Maidaid Halcyon Barista Compact Installation And User Manual

Barista Compact

Espresso coffee machine

Installation and user manual

Maidaid Barista Compact Installation and user manual V1.0

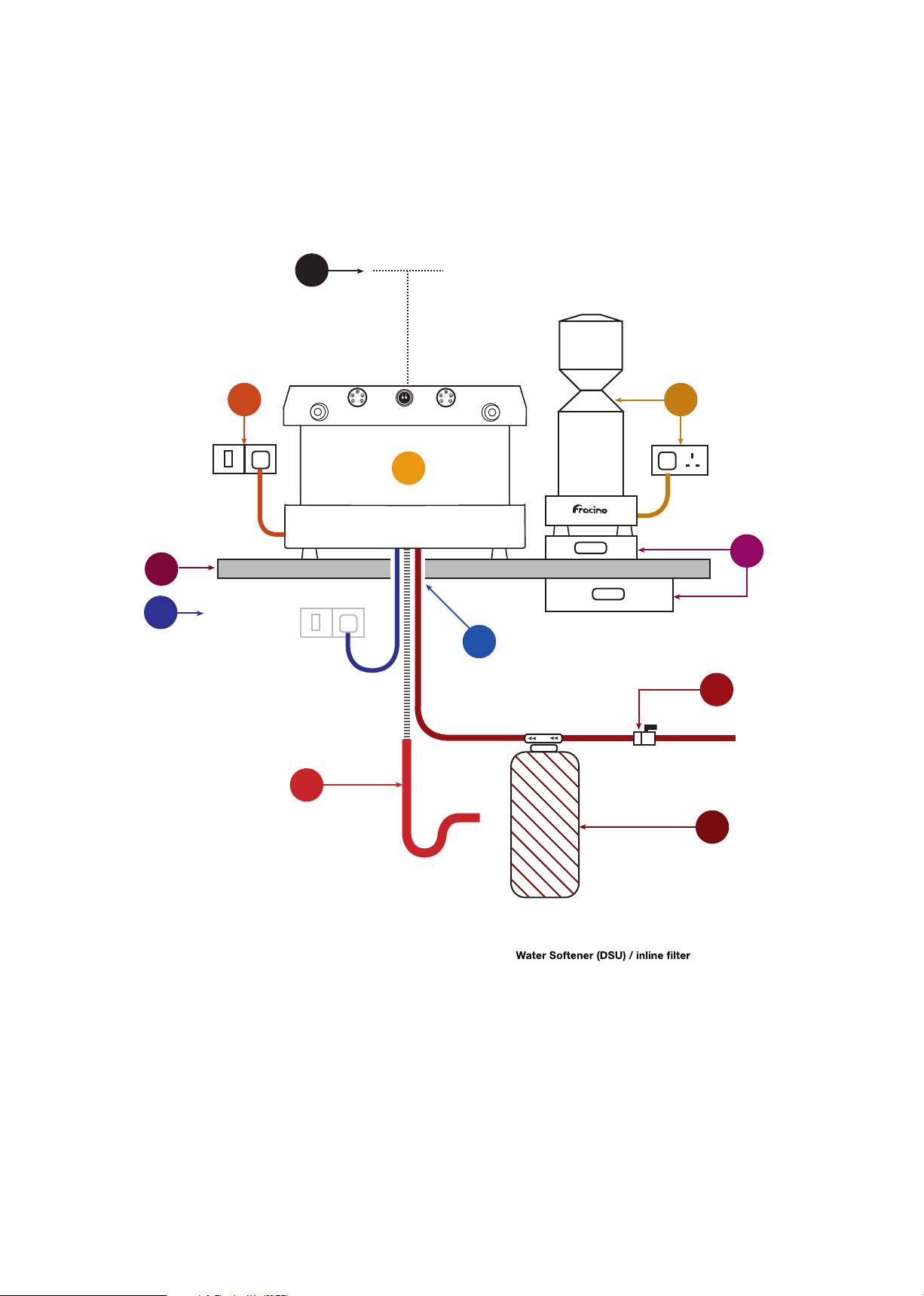

Installation

Overview

7

10

Power

(2nd Position

Switch or plug)

11

300mm

1

23

PowerPower

8

9

5

4

Coee Machine.

1

Grinder – 13 amp socket required.

2

Power connection for coee machine

(must be within 1 metre). Switch or plug.

3

1.5” (Minimum Diameter) Stand pipe for

waste as for washing machine.

4

¾'' B.S.P Washing machine type valve

5

for mains cold water with isolator handle.

Waste

6

if required.

Counter.

7

Under counter or under grinder

8

Knock-out drawer.

Hole in counter: 2'' Diameter.

9

Alternative position for power supply

(must be within 1 metre). Switch or plug.

10

Please ensure a gap of 300mm is maintained

above the top tray of the machine to allow for

11

cup storage and service access.

Cold

Water

(15mm)

6

Preparing for

Installation

1

A

Services and

equipment required for

Warning: Installation of this appliance must only be carried out by trained persons

available. All services must be in place prior to installation. ALL CALLS TO UNPREPARED

SITES MAYBE FULLY CHARGEABLE.

Mains water:

15mm mains cold water supply with ¾'' BSP standard washing machine stop cock.

Note: Min inlet water pressure is : 100kPa (1 Bar)

Max inlet water pressure is : 600kPa (6 Bar)

and set between the above parameters, normally 300kPa (3 Bar).

Mains waste:

Water and waste connections to be directly beneath the location of the machine

installation

Power supply: As below

Note: Socket to be located on the same side of the coee machine that the grinder will

stand. (Recommended right hand side - see installation overview).

Grinders - All models 13amp

Coee Machines - Standard Power Ratings

Group kw amp

2 Group 2.85kw 13amp single phase

Note:

Note: The appliance must be installed in a location where the ambient temperature is

always between 5°C and 30°C.

Warning: The power supply and method of connection must comply with any national rules

or regulations which may be present in the country in which the appliance is installed. It is

connection BEFORE the appliance is installed.

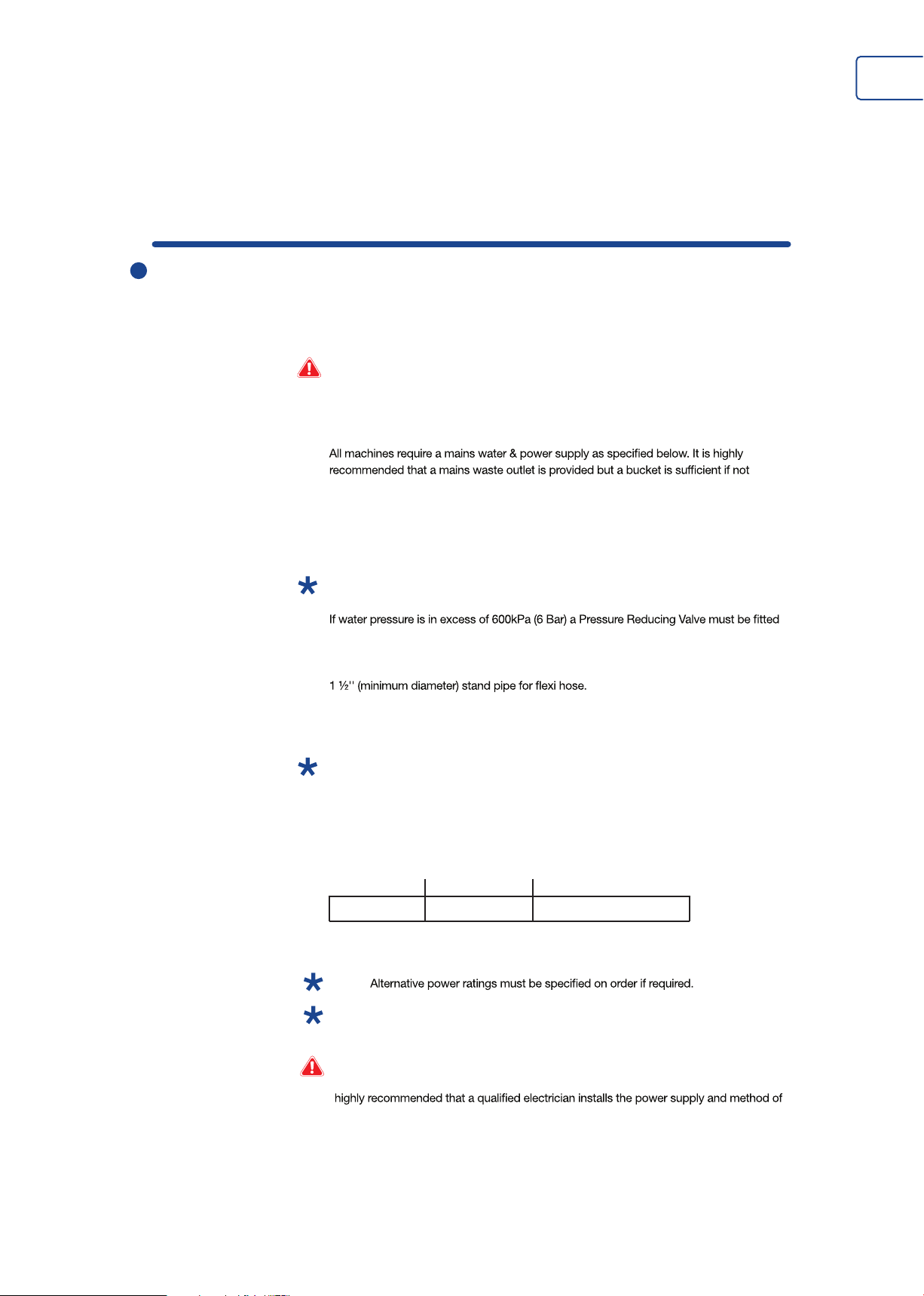

B

Preparing the areafor installation

Note: The appliance must be installed in a location where it can be over seen by trained

personnel and its use and maintenance is restricted to trained personnel.

Plan view for drilling counter for Coee Machine Area for Grinder

(1)

110mm

(2)

300mm

(3)

240mm

Work out the location of the coee machine on the bar or counter and nd the position.

Drill a 2’’ hole using the measurements below as a guide. All the coee machines power

and waste connections feed from the bottom at the centre of the coee machine. These

connections then feed down through the 2’’ hole in the bar or counter.

450mm

2

(1) Depth from the back of the machine to the hole.

(2) Length from the side of the machine to the hole.

(3) Hole in counter: 2'' Diameter

Note: The power connections for the coee machine and grinder must be within 1 metre

behind or beneath the machine. The power point and method of isolation must be easily

accessible at all times.

The water and waste connections for the coee machine must be directly beneath it.

All services, including hole in bar counter, must be in place prior to engineer arriving to install

the coee machine.

Ensure that the surface the coee machine is to be placed on is suciently strong and stable

enough to carry the weight of the coee machine.

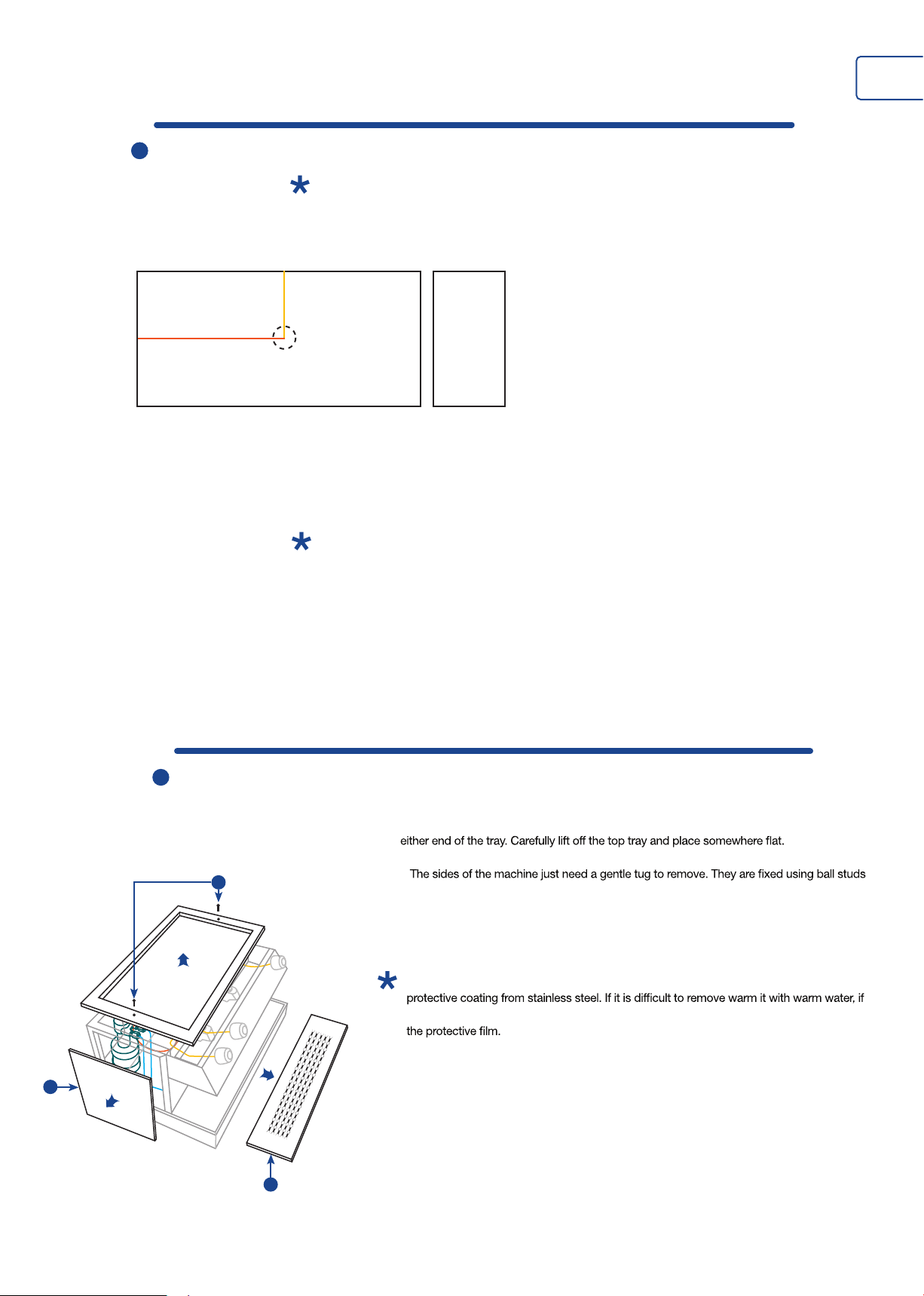

E

Preparing the machine for installation

1

1) Remove the top tray of the machine by locating and unscrewing the two M4 screws at

2)

for quick and easy access.

3) Remove the drip tray to reveal the waste funnel. This is done by lifting it upwards at the

front as it simply rests in place again for easy access and cleaning.

Note: Remove all packaging before working on / installing the machine and remove plastic

any glue is left on use a solvent like WD40 to remove it – DO NOT use abrasives to remove

2

3

Installing the

coffee machine

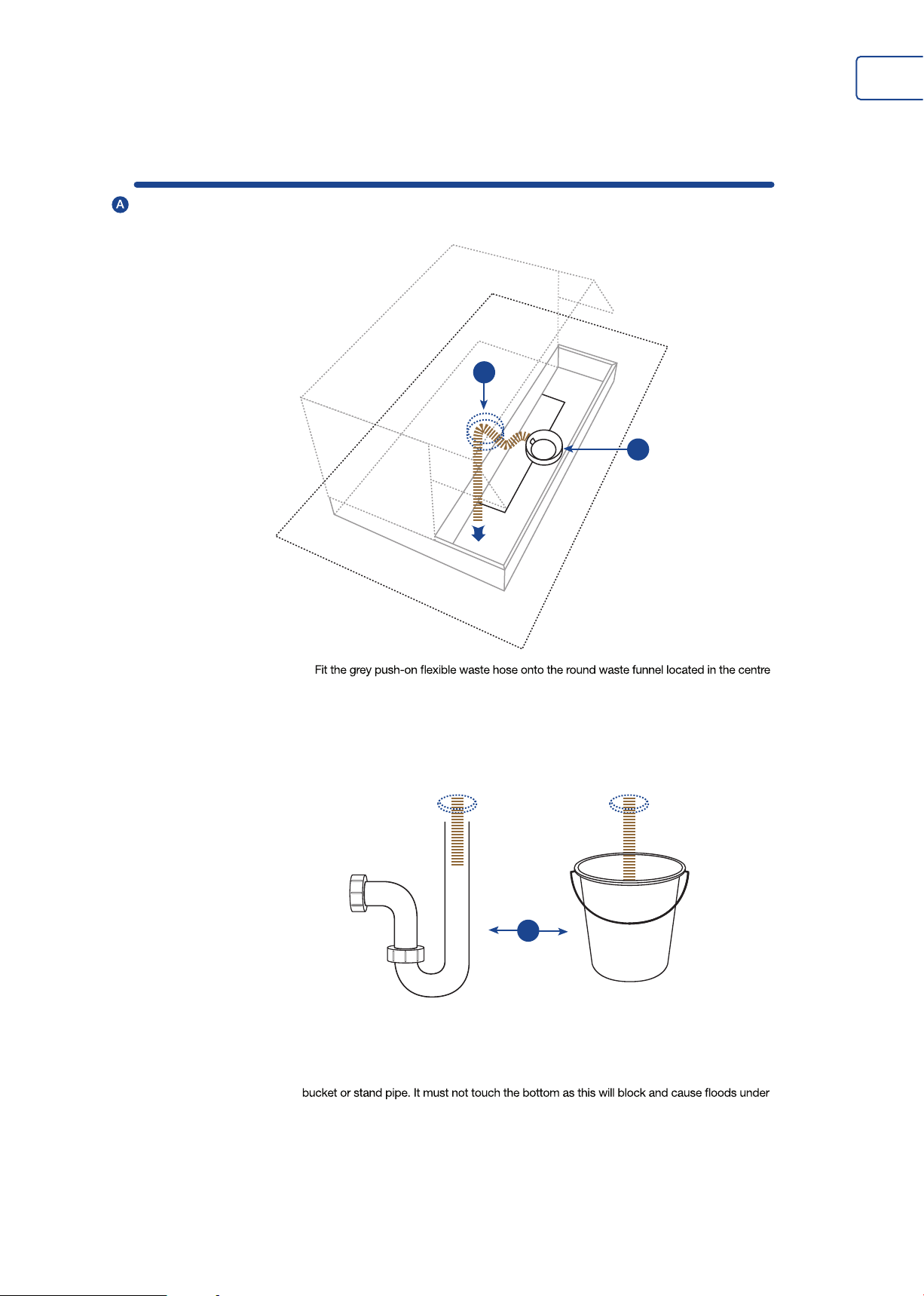

Connecting the waste pipe

3

2

1

1)

of the machine and tighten with the wormdrive clip provided. 2) Then feed the waste hose

under the machine and down through the 2” hole already cut out. Pull taught and ensure no

kinks are present in pipe.

75mm

3

3) Place the waste pipe into a bucket below the machine or into the stand pipe with a ‘P’ or

‘S’ trap to prevent smell. Ensure waste pipe is cut to length and is only 75mm into the

the machine. Clip or cable tie the pipe into position to prevent it from moving.

B

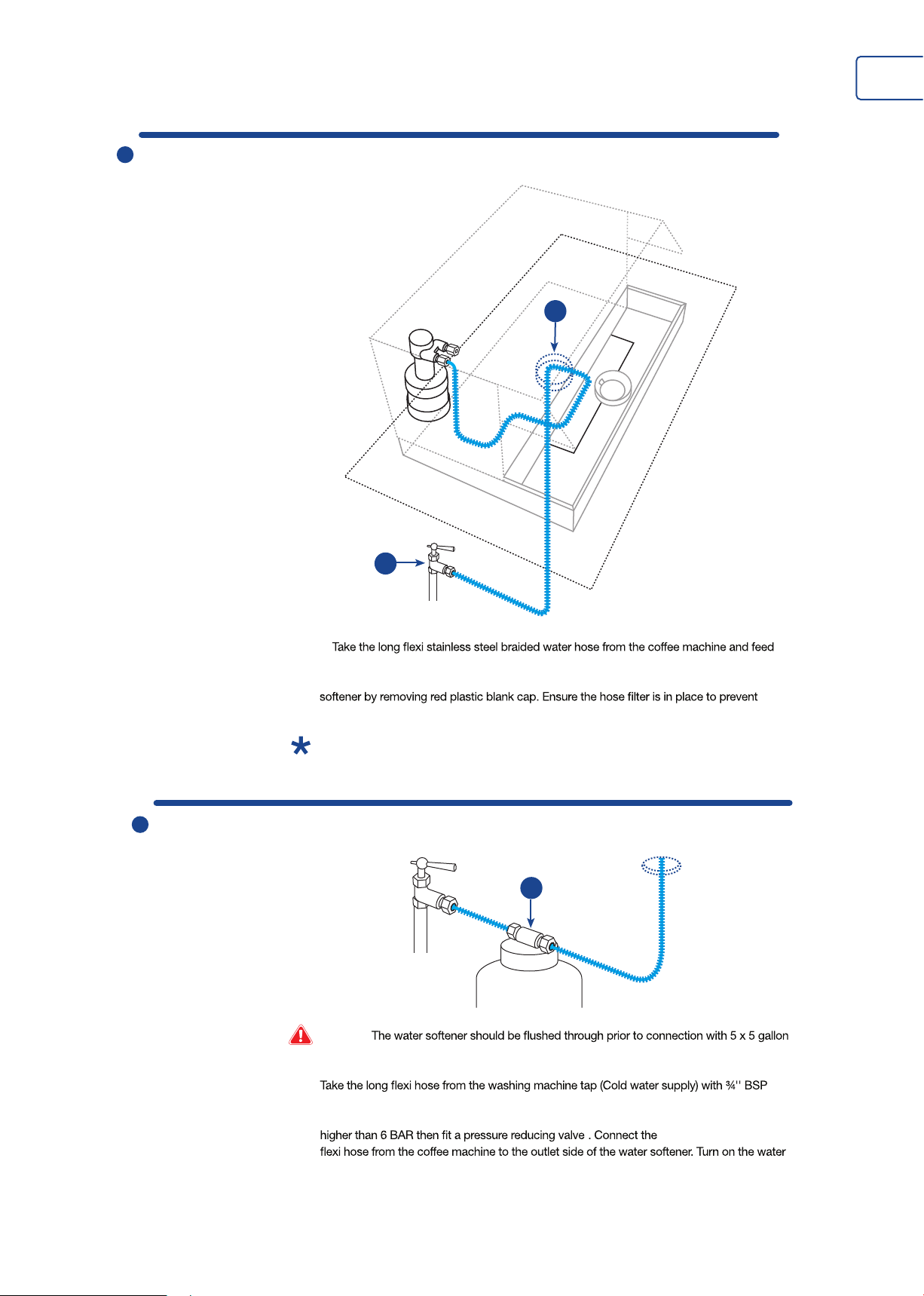

Connecting the water supply

4

1

2

1)

the water hose under the machine and down through the 2” hole already cut out. 2) Connect

this to a washing machine tap (Cold water supply) with ¾'' BSP male thread or to the water

debris entering the machine.

Note: It is highly recommended that the new hose sets supplied with the coee machine are

used. Old hose sets should not be re-used.

C

Connecting the water Softener (if required)

1

Warning:

(Approx. 25L) buckets or until the water runs clear.

male thread and connect to the inlet side of the water softener. 1) This is indicated on the

top label of the water softener. Ensure the water pressure does not exceed 6 BAR. If it is

supply and check for leaks.

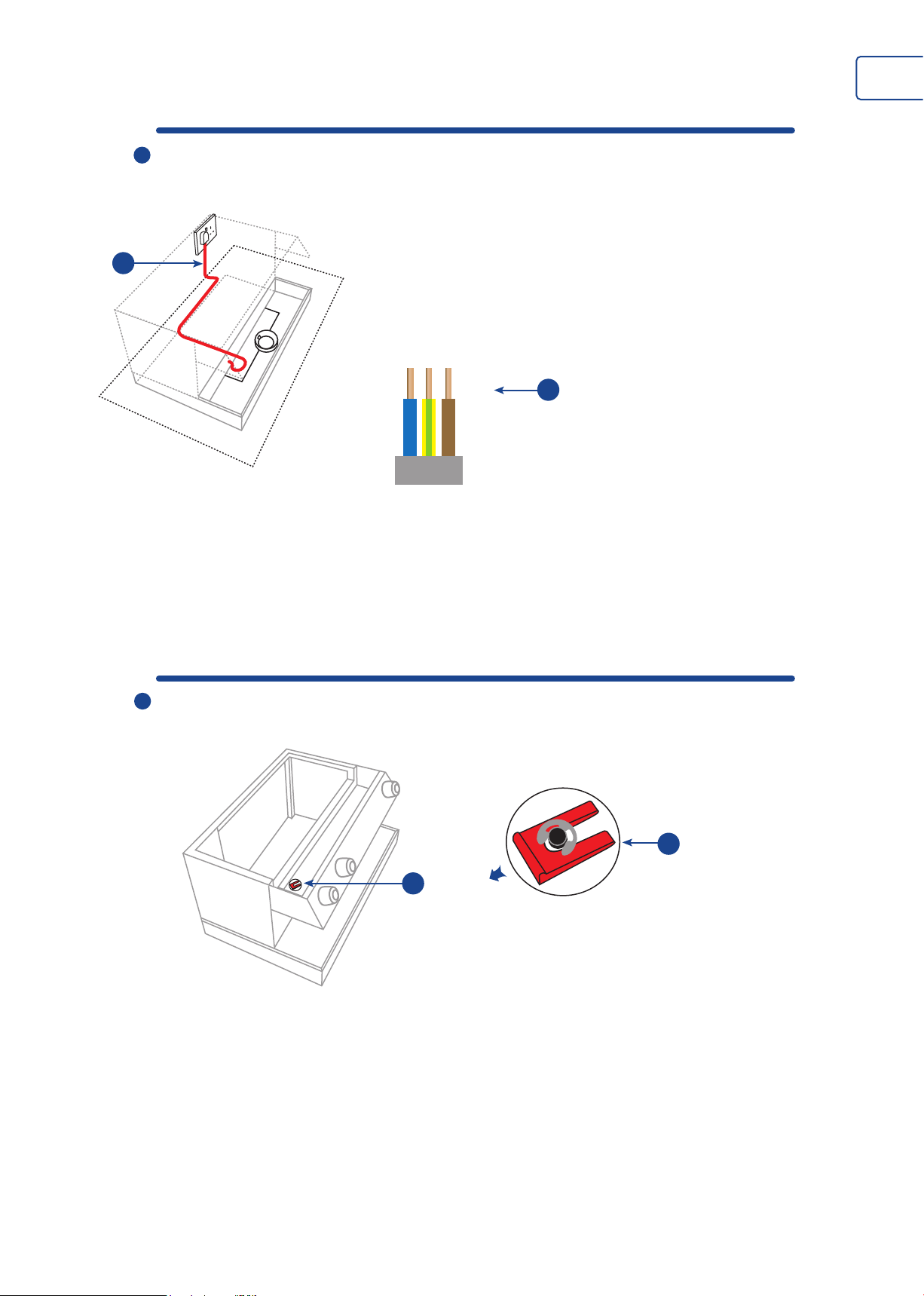

D

Connecting the power supply

5

1

Before turning

the machine on

1) Run the mains cable through the hole in the bottom of the machine or underneath to the

nearest power supply. Make sure your mains supply is within 1 metre of the machine and

has easy access for power isolation.

Single phase 13amp

2

Brown = live

Blue = neutral

Green -Yellow = earth

2) Connect the machine cable to a double pole isolator mains supply or 13 amp plug. The

power supply will depend on the size of the machine and the rating plate. The use of

commando plugs is good for ease of total isolation.

A

Remove the red air release valve clip.

1) Remove the RED plastic clip from the air release valve on top of the sight glass. Failure to

do so will cause air locks and milk to be sucked back into the boiler.

2) Slide the red clip out from under the E-clip. Do not remove the E-clip as this is needed

for the machine to function correctly and will cause the air release valve to come apart

if removed.

2

1

Loading...

Loading...