cap gasket

31. Filler cap

32. Acorn nut

33. Nut Clip

4-2 2003 Dyna Police: Fuel System

Figure 4-3. Fuel Tank Assembly

Page 31

HOME

CLEANING AND INSPECTION

1WARNING1WARNING

Use only non-ferrous (non-sparking) metal balls, such as

lead pellets, to loosen deposits. Metal balls, such as

steel ball bearings, could produce a spark igniting the

fumes in the tank. The resulting flames or explosion

could result in death or serious injury.

1. Clean the tank interior with commercial cleaning solvent

or a soap and water solution. Shake the tank to agitate

the cleaning agent. If necessary, non-ferrous metallic

balls or pellets may be added to the tank to assist in

loosening deposits.

NOTE

Be sure to count the number of pellets going into the tank and

the number that come out. An extra pellet in the tank could

cause fuel delivery problems.

2. Flush the tank thoroughly after cleaning and allow it to air

dry.

1WARNING1WARNING

Extreme caution should be taken when repairing tanks. If

all traces of fuel are not purged, an open flame repair

may result in a tank explosion which could result in

death or serious injury.

3. Inspect the crossover hose, continuous venting system

vent line (if applicable) and fuel line for cuts, cracks or

holes. Replace lines as needed.

4. Inspect the tank for leaks and other damage. If tank is

damaged,

replace

it.

INSTALLATION

PART NO. SPECIALTY TOOL

HD-97087-66B Hose clamp pliers

1. See Figure 4-3. Install fuel tank (12).

2. Install continuous venting system vent line (17) to fitting

on fuel tank.

3. Connect the fuel line hose (22) to fuel supply valve (24)

located under left side of fuel tank; Install

clamp (15) using HOSE CLAMP PLIERS (Part No. HD97087-66B).

4. Connect vacuum hose (28) to fuel supply valve (24).

5. Install the front mounting bolt (14), flat washers (13), and

acorn nut (32).

6. Install rear mounting bolt (11), flat washers (13), and

acorn nut (32).

7. Tighten acorn nuts (32) to 120-216

Nm).

NOTE

For instructions on properly disconnecting and connecting

the fuel gauge, see 8.15 FUEL GAUGE.

8. Connect fuel gauge connector.

NOTE

For instructions on properly removing and installing Deutsch

electrical connector wire terminals, refer to the Dyna Models

Service Manual.

9. See 2.6 WINDSHIELD. Install windshield.

10. See Figure 4-2. Connect wire harness connectors (1, 2,

3, 4 and 5).

11. See Figure 4-1. Install console outer assembly (1).

a. Install the two screws (4) above ignition switch and

one (4) ahead of seat.

b. Tighten and secure.

12. Connect microphone to jack connection on console.

13. See Figure 4-3. Verify fuel supply valve (24) is in OFF

position.

14. Fill tank and check for leaks.

in-lbs

new

hose

(13.6-24.4

2003 Dyna Police: Fuel System 4-3

Page 32

HOME

NOTES

4-4 2003 Dyna Police: Fuel System

Page 33

able Of Contents

T

ELECTRIC STARTER 5

NOTE

All service information in the Dyna Models Service Manual applies to the FXDP police

model motorcycle.

Page 34

Page 35

T

able Of Contents

NOTE

All service information in the Dyna Models Service Manual applies to the FXDP police model

motorcycle.

DRIVE 6

Page 36

Page 37

T

able Of Contents

NOTE

All service information in the Dyna Models Service Manual applies to the FXDP police model

motorcycle.

TRANSMISSION 7

Page 38

Page 39

able Of Contents

T

SUBJECT PAGE NO.

8.1 Bulb Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.2 Torque Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.3 Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

8.4 Rear Marker Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

8.5 Pole Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8.6 Siren and Public Address System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

8.7 Siren/Speaker and Mounting Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

8.8 Handlebar Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

8.9 Siren Amplifier and Mounting Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

8.10 Adjusting Whelen 100 Watt Siren Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

8.11 Microphone and Jack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

8.12 Enabling Air Horn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

8.13 Electrical Connector Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

8.14 Charging System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-21

8.15 Fuel Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-31

NOTE

This section provides information unique to the FXDP police model motorcycle. Any information not presented in this supplement can be found in the Dyna Models Service Manual.

ELECTRICAL 8

Page 40

Page 41

4

HOME

BULB CHARTS 8.1

GENERAL

Refer to Ta bl e 8-1. The bulb chart lists the light bulbs and

LED assemblies used on FXDP police models.

Contact Whelen Engineering for Cycle Signal Lamp replacement bulbs. In the United States, dial 203-526-9504.

NOTE

Table 8-1. Bulb Chart

LAMP DESCRIPTION

(ALL LAMPS 12V)

Headlamp

Low beam

High beam 5.00 60

Tail and stop lamp

Ta il lamp

Stop lamp 2.25*/2.10** 27*/25**

Turn signal lamps

Front turn signal/running lamps 2 2.25/0.59 27/7 68168-89

Rear turn signal 2 2.25 27 68572-64B

Passing/Pursuit lamp

Left (red) 1

Right (blue) 1 68728-64

Rear strobe, if provided 1 N/A 20 67598-88

Instrument Panel/Gauge Lamps

High Beam Indicator 1

Oil Pressure Indicator 1

Neutral Indicator 1

Tu rn Signal Indicator 2

Fuel Gauge‡

Speedometer‡

Odometer‡

Engine‡

Pursuit‡

*

Early 2003 bayonet mount bulb type.

**

Late 2003 wedge mount bulb type.

‡

Illuminated with LEDs and are

NUMBER OF

BULBS

(REQUIRED)

1

1

N/A N/A N/A N/A

not

repairable. Assembly must be replaced if LED fails.

CURRENT DRAW

(AMPERAGE)

4.58 55

0.59 7

2.5 30

0.15 2.1 68024-94

WATTAGE

68168-89A*/68167-88

HARLEY-DAVIDSON

PA RT NUMBER

68329-03

68727-64A

**

2003 Dyna Police: Electrical 8-1

Page 42

HOME

TORQUE VALUES 8.2

ITEM

Battery negative cable ground

stud

Circuit breaker ring terminal 20-30

Fuel gauge sending unit plate

screws

Siren amplifier mounting

bracket screws

Siren amplifier mounting

screws

Stator mounting screws 55-75

Voltage regulator 60-80

120-180

18-22

60-84

60-84

TORQUE NOTES

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

13.6-20.3 Nm page 8-22, 8-25

2.2-3.4 Nm page 8-22

2.0-2.5 Nm page 8-31

6.8-9.5 Nm page 8-14

6.8-9.5 Nm page 8-14

6.2-8.5 Nm page 8-25

6.7-9.03 Nm page 8-22

8-2 2003 Dyna Police: Electrical

Page 43

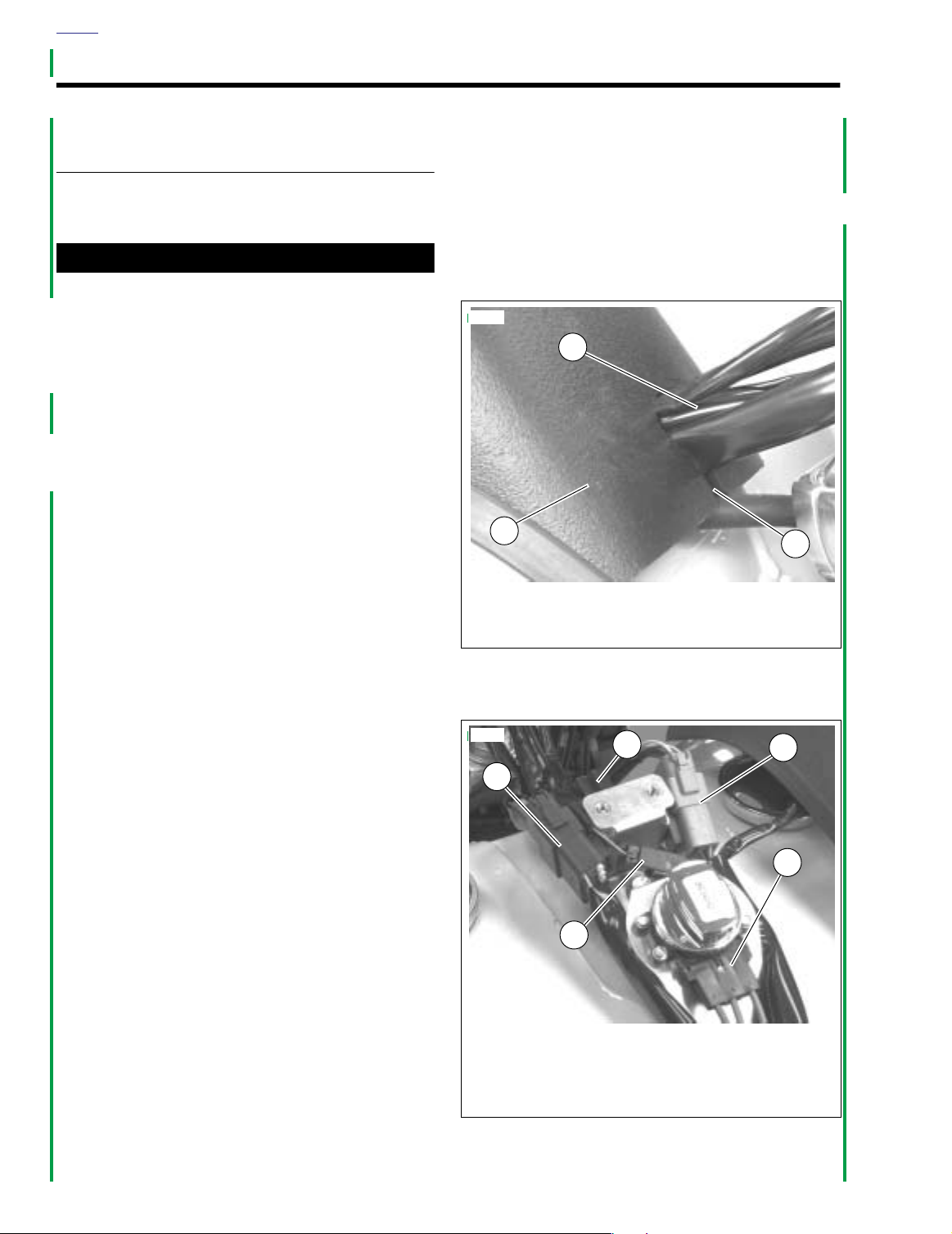

HOME

p0065x8x

1. Cover

2. Grommet

3. Bracket

4. Nut

5. Stud

5

4

1

2

3

0

0

Siren

Instruments

Pursuit

P & A

*

Security

Accessories

Ignition

Lights

p0064x8x

*

Turn signal use only.

Security not available on FXDP models.

Police Accessory

FUSES 8.3

GENERAL

Fuses are provided to protect electrical components. To

inspect or replace the fuses, carefully follow the procedures

below. If an electrical fault occurs after replacement of a fuse,

see your Harley-Davidson dealer for service.

SYSTEM FUSES

1. Place the Ignition/Light Key Switch in the OFF position.

2. See Figure 8-1. Pull cover (1) away from electrical panel

grommets (2) (no tools required).

NOTE

Tw o spare fuses (one 10 amp and one 15 amp) can be found

in the relay block at the front of the electrical panel. For fuse

ratings and color, refer to Tab l e 8-2.

3. See Figure 8-2. Replace suspect fuse.

NOTE

Electrical panel cover has a drain hole. Make sure drain hole

is on bottom when installing cover.

4. See Figure 8-1. Push electrical cover (1) onto four grom-

mets (2).

Figure 8-1. Accessing Fuse Block

Table 8-2. Fuses

CIRCUIT

Siren 10 Red

Brakes/Pursuit Lamps 15 Blue

P& A 10 Red

Police Accessory 15 Blue

Tu r n Signals 15 Blue

Accessory 15 Blue

Instruments 15 Blue

Ignition 15 Blue

Lights 15 Blue

RATING

(AMPERES)

COLOR

Figure 8-2. Fuse Functions

2003 Dyna Police: Electrical 8-3

Page 44

HOME

REAR MARKER LAMP 8.4

GENERAL

The marker lamps combine the filament and blue lens in one

integral component. When the filament burns out, the entire

lamp is replaced.

REMOVAL

1. See Figure 8-3. Pull pin connector (1) free of pin socket

at rear of marker lamp (2).

2. See Figure 8-4. Grasp the lamp (2) and rotate counterclockwise to free lamp from mounting.

INSTALLATION

1. See Figure 8-4. Insert

clockwise to lock in place.

2. See Figure 8-3. Push pin connector (1) into pin socket

(3) at rear of lamp.

3. Verify operation of lamps.

new

lamp in opening and turn

p0089x8x

3

1. Pin connector

2. Marker lamp

3. Pin socket

Figure 8-3. Marker Lamp Assembly

4580p

2

1

8-4 2003 Dyna Police: Electrical

Figure 8-4. Marker Lamp Removal/Installation

Page 45

HOME

1. Knurled ring (taper up)

2. Lower bracket

3. Knurled ring (taper down)

2

8247

1

3

8248

POLE LAMP 8.5

GENERAL

Harley-Davidson police motorcycles are shipped from the factory with the brackets necessary to mount a police pole lamp.

Mounting Pole Lamp

1. Cut all but approximately 10.0 in. (254 mm) of wire off the

pole lamp.

NOTE

The connector is the type that can only go together one way.

Be sure you match the wires correctly. The black wire should

go to the black and the green/red wire should go to the red. If

wires are not correctly matched, the polarity for the lamp will

be wrong and the lamp will not work.

2. Follow directions in the Dyna Models Service Manual

Appendix B to terminate connector wires.

3. See Figure 8-6. Unscrew both knurled rings (1, 3) from

the pole lamp and slide them off the assembly.

4. See Figure 8-5. Slide the pole lamp through the upper

mounting bracket.

8249

Figure 8-5. Upper Mounting Bracket

5. See Figure 8-6. Slide the knurled ring (1) onto the bottom of the pole with taper up.

6. Slide the knurled ring (1) and bottom of the pole lamp

through lower bracket (2).

a. Screw the knurled ring (3) onto pole from bottom of

lower bracket (2) with taper down.

b. Tighten and secure rings (1, 3) to lock pole in posi-

tion.

c. Snap the wire connector together.

d. See Figure 8-7. Use cable straps to secure wire

assembly to pole lamp. Verify wire assembly is not

touching saddlebag surface.

Figure 8-6. Pole Lamp Installation

Figure 8-7. Cable Straps

2003 Dyna Police: Electrical 8-5

Page 46

HOME

SIREN AND PUBLIC ADDRESS SYSTEM 8.6

GENERAL

The siren and public address (PA) system consists of: amplifier, speaker, microphone, microphone jack, siren, horn/siren

switches and connecting wiring.

The Whelen 100 watt siren amplifier, WS-320, (Part No.

91156- 93) uses a waterproof connector [72].

Table 8-3. Troubleshooting

PROBLEM

Siren and PA not

operational.

Siren and PA not

operational.

Siren functions, PA

not operational.

Connector not properly installed. Be sure connector is properly oriented and screw is tight.

Faulty amplifier or speaker. Substitute a known good amplifier and check system func-

PA gain control not properly

adjusted.

3.2 Inoperative microphone.

Microphone jack or connecting

leads do not provide good electrical connection.

Wrong microphone.

CAUSE SOLUTION

TROUBLESHOOTING

If siren and/or PA system are inoperative, refer to the following troubleshooting chart.

Apply wheel bearing grease to connector pins and sockets

to reduce corrosion.

tion. If system is still inoperative, substitute a known good

speaker and check for system operation.

NOTE

If neither an amplifier nor speaker is available, see 8.7

SIREN/SPEAKER AND MOUNTING BRACKET TROUBLESHOOTING. If speaker checks “good”, continue at 8.6

SIREN AND PUBLIC ADDRESS SYSTEM VOLTAGE

CHECKS and 8.6 SIREN AND PUBLIC ADDRESS SYSTEM RESISTANCE AND CONTINUITY CHECKS.

See 8.10 ADJUSTING WHELEN 100 WATT SIREN AMPLI-

FIER.

Substitute a known good microphone. If known good microphone is not available, see 8.11 MICROPHONE AND JACK.

See 8.11 MICROPHONE AND JACK.

Some Whelen microphones are electrically different and

cannot be interchanged.

8-6 2003 Dyna Police: Electrical

NOTE

Microphones used with WS-320 amplifiers should be marked

010245648-00.

Page 47

HOME

VOLTAGE CHECKS

See Figure 8-8., Refer to Ta ble 8-5., and appropriate wiring

diagrams located in the Appendix. Measure the voltages at

the motorcycle siren harness connector (pins 1C, 2F, and 1F)

as listed in Ta bl e 8-5. The ignition switch must be ON while

checking voltages. Connect common or negative lead of voltmeter to a good ground. If voltages specified in Ta b le 8-5. are

not present, refer to applicable wiring diagram to diagnose

problem.

p0011a8x

Figure 8-8. Pin Connector From Motorcycle Harness

Table 8-4. Pin Connector

From Motorcycle Harness

Pin No.

1A Ground (-) to motorcycle

3A Speaker (+)

1C

3C Speaker (-)

1D

2D Push-to-talk (mic)

1E Mic (-)

1F

2F

3F Mic (+)

12 Vdc supply to amplifier.

Present when ignition is on.

Air horn enabled - 12 Vdc is present

when connected to horn circuit and button is pushed. See 8.12 ENABLING AIR

HORN.

Yelp, 12 Vdc is present when siren/horn

switch is ON.

Wail, 12 Vdc is present when siren

switch is ON.

Description/Function

Table 8-5. Voltage Checks at Motorcycle Siren Harness

Switch

Ignition ON 12 Vdc Do Not Measure Do Not Measure

Siren OFF

Siren/Horn ON

Siren ON

Siren/Horn OFF

Siren/Horn ON

Siren ON

Switch

Position

1C 2F 1F

Do Not Measure 0 Vdc 12 Vdc

Do Not Measure 12 Vdc 0 Vdc

Do Not Measure 12 Vdc 12 Vdc

VOLTAGE MEASURED AT PINS

2003 Dyna Police: Electrical 8-7

Page 48

HOME

RESISTANCE AND CONTINUITY CHECKS

See Figure 8-8. Refer to Ta b le 8-6. Perform checks with both

battery cables removed.

CAUTION

DO NOT connect ohmmeter probes to a “live” circuit or

ohmmeter will be damaged. If ohmmeter readings in

Tabl e 8-6. are not obtained, refer to applicable wiring dia-

gram at rear of this manual to diagnose the problem.

If you do not obtain the ohmmeter readings shown in Ta bl e 8-

6., refer to applicable wiring diagram at rear of this manual to

diagnose the problem.

Table 8-6. Resistance/Continuity Checks (Battery Cables Disconnected)

OHMMETER PROBE LOCATION

(PINS)

3A & 3C 6-10 Ohms

3F & 1E Infinity

Press and hold PTT switch with probes

on pins 2D & 1E.

Common probe to ground, other probe

to pin 1A.

OHMETER

0-1 Ohms

0-1 Ohms Checks amplifier to motorcycle ground.

COMPONENT AND WIRE BEING

CHECKED

Speaker coil voice and leads from pin

connector to speaker.

Verifies microphone circuit is not

shorted.

Verifies PTT switch is functioning and

two microphone leads from connector

have continuity.

See Figure 8-17. for microphone jack

connections. To check third lead, place

one probe on pin 3F and the other

probe on tip terminal of microphone

jack.

8-8 2003 Dyna Police: Electrical

Page 49

HOME

8882

1. Front mounting screw (2)

2. Flat washer (4)

3. Rubber washer (4)

4. Horn

5. Drain hole

6. Cone

7. Locknut (2)

4

1

6

2

5

23

7

SIREN/SPEAKER AND MOUNTING BRACKET 8.7

TROUBLESHOOTING

If siren is inoperative, check voice coil impedance as follows:

1. See Figure 8-9. Disconnect siren connector (1) [57] and

measure impedance by connecting ohmmeter leads to

siren leads. Measured resistance must be 6-10 ohms.

2. Replace siren if resistance is not within allowable range.

8881

1

3

4

1. Siren connector [57]

2. Siren driver

3. Mounting bracket

4. Rear mounting screw

5. U-bolt (2)

6. Engine guard

2

6

5

REMOVAL

Siren

1. See Figure 8-9. Disconnect siren connector [57] (1). Cut

any cable straps securing siren wiring to engine guard.

2. See Figure 8-10. Remove self-locking nuts (7) from front

mounting screws (1) at the side and top of the siren horn

(4). Remove screws, flat washers (2) and rubber washers (3), and retain for reuse.

3. See Figure 8-9. Remove rear mounting screw (4) from

back of mounting bracket (3) and remove siren.

Mounting Bracket

1. See Figure 8-9. Remove locknuts from u-bolts (5).

2. Remove u-bolts and mounting bracket (3) from engine

guard (6).

Figure 8-9. Siren and Mounting Bracket

A binding voice coil or torn speaker cone could also cause

siren to be inoperative. To check for these conditions, connect

siren to shop stereo. If siren works, it is functional.

NOTE

Figure 8-10. Siren Mounting and Drain Hole Location

2003 Dyna Police: Electrical 8-9

Page 50

HOME

INSTALLATION

Siren

1. See Figure 8-9. Install

with rear mounting screw (4). Finger tighten only at this

time.

●

See Figure 8-10. Be sure drain hole (5) is facing down to

provide good drainage. Rotate siren driver housing until

drain hole points straight down.

●

Line up holes in siren horn (4) with holes in mounting

bracket. If necessary, unscrew cone (6) and turn horn

slightly until holes line up properly. Then hand-tighten

cone securely.

2. See Figure 8-10. Secure siren to mounting bracket side

and top:

a. Insert each front mounting screw (1) through mount-

ing bracket, a flat washer (2), rubber washer (3) and

siren horn (4).

b. Install another rubber washer, flat washer, and lock-

nut (7) on screw. Tighten locknut securely.

3. Tighten rear mounting screw.

new

siren in mounting bracket (3)

NOTES

Mounting Bracket

1. If siren has not been installed on mounting bracket, do so

at this time. See siren installation procedure above.

2. See Figure 8-9. Install mounting bracket (3) on right side

of engine guard (6).

3. Place u-bolts (5) on engine guard and through mounting

bracket holes.

4. Thread locknuts onto u-bolts. Position mounting bracket

squarely in corner of right side of engine guard, and

tighten locknuts evenly and securely.

5. Connect siren connector [57] (1). Secure siren cable to

engine guard with cable straps.

CAUTION

Do not use a high pressure washer near the siren. High

pressure washers can force water into the siren, ruining

it.

NOTE

If siren center cone is removed for easier installation, apply 23 drops of Loctite 242 (blue) on center cone threads and

tighten cone securely with hand.

8-10 2003 Dyna Police: Electrical

Page 51

HOME

CAUTION

1. Clutch hand lever

2. Siren wail switch

3. Headlamp switch

4. Turn-left signal switch

5. Horn/Siren yelp switch

p0067x8x

32

5

1

4

HANDLEBAR SWITCHES 8.8

HORN/SIREN YELP SWITCH

Consult the Dyna Models Service Manual for assembly/disassembly procedures and general repair procedures.

Removal

1. See Figure 8-11. For disassembly of left side handlebar

switches, refer to the Dyna Models Service Manual.

2. From inside the switch housing, carefully cut cable strap

to free conduit from the turn signal switch bracket.

3. Remove the Phillips screw (with lockwasher) to release

the turn signal switch bracket. Remove the switch

assembly from the housing.

4. Remove the two T8 TORX screws and the Phillips screw

(with lockwasher) to release the lower bracket. Carefully

lift out the bracket so as not to disturb the spring-loaded

ramp on the inboard side of the housing.

5. Carefully remove the keycap disengaging slot from hook

on ramp.

6. While holding down the ramp, pull both switches from the

housing.

7. Cut the wires from the old switches as follows:

Y/BK wire: 1-1/4 in. (31.75 mm)

●

●

O/W wires: 1-7/8 in. (42.63 mm)

TN/BK wire: 1-1/2 in. (38.1 mm)

●

8. For general repair procedures, refer to the Dyna Models

Service Manual.

●

Replacement Horn/Siren Yelp Switch wires are cut to

length and partially stripped (Yellow/Black wire: 3-3/4 in.

(95.25 mm); Orange/White wires: 3-1/2 in. (88.9 mm);

Tan/Black wire: 3-3/8 in. (85.73 mm)).

If the ramp and spring mechanism becomes loose, install

●

as follows: Using the blade of a small screwdriver, compress spring and place in wider portion of channel at bottom of ramp. Verify that spring is evenly compressed and

is not cocked or skewed. Push spring so that it bottoms

in channel. With tab side of ramp facing inboard and

hook end on switch side of casting, install ramp so that

narrow channels engage pins cast into housing.

Installation

1. Install the switches in the housing with contacts facing

tabs on ramp. For best results, install one switch at a

time. Ribs cast in lower housing hold switches in position.

The Horn switch with the Yellow/Black lead (pivot point

towards rider) is installed at the bottom, while the Siren

Yelp switch with the Brown/Black lead (pivot point

towards the front) is at the top. Route switch wires in

channel on the outboard side of the ribbed area.

2. Install the keycap engaging slot with hook on ramp.

3. Install lower bracket sliding pin through keycap and

engaging hole in lower casting.

NOTE

Figure 8-11. Left Handlebar Controls

4. Slide T8 TORX screws through holes in lower bracket

and switches and thread into lower casting until snug.

5. Install Phillips screw (with lockwasher), to secure lower

bracket to threaded boss in housing. Verify operation of

Horn and Siren Yelp switches to ensure that both are

spring returned.

6. Install Clutch Interlock Switch in bore of lower switch

housing, if loose.

7. Insert tapered end of

into round hole in turn signal switch bracket and then

feed back through using the adjacent hole. Reserve the

NOTES

oblong hole for the bracket screw.

8. Be sure that all splices are positioned above the turn signal switch bracket.

9. Place the turn signal switch assembly into the housing

aligning the oblong hole in the bracket with the lower

bracket weld nut. Be sure that bracket is fully seated.

Ta bs on each side are captured in slots cast into switch

housing.

10. Install Phillips screw (with lockwasher) to secure bracket

inside housing.

If routed incorrectly, wires may be pinched by casting or

handlebar resulting in switch failure.

11. Loop switch wires so that spliced lengths are positioned

directly over bracket screw.

12. Capturing conduit about 1/4 in. (6.4 mm) from end,

securely tighten cable strap to draw conduit to bracket.

Remove any excess cable strap material.

13. On opposite side, install second 7 in. (177.8 mm) cable

strap capturing conduit and wire splices. Securely tighten

cable strap to draw splices to conduit. Remove any

excess cable strap material.

14. Route wire bundle to upper switch housing below and

then forward of the main wire harness positioning conduit

in channel next to angular arm of bracket. Secure bundle

to arm placing

new

7 in. (177.8 mm) cable strap

new

cable strap 1/4 in. (6.4 mm) from end

2003 Dyna Police: Electrical 8-11

Page 52

HOME

of conduit. Cut any excess cable strap material. If necessary, bend angular arm of bracket downward to firmly

secure Clutch/Starter Interlock Switch in installed position.

15. For assembly of left side handlebar switches, refer to the

Dyna Models Service Manual.

CLUTCH INTERLOCK SWITCH

NOTE

All Police models have a clutch/starter interlock that prevents

the motorcycle from being started unless the clutch lever is

pulled in.

Removal

1. For disassembly of left side handlebar switches, refer to

the Dyna Models Service Manual.

2. From inside the switch housing, carefully cut cable strap

to free conduit from the turn signal switch bracket.

CAUTION

If routed incorrectly, wires may be pinched by casting or

handlebar resulting in switch failure.

5. Loop switch wires so that spliced lengths are positioned

directly over bracket screw.