BOOK NO.

22102

MAIMIN°

©1980

EDITION

H.

MAtMIN

CO.,

4

INC.

-ROUND

I.

DESCRIPTION

l

~

l.

General

Your new Maimin round knife machine

ready for

handle (Key No.

screws

machine to

nameplate

2-3). The knife guard (Key No. B247) acts as a protective

guard for the operator so

times. The ball

only be slightly

the operator's hand from accidentally touching the knife.

1-2

..

' There are two types

for the round knife machines.

used

pendicular to the knife. It sharpens a faster cutting edge.

The

almost parallel

smoother cutting

or

plastics. .

O!}eration. It is merely necessary

as.

described

a!!

electrical outlet

oCthe machine

on

above the top

Sharpeners Available

is

the

gliding

#

15

grinder

to

KNIF£.

B2

10)

and lock it into place

in

paragraph

of

and

that

the

bottom

of

of

sharpening devices available

\[he

grinder

utilizes slightly larger stones which

the knife. This type

edge

in

which the stones are set per·

for cutting sheer fabrics, synthetics,

INSTRU<;TIONS

is

delivered

to

insert the

with

the two

2·2.·

Th;en connect the

the same ·voltage

begin cutting.-(see paragraph

it

should be down at all

of

the knife guard should

the lay in

sharpener

order

of

sharpener

most

as

to

prevent

generally

gives

on

are

AND

1·3.

carbon steel and high

used for cutting most materials. However, hard materials

such as fiberglass and heavy canvas

bon steel knife requiring use

which keeps

the

1-4.

Part Numbers

PARTS

Knives

Available·

The

cutting knives come in two grades which are

its cutting edge longer.

Knife · 4" (Model 54)

Knife·

5-1/4" (Model 59)

Knife

·

6"

(Model 86)

Knife·

7"

(Model87

of

LIST

speed·

Kriives

CATALOG-

ste-eL

Carbon steel knives are

will

of

the

high speed steel knife

Carbon

Steel

30303

30307

30310

& 37)

30311

quickly dull the car-

II. OPERATION

2-1. Safety Instructions

A.

Be

sure machine

B.

Use

correct electrical wiring:

U.S.A. only 1 phase:

a

International

IP+N+-4:-:

3P+-;:-:

is

properly grounded

Use

3phase:

Use

.·

Use3;x

Use4x

AWG

16/3 SJ, SJT

AWG

l6/4·SJ,

l,Omm2CEE(2)61

l,Omm2CEE(2)61

High Speed

Steel

303.22

30324

30325

30326

SJT

'

NUMBERS

IH PARENTHESIS FOLLOWING PART HAMES

ARE

KEY NUMBERS

FROM

PARTS

PLATES-

HOT PART NUMBERS

C.

Keep cutting area clean and well lit.

D.

Keep visitors away from

E.

Do

not

use machine in

F.

Store machine

G. Keep machine clean

safest performance.

H.

Always disconnect machine

fore servicing, and when changing blade.

in

dty

and

I. Remove knife key from knife

ing motor.

J.

·:se

sure switch

cord.

K.

Disconnect electrical cord before carrying

macrune.

L.

Keep knife guard in place and

blade.

2-2.

To

Attach Handle

Insert the metal stud

into its

the handle screw

· into the standard, and tighten

position with the handle lock screw

on

2-3.

(B41). Flip switch

2-4.

raise knife guard

should

tor safety. When

knife guard to the roller plate.

bole

the side

To

Start

Attach

To

Cut

Loosen

only

in

the upper rear

(8211)

or"

the standard. ·

current connector

(847)

the

(8247)

be

slightly above

the

is

off

before connecting electrical

of

ofthe

through

it.

to

"on,

guard

carrier screw (B248) slightly and

to

hdght

the

machine is

cutting

damp

location.

blade sharp for best and

the

handle

the

Then

(8214)

(840)

position.

oflay

top

not

area.

or

wet

location.

·

when

not

in use, be-

lock

before start·

hands

away from .

(Key

No.

standard

flange

lock

to

of

being used, lower the

(8216).

of

the

the handle into

and

nut

the

terminal pins

.·The

knife guard

the lay for

8210)

Put

handle

(B213)

opera•

3-2.

To

Lubricate

Grease

by

turning

ard one complete turn. When the grease

screw it,

used

is

thus

require

3-3. To

. After repeated use, the ·sharpening stones (B2S9)

become coated with grease

knife effectively.

Stone Cleaner directly

cleaning fluid

The

dirt

not

be

run

inflammable cleaning fluid.

3-4.

To

a) Gliding Grinder (Plate

(8254).

stone

in the grinder frame

.screw, and

frame.

washer

slide the neck

ing sure

neck

slot. Then

washer

is

Unscrew

with

Be

(8255).

that

of

the

and

explained in paragraph

the

gear

(8239)

the

grease

cup

fill

it with grease and replace.

Lubriko M32.

no

lubrication. ·

Clean

Stones

on

will

be

near ll18terial

CbangeStones

First remove knife. Loosen stone Jock $crew

bushing

pun

the stone with bushing

careful

When installing the new stone with bushing,

of

the

stone

the

stone lock

screwed iilto

The

To

remove this coating, spray Maimin

a toothbrush

flung off; therefore, the sharpener should

the

stone adjusting screw

(8259)

(B2S8), Then remove the stone lock

not

to

lose

the

stone bushing into

coil spring

bushing and the stud

scr.ew

the

4-la.

and pinion

(8215)

onto

to

slides

on

motor

bearings are sealed and

and

dirt

a~d

the stones

to

scrub

avoid staining.

3)

out

the coil spring

is

in its position between the

should be fitted 'through the

stone bushing.

(B202)

the side

cup

The

do

not

or

the

stones. Sharpen.

(8257)

to

the

end

out

of

(8256)

the

slot, first mak-.

on

the

inside

The

is

Do

.,

monthly

of

the stand-

empty

grease

t~

sharpen the

put

a little

not

use

until the

of

the slot

the grinder

and the .

of

the

adjustment

un- <

be

· 2·5.

To

Sharpen Knife

With motor ruMing; firmly depress

trigger (B204) until

knife.

When sharpening the knife with

is

important that a light

used

on

the. trigger

ened bevel

Ill.

3-l.

NUMBERS

on

the

CARE & MAINTENANCE

Maintenance Schedule

Monthly:

Grease gear (paragraph

Clean sharpening

Clean motor(paragraph 3-8)

Six Months:

Every

Clean rollers (paragraph 3-9)

IH

both emery stones

but

constant fmger pressure be slightly and swung down.

to

maintain

kriife. interchange these

PARENTHESIS

the

same width

3·2)

stones (paragraph 3-3)

FOLLOWING

turn

the

PART

the

grinder ·

against the · Loosen

#15

grinder, it • remove the

of

sharp- frame arches completely

· and the entire assembly

HAMES

ARE

KEY

b)

#15

Grinder (Plate

the

top.

two. The frame arch .can then

bushings

adjusting bushings

bushings are removed from the end

the two

shaft. When putting

sure that

tween the

ings are then

frame

adjusting bushings

screws until

in

(8345)

(f

15 grinder stones with bushings are slid

the

(8347).

paragraph 4·1

NUMBERS

two

can then

(8339)

on

stone shaft spring

two

stones with bushings.

put

into

The frame arches are fitted properly over the

but

the

sharpener stones are adjusted as described·:

b.

FROM

PARTS

4)

four frame arch screws {8346) and

It

is

possible to· remove the

but

care should be t3ken

arches. The #15 grinder stones with

be

lifted

and the stone shaft {8344). The

new stones with bushings, make

(8343)

place behind the sharpening stones,

is

put

back

are

not

locked into place with the. ·

PLATES-

be

out

together with the

of

the shaft, and then

is

on

the shaft be-

Th~

adjusting bush-

on

the

·11

HOT

PART

NUMBERS·

pulled

out

two

not

to

off

the

s grinder

..,.

3-5.

To

Change

Detach

lower knife guard

Loosen

plate (8223) forward. Lift check spring (B260)

grinder frame

.grinder track

install knife. Remove knife

coumer·clockwise viith the knife key.

driver

damage

knife key handle towards the handle

move the knife key handle downward sharply,

against

sary

point the knife key handle towards the knife guard and

move the knife key handle downward sharply against the

roller plate

b~vel.

hole, must

the

wipe the

the two

or

the

If

the

the

to

loosen. the knife lock. To tighten the knife

A knife must be installed with its trademark

facing outward. The knif.e, with its specially shaped

gear; and the knife must·lie fiat against

knife clean before fitting

Knife

current

(8258),

(B220)

a punch to remove

knife lock and the gear bearing.

knife'lock does

r\)ller plate (8224). Repeat this action

lip

(B237).

be.fitted

connector (B40) from machine and

(B247).

throat

over the similarly shaped shoulder on

Lay

the machine on its side.

plate screws

and pull

for

sufficient clearance to remove

<!3232),

the

frame to the end

lock

(8245) by turning

Do

the

knife lock

not

readily unscrew,

of

it

onto

and slide

not

the

machine and

the

gear. Always

the

machine.

throat

on

top

use

a screw-

as

they will

point

striking it

if

neces-

l{)<:k,

and

3-6. To Remove Gear (8239)

First remove the knife

3-5. Unscrew gear cap

Then reinove gear screw

has a left-hand thread).

Take

off

the

grease

screws (8222). Lift

IMPORT ANT: When the spiral gear was

trunnion shaft. a few trunnion washers

the

behind

mesh

may

Do not lose these trunnion washers.

them on

any length.

the trunnion washers will not slip off.

3-7. To Clean

(8258) with compressed air. Check

freely. With a

so

that the grinder fnime will slide easily

3-8. To Clean

gear

of

the

gear

cause these trunnion washers to stick to the bearing.

the

tfunnion shaft.

of

time,

Sh~pener

Blow the lint and dust

clean cloth wipe

Motor

(8246)

Uft

ckculator.(B22!)

out

the

on

the trunnion shaft to create the

and·

the pinion. The greaSe on

put

the

as

described

by

turning counterclockwise.

(8244.)

by

thread seal

turning clockwise

by

gear with bearing.

Be

If

the

g.ear

is

gear screw back in place so

off

the grinder assembly

that

offthe

grinder track (B220)

in

paragraph

(8242)

off

removing its two

mounted

(8238)

on

were placed

certain

to be reriwved for

to

the

stones rotate

it.

the gear.

on

proper

the·

gear

replace

that

running, point a stream

the

motor

the

fan

to

eject

3·9. To Clean Rollers

of

of

or

it

rtot

Do

If

the

roll freely, blow

not

oil

lise a powdered

IV. ADJUSTMENTS & REPAIRS.

the.

4-1. To Adjust

a) Gliding Grinder (Pl'ate 3)

Unscrew

and then move the stones

turning

.stone lock

against

the

the trigger

knife should.

knife

moved closer

further away from

the stones are adjusted

screws .

(it

ing

from

at approximately

is

equal

the

.in

the frame arch

4-::!.

towards

knife and

I

/16"

throat plate slot. Adjust

two

roller plate

Press in the

spring (B236). When

tion,

teeth on the lip

the

stone

the

knife

(B104) is pulled slo.wly. The ground bevel

,..

approximately

b) # 15

Loosen

bushing (B339) to move.

the

knife. The

pulled slowly.

on

11oth

width. When the stones are .adjus.ted correctly, tighten

To Adjust

. As

the

the

·knife so

the

(

I.6mm).

throat

plate screws (B232) which are underneath the

(8224).

throat

release

of

compressed air into the

and

then

in

the

side

of

the

the

dust

and

lint.

rollers (8230) in. the roller plate

out

the

dust

or

as

it

will

collect .dirt causing the rollers

graphite

Sharpener

adjusting screw

screw.

at

be

ab~ut

together

yrinder

frame

the

The

sides and should be

screws

Throat

knife wears, move

front

The

plate lock (8235)

the

throat

spring. Tighten

for

lubrication

the

stone

to

Both

stones should begin revolving

approximately

the same

1/16;?

to

obtain

the

knife

to

properly,

(Plate

4)

arch

screws (B346).

the·

stones

should

same

time

ground

to

that

of

knife

the

bevel

lock

the

Plate

the

space between the edge

the slot

of

should

the

throat

throat

plate lock

the

lock· screw {8254)' one turn

or

away from the knife by

(8257).

the same

width

on

(

i.6mm).

a narrower bevel and

obtain a wider bevel. After

tighten the stone lock

stones towards

rotate

when the grinder trigger

on

the knife should be

about

stonedn

the

throat

the

throat

be

in

the middle

plate

to

slide it along the

plate

is

in the desired posi·

to

catch between the

throat

plate screws.

top

bottom

housing

(B224)

dirt in

if

against the knife

position.

by

the

rollers.

to

bind.

necessary.

Then

tighten the

moment

both

The stones are

Turn

3/32"

plate

plate

loosening the

on

sides

of

adjust·

or

away

(2.4mm)

(8223)

of

is

about

of

when

the

the

lip

of

by

do

the

the

Over a period

side the

motor

NUMBERS

IN

of

time, dust and lint will build up in· ·

and prevent proper cooling. With the

PARENTHESIS FOLLOWING

PART

NAMES ARE KEY NUMBERS FROM PARTS

motor

PLATES-

(continued

HOT PART NUMBERS

on back

corer}

PlAT£

SINGLE

PHASE

MOTOR

-i~

·'·

842

84:5 .

t""'N~---.

~~-t----~815

--827

8:50

ALWAYS

GIVE

MACttNE

SERIAL

NUMBER

WHEN

ORDERING

PARTS.

ORDER

BY

PART NUMBER-

HOT

KEY

HUMBER.

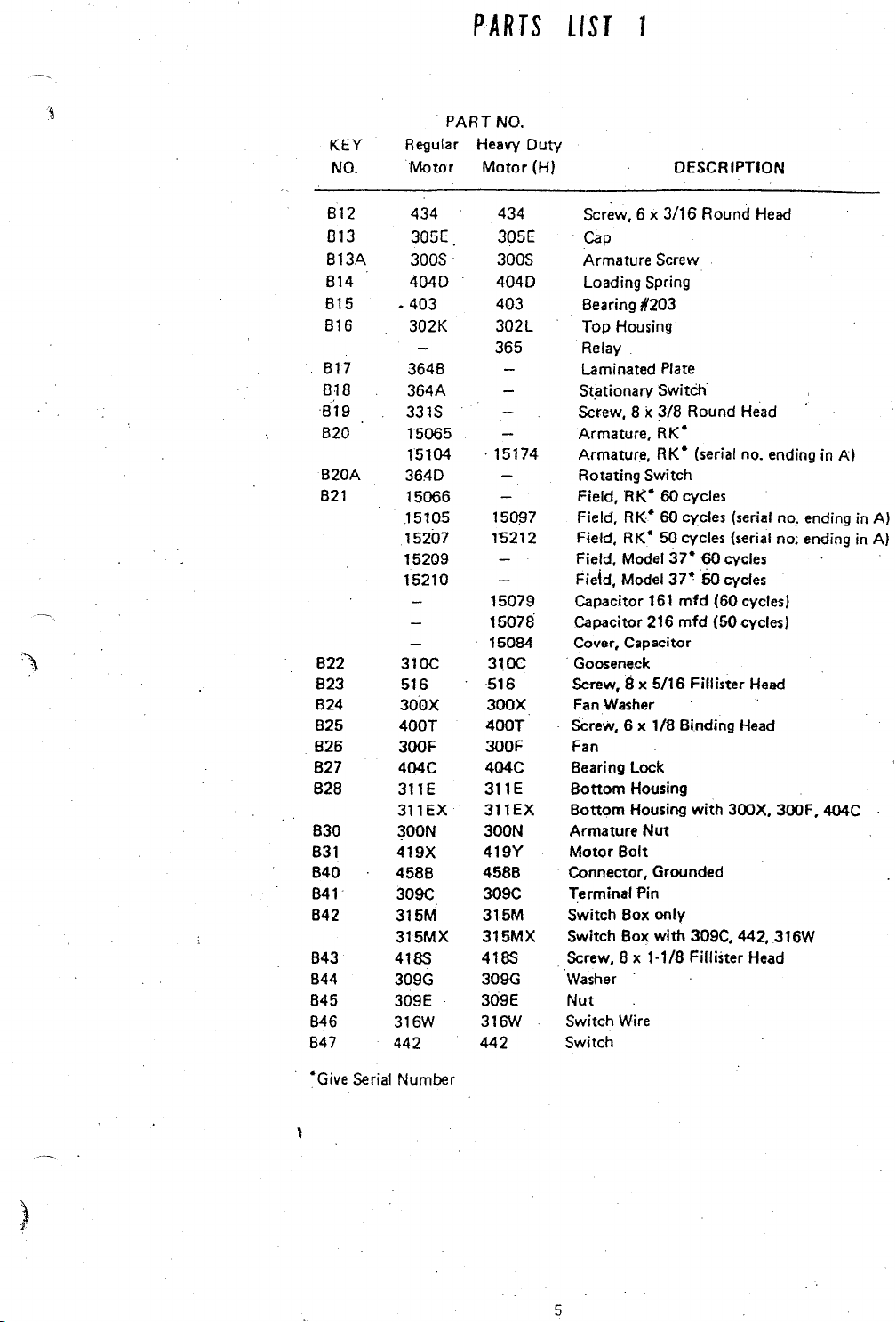

PARTS

LIST

1

'\

~

·~

PART

KEY

NO.

812

813

813A

814

815 • 403 403

816

817

818

819

820

B20A

821

B22

B23

B24

B25

826

827

828

B30

B31

B40

841

842

843

844

845

846

847

R~ular

Motor

434 434

305E 305E

300S·

4040 4040

302K

3648 Laminated Plate

364A

331S

15065

15104

3640

15066

.15105

15207

15209

15210

310C 310C

516

300X

400T

300F

404C

311E

311EX

300N

419X

458B

309C

315M

315MX 315MX

4185

309G

309E

316W

442

Heavy

Motor

419Y

4588

309C

315M

418S

309G

309E

316W

442

NO.

Duty

(H)

Screw, 6 x

Cap

300S

302L

365 Relay

. 15174

15~7

15212 Field,

15079

15078

15084

516

300X

400T

300F

404C

311E

311EX

300N

Armature Screw

Loading Spring

Bearing #203

Top Housing

Stationary

Sctew, 8 x

Armature,

Armature, RK

Rotating Switch

Field,

Field,

Field,

Field,

Capacitor

Capacitor 216

Cover, Capacitor

·Gooseneck

Screw, 8 x 5/16 Fillister

Fan

SCrew,

Fan

Bearing Lock

Bottom

Bottom

Armature

Motor

Connector, Grounded

Terminal Pin

Switch Box only

Switch Box

Screw, 8 x

Washer

Nut

Switch Wire

Switch

DESCRIPTION

3/16

Switch

3/8

RK"

• (serial no. ending in

HK"

60 cycles

RK"

60 cycles (serial no. ending in

RK"

50 cycles (serial no; ending in A)

Model

37"

Model

37"

161

mfd

mfd

Washer

6 x 1/8 Binding

Housing

Housing

Nut

Bolt

with

1-1/8 Fillister Head

Round

Round

60

5o

with

309C, 442, 316W

Head

Head

cycles

cydes

(60 cycles)

(50 cycles)

Head

Head

300X, 300F, 404C

Al

AI

"Give

Serial Number

)

1

5

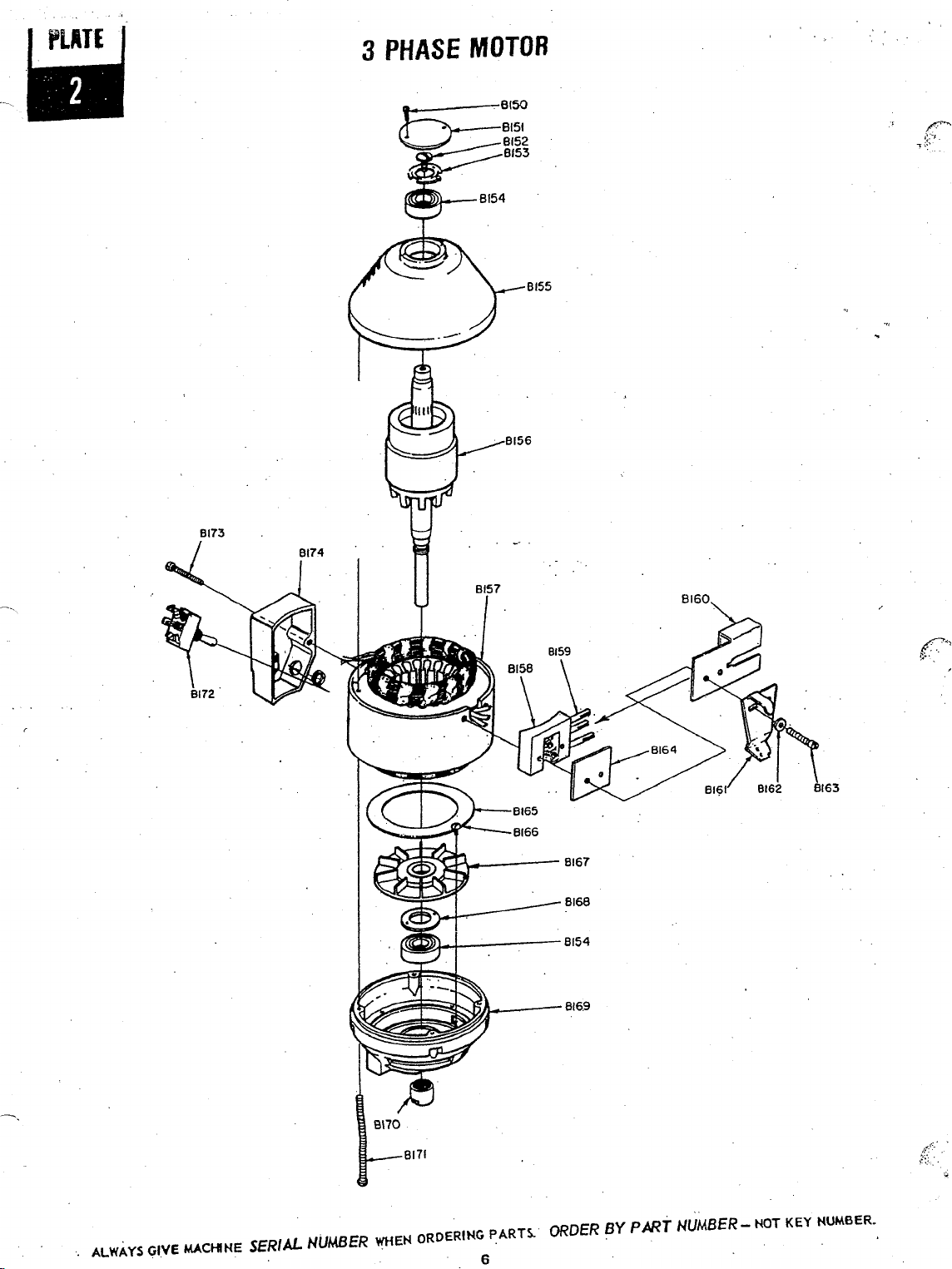

3

PHASE

MOTOR

ALWAYS

GIVE

MACHINE

SERIAL

NUMBER

WHEN

ORDERING

PART!..

6

ORDER

BY P /JRT

NUMBER-

HOT

KEY

HUMBER.

PARTS

LIST

2

~-,

~·

'~

PART

NO.

KEY Regular

NO.

8150

6151

6152 300S

6153

6154

6155

8156

BHi7

8158

8159

Bl60

~161

816~

-

8.163

Motor

434

305E

404D

403

302M

15031

15104 15214 Armature,

497P

'15Q~O

15201 15213

405A

406A

458M

310K 310K Gooseneck, 3

:329i..w.

310B 3108 Screw; 8 x 1-3/8 Fillister

'8164 4058

8165

8166

8167 300F 300F.

8168

8169

8170

8171

8172

8173 418S

8174 315P

300X

400T

404C 404C

. 311E 311E

311EX

300N 300N

419X

4428

315PX

Heavy

Motor

404D

403

302M

497P

405A

406A Terminal Pin, 3 ph.

458M Ground

-329LW

4058

3.00X

400T

311EX Bottom Housing w/300X,

419Y

4428

418S

315P

315PX

434

305E

300S

Duty

(HI

Screw,

6 x

Cap

Armature Screw

Loading Spring

Bearing

Top Housing

Armature,

Support

Field,

f=ield~

Terminal Black

Washer-

Cover, 3

Fan

Screw, 6 x 1/8 Binding

Fan

Bearing Lock

Bottom Housing

Nut

Motor

Switch, 3 ph.

Screw, 8 x 1-1/8 Fillister

Switch Box

Switch Box

l¥203

Washer

RK•

RK•

Shield, 3

ph

Washer

Bolt

only

with

DESCRIPTION

3/16

Round

Head

RK•

RK•

(serial no. ending in

(serial no. ending in A)

with

406A

ph.

ph~

Head · .-

•.

Head

only

300F, 404C

Head

442B

-AI

*Give Serial Number

\

7

STANDARD

WITH

GLIDING

GRINDER & ROLLER

PLATE

8203

STANDARD SIZE IS

MARKED.

HERE

~~820<

i -azoz

I

i

I

8239

8238

8251

8250

8243

!f.~:.;·)

. l

8237

ALWAYS

GIVE

MACHINE

SERIAL NUMBER

WHEH

ORDERING PARTS.. ORDER

8

BY

PART

XY

ROLLER PLATE

NUMBER-

NOT

KEY HUMBER.

PARTS

liST

3

KEY

NO.

. 8201

8202

8203

8204

6205

B206

8207

'£!208

6209'

8210

8211

8212

8213

8214

8215

8216

8217

8218

8219

8220

8221'

6222

R223

8224

8225

8226

6227

8228

8229

8230

8231

8232

8233

8234

.

8235

8236

8237.

8238

8239

PART

NO.

323PJ

323PA

323J

323H

323M

323C

333

332

334

335K

802S

335A

.

335B

335C

3350

335XA

335X8

.

335XC

335XD

'336

3li1C

3410

342

518W

5108

510C

31.1G

318A

317H

.317M

3170

317E

1256

311W

311S

328T

328V

.348J

348A

348M

~c

348S

313K

l13R

- 313H

313N

337

340T

.,

3405

337P

340

339P

437

438W

313S

·339M

340

313L

337J

337L

3918

391E

391G

·

JS1H

391K

391M

319J

319H

319M

319C

DESCRIPTION

Pinion

Pin-#£

Pinion

Pin-

Pinion-

R4

or

PinionPinion-

248)

Pinion-

86

or87)

Trigger

Screw

Trigger

Trigger

Spring

Link

Knuckle

Screw,

6 x

Link-

4"

Link-

59

Link-

86

Link-

37

Link

with

Link

yJith 332, 334 - 59

Link

with

Link

with

Link

Screw

Handle

Assembly

Offset Handle Assembly

. Screw, 8 x

Washer

Lock

Nut

Screw, 10

Grease·

Cup··

Standard - 6 (4'-'l

StandardStandard - 248

Standard Standard Rollpin

Lock Washer

Screw.

12 x

Track (except

Track (4"1

Grease

·Circulator -

(for

standard marked 6) ·

Grease

Circulator

(for

standard marked

Grease

Circulator -

(for

standard marked

Grease

Circulator -

(for

standard marked 26

Screw,

4 x

. Throat Plate

Throat Plate

Throat

Plate, Slit-ter

Plate, Neckwear,.-

Throat

Roller Plate

8-1/4" x 5-1/2"

Standard Screw,

Standard Screw

Lip

Pin

Lip

Screw

Roller Shaft

Roller Shell

Washer

Throat Plate

Screw,

RoUer

Shaft

Lip Screw

Plate

Throat

Lip

Spring.

Roller

Plate

Trunnion

Trunnion Washer

T

~nnion

nnio.n

T

Trunnion Washer 1¥9·.002"

Trunnion Washer

·

Gear

with

(for

with

Gear

(for standard marked 59)

Gear

with

(for standard marked 248)

Gear

with Bearing -

{for standard marked 86

Pinion

all

other

#6

(for

~tandard

61

#9

(for

standard marked 59)

#248

(for

standard marked

#5

(for

standard marked

3/1GBind.

& 87

332,

334

- 4'.'

332, 334 -

332,

334-'

3/4

Oval

Hd.

x

3/8

Set

59

(SY."I

(511."1

86

(6"1

87

{7")

5/8

And.

4"1 _ ·

.m5

-

ml

#248

#5

3/16'Fiat

with

only

Lip

Washer

Washer l¥5·.002"

Washer NS-.005"

Bearing-

standard marked

Bearing - =9

Bearing·-

for

59, 86, 37

for

4"

Lip

Rear

with

with

Lock

Hd:

~7

& Rollers -

(20.9

Hollers,

Rollers,

66·.005"

#9·.005"

H6·.002"

..S

=248

pinions

marked

Hd.

86 & 87

31

Hd.

591

2481

.

or

871

: B271

·em

x 13.9 em)

Sack B279

Front

R4

or

61

=5

or

871

KEY

NO.

8240

8241

8242

8243

B244'

8245

8246'

6247

6248

8249

B250,

8251

B252

6253

8254

8255

B256

6257

8:258

6259

8260

8261

8262

8270

8272

8273

B274

8275

B276

B277

8278

8280

8281

B282

8283

8284

B285

6286

8287

8288

PART

NO.

320J

320A

320C

321J

321A

321C

321CW

347J

347A

347C

30303

30307

30310

30311

30322

30324

30325

30326

322J:

322A

322C

326J

326A

326C

·

349A

329A

3298

- 329C

3290

3295.

329LC.

329LS

329LW

329L328Z

331S

329LW

328J

328Z

328F

328

'.

330

330N

328E

8225

B1.8S

337C

340T

340S

427

329LW

438W

313S

339T

437

340

431A

329LW

340

'433B

.

802S

340

329LW

431B

430A

327K

390A

3908

390C

3900

390S

22028

DESCRIPTION

Gear Bearing (200K.) -

Gear Bearing

Gear Bearing (104) -

Bearing Lock - #6

·Bearing Lock Bearing Lock -

Washer, Bear!ng

Thread

Thread

Thread

KnifeKnifeKnifeKnifeKnife,

Knife,

Knife,

Knife,

· Gear

Gear

Gear

Knife

Knife Lock - 59

Knife

Gear

Knife

Knife

Knife

Knife

Screw, Guard Carrier·

Spring Cup

Spring

Washer

Guard Carrier

Screw, 6 x 7/16

Screw,

Washer

Coil Spring

-

S_crew,

Grinder Frame

Grinder Frame-with Stones

·Stones

Stones Only, Pair

Check Spring

Screw, 6 x 1/4 Bind. Hd.

Screw, 6 x

XY

ROLLER

XY

Roller Plate

9-3/4".x6-3/4"

Standard Screw, Rear

Standard Screw

Screw, 10 x 7/16

Washer

Washer

Screw,

XY

Roller Shafts

Front & BacK.

Roller Shell

Screw

Shaft

Washer

Screw

XV

Lip

Screw,

Screw

Washer

Shaft

XY

Roller Plate

PARTS NOT

Adjustable Knife Key

Backguard - 54

Backguard - 59

Backguard - 86 •

Backguard - 87

Backguard Screw

Tube

(103)-

*l

or

"1'5

Lock-

Seal

- :.6

Seal

-~ or

Seal

- ,.5

(for

4"

(for

5-1/4"

(for

6"

Cforim

7"

High

Speed

High

High

High

ScrewScrewScrew-

Lock'Lock

Cap-

GuardGuardGuard Guard--

8 x 3/8 Rnd. Hd.

6 x 7/16 F'il. Hd.

with

Throat Plate

for

Lip, Long

Spring

6 x 3/16 Bind. Hd.

for

Up,

of

Grease

Steel-

Speed

Steel-

Speed

Steel -

Speed

Steel -

4"

·

59 -..

_.

86 &

87

4"

-:-

86 &

87

59

4"

5-1/4''

6''

7"-

Fil.

Only

Bushing, Pair

1/4

Flat. Hd.

PLATE

with

(24.7cmx17.1

Flat

'!Yith

Short

Lip

ILLUSTRATED

41<248

541

59)

86)

Hd.

Lip

Hd.

m1

..9 or ;r248

;;5

#248

#5

4"

5-'1/4"

6"

7"

& Rollers

Rollers,

em)

STANDARD

WITH

#15

GRINDER & ROllER

PLATE

.,.:-·

8316

STANDARD

MARKED

6302

8301

v

SIZE

HERE

IS

-

-~

8337

~

8336

8335

8370

8345

8338

8334

'

8333

8332

ALWAYS

GIVE

MACHINE

SERIAL

NUMBER

WHEH

ORDERING

10

PARTS.

ORDER

9390·

8391--®

8392~

BY

PART

. I

(!)...8384

$.....83s5

h386

67

I

~

NUMBER-

XY ROLLER

f=i

I

·~

8'!.93.

NOT

I

I

8394

KEY

PLATE

6397

6396

6395

.

NUMBER.

LIST

KEY

NO.

8336

8337

B338

8339

8340

8341

B342

8343.

8344.

8345

8346

8348

9349

8350

8351

8352

8354

8356

B356

B357

8358

83598360

8362

B364 802S

8365

8366

8367

8368

8369 329LC

8370 329S Screw,

8380

B38t

8382

8383

B384

8385

B386

8387 339T

8388

8389

839()B391 329LW

B392 340 Screw

B393

8394

8395

8396 329LW

8397

8398

KEY

NO.

8301

8302

.8303

8304

B305

.B306

B307 802S

B308

8309

8310

8311

8312

B313 348J

B314 388T

B315

B316

B317 340T

8318

B319

8320·

8321

8322

8323

8324

8325

8326

8327 337J Lip Spring

8328

8329

8330

8331

8332 320J

8333

8334 347J

8335

PART NO.

323PJ Pinion Pin - #6 Pinion

323PA

323J

323H

323M

323C

341C

3410

342

518W

510C . Screw, 10

5108

311G

311W Lock

311S Screw, 12 x

805P

421

348S Screw, 4 x

34BA

348M

348C

388H Standard

388W

3880 Standard

388E Standard

313K

313R

313H Throat Plate, Hospital 8361

313N .Throat

337

.340S Standard Screw

337P

340

339P

437

438W

313S Screw, Throat Plate

339M Roller Shaft

340

313L

337L Roller Plate

3918 Trunnion

391E

391G Trunnion

391H

3.91K

391M.

319J

319H

319M

319C

320A

320C

321J

321A

321C

321CW

347A

347C

30303

30307

30310

30311

30322

Pinion

Pinion PinionPinion

marked

·Pinion

86

Handle Assembly

Offset Handle Assembly

Screw, 8 x

Washer

Lock

Nut

Grease

Screw,

Washer

Roll

pin 8347

Cap

Screw

Grease

(for standard marked 6)

Grease

(for standard marked 59)

Grease

(for

Grease

(for

Sta$rd

Standard

Throat

Plate

Plate

Throat

Plate, Neckwear

Roller Plate

8-1/4" x S.1/2"

Standard Screw,

Lip

Pin

Lip

Screw

Roller Shaft

Roller Shell Only

Washer

Lip

Screw

Throat

Plate Lock

Trunnion

Ttunnion

Trunnion

Trunnion

Gear

with Bearing - #6

(for standard marked 6}

Gear

with Bearing - #9

(for standard marked 59)

Gear

V~~ith

(for standard marked

Gear

with Bearing -

stangard marked 86 or

(for

Gear

Bearing

Gear

Bearing

Gear

Bearing

Bearing

Lock - #6

Beari~g

Lock

Bearing

L.ock

Washer,

Seal

Thread

Thread

Seal

Thread

Seal

KnifeKnifeKnifeKnife

-7"

Knife, High

PARTS

DESCRIPTION

Pin-

all other pinions

#6

(for

standard marked 6)

#9

(for

.;..

- #5

or87)

Cup

6 x

Circulator - #6

Circulator - #9

Circulator-

standard marked 248)

Circulator - #5 8353 387

standard marked

for

for

for·#15

for

for

Washer

Washer

Washer

Washer

Washer

Washer

Bearing - #248

Bearing Lock - #5

4"

5-1/4"

6"

standard marked 59)

#248

(for

~48)

3/4

x

3/16

3/16

tor

with

with

with

Lip

standard·

(for

standard marked

Oval Hd.

3/8

Set

Bind. Hd.

5/8

And. Hd.

Flat Hd.

#248

#16

Grinder-6 (4")

#15

Grinder

Grinder-

#15

Grinder-

#1

6 Grinder

69, 86, 37

for

4",

87

Lip & Rollers-

(20.9cm x 13.9.cm.) B363

Rear

Rollers, Beck

Rollers,

#6-.005"

19-.005"

15-.002''

#5-.005"

19·.002''

#6-.002''

#5

{200Kl

- #6

(103)-

H041-

-

- lr3 or #248

- #5

Speed

..:..

#9 or #248

- #5

m;

!for

(for 59)

!for

(for

Steel-

#9

#5

541

86)

871

86

or

-·59

248 (5-1/4"1

86

..,.

87 (7"1

Front

2481

871

or #248

4"

87)

(6-1/4")

(6'1

4

PART

NO.

30324

30325

30326

322J

322A

322C

326J

326A

326C Knife Lock - 86

349A

383A

415N

381A

382

381T

381S

381

3855

384

.

380

380A

1341

423P Pin

386B

8400

386

335K

332

333

1341

386

385T

385S

838N

310F

310K

329LW

310H

3108

389

329A

3298

329C

3290

329LW

329LS Spring

337C

340T

3405

427

329LW

438N

313S

437 Roller Shell Only

340

431A

433B

ao2s

340

4318

430A

327K

390A

3908

390C

3900

390S

22028

Nut

Tail Bushing

Spring, Stone Shaft

Stone Shaft ·

#15

Screw,

#15 Grinder Frame only

· #15 Grinder Complete

#15 Grinder Complete

Retaining Ring

#15 Grinder

Retaining Ring

Coil Spring

#15

Link

Trigger

Trigger

Retaining

#16 Grinder Bracket

#15

Screw,

Nut

#15

Gooseneck

Washer

Screw, 8 x 5/16 Bind. Hd. ·

Screw,

Screw,.6

#15

Knife Guard Knife

Knife Guard

Knife Guard W!lsher

Spring

XV

XV

Standard

Standard Screw

Screw, 10 x 7/16 Flat Hd.

Washer

Washer

Screw, Throat Plate

XV

Screw

Shaft

Washer

XV

Screw, 6 x 3/16 Bind. Hd.

Screw

Washer

Shaft

XY Roller

PARTS NOT ILLUSTRATED

Adjustable Knife Key

Beckguard • 54

Backguard • 59

Backguard • 86

Backguard - 87

Backguard Screw

Tube

DESCRIPTION

Knife, High

Knife, High

Knife, High

Gear

Gear

Gear

Knife

Knife Lock - 59

Gear

AdJusting Bushing

#15

Frame, Bracket

Grinder Link

Speed

Steel -5-1/4"

Spited

Steel -

Speed

ScrewScrew - 59

Screw - 86 & 87

Lock-

Cap- 59

Grinder Stones only, pair

Grinder Stones

6 x 1/2 Fit.

Knuckle.

4"

4'!

Shaft

Steel -7"

&

87

·

with

Hd.

& Stones

Screw

Rin~

Grinder Bracket

6 x

1/2

Grinder Gooseneck

for 3 phase

(3

phase),

x 3/16 Bind.

Grinder Guard Carrier

Guard-

-

Cup

Guard Carrier

ROLLER PLATE

RoUer

Plate

9-3/4"

x 6-3/4" (24. 7

Screw,

Roller Shaft with Rollers,

&

for

Lip, Long

Lip Spring

for

Lip, Short

Plate

of

Grease

Back

Front

for

Fll.

Hd.

motor

8 x 1-3/8 Fil.. Hd.

H"d.

4"

5-1/4"

6"

7"

with

Lip &

Rear

Lip

6"

Bushings, pair

with

for

37

37

Rollers-

em

x 17.1

em)

(continued from

4-3.

To

Adjust Play

The gear

gether initially to obtain a close

the gear and pinion wear

(or

backlash} between the teeth on the gear and the pinion.

Provided the gear bearing

movement

gear and the

trunnion washers (8238). ·Remove the gear (see paragraph

3-6},

and take out the thinnest trunnion washer. These

trunnion washers

visable

order to check to

There must always

gear and pinion

moving the trunnion washer, it

gear and gear

4-4.

then the bearing

knife key. The bearing (B240) isremoved from

tapping it lightly from the opposite side

Care must

When the bearing

gear and

Into the gear

damage the balls

to

T.o

Replace the Gear Bearing

The gear must

lightly oil it. The new gear beating

page

3}

In

Gear

(B239)

of

knife) the backlash between the teeth on the

pinion

remove the thinnest trunnion washer first in

wilf

screw to check the backlash.

lock (B24l) should

be

taken not to injure the teeth

is

by

lightly tapping its outside rim so

of

the bearing. To make sure

and pinion (B202) are lapped

fit.

Over a period

so

that there

is

in

can be reduced by removing one

are

available in two thicknesses.

see

if

the backlash has been eliminated.

be

a slight amount

screech when run together. After

be

removed from the machine., and

removed, clean the inside seat

is

an increase in play

good condition

of

backlash

is

necessary

be

unscrewed with the

with a small mallet.

may

that

to

replace the

the

of

be pressed

of

(no

or

It

is

or

gear by

the gear.

of

as

not

the bear-

ing is seated firmly in the gear, place the old bearing on top

of

the new one and tap the outside rim

to

force the new one

bearing into position by replacing the gear bearing lock.

all

the way into the gear. Lock the

of

to-

time

4-5. To Replace Motor

side

two

Loading Spring

by

ad-

Switch Box (B42). Remove the

Lift

large screwdrivenlightly

the

ping upwards lightly. Tap bearing out from inside the hous-

re-

ing (through hole .in Stationary Switch B 18). Replace Top

Housing onto Field and tighten Motor Bolts. Then put in

new bearing

ping

prevent harming inner

three screws (8219). Pull Pinion (B202)

Unscrew Armature

Bolts {B31) and then Bottom Housing (B28). Remove

the

Bearing Lock

out. Clean the seat for bearing in Bottom Housing and

to

ly oil. Replace bearing

assemble motor. Tighten Armature Nut securely.·

a) Top Housing

Remove

(Bl4).

turning clockwise. Loosen the two screws

off

Top Housing

by

placing old bearing

it

into housing. Rotate old bearing wheh tapping to,

b)

Bottom Housing Ball Bearing

Remove

(827)

Bearing

BaU

Bearing

the two screws

Unscrew Armature Screw (B13A) •

(Bl6)

from Field (B2I) by inserting

in

to

or

outer race

motor

from standard by unscrewing the

Nut

(B30). Take

with

Knife ·Key, and tap old bearing

as

described in para. 4-Sa and

(815

or

(8

I

i),

Cap

four

Motor Bolts (831).

the ventilation slots and tap·

on

top

of

of

new bearing.

(B

15

orB

off

armature shaft.

out

the. four Motor

the old bearing

Bl 54)

(8

13), and

(843)

holding

it while tap-

154).

light-

re-

HUMBERS IN PARENTHESIS FOLLOWING

Maimin

tr

84

7. 709.2500 .

Technology

USA

800.243.4645

PART

Group,

NAMES ARE

rnc.

~·

84

7.

KEY

NUMBERS

70

N.KingStreet,EikGroveVillage,IL

709.2599

FROM

PARTS

PLATES-

_Q www.maimin.com · sales@maimin.com

HOT PART NUMBERS

60007

USA,

59supp1e59supple

H.

Maimin

Co.,

Inc.

P.O. Box 549, Rte.341

Kent,

CT

06757

USA

SUPPLEMENT PARTS

MODEL 59, SINGLE PHASE ROUND KNIFE

ONLY

Key No.

Bl3

Bl4

Bl6

FOR

R59-33,

SERIAL NUMBERS BEGINNING

OR

Part Number

446Q

15195

365K

365L

SHEET

R59-43 AND ENDING

HOLE PLUG %"

WAVE

STARTING

GASKET-

FOR

WITH

Description

MAIMIN

MACIDNE

WITH

12532

WASHER

OR

SWITCH

STARTING

2/04/00

1

of

Page

1

R59-13, R59-23,

IDGHER

SWITCH

Bl56

Bl57

B202

B302

15286B

15286B

323HA

323HS

323HA

323HS

302P

857N

Always give SERIAL NUMBER when ordering parts.

R59 SINGLE

(DESIGNATE

R59 SINGLE

(DESIGNATE VOLTAGE)

PINION

PINION SPACER

PINION

PINION

PARTS

NOT

ILLUSTRATED

TOP HANDLE

KEPNUT (TOP HANDLE) 2

8-32

Order

by PART NUMBER not Key Number.

PHASE

VOLT

PHASE

#9

(FOR

#9

(FOR

SPACER

AGE)

59)

59)

MOTOR

MOTOR

ASSEMBLY

ASSEMBLY

59supple59supple

H.

Maimin

P.O.

Kent,

Cd.;

'

Box 549

CT.

06757

'.

Inc.

U.S.A.

Key No.

Bl2

B23

B43

BlSO

Bl73

B209

B210

B228

B259

B283

B320

B324

B393

SUPPLEMENT

Part

802S

331S

310B

802S

310B

336S

464S

436S

23007

330L

330M

433A

436S

23007

441S

433A

PARTS

No.

PARTS

LIST

FOR

ALL

NOT

ILLUSTRATED

ROUND

KNIFE

Description

Screw,

Screw,

Screw,

Screw,

Screw,

Linkage

Soft

Lip

6 X

8-32 X 3/8

8-32 X 1;

6 X

8-32 X 1;

Screw

Grip

Screw

Handle

Washer

Stone

Stone

Assembly,

with

Spring -Lip

Lip

Screw

Washer

Screw,

6-32 X 5/16

Spring -Lip

MACHINES

3/16

Pan

Fillister

3/16

Pan

Fillister

Assembly

Pair

Bushing,

Head

Round Head

Head

Head

Head

Pair

Fillister

Head

Always

464E

464NB

give

Order

machine

by

PART

Handle

Handle

SERIAL

NUMBER

NUMBER -not

Stud,

Nut,

when

3/8-24

3/8-24

order~ng

Key Number.

X

1~

Hex X

parts.

Soc.

3/4

Set

Lg.

Screw

5/16/95

~ent,

CT.

-~

,06757

~-

Parts

List

Supplement

for

Round

with

11,

SERIAL

21,

Example:

Key

No.

Bl3

Bl4

Bl6

Part

446Q:

15195

15292

No.

15293

365K

365L

Bl7

B20

497P

15301

15305

15302

-~

B21

15289

15309

15290

15303

15306

15307

B31

.15295

Knife Machines

NUMBERS

31,

41

in

second group

RXX-11-XXXXX

Description

Hole

Wave

Top

Plug

Washer

Housing

Cover Starting

Gasket ~ Starting

· .support Washer

R248

Armature

R37

Armature

RS4

Armature

R59

Atma.ture

R87

Armature

Shell & Field

Shell & Field

R3 7 Shell & Field

R37

Shell & Field

Bolt

8-32 X 4

containing

3/4"

Starting

Switch

Assembly

Assembly

5/8

Switch

Switch

120V

.•

220V.

Ass~fnb.ly

Assembly

Lg.

Round

120V.

220V.

Hd.

3/23/93

·H. Maimin Co., Inc.

P.O.

Box 549, Route 341

Kent, CT 06757 USA

Tel: 860-92746001800-2434645

Fax: 860-9274703

Key

Number

813

814

816

820

821

831

8202

8302

SUPPLEMENT

PARTS

MODEL

ONLY

12,

FOR

22,

SERIAL NUMBERS CONTAINING

32,

42,

82

Example:

Part

Number

4460

15195

15292

15293

365K

365L

15361

15290

15303 Shell

15295

323HA

323HS

323HA

323HS

Description

Hole Plug 3/4"

Wave Washer

Top Housing

Cover - Starting Switch

Starting Switch

Gasket R59 Armature

Shell

Bolt 8-32 X 4-5/8 Lg. Round Hd.

Pinion

Pinion Spacer

Pinion

Pinion Spacer

SHEET

FOR

MAIMIN

59

IN

THE

SECOND

GROUP

R59-XX-12345

Starting Switch

& Field Assembly 120V ·

& Field Assembly

#9

(For 59)

#9

(For 59)

220V

NOT

PARTS

302P

857N

Top Handle

8-32 Kepnut (Top Handle) 2

ILLUSTRATED

g\apps\works\SPR59-01.WPS

on

7/23/97

MAIM

IN®

MODEL

37

(see

&

Parts

List

STANDARD & ROLLER

Malmln

Catalog

Round

for

Knife

motor

Instructions

and

grinder

Al35

PLATE

parts)

Alii

All2

KEY

NO.

PART

NO.

A101

A102

A103

A104

A105

A106 337C

A107

A108 340S

A10Ba

A109

A110

A111 339T

A112

A113

A113a 4318

A114 329LW

A115

A116

A117

A118

A119

A120

3410

342

618W

610C

610B

311G

356A

388R

340T

427

329LW

313S

438W

340

431A

340

4338

B02S

430A

313K

391G

DESCRIPTION

Offset Handle Assembly

Screw, B x

Lock Washer

Screw, 10 x

Nut A124

Grease Cup

Standard for Gliding

Standard

XY

Standard Screw, Rear A129

Standard

Screw, 10

Washer

Screw,

Washer

XY

Screw

Shaft

Shaft

Washer

Screw

XY

Screw,

XY

Throat

Trunnion Washer

3/4

3/8

for

#16

Roller Plate with

lip

and Rollers A128

Screw

x

7/16

Throat

Plate

Roller Shafts with Rollers -

Front

and Back

for

Lip, Long

for

L.ip,

Short

L.ip

Spring

6 x

3/16

Roller Plate Lip

Plate for 37

All3o

Oval

Hd.

Set

Grinder-

Grinder -

Flat Hd. A131

Bind. Hd.

#5

37

37

KEY

NO.

A121

A122

A123

A126

A126

A127

A130

A132

A133

A134

A135

A136

A137

For maintenance and repair instructions see Maimin

Round Knife Instructions

To remove

(Al28):

Take

out

(Al34); then the two screws

(Al32).

Unscrew Gear Screw

left-hand thread). Lift

Gear Screw (A 131) counter-clockwise

thread). Remove Bevel-spur

PART

NO.

364

320C

321C

321CW

30311

30326

326C

322C

391A

360

320J

321J

351

362

348S

353

3168

3238

323PA

PARTS

300NA

300SA Armature Screw - 37

390F Backguard - 37

"",.,,....,....,.,

DESCRIPTION

Spur

Gear with Bearing

Gear Bearing ( 1

Bearing Lock

Washer, Bearing Lock

-7"

Knife

Knife, High Speed Steel •

Knife Lock

Screw (Left Hand Thread)

Gear

Trunnion Washer

Bevel

-Spur

Gear with Bearing

Gear Bearing

Bearing Lock

Gear

Cover

Screw,

Crescent

Screw,

P.lnion

Pinion Pin

NOT

Armature

ru.1 ~ ..

(200K)

Screw (Right Hand Thread)

Plate

4 x

3/16

Plate

4 x

1/4

(#8l

ILLUSTRATED

Nut-

P"l..-

&.lll!lft~n

Spur Gear

the two screws

out

04)

7"

#6

Flat Hd.

Rnd. Hd.

37

.._,_,..

& Parts List Catalog.

(Al21)

and Bevel-Spur Gear

(Al35)

and Crescent Plate

(Al33)

(Al26)

and Cover Plate

clockwise

(it

Spur Gear (Al21). Unscrew

(it

has right-hand

Gear (A 128).

lii"""V

...

uu.•n~n

has

H.

Maimin

P.O.

Box

Kent, CT 06757 USA

Tel: 860-927-4600/800-243-4645

Fax:

Co.,

Inc.

549,

Rout~

860-927-4703

341

SUPPLEMENT.

ONLY

13, 23, 33, 43, 83

Key. ·Part

Number Number

813

814

816

446Q

15195

365J

365L

821 153088

15076

15084A

8202 323CA

323CS

8302 323CA

323CS

FOR

SERIAL

Example:

PARTS

SHEET

FOR

MAIMIN

·MODEL87

NUMBERS

IN

THE

SECOND

CONTAINING

GROUP

R87-XX-12345

Description

Hole Plug 3/4"

Wave Washer

Starting

Gasket - Starting Switch

Motor assembly 120v/220v

Capacitor 270mFD

Capacitor Cover

Pinion #5 (For 87)

. Pinion Spacer

Pinion

Pinion Spacer

#5 (For 87)

.

Switch

PARTS

302P

857N

NOT

ILLUSTRATED

Top Handle

8-32 Kepnut (Top Handle) 2

g\apps\works\SPRB?-02

on

05/25/99

MAIMIN°

(see

.,

Malmln

Round

Knife

SLITTER

STANDARD

Instructions & Parts

List

Catalog

for

all

other

parts)

KEY

NO.

A270

A271

A272

A273

A274

A275

A276

A277

A278

A279

A280

-~

A281

A2S2

A283

A284

A285

PART

395H

395HX

395A

395AX

395C

395CX

395E

395EX

836N

421

427

395P

396H

396A

396C

396E

3408

427

3135

438W

329LW

3370

313T

427

392H

392A

392C

392E

436T

397

NO.

DESCRIPTION

Slitter

StandardSlitter Standard with

Slitter Standard

Slitter

S~andard

Slitter Standard Slitter Standard with

Slitter Standard - 87 (Give Sei'ial No.)

Slitter Standard with

Nut with Lock Washer

Cap Screw ·

Screw,

Support

Support for Slitter Standard - 59

Support for Slitter Standard - 86

Support for Slitter Standard Standard Screw

Screw,

Screw for

Washer for Throat

Washer

Rollerplate with Rollers for Slitter

Slitter Throat Plate

Screw,

Backguard,

Backguard,

Backguard, Slitter - 86

Backguard, Slitter - 87

Screw, 6 x 3/16 Flat Hd.

10 x 7/t6

Pin

-Support

for Slitter Standard - 54

10

x 7/16 Flat Hd.

Throat

(See

XY Roller

for component parts)

10

x 7/16 Flat Hd.

Slitter Slitter-

54 (Give Serial No.I ·

Support -54

-59

(Give Serial No.)

with

Support

86

(Give Serial No.)

Support -86

Support

Flat Hd.

to

Standard

Plate

Plate

Plate-

54

59

Filler Plate

Plate

-

59

- 87

87

3-

For

maintenance and repair instructions see Maim

Round Knife Instructions & Parts List Catalog.

.

---.

·····-

....

r.

.,,.,..

III:V

UIIUP.FR.

Loading...

Loading...