MAINE ENERGY SYSTEMS AutoPellet Air TOUCH 17, AutoPellet Air TOUCH 28 Operating Manual

Please read carefully prior

to installing and servicing.

SAVE THESE INSTRUCTIONS

Operating

Manual

Pellet heating with auger

delivery or vacuum suction

system for the end-user

AutoPellet Air Furnace

17 — 28

FA_V2.05

AutoPellet Air TOUCH

USA

PE 604 USA_FA 1.0 · www.maineenergysystems.com

Title:

Operating Manual AutoPellet Air Furnace 17 — 28

Article number:

PE 604 USA_FA 1.0

Version valid

from:

07/2015

Approved: Wohlinger Christian

Author & Manufacturer

MAINE ENERGY SYSTEMS LLC

8 Airport Road — P.O. Box 547 Bethel

Maine 04217

E-Mail: info@maineenergysystems.com

© MAINE ENERGY SYSTEMS LLC

www.maineenergysystems.com

Subject to modifcations

Operating Manual AutoPellet Air Furnace 17 — 28

11 DDeeaarr CCuussttoommeerr.............................................................................................................................................................................................................................................................................................. 55

22 UUssee oonnllyy ffoorr tthhee ppuurrppoossee iinntteennddeedd .......................................................................................................................................................................................................................... 66

33 TTyyppeess ooff ssaaffeettyy wwaarrnniinngg ssiiggnn................................................................................................................................................................................................................................................77

44 WWaarrnniinnggss aanndd ssaaffeettyy iinnssttrruuccttiioonnss.............................................................................................................................................................................................................................. 88

4.1 Basic safety instructions ................. ............ ............................... ............ ....... ............ ............ ....... ..... ....... ..... 8

4.2 Warning signs....... ............ ....... ..... ....... ............ ............ ....... ............ ................... ............ ............................... 8

4.3 What to do in an emergency....... ............................... ............ ................... ............ ....... ..... ....... ............ .......10

55 PPrreerreeqquuiissiitteess ffoorr iinnssttaalllliinngg aa ppeelllleett FFuurrnnaaccee ............................................................................................................................................................................................1111

5.1 Guidelines and standards for installing a pellet Furnace . ............................... ............ ................... ............ ... 11

5.2 Furnace room circulating air ........ ............ ....... ..... ....... ............ ................... ............ ............................... ....... 11

5.3 Furnace room supply air ... ............................... ............ ................... ............ ....... ..... ....... ............ ............ ..... 12

5.4 Flue gas system. ............ ............ ................... ............ ............................... ............ ................... ............ ......... 13

5.5 Safety systems ............ ............ ....... ............ ............ ................... ............ ............................... ............ ........... 15

5.6 Installation with an existing Furnace. ............ ............ ................... ............ ............................... ............ ........ 15

66 FFuueell ................................................................................................................................................................................................................................................................................................................................ 1166

6.1 Specification for high quality pellets as PFI (Pellet Fuel Institut) .......... ....... ............ ............ ....... ..... ....... .... 16

6.2 Storing the pellets .......... ................... ............ ............................... ............ ................... ............ ............ ....... . 17

6.3 Measures for the ventilation of storage rooms . ............ ............ ....... ............ ............................... ............ .... 17

77 TThhee ppeelllleett FFuurrnnaaccee .............................................................................................................................................................................................................................................................................. 1188

7.1 Pellet suction system..... ..... ....... ............ ............ ....... ............ ............ ................... ............ ............................ 20

7.1.1 Assembly of the vacuumsystem. ............ ................... ............ ................... ............ ............ ....... .... 20

7.2 Storage systems.... ............ ............................... ............ ................... ............ ....... ..... ....... ............ ............ .....22

7.2.1 Flexilo textile tank . ............ ................... ............ ............................... ............ ................... ............ ..22

88 OOppeerraattiinngg tthhee FFuurrnnaaccee.............................................................................................................................................................................................................................................................. 2233

8.1 Operating the heating system ..... ............ ............ ....... ..... ....... ............ ................... ............ ..........................23

8.2 Description of the control panel .......... ................... ............ ............................... ............ ............................ 24

8.3 Setting language, date and time at Pelletronic Touch.......... ............ ................... ............ ............ ....... ........25

8.4 Emptying the ash pan ........ ................... ............ ............................... ............ ............................... ............ ....27

8.5 Emptying the ash box ............................... ............ ................... ............ ................... ............ ............ ....... .... 28

99 OOppeerraattiinngg DDeevviiccee wwiitthh TToouucchh ssccrreeeenn ..............................................................................................................................................................................................................3300

9.1 Opening window.... ............ ................... ............ ............ ....... ............ ............ ....... ..... ....... ............ ............ .... 30

9.2 User controls and their function........ ....... ............ ............ ................... ............ ............................... ............ . 31

9.3 Main Menu ........................... ............ ............................... ............ ................... ............ ....... ..... ....... ............ .. 33

1100 MMooddee ...................................................................................................................................................................................................................................................................................................................... 3344

1111 MMeeaassuurriinngg VVaalluueess................................................................................................................................................................................................................................................................................ 3355

1122 WWeeaatthheerr ............................................................................................................................................................................................................................................................................................................ 3366

1133 EEccoo MMooddee........................................................................................................................................................................................................................................................................................................ 3377

1144 HHeeaattiinngg CCiirrccuuiitt...................................................................................................................................................................................................................................................................................... 3388

14.1 Measuring values Heating circuit......... ................... ............ ............................... ............ ............................ 39

14.2 Time programme Heating circuit........ ................... ............ ............................... ............ ............................40

14.3 Party ..... ................... ............ ............................... ............ ................... ............ ............ ....... ............ ............ .. 41

14.4 Vacation ..... ............ ............ ....... ..... ....... ............ ............ ....... ..... ....... ............ ................... ............ ............... 41

14.5 Heating curve and Heating limits.. ....... ..... ....... ............ ............ ....... ..... ....... ............ ............ ....... ............ ... 42

1155 FFuurrnnaaccee ..............................................................................................................................................................................................................................................................................................................4455

15.1 Measuring values........ ............................... ............ ................... ............ ....... ............ ............ ....... ..... ....... .... 45

15.2 Locktime.................. ............ ................... ............ ............ ....... ............ ............ ....... ..... ....... ............ ............ . 46

15.3 Continuous running........ ............ ............................... ............ ................... ............ ............ ....... ............ ...... 46

15.4 Full Power . ....... ..... ....... ............ ............ ....... ..... ....... ............ ............ ....... ............ ............ ................... ........ 47

15.5 Fan.... ............ ............ ....... ............ ............ ....... ............ ............ ................... ............ ............................... ..... 47

15.6 Suction turbine........ ............ ............................... ............ ................... ............ ............ ....... ............ ............ . 49

1166 GGeenneerraall................................................................................................................................................................................................................................................................................................................5500

16.1 Chimney ... ....... ............ ............ ....... ..... ....... ............ ............ ....... ............ ............................... ............ .......... 50

16.2 Favorite .......... ............................... ............ ................... ............ ............ ....... ............ ............ ....... ..... ....... .... 51

16.3 Local Settings....... ....... ..... ....... ............ ............ ....... ............ ............ ................... ............ .............................52

16.4 Malfunction .. ............ ....... ............ ............ ....... ............ ............ ................... ............ ............................... ..... 53

16.5 Information........... ....... ..... ....... ............ ............ ....... ..... ....... ............ ............ ....... ............ ............ ................ 53

Contents

Contents

16.6 ModBUS .... ............ ............................... ............ ................... ............ ............ ....... ............ ............ ....... ..... ... 54

16.7 E-Mail................ ............ ............................... ............ ....... ............ ............ ....... ..... ....... ............ ............ ....... . 55

16.8 IP Config...... ................... ............ ............................... ............ ............................... ............ ................... ...... 56

1177 SSooffttwwaarree ..........................................................................................................................................................................................................................................................................................................5599

1188 MMaaiinntteennaannccee aanndd sseerrvviicciinngg..............................................................................................................................................................................................................................................6600

18.1 Cleaning the Furnace every year ........................ ............ ....... ............ ............ ....... ..... ....... ............ ............ . 60

18.2 Maintenance intervals ...................... ............ ................... ............ ............ ....... ............ ............ ....... ..... ....... 63

18.3 Repairs ........................ ............ ............................... ............ ................... ............ ............ ....... ............ ......... 63

18.4 Checking the Furnace room and storage room ....... ............ ....... ............ ............ ....... ..... ....... ............ ...... 63

Operating Manual AutoPellet Air Furnace 17 — 28

Dear Customer 5

11 Dear Customer

Maine Energy Systems specializes in wood pellet heating, our company enjoys an exclusive license from

ÖkoFEN to manufacture AutoPellet Air here in the USA. We represent expertise, innovation and quality. We

are delighted that you have decided to purchase our product.

• This instruction manual is intended to help you operate the product safely, properly and economically.

• Please read this instruction manual completely and take note of the safety warnings.

• Keep all documentation supplied with this unit in a safe place for future reference.

Please pass on the documentation to the new user if you decide to part with the unit at a later date.

• Installation and first start up must be carried out by an installer certified by Maine Energy Systems.

• Please contact your authorised dealer if you have any questions.

We place great importance on the development of new products. Our R&D department continues to

question accepted solutions and works continually on new improvements. That is how we maintain our

technological lead. We have already received several awards for our products in Austria and abroad.

Our products fulfil European and USA requirements regarding quality, efficiency and emissions.

Operating Manual AutoPellet Air Furnace 17 — 28

6

Use only for the purpose intended

22 Use only for the purpose intended

The pellet furnace is designed heat air to provide heat for buildings. It is not permissible to use the furnace for

any other purpose.

The pellet furnace fulfils the requirements of UL 391-2010 and CSA B366.1–2011.

PE 604 USA_FA 1.0

Types of safety warning sign

7

33 Types of safety warning sign

The warning signs use the following symbols and text.

Types of safety warning sign

1. Risk of injury

2. Consequences of risk

3. Avoiding risk

1. Risk of injury:

Danger - indicates a situation that could lead to death or lifethreatning injury.

Warning - indicates a situation that could lead life-threatning or

serious injury.

Caution - indicates a situation that could lead to injury.

Note - indicates a situation that could lead to property damage.

2. Consequences of risk

Effects and consequences resulting from incorrect operation.

3. Avoiding risk

Observing safety instructions ensures that the heating system is

operated safely.

Operating Manual AutoPellet Air Furnace 17 — 28

8

Warnings and safety instructions

44 Warnings and safety instructions

Observing safety instructions ensures that the heating system is operated safely.

4.1 Basic safety instructions

• Never get yourself into danger; give your own safety the utmost priority.

• Keep children away from the Furnace room and storage room.

• Observe all safety warnings on the Furnace and in this user manual.

• Observe all instructions relating to maintenance, servicing and cleaning.

• Never make any changes to the heating system or flue gas system.

• Never close or remove safety valves.

4.2 Warning signs

RRiisskk ooff ppooiissoonniinngg

Make sure that the pellet Furnace is supplied with sufficient combustion air.

The openings in the combustion air inlet must never be

partially or completely closed.

Ventilation systems, central vacuum cleaning systems,

extractor fans, air conditioning systems, flue gas blowers, dryers, fuel storage ventilation fans or similar

equipment must never be allowed to draw air from the

Furnace room and cause a drop in pressure.

The Furnace must be connected tight to the chimney

using a flue gas tube.

Clean the chimney and the flue gas tube at regular

intervals.

The Furnace room and pellet storage room must be sufficiently supplied with air and ventilated.

Before entering the storage room it must be ventilated

with sufficient air and the heating system switched off

RRiisskk ooff eelleeccttrriicc sshhoocckk

Always disconnect / de-energize the power supply before working on the Furnace.

RRiisskk ooff eexxpplloossiioonn

DO NOT BURN GARBAGE, GASOLINE, NAPHTHA, ENGINE OIL, OR OTHER INAPPROPRIATE MATERIALS.

DO NOT USE CHEMICALS OR FLUIDS TO START THE

FIRE.

Switch off the heating system before filling the storage

room.

PE 604 USA_FA 1.0

Warning signs

9

RRiisskk ooff ffiirree

Do not store any flammable materials in the Furnace

room.

Do not hang out any washing in the Furnace room.

Do not operate with fuel loading or ash removal doors

open.

RRiisskk ooff bbuurrnnss

Do not touch the flue gas connector or flue gas pipe.

Do not reach into the ash chamber.

Use gloves to empty ash box if Furnace not equipped

with automatic ash compression

Do not clean the Furnace until it has been allowed to

cool down.

HHOOTT SSUURRFFAACCEESS

Keep children away.

Do not touch during operation.

Do not operate if maximum draft as listed on Furnace

nameplate is exceeded.

Doing so can allow non-controlled combustion.

RRiisskk ooff ccuutt iinnjjuurriieess dduuee ttoo sshhaarrpp eeddggeess..

Use gloves for performing all work on the Furnace.

DDaammaaggee ttoo pprrooppeerrttyy

The pellet Furnace is suitable only for pellets which

comply with PFI premium or EnPlus -A1 pellets specifications. The use of any other fuel voids your warranty

and can cause damage to the pellet Furnace and

chimney.

DDaammaaggee ttoo pprrooppeerrttyy

Do not use the heating system if it, or any of its components, come into contact with water.

If water damage occurs, check the heating system and

replace damaged parts.

All cover plates, enclosures, and guards must be maintained in place at all times, except during maintenance

and servicing.

Operating Manual AutoPellet Air Furnace 17 — 28

10

What to do in an emergency

4.3 What to do in an emergency

RRiisskk ttoo lliiffee

Never get yourself into danger; give your own safety

the utmost priority.

What to do in the event of a fire

• Switch off the heating system.

• Call your local fire department and or 911.

• Use approved fire extinguishers (fire protection class ABC).

What to do if you smell smoke

• Switch off the heating system.

• Close the doors leading to living areas.

• Ventilate the central heating room.

PE 604 USA_FA 1.0

Prerequisites for installing a pellet Furnace

11

55 Prerequisites for installing a pellet Furnace

You must fulfil the following conditions before operating a fully automatic pellet Furnace.

5.1 Guidelines and standards for installing a pellet Furnace

Overview of standards and guidelines applying to the installation of a pellet Furnace.

Check whether you need to obtain planning permission or approval from the authorities for installing a new

heating system or changing your existing system. Installation must meet all requirements for pellet fired heating systems in your specific location.

All equipment shall be installed in accordance with the instructions of the manufacturer and in a manner acceptable to the authority having jurisdiction by experienced personnel. When required by the authority having jurisdiction, such personnel shall be licensed to perform this service.

In Canada, the installation of the solid fuel furnace shall comply with the applicable requirements of CSA

B365, and if changes are made to the installation of the oil furnace, these shall comply with CSA B139.

If changes are made to an electric furnace during the installation, the changes shall comply with the Canadian

Electric Code. Part 1.

5.2 Furnace room circulating air

The pellet Furnace is installed in the Furnace room.

1. Safety instructions for the Furnace room

RRiisskk ooff ffiirree

Do not store flammable materials or liquids in the vicinity of the pellet Furnace.

Do not permit unauthorised persons to enter the Furnace room - Keep children away.

Do not operate with fuel loading or ash removal doors

open.

2. Air supply and ventilation of Furnace room

The Furnace room must be fitted with air supply and ventilation openings (at least 31 inch²/200cm²).In

any case you must comply with the state and local regulations

3. Damage due to frost and humid air

The Furnace room must be frost-proof to ensure trouble-free operation of the heating system. The temperature of the Furnace room must not fall below 37°F and must not exceed 90°F. The air humidity in the

Furnace room must not exceed 70%.

4. Danger for animals

Make sure that household pets and other small animals cannot enter the Furnace room. Fit mesh over any

openings.

5. Flooding

If there is a risk of flooding, switch off the pellet Furnace and disconnect from the power supply before

water enters the Furnace room. You must have all components that come into contact with water replaced, before you start up the pellet Furnace again.

Operating Manual AutoPellet Air Furnace 17 — 28

12

Furnace room supply air

5.3 Furnace room supply air

The pellet Furnace is installed in the Furnace room.

1. Safety instructions for the Furnace room

RRiisskk ooff ffiirree

Do not store flammable materials or liquids in the vicinity of the pellet Furnace.

Do not permit unauthorised persons to enter the Furnace room - Keep children away.

Do not operate with fuel loading or ash removal doors

open.

2. Air supply and ventilation of Furnace room

The Furnace room must be fitted with air supply and ventilation openings (at least 31 inch²/200cm²).In

any case you must comply with the state and local regulations

3. Combustion air supply

The pellet Furnace needs a supply of combustion air. The supply of combustion air can:

a. take place using one or more air supply and ventilation openings in total min. 31 inch².

b. The air must not be used directly from the outside without preheating (background: This could lead

to a condensation of the boiler.

Never operate the pellet Furnace if the air intake openings are partially or completely closed.

Contaminated combustion air can cause damage to the pellet Furnace. Never store of use cleaning detergents containing chlorine, nitrobenzene or halogen in the room where the heating system is installed, if

combustion air is drawn directly from the room. It is recommended that no washing or drying of laundry

is done in the Furnace room or where the Furnace may draw air from.

Do not hang out washing in the Furnace room.

Prevent dust from collecting at the combustion air intake to the pellet Furnace.

4. Damage due to frost and humid air

The Furnace room must be frost-proof to ensure trouble-free operation of the heating system. The temperature of the Furnace room must not fall below 37°F and must not exceed 90°F. The air humidity in the

Furnace room must not exceed 70%.

5. Danger for animals

Make sure that household pets and other small animals cannot enter the Furnace room. Fit mesh over any

openings.

6. Flooding

If there is a risk of flooding, switch off the pellet Furnace and disconnect from the power supply before

water enters the Furnace room. You must have all components that come into contact with water replaced, before you start up the pellet Furnace again.

PE 604 USA_FA 1.0

Flue gas system

13

5.4 Flue gas system

The flue gas system consists of a chimney and a flue gas tube. The flue gas tube connects the pellet heating

system to the chimney. The chimney leads the flue gas from the pellet heating system out into the open.

1. Design of the chimney

The dimensions and design of the chimney is very important. The chimney must be able to ensure sufficient draft to safely draw away the flue gas regardless of the status of the Furnace. Low flue gas temperatures can cause sooting and moisture damage on chimneys that are not insulated. For this reason moisture-

resistant chimneys (stainless steel or ceramic) should be used. An existing chimney that is not damp-resistant needs to be rennovated before use. Follow guidelines below:

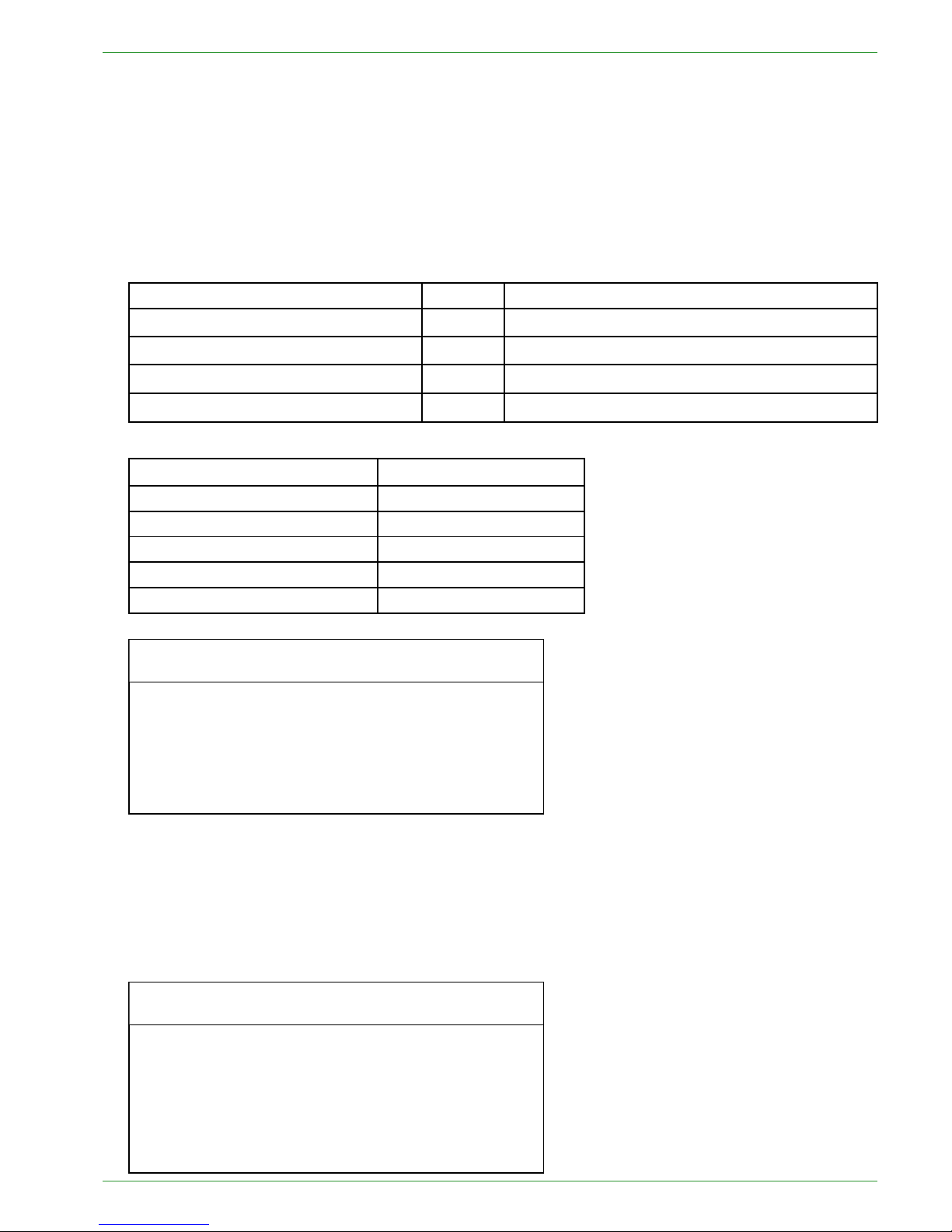

Furnace size Furnace

Flue gas tube diameter (at Furnace)

inch/mm 6.3/160

Flue gas temp. / rated power

°F

Flue gas temp. / partial load

°F

Min. draft – full load/part load in/wc – 0.04 / – 0.02

Chimney size Min. Height

6in x 6in

17ft

7in x 7in

16ft

8in x 8in

16ft

6in round 19ft

7in round 17ft

Person(s) operating a pellet fired furnace is/are responsible for operation in a manner that does not create a

public or private nuisance condition. The manufacturer's

distance and stack height recommendations and the requirements in any applicable laws or other requirements

may not always be adequate to prevent nuisance conditions due to terrain or other factors.

Recommended and UL-103HT approved chimney materials are:

a. Selkirk sure temp

b. Supervent (JSC)

c. Security chimneys (secure temp ASHT)

Use flue gas pipe from chimney to Furnace as required by your local code.

UUnnrreegguullaatteedd ccoommbbuussttiioonn

Please observe that combustion air openings and flue

pipes are not reduced in size or closed. Make end user

aware of these guidelines and their potential danger.

Clean the chimney and the flue gas tube at regular

intervals.

Check if the draft inducer is clean and in a good

condition.

Operating Manual AutoPellet Air Furnace 17 — 28

14

Flue gas system

2. Flue gas temperature

The flue gas temperatures are approximately the same for all AutoPellet Air covered in this manual.

The dewpoint of flue gas with wood pellets (max. 10% water content) is approx. 120°F.

It is possible to increase the flue gas temperature to prevent condensation inside the chimney and avoid

damage due to damp. Only authorised installers may increase the flue gas temperature.

Note:

The increase in flue gas temperature results in reduced efficiency and thus increases fuel

consumption.

3. Negative pressure of the chimney

The Furnace must be connected to a chimney or a vertical venting system that is capable of handling and

producing a negative breeching pressure of –0.4 “WC. Use a draft gauge to verify the indicated draft value, adjust barometric damper as required. Drill a small hole in the connection pipe at about 2in/ 50mm

from the Furnace flue outlet and use this hole as your measuring point.

Chimney draft

The suction effect of the chimney draft must extend all the way to the Furnace flue pipe connection. The

maximum flow rate that can be drawn through the chimney limits the maximum performance of the chimney connection. The Furnace performance must be reduced if the chimney does not possess the necessary cross-section. This may only be performend by authorised personnel.

4. Power venter

AutoPellet Air are approved by the manufacturer for installation with the Field Controls SWGAF power venter which is approved for wood pellet burning appliances.

Furnaces installed with SWGAF power venters must follow all manufacturer´s installations and must comply with all applicable codes from agencies having authority

over the installation.

5. Cleaning

Clean the flue gas tube and chimney regularly. Solid fuel burning appliances need to be cleaned frequently because soot, creosote, and ash may accumulate. The hotter the fire, the less creosote is deposited.

Cleaning intervals can vary in warm periods due to this and become more frequent.

RRiisskk ooff cchhiimmnneeyy ffiirree

Creosote-formation and need for removal:Low flue gas

temperature can cause creosote. Creosote can condense in a relatively cool chimney. As a result, creosote residue accumulates on the flue lining. If ignited, this

creosote will create an extremely hot fire. The chimney

and the chimney connector should be inspected at least

twice monthly during the heating season to determine if

a creosote buildup has occurred. If creosote has accumulated it should be removed to reduce the risk of a

chimney fire.

OOxxiiddaattiioonn ooff cchhiimmnneeyy

Do not use metal brushes to clean chimneys made of

stainless steel.

Your state and local regulations must be observed.

PE 604 USA_FA 1.0

Safety systems

15

5.5 Safety systems

The following safety measures are the prerequisite for safe operation of your system.

Emergency stop switch

Every heating system must be able to be switched off with an Emergency Stop switch. The

Emergency Stop switch must be outside of the Furnace room.

Safety temperature sensor

The pellet Furnace is equipped with a safety temperature sensor. This is located on the pellet Furnace. If the Furnace temperature exceeds 230°F then the heating system switches

off.

5.6 Installation with an existing Furnace

AutoPellet Air Furnaces are not to be connected to a chimney flue serving another appliance. However, when

all State and local codes allow for the sharing of chimney flues, the AutoPellet Air Furnaces and another appliance burning pellets or a different fuel can be operated simultaneously while connected to a single existing

chimney or flue gas system providing the following conditions are met:

• All state and local codes permit the specific installation

• All appliances are installed in accordance with the manufacturer’s installation specifications or if lacking

manufacturers specifications, the appliance in question is installed in a manner commonly recognized as

safe and correct for the application and circumstances

• The chimney or flue gas system must be able to handle the combustion products of either appliance and

both appliances when operated simultaneously

AAvvooiidd cclleeaarraannccee iissssuueess tthhaatt ccaann mmaakkee sseerrvviicciinngg ddiiffffiiccuulltt::

Be sure to follow suggested clearances when installing the AutoPellet Air Furnaces with an existing Furnace to be sure that

service and cleaning can be performed adequately.

AAvvooiidd ccooddee vviioollaattiioonnss::

When connecting to or with an existing Furnace , contact the authority having jurisdiction to be sure the type of installation planned is allowed.

Document the type of Furnace that the AutoPellet Air Furnace is

connected to or with.

Pellet Furnace: Make and Model number:

____________________

Existing Furnace: Make and Model number:

_____________________

PPoossssiibbllee eessccaappee ooff fflluuee ggaass::

Do not connect this unit to a chimney flue serving another appliance unless multiple appliances into a single flue is authorized by

all authorities having jurisdiction.

Operating Manual AutoPellet Air Furnace 17 — 28

16

Fuel

66 Fuel

Wood pellets are natural wood (dried sawdust or waste from machining) that has been formed into pellets

under high pressure. They have a very low moisture content and very high calorific value. The manufacture of

wood pellets is regulated by European standard EN ISO 17225–2.

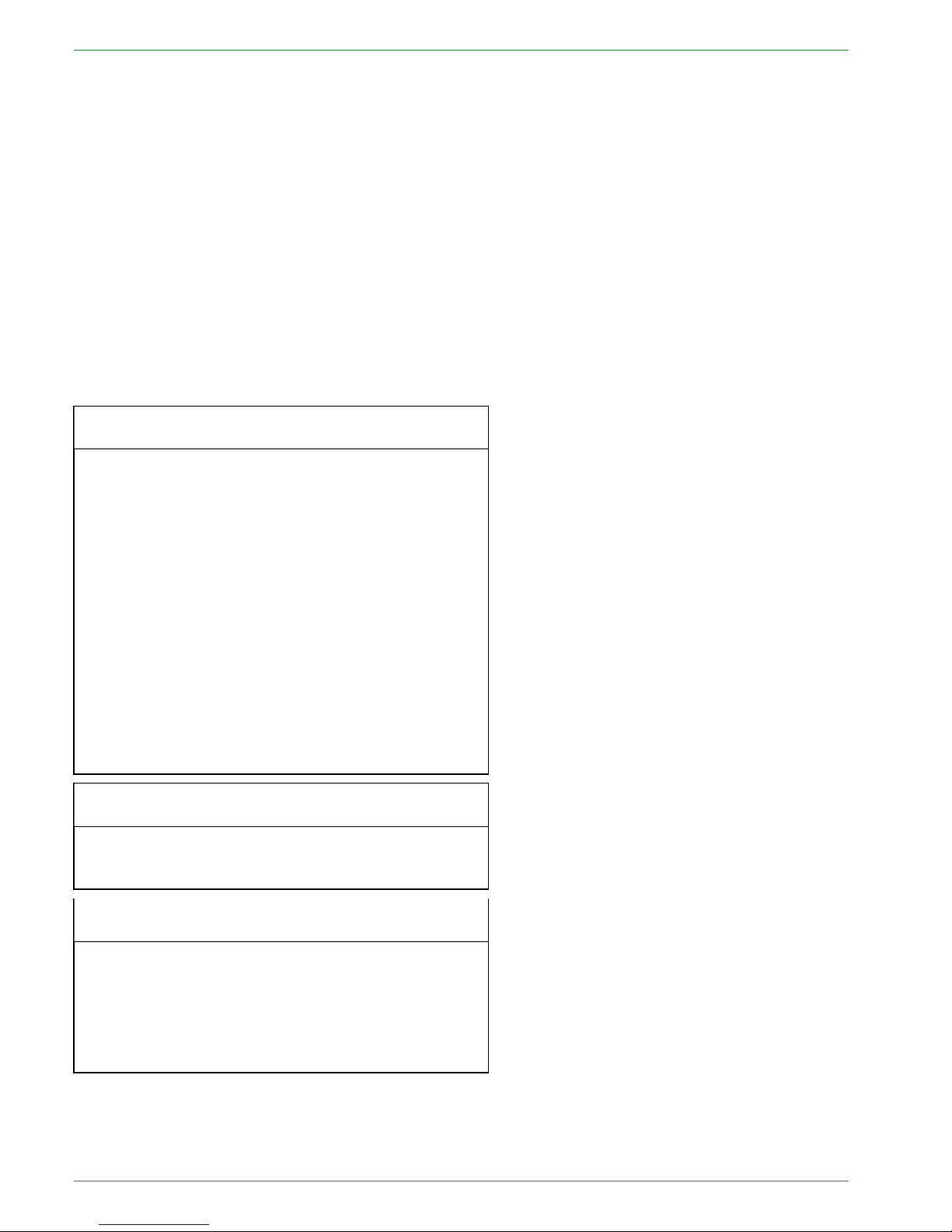

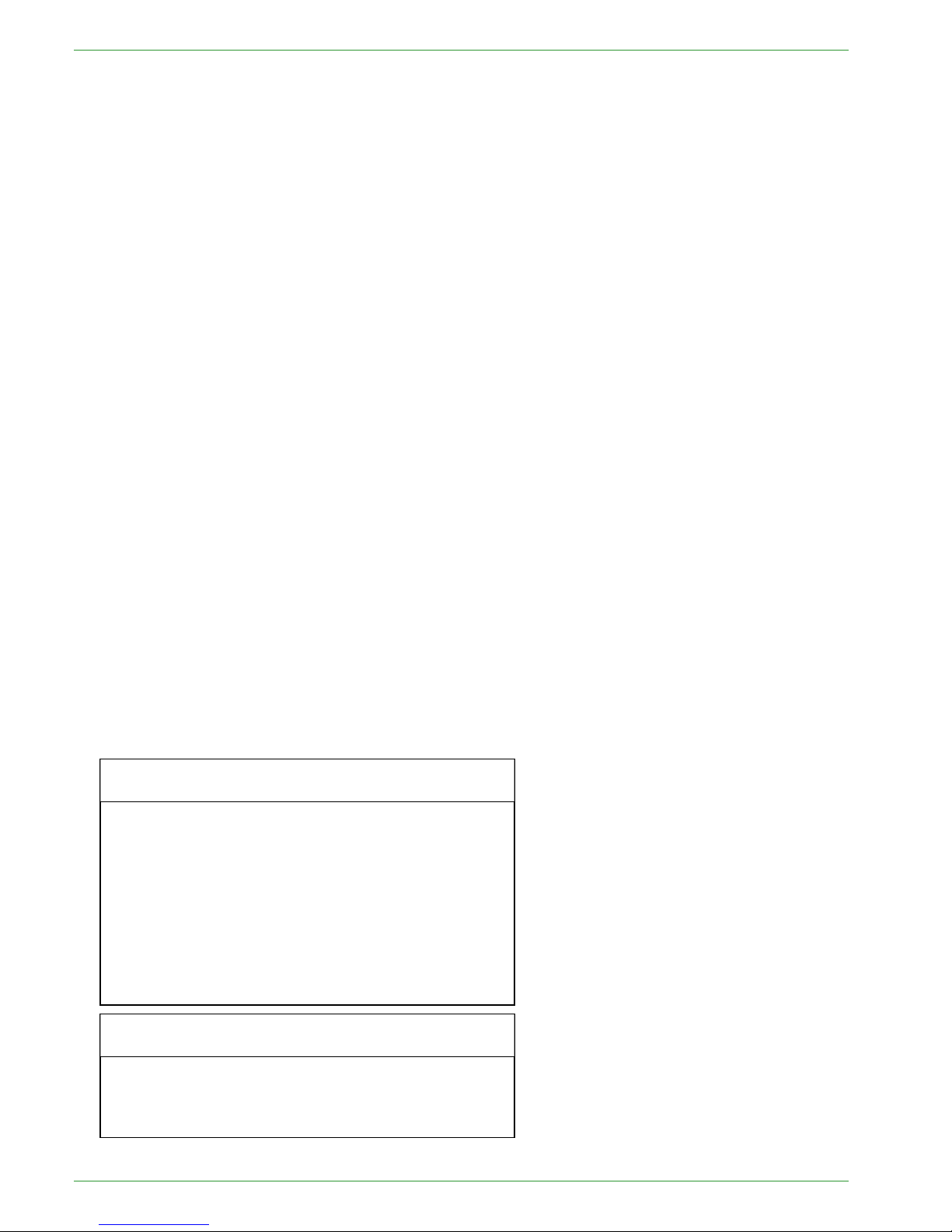

6.1 Specification for high quality pellets as PFI (Pellet Fuel Institut)

Calorific value

min. 7200 BTU/lbs

Bulk density

min. 40 Lb/cft

Water content

max. 10%

Ash content

max. 1.0%

Ash melting point at least 2192°F

Length

max. 1.5 inch / 40 mm

Diameter

1/4” – 5/16” / 6 – 8mm

Fine material

max. 0.5 %

Contents

100% untreated natural wood

TThhee ppeelllleett FFuurrnnaaccee iiss ssuuiittaabbllee oonnllyy ffoorr ppeelllleettss ooff nnaa-ttuurraall wwoooodd tthhaatt ccoommppllyy wwiitthh PPFFII pprreemmiiuumm ssppeecciiffiiccaa-ttiioonnss.. UUssiinngg nnoonn--ppeelllleettiisseedd ffuueellss oorr ppeelllleettss tthhaatt aarree

nnoott mmaannuuffaaccttuurreedd ffrroomm nnaattuurraall wwoooodd wwiillll lleeaadd ttoo tthhee

wwaarrrraannttyy bbeeccoommiinngg vvooiidd aanndd wwiillll ccaauussee ddaammaaggee ttoo

tthhee ppeelllleett FFuurrnnaaccee aanndd tthhee cchhiimmnneeyy..

NNeevveerr uussee ppeelllleettss tthhaatt ccoonnttaaiinn ttrreeaatteedd wwoooodd,, ccoolloo-rreedd ppaappeerr pprroodduuccttss,, ccaarrddbbooaarrdd,,ssoollvveennttss,, ppllaassttiicc,,

ttrraasshh oorr ggaarrbbaaggee

Never burn trash, plastics, gasoline, solvents, naphtha,

household garbage, material treated with petroleum

products such as particleboard, railroad ties and pressure treated wood, leaves, paper products, cardboard.

PE 604 USA_FA 1.0

Storing the pellets

17

6.2 Storing the pellets

1. Pellets are to be stored in a place where they are kept dry all year.

2. Install a back-ventilated partition to prevent pellets from contacting damp walls, or use a fabric tank.

3. Refer to our planning hints for pellet storage rooms and warning signs.

4. Legislation in your country must be observed regarding building specifications for storage rooms.

5. ÖkoFEN also offers FleXILO fabric tanks for storing pellets.

6.3 Measures for the ventilation of storage rooms

To avoid any kind of danger through possible degassing of the pellets, make sure you obey the following

guidelines:

• The storage room has to be insulated towards the living area.

• The storage room has to be ventilated to the outdoors.

For further information please consult your expert adviser.

Operating Manual AutoPellet Air Furnace 17 — 28

18

The pellet Furnace

77 The pellet Furnace

The pellet Furnace is equipped with an automatic cleaning system and an ash box with ash compression

system. The installed programmable logic controller system enables fully automatic operation and highest

efficiency. We offer an optional automatic de-ashing system for the highest level of cleanliness and comfort.

AutoPellet Air types and power ratings

We offer the Pellet Furnace with the following power ratings:

Suction-feed systems: 58,000 to 95,000 BTU/hr

All sizes / outputs of the AutoPellet Air Furnace are available with external automatic ash compression

system.

Note:

Refer to the data plate for the power rating of your AutoPellet Air. The data plate is located on the

rear side of the AutoPellet Air. Here you will find the type designation, manufacturer's serial number

and year of build.

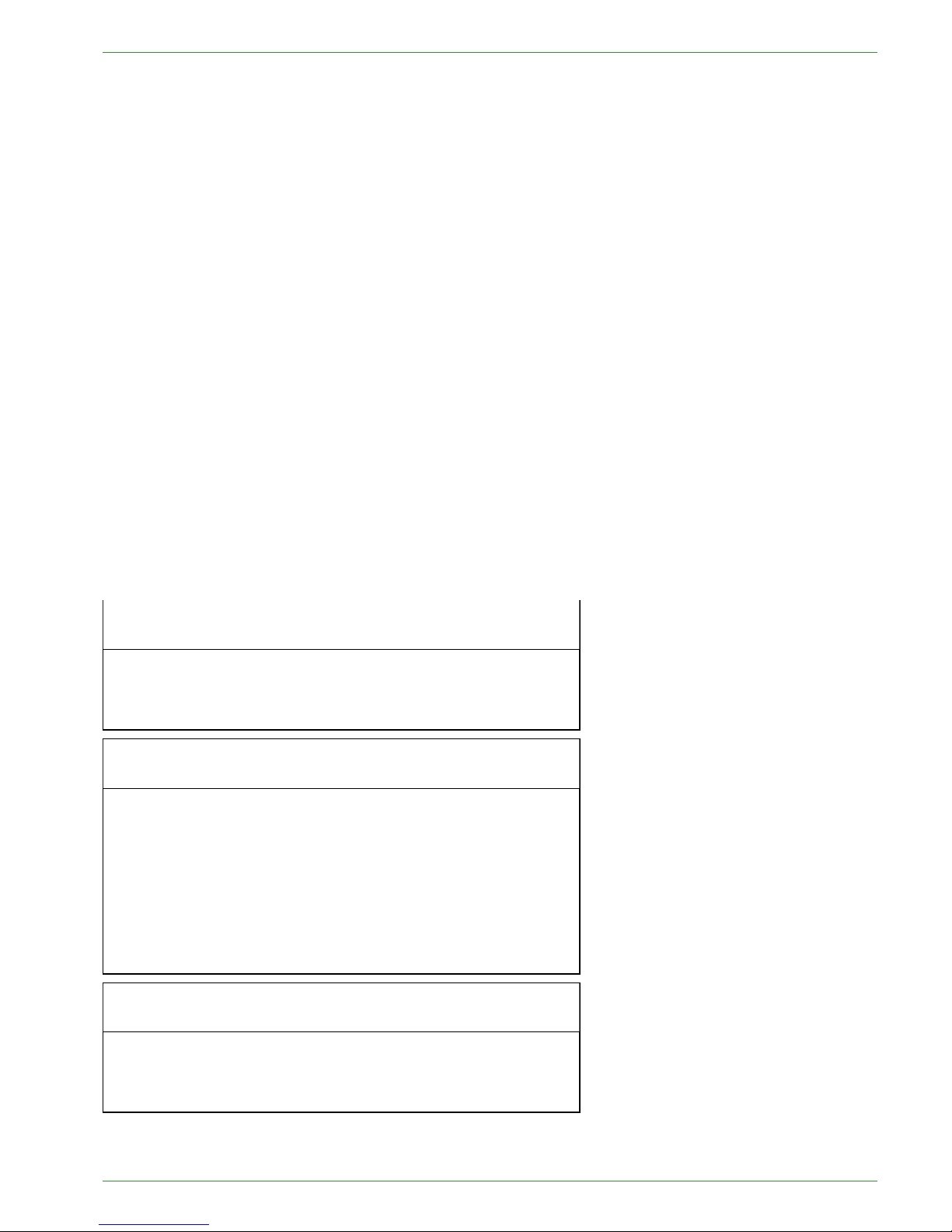

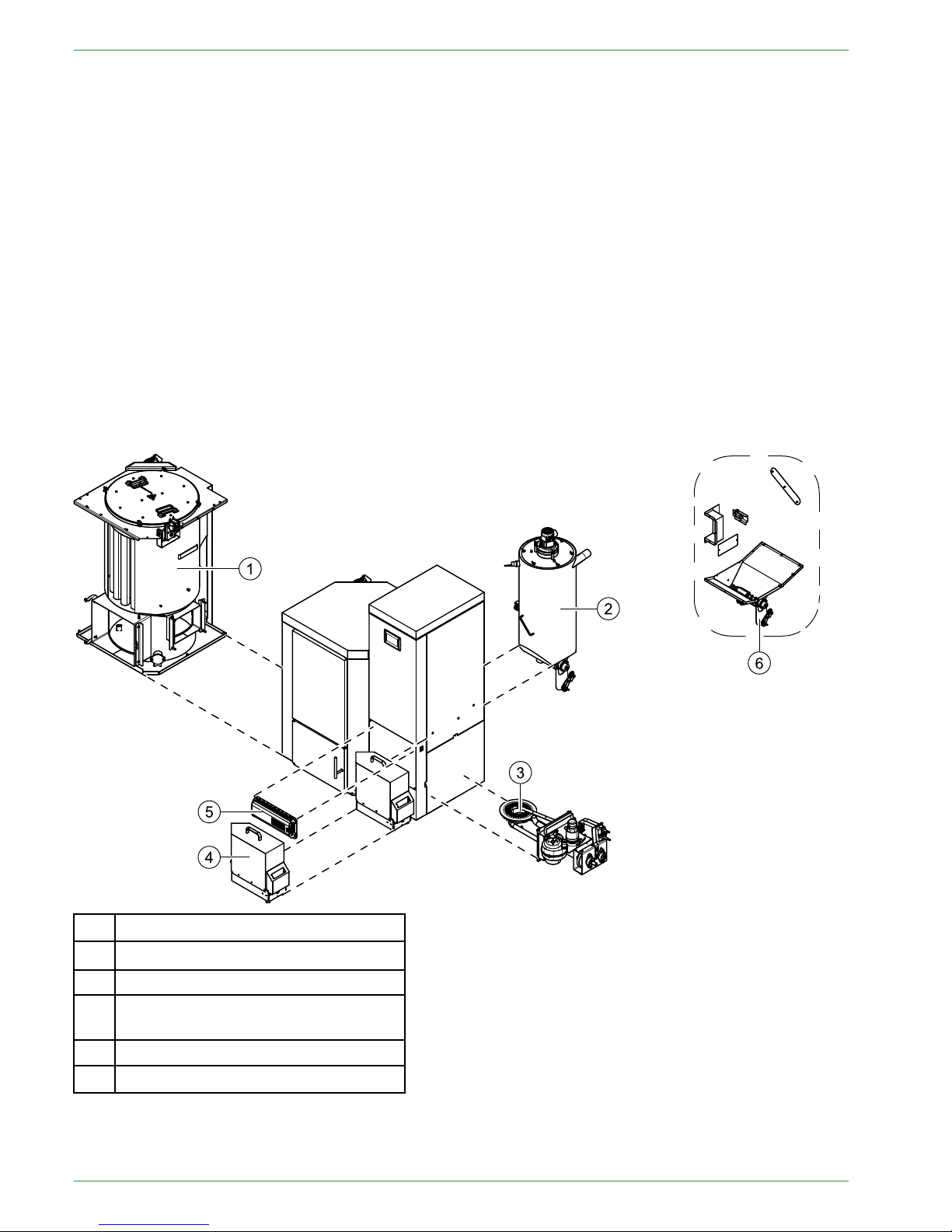

Key components of the AutoPellet Air

1

Furnace (heat exchanger)

2

Vac Hopper / Day tank

3 Burner

4

External automatic ash compression

system

5

Furnace controller

6

Additional parts hand filling

PE 604 USA_FA 1.0

The pellet Furnace

19

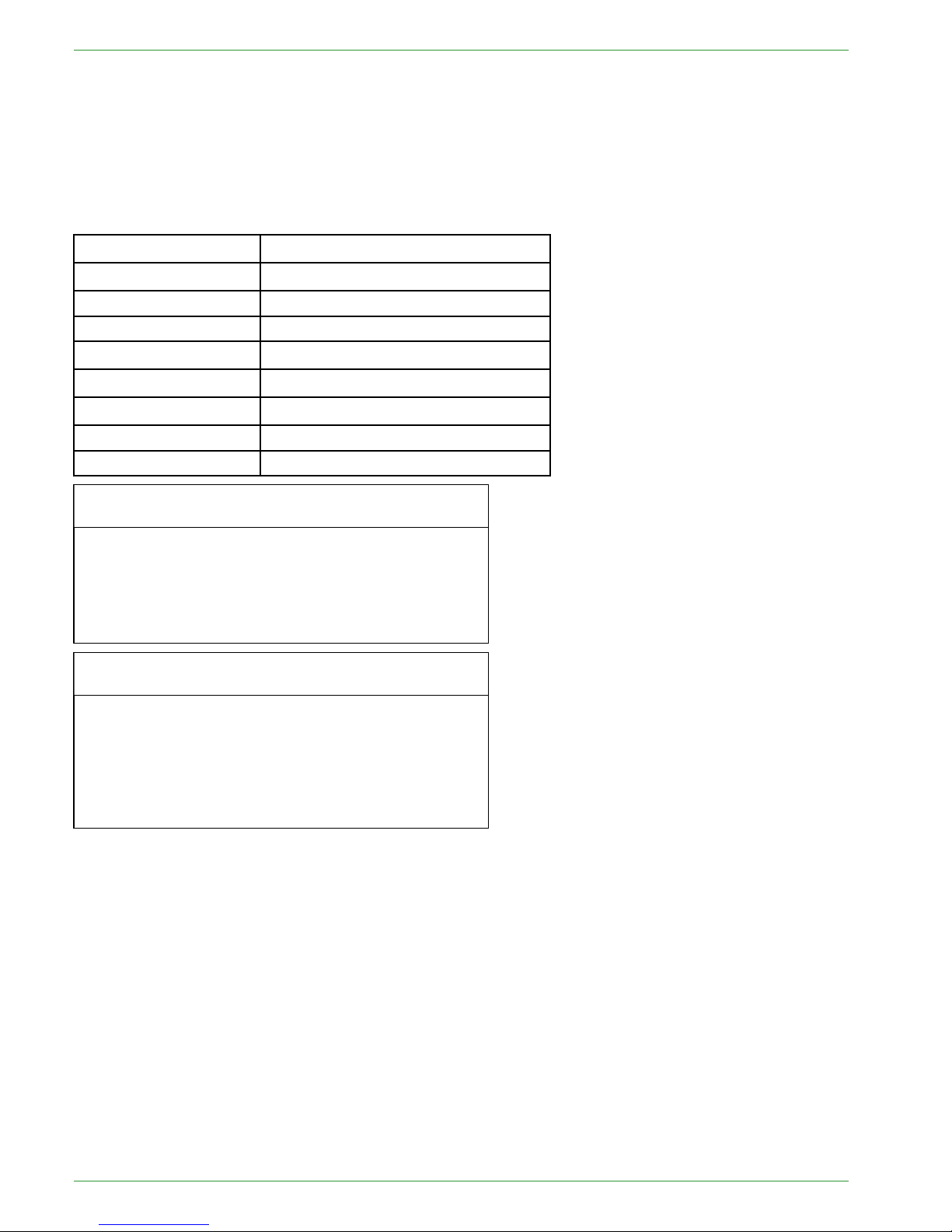

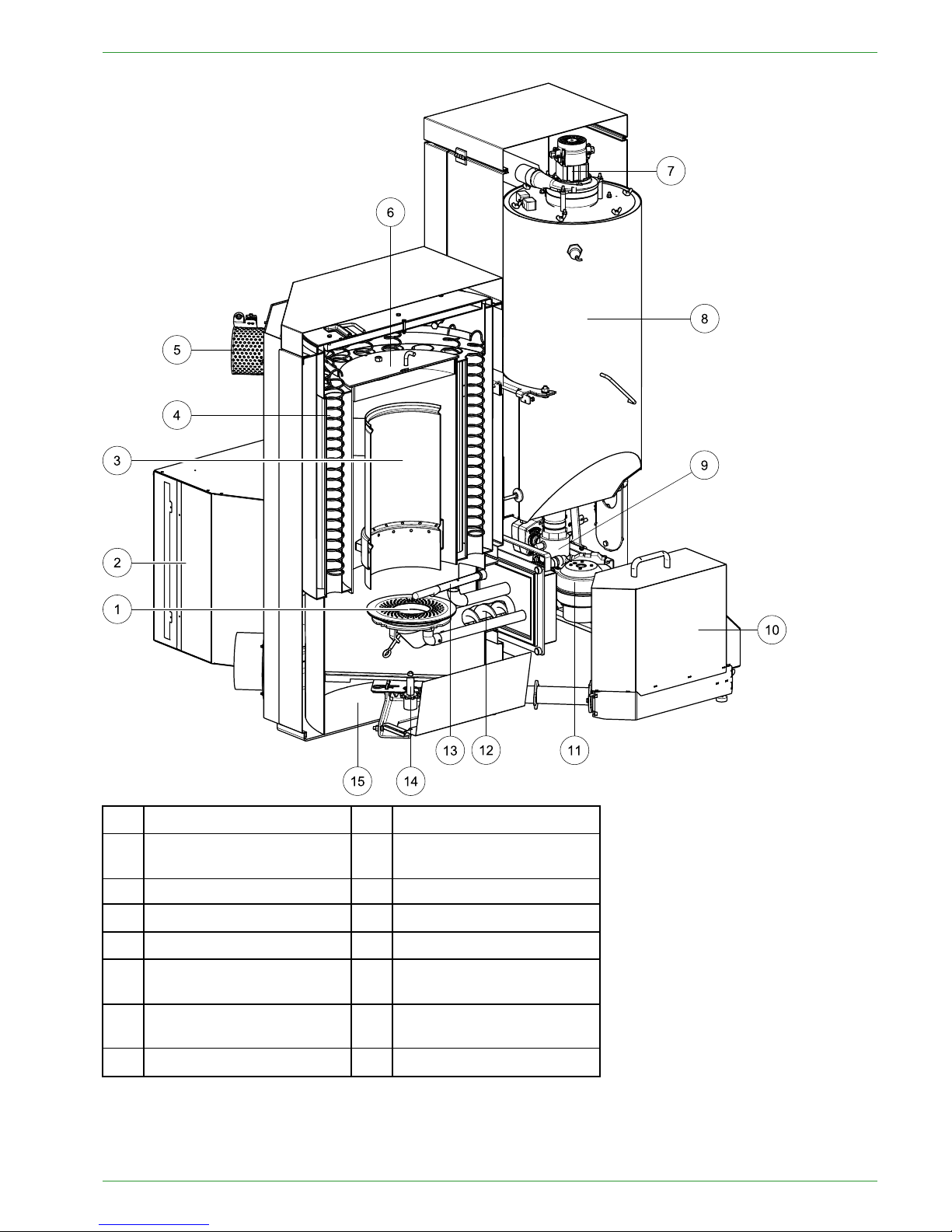

1

Burner plate

9

Fire protection – ball valve

2

Fan

10

External ash box

(optional)

3

Flame tube

11

Burner fan

4

Heat exchanger

12

Burner auger

5

Flue gas fan

13

Electronic ignition

6

Combustion chamber

cover

14

De-ashing system

(optional)

7

Suction turbine

15

Ash chamber / Fire

chamber

8

Vac hopper / Day tank

Operating Manual AutoPellet Air Furnace 17 — 28

20

Pellet suction system

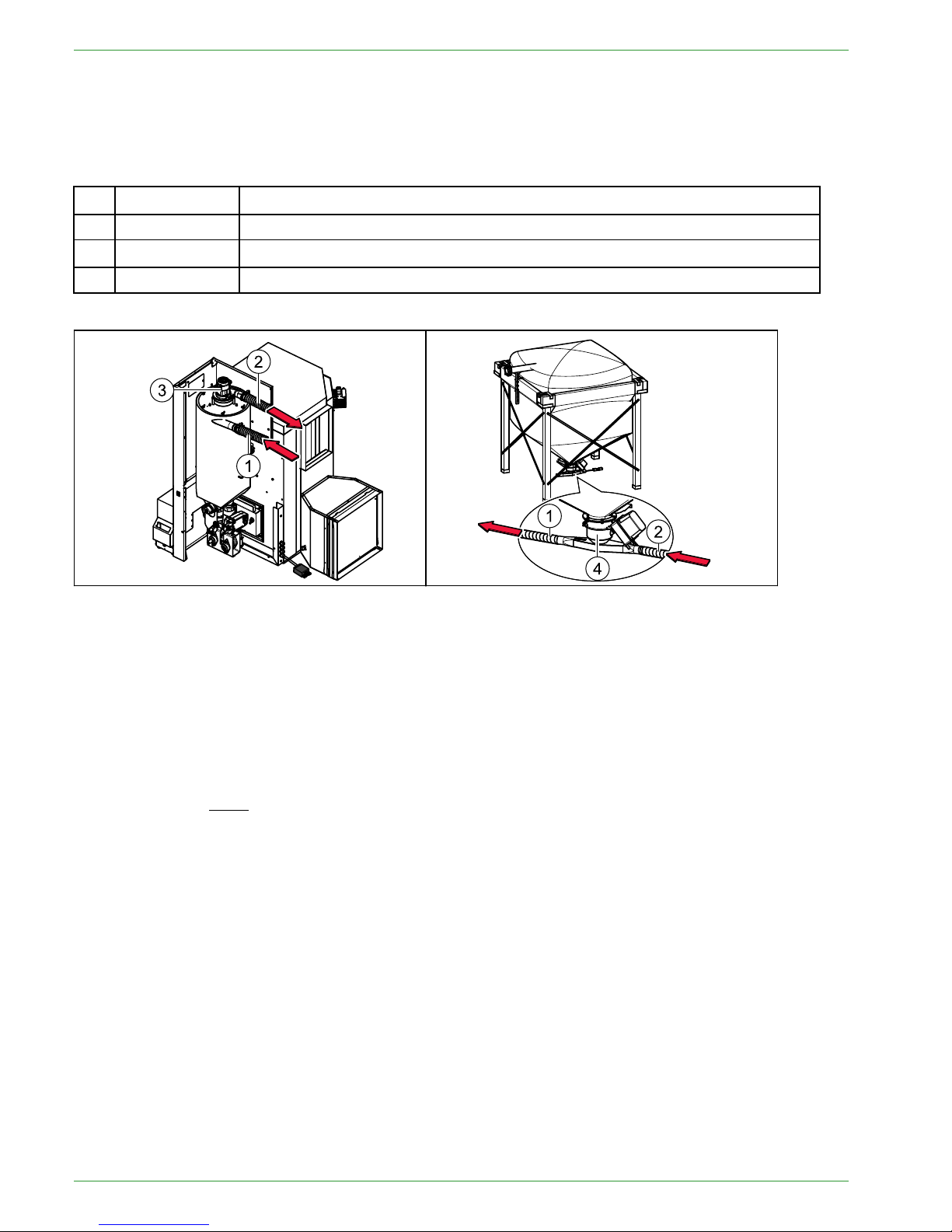

7.1 Pellet suction system

The pellet suction system consists of a pellet line, an air line and a suction turbine. The suction turbine in the

hopper conveys pellets in the pellet line from the storage room or textile tank to the hopper.

Key components of pellet suction system

1

Pellet hose Hose from textile tank to the hopper.

2

Air hose Hosee from the suction turbine to the textile tank.

3

Suction turbine Located above the hopper underneath the AutoPellet Air burner casing.

4

Suction switch Located underneath the textile tank.

Pellet Furnace FleXILO textile tank

77..11..11 AAsssseemmbbllyy ooff tthhee vvaaccuuuummssyysstteemm

The pellet hose and the air hose are flexible spiral hoses made out of plastic. A copper braid avoids the static

loading of the spiral hose.

To avoid damage to the spiral hose, you must observe the following assembly guidelines:

Bending radius The hose should be led as briefly as possible and with a few curves as necessarily. Bend-

ing radius may never be smaller than 12 inch.

Upward

gradients

Max difference in height = 19 feet

Note: A difference in height of up to 10 feet can be overcome at one time. Larger diffe-

rences in height must by interrupted with a 4 foot horizontal run of the pellet hose.

Impact

protection

The spiral hose can be mounted up to 19 feet exactly straight. In such cases however, it is

very important to create a slight "S" in the pellet piping before a sharp curve to slow

down the pellets to prevent hose damage.

Installation in

the soil and

openings:

When installing pellet lines underground remember! The pellet lines are not designed for

direct burial and require protection from being crushed or chewed by varmints.

Protective piping should be minimum 4 inch and sealed at each end. There should be no

bends greater than 15 degrees in the underground sections of the pellet hose.

Tightness To avoid problems with your pellet lines, it is important to have all hose connections se-

cured completely air tight with hose clamps.

Static

neutralization

The hoses are provided with a copper braid, those the hose keeps antistatic. In order to

ensure the function of the anti-statics, those copper braid must be attached at each end

to the existing grounding become.

Fire protection

At a wall break-through to the heating room must be installed a fire protection seal in the

pellet- and the air hose.

PE 604 USA_FA 1.0

Loading...

Loading...