Page 1

Model

Overall

Height

Height

to Horn

Knee

Switch

Height

Base

Width

Base

Depth

Lid

Swing

Radius

Capacity

Litres

Capacity

Lbs.

FC-20

43.6”

41.7”

24.3” to

27.8”

17.1”

21.1”

15.6” 20 45

FC-30

47.4”

45.4”

26.6” to

30.1”

19.4”

22.7”

17.3” 30 65

EI - 50

49.2”

47.5”

22.6”

21.3”

21.3”

19.3” 50 105

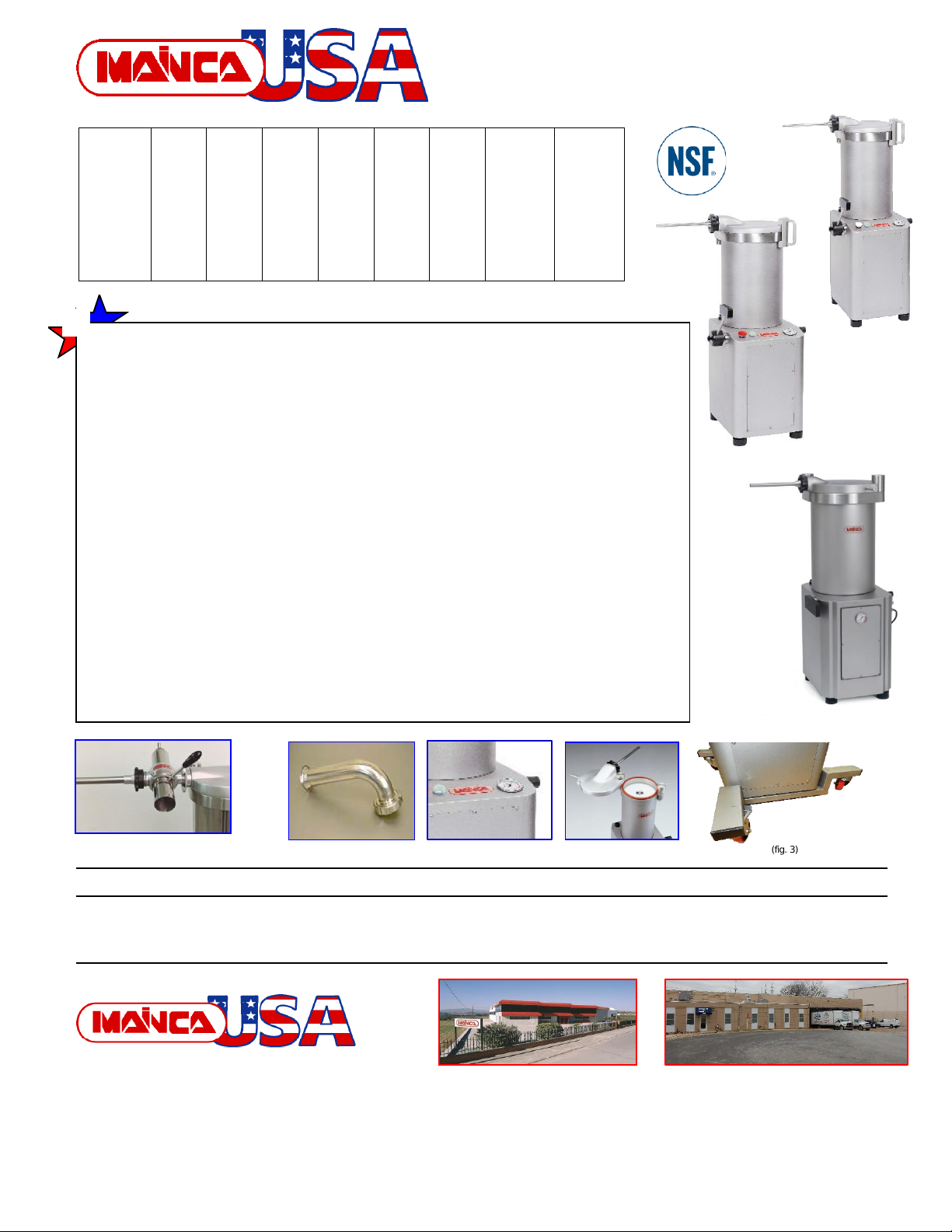

Manual Portion Control Head Depositing Tube (fig. 1) (fig. 2) (fig. 3)

Technical Data Model FC-20 FC-30 EI-50

Motors:

3 Phase, 220V, 60Hz HP / Amps 1.25 / 4.5 1.75 / 5.8 2.25 / 7.4

1 Phase, 220V, 60Hz HP / Amps 1.50 / 10.5 2.50 / 11.5 2.50 / 11.5

1 Phase, 110V, 60Hz HP / Amps 1.50 / 21.0 2.50 / 26.0 2.50 / 26.0

Net Weight: LBS. 198 295 490

8064 Chivvis Drive

St. Louis, MO 63123

Fax (314) 353-6655

(877) 677-7761

Mainca USA Inc. reserves the right to alter

any specification without prior notice.

FC Stuffers

FC-20

Mainca World Headquarters Barcelona, SPAIN

Mainca USA Headquarters St. Louis, MO USA

FEATURES & BENEFITS

ALL STAINLESS CONSTRUCTION For Durable Long Life

STAINLESS STEEL PISTON (Optional S/S Lid on EM-20 & EM-30) For USDA Approved Facilities

ADJUSTABLE SIDE MOUNTED KNEE SWITCH For More Comfortable Operation & Less Knee Strain

POWERFUL MOTOR & OVERSIZED RAM For Faster Stuffing with Stiff Products

VARIABLE SPEED WITH BUILT-IN PRESSURE GAUGE For Precise Product Control & Power (fig. 1)

ENCLOSED OIL RESERVOIR Eliminates Spills while Moving

THREE STUFFING HORNS INCLUDED For Maximum Flexibility (Choose from 10, 12, 15, 20, 25, 30 or 40 mm)

WATER TIGHT CONSTRUCTION For Carefree Hose-Down Cleaning

AUTO PISTON DECOMPRESSION For Less Overstuffing & Bleed-off when Knee Switch is Released

REMOVABLE PISTON & SWING-OUT LID For Easy Cleaning (fig. 2)

SMOOTH PRODUCT DISCHARGE PATH Eliminates Clogging & Product Discoloration

KNEE SWITCH “AUTO-ON” For Noise Free Idle Time (3 phase only)

ANTI-TILT TROLLEY & CASTORS For Safe, Stable, Easy, Strain-Free Moving (fig. 3)

OPTIONS:

MANUAL PORTION CONTROL HEAD For Precise Filling of Bags & Casings

DEPOSITING “L” TUBE with FLAP VALVE For Quick, Accurate, Drip-less Filing of Liquid Products

FC-30

EI-50

Available Exclusively

Through Authorized

Mainca USA Distributors

Loading...

Loading...