MAINE ENERGY SYSTEMS PE 12, PES 32, PE 25, PE 20, PE 32 Operating Manual

...

OperatingManual

Pleasereadcarefullyprior

toinstallationandservicing.

SAVETHESEINSTRUCTIONS

PE149USA4.1

PELLETBOILER

PE12–32

CMP0.62B–US_ST610

ENGLISH—USA

downloadfrenchversion:

www.maineenergysystems.com/manuals.htm

Title:

OperatingManualPE12-32

Itemnumber:

Numberofversion:

Versionvalidfrom:11/2012

Author:

PE149USA4.1

04.01

MAINEENERGYSYSTEMSLLC

8AirportRoad–P .O.Box547Bethel

Maine04217

e-mail:info@maineenergysystems.com

web:www.maineenergysystems.com

©MAINEENERGYSYSTEMSLLC

Subjecttomodications

Contents

1DearCustomer...............................................................................................................................................4

2Useonlyforthepurposeintended.................................................................................................................5

3Typesofsafetywarningsign..........................................................................................................................6

4Warningsandsafetyinstructions...................................................................................................................7

4.1Basicsafetyinstructions.................................................................................................................................7

4.2Warningsigns................................................................................................................................................7

4.3Whattodoinanemergency...........................................................................................................................8

5Prerequisitesforinstallingapelletboiler.......................................................................................................9

5.1Guidelinesandstandardsforinstallingapelletboiler.......................................................................................9

5.2Boilerroom...................................................................................................................................................9

5.3Fluegassystem............................................................................................................................................10

5.4Safetysystems..............................................................................................................................................12

6Fuel................................................................................................................................................................13

6.1SpecicationforhighqualitypelletsasPFI(PelletFuelInstitut)........................................................................13

6.2Storingthepellets..........................................................................................................................................13

7Productdescription........................................................................................................................................14

7.1Thepelletboiler.............................................................................................................................................15

7.2Augerdeliverysystem....................................................................................................................................17

7.3Storagesystems............................................................................................................................................17

8Operatingthepelletboiler..............................................................................................................................18

8.1Operatingtheheatingsystem.........................................................................................................................18

8.2Descriptionofthecontrolpanel.......................................................................................................................18

8.3Descriptionoperatingdevice..........................................................................................................................19

8.4Settinglanguage,dateandtime.....................................................................................................................20

8.5Menuconguration........................................................................................................................................22

8.6Emptyingtheashpan....................................................................................................................................24

8.7Emptyingtheashbox....................................................................................................................................25

9Maintenanceandservicing.............................................................................................................................27

9.1Maintenance.................................................................................................................................................27

9.2Cleaningtheboilereveryyear........................................................................................................................27

9.3Maintenanceintervals....................................................................................................................................30

9.4Repairs.........................................................................................................................................................30

9.5Checkingtheboilerroomandstorageroom....................................................................................................30

10Malfunctions.................................................................................................................................................31

PE149USA4.1

OperatingManualPE12-32

DearCustomer

4

1DearCustomer

Wearespecialistinpelletheating,licensedbyÖkoFEN

Expertise,innovationandqualityfromasinglesource.Itisbasedonourtraditionthatwetakeonfuturechallenges.We

aredelightedthatalsoyouhavedecidedtopurchaseourproduct.

•Thisinstructionmanualisintendedtohelpyouoperatetheproductsafely,properly

andeconomically.

•Pleasereadthisinstructionmanualrightthroughandtakenoteofthesafety

warnings.

•Keepalldocumentationsuppliedwiththisunitinasafeplaceforfuturereference.

Pleasepassonthedocumentationtothenewuserifyoudecidetopartwiththe

unitatalaterdate.

•Duringinstallationand/orrststartuptheserviceengineermustcarryoutthe

followingwork.

•Theinstallationhastobeperformedbyaqualiedinstaller.

•Pleasecontactyourauthoriseddealerifyouhaveanyquestions.

Weplacegreatimportanceonthedevelopmentofnewproducts.OurR&Ddepartmentcontinuestoquestionaccepted

solutionsandworkscontinuallyonnewimprovements.Thatishowwemaintainourtechnologicallead.Wehavealready

receivedseveralawardsforourproductsinAustriaandabroad.

OurproductsfullEuropeanandUSArequirementsregardingquality,efciencyandemissions.

OperatingManualPE12-32

PE149USA4.1

Useonlyforthepurposeintended

2Useonlyforthepurposeintended

Thepelletboilerisdesignedtoheatwaterforcentralorotherindirectheatingsystemsandhotwatersupplyforbuildings.

Itisnotpermissibletousethepelletboilerforanyotherpurpose.Reasonableforeseeableinadvertentusesforthe

pelletboilerarenotknown.

TheboilerfullstherequirementsofUL391,“StandardforSafetyforSolid-FuelandCombination-FuelCentraland

SupplementaryFurnaces,”2006,andCAN/CSA-B366.1–M91,“Solid-Fuel-FiredCentralHeatingAppliances”

OMNICerticate:

5

PE149USA4.1

OperatingManualPE12-32

Typesofsafetywarningsign

6

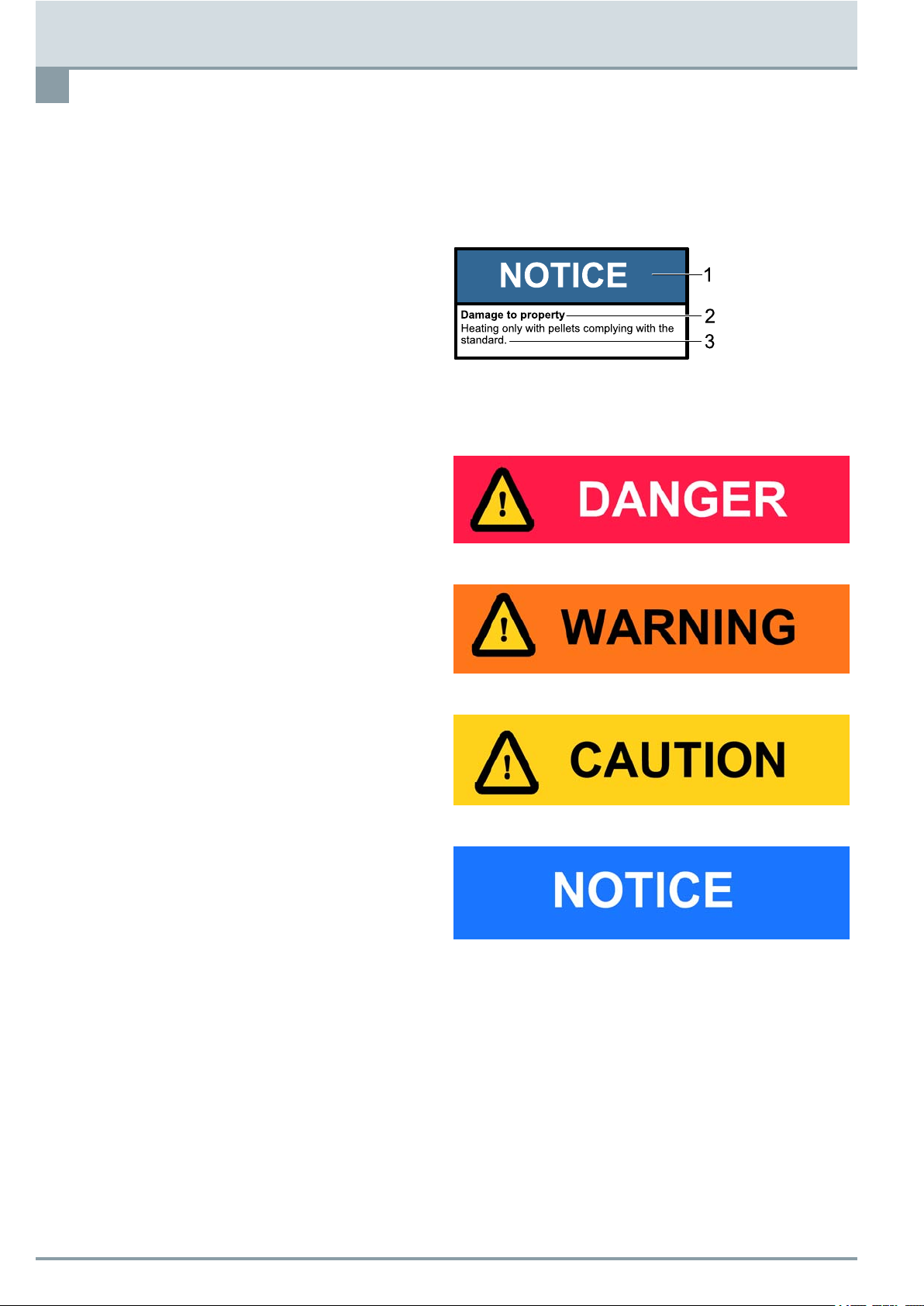

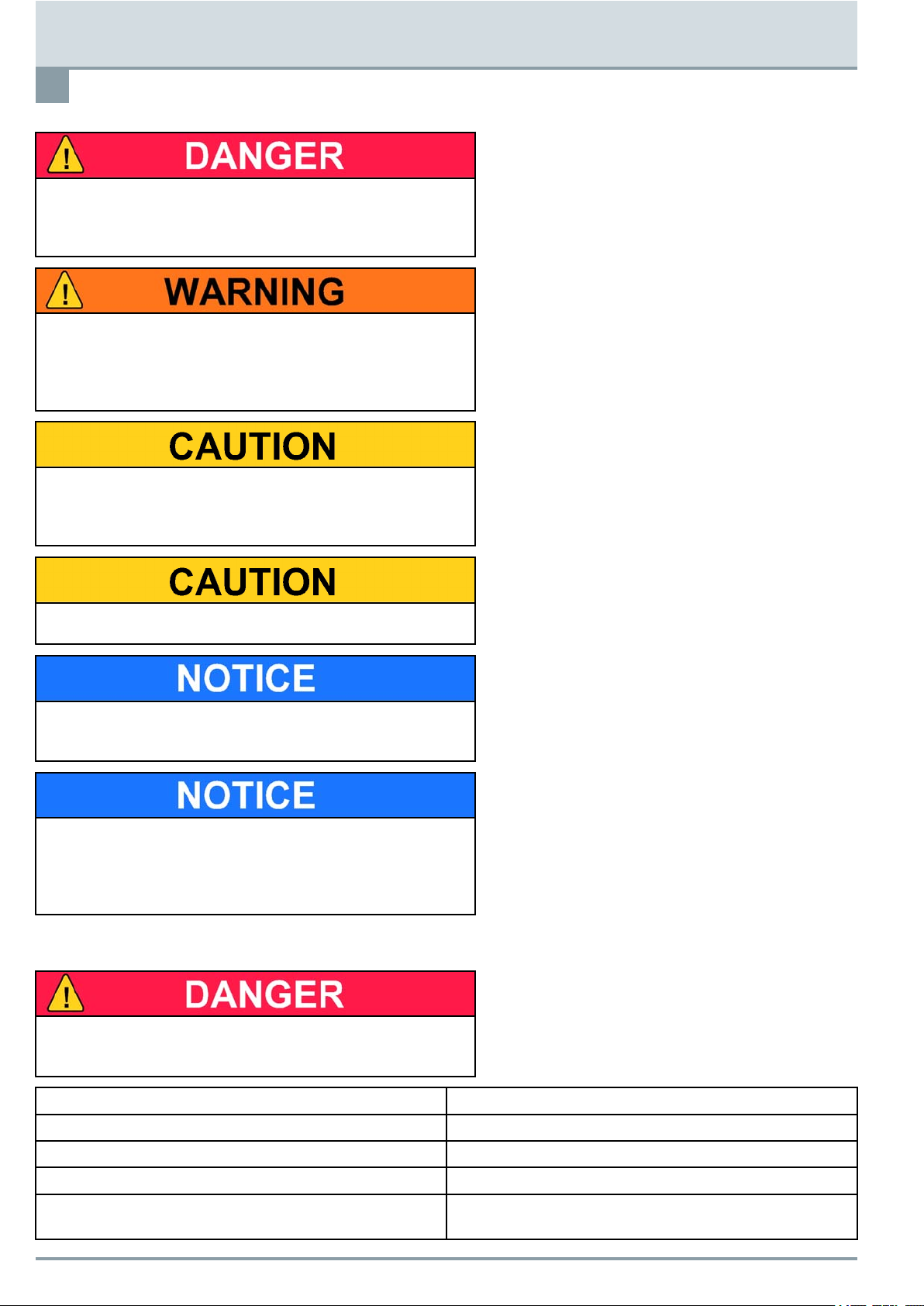

3Typesofsafetywarningsign

Thewarningsignsusethefollowingsymbolsandtext.

Typesofsafetywarningsign

1.Riskofinjury

2.Consequencesofrisk

3.Avoidingrisk

1.Riskofinjury:

Danger-indicatesasituationthatcouldleadtodeathor

life-threatninginjury.

Warning-indicatesasituationthatcouldlead

life-threatningorseriousinjury.

Caution-indicatesasituationthatcouldleadtoinjury.

Note-indicatesasituationthatcouldleadtoproperty

damage.

2.Consequencesofrisk

Effectsandconsequencesresultingfromincorrect

operation.

3.Avoidingrisk

Observingsafetyinstructionsensuresthattheheating

systemisoperatedsafely.

OperatingManualPE12-32

PE149USA4.1

Warningsandsafetyinstructions

4Warningsandsafetyinstructions

Observingsafetyinstructionsensuresthattheheatingsystemisoperatedsafely.

4.1Basicsafetyinstructions

•Nevergetyourselfintodanger;giveyourownsafetytheutmostpriority.

•Keepchildrenawayfromtheboilerroomandstorageroom.

•Observeallsafetywarningsontheboilerandinthisusermanual.

•Observeallinstructionsrelatingtomaintenance,servicingandcleaning.

•Thepelletheatingsystemmayonlybeinstalledandstartedupforthersttimebyanauthorisedinstaller.

Professionalinstallationandstartupistheprerequisiteforsafeandeconomicaloperation.

•Nevermakeanychangestotheheatingsystemoruegassystem.

•Nevercloseorremovesafetyvalves.

7

4.2Warningsigns

Riskofpoisoning

Makesurethatthepelletboilerissuppliedwithsufcient

combustionair.

Theopeningsinthecombustionairinletmustneverbe

partiallyorcompletelyclosed.

Ventilationsystems,centralvacuumcleaningsystems,

extractorfans,airconditioningsystems,uegasblowers,

dryersorsimilarequipmentmustneverbeallowedtodraw

airfromtheboilerroomandcauseadropinpressure.

Theboilermustbeconnectedtighttothechimneyusing

auegastube.

Cleanthechimneyandtheuegastubeatregularintervals.

Theboilerroomandpelletstorageroommustbesufciently

suppliedwithairandventilated.

Beforeenteringthestorageroomitmustbeventilatedwith

sufcientairandtheheatingsystemswitchedoff.

Riskofelectricshock

Switchoffthesystembeforeperformingworkontheboiler.

Riskofexplosion

DONOTBURNGARBAGE,GASOLINE,NAPHTHA,

ENGINEOIL,OROTHERINAPPROPRIATEMATERIALS.

DONOTUSECHEMICALSORFLUIDSTOSTARTTHE

FIRE.

Switchofftheheatingsystembeforellingthestorageroom.

PE149USA4.1

OperatingManualPE12-32

Warningsandsafetyinstructions

8

Riskofre

Donotstoreanyammablematerialsintheboilerroom.

Donothangoutanywashingintheboilerroom.

Donotoperatewithfuelloadingorashremovaldoorsopen.

Riskofburns

Donottouchtheuespigotortheuegastube.

Donotreachintotheashchamber.

Useglovestoemptytheashbox.

Donotcleantheboilerbeforeitcooleddown.

HOTSURFACES

Keepchildrenaway .

Donottouchduringoperation.

Maximumdraftmarkedonnameplate.

Riskofcutinjuriesduetosharpedges.

Useglovesforperformingallworkontheboiler.

Damagetoproperty

HeattheAutopelletheatingsystemusingpelletsthat

complywithPFIpremiumspecicationsonly.

Damagetoproperty

Donotusetheheatingsystemifit,oranyofitscomponents,

comeintocontactwithwater.

Ifwaterdamageoccurs,checktheheatingsystembyan

authorizedservicetechnicianandreplacedamagedparts.

4.3Whattodoinanemergency

Exhaustgascauseasphyxiationandendangerlife

Nevergetyourselfintodanger;giveownsafetyutmost

priority.

WhattodointheeventofareWhattodoifyousmellsmoke

Exitthebuilding

CalltherebrigadeClosethedoorsleadingtolivingareas.

Switchofftheheatingsystem.

Useapprovedreextinguishers(reprotectionclass

ABC).

OperatingManualPE12-32

Switchofftheheatingsystem.

Ventilatetheboilerroom.

PE149USA4.1

Prerequisitesforinstallingapelletboiler

5Prerequisitesforinstallingapelletboiler

Youmustfullthefollowingconditionsbeforeoperatingafullyautomaticpelletboiler.

5.1Guidelinesandstandardsforinstallingapelletboiler

Overviewofstandardsandguidelinesapplyingtotheinstallationofapelletboiler.

Checkwhetheryouneedtoobtainplanningpermissionorapprovalfromtheauthoritiesforinstallinganewheating

systemorchangingyourexistingsystem.Legislationinyourcountrymustbeobserved.

5.2Boilerroom

Thepelletboilerisinstalledintheboilerroom.

1.Safetyinstructionsfortheboilerroom

9

Riskofre

Donotstoreammablematerialsorliquidsinthevicinityof

thepelletboiler.

Donotpermitunauthorisedpersonstoentertheboilerroom

-Keepchildrenaway.

Donotoperatewithfuelloadingorashremovaldoorsopen.

2.Airsupplyandventilationofboilerroom

Theboilerroommustbettedwithairsupplyandventilationopenings(atleast31inch²/200cm²).Inanycase

youmustcomplywiththestateandlocalregulations

3.Combustionairsupply

Thepelletboilerneedsasupplyofcombustionair.Thesupplyofcombustionaircan:

a.takeplaceusingoneormoreairsupplyandventilationopeningsintotalmin.31inch²/200cm²

b.orthroughaspecialairsupplylinedirectlyfromoutside,wherethediameteroftheairsupplylinemustbeat

least4inch/100mminfortypePE(S)12–PE(S)32.AmbientairindependentoperationofPES36-56typesis

alsoavailableonrequest.

Neveroperatethepelletboileriftheairintakeopeningsarepartiallyorcompletelyclosed.

Contaminatedcombustionaircancausedamagetothepelletboiler.Neverstoreofusecleaningdetergents

containingchlorine,nitrobenzeneorhalogenintheroomwheretheheatingsystemisinstalled,ifcombustionair

isdrawndirectlyfromtheroom.Itisrecommendedthatnowashingordryingoflaundryisdoneintheboiler

roomorwheretheboilermaydrawairfrom.

Donothangoutwashingintheboilerroom.

Preventdustfromcollectingatthecombustionairintaketothepelletboiler.

4.Damageduetofrostandhumidair

Theboilerroommustbefrost-prooftoensuretrouble-freeoperationoftheheatingsystem.Thetemperatureof

theboilerroommustnotfallbelow37°Fandmustnotexceed90°F .Theairhumidityintheboilerroommust

notexceed70%.

5.Dangerforanimals

Makesurethathouseholdpetsandothersmallanimalscannotentertheboilerroom.Fitmeshoveranyopenings.

6.Flooding

Ifthereisariskofooding,switchoffthepelletboileringoodtimeanddisconnectfromthepowersupplybefore

waterenterstheboilerroom.Youmusthaveallcomponentsthatcomeintocontactwithwaterreplaced,beforeyou

startupthepelletboileragain.

PE149USA4.1

OperatingManualPE12-32

Prerequisitesforinstallingapelletboiler

10

5.3Fluegassystem

Theuegassystemconsistsofachimneyandauegastube.Theuegastubeconnectsthepelletheatingsystemto

thechimney .Thechimneyleadstheuegasfromthepelletheatingsystemoutintotheopen.

1.Designofthechimney

Thedimensionsanddesignofthechimneyisveryimportant.Thechimneymustbeabletoensuresufcientdraftto

safelydrawawaytheuegasregardlessofthestatusoftheboiler.Lowuegastemperaturescancausesooting

andmoisturedamageonchimneysthatarenotinsulated.Forthisreasonmoisture-resistantchimneys(stainless

steelorceramic)shouldbeused.Anexistingchimneythatisnotdamp-resistantneedstoberennovatedbefore

use.Followguidelinesbelow:

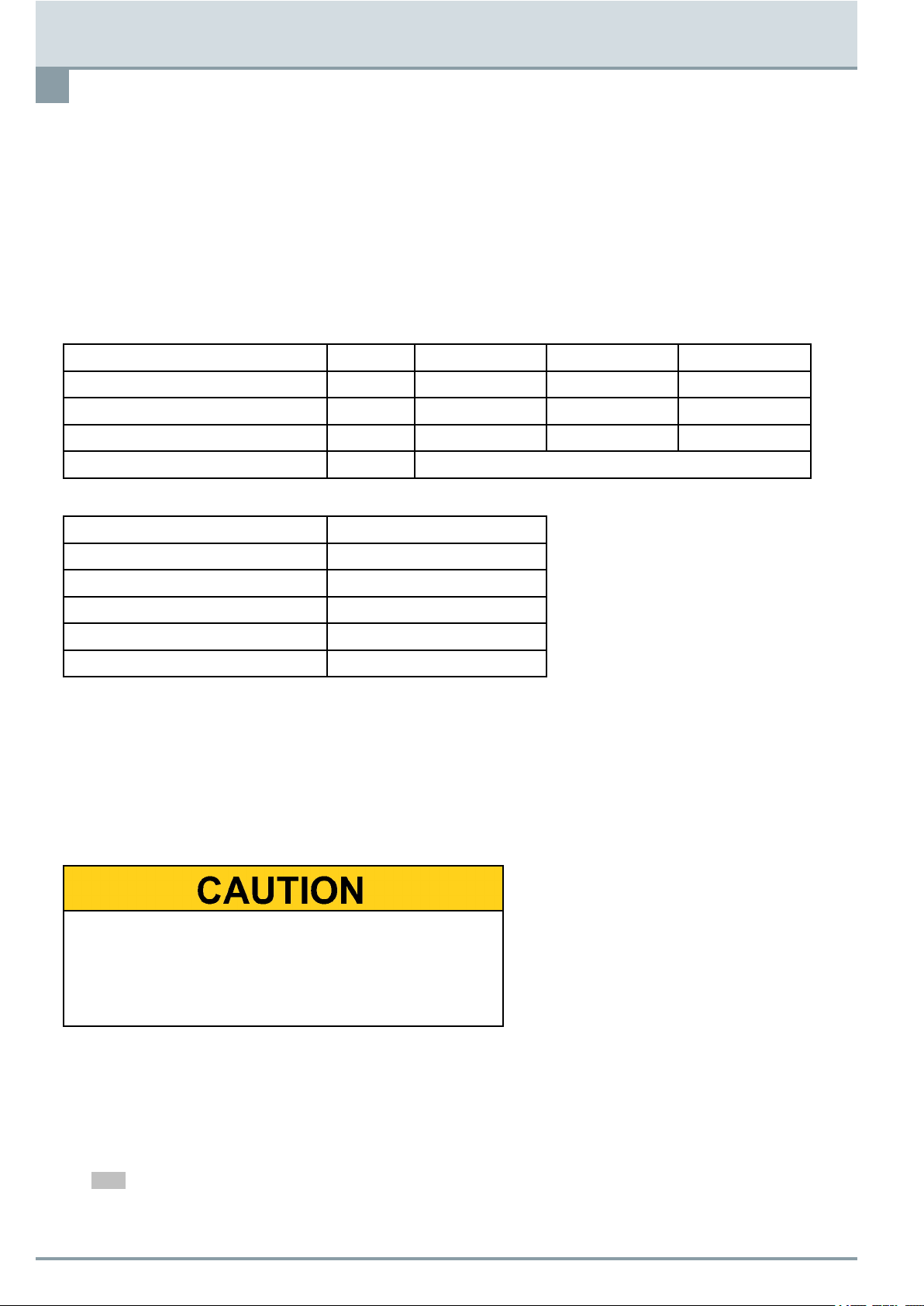

Boilersize

Fluegastubediameter(atboiler)inch/mm5/1306/1507/180

Fluegastemp./ratedpower°F

Fluegastemp./partialload°F

Min.draft–fullload/partloadin/wc0.03/0.01

Chimneysize

6in/150mmx6in/150mm17ft/5,2m

7in/180mmx7in/180mm16ft/4,8m

8in/200mmx8in/200mm16ft/4,8m

6in/150mmround19ft/5,8m

7in/180mmround17ft/5,2m

RecommendedandUL-103HTapprovedchimneymaterialsare:

a.Selkirksuretemp

b.Supervent(JSC)

c.Securitychimneys(securetempASHT)

Min.Height

PE(S)12–20PE(S)25–32PE(S)36–56

320320360

212212230

Useheavygauge(26gaorbetter)blacksmokepipetoconnecttoexistingchimney

Unregulatedcombustion

Pleaseobservethatcombustionairopeningsanduepipes

arenotreducedinsizeorclosed.Makeenduserawareof

theseguidelinesandtheirpotentialdanger.

Cleanthechimneyandtheuegastubeatregularintervals.

Checkifthedraftinduceriscleanandinagoodcondition.

2.Fluegastemperature

Theuegastemperaturesarethesameforallboilertypes:

Thedewpointofuegaswithwoodpellets(max.10%watercontent)isapprox.120°F .

Itispossibletoincreasetheuegastemperaturetopreventcondensationinsidethechimneyandavoiddamage

duetodamp.Onlyauthorisedspecialistpersonnelmayincreasetheuegastemperature.

Note

Theincreaseinuegastemperatureresultsinreducedefciencyandthusincreasesfuelconsumption.

OperatingManualPE12-32

PE149USA4.1

Prerequisitesforinstallingapelletboiler

3.Negativepressureofthechimney

Theboilermustbeconnectedtoachimneyoraverticalventingsystemthatiscapableofhandlingandproducinga

negativebreechingpressureof–0.020“WC(-5Pa).Useadraftgaugetoverifytheindicateddraftvalue,adjust

barometricdamperasrequired.Drillasmallholeintheconnectionpipeatabout2in/50mmfromtheboilerue

outletandusethisholeasyourmeasuringpoint.

Chimneydraft

Thesuctioneffectofthechimneydraftmustextendasfarasthepelletboiler.Themaximum

owratethatcanbedrawnthroughthechimneylimitsthemaximumperformanceofthe

pelletboiler.Theboilerperformancemustbereducedifthechimneydoesnotpossessthe

necessarycross-section.Thismayonlybeperformendbyauthorisedpersonnel.

Toostrongachimneydraftincreasesheatlosswhile

idlingandreducestheefciencyoftheheatingsystem.

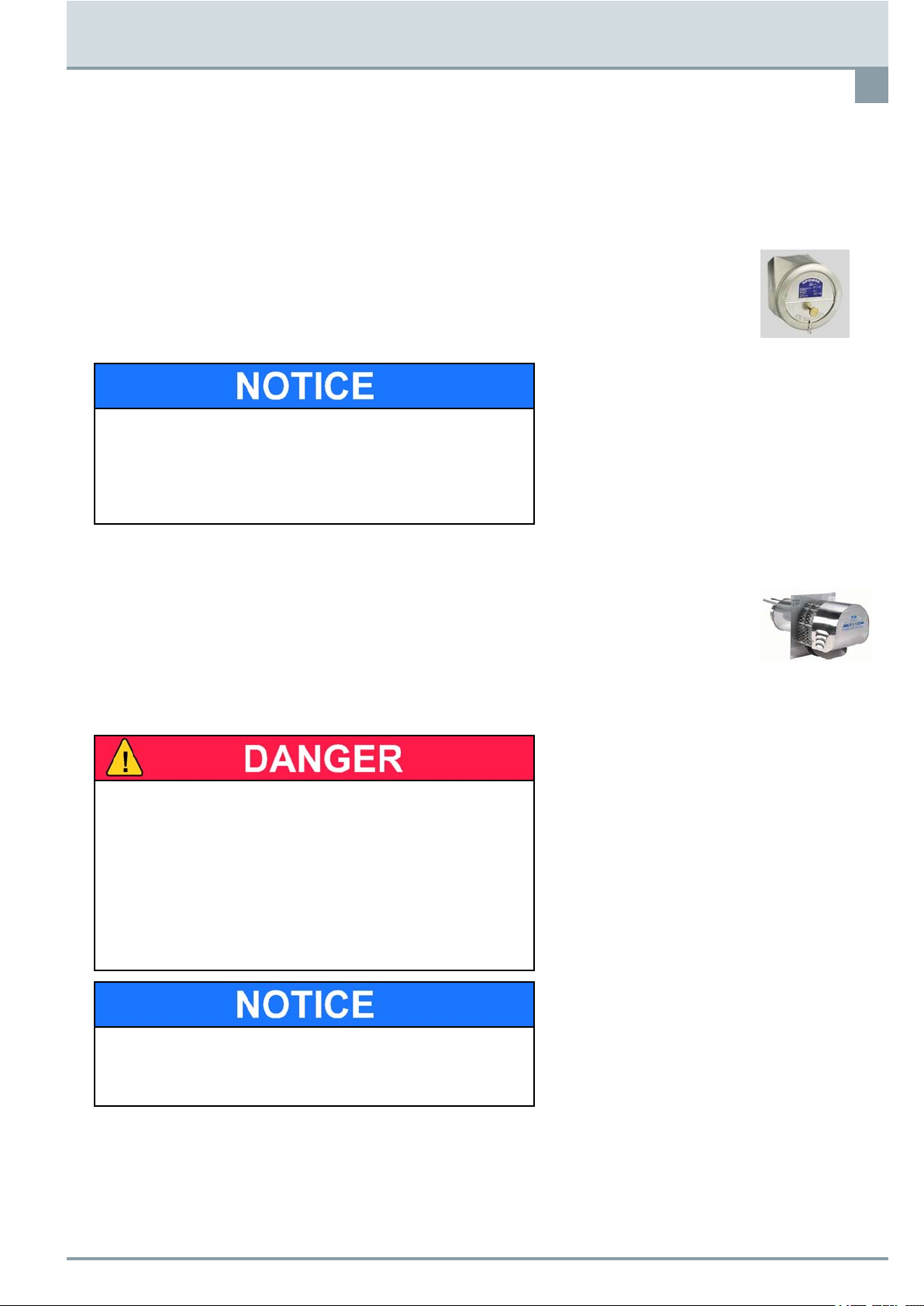

Werecommendinstallingachimneydraftregulator

(barometricdamper).Chimneydraftregulatorsareinstalled

directlyintotheuegastubeorchimney.

Yourstateandlocalregulationsmustbeobserved.

11

4.Powerventer

AutoPelletboilersareapprovedbythemanufacturerforinstallationwiththeFieldControls

SWGAFpowerventerwhichisapprovedforwoodpelletburningappliances.

BoilerinstalledwithSWGAFpowerventersmustfollowallmanufacturer´sinstallationsand

mustcomplywithallapplicablecodesfromagencieshavingauthorityovertheinstallation.

5.Cleaning

Cleantheuegastubeandchimneyregularly.

Riskofchimneyre

Creosote-formationandneedforremoval:Lowgasue

temperaturecancausecreosote.Thecreosotecondense

intherelativelycoolchimney.Asaresult,creosoteresidue

accumulatesontheuelining.Wheningnited,thiscreosote

makesahotre.Thechimneyandthechimneyconnector

shouldbeinspectedatleasttwicemonthlyduringthe

heatingseasontodetermineifacreosotebuilduphas

occurred.Ifcreosotehasaccumulateditshouldberemoved

toreducetheriskofachimneyre.

Oxidationofchimney

Donotusemetalbrushestocleanchimneysmadeof

stainlesssteel.

Yourstateandlocalregulationsmustbeobserved.

PE149USA4.1

OperatingManualPE12-32

Loading...

Loading...