GROUNDING INSTRUCTIONS

This machine must be graunded. In the event af malfunctian ar breakdawn, grounding pravides a path af least resistance

far electric current

Terminal Pins; this Ground Shield is designed to' be used with a Maimin Grounded Connectar, part number 458A ar 458B.

See wiring instructians supplied with the Connectar.

to' reduce the risk af electric shack. This machine is equipped with a Graund Shield surraunding the

DAN GER-Improper connectian af the Maimin Cannector can result in a risk af electric shack. Check with a

qualified electrician ar serviceman if the graunding instructians are

the machine is properly grounded.

DO' nat madify the Ground Shield provided with this machine.

Use carrect wire sizes with the Maimin Graunded Connectar.

U.S.A. ONLY: 1 phase: Use AWG16/3 SJ, SIT ar SJE

3 phase: Use A WG 16/4 SJ, SIT ar SJE

INTERNATIONAL; 1P+N+: Use 3 xl, 0 mm CEE (2) 61

3P+ : Use 4 xl, 0 mm CEE (2) 61

nat campletely understaad ar if in daubt as to whether

I. DESCRIPTION

1.1 GENERAL

Your new Maimin Sabre straight knife machine is delivered

ready for operation. It is merely necessary to connect it to an

electrical outlet of the correct voltage, oil it, and then begin

cutting. The straight knife machine can be used for cutting

various types of materials from a few ply to the full capacity

of the machine. However, for best results, it is recommended

that the minimum height ofthe lay be no lower than the bottom

ofthe cutting blade at its highest position. The Presserfoot Leg

(Key No. A403)acts as aprotective guard forthe operator sothat

it should be down at alltimes. The Presserfoot should lie lightly

on top of the lay when cutting in order to prevent the material

from vibrating.

1.2 FLEXIBANDS AVAILABLE

Three different grits of "FlexiBands" are available for sharp-

ening the blade:

Coarse - For hard or caarse materials

(Part 1450- Box

(Part 1457-

Medium - For fine woolens, synthetics and cottons

(Part 1451- Box of 1(0)

(Part 1458- Box

Fine - Far sheer fabrics, very saft materials

(Part 1452-

(Part 1459- Bax of 5(0)

af 1(0)

Bax of 5(0)

af 5(0)

Bax af 1(0)

II. OPERATION

2.1 UNPACKING A NEW MACHINE

During shipment oil may have flawed antaPulley A303 which

can cause sharpener

is 1.5seconds. If longer, oil is causing Pulley to slip. TO' remove

oil, disconnect power, remove Brake A342, wipe oilfrom Pulley

and Crank A505. Replace Brake.

2.2 TO START

Fill ail cups. Attach Cannector A525 to Terminal Pins A523.

Move switch A550 from "off' to "on" (USA) or

(International).

Caution: 3 phase motor must turn counter-clockwise when

viewed from rear. (FlexiBand against Blade must rotate from

back to front).

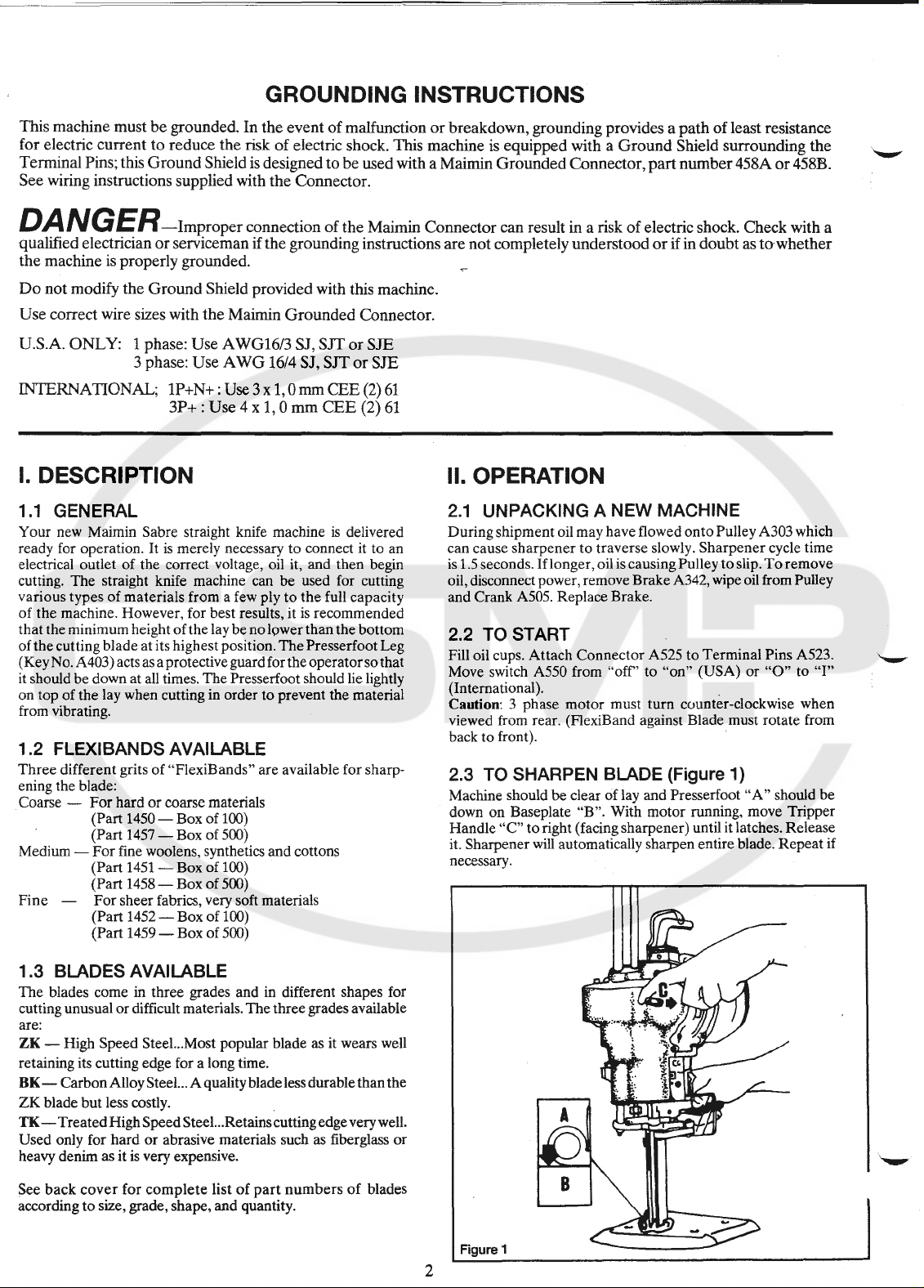

2.3 TO SHARPEN BLADE (Figure 1)

Machine should be clear of lay and Presserfoot "A" should be

down on Baseplate "B". With motor running, move Tripper

Handle "c"to' right (facing sharpener) until it latches. Release

it. Sharpener will automatically sharpen entire blade. Repeat if

necessary.

to' traverse slowly. Sharpener cycle time

"0" to "I"

1.3 BLADES AVAILABLE

The blades come in three grades and in different shapes far

cutting unusual or difficult materials. The three grades available

are:

ZK - High Speed Steel...Mast popular blade as it wears well

retaining its cutting edge for a long time.

BK- Carban Alloy Steel... A quality blade lessdurable than the

ZK blade but less costly.

TK - Treated High Speed Steel...Retainscutting edge verywell.

Used only

heavy denim as it is very expensive.

See back cover for camplete list of part numbers of blades

according to size, grade, shape, and quantity.

far hard or abrasive materials such as fiberglass or

Figure 1

2

Loading...

Loading...