H~Jaaimin

Co.,

Inc.

119West40thst.,NewYork,

N.Y.

1oo1su.s.A.

BOOK

NO.

22101

~'

'o,',:~':,~;-:,;,'::::';~',::~{

'",_

,'

;'>'

o;:\"''"

Edition 5

© 1980 H.M.C.

SAFETY

INSTRUCTIONS

for

Maimin Cutting Machines

1.

BE SURE MACHINE IS PROPERLY GROUNDED

The cutting machine should be grounded while in use

to

protect the operator

from electrical shock. Surrounding the Terminal Pins

is

a Ground Shield which

is

designed to be used with a Maimin Grounded Connector (#458B, or

#458A

for 3 phase machine).

See

tag supplied with Connector for wiring instructions.

2.

USE CORRECT ELECTRICAL WIRING

U.S.A. ONLY 1 phase:

Use

AWG

16/3 SJ, SJO, SJT

3 phase:

Use

AWG

16/4 SJ, SJO, SJT

INTERNATIONAL 1P+N+b:

Use

3x1,0 mm2 CEE(2)61

3P+f:-

Use

4x1,0 mm2 CEE(2)61

3.

KEEP CUTTING AREA CLEAN

A cluttered table can cause accidents.

4.

A VOID DANGEROUS ENVIRONMENT

Do

not use machine in a damp or wet location.

The work area should be well lit.

5.

KEEP VISITORS AWAY

They should be kept at a safe distance from the cutting area.

6. STORE MACHINE PROPERLY

When

not in use, the machine should be stored in a dry location.

7.

MAINTAIN MACHINE WITH CARE

Keep machine clean and blade sharp for best and safest performance.

Follow instructions for lubricating.

8. ALWAYS DISCONNECT MACHINE:

- when not in use

-before

servicing

- when changing blades

9. REMOVE KNIFE KEY AND WRENCHES

The knife key and other wrenches must be removed from machine before

starting motor.

10. AVOID ACCIDENTAL STARTING

Disconnect electrical cord before carrying machine.

Be

sure switch

is

off

before connecting cord.

11. KEEP GUARDS IN PLACE AND IN WORKING

ORDER

12. KEEP HANDS AWAY FROM CUTTING BLADE

Contents

SECTION I Description

1-1. General

1-2.

Stones Available

1-3. Blades Available

SECTION II Operation

2-1. To Start

2-2.

To Cut

2-3. To Sharpen Blade

2-4. To Shift Edge Control Arm

SECTION

Ill

Care and Maintenance

3-1. Schedule

3-2. To Oil

3-3. To Clean Stones

3-4. To Change Stones

3-5. To Change Blade

3-6. To Clean

Inserts

3-7. To Clean Commutator

3-8. To Clean Sharpener

3-9. To Clean

Motor

3-10. To Clean Rollers

SECTION IV Trouble Shooting Guide

4-1. Sharpener Trouble Shooting

4-2. Machine Trouble Shooting

SECTION V Adjustments and Repairs

5-1. Sharpener

(a)

Guide Spring Adjustment

(b) Edge Control Arm Adjustment

(c)

Pulley Brake Adjustment

(d)

Presserfoot Leg Adjustment

(e)

Pulley Rubber Replacement

(f)

Stone Carrier Adjustment

(g)

Sharpener Removal

(h)

Sharpener Disassembly

(i)

Slide Disassembly

(j) Frame Disassembly

(k) Sharpener Assembly

5-2. Machine

(a) To Change Carbon Brushes

(b) To Adjust Crosshead and Gibbs

(c) To

Set the Position of the Standard

(d) To Replace the Inserts

(e) To Remove the Crank

(f) To Replace the

Motor

Bearings

(g) To Replace Crank

Pin Bearing

(h) To Reassemble Motor

SECTION

VI

Parts

List

Plate

1.

Sharpener Slide Assembly

Plate

2.

Sharpener Frame Assembly

Plate

3.

Machine Assembly

2

2

2

3

3

3

3

3

4

4

4

4

4

5

5

5

5

5

6

7

7

7

7

7

8

8

8

9

9

9

9

9

9

9

10

10

10

11

11

11

12

14

16

Instruction~

and

Parts

List

MaiminModeiK

SECTION

I

DESCRIPTION

1-1. GENERAL

Your new

Maimin

"POWR"

straight

knife

machine

is

delivered

ready

for

operation.

It

is

merely

necessary

to

connect

it

to

an

electrical

outlet

of

the

correct

voltage,

oil

it, and

then

begin

cutting. The

straight

knife

machine

can

be

used

for

cutting

various

types

of

materials

from

a few

ply

to

the

full height of

the

standard.

However,

for

best

results,

it

is

recommended

that

the

minimum

height

of

the

lay

be

no

lower

than

the

bottom

of

the

cutting

blade

at

its

high-

est

position.

On

the

left

side

of

the

sharpener

you

will

note a

lever -the

Edge

Control

Arm

(Key

No.

K136B)* - which

permits

sharpening

of

either

a rough

or a smooth

edge on the

blade

for

cutting

different

types

of

materials.

The

presserfoot

leg

(Key

No.

K10)

acts

as a pro-

tective

guard

for

the

operator

so

that

it

should

be

down

at

all

times.

The

presserfoot

should

lie

lightly

on top of

the

lay

when

cutting

in

order

to

prevent

the

material

from

vibrating.

1-2.

SHARPENING STONES AVAILABLE

There

are

three

different

grits

of

sharp-

ening

stones

(Key

No.

K15)

available

for

use

in

this

machine:

#60

grit -coarse.

Recommended

for

hard

and

coarse

materials.

Can

be

used

on

ZZT

and

ST

blades.

#100

grit

- fine.

Recommended

for

fine woolens,

syn-

thetics

and cotton. Can

be

used

on

all

blades.

#150

grit -very

fine.

Recommended

for

sheer

fabrics

and

very

soft

materials.

Can

be

used

on

BT

and

ZZT

blades.

1-3.

BLADES

AVAILABLE

The

cutting

blades

(K234)

come

in

three

grades,

and

also

in

several

different

shapes

for

cutting

unusual

or

difficult

materials.

The

three

grades

available

are:

BK -Carbon

Alloy Steel.

A good

quality

steel

but

less

dur-

able

than

the

ZZT

blade.

ZK - High Speed

Steel.

Most

popular

blade

available

as

it

*See

Plates

1,

2,

and 3

for

key

number

identifi-

cation.

2

wears

well,

retaining

its

cutting

edge

for

a long

time.

TK -

Treated

high

speed

steel.

Used only

for

special

materials

such

as

fiberglass

and

heavy

can-

vas

that

dull the

cutting

edge

very

quickly.

Retains

cutting

edge

very

well

but

is

very

expensive.

The

various

shaped

blades

are

illustrated

and

their

uses

are

described:

Regular

Blade

(K)

-

Recommended

for

gen-

eral

purpose

cutting. A vail

able

in

BK

and

ZK

grades.

Long

Blade

(K)

-

1/8"

longer

and with

dif-

ferent

shaped

bottom

corner

than

regular

blades,

it

is

used

for

loosely

woven

or

veryhardmate-

rials.

For

terry

cloth,

quilting,

denim,

ZK

and

TK

grades

only.

Also

available

with

Teflon

Coating

in

6",

8",

9"

sizes

to

reduce

fusing

of

synthetic

materials.

Slotted

Blade

(K)

-

For

synthetic

leather,

supported

fabrics,

rubber-backed

fabrics,

and

certain

types

of

plastics.

ZK

grade

only,

Wave Blade -

Popularly

usea

tor

plastics.

Also

taffeta

and

buckram.

BK

and

ZK

grade

available.

Saw

Blade

(K)-

Used

for

rubberized

fabrics,

canvas,

crinoline,

BK

only,

111111111111111111111111111111111111111111111111111

J

Serrated

Blade

(K)

-

For

fabrics

with

de-

signs

adhering

to

surface.

BK

only,

SECTION

II

OPERATION

2-1.

TO

START

(a) Oil

crosshead

(K241)

at

oil

c::;p

X25 8

(b)

Plug

in corcnector to

termir.al

pir.s

CK24c

•

(c)

Flip

switch

(K259) to

"on"

position.

2-2.

TO

CUT

(a)

Raise

presserfoot

to

height

of

lay

by

pressingdown

onpresserfoottrigger

(K162)

and

lifting

presserfoot

lift

(K7).

(b) When

entering

lay,

lower

presserfoot

until

it

rides

on

top

of lay. Then

release

presserfoot

trigger.

(c) When

making

turns,

it

is

sometimes

advisable

to

let

the

presserfoot

ride

freely

on

top of

lay

by

pressingdownpresserfoot

tri5ger.

(d) When

the

machine

is

not

in

use,

lower

the

presserfoot

to

the

baseplate.

The

presser-

foot

leg

acts

as a safety

guard

for

the

knife.

2-3.

TO

SHARPEN BLADE

(a)

Remove

machine

from

lay

and

make

sure

presserfoot

is

down

on

the

baseplate.

(b) With

motor

running,

pull

sharpener

trigger

(KllO)

outwards

and

release

it.

Sharp-

ener

will

automatically

sharpen

the

entire

blade.

Repeat

if

necessary.

(c) The

sharpening

cycle

will

have

to

be

repeated a number

of

times

to

sharpen

the

in-

itial

edge on a new

blade.

Thereafter,

it

will

only

be

necessary

to

sharpen

once

or

twice

to

renew

the

edge.

(d) Note: Do NOT

press

the

presserfoot

trigger

when

sharpening

as

this

will

loosen

presserfoot

leg

which

guides

the

sharpener.

2-4.

TO

SHIFT EDGE CONTROL ARM

a '

E.~e

: :c::..-::

;;.:

= . K13 6 B)

protrudes

::-J=

~

:e:

s::>:

-:i.

s~-;:e::e::-.

1:

i

~:.:.

s=a.-;:e::.e::-

:::.::

Jpe::-ating,

:::xr•e

:he

a:=.

::J;"'L..-::s :::- :i::-;;;-r:.,ards.

snap :nw

po:s

=·:c...

simply

It

will

(c)

In

the

·1[?

;os::::::

=arked

S),

the

sharpener

will.

put

a

s:::::o::t..::e::-

~e

on

the

blade.

In

the

"00~

..

pos~:ic.:::

::;:::a:keC.

~

1.

the

sharp-

ener

will

put a rougher

edge

J::

±e

c::ade.

(d) The

rougher

edge

is

~ee

:J:

:t-.ard

or

coarse

materials

and

also

for cu:d!lg

:r_:-o:.lgh

the

body

of

the

lay. The

smoothe:

edge

:.s

:or

finer

or

bulky

materials

and

for

t!immir..g.

EDGE

CONTROL

ARM

(Kl36B)

SECTION

Ill

CARE

AND

MAINTENANCE

3-1.

MAINTENANCE

SCHEDULE

Daily:

Before

starting

motor,

fill

the

oil

cup (K258)

to

the

crosshead

two

times

daily

for

the

first

month

...

then

once

a

day

thereafter.

3

4

Weekly: Clean

stones

(K15)

Clean

sharpener

Clean

inserts

(K253)

Oil

gears

under

carrier

block (K43)

Monthly: Clean

motor

Every

six

months: Check

carbon

brushes

(K218), Clean

commutator

on

armature

(K226), Adjust

crosshead

and gibbs (K243)

and Clean

rollers

(K227)

3-2.

TO

OIL

Oil the machine daily

as

noted above. Be

sure

to

use

either

Maimin

oil

or

a good

grade

of

"30

weight" oil.

Do

not

use

sewing machine

oil

or

any

other

light oil

as

they

are

not

de-

signed to give the

lubrication

needed

for

the

cutting machine.

All new machines have

grease-

sealed

ball

bearings

which

require

no

lubrica-

tion.

3-3.

TO

CLEAN

STONES

After

repeated

use,

the

sharpening

stones

bef'ome coated with oil and

dirt

and

do

not

sharp-

en the blade effectively. To

remove

this

coat-

ing,

spray

Maimin Stone

Cleaner

directly

onto

the stone

rims.

Or

put a little

cleaning fluid on

a toothbrush, and

scrub

the

stone

rims.

Be-

cause

some

of the cleaning fluid may

get

on the

gears

near

the

stones,put

a few

drops

of oil on

the

gears

under

the

Carrier

Block (K43)

after-

wards.

3-4.

TO

CHANGE

STONES

To

remove

the

stones,

use a screwdriver

in the

slotted

screw

head underneath the

stones

and

turn

in the

direction

as

shown below.

Note:

that

the

stone

screws

unloosen by

turning

in

opposite

directions.

To

put on new

stones,

tighten by turning the

stone

screws

in

reverse

direction

of

that

shown in the

diagram.

TO

REMOVE

STONES

3-5.

TO

CHANGE

BLADE

The

blades

used

in your model "K"

ma-

chine

must

have the

"cut-out"

in

the

blade

as

illustrated

in the

diagram

below,

or

the

stones

will

be

damaged and

the

blade will not

be

sharp-

ened

properly.

To

remove

the blade, lower the blade to

its

bottom position by turning

fibre

knob (K220)

and

raise

the

presserfoot

leg (KlO). Unlock the

knife bolt and nut

(K239)

with the knife key.

Slide blade out, and

clean

inserts.

Slide the new

blade up through the

inserts

until

its

"T"

-shaped

shoulder

is

firmly

against

the knife locking bolt.

Hold the lower

part

of the blade up and

against

the back of the

inserts.

Lock the knife

secure-

ly. Always

use

genuine Maimin blades with the

patented

"T"

slot.

"T"

SLOT

Always tighten the knife locking bolt and

nut

before

running

the

machine to

prevent

damage

to the

crosshead

and gibbs.

Before

in-

stalling

a new blade, the bottom edge should

be

sharpened

on an oil

stone

to

prevent

ravelling

and to

insure a clean

cut on loosely woven

fabrics.

For

very

soft

or

very

hard

materials,

it

is

also

recommended

that

the bottom

front

corner

of

the

blade be rounded slightly.

3-6.

TO

CLEAN

INSERTS

The

inserts

(K253) which guide the knife

in

the

standard

must

be

cleaned

occasionally

and

whenever

the

knife

is

changed.

Otherwise

dirt

collected

in

the

inserts

can

cause

the knife

to cock and not

sharpen

properly.

Clean the

inserts

by

sliding the

saw-tooth

slot

cleaner

(or

bottom

back

corner

of

the blade )

up

and

down the

back

of the

inserts.

3-7.

TO

CLEAN

THE

COMMUTATOR-

(Single

Phase

Motor

Only

except

Powrtron)

The

copper

commutator

on

the

armature

(K226)

develops a black

carbon

ring

after

con-

siderable

use.

This

carbon

ring

pre\·ents

pro-

per

contact

between

the

carbon

brushes

(K218)

and the

copper

commutator

which

causes

arcing

and

prevents

the

motor

from

reaching

full

speed

quickly.

While the

motor

is

running.

touch

a

piece

of

the

commutator

chalk

or

fine

emery

cloth

lightly

against

the

copper

commutator

to

clean

off

this

black

carbon

ring.

3-8.

TO

CLEAN

THE

SHARPENER

Run

the

sharpener

to

its

lowest

position,

turn

off the

motor,

and

blow

out

the

lint

and

dust

with

compressed

air.

Check

the

gears

to

see

that

no

dirt

or

bits

of

cloth

are

packed

in

the

teeth.

Put

one

drop

of

oil

on

each

of

the

gears

underneath

the

carrier

block

(K43) and

the

gears

attached

to the

frame

(Kl

05)

to

insure

smooth

running.

3-9.

TO

CLEAN

MOTOR

0\"er a period

of

time,

dust

and

lint

will

build

up

inside

the

motor

and

prevent

proper

cooling. With the

motor

running,

point a stream

of

compressed

air

into

the

back

of the

motor

and then into the

side

of

the

front

housing

by

the fan to

eject

the

dust

and lint.

3-10.

TO

CLEAN

ROLLERS

If

the

rollers

(K22

7)

in the

baseplate

(K255)

do not

roll

freely.

blow out the

dust

or

dirt

in

the

rollers.

Do

not

oil

as

it

will

collect

dirt,

causing

the

rollers

to

bind. Use a

powdered

graphite

for

lubrication

if

necessary.

SECTION

IV

TROUBLE

SHOOTING

GUIDE

4-1. SHARPENER TROUBLE

SHOOTING

1.

Blade

Edge

Not

Sharp

-

a.

Check

for a worn

out

blade.

b.

Check

the

stones

for

excessive

wear

or

dirtiness.

(Par.

3-3)

c.

Checkfor

weakor

brokenguidesprings.

(Par.

5-la)

d.

Check

for

misalignment

of

the

standard

and

presserfoot

leg.

(Par.

5-ld)

e.

Check the

pulley

for

excessive

wear

or

oiliness.

(Par.

5-le)

2.

Bevel

Too

Wide -

a.

Presserfoot

leg

set

too

close

to

the

standard.

(Par. 5 -ld)

b.

Standard

set

too

far

forward.

(Par.

5-2c)

c.

Check

for

excessive

stiffness

of

the

guide

springs.

(Par.

5-la)

d.

Stones

out-of-shape

because

of not

us-

ing

"cut-out"

blades.

(Par.

3-5)

3.

Bevel

Too

Narrow

-

a.

Trouble

shoot

under

#1,

above.

b.

Standard

set

too

far

back.

(Par.

5-2c)

4. One Side of

Blade

Not

Sharpening

-

a.

Check

for a weak

or

broken

guide

spring.

(Par.

5-la)

b.

Check

for

worn

inserts.

(Par.

5-2d)

5. Uneven

Blade

Wear

-

a.

Check the

pulley

for

excessive

wear

or

oiliness.

(Par.

5-le)

b.

Presserfoot

leg

loose

when

sharpener

operating.

Do not

press

presserfoot

trigger

when

sharpening

c.

Check

that

presserfoot

leg

is

straight.

6.

Blade

Sharpening

at

an

Angle -

a.

Check

for

dirt

in

the

inserts.

(Par.

3-6)

b. Make

certain

that

the

blade

is

tight

against

the

back

of

the

inserts.

(Par.

3-5)

c.

Check

for

misalignment

of

the

presser-

foot

leg

and

the

standard.

(Par. 5 -ld)

d.

Check

for

loose

crosshead

and

gibbs.

(Par.

5-2b)

7.

Bottom

of

the

Blade

Chewed

Out

-

a.

Check

for a stone

loose

on

its

bushing.

5

b. Stone

rims

unevenfrom

not

using

"cut-

out"

blade.

(Par.

3-5)

8.

Sharpener

Overrunning

-

a.

Check

for a weak

or

broken

pulley

brake.

(Par.

5-1c)

b.

Check

for

too low a

setting

of

the

trigger

stop

screw

(K21).

9.

Sharpener

Not Running Smoothly -

a.

Check Molded

Pulley

for

excessive

oil

or

wear

(Par.

5-le)

b.

Oil

Gears

under

Carrier

Block (K43) and

gears

on

Upper

Gear

Block

(Kl70A)

10.

Sharpener

Traverses

But

the

Stones

Fail

to

Rotate

-

a.

Check

that

gear

shift

is

engaged

pro-

perly.

(Par.

5-1b)

b.

Check

for

broken

teeth

on

842

and

887

gears.

(Par.

5-1j)

11.

Sharpener

Fails

to

Operate

-

a.

Make

certain

that

the

presserfoot

leg

is

all

the way down.

(Par.

2-3)

b.

Check

the

Molded

Pulley

for

excessive

oil

or

wear

(Par.

5-le).

c.

Check

for

cloth

jammed

in

the

gears.

d.

Check

for

stripped

829

or

830

gear

(K150,

K147).

12.

Presserfoot

Leg

Slipping -

a.

Check

for a weak

or

broken

presser-

foot

trigger

spring.

(Par.

5-1h)

b.

Check

front

plate

for

worn V Block

.

(Par.

5-lj)

6

c.

Check

that

thick

section

of

cam

shoe

is

against

presserfoot

leg.

(Par.

5-lk)

13.

Presserfoot

Leg

Fails

to

Operate

-

a.

If

the

sharpener

is

not

all

the

way up -

(1)

The

motor

is

stopping

before

the

sharpening

cycle

is

completed.

(2)

The

pulley

brake

and/

or

trigger

stop

screw

is

set

too high.

(3)

Oilonpulleycauses

slipping"

(Par.

5-le)

b.

If

the

safety

lock

screw

is

interfering-

(1)

Reset

safety

lock

screw

(K115).

14.

Latch

Slipping

From

Chain

Roller

a.

Check

for a worn

latch

(K3)

and/

or

latch

spring

(K2).

b.

Check

for a worn

chain

roller

(K106).

15.

Sharpener

Screeching

-

a.

Make

certain

that

the

edge

control

arm

is

engaged.

(Par.

2-4)

b.

Oil

gears

under

carrier

Block

(K43) and

on

upper

gear

block

(K170A).

16.

Material

Ravelling

Beneath

Stroke

of

Blade-

a.

Make

certain

that

the

bottom

of

the

blade

was

sharpened

prior

to

inserting

into

the

machine

and

that

the

bottom

front

corner

of

the

blade

was

rounded.

(Par.

3-5)

4-2.

MACHINE

TROUBLE

SHOOTING

1.

Bottom

Corner

of

Blade

Breaks

-

a.

Inserts

badly

worn-

change.

(Par.

5-2d)

b.

Need

wide

slot

throat

plate

for

cutting

hard

materials.

c.

Latch

slipped

off

chain

roller.

(Par.

4-1[14])

2.

Motor

Slow in

Reaching

Full

Speed

-

a.

Check

that

proper

voltage

is

being

deli-

vered

in

line.

b.

Single

phase

(except

Powrtron):

(1)

Brushes

worn.

(Par.

5-2a)

(2)

Commutator

dirty.

(Par.

3-7)

c.

Three

phase:

(1)

Fuse

on

one

line

probably

out.

(2)

Ground

wire

incorrectly

connected

to

machine.

3.

Motor

Binds

at

One Spot -

a.

Check

freeness

of

crosshead

and

gibbs.

(Par.

5-2b)

b.

Check

alignment

of

standard

with

blade

in

crosshead.

(Par.

5-2c)

c.

Check

for

bent

standard.

4.

Motor

Becomes

Hot -

a.

Clean

commutator.

(Par.

3-7)

b.

Check

brushes.

(Par.

5-2a)

c.

Clean

lint

and

dust

out

of

motor.

(Par.

3-9)

d.

Three

phase:

(1)

One

electric

line

not

working.

e.

Single

phase:

(1)

Back

housing

incorrectly

aligned

with

field.

(Par.

5-2h)

5.

Motor

Rotates

Wrong

Way -

a.

Single

phase:

(1)

Back

housing

incorrectly

aligned

with

field.

(Par.

5-2h)

b.

Three

phase:

(1)

Change

any

two

wires

in

terminal

block

or

connector.

6.

~1otor

Does

::\ot

Start

-

a.

Check

that

connector

is

firmly

attached

to

terminal

pins.

(Par.

2-1)

b.

Check

ior

burned-out

switch

(K259).

c.

Check

ior

broken

shunt

wire

(K223).

7.

Terminal

Block

a:-.d

or

Connector

Becomes

Yery

Hot-

a.

Ir.serts

L-:

cor..r.ector

worn-

change

con-

nector.

b.

Termir.al

f:i.:-.s

'.K248)

worn-

change

pins.

8.

Machine

Does

:;:;:

Roll

Freely

on

Table

-

a.

Clea:-. :::olle:s

L-.

ro~ler

carriers.

(Par.

3-10)

b.

Check

co:-.o.:u:;,;: o:

surface

of

cutting

table.

SECTION

V

ADJUSTMENTS

AND

REPAIRS

S-1. SHARPENER

(a) Guide

Spring

Adjustment -The

pres-

sure

of

each

stone

against

the

blade

should

be

approximately

equal

to

produce

the

same

width

bevel

on

each

side

of

the

blade.

To

change

the

bevel

width,

change

the

guide

spring

pressure:

first

release

the

spring

(K17)

from

the

hook

in

the

guide

for

stone

carrier ( K13).

Then

un-

screw

the

stud

(K16)

for

spring

until

the

short

end of

the

guide

spring

can

be

pulled

out

of

the

hole

in

the

slide

( K22

).

To

increase

spring

pressure,

put

that

short

end

of

the

spring

in

the

next

hole

above,

and

tighten

the

stud.

Engage

the

spring

in

the

guide.

There

are

two

holes

for

each

guide

spring

drilled

into

the

slide.

If

the

spring

is

already

in

the

top

hole

and

requires

increased

pressure,

it

is

necessary

to

replace

the

guide

spring.

Put

the

short

end

of

the

new

guide

spring

in

the

lowest

hole.

(b)

Edge

Control

A.rm

Adjustment

-

If

the

edge

control

arm

(K136B)

slides

out

of

position

when

the

sharpener

is

operating,

then

it

is

necessary

to

increase

the

spring

pressure

on

the

arm

lock

pin

(K152B). To do

this,

turn

the

arm

lock

set

screw

(K152D) one

full

turn

or

until

the

edge

control

arm

will

not

slide

out

of

engagement

when

the

sharpener

is

running.

(c)

PulleyBra..J.ce.-\djustment-

Ifthe

sharp-

ener

starts

by

itself

or

fails

to

stop

running,

the

fault

is

generally

the

Pulley

Brake

(K245).

Re-

move

the

Pulley

Co\·er

(K207),

insert a screw-

driver

under

the

Brake

(at a

point

one-third

the

distance

from

the

lower

tip)

and

across

the

sides

of

the

Pulley

Cover.

Bend

the

bottom

portion

ofthe

Brake

downwards,

and

remove

the

screw-

driver.

The

Brake

should

then

be

curved

so

that

its

bottom

tip

touches

the

Pulley

Cover.

7

Fasten

the

Pulley

Cover

to

the

Front

Housing

again.

If

the

Pulley

(Kl22A)

still

turns

when

the

machine

is

operating,

the

curve

in

the

Brake

must

be

increased

by

repeating

the

method

above.

If

the

sharpener

stops

too

far

below

the

top

of

its

traverse,

the

curve

in

the

Brake

must

be

reduced

by

removing

the

Pulley

Cover

and

depressing

the

Brake

with a finger.

(d)

Presserfoot

Leg

Adjustment

- To

ob-

tain

the

proper

uniform

bevel

on

the

blade,

it

is

necessary

that

the

presserfoot

leg

(KlO)

be

at

the

right

distance

from

the

standard

(K229).

With

the

presserfoot

leg

all

the

way

down,

the

distance

from

the

back

of

the

leg

to

the

stand-

ard

should

be

equal

at

both

the

top of

the

stand-

ard

and

at

the

bottom

of

the

standard.

For

the

model

"K"

machine,

this

distance

should

be

approximately

1-1/8"(29

mm).

See

illustration

below:

PRESSERFOOT

LEG

(KlO)-

1"

1{

STANDARD

(K229)

~

If

the

presserfoot

leg

is

too

far

in

at

the

bottom,

then

the

stones

will

sharpen

behind

the

blade

edge

on

the

lower

part

of

the

blade.

This

condition

can

be

corrected

by

pulling

the

press-

erfoot

leg

out

slightly

and

squeezing

the

press-

erfoot

toes

together

with

pliers.

This

will

cause

the

presserfoot

leg

to

set

further

out

at

the

bottom.

8

If

the

presserfoot

leg

is

too

far

out

at

the

bottom,

the

blade

will

have a tendency

to

hook

out. To

correct

this,

lightly

tap

the

curved

front

of

the

presserfoot

with a mallet.

This

will

cause

the

presserfoot

toes

to

spread

slightly

and

permit

the

presserfoot

leg

to

move

in

closer

to

the

standard.

(e)

Pulley

Replacement -Occasionally

oil

gets

on

the

Crank

(K206) and

the

Molded

Pulley

(Kl22A)

causing

the

Pulley

to

slip

and

the

sharp-

ener

to

operate

improperly.

With a

cloth

wipe

the

oil

from

the

Pulley

and

the

side

of

the

Crank

while

turning

the

motor

by

the

Knob (K220).

To

change a worn

Molded

Pulley

(K122A).

Remove

sharpener

from

machine.

Insert

rod

into hole in

front

of

Pulley

Shaft (K117 A),

and

unscrew

Pulley

Nut (K120).

Slide

Molded

Pul-

ley

off

shaft,

replace

with new

one,

and

lock

tightly

with

Pulley

Nut.

Fasten

sharpener

onto

machine,

and

replace

Pulley

Cover.

(f) Stone

Carrier

Adjustment -After

con-

siderable

use,

the

stone

carriers

(K33, 35) may

wear

so

that

there

will

be

vertical

movement

of

the

stone

carriers

on

the

carrier

tube

(K32).

This

play

could

permit

the

stones

to

drop

too

low

on

the

blade

and

cause

cutting-in

of

the

bottom

of

the

blade.

To

remove

the

vertical

play

of

the

stone

carriers,

first

remove

the

guide

springs

(Kl

7,

19)

and

sharpening

stones

(K15

).

Then

loosen

the

carrier

tube

lock

screw

(K30),

and

turn

the

carrier

tubeelockwise

1/4

turn.

Check

that

the

play

has

been

removed

but

that

both

stone

carriers

still

move

freely.

When

the

adjustment

is

correct,

tighten

the

carrier

tube

lock

screw

tightly.

(g)

Sharpener

Removal -To

remove

the

sharpener

in

preparation

for

disassembly,

re-

move

the

Presserfoot

Lift ( K7

) by

unscrewing

the

two

Presserfoot

Lift

Screws

(K9).

Pull

the

Latch ( K3 ) forward

to

clear

the

Chain

Roller

(K106),

and

simultaneously

pull

the

Slide (K22)

half

way down the

Frame

(Kl05).

Then

remove

the

Pulley

Cover

(K207)

and

the

four

Sharpener

Screws

(KlOl,

K153,

Kl23),

noting

that

these

four

screws

are

of

different

lengths

and

must

be

replaced

in

the

proper

locations

when

the

sharpener

is

attached

to

the

machine

again.

Pull

the

sharpener

away

from

the

Front

Hous-

ing

(K213).

(h)

Sharpener

Disassembly -Remove

the

Presserfoot

Leg

(K10)

by

pressing

down

on

the

Presserfoot

Trigger

(K162)

and

pulling

the

leg

out

through

the

bottom

of

the

sharpener.

Re-

move

the

Bearing

Block

(K5)

by

unscrewing

its

two

screws

(K4).

Then

pull

the

Slide

rK22\

fror.:

the

Frame

(K105). Do

not

lose

the

Presserfoot

Cam

Shoe (K169).

(i)

Slide

Disassembly

- Unhook

both

guide

springs

(K17,19)from

the

stone

carrier

guides

(K13,23).

Unscrew

the

two

spring

studs

(K16)

and

the

two

carrier

block

screws

(K18).

The

slide

will

then

come

off

the

carrier

block

(K43 ).

The

stone

carrier

guide

can

be

removed

by

unscrewing

the

two

slide

guide

screws

(K14).

The

slide

guide

( K45 )

consists

uf two

parts

(snapped

together)

and

can

be

pried

apart.

The M Transfer

Gear

(K50)

and

the M Re-

verse

Gear

(K48)

will

slip

off

their

shafts

after

removing

the

Retaining

Rings

(K46).

The

Long

Gear

Shaft (K47)

and

the

Short

Gear

Shaft

(K49)

will

come

out

of

the

Carrier

Block

by

unscrew-

ing

the

two

Lock

Screws

(K38A

).

To

remove

the

stone

carriers

(K33,35),

open

and

pull

off

the

carrier

tube

snap

ring

(K37).

The

stone

carriers

will

then

slide

off

the

tube.

Take

off

the

snap

ring

(K36)

to

re-

move

the

lower

stone

carrier

gear

(K34). Do

not

lose

the

tube

washers

(K32A).

(j)

Frame

Disassembly

-Remove

presser-

foot

cam

shoe

(Kl69).

Remove

the

front

plate

(K163) by

unscrewing

the

two

spacer

rod

screws

and

the

two

front

plate

screws

(K167).

Remove

the

presserfoot

trigger

spring

(K1G1)

by

lifting

up

on

the

prcsserfoot

trigger.

Take

off

the

side

cover

(K130)

by

removing

the

holding

screw

(Kl29).

The

16-tooth

bevel

gear

(K135)

can

be

re-

moved

by

unscrewing

the

stud

for

bevel

gear

bushing

(Kl71)

then

lifting

out

the

bushing

(K134)

and

gear.

The

pulley

support

spring

(K159)

can

be

removed

by

pushing

up on

the

pulley

bracket

(Kll4)

and

prying

the

spring

out

of

the

socket

in

the

pulley

bracket

with a

screwdriver.

The

upper

gear

block

(Kl

70A)

can

be

removed

from

the

frame

by

unscrewing

the

two

screws

(Kl02

& K144).

The

frame

can

then

be

lifted

from

the

upper

gear

block.

(k)

Sharpener

A~>sembly

-

Insert

the

as-

sembled

slide

into

the

assembled

frame

mak-

ing

sure

that

the

square

shaft

(K6)

fits

into

the

bevel

gear

(Kl35

).

Place

the

cam

shoe

(K169)

on

the

cam

(K131).

The

heavier

section

of

the

cam

shoe

should

be

against

the

presserfoot

leg.

Slide

the

presserfoot

leg

up

into

the

slide

and

the

frame,

holding

down

on

thepresserfoot

trigger

to

permit

the

leg

to

move

up

past

the

cam.

Replace

the

bearing

block

top

(K5)

onto

the

square

shaft

with

the

wider

section

of

the

bearing

block

top

facing

the

chain.

Attach

the

s::arpe:-.er

to

the

front

housing

with

the

four

screws.

Tighten

the

screws

evenly

and

in

a

c:ocJ.:-.,·ise

cirection.

Run

the

sharpener

until

the

chain

roller

1Kl06)

engages

the

latch.

Run

:he

s:C.arper,er

beiJre

replacing

the

pulley

cover

:o

ma~e

s:.:re

:hat

:he

sharpener

is

operating

proper::;.

L\1PORTA.:\T -

ii

the

stones

are

on

the

sharpe:-.er.

be

s·.:re &.at

there

is a knife

in

the

rr:;achi:-.e.

Replace

the

presserioot

lift

on

the

press-

erfoot

leg.

Rep:.ace t.::e p·.1lley

cover.

Run

the

sharper.er

3.5aL".

::::

=.ake

sure

that

the

pulley

brake

is

properly

c.::i:·.:sted.

S-2.

MACHINE

(a)

To

C::.a::.~

:c=-:::o:n

3r'.lshes

(single

phase

mactbes

exce?'( ?c·-'·rtron) -

If

the

motor

starts

slowly.

:rco<0:y

the

carbon

brushes

(K2

Hl)

are

w Jr::. J·.:t

::r

G':e

commutator

is

dirty

(See paragra;X-.

3--1.

To

change

the

carbon

brushes,

unscre·.;· rt.e

tv.-o

cap

screws

(K217),

pull

out the ole

:::r·..:::::-.es,

anc

replace

with new

ones.

(b)

To

Adjust

the

Crosshead

and

Gibbs

-

After

six

months

;.:se,

readjust

the

crosshead

(K241)

and

gibbs

(K243) to

insure

quieter

and

smoother

operation.

First

remove

the

sharp-

ener

and

blade

from

the

machine

and

then

the

slide

cam

(K124A)

on

the

right

side

of

the

front

housing.

Be

sure

to

retighten

knife

locking

holt

ing

bolt

and

nut

(K239).

Loosen

both

loc:~~:J.::!;

:::cre\1·s on

the

connect.-

ing

rod

(l\::201,.

~n:::ert

3.

=6

3:2

screw

(you

can

use a Slide

Ca:-::

Sere.':

l\:1:2-±B)

into

wrist

pin

(K256) and dr3.\\

wrist

pin

forward

to

prevent

end

play.

Tighten

:he

lower

connecting

rod

locking

screw,

rotate

the

motor

by

hand

a few

times

to

seat

the

connecting

rod

properly

on

the

crank

oin

(l\::20:3\

:md

tighten

the

upper

locking

screw.

Loosen

slightly

the

three

screws

on

the

right

hand

gibb

(K243)

on

the

same

side

of

the

housing

as

the

two

adjusting

screws

(K260).

Then

loosen

the

adjusting

screw

nuts

and

turn

both

upper

and

lower

adjusting

screws

just

enough

to

allow

the

crosshead

to

slide

up

and

down

without

side

play.

9

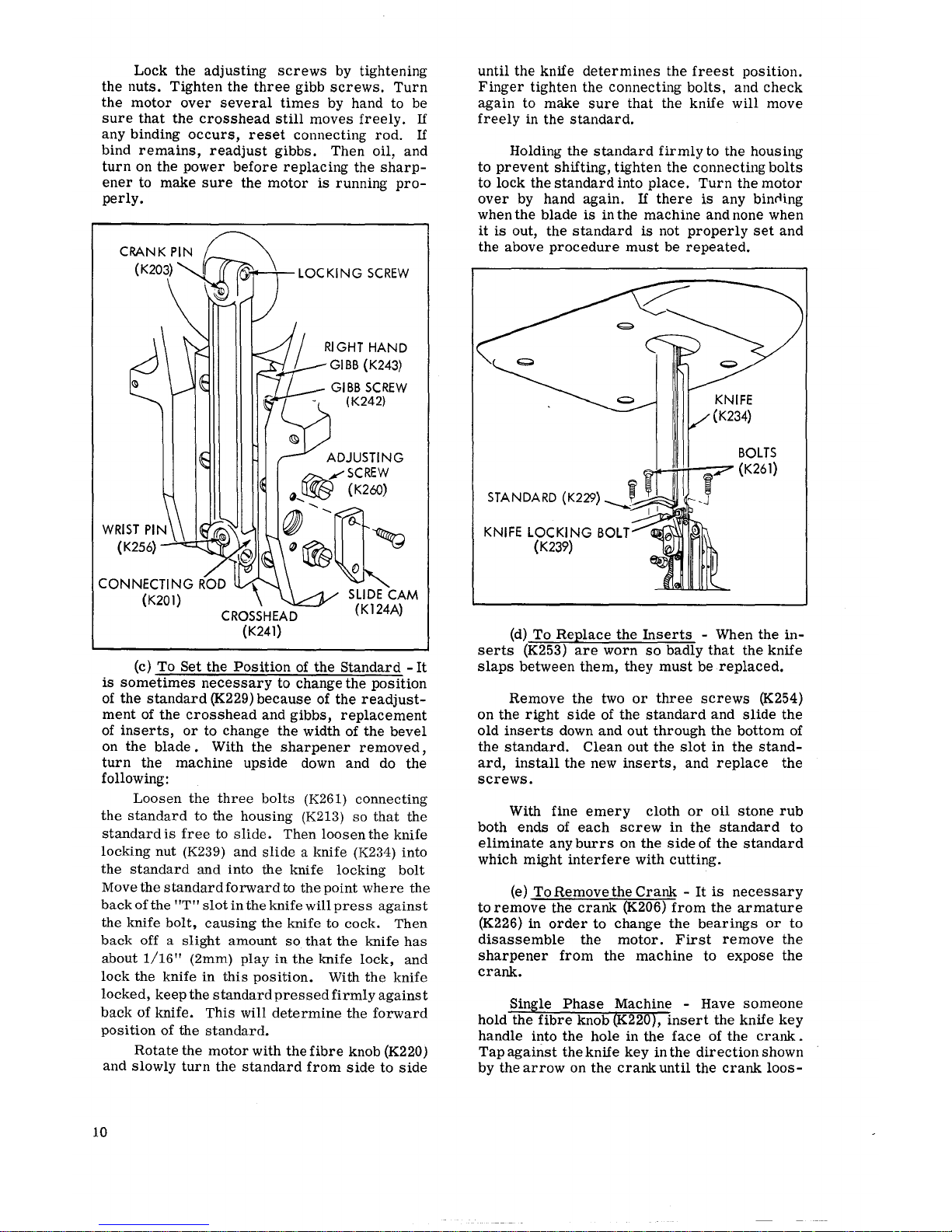

Lock

the

adjusting

screws

by tightening

the

nuts.

Tighten

the

three

gibb

screws.

Turn

the

motor

over

several

times

by hand to be

sure

that

the

crosshead

still

moves

freely.

If

any binding

occurs,

reset

connecting

rod.

If

bind

remains,

readjust

gibbs.

Then

oil, and

turn

on

the

power

before

replacing

the

sharp-

ener

to

make

sure

the

motor

is

running

pro-

perly.

CRANKPIN

~

(K20~~

LOCKING

SCREW

RIGHT

HAND

GIBB

(K243)

GIBB

SCREW

(K242)

ADJUSTING

~SCREW

~~~:

·(®~

CROSSHEAD

(K241)

SLIDE

CAM

(Kl24A)

(c)

To

Set

the

Position

of

the

Standard

-It

is

sometimes

necessary

to

change

the

position

of

the

standard

(K229)

because

of

the

readjust-

ment

of

the

crosshead

and

gibbs,

replacement

of

inserts,

or

to

change

the

width of

the

bevel

on

the

blade

• With

the

sharpener

removed,

turn

the

machine

upside

down and do

the

following:

Loosen

the

three

bolts

(K261)

connecting

the

standard

to the

housing

(K213)

so

that

the

standard

is

free

to

slide.

Then

loosen

the

knife

locking

nut

(K239)

and

slide

a knife

(K234)

into

the

standard

and into the knife locking

bolt

Move

the

standard

forward

to

the

point

where

the

back

of

the

"T"

slot

in

the

knife will

press

against

the knife

bolt,

causing

the

knife to cock.

Then

back

off a

slight

amount

so

that

the

knife

has

about

1/16"

(2mm)

play

in

the

knife

lock,

and

lock

the

knife

in

this

position.

With

the

knife

locked,

keep

the

standard

pressed

firmly

against

back

of

knife.

This

will

determine

the

forward

position

of

the

standard.

Rotate

the

motor

with

the

fibre

knob (K220)

and

slowly

turn

the

standard

from

side

to

side

10

until

the knife

determines

the

freest

position.

Finger

tighten

the

connecting

bolts,

and

check

again

to

make

sure

that

the knife

will

move

freely

in

the

standard.

Holding

the

standard

firmly

to the housing

to

prevent

shifting,

tighten

the

connecting

bolts

to

lock

the

standard

into

place.

Turn

the

motor

over

by hand

again.

If

there

is

any bincling

when

the

blade

is

in the

machine

and none when

it

is

out,

the

standard

is

not

properly

set

and

the above

procedure

must

be

repeated.

KNIFE

LOCKING

BOLT

(K239)

BOLTS

~.....,_,..;..---:?"

(

K26

1)

(d)

To

Replace

the

Inserts

- When

the

in-

serts

(K253)

are

worn

so

badly

that

the

knife

slaps

between

them,

they

must

be

replaced.

Remove

the

two

or

three

screws

(K254)

on

the

right

side

of the

standard

and

slide

the

old

inserts

down

and

out

through

the

bottom

of

the

standard.

Clean

out

the

slot

in

the

stand-

ard,

install

the

new

inserts,

and

replace

the

screws.

With fine

emery

cloth

or

oil

stone

rub

both

ends

of

each

screw

in

the

standard

to

eliminate

any

burrs

on

the

side

of

the

standard

which

might

interfere

with

cutting.

(e)

To

Remove

the

Crank

-

It

is

necessary

to

remove

the

crank

(K206)

from

the

armature

(K226) in

order

to

change

the

bearings

or

to

disassemble

the

motor.

First

remove

the

sharpener

from

the

machine

to

expose

the

crank.

ens

on

the

armature.

The

crank

has a left-

hand

thread

and

must

be

turned

clockwise

to

be

re-

moved

from

the

armature.

3

Phase

Machine -The

crank

is

secured

by a stud

locked

against

the

armature

shaft.

The

stud

is

held

in

position

by a 1/4-20

set

screw.

Insert a 1/8"

Hex Key

into

set

screw

located

in

front

of

crank,

and

loosen

screw,

Remove

crank

as

described

above,

(f)

To

Replace

the

Motor

Bearings -The

motor

bearings

must

be

changed

if

the

motor

operates

noisily

without

the

crosshead

and

gibbs.

Back

motor

bearing

(K219) -

It

is

neces-

sary

first

to

remove

the

back

housing

(K222)

and

then

push

the

bearing

out.

Replace

the

back

housing

and

tighten

the

motor

bolts

(K224).

Then

put

in

the

new

back

bearing.

When

in-

stalling

a new

bearing,

place

the

old

bearing

behind

it

while

tapping

it

into

the

back

housing.

Rotate

the

old

bearing

when tapping

so

that

the

pressure

will

be

evenly

distributed.

In

this

way,

neither

the

inner

nor

the

outer

race

of

the

new

bearing

will

be

harmed.

Front

motor

bearing

(K246)

-Remove

the

armature

(K226)

after

removing

the

crank

and

back

housing.

Unscrew

the

bearing

lock

(K244)

and

then

(from

the

armature

side)

push

the

bearing

forward

and

out.

Install

the

new

bear-

ing

as

described

in

the

previous

paragraph.

(g)

To

Replace

Crank

Pin

Bearing -The

crank

pin

bearing

(K204)

must

be

changed

when

the

crank

pin

(K203)

is

loose

in

the

bearing

or

when

the

crank

pin

does

not

turn

smoothly

in

the

bearing.

Remove

the

bearing

lock

(K202)

on

the

face

of

the

crank,

remove

the

screw

in

the

back

of

the

crank,

and

tap

the

bearing

out

from

the

back.

(h)

To

Reassemble

Motor

- (Single

phase

Powrcrest

II only)

It

is

extremely

important

that

the

stator

(K216)

and

the

back

housing

(K222)

be

replaced

in

proper

position

on

the

front

housing

or

the

motor

itself

will

not

funcltion

properly.

The

stator

should

be

replaced

on

the

front

housing

so

that

the

model

name

or

"M"

in-

signia

on

both

sides

of

the

nameplate

are

in

the

same

horizontal

plane

The

Back

Housing

has a line

scribed

on

the

underside

which

matches a line

scribed

on

the

underside

of

the

Stator.

These

two

lines

must

be

in

line

with one

anotherwhen

the

Back

Hous-

ing

is

replaced

onto

the

Stator.

See

illustration

below.

UNDERSIDE

OF

HOUSING

11

12

ALWAYS GIVE MACHINE

SERIAL

NUMBER

WHEN ORDERING

PARTS

K3

~~

Kl

~

K21

K20

K16~

"';,

KlB

K6

K48

K33

""'

"'-._

"'-._

'1

I

I

I

r

~K34

'

I

~

I

I

~K36

I

Kl5 I

~

Kl5

1

K37

•

I . .

-.>.;;;:::

•.•

•.

K

-

ORDER

BY

PART

NUMBER

- NOT KEY

NUMBER

I"AKT:i

Ll:il

1

PART

PART

KEY

NO.

DESCRIPTION

KEY

NO.

DESCRIPTION

K1

802S Latch Spring Screw

K24

1245

Collar Washer, K Square Shaft

K2 802 Latch Spring

K25

813

Square Shaft Collar

K3

801

Latch

K26

1265 Spring

For

Presserfoot

Leg

Guide

K4

822S Screw For Bearing Block

Top

K27 1262

Pin

for

1265

Kfi.

811

Bearing Block

Top

K29

1254

Carrier Tube Bushing

K6 1229 K

Square Shaft (give

size)

K30

1255

Lock

Screw, Carrier Tube

K7

824

Presserfoot

Lift

K32

1258

Carrier Tube

K9 824U

Screw For K Presserfoot

Lift

K32A

1259

\'..'asner

For

Tube

K10

1171 K Presserfoot

Leg

(give

size)

K33

1275

K

Stone Carrier, Right

K11 1269

Pivot Screw For 1266

K34

1285

Gea'. Stone Carrier, 32 T

K12

1266 Presserfoot

Leg

Guide

K35

1276

K

S:one Carrier,

Left

K13

1291 Guide

For

Stone Carrier, Right

K36

1261

Snao

~

·r~

~=or

1276

K14

1328 Screw For Slide Guide K37 1277

S'la:::'

==\

·r2

;::Jr 1258

K15

1300 #60 K Stones w/Bushing, Pair

K38A

824T

Sc---=.··

::·

::::::k

sc:Jd

1468 & 1469

1301

#1

00 K Stones w/Bush ing, Pair

K40A

805P

9c

:::~"c:;c1280

1302

#150

K Stones w/Bushing, Pair

K41

1280

<

Sc:

....

~--~

SCi~~

~ear

K16

1296

Stud For Spring

K42

1279

'.',

::s~:;'

:::,

SJJ3'e

Shaft Gear

K17 1294

Spring, Right, For Guide 1291

K43

1475

C::--

...

~--

3 ::-:.

:.

1234

and

1255

K18

822S Screw For Carrier Block

K45

1329 s

==

·..:

.....

==

:.

0"

K19 1295 Spring, Left,

For

Guide 1290

K46

1464

~=:=--~~-~

K20

803N Trigger Stop

Nut

K47 1469

,::;,=-

s~

::":

-

:::'l;c

K21 803 Screw For Trigger Stop

K48

1465

,,, ~ =·

-=

....

s=

::;-=;3

...

K22

1200 K Slide (give size

and

stroke)

K49

1468

G~::

..

Sia;:. S .... o ..

t

K23

1290

Guide

For

Stone Carrier,

Left

K50

1466

•.• ~ ...

.::..,s.:=

..

~:=ear

ALWAYS

GIVE

MACHINE

SERIAL

NUMBER

WHE:'\

OR:!:::-·,::;

:::.:.,::ns.

ORDER

BY

PART

NUMBER-NOT

KEY

\,L;'.'3!:):;).

13

ALWAYS

GIVE

MACHINE

SERIAL

NUMBER

==::::..~~~WHEN

ORDERING PARTS

K122A

\

K1~~~.

3

L

Ki

114

A~

K!lS

K117A

~1Jr·

.

'fj'§J~~

Kll2

\-~

\.

~-@?

~

Klll

\.,.-I.'

-~-

-~

-·

"'"

'[)

"'---

-

--

- -

-l

-

_@;-..::::

1·~

~--

~t---l

I

--u.>-,

----

FK146AI

.

K143A

IKl

44

~

0

~

I

KllO

I

K145

)2))

_j

K146B

I

IK156

K146

~~\

I

I

K103A-IJ

K101

SQUEEZE

TRIGGER

ASSEMBLy

K186

~

K188 K187

~

~~~'

K189~

K183,---

r

K190

K191

K184

K182

K192 K193

K180

14

KEY

K1

01

K102

K103

K103A

K105

K106

K107

K108

K109

K110

K111

K112

K113

K113A

K114A

K115

K116

K117A

K120

K122A

K123

K124A

K124B

K129

K130

K131

K132

K133

K134

K135

K136A

K136B

K137

K138

K139

K139A

K140

K141

K142

K143A

PART

NO.

859C

822S

837

837R

1100

834R

835

836

836A

1125

840

840A

838C

840P

840D

1492

1156

836N

838B

1491

838N

1499

1187

1327

1328

802S

1325

856

816FS

858A

841B

842B

1164

1165

1165X

1160

843

1151

829B

836N

802S

831

1340

K144

516

K145

848C

K146 839

K146A

805P

K146B 839W

K147

830

*830A

K148A

1190

*1190B

PARTS

LIST 2

DESCRIPTION

Screw, Lower Right,

to

Fasten K

Sharpener

to

Machine

Screw For Upper Gear Block

Driver

Sprocket

Pin

K Frame (give size

and

stroke)

Chain Roller

ld ler Sprocket

Stud

For Idler Sprocket

Eccentric Stud (w/807W)

K Chain (give size and stroke)

Trigger For

Sharpener

Spring

For Sharpener Trigger

Bearing

For

Pulley

Support

(outer)

Trigger

Pin

Retaining Ring

Pulley Bracket w/Bushings

(for

1491 & 1497)

Safety Lock Screw

Safety

Lock

Nut

Bearing For Pulley

Support

(inner)

Shaft For Pulley

(with

1492 & 1497)

Nut

For Pulley

Slip Pulley

Sharpener

Anchor

Screw -

3/8"

Slide Cam,

nylon

Screw

For

Slide

Cam

Screw

For

Side Cover

K Side Cover

Presserfoot

Cam

Screw

For

Cam

Bracket

Cam

Bracket

Bushing For Bevel Gear

Bevel Gear 16

Shifter

Plate

Edge

Control

Arm

Edge

Control

Arm

w/887

Snap Ring

For

Pivot Stud

Gear

28/16

Mitre

Assembly

Spacer Rod

Stud

For

829

Gear

Nut

For

Idler Sprocket

Screw

For Cover Slide

Top

Cover Slide

Top

Rod

For

Pulley Bracket

(with

1158A)

Front

Bracket Screw, Upper

Spacer,

Front

Bracket

Gear 16 Teeth

Pin, Gear

Washer, Gear

Gear Assembly

50/12

Teeth

Gear Assembly

50/20

Teeth

Gear

28/12

T (large bore)

Gear

28/26T

(large bore)

KEY

PART

!\0.

K149A

1186

K150 829

K150A

K151

K152A

·329c

1481

828

1184

1184X

K152B 1188

K152C 1189

K152D 1192

K153

K154

K155A

K156

K157

K158

K159

K161

K162

K163

K164A

K164B

K165

K166

K167

K168

K169

K170A

K171

K172

K180

K181

K182

K183

K184

K185

K186

K187

K188

8483

410

1185

802S

864S

887

+8873

1191

492

489

1193X

1341

1158C

427

1159

870S

1194

856L

1158A

841.~

490

480.A

1256

480D

323PJ

481C

4813

480E

480E

481G

481E

481D

K189

490

K 190

481

F

K191

480F

480G

K192 480H

K193

481A

480X

DESCRIPTION

Retaining Ring

Gear Assembly

64/20

Teeth

Gear Assembly

56/20

Teeth

Retaining Ring

Sprocket Gear 32 Teeth

<

Front

Bracket

(for

edge

control

::rc-r

;, 1185, 1186

<

F•.Jnt

3racket

w/1185,

1186,

1122

..:,-~

:...oc"'

P n

So-~;.~-~

Lock

->~

:_:,:<

Se:

Screw

S:-:::

.. Lc :.er

Le"t

to

Fasten

S-c·:.:;-:;r

:::;

'.lachine

F-:-:

::-:::.::::: S::-e'.'.', Lower

:_:::·;

S:~::

F::- E·]ge Control

Arm

< ~ .::

S:

...

:

?-::;;::-.,::::::a~

Sroe

~:::;-

;:::;:,-:;

C•C'<

S:_::

=:·

:O::.e

Ge:or

8-.Jshing

:::::~

:.

:-

~S:JE

and

Pins

S:

.. ~ .·.

;

:>J.:;

3

Socket

Cap

S:·:::. ':-,::; 3 Socket

Cap

P-e::s::--Too:

Le'.

er

P-::sse-"'oo: Lever

with

490

Se-e:.

5 16x3 8 Set

Sere:. i

4x3

8 Shoulder

:::o

cr

·:,

ith

Screw

Cc

ar

;, ith 480H

and

481 A

Spr;ng

Sere.";

6x 1 8 Round Hd.

Sq..Jeeze

Trigger Assembly

with

480D

and

481

D

* For

Half

Speed

and

Cyclomatik

Machines

Only

ALWAYS

GIVE

MACHINE

SERIAL

NUMBER

WHEN

ORDERING

PARTS.

ORDER

BY

PART

NUMBER-NOT

KEY

NUMBER.

15

ALWAYS

GIVE

MACHINE

SERIAL

NUMBER

WHEN

ORDERING

PARTS

K211

__;r(

~

K210 U

K262~-~

~K263

~:

K209 I '

d.

I

~

"' '

~

l.,

1

K208:(

,,

K249 K

212

"--

K248

"

" K207 K247'-..

~~\'~

K245~

K244

K246~

K205 () K257

K206~~-\W

K204

K202 K203

~~

~

K243""

'1,

~~~

K242~~

K2411

~

,

____

D I

...---__.....-

1

11

K256

----~

ta

\',

___-

___-

K239

;f'O,

J

~

K240

c

K201

K215

K254

K239

_/>

~

'~(C))

! '

~

K255

~"i

_:®

I

K264

K232

I K230

~

K227

~K231

K228

K234

16

/

/

K223

/1

/

/

/

I

_)

K226

__-//

f

i__-~K224

r-------

-~

_ ... -

I

I

I

I

I

I

I

I

~..J

~~'

K290

K291

K289

PARTS

LIST

3

PART

PART

KEY NO.

DESCRIPTION

KEY

NO.

DESCRIPTION

1

3

1 3

PHASE

PHASE

PHASE

PHASE

K201

412A

412A

Connecting Rod ~ H

K241

411 411

Crosshead

with

Wrist Pin

412B

412B

Connecting Rod ~ M

K242

490A

490A

Screw

8x3/4

Fil. Hd.

412C 412C Connecting Rod ~ L

K243

409 409 Gibbs,

Pair

4120

4120

Connecting Rod ~

Ll

K244

404C 404C Bearing Lock

K202

413W 413W Bearing Lock

K245 867 867

Brake

K203 415

415

Crank

Pin

K246 403 403

Bearing #203

K204

414 414 Crank Bearing

K247

822S 822S Screw

6x1/4

Bind. Hd.

K205

415N 415N

Crank

Pin

Nut

K248 406

406A

Terminal

Pin

K206

413BX 413GX Crank

with

413W, 414,

415~

H

K249

405

405A

Terminal Block

with

Pins

413CX

413HX

Crank

with

413W,

414,415 ~ M

K250

441C 441C Cover, Switch

4130X

413JX Crank

with

413W,

414,415 ~ L

K251

441S 441S

Screw

6x5/16

Fil. Hd.

413EX

413KX

Crank

with

413W,

414,415 ~ Ll

K252 423 423 Handle Only

K207

866X 866X

Pulley Cover

with

Brake

423A 423A

Handle with Block

K208

867N

867N

Nut

423B 423B Handle, Upturned,

with

Block

K209

516

516

Screw,

8x5/16

Fil. Hd. 423E 423E

Handle Assembly Drilled

for

Oiler

K210

4070 4070

Top

Handle

K253

428A

428A

Insert

for

Standard ~ 9"