®

BOOK NO, 22104

Straight

with

Flexi-Ban~d

Knife

(Mode/A)

SABRE900

SABRE800

SABRE700

Instructions

and

Parts

I

I

Cutting

Sharpener

List

Machine

iti'Jo

·~

©

1982

H.

MAIMIN

SAFETY

1.

BE SURE

operator

2,

USE

U.S.A. only I phase: Use AWG 16/3 SJ, SJT

INTERNATIONAL

3. KEEP

4. AVOID DANGEROUS ENVlRONMENT. Do

5. KEEP VISITORS AWAY. They should be kept at a safe distance from the,cutting area.

STORE

6.

7. MAINTAIN

instructions for lubricating.

8.

ALWAYS DISCONNECT MACHINE when not in use, before servicing, and when changing blades.

9.

REMOVE KNIFE KEY AND WRENCHES. The knife

starting motor.

10. AVOID ACCIDENTAL STARTING. Disconnect electrical cord before carrying machine.

connecting

I

~~·

~EEP

~KEEP

CO.,

INC.

INSTRUCTIONS

MACHINE

from electrical shock. Use a Maimin Grounded Connector (#458B,

CORRECTELECTRICAL

.

CUTTING

MACHINE

MACHINE

cord.

GUARDS IN PLACE AND

HANDS AWAY FROM CUTTING BLADE.

IS PROPERLY GROUNDED. The cutting machine should be grounded while in use to protect the

WIRING

3 phase: Use AWG 16/4 SJ,

1P

+ N +

1:

Use 3x

l,

0

3P+

J_:

~

Use

AREA

CLEAN. A cluttered table can cause accidents.

PROPERLY. When not in use, the machine should be stored in a dry location.

WITH CARE. Keep machine clean and blade sharp for best and safest performance. Follow

IN

rtJ.m'

4x

1,

0 rnm' CEE(2)61'

not

WORKING ORDER.

SJT

CEE(2)6l

use machine in a

key

and other wrenches must be removed from machine before

damp

or

#458A for 3 phase machine).

or

wet location. The work area should be well lit.

Be

sure switch

is

off

before

H. MAIMIN CO., INC.,

P.O.

Box

549 ~ Route

341,

Kent, Connecticut

06757,

U.S.A.

I.

DESCRIPTION

1.1

GENERAL

Your new Maimin Sabre straight knife machine

It

is

ready for operation.

electrical outlet

ting. The straight knife machine can

of

types

machine. However, for best results, it

minimum height

cutting blade

No. A403) acts as a protective guard for the operator so

be

should

on top

of

from vibrating.

of

materials from a

of

at

its highest position. The Presserfoot Leg

down

at

the lay when cutting in order to prevent the material

merely necessary

the correct voltage, oil it, and then begin cut-

few

the

lay be no lower than the

all times. The Presserfoot should lie lightly

be

used for cutting various

ply to the full capacity

is

recommended

is

delivered

to

connect it to an

that

bottom

of

of

(Key

that

the

the

the

1.2 FLEXIBANDS AVAILABLE

Three different grits

ening the blade:

Coarse - For hard

Medium -

Fine -

(Part

For

(Part

For

(Part

of

"FlexiBands" are available for sharp-

or

coarse materials

1450-

fine woolens, synthetics and cottons

1451

sheer fabrics, very soft materials

1452-

Box

- Box

Box

of

of

of

100)

100)

100)

1.3 BLADES AVAILABLE

The blades come in three grades and in different shapes for cutting unusual

are:

ZK-

retaining its cutting edge for a long time.

BK-

the ZK blade

TK

_:._

well. Used only for hard

glass

See back cover for complete list

cording to size, grade, shape, and quantity.

or

difficult materials. The three grades available

High Speed Steel

Carbon Alloy Steel

Treated High Speed Steel . . . Retains cutting edge very

or

heavy denim as

but

less costly.

...

Most popular blade as it wears well

...

A quality blade less durable than

or

abrasive materials such as fiber-

it

is

very expensive.

of

part numbers

of

blades ac-

II.

OPERATION

2.1

UNPACKING A NEW MACHINE

During shipment oil may have flowed onto Pulley A303 which

can cause sharpener to traverse slowly. Sharpener cycle time

1.5

seconds.

oil, disconnect power, remove Brake A342, wipe oil from

Pulley and Crank

paragraph 2-11.

If

longer, oil

is

causing Pulley to slip.

A505. Replace Brake as described in

To

is

remove

2.2 TO START

it

Fill oil cup. Attach Connector

Move switch

(International).

Caution: 3 phase

viewed from rear.

A550 from

motor

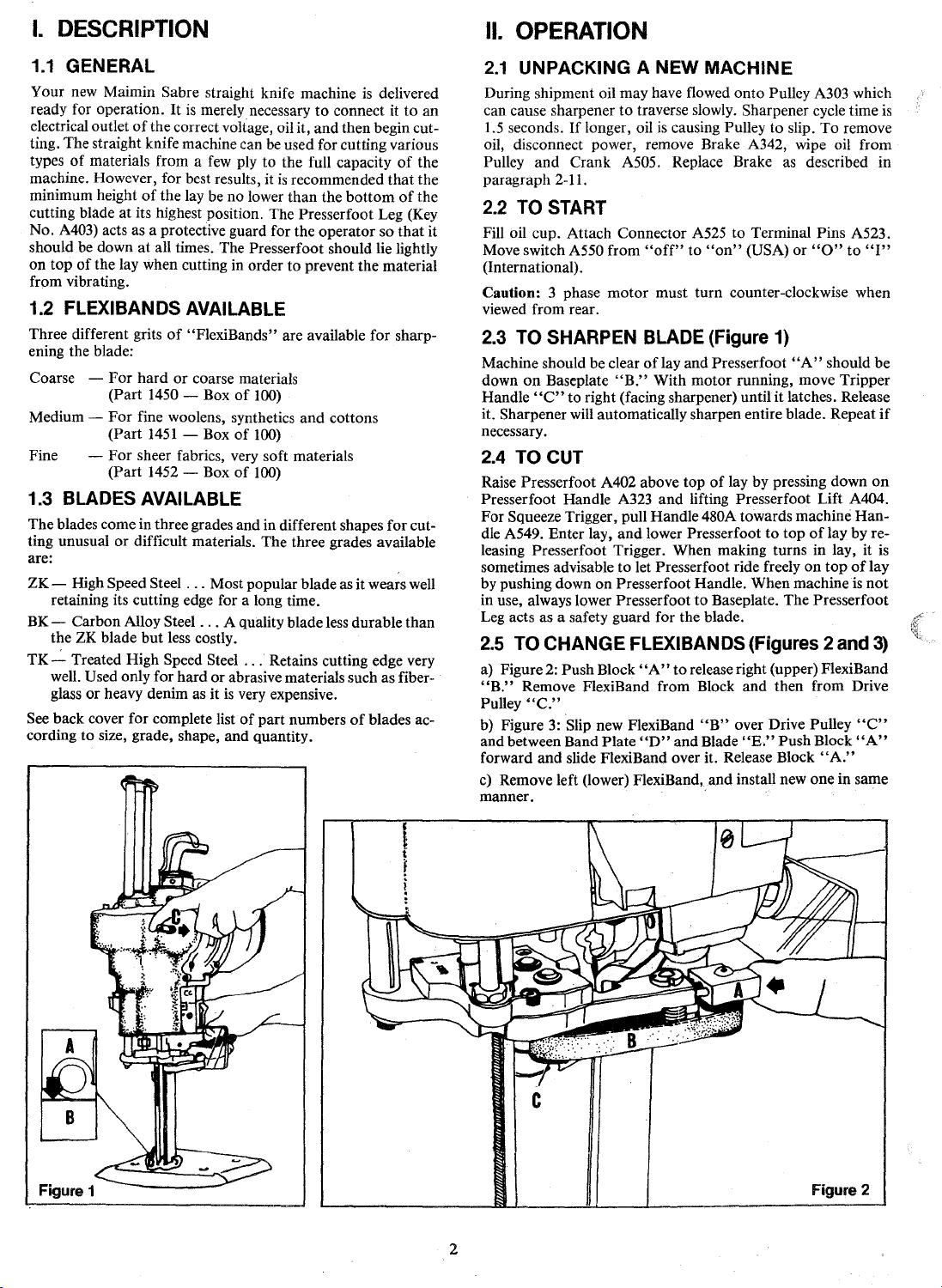

2.3 TO SHARPEN BLADE (Figure

Machine should be clear

down

on

Handle

it. Sharpener will automatically sharpen entire blade. Repeat

necessary.

Baseplate

"C"

"B."

to right (facing sharpener) until it latches. Release

A525

to Terminal Pins A523.

"off"

to

"on"

(USA)

or

"0"

to

must turn counter-clockwise when

1)

oflay

and Presserfoot

With motor running, move Tripper

"A"

should be

"I"

if

2.4 TO CUT

Raise Presserfoot A402 above top

Presserfoot Handle A323 and lifting Presserfoot Lift A404.

For Squeeze Trigger, pull Handle 480A towards machine Handle A549. Enter

leasing Presserfoot Trigger. When making turns in lay,

sometimes advisable to let Presserfoot ride freely on

by pushing down

in use, always lower Presserfoot

Leg acts as a safety guard for the blade.

Jay,

and lower Presserfoot

on

Presserfoot Handle. When machine

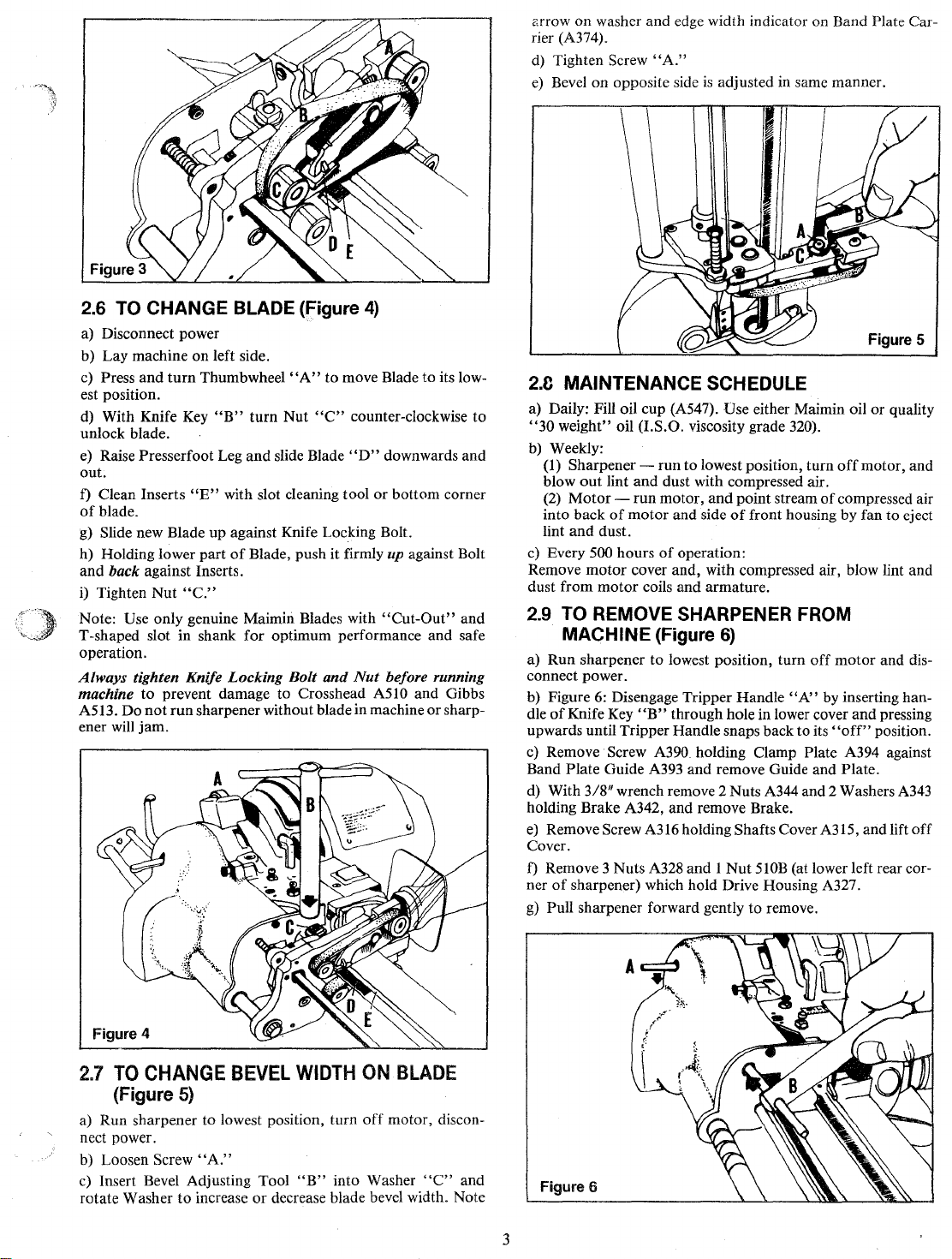

2.5 TO CHANGE FLEXIBANDS (Figures 2 and

a) Figure

"B."

Pulley

b) Figure

and between Band Plate

forward and slide FlexiBand over it. Release Block

c)

manner.

2:

Push Block

Remove FlexiBand from Block and then from Drive

"C."

3:

Slip new FlexiBand

Remove left (lower) FlexiBand,and install new one in same

"A"

"D"

of

lay by pressing down

to

top

of

lay by re-

top

to

Baseplate. The Presserfoot

to

release right (upper) FlexiBand

"B"

and Blade

over Drive Pulley

"E.''

Push Block

"A."

of

is

"C"

"A"

on

it

lay

not

3)

is

c

Figure

1

2

Figure 2

ctrrow

on

rier (A374).

d)

e)

washer and edge width indicator on Band Plate Car-

Tighten Screw

Bevel on opposite side

"A."

is

adjusted in same manner.

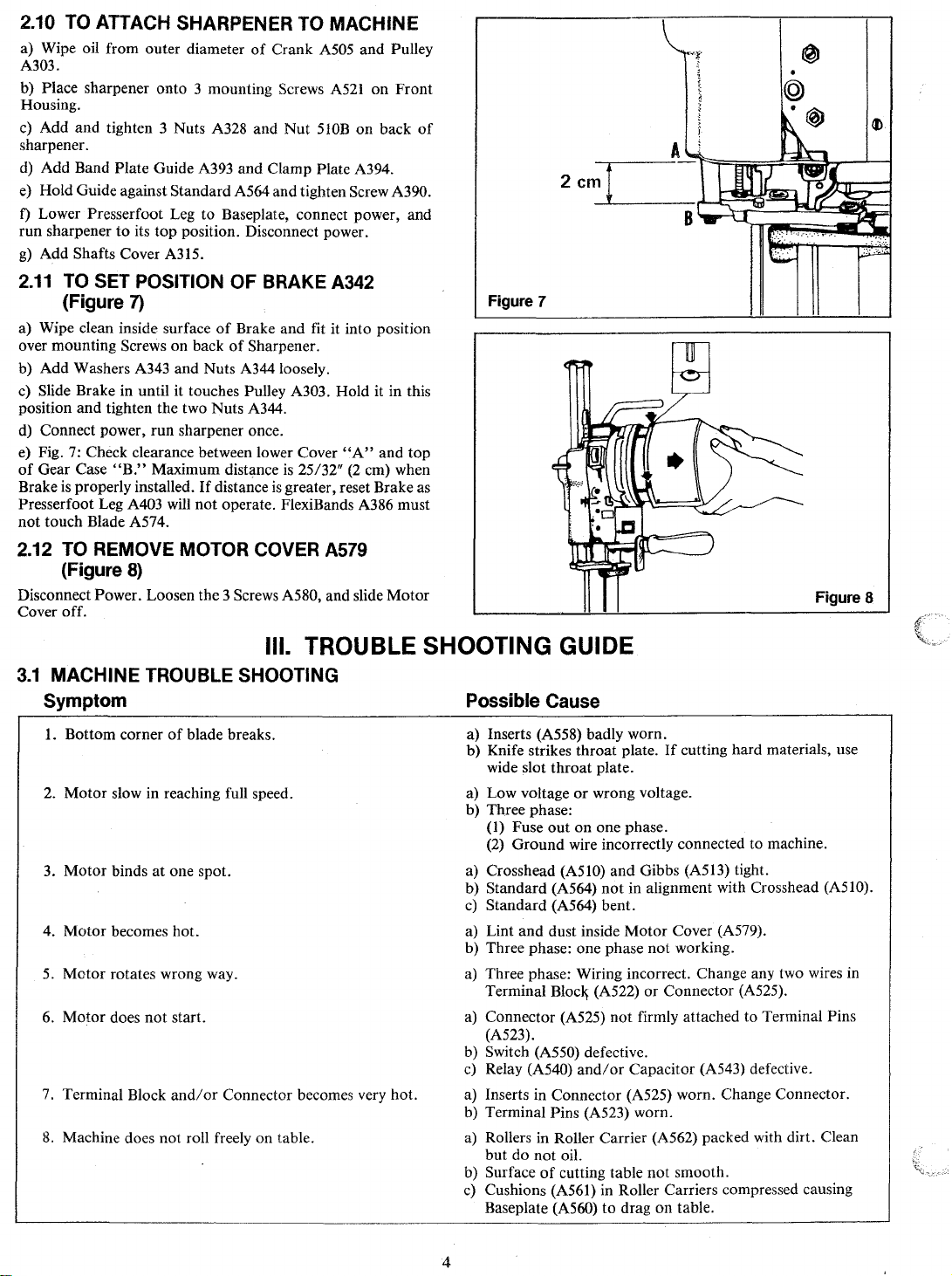

2.6 TO CHANGE BLADE (Figure

a) Disconnect power

b) Lay machine

c)

Press

est position.

d) With Knife Key

unlock blade.

e)

out.

f)

of

g)

h) Holding lower part

and

i) Tighten

Note: Use only genuine Maimin Blades with

T -shaped slot in shank for optimum performance and safe

operation.

Always

machine

A513. Do

ener

and

Raise Presserfoot Leg

Clean Inserts

blade.

Slide new Blade up against Knife Locking Bolt.

back against Inserts.

tighten Knife Locking

will

jam.

on

left side.

turn

Thumbwheel

"B"

"E"

with slot cleaning tool

of

Nut

"C."

to

prevent damage to Crosshead A510 and Gibbs

not

run

sharpener without blade in machine

"A"

turn

Nut

and

slide Blade

Blade, push it firmly

Bolt

4)

to

move Blade

"C"

counter-clockwise

"D"

or

"Cut-Out"

and

Nut

to

its low-

to

downwards and

bottom corner

up

against Bolt

and

before running

or

sharp-

Figure

5

2.C

MAINTENANCE SCHEDULE

a) Daily: Fill oil cup (A547). Use either Maimin oil or quality

"30

weight" oil (I.S.O. viscosity grade 320).

b)

Weekly:

(1) Sharpener -

out

blow

(2)

Motor-

into back

and

lint

c) Every

Remove

dust from

dust.

500 hours

motor

motor

lint

run

to

and

run

of

motor

cover and, with compressed air, blow lint and

coils and armature.

lowest position, turn

dust with compressed air.

motor,

and

and side

of

operation:

point stream

of

front housing by fan to eject

off

motor, and

of

compressed air

2.9 TO REMOVE SHARPENER FROM

MACHINE

a) Run sharpener

connect power.

b) Figure 6: Disengage Tripper Handle

dle

of

Knife Key

upwards until Tripper Handle snaps back to its

c)

Remove Screw A390 holding Clamp Plate A394 against

Band Plate Guide A393 and remove Guide and Plate.

d) With

holding Brake A342, and remove Brake.

e)

Cover.

f)

ner

g)

3/8"

Remove Screw A316 holding Shafts Cover A315, and lift

Remove 3 Nuts A328 and 1

of

sharpener) which hold Drive Housing A327.

Pull sharpener forward gently

(Figure

to

"B"

wrench remove 2 Nuts A344 and 2 Washers A343

6)

lowest position, turn

through hole in lower cover

Nut

SlOB

to

off

motor

"N'

by inserting han-

"off"

(at lower left rear cor-

remove.

and

position.

and dis-

pressing

off

Figure 4

2.7

TO

CHANGE

(Figure

a) Run sharpener to lowest position, turn

nect power.

b) Loosen Screw

c)

Insert Bevel Adjusting Tool

rotate Washer

to

5)

"A."

increase

BEVEL

WIDTH

"B"

or

decrease blade bevel width. Note

ON

off

motor, discon-

into Washer

BLADE

"C"

and

3

Figure 6

2.10 TO ATTACH SHARPENER TO

a) Wipe oil from outer diameter

A303.

b) Place sharpener onto 3 mounting Screws

Housing.

c) Add and tighten 3 Nuts A328 and

sharpener.

d) Add Band Plate Guide A393

e) Hold Guide against Standard A564 and tighten Screw

f)

Lower Presserfoot Leg to Baseplate, connect power, and

run sharpener

g)

Add Shafts Cover A315.

2.11

a) Wipe clean inside surface

over mounting Screws on back

b) Add Washers A343 and Nuts A344loosely.

c) Slide Brake in until it touches Pulley A303. Hold it in this

position and tighten the two Nuts A344.

d) Connect power,

e) Fig. 7: Check clearance between lower Cover

of

Gear Case

is

Brake

Presserfoot Leg

not

touch Blade A574.

to

its

top

position. Disconnect power.

TO SET POSITION

(Figure

properly installed.

7)

run

sharpener once.

"B."

Maximum distance

A403 will

not

of

Crank A505 and Pulley

and

Clamp Plate A394.

OF

BRAKE A342

of

Brake and fit it into position

of

Sharpener.

If

distance

is

operate. FlexiBands A386 must

MACHINE

A521

on

Front

Nut

510B

on

back

A390.

"A"

and

is

25/32"

(2

greater, reset Brake as

top

em) when

2.12 TO REMOVE MOTOR COVER A579

(Figure

Disconnect Power. Loosen the 3 Screws A580, and slide

Cover off.

8)

Motor

of

Figure 7

Figure 8

3.1

MACHINE

TROUBLE SHOOTING

Symptom

1.

Bottom corner

2.

Motor

slow in reaching full speed.

3.

Motor

binds

Motor

4.

5.

6.

7.

8.

becomes hot.

Motor rotates wrong way.

Motor

does

Terminal Block

Machine does not roll freely on table.

of

at

one spot.

not

start.

and/or

blade breaks.

Ill. TROUBLE SHOOTING GUIDE

Possible

a) Inserts (A558) badly worn.

b) Knife strikes throat plate.

wide slot throat plate.

a) Low voltage

b) Three phase:

(1)

Fuse

(2)

Ground

a) Crosshead

b) Standard (A564)

c)

Standard (A564) bent.

and

a) Lint

b) Three phase: one phase not working.

a) Three phase: Wiring incorrect. Change any two wires

Terminal

a) Connector (A525) not firmly attached to Terminal Pins

(A523).

Connector becomes very hot.

b) Switch

c)

a) Inserts in Connector (A525) worn. Change Connector.

b) Terminal Pins (A523) worn.

a) Rollers in Roller Carrier (A562) packed with dirt. Clean

b) Surface

c)

(A550) defective.

Relay (A540)

but do

not

Cushions (A561) in Roller Carriers compressed causing

Baseplate

of

Cause

If

cutting hard materials, use

or

wrong voltage.

out

on one phase.

wire incorrectly connected to machine.

(A510) and Gibbs (A513) tight.

not

in alignment with Crosshead (A510).

dust inside

Bloc~

oil.

cutting table

(A560)

Motor

Cover (A579).

(A522)

or

Connector (A525).

and/or

Capacitor (A543) defective.

not

smooth.

to

drag on table.

in

4

3.2 SHARPENER TROUBLE SHOOTING

Symptom

I.

No bevel on one side

2. Bevel

3. Sharpener runs

4.

5.

6. Band cut

7. Block (A397) falls

8. Block (A397) pivots, twisting band.

9.

10.

II.

12.

13.

14.

15. Presserfoot Leg does

16.

not

high enough

Sharpener does

Sharpener does

off

by blade.

Sharpener runs slowly.

Sharpener overruns

Sharpener runs continuously.

Sharpener runs only when tripper handle

Sharpener jams.

Presserfoot Leg (A403) does not move freely.

Safety

not

working.

but

not

not

bands

run

run

off

top

of

blade.

on

but

and

during

position.

not

hold.

blade.

do

not rotate.

bands rotate.

bands

do

not

band

changing.

rotate.

is

held.

Possible

a) Idler Pulley (A396) needs oil.

b) Broken Torsion

c)

Band Plates (A381, A387)

d) Bands

(A381, A387).

a) Cam (A515, A516) out

Square Shaft Gear (A336) broken.

a)

b) Retaining Ring

c)

Clamp (A364)

d) Cluster Gear

a) Keeper

b) Boat

a) Presserfoot Leg

Oil

b)

c) Retaining Ring (A320) missing.

d) Cluster Gear

e)

Worm (A311) broken.

a) Band Plate

a) Retaining Ring

.Stud (A383) broken.

a)

a)

Oil

b) Band Plate Guide (A393)

(A564).

a)

Brake (A342)

b) Screw (A363)

Screw (A363)

a)

(A367).

b) Screw (A363) missing.

c)

Retaining Ring (A345) missing.

Spring (A341) broken.

d)

a)

Spring (A357) broken.

Spring Pin (A359, A313) broken.

b)

a) Sharpener run without knife in machine.

b) Boat

c) Diamond

Sharpener

a)

b) Dirt

c) Brake (A342)

a) Lock

b)

Trigger Spring (A322) broken.

a) Leg Guide

b)

Safety Pin (A347) missing.

c)

Screw

Cause

Spring (A382, A388).

do

not

cross due

(A338) missing.

out

of

(A332) broken.

Plate

(A334) loose.

(A333) worn.

on

Crank

(A505)

(A332) broken.

(A387) defective.

on

Crank

(A505)

too

too

too

(A333) broken.

Shaft (A356) bent.

not

or

oil in Leg Guide (A354).

too

(A330) loose

(A354) broken.

and

Nut (327A) loose

position.

(A403)

and/or

(A398) missing.

and/or

far from Pulley (A303).

low.

low - less than

at

top

position.

close to Pulley.

on

Shaft (A325).

do

not

rotate freely.

to

interference

of

position.

not

down completely.

Pulley (A303).

Pulley (A303).

too

tight against

1"

or

missing.

above

of

Band Plates

Standard

Gear

Case

5

A315B

MODEL A SHARPENER

A315A

'309A:3QB

A307A306

OS\

~

A305

A301

~

A304

A30~~

~

~~

A302

342

A

01

A:3QO

A377

A378~

A403

A391A

·~b::

481J

·~~

490481F~~r

480G

480H

481A

A379~

6

PARTS

LIST

1

r

~-~

KEY PART

NO.

A300

A301

A302

A303

A304 23235

A305

A306

A307 23232

A308

A309

A310

A311

A312

A313

A314

A314A

A315

A315A

A315B

A316

A317

A318

A319

A320

A321

A322

A323

A324

A325

A326

A327

A327A

A328

A329

A330

A331

A332

A333

A334

A335

A336

A337

A338

A339

A340

A341

A342

A343

A344

A345

A346

A346A

A347

A348

A349

A350

A351

A352

A353

A354

A355

A356

A356A

A356B

A357

A358

A359

A360

NO.

838N

1499D

1498A

1498

23196

23231

839W

23234

23066

23067

23036

23267

23005

402BK

23229A

23229B

23229C

23229D

402BF

402BJ

23056

481F

23192

23193

23017

23219

23233

492

23047

490

23049

23053

23274

510A

510B

23252

23271

23050

23243

23189

23119

23120

23259

23203

23273

1277

23251

23019

23031

23200

23007

510B

23016

23284

23289

23283

23011

23013

23190

23054

23205

23258

23207

23122

23093A·W Diamond

23286

23287

23008

23007

23267

23211A

23211B

23211C

23211 D

DESCRIPTION

1/4-20 Hex

Nut,

Washer, 1/4 x 9/16 x 3/64

Clamp

only

Pulley

Bushing

Worm

Shaft

Bearing, flanged .314 x .439 x 3/4

End Cap

Washer, .32 x

Retaining Ring,

Spring Pin,

Worm

Push

Rod

Spring Pin, 1/16 x 3/8

Cam

Tapered Plug #12

Shafts

Cover,

Shafts

Cover,

Shafts

Cover,

Shafts

Cover.

Tapered Plug #9

Tapered Plug

Screw,

Screw, 1/4 x 3/8

Cartridge w/Worm

Cartridge

Spring

Retaining Ring,

Bearing .314 x .44 x 1/2

Trigger

Presserfoot Handle

Screw,

Shaft

Tripper Handle

Housing

Drive

Screw, 10

Nut, 10·32 Hex

10·32

Nut,

Screw, 8 x 5/8

Lock

Cup

Cluster

Boat

Keeper Plate

Screw, 6 x 1/4

Square

Block

Gear

Retaining Ring,

Screw,

Screw,

Spring

Brake

Washer, 13/64 x 7/16 x 1/32

Nut,

10·32 Hex

Retaining Ring, 5144·25

Link

Assembly

Washer, .257 x

Safety Pin

Pin

Spring Pin,

Tripper

Screw,

Leg Keeper

Screw, 4 x 5/16

Leq

Guide

Screw, 6 x

Screw,

11" & 14" Machines Only

Washer, Nylon,

11"

& 14" Machines Only

Spring

Washer, 13/64 x 7/16 x 1/32

Spring Pin, 1/16 x 3/8

Square Shaft,

Square Shaft,

Square Shaft,

Square Shaft,

1/2

x 1/32

5100-31

7164

x 1/2

5" -8"

9"

11

"

14"

#"16

1/4 x 1/2

Spring

5/16 x 3/8 Set

Gear

Shaft

10

6 x 5/8 Socket Cap

6 x 1/8

10 x 1/2

Always

Socket

Cap

Shoulder

only

x

Socket

x 3/4

1/4

Shaft

& Pulley

5555·23

with

Bushings

1/2

Socket Set Cup

(3)

Socket

Hd. Cap

(2)

Gear

with

Bushings

5100-50

Slot

Set Flat Pt.

(2)

w/23283

9116 x 1132

3/32 x 5/16

Socket

Set Cup

(2)

Button Hd. Socket Cap

Assy

(give size & stroke)

Button Hd. Soc. Cap

.191 x 17132

5"-

8"

9"

11"

14"

Give

Machine

Order

By

(2)

(2)

(2)

x 3/16

PART

(4)

SERIAL

NUMBER-

KEY PART

NO.

A360A

A361

A362 23226

A363 23290

A364

A365 824T

A366

A367

A368 23086

A369

A370 23210

A371

A372

A373

A374

A375

A376 23084

A377 23098

A378

A379

A380

A381

A382

A383

A384 23116

A385 23117

A386

A387

-

A388 23109

A389 23223

A390

A391

A391A

A392

A393

A394

A395

A396

A397

A398

A399

A400

A401

A402

A403

A404

A405

NUMBER

Not

NO.

23277 Screw, 6 x 3/8 Knurled Nylon

23244 Cover

23212 Clamp w/23263

23263

510B

23275

23091A

23086

23208

23209

23276

23261

23099

23097

23227

23165

23110

23115

1450

1451

1452

23164

23019

23122

402BH Tapered

23225

23250

23272

23282

23249

23114

23293

23111

23288

23112

23172

23116

23040

23040A Presserfoot,

23040B

23039A

23039B

23039C

23039D

23039E

23039F

23039G

824

23122

323PJ

480A

48QD

480E

480G

480H

480Y

481A

481B

481C

481J

481H

481F

490

1256

23292 Ball,

When

Key

Number

SQUEEZE TRIGGER ASSEMBLY

Ordering

DESCRIPTION

Screw, 6 x

Screw,

Screw, 10 x

Screw, 6 x 3/8 Socket Cap

Nut, 10-32 Hex

Gear Case

Bearing, flanged .252 x .377 x 1/4

Bearing, flanged .252 x .377 x 1/2

Drive Gear

Bearing, flanged .252 x .377 x

Driven Gear,

Driven Gear, right

Band

Washer, 3/16 x

Screw,

Rubber Tire

Drive Pulley

Screw,

Retaining Ring

Band

Spring,

Stud,

Spring Pin, 3/32 x 1/4

Spring

FlexiBand,

FlexiBand,

FlexiBand,

Band Plate,

Spring,

Eccentric

Screw,

Screw, 6 x 1/4

Washer(2)

Band Plate Guide,

Band

Band

Clamp

Stud,

Pulley, Idler, w/Bushing

Block

Retaining Ring,

Screw, 8 x 1/2

Screw, 4 x 1/4 Socket Hd. Cap

Spring Pin, 3/32 x 1/4

Presserfoot,

Presserfoot, 14"

Presserfoot Leg -

Presserfoot Leg,.--

Presserfoot Leg -

Presserfoot Leg -

Presserfoot Leg -

Presserfoot Leg -

Presserfoot Leg -

Presserfoot

Sere','/, 6 x

Pin

Handle

Bracket

Screw,

Collar w/481A and 480H

Spring

Squeeze

Screw, 6 x

Cam

Cam

Presserfoot Lever

Presserfoot Lever

Screw, 1/4 x 3/8 Shoulder

Screw,

Spring Pin, 3/32 x 1/2

Parts.

1/4

10

x 1·1/2 Fillister Hd.

1/2

with

left

Plate Carrier

10 x 1/2

(2)

(2)

4 x

118

Soc. Set

Plate,

right

Torsion, right

118

X 1-1/8

(2)

CoarseMediumFine-

left

Torsion,

Stud

6 x 5/8 Socket Cap

Plate Guide,

Plate Guide,

Plate ·

Idler

(2)

wl

5/8

(2)

Button

Plug

#14

Pulley

Button

5"9" & 11

Lift

114

Button

Assembly

10

x 5/8 Socket Cap

Trigger

1/8

Round Hd.

480E and 323PJ

5/16 x 3/8 Set

Socket Hd. Cap

Slot

Set

Flat

(4)

Bushings

w/Bushings

112

x 3/64

Socket Hd. Cap

Flat

(2)

(2)

100/box

100/box

Hd

(2)

8"

11"

(2)

(2)

Hd.

(2)

(2)

"

Hd.

(2)

Pt.

5100-25

(4)

100/box

left

5"9",

14"

(2)

5144-12

8"

"

5"

6"

7"

8"

9"

11

14"

Assy w/4800 and

w/490

(2)

Pt.

1/4

(2)

;)J7

ot/tfi?

481

J

30·"

...

7

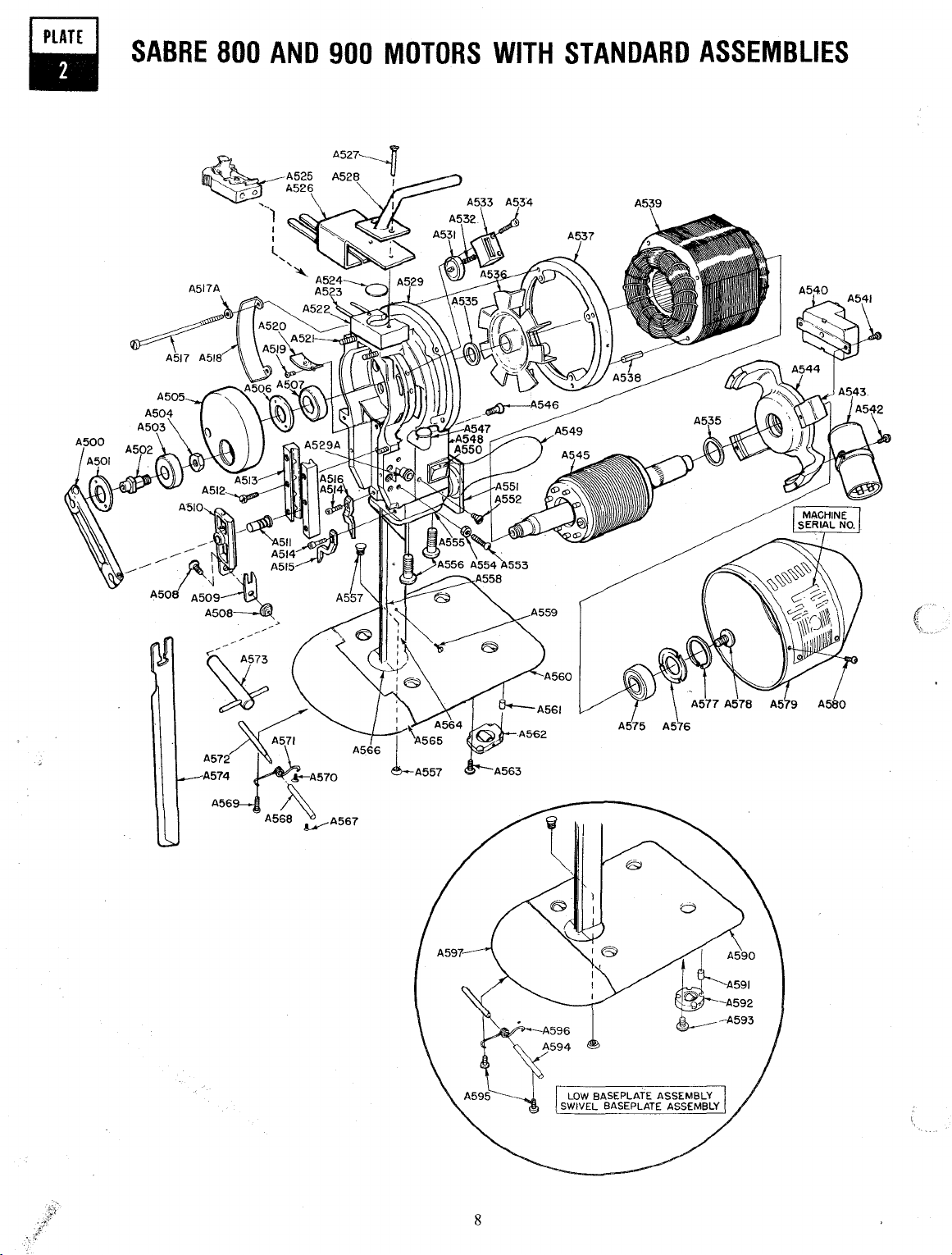

SABRE

800

AND

900

MOTORS

WITH

STANDARD

ASSEMBLIES

~

~/

A572:N

A574

A56

.~A570

!:\

A568

~A567

8

PARTS

LIST

2

KEY

NO. PHASE PHASE

A500

A501

A502

A503

A504 415N 415N Crank

A505

A506 404C

A507 403

A508 416

A509

A510

A511

A512 409A 409A

A513 409C 409C

A514 23226

A515 23151 23151

A516 23152

A517 419Z 419Z

A517A 419R

A518 402W

A519

A520 402L 402L

A521

A522 405

A523 406

A524

r·

I

A525 458B

A526 458K 458M

A527

A528

A529 402CC

A529A 402BG

A531

A532

A533

A534

A535 497P

A536

A537

A538

A539

A540 365G

A541 802S

A542 824S

A543

A544

A545

A546

PART NO.

1 3

412A

412B

412C

4120

413W

415

414

413BX 413LX

413CX 413MX Crank w/413W, 414, 415-M

4130X

413EX

411A

411

411P

419ZB

802S

23230 23230

405F 405B

408A

4070

468J

468C 468C

4680

468A

468S

400J

3020C

30200

15097 A 15202A Stator, Sabre 800, 60 HZ*

15211

15222 Stator,

15226 Stator, Sabre 900,

365E

3650

365H

15079

15076

3020A

15223

15224

441S 441S

412A

412B

412C

4120

413W

415 Crank Pin

414 Crank Bearing

413NX Crank w/413W,

413RX Crank w/413W, 414,

413VA Screw, 1/4 x

413VB Screw,

404C

403

416

411A T-Siot

411

411P

23226 Screw, 6

23152

419ZB Bolt,

419R Washer,

402W

802S

405A

406A

458A

408B Screw, 8 x 2 Flat Hd.

4070

402CO

402BG

468J

4680

468A

468S

497P

400J

3020C

30200

15202A Stator, Sabre 800, 50 HZ* A574 Blade (see back cover)

483

3020B

15223

DESCRIPTION

Connecting

Connecting

Connecting

Connecting

Bearing

Crank w/413W,

Bearing

Bearing #203

Knife

Crosshead w/411 P

Wrist

Screw, 8 x 3/4

Gibbs, pair

Cam, Right

Cam, Left

Bolt,

Windguard

Screw, 6 x 3/16

Guard 424B 424B Standard -

Oil

Screw,

Terminal

Terminal Pin (2,3)

Fibre Cover

Current

Ground

Screw, 8 x 1-3/4 Flat Hd.

Top Handle

Front Housing w/23230

Tapered Plug

Thumbwheel w/Shaft

Spring 427 427

Thumbwheel

Thumbwheel

Screw, 6 x 7/8 Socket Hd.

Support

Fan

Adaptor

Spring Pin, 5 x 20

Relay, Sabre

220/50/1, 110/50/1

Relay, Sabre

Relay, Sabre 900,

Relay, Sabre

Voltage Change Panel,

Screw, 6 x 3/16

Screw,

Capacitor

Capacitor

Spider

Armature Assembly, Sabre

Armature Assembly, Sabre

Screw, 6 x 5/16

Rod-

H

Rod-

M

Rod - L

Rod-~

Lock

Nut

10

x 3/16 Flat Pt. Soc. Set

Lock

Bolt

&Nut

Lock

Pin

x

1/4

10

x 3-1/2, Sabre 800

10

x 3-3/4, Sabre 900

.200 x 3/8 x .036 A562 436 436

10

x·

718

Block

Connector

Shield

Washer

Ring

Sabre 900,

6 x 3/8

161

270

Ll

414,

415-H

414,

415-L

415-LI

1/4

Flat

Pt.

Fillister

Socket Hd.

Flat Pt. Soc. Set

#7-S

Support

Assembly

800,

800, 703 ·-220/60/1

900,

Binding

mfdmfd-

Hd.

Binding

with

Pins

(3)

mm

(4)

6.0

HZ*

50

HZ*

692-

716

- 60 HZ A580 23122 23122 Screw, 6 x

710.'-

Binding

Hd.

Sabre800 440M 440M

Sabre 900

Fillister

KEY

NO.

A547

A548

A549

A550 442G

A551

A552

Soc. Set

(6)

(2)

(4)

(4)

Hd.

(2)

(3)

(2)

120/60/1, A577

50' HZ

50

HZ .

Hd.

(2)

800

900 A596 433B 433B Spring, Lip, small

Hd.

(2)

A553

A554

A555 464C

A556

A557 435 435 Cone

A558 428A 428A Insert

A559 428S

A560

A561

A563

A564

A565 430 430

A566

A567

A568 431B 431B

A569

A570

A571

A572

A573 457 457

A575

A576

A578

A579

A590

A591

A592 436E

A593 340 340

A594

A595

A597 430B 430B Lip,

PART NO.

1 3

PHASE PHASE DESCRIPTION

Oil

402BO 402BO

466E

466B

464B 464B

464P

443

464R 464R

818S

410 410

410N

425

428B 428B

428C

4280

428E

428H

428M 428M

429

436K 436K Rubber

436S 436S Screw,

424A

424C 424C

4240 4240

424E 424E

424H 424H

424M

426A 426A

426B 426B

426C 426C

426E 426E V Throat

426F 426F V Throat

426V

427N 427N

436S 436S Screw, 10 x 5/32 M Hd.

802S

802S

433B

431A

403 403 Bearing #203

4040

404E

404F

3020B

429B

440A

436L

431C

802S

466E Cover,

464P

442G

818S

410N

464C

425

428C

4280

428E

428H

428S

429

424A

424M

426V

802S

802S Screw, 6 x 3/16

433B

431A

4040

404E

404F

3020B

429B

440A Swivel Baseolate

436L Cushion,

'436E

431C Axle

802S

Cup

Switch,

USA-120V)

Switch,

Cover,

(USA-120V)

Tapered Handle

Curved

Switch,

Switch,

(USA-120V)

Shield

Screw, 6 x

Screw, 8 x 1/2

Nut

(2)

Handle

Bolt, 3/8

Lock & Nut

for

Insert

for

Insert

for

Insert

for

Insert

for

Insert

for

Insert

for

Insert

Screw

Baseplate

Cushion

Roller Carrier

10 x 5/32 M Hd.

StandardStandard-

StandardStandardStandard StandardLip

Throat

Plate -

Throat

Plate -

Plate, Wide

Throat

V Throat Plate w/Nest

10 x 7/16 Flat Hd.

Screw,

Nest

Shaft,

Short

Screw, 6 x 3/16

Spring,

Up,

Shaft, Long

Knife

Key

Loading

Retaining

Lock

Screw

Motor

Cover

Low

Baseplate

Roller Carrier, Low

Swivel Roller Assembly (rear)

Screw, 10 x 1/8 M Hd.

Screw, 6 x 3/16

Low

Sabre 800 (except

Sabre 900 & Sabre 800

w/Bushing

1/4

Flat Hd.

Fillister

x 1

Button

Standard Standard Standard StandardStandard StandardStandard-

with

Rollers & Lip

Assembly

9"

8"

7"

6"

5"

11

"

14"

5" -8"

9"

Binding

Binding

Small

Ring-

114

Button

with

BindingHd.

only

Hd.

Slot-

5"-

9"-

5008-156

Rollers &

with

1-:landle

Sabre 800 (except USA-120V)

Sabre 900 & Sabre 800

Block

PlatePlate-

Spring

Small

Hd.

(2)

(3)

9"

8"

7"

6"

5"

11"

14"

5"-

8"

14"

Hd.

Hd.

Hd.

(3)

Lip

Rollers &

8"

Lip

Always Gi\te

Order By PART

Machine

*Specify

SERIAL NUMBER When Ordering Parts.

Voltage

NUMBER-

9

Not

Key

Number

SABRE

A623

700

MOTOR

A626--J'i

A625~-

A624

--:~I

I

~

~

'

,,

" •

U

I

L

WITH

STANDARD

ASSEMBLY.

1-tL

A633 A634

A600

A671

10

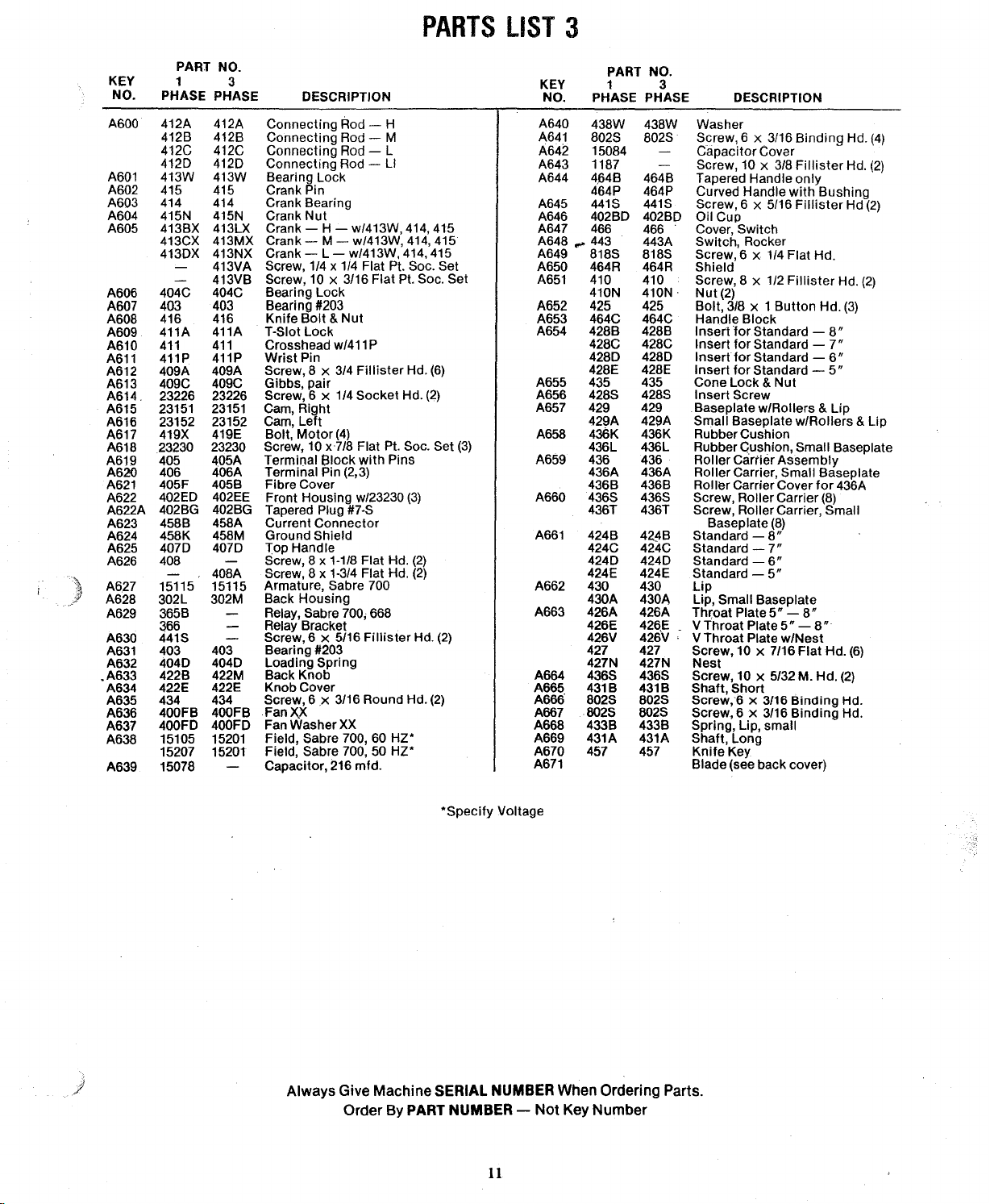

PARTS

LIST

3

KEY

NO.

ASOO

A601 413W 413W Bearing Lock

A602

A603 414 414 Crank Bearing

A604 415N 415N Crank

A605 413BX 413LX

A606

A607 403

A608

A609 411A

A610

A611

A612

A613 409C

A614. 23226

A615 23151

A616 23152

A617 419X

A618

A619

A620

A621

A622

A622A

A623 458B

A624 458K

A625

A626

A627 15115 15115

A628

A629 365B

A630

A631

A632

.A633

A634

A635

A636

A637

A638

A639

PART NO.

1

PHASE PHASE

412A 412A

412B

412C 412C

4120

415 415

413CX 413MX

4130X

404C

416

411

411P

409A

23230 23230

405

406

405F 405B Fibre Cover

402EO

402BG 402BG

4070

408

302L

366

441S

403

4040

422B 422M

422E

434 434

400FB

400FO 400FO

15105 15201

15207 15201

15078

3

DESCRIPTION

412B

4120

413NX

413VA

413VB

404C

403

416

411A

411

411P

409A

409C

23226

23151 Cam, Right

23152

419E

405A

406A

402EE

458A Current

458M Ground

4070

408A

302M

403

4040

422E

400FB

Connecting

Connecting

Connecting

Connecting

Crank

Pin

Nut

CrankCrankCrank-

Screw,

1/4 x

Screw,

10

Bearing

Bearing #203

Knife

T·Siot

Crosshead w/411 P

Wrist

Screw,

Gibbs,

Screw, 6 x 1/4

Cam,

Bolt,

Screw, 10 x·7/8

Terminal

Terminal Pin (2,3) 436A 436A

Front Housing w/23230

Tapered Plug #7-S 436T 436T

Top Handle 424C

Screw,

Screw,

Armature,

Back

Relay,

Relay Bracket

Screw,

Bearing #203

Loading Spring

Back

Knob

Screw, 6

Fan

Fan

Field, Sabre 700,

Field, Sabre 700, 50

Capacitor, 216

Lock

Bolt & Nut

Lock

Pin

8 x 3/4

pair

Left

Motor

Connector

Shield

8 x 1-1/8 Flat Hd.

8 x 1-3/4 Flat Hd.

Housing

Sabre 700; 668

6 x 5/16

Knob

Cover

XX

Washer

HML-

Block

.x

KEY 1 3

NO. PHASE PHASE

Rod - H

Rod - M

Rod - L A642 15084

Rod - Ll

w/413W, 414,415

w/413W, 414,415

w/413W, 414,415

1/4

Flat Pt. Soc. Set

x 3/16

Flat

Pt. Soc. Set

Fillister

Socket

(4)

Flat Pt. Soc. Set

with

Sabre 700

3/16 Round Hd.

XX

mfd.

Pins

.

Fillister

60HZ*

HZ*

Hd.

Hd.

(3)

(2)

(2)

Hd.

(6)

(2)

(3)

(2)

(2)

A640

A641

A643 1187

A644

A645

A646 402BO 402BO Oil

A647 466

A648

A649

A650

A651

A652 425

A653 464C 464C Handle

A654 428B 428B

A655 435

A656 428S 428S

A657 429 429

A658 436K

A659 436

A660 436S

A661

A662 430

A663 426A 426A

A664 436S

A665 431B 431B

A666

A667 -802S

A668

A669 431A 431A Shaft, Long

A670

A671

438W 438W

802S

4,64B

464P 464P

441S 441S

... 443

818S 818S

464R 464R

410

410N

428C 428C

4280

428E 428E

429A 429A

436L

436B 436B

424B

4240

424E

430A

426E

426V

427 427

427N 427N

802S 802S Screw,

4338

457

PART NO.

802S Sc;rew,

464B

466 Cover,

443A

410

410N ·

425

4280

435

436K Rubber Cushion

436L

436

436S Screw, Roller

424B

424C Standard -

4240

424E

430

430A

426E

426V ·

436S Screw, 10

802S

4338 Spring, Lip, small

457

Washer

Capacitor

Screw, 10 x 3/8

Tapered Handle

Curved Handle

Screw,

Cup

Switch, Rocker

Screw,

Shield

Screw,

Nut(2)

Bolt, 3/8

Insert

Insert

lnsertfor

Insert

Cone

Insert

Baseplate

Small

Rubber Gush ion, Small Baseplate

Roller

Roller

Roller Carrier Cover

Screw, Roller Carrier, Small

Baseplate

Standard Standard-

Standard-

Lip

Lip, Small Baseplate

Throat

V

Throat

Throat

V

Screw, 10 x 7/16

Nest

Shaft,

Screw, 6 x 3/16

Knife

Blade (see back cover)

DESCRIPTION

6 x 3/16

6 x 5/16

Switch

6 x 1/4

8 x 1/2

Block

·for Standard for

for

Lock & Nut

Screw

Baseplate

Carrier

Carrier, Small Baseplate

Plate

Short

6 x 3/16

Key

Binding

Cover

Fillister

only

with

Fillister

Flat

Fillister

x 1

Button

StandardStandardStandard -

w/Rollers &

w/Rollers & Lip

Assembly

Carrier

(8)

8"

7"

6"

5"

5"-

Plate

Plate

8"

5" -8"

w/Nest

Flat

x 5/32 M. Hd.

Binding

Binding

Hd.

Hd.

Bushing

Hd

Hd.

Hd.

Hd.

(3)

8"

7"

6"

5"

Lip

for

436A

(8)

Hd.

(6)

(2)

Hd.

Hd.

(4)

(2)

(2)

(2)

*Specify

j

Always Give Machine SERIAL NUMBER When Ordering Parts.

Voltage

Order By PART NUMBER -

11

Not

Key Number

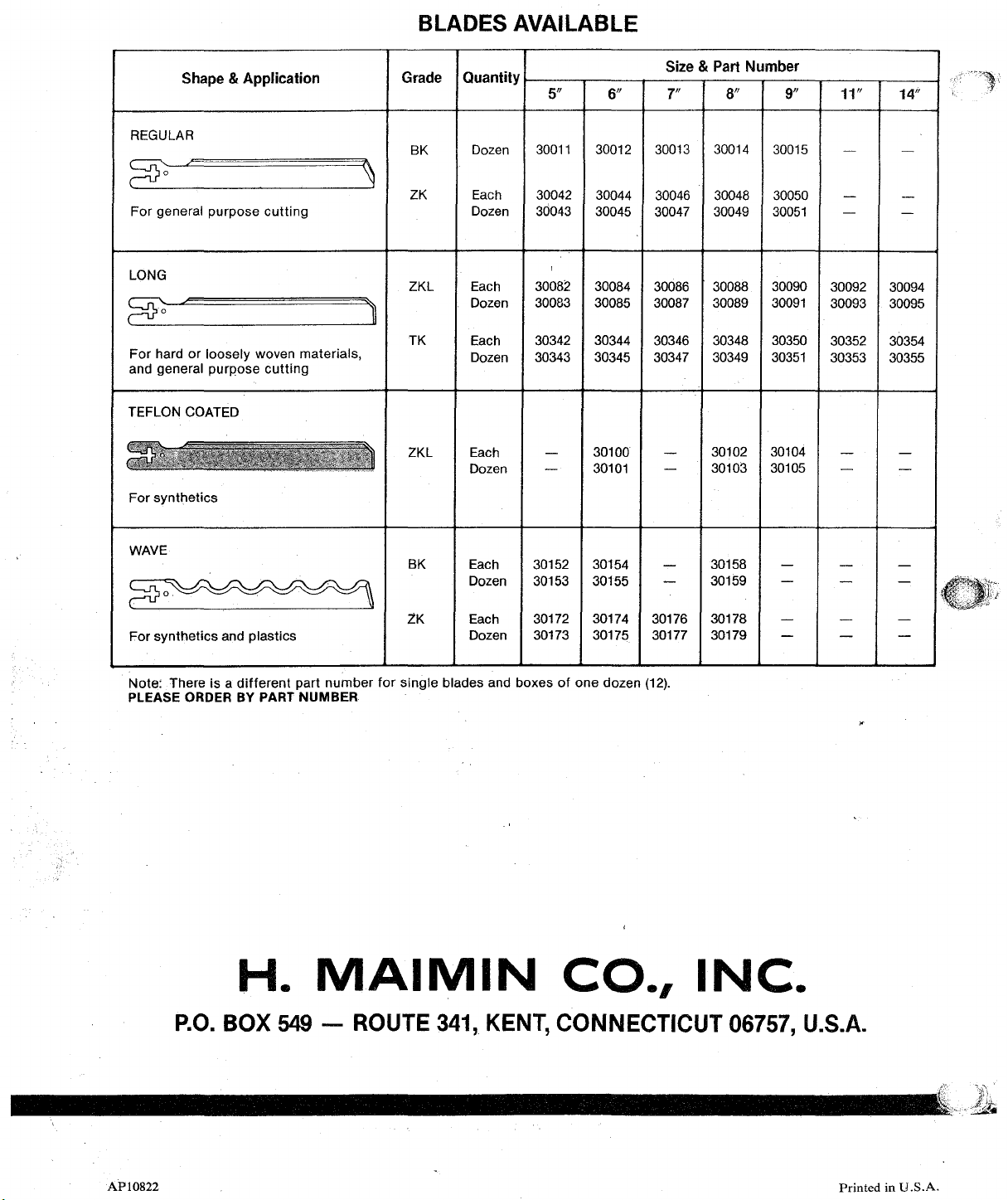

BLADES

AVAILABLE

Shape

& Application

REGULAR

~

~

For general purpose cutting

LONG

~

~

For hard or loosely woven materials,

and general purpose cutting

TEFLON

For synthetics

COATED

Grade

~

'~

BK

ZK

ZKL

TK

ZKL

Quantity

Dozen

Each 30042

Dozen

Each 30084

Dozen

Each

Dozen

Each

Dozen

5"

30011

30043

30082

30083

30342 30344

30343

30012

30044

30045

30085

30345

30100

30101

6"

Size & Part

7"

30013

30046

30047

30086

30087

30346

30347

Number

8"

30014

30048 30050

30049

30088

30089

30348

30349

30102

30103

9"

30015

30051

30090

30091

30350

30351

30104

30105

11"

30092

30093

30352

30353

14"

30094

30095

30354

30355

WAVE

20~

For synthetics and plastics

Note: There is a different part number for single blades and boxes of

PLEASE ORDER

P.O.

BY

PART NUMBER

H.

BOX

MAIMIN

549-

ROUTE

BK

ZK

Each

Dozen

Each

Dozen

341,

30152 30154 30158

30153

30172

30173

KENT,

CONNECTICUT 06757, U.S.A.

30155

30174

30175

one

dozen

30176

30177

(12).

CO.,

30159

30178

30179

INC.

f

AP10822

Printed

in

U.S.A.

Loading...

Loading...