Maimin 59, 86, 87, 37 User Manual

BOOK NO.

22102

MAIMIN°

©1980

EDITION

H.

MAtMIN

CO.,

4

INC.

-ROUND

I.

DESCRIPTION

l

~

l.

General

Your new Maimin round knife machine

ready for

handle (Key No.

screws

machine to

nameplate

2-3). The knife guard (Key No. B247) acts as a protective

guard for the operator so

times. The ball

only be slightly

the operator's hand from accidentally touching the knife.

1-2

..

' There are two types

for the round knife machines.

used

pendicular to the knife. It sharpens a faster cutting edge.

The

almost parallel

smoother cutting

or

plastics. .

O!}eration. It is merely necessary

as.

described

a!!

electrical outlet

oCthe machine

on

above the top

Sharpeners Available

is

the

gliding

#

15

grinder

to

KNIF£.

B2

10)

and lock it into place

in

paragraph

of

and

that

the

bottom

of

of

sharpening devices available

\[he

grinder

utilizes slightly larger stones which

the knife. This type

edge

in

which the stones are set per·

for cutting sheer fabrics, synthetics,

INSTRU<;TIONS

is

delivered

to

insert the

with

the two

2·2.·

Th;en connect the

the same ·voltage

begin cutting.-(see paragraph

it

should be down at all

of

the knife guard should

the lay in

sharpener

order

of

sharpener

most

as

to

prevent

generally

gives

on

are

AND

1·3.

carbon steel and high

used for cutting most materials. However, hard materials

such as fiberglass and heavy canvas

bon steel knife requiring use

which keeps

the

1-4.

Part Numbers

PARTS

Knives

Available·

The

cutting knives come in two grades which are

its cutting edge longer.

Knife · 4" (Model 54)

Knife·

5-1/4" (Model 59)

Knife

·

6"

(Model 86)

Knife·

7"

(Model87

of

LIST

speed·

Kriives

CATALOG-

ste-eL

Carbon steel knives are

will

of

the

high speed steel knife

Carbon

Steel

30303

30307

30310

& 37)

30311

quickly dull the car-

II. OPERATION

2-1. Safety Instructions

A.

Be

sure machine

B.

Use

correct electrical wiring:

U.S.A. only 1 phase:

a

International

IP+N+-4:-:

3P+-;:-:

is

properly grounded

Use

3phase:

Use

.·

Use3;x

Use4x

AWG

16/3 SJ, SJT

AWG

l6/4·SJ,

l,Omm2CEE(2)61

l,Omm2CEE(2)61

High Speed

Steel

303.22

30324

30325

30326

SJT

'

NUMBERS

IH PARENTHESIS FOLLOWING PART HAMES

ARE

KEY NUMBERS

FROM

PARTS

PLATES-

HOT PART NUMBERS

C.

Keep cutting area clean and well lit.

D.

Keep visitors away from

E.

Do

not

use machine in

F.

Store machine

G. Keep machine clean

safest performance.

H.

Always disconnect machine

fore servicing, and when changing blade.

in

dty

and

I. Remove knife key from knife

ing motor.

J.

·:se

sure switch

cord.

K.

Disconnect electrical cord before carrying

macrune.

L.

Keep knife guard in place and

blade.

2-2.

To

Attach Handle

Insert the metal stud

into its

the handle screw

· into the standard, and tighten

position with the handle lock screw

on

2-3.

(B41). Flip switch

2-4.

raise knife guard

should

tor safety. When

knife guard to the roller plate.

bole

the side

To

Start

Attach

To

Cut

Loosen

only

in

the upper rear

(8211)

or"

the standard. ·

current connector

(847)

the

(8247)

be

slightly above

the

is

off

before connecting electrical

of

ofthe

through

it.

to

"on,

guard

carrier screw (B248) slightly and

to

hdght

the

machine is

cutting

damp

location.

blade sharp for best and

the

handle

the

Then

(8214)

(840)

position.

oflay

top

not

area.

or

wet

location.

·

when

not

in use, be-

lock

before start·

hands

away from .

(Key

No.

standard

flange

lock

to

of

being used, lower the

(8216).

of

the

the handle into

and

nut

the

terminal pins

.·The

knife guard

the lay for

8210)

Put

handle

(B213)

opera•

3-2.

To

Lubricate

Grease

by

turning

ard one complete turn. When the grease

screw it,

used

is

thus

require

3-3. To

. After repeated use, the ·sharpening stones (B2S9)

become coated with grease

knife effectively.

Stone Cleaner directly

cleaning fluid

The

dirt

not

be

run

inflammable cleaning fluid.

3-4.

To

a) Gliding Grinder (Plate

(8254).

stone

in the grinder frame

.screw, and

frame.

washer

slide the neck

ing sure

neck

slot. Then

washer

is

Unscrew

with

Be

(8255).

that

of

the

and

explained in paragraph

the

gear

(8239)

the

grease

cup

fill

it with grease and replace.

Lubriko M32.

no

lubrication. ·

Clean

Stones

on

will

be

near ll18terial

CbangeStones

First remove knife. Loosen stone Jock $crew

bushing

pun

the stone with bushing

careful

When installing the new stone with bushing,

of

the

stone

the

stone lock

screwed iilto

The

To

remove this coating, spray Maimin

a toothbrush

flung off; therefore, the sharpener should

the

stone adjusting screw

(8259)

(B2S8), Then remove the stone lock

not

to

lose

the

stone bushing into

coil spring

bushing and the stud

scr.ew

the

4-la.

and pinion

(8215)

onto

to

slides

on

motor

bearings are sealed and

and

dirt

a~d

the stones

to

scrub

avoid staining.

3)

out

the coil spring

is

in its position between the

should be fitted 'through the

stone bushing.

(B202)

the side

cup

The

do

not

or

the

stones. Sharpen.

(8257)

to

the

end

out

of

(8256)

the

slot, first mak-.

on

the

inside

The

is

Do

.,

monthly

of

the stand-

empty

grease

t~

sharpen the

put

a little

not

use

until the

of

the slot

the grinder

and the .

of

the

adjustment

un- <

be

· 2·5.

To

Sharpen Knife

With motor ruMing; firmly depress

trigger (B204) until

knife.

When sharpening the knife with

is

important that a light

used

on

the. trigger

ened bevel

Ill.

3-l.

NUMBERS

on

the

CARE & MAINTENANCE

Maintenance Schedule

Monthly:

Grease gear (paragraph

Clean sharpening

Clean motor(paragraph 3-8)

Six Months:

Every

Clean rollers (paragraph 3-9)

IH

both emery stones

but

constant fmger pressure be slightly and swung down.

to

maintain

kriife. interchange these

PARENTHESIS

the

same width

3·2)

stones (paragraph 3-3)

FOLLOWING

turn

the

PART

the

grinder ·

against the · Loosen

#15

grinder, it • remove the

of

sharp- frame arches completely

· and the entire assembly

HAMES

ARE

KEY

b)

#15

Grinder (Plate

the

top.

two. The frame arch .can then

bushings

adjusting bushings

bushings are removed from the end

the two

shaft. When putting

sure that

tween the

ings are then

frame

adjusting bushings

screws until

in

(8345)

(f

15 grinder stones with bushings are slid

the

(8347).

paragraph 4·1

NUMBERS

two

can then

(8339)

on

stone shaft spring

two

stones with bushings.

put

into

The frame arches are fitted properly over the

but

the

sharpener stones are adjusted as described·:

b.

FROM

PARTS

4)

four frame arch screws {8346) and

It

is

possible to· remove the

but

care should be t3ken

arches. The #15 grinder stones with

be

lifted

and the stone shaft {8344). The

new stones with bushings, make

(8343)

place behind the sharpening stones,

is

put

back

are

not

locked into place with the. ·

PLATES-

be

out

together with the

of

the shaft, and then

is

on

the shaft be-

Th~

adjusting bush-

on

the

·11

HOT

PART

NUMBERS·

pulled

out

two

not

to

off

the

s grinder

..,.

3-5.

To

Change

Detach

lower knife guard

Loosen

plate (8223) forward. Lift check spring (B260)

grinder frame

.grinder track

install knife. Remove knife

coumer·clockwise viith the knife key.

driver

damage

knife key handle towards the handle

move the knife key handle downward sharply,

against

sary

point the knife key handle towards the knife guard and

move the knife key handle downward sharply against the

roller plate

b~vel.

hole, must

the

wipe the

the two

or

the

If

the

the

to

loosen. the knife lock. To tighten the knife

A knife must be installed with its trademark

facing outward. The knif.e, with its specially shaped

gear; and the knife must·lie fiat against

knife clean before fitting

Knife

current

(8258),

(B220)

a punch to remove

knife lock and the gear bearing.

knife'lock does

r\)ller plate (8224). Repeat this action

lip

(B237).

be.fitted

connector (B40) from machine and

(B247).

throat

over the similarly shaped shoulder on

Lay

the machine on its side.

plate screws

and pull

for

sufficient clearance to remove

<!3232),

the

frame to the end

lock

(8245) by turning

Do

the

knife lock

not

readily unscrew,

of

it

onto

and slide

not

the

machine and

the

gear. Always

the

machine.

throat

on

top

use

a screw-

as

they will

point

striking it

if

neces-

l{)<:k,

and

3-6. To Remove Gear (8239)

First remove the knife

3-5. Unscrew gear cap

Then reinove gear screw

has a left-hand thread).

Take

off

the

grease

screws (8222). Lift

IMPORT ANT: When the spiral gear was

trunnion shaft. a few trunnion washers

the

behind

mesh

may

Do not lose these trunnion washers.

them on

any length.

the trunnion washers will not slip off.

3-7. To Clean

(8258) with compressed air. Check

freely. With a

so

that the grinder fnime will slide easily

3-8. To Clean

gear

of

the

gear

cause these trunnion washers to stick to the bearing.

the

tfunnion shaft.

of

time,

Sh~pener

Blow the lint and dust

clean cloth wipe

Motor

(8246)

Uft

ckculator.(B22!)

out

the

on

the trunnion shaft to create the

and·

the pinion. The greaSe on

put

the

as

described

by

turning counterclockwise.

(8244.)

by

thread seal

turning clockwise

by

gear with bearing.

Be

If

the

g.ear

is

gear screw back in place so

off

the grinder assembly

that

offthe

grinder track (B220)

in

paragraph

(8242)

off

removing its two

mounted

(8238)

on

were placed

certain

to be reriwved for

to

the

stones rotate

it.

the gear.

on

proper

the·

gear

replace

that

running, point a stream

the

motor

the

fan

to

eject

3·9. To Clean Rollers

of

of

or

it

rtot

Do

If

the

roll freely, blow

not

oil

lise a powdered

IV. ADJUSTMENTS & REPAIRS.

the.

4-1. To Adjust

a) Gliding Grinder (Pl'ate 3)

Unscrew

and then move the stones

turning

.stone lock

against

the

the trigger

knife should.

knife

moved closer

further away from

the stones are adjusted

screws .

(it

ing

from

at approximately

is

equal

the

.in

the frame arch

4-::!.

towards

knife and

I

/16"

throat plate slot. Adjust

two

roller plate

Press in the

spring (B236). When

tion,

teeth on the lip

the

stone

the

knife

(B104) is pulled slo.wly. The ground bevel

,..

approximately

b) # 15

Loosen

bushing (B339) to move.

the

knife. The

pulled slowly.

on

11oth

width. When the stones are .adjus.ted correctly, tighten

To Adjust

. As

the

the

·knife so

the

(

I.6mm).

throat

plate screws (B232) which are underneath the

(8224).

throat

release

of

compressed air into the

and

then

in

the

side

of

the

the

dust

and

lint.

rollers (8230) in. the roller plate

out

the

dust

or

as

it

will

collect .dirt causing the rollers

graphite

Sharpener

adjusting screw

screw.

at

be

ab~ut

together

yrinder

frame

the

The

sides and should be

screws

Throat

knife wears, move

front

The

plate lock (8235)

the

throat

spring. Tighten

for

lubrication

the

stone

to

Both

stones should begin revolving

approximately

the same

1/16;?

to

obtain

the

knife

to

properly,

(Plate

4)

arch

screws (B346).

the·

stones

should

same

time

ground

to

that

of

knife

the

bevel

lock

the

Plate

the

space between the edge

the slot

of

should

the

throat

throat

plate lock

the

lock· screw {8254)' one turn

or

away from the knife by

(8257).

the same

width

on

(

i.6mm).

a narrower bevel and

obtain a wider bevel. After

tighten the stone lock

stones towards

rotate

when the grinder trigger

on

the knife should be

about

stonedn

the

throat

the

throat

be

in

the middle

plate

to

slide it along the

plate

is

in the desired posi·

to

catch between the

throat

plate screws.

top

bottom

housing

(B224)

dirt in

if

against the knife

position.

by

the

rollers.

to

bind.

necessary.

Then

tighten the

moment

both

The stones are

Turn

3/32"

plate

plate

loosening the

on

sides

of

adjust·

or

away

(2.4mm)

(8223)

of

is

about

of

when

the

the

lip

of

by

do

the

the

Over a period

side the

motor

NUMBERS

IN

of

time, dust and lint will build up in· ·

and prevent proper cooling. With the

PARENTHESIS FOLLOWING

PART

NAMES ARE KEY NUMBERS FROM PARTS

motor

PLATES-

(continued

HOT PART NUMBERS

on back

corer}

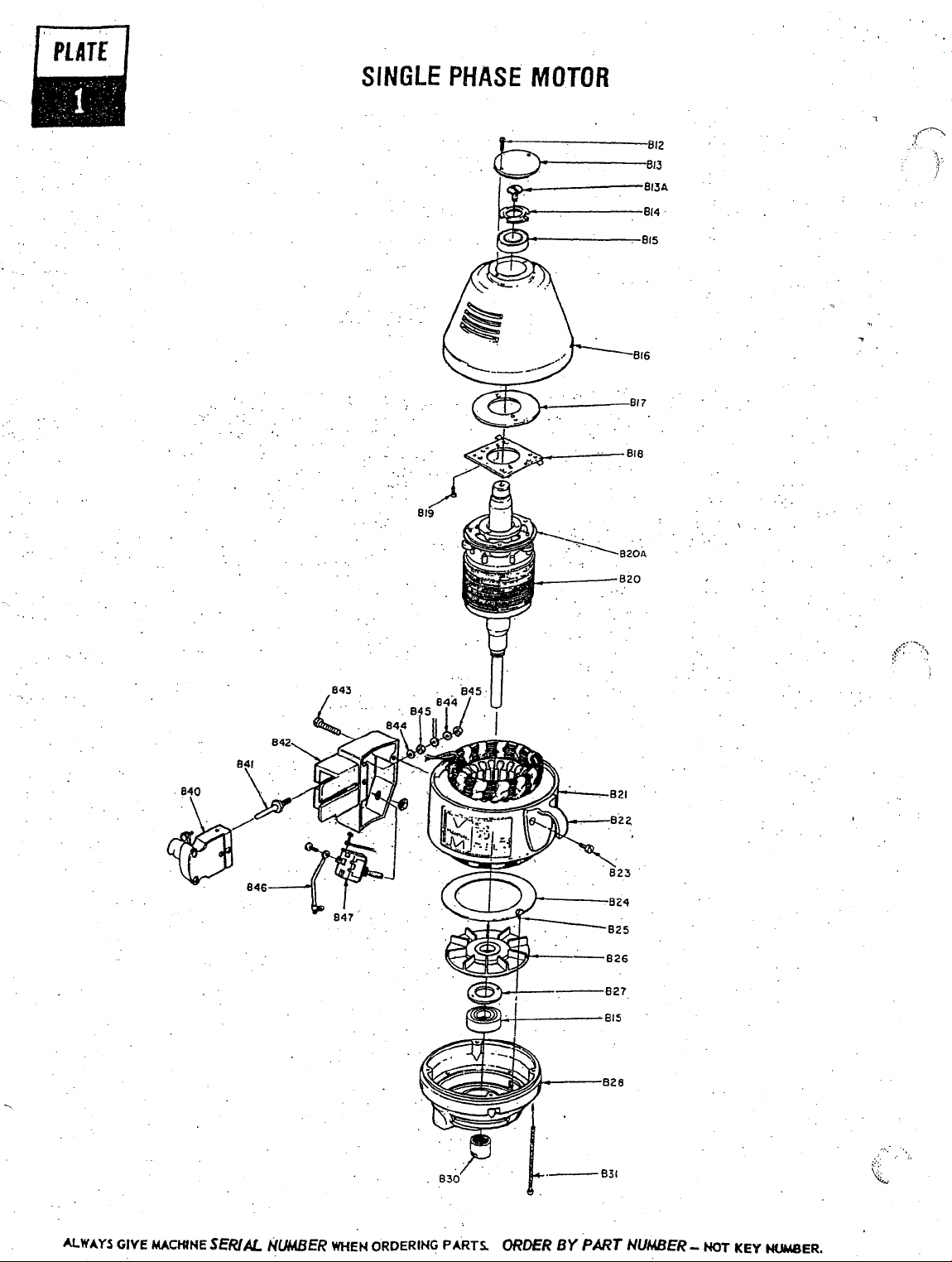

PlAT£

SINGLE

PHASE

MOTOR

-i~

·'·

842

84:5 .

t""'N~---.

~~-t----~815

--827

8:50

ALWAYS

GIVE

MACttNE

SERIAL

NUMBER

WHEN

ORDERING

PARTS.

ORDER

BY

PART NUMBER-

HOT

KEY

HUMBER.

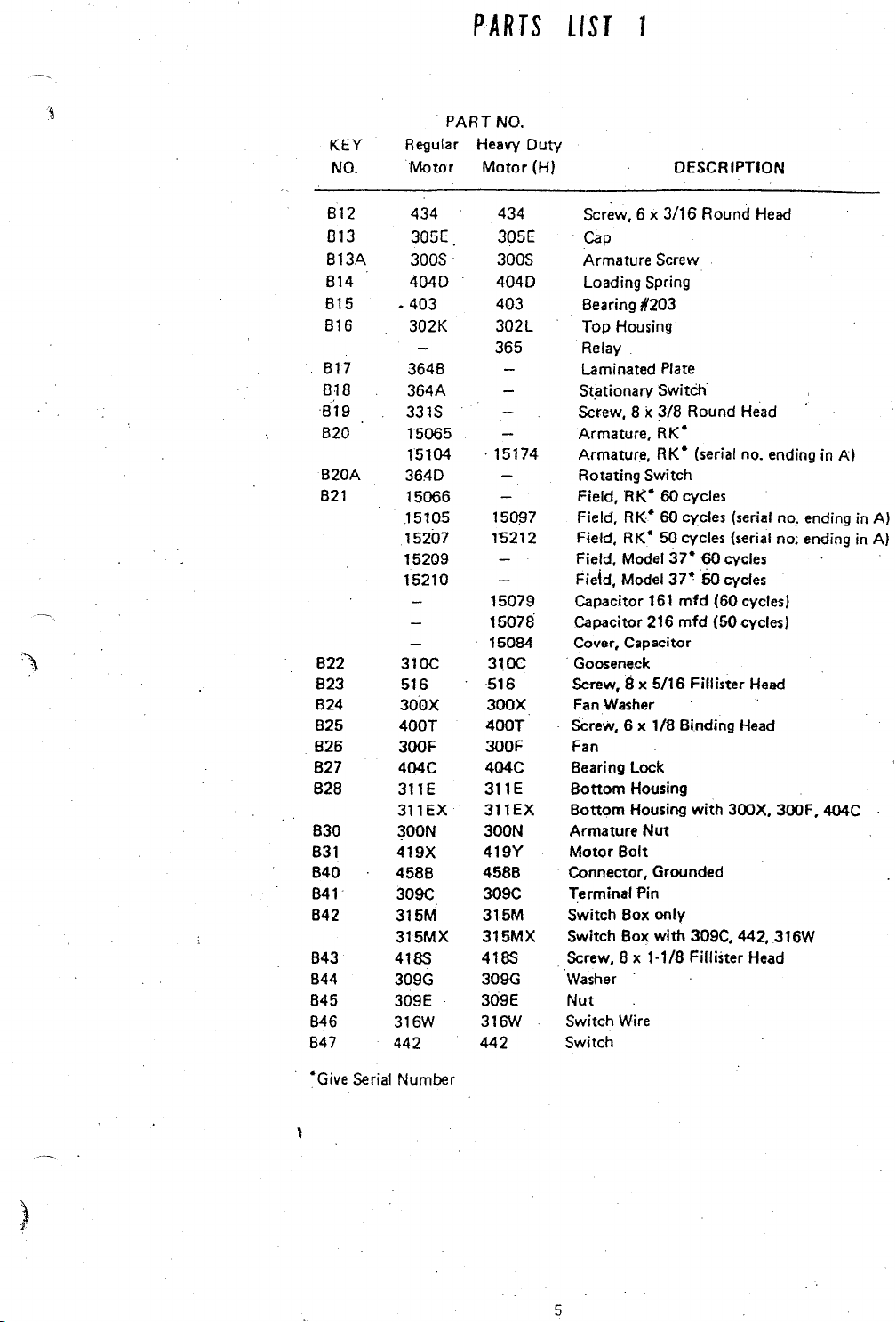

PARTS

LIST

1

'\

~

·~

PART

KEY

NO.

812

813

813A

814

815 • 403 403

816

817

818

819

820

B20A

821

B22

B23

B24

B25

826

827

828

B30

B31

B40

841

842

843

844

845

846

847

R~ular

Motor

434 434

305E 305E

300S·

4040 4040

302K

3648 Laminated Plate

364A

331S

15065

15104

3640

15066

.15105

15207

15209

15210

310C 310C

516

300X

400T

300F

404C

311E

311EX

300N

419X

458B

309C

315M

315MX 315MX

4185

309G

309E

316W

442

Heavy

Motor

419Y

4588

309C

315M

418S

309G

309E

316W

442

NO.

Duty

(H)

Screw, 6 x

Cap

300S

302L

365 Relay

. 15174

15~7

15212 Field,

15079

15078

15084

516

300X

400T

300F

404C

311E

311EX

300N

Armature Screw

Loading Spring

Bearing #203

Top Housing

Stationary

Sctew, 8 x

Armature,

Armature, RK

Rotating Switch

Field,

Field,

Field,

Field,

Capacitor

Capacitor 216

Cover, Capacitor

·Gooseneck

Screw, 8 x 5/16 Fillister

Fan

SCrew,

Fan

Bearing Lock

Bottom

Bottom

Armature

Motor

Connector, Grounded

Terminal Pin

Switch Box only

Switch Box

Screw, 8 x

Washer

Nut

Switch Wire

Switch

DESCRIPTION

3/16

Switch

3/8

RK"

• (serial no. ending in

HK"

60 cycles

RK"

60 cycles (serial no. ending in

RK"

50 cycles (serial no; ending in A)

Model

37"

Model

37"

161

mfd

mfd

Washer

6 x 1/8 Binding

Housing

Housing

Nut

Bolt

with

1-1/8 Fillister Head

Round

Round

60

5o

with

309C, 442, 316W

Head

Head

cycles

cydes

(60 cycles)

(50 cycles)

Head

Head

300X, 300F, 404C

Al

AI

"Give

Serial Number

)

1

5

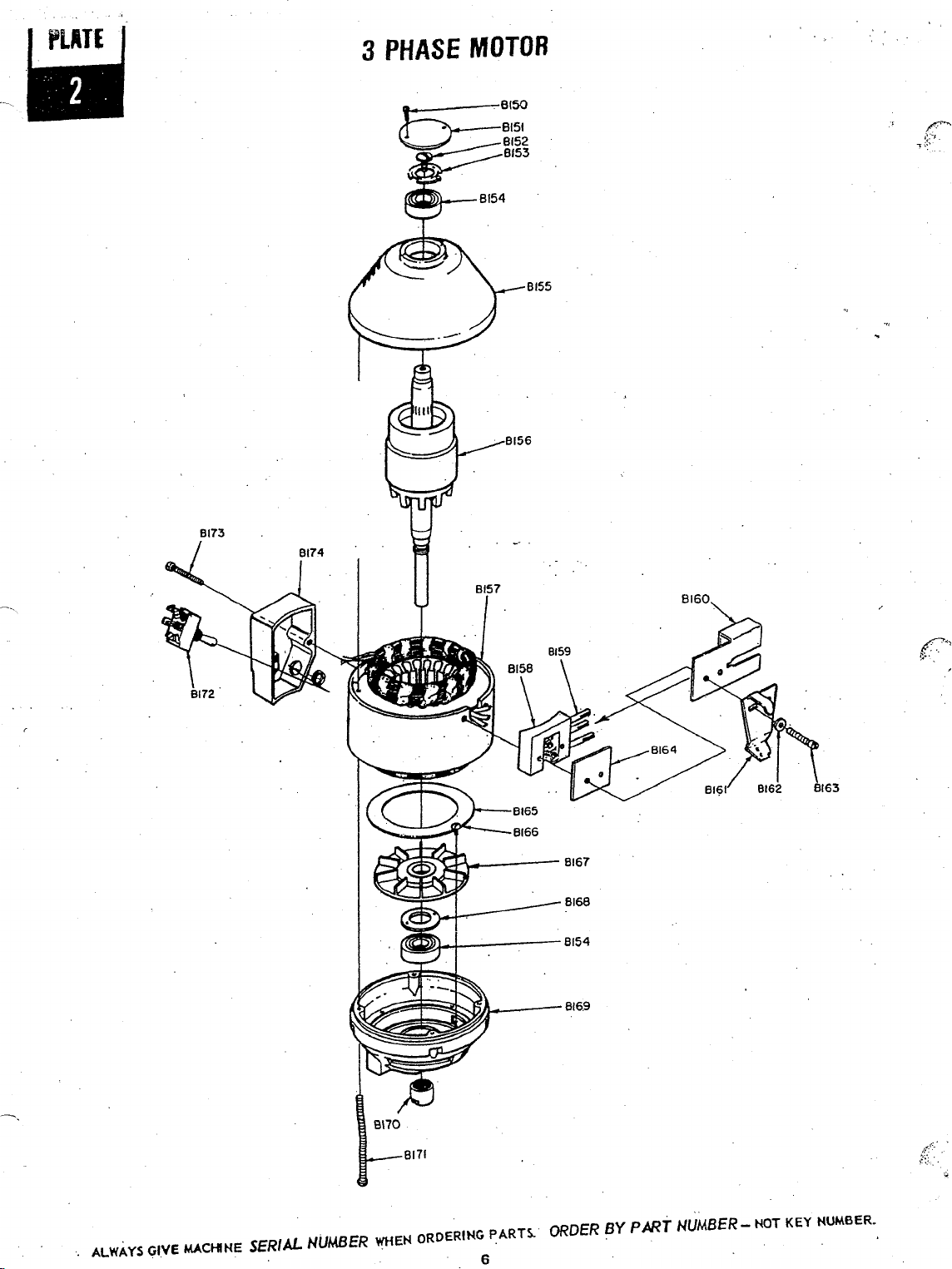

3

PHASE

MOTOR

ALWAYS

GIVE

MACHINE

SERIAL

NUMBER

WHEN

ORDERING

PART!..

6

ORDER

BY P /JRT

NUMBER-

HOT

KEY

HUMBER.

Loading...

Loading...