Mahr Digimar 817 CLM Operating Instructions Manual

Digimar 817 CLM Quick Height

Height Measuring Instrument

Operating instructions

3759019

Version 1.02-30 en

Mahr GmbH Esslingen

D-73702 Esslingen • Postfach 10 02 54

Telefon (07 11) 9 31 26 00 • Fax (07 11) 9 31 27 25

e-mail: mahr.es@mahr.de

http: //www.mahr.de

2

Mahr GmbH • Digimar 817 CLM

Safety Instructions

This height measuring instrument employs the state-of-the-art technology and complies with recognized safety

regulations.

Nevertheless, the operator or third parties can risk life or limb if the following safety instructions are not strictly

observed!

1. All operators must read the safety instructions and the enclosed operating instructions thoroughly before

putting the height measuring instrument into operation.

2. This height measuring instrument must only be used if it is in perfect technical condition. Any malfunctions,

particularly those impairing safety, must be eliminated immediately.

3. This height measuring instrument must only be used for the intended purposes and in accordance with the

operating instructions provided. The operating instructions must be stored in the immediate proximity of the site

where the height measuring instrument is being used.

4. Before connecting the height measuring instrument to the mains, make sure that the voltage specified on the

rating plate agrees with the local mains voltage. If the two voltages do not agree, do not connect the height

measuring instrument under any circumstances!

5. The height measuring instrument may only be connected to socket outlets with properly grounded contacts.

Extension cables must meet the stipulations of the local electrical standards or similar.

6. Any modification or manipulation of the height measuring instrument requires the express written approval of

Mahr GmbH and must be carried out by qualified personnel. Unauthorized opening of the height measuring

instrument and unauthorized intervention invalidates the warranty and frees Mahr GmbH from any liability.

Before opening the height measuring instrument, switch off the unit and pull the mains plug from the mains

socket outlet.

7. Before cleaning the height measuring instrument, pull the mains plug from the mains socket outlet. Never let

any liquids penetrate the height measuring instrument! Do not use cleaning agents that are harmful to plastics.

8. If a fuse needs replacing, only a fuse of the same type - in terms of Amperage and blow characteristics - may

be used. When exchanging fuses, follow the procedure outlined in the operating instructions.

9. All relevant safety and accident prevention regulations must be complied with. Your safety expert will provide

further instructions based on local circumstances and in-house guidelines.

10. Do not operate the height measuring instrument in rooms filled with explosive gases. An electrical spark could

trigger an explosion.

11. Never move the height measuring instrument to the edge of the base plate at speed. The air cushion carrying

the column will be unable to dissipate quickly enough to decelerate the height measuring instrument before it

reaches the edge. This could cause the height measuring instrument to fall off the base plate and harm the

operator.

When returning the height measuring instrument, please ONLY ship the height measuring

instrument in its original carrying case and on an appropriate pallet!

Failure to do this will invalidate the warranty!

3

Mahr GmbH • Digimar 817 CLM

Table of contents

1. Delivery and setting up

1.1 Scope of supply ......................................................................................................... 7

1.2 Unpacking................................................................................................................... 8

1.3 Description and explanation of the Height measuring instrument ..................... 15

1.3.1 Height measuring instrument ..................................................................................... 15

1.3.2 Keypad .................................................................................................................. 16

1.3.3 Display .................................................................................................................. 19

1.3.4 Interface connection................................................................................................... 20

1.3.5 Description of the symbols ......................................................................................... 21

2. Commissioning / First steps

2.1 Switching ON............................................................................................................ 25

2.2 Basic settings........................................................................................................... 25

2.3 Setting the reference point ..................................................................................... 26

2.4 Calibrating a probe .................................................................................................. 26

2.5 Auto-Off function ..................................................................................................... 27

2.6 First measurement ................................................................................................... 27

3. Brief guide to measurement methods

3.1 Start a measurement procedure with the function keys ...................................... 28

3.2 Start a measurement procedure in Quick Mode ................................................... 31

3.3 Start a measurement procedure with the speed keys .......................................... 34

3.4 Abort a measurement .............................................................................................. 35

4. Operation and measuring in detail

4.1 Standard calibration / calibrate a probe................................................................. 36

4.1.1 Calibrating a probe using a setting standard .............................................................. 36

4.1.2 Calibrating a twin probe ............................................................................................. 37

4.1.3 Calibrating a probe using a ledge .............................................................................. 38

4.1.4 Deviations .................................................................................................................. 39

4.2 Zero points ............................................................................................................... 40

4.2.1 Set the zero point on the base plate .......................................................................... 40

4.2.2 Workpiece zero point 01 ............................................................................................ 41

4.2.3 Workpiece zero point 02 ............................................................................................ 42

4.2.4 Workpiece zero point 03 ............................................................................................ 43

4.2.5 Switching between the zero points ............................................................................. 43

4.2.6 Entering a PRESET value .......................................................................................... 44

4.2.7 Expanding the measuring range ................................................................................ 46

4.2.8 Zero point errors ........................................................................................................ 48

4.2.9 Further zero point functions ....................................................................................... 48

4

Mahr GmbH • Digimar 817 CLM

4.3 Basic measuring functions ..................................................................................... 49

4.3.1 Contacting from above (plane) ................................................................................... 49

4.3.2 Contacting from below (plane) ................................................................................... 49

4.3.3 Determine the center and the width of the ledge ....................................................... 49

4.3.4 Determine the center and the width of the groove ..................................................... 49

4.3.5 Determine the center and the diameter of the bore ................................................... 50

4.3.6 Determine the center and the diameter of the shaft ................................................... 50

4.3.7 Reversal point of a bore from above / below ......................................................... 50/51

4.3.8 Reversal point of a shaft from above / below ............................................................. 51

4.4 Dynamic measuring functions ................................................................................ 52

4.4.1 MIN/MAX-Function ..................................................................................................... 52

4.4.2 Measuring the perpendicularity error ......................................................................... 53

4.5 Measuring in 2D mode ............................................................................................. 56

4.5.1 Manually enter a tilting angle ..................................................................................... 58

4.5.2 Entering a tilting angle (arithmetic workpiece alignment) ........................................... 59

4.5.3 Determine the distance and angle between 2 elements ............................................ 60

4.5.4 Determine the distance and angle between 3 elements ............................................ 61

4.5.5 Index circle / best fit circle .......................................................................................... 64

4.5.6 Coordinate transformation – aligning the workpiece arithmetically ............................. 66

4.6 Measuring a taper / calculating an angle ............................................................... 70

4.7 Measuring with a taper probe ................................................................................. 71

4.8 Variable function keys ............................................................................................. 73

4.8.1 Measuring a distance ................................................................................................. 73

4.8.2 Calculating the height of a symmetry line ................................................................... 74

4.8.3 AUTO .................................................................................................................. 75

4.8.4 Automatically setting the zero point ........................................................................... 75

4.8.5 Automatically setting the distance .............................................................................. 76

4.8.6 Relative zero point ..................................................................................................... 77

4.8.7 Absolute zero point .................................................................................................... 78

4.8.8 Displaying the characteristics .................................................................................... 78

5. Deleting, saving and printing measured values

5.1 Delete measured values .......................................................................................... 79

5.2 Save measured values............................................................................................. 80

5.3 Print measured values / results .............................................................................. 82

6. Basic settings

6.2 Standstill-time(s) ...................................................................................................... 86

6.3 Contacting speed ..................................................................................................... 86

6.4 Resolution ................................................................................................................ 86

6.5 Unit of measurement mm / inch ............................................................................. 86

6.6 Languages ................................................................................................................ 86

6.7 Date and time ........................................................................................................... 87

6.8 LCD settings ............................................................................................................. 87

6.9 Acoustic signal ........................................................................................................ 87

6.10 Auto – OFF................................................................................................................ 87

6.11 Quick-Mode .............................................................................................................. 88

6.12 Perpendicularity error.............................................................................................. 88

5

Mahr GmbH • Digimar 817 CLM

6.13 Data and printer ....................................................................................................... 89

6.13.2 DATA automatic transmit ON / OFF ........................................................................... 89

6.13.3 USB printer menu ...................................................................................................... 89

6.13.3.2 Print measured values / reults .................................................................. 89

6.13.3.3 Changing record head data ...................................................................... 89

6.13.3.4 Changing record head form ...................................................................... 90

6.13.3.5 Printer page length ................................................................................... 90

6.13.3.6 Change customer-specific headline.......................................................... 90

6.13.3.7 Color printer Yes / No ................................................................................ 91

6.13.3.8 Printer specification .................................................................................. 91

6.13.4 Interface RS232 OUT ................................................................................................ 91

6.13.5 DATA parameter RS232 OUT..................................................................................... 93

6.13.6 Administer the USB memory ...................................................................................... 93

6.14 Advanced settings ................................................................................................... 94

6.14.2 Temperature compensation........................................................................................ 94

6.14.3 Parameters for calibrating a probe ............................................................................. 95

6.14.4 Function key............................................................................................................... 95

6.14.5 Entering a password .................................................................................................. 96

6.14.6 Correction tables ........................................................................................................ 96

6.14.6.2 Factory correction table ............................................................................ 97

6.14.6.3 Customer specified correction table ......................................................... 97

6.14.6.4 Create a new correction table Z................................................................ 97

6.14.6.5 Print a correction table .............................................................................. 97

6.14.6.6 Perpendicularity correction table............................................................... 98

6.14.6.7 Service menu (reserved) .......................................................................... 98

6.14.6.8 Embedded service test ............................................................................. 98

6.14.7 Delete menu / clear function ...................................................................................... 98

6.14.8 Import language text file (USB) .................................................................................. 99

6.14.9 Probing parameters ................................................................................................... 99

7. Measuring program

7.2 Create a learn program (teach-in method)........................................................... 100

7.3 Create a new measuring program ........................................................................ 101

7.4 Change an existing measuring program ............................................................. 105

7.5 Print a measuring program ................................................................................... 105

7.6 Control limits (based on measuring values) ....................................................... 106

7.7 Control limits (based on tolerances).................................................................... 107

7.8 File administration ................................................................................................. 107

7.9 Data administration ............................................................................................... 110

7.10 Start a program ...................................................................................................... 114

8. Statistics

8.2 Entering and selecting production data .............................................................. 115

8.3 Control charts settings .......................................................................................... 117

8.4 Statistics and histograms ..................................................................................... 117

8.5 Control charts ........................................................................................................ 121

8.6 Pareto menu ........................................................................................................... 124

6

Mahr GmbH • Digimar 817 CLM

9. Communication

9.1 Description of the interfaces ................................................................................ 126

9.2 Software ................................................................................................................ 127

10. Additional functions

10.1 Software update ..................................................................................................... 129

10.2 Initialization of the internal memory .................................................................... 131

10.3 Storing additional languages ................................................................................ 132

10.4 Customer calibration ............................................................................................. 134

11. Self-help, maintenance and care

11.1 Troubleshooting ..................................................................................................... 140

11.2 Maintenance and care ........................................................................................... 142

12. Accessories ................................................................................................................ 144

13. Technical data ................................................................................................................ 148

14. Alphabetical index ................................................................................................................ 150

15. Declaration of conformity

7

Mahr GmbH • Digimar 817 CLM

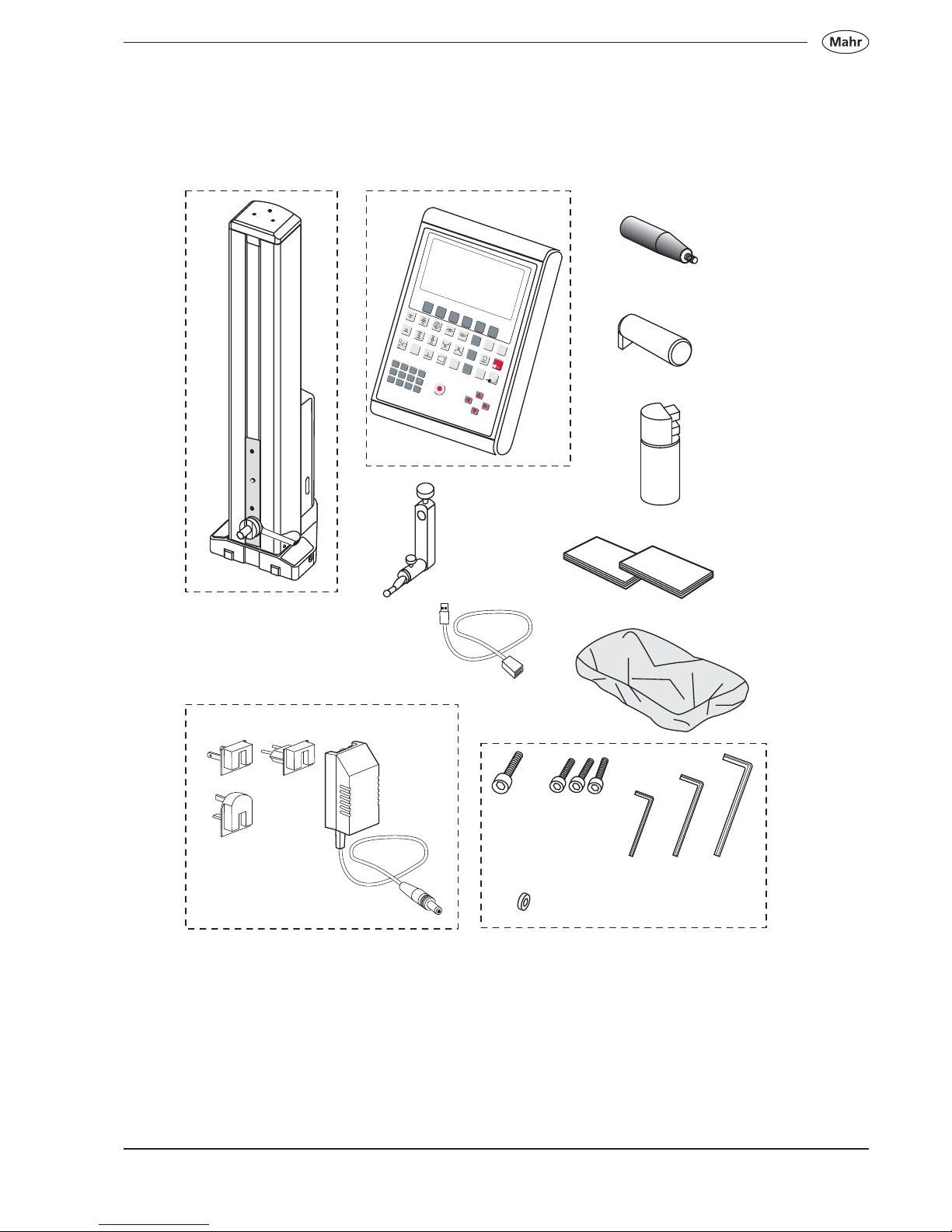

1. Delivery and setting up

1.1 Scope of supply

C

K

M6

L

M4

3x

M

3 mmN4 mmO5 mm

G

H

2

D

M

A

X

M

IN

D

IS

P

S

T

A

T

P

R

O

G

C

O

N

F

IG

C

A

L

D

A

T

A

C

E

O

N

O

FF

1

2

3

+

4

5

6

7

8

9

0

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

Q

u

i

c

k

0

H

e

i

g

h

t

B

I

J

F

E

D

A

P

Q

8

Mahr GmbH • Digimar 817 CLM

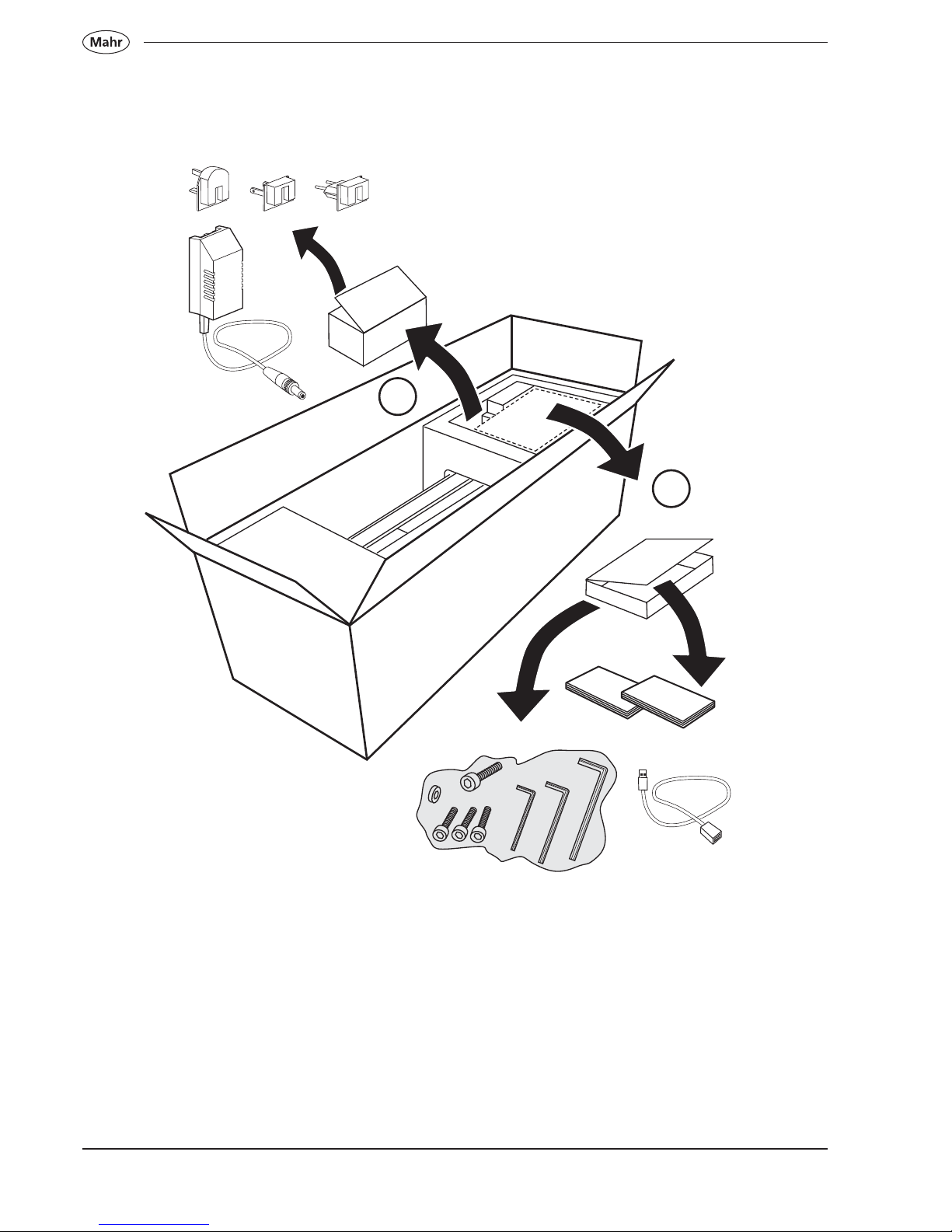

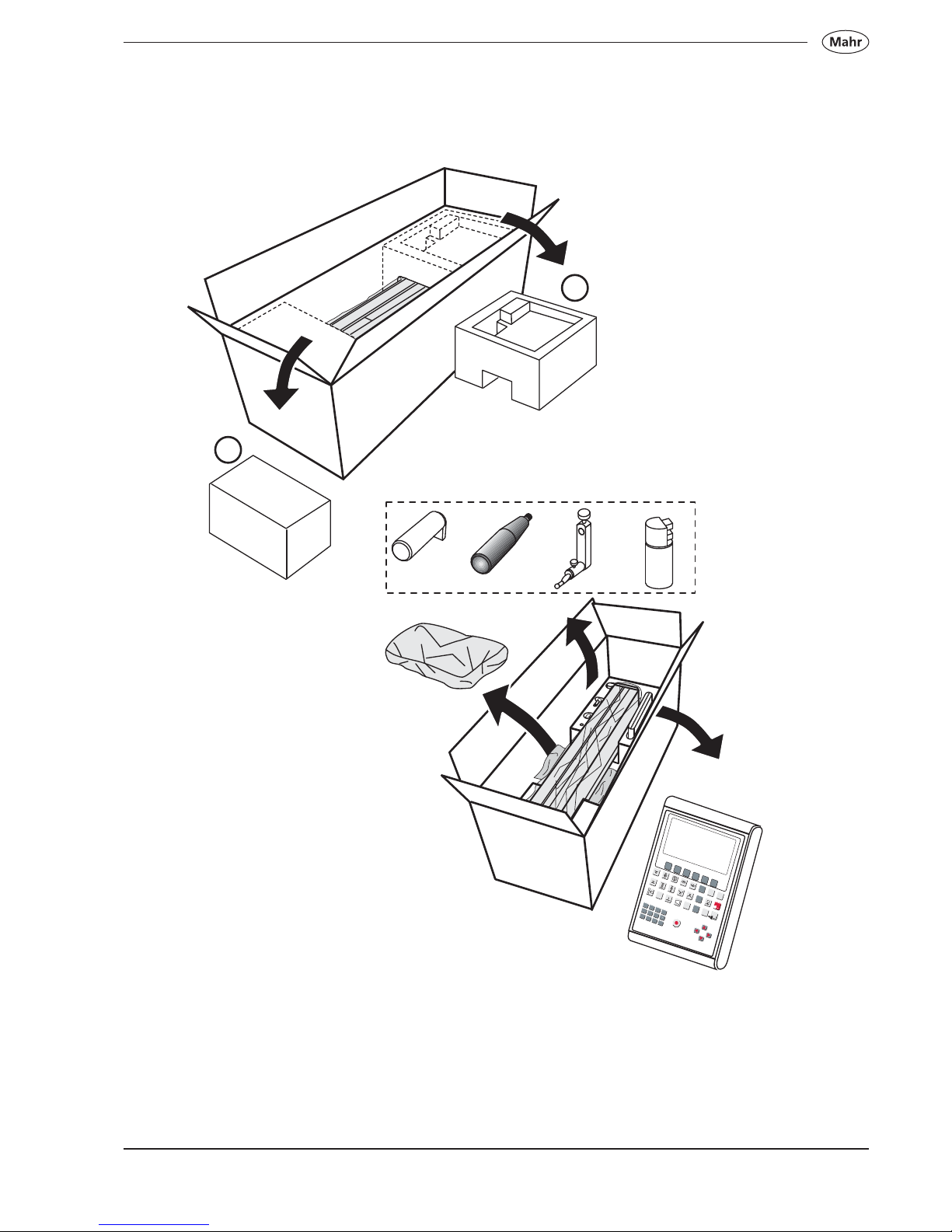

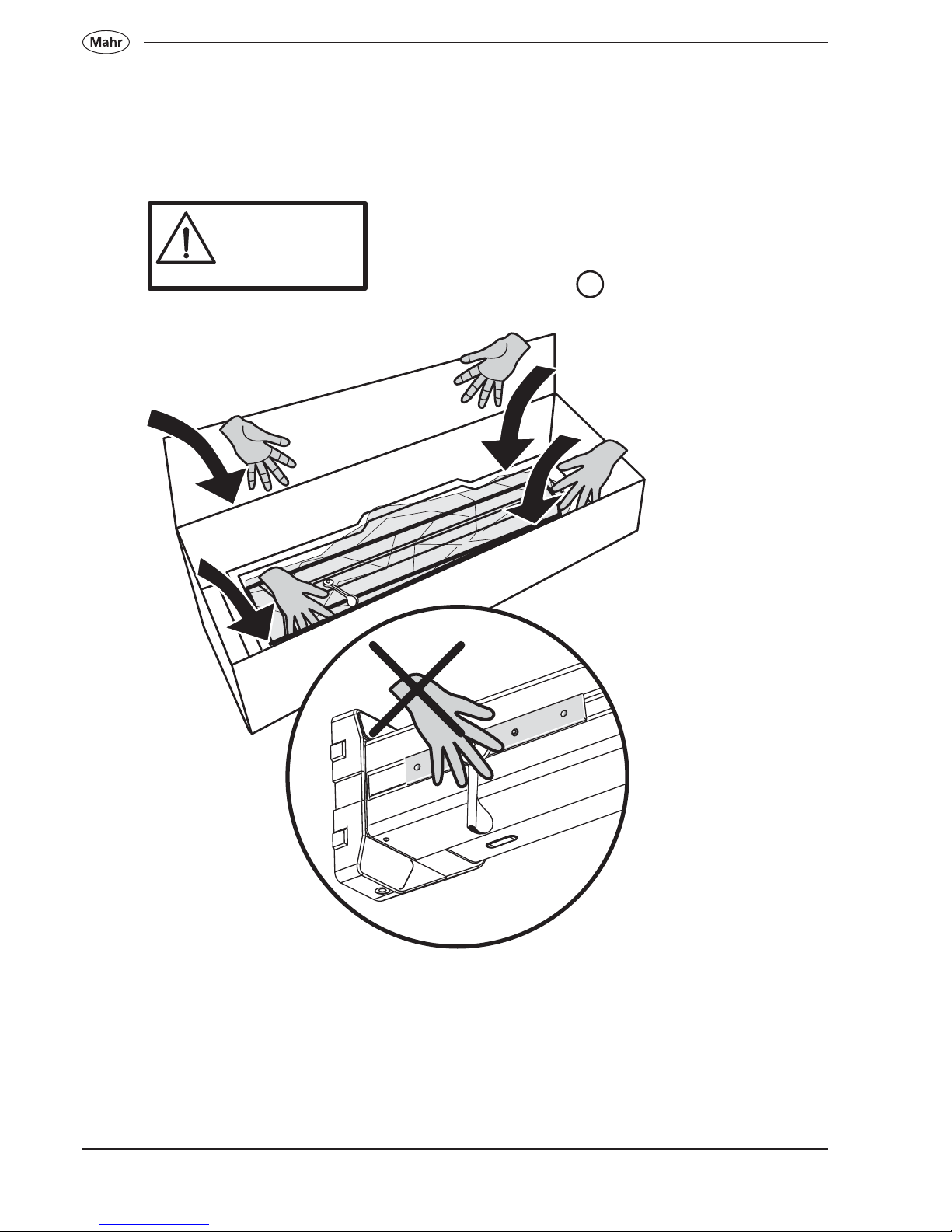

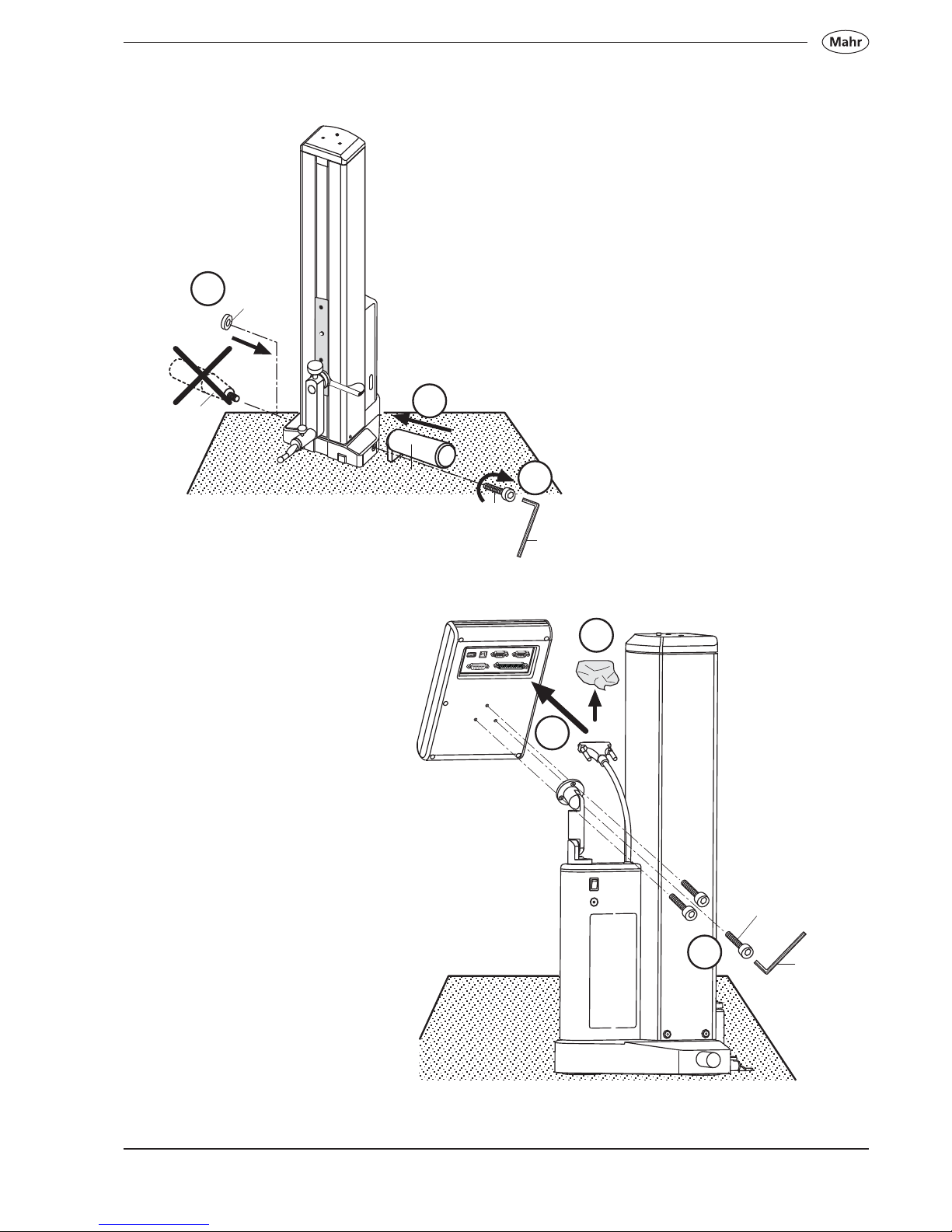

1.2 Unpacking

1

2

N

I

C

K

L

M

O

P

Q

9

Mahr GmbH • Digimar 817 CLM

3

4

2D

M

AX

M

IN

DISP

ST

A

T

PROG

C

O

N

F

IG

CA

L

D

A

TA

CE

O

N

O

F

F

1

2

3

+

4

5

6

7

8

9

0

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

Q

u

i

c

k

0

H

e

i

g

h

t

DE

F

G

H

B

J

10

Mahr GmbH • Digimar 817 CLM

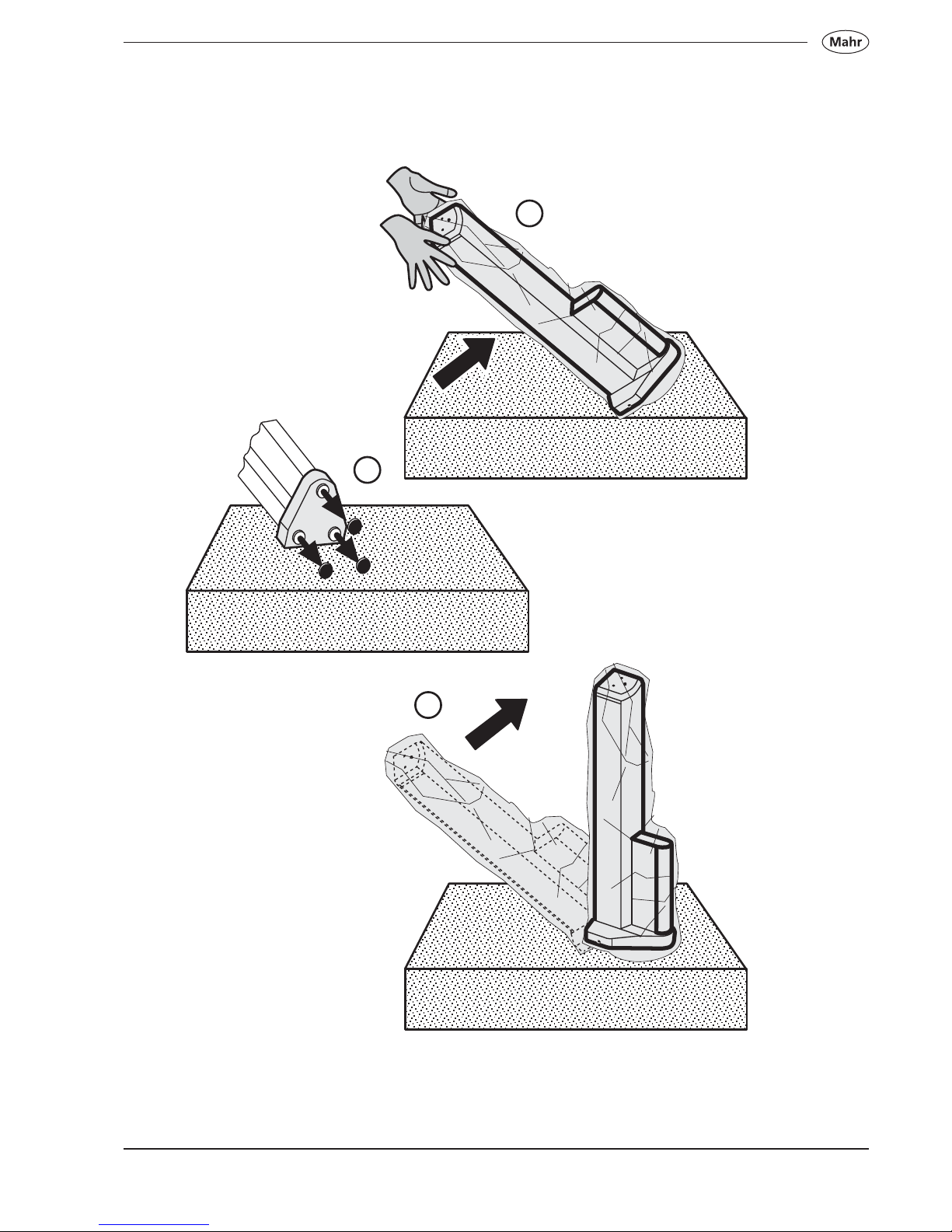

5

350 mm 25 kg

600 mm 30 kg

1000 mm 35 kg

11

Mahr GmbH • Digimar 817 CLM

6

45°

7

8

90°

12

Mahr GmbH • Digimar 817 CLM

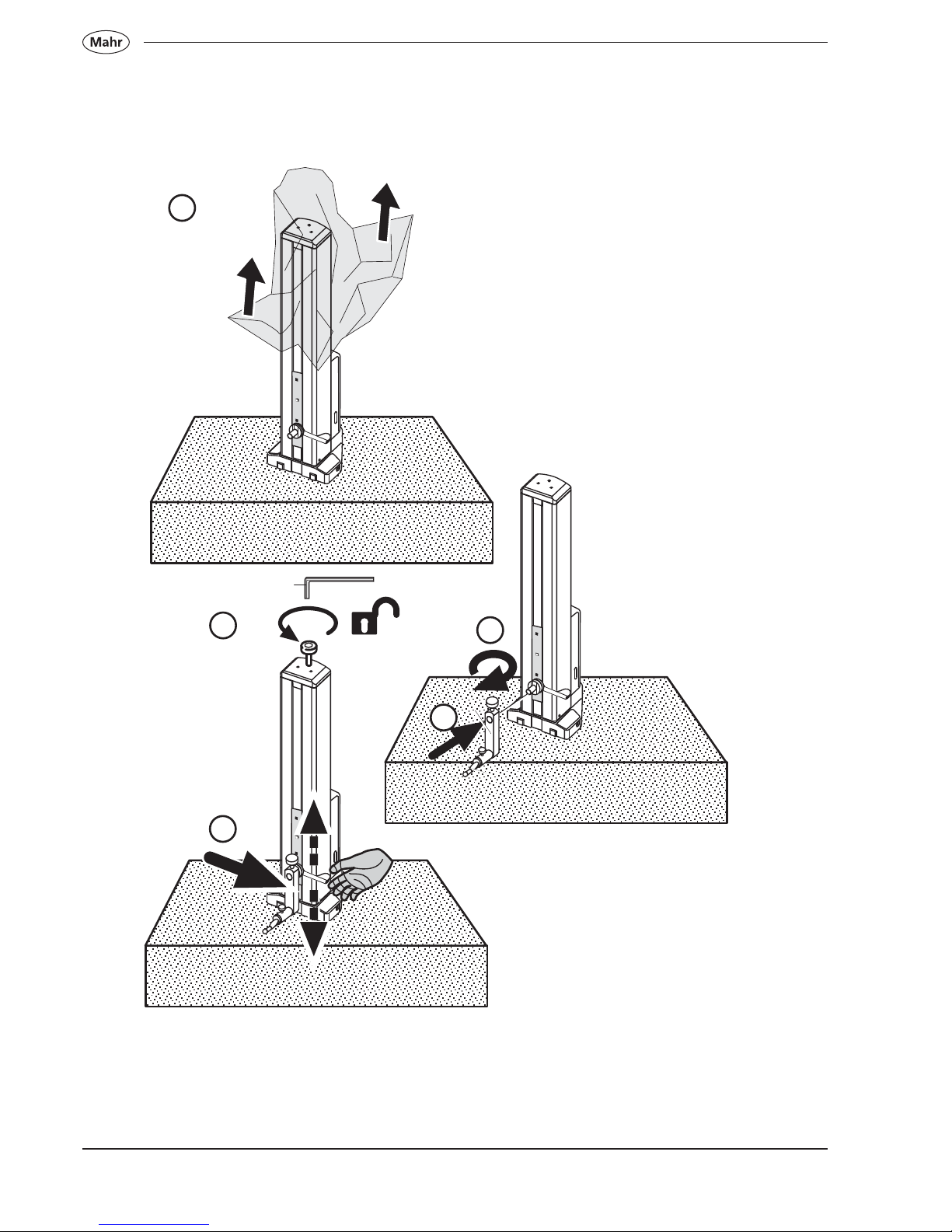

9

11

G

H

10

12

13

M

13

Mahr GmbH • Digimar 817 CLM

B

3x L

M

19

17

18

P

D

E

K

N

14

15

16

14

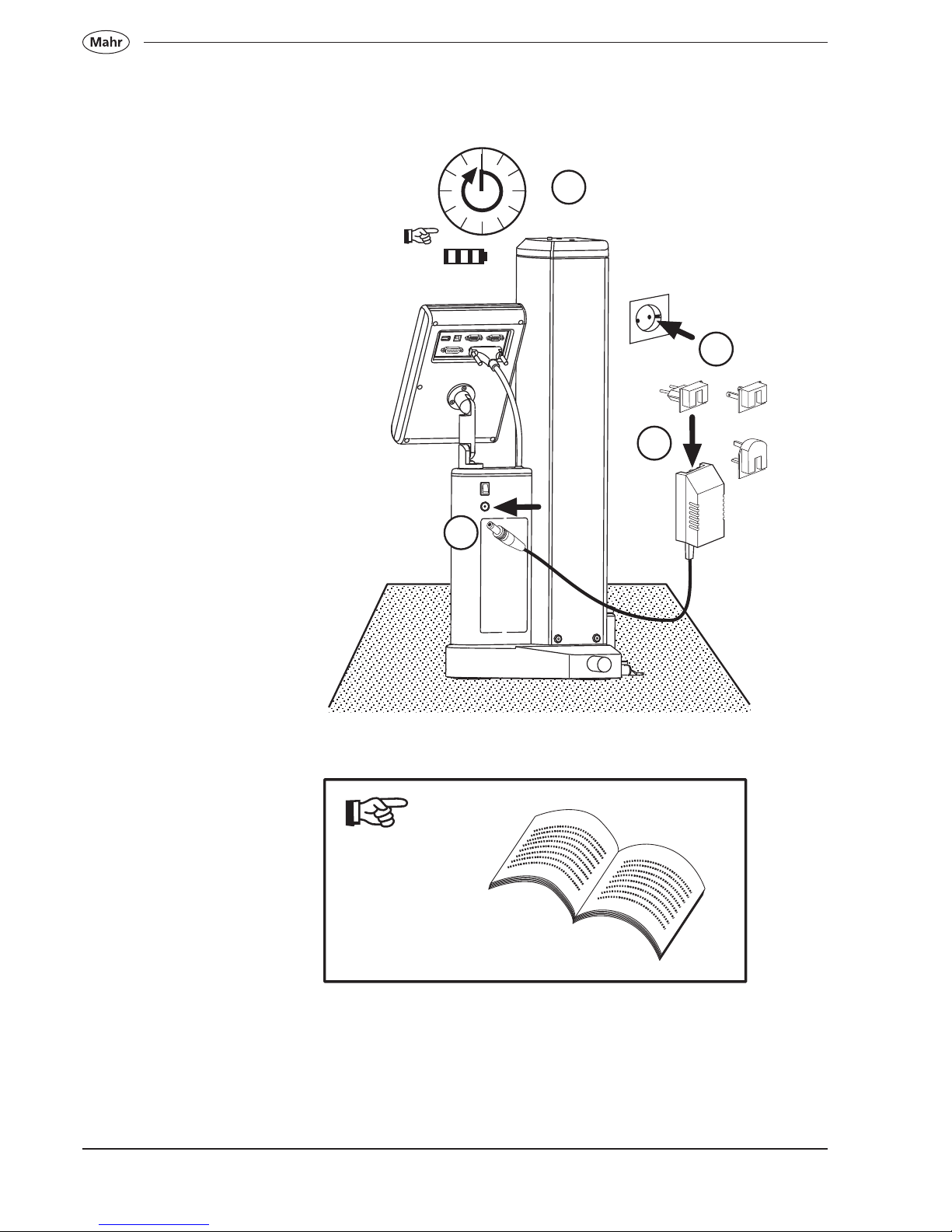

Mahr GmbH • Digimar 817 CLM

100-240 V~ / 50-60 Hz

I

~12 h

+

21

22

Euro US

UK

20

23

15

Mahr GmbH • Digimar 817 CLM

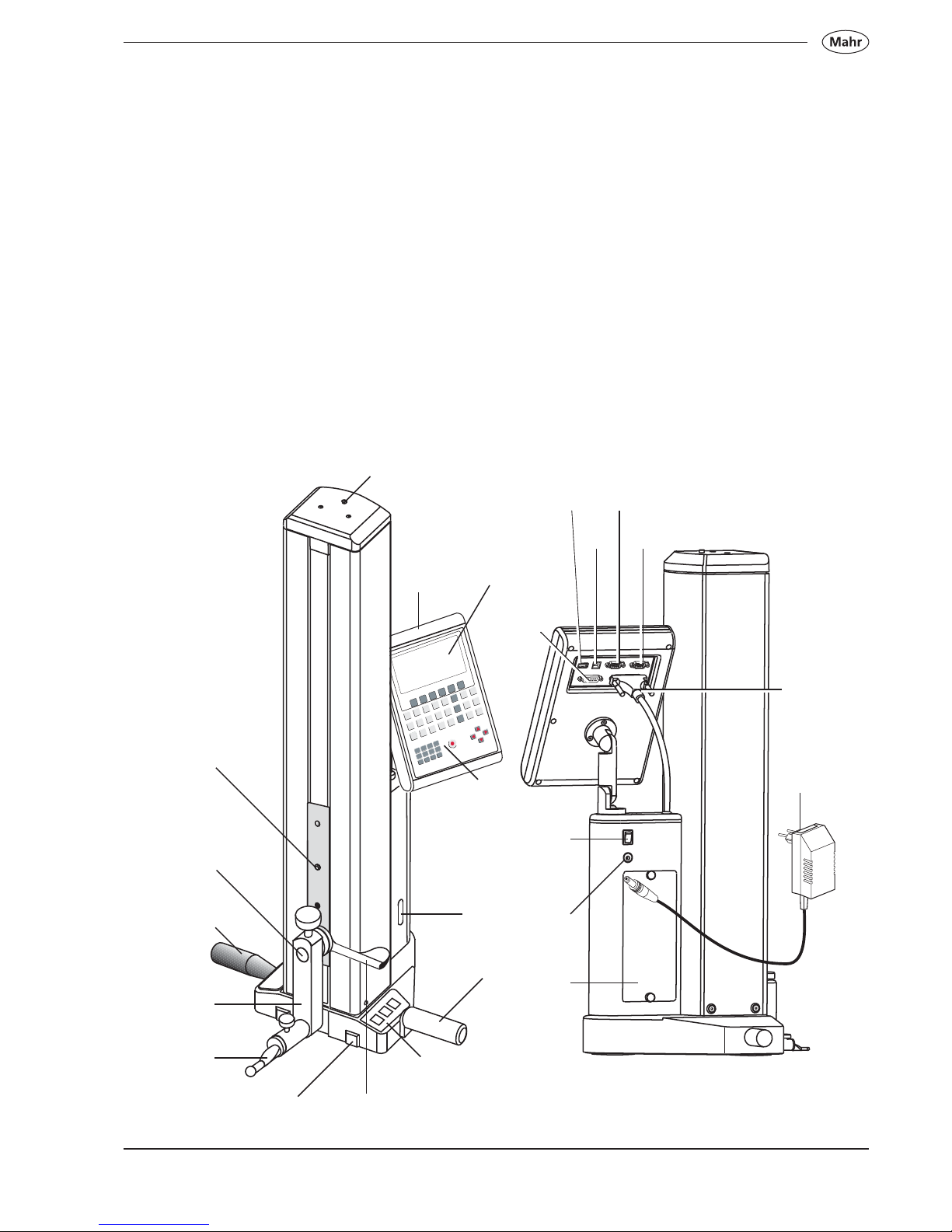

1.3 Description and explanation of the height measuring instrument

1.3.1 Height measuring instrument

1 Transport protection screw 14 Switch for activating the air bearings

2 Mount for probing element carrier 15 Socket for mains power charger

3 Probing element carrier 16 ON/OFF switch (power supply)

4 Contact point 17 Rechargeable battery compartment (accumulator)

5 Limit plate 18 Interface connection for the measuring column (HEIGHT

6 LED display GAGE)

7 Handle for manually moving the slide 19 Interface connection for digital indicators (INPUT 1)

8 Control and evaluation unit required for perpendicularity checks

9 Display 20 Interface connection for incremental probes P1514H

10 Keypad (INPUT 2) required for perpendicularity checks

11 Quick-keys 21 RS232 OUT to send individual measured values to a PC

12 Hand grip and/or a statistics printer

13 Transport handle 22 USB B port for connection to a PC

23 USB A port for connecting a for printer

24 Plug for mains power supply

1

9

10

14

12

11

7

5

3

4

2

13

6

17

15

16

18

19

21

22

23

20

24

8

16

Mahr GmbH • Digimar 817 CLM

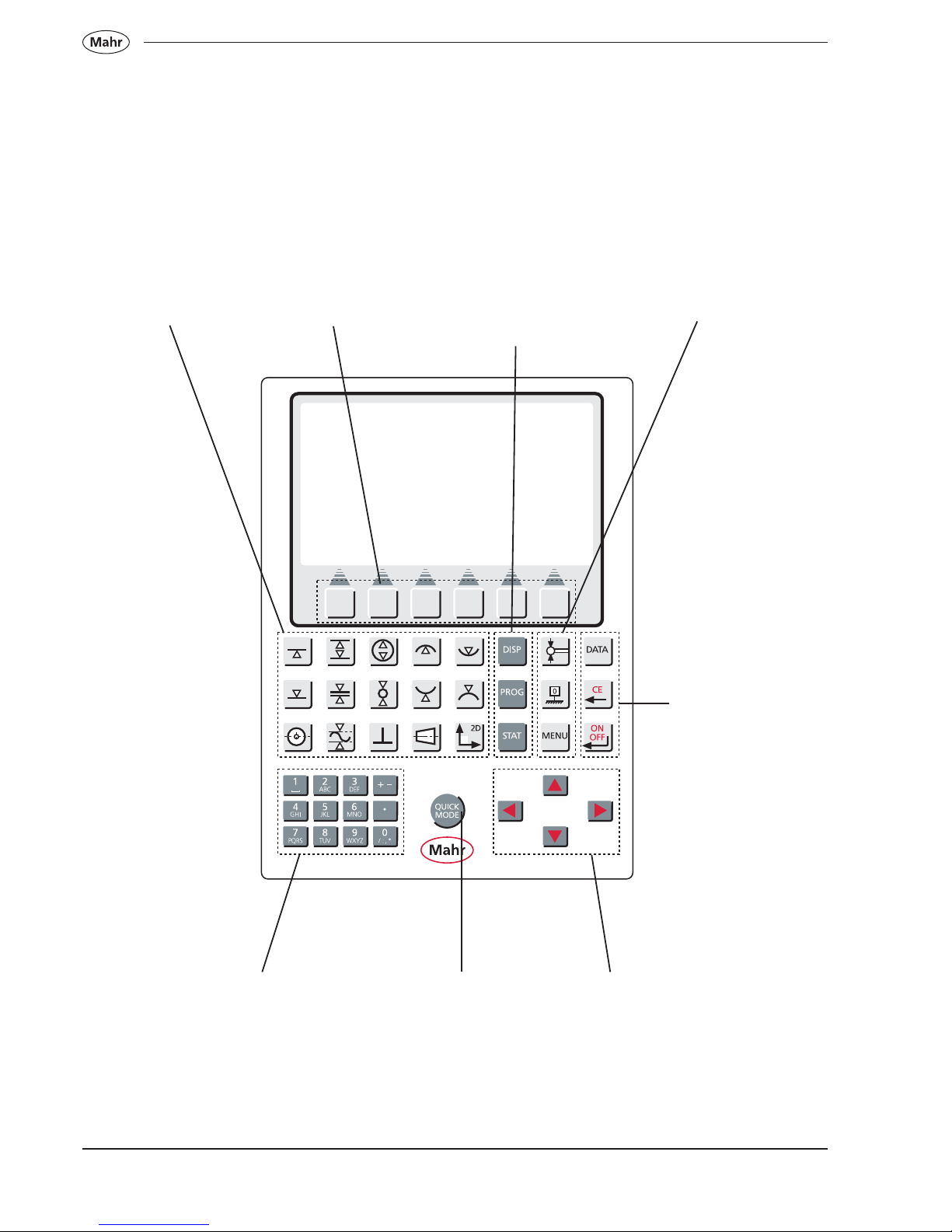

1.3.2 Keypad

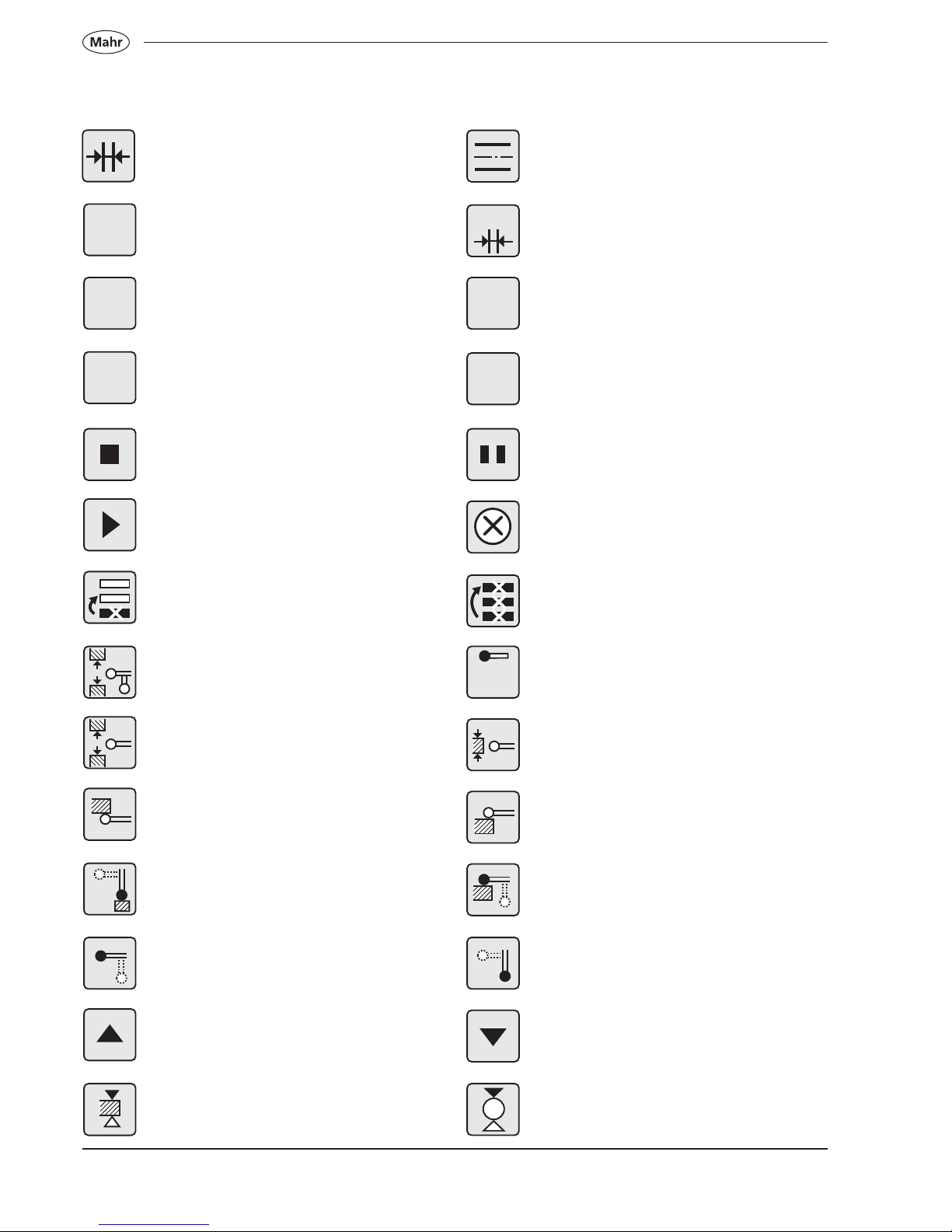

Measuring function

keys

Variable

function keys

Calibration and

set up function keys

Delete and accept

function keys

Keypad

Active / deactive the

Quick Mode

Arrow keys

Evaluation function

and measuring

program keys

17

Mahr GmbH • Digimar 817 CLM

1.3.2.1 Measuring functions

– Refer to chapters 4.3 - 4.7

1.3.2.2 Evaluation functions and measuring program

Show or hide the measuring results

Measuring program functions – See chapter 7

Statistics functions – See chapter 8

Calibrate a probe – See chapter 4.1

Zero point – See chapter 4.2

Menu settings – See chapter 6

Data transmission / select data for transmission – See chapter 9.1

Delete values and return to sub menu /cancel – See chapter 5

Confirm a function – switch the Height Measuring Instrument ON / OFF

1.3.2.3 Calibration and set up functions

1.3.2.4 Delete or accept a function

18

Mahr GmbH • Digimar 817 CLM

1.3.2.5 Variable function keys

Depending upon the measuring task, the bitmap symbols above the variable function keys change accordingly. By

pressing the individual key, the function will be activated or you will enter a subdirectory / lower level. The different

meanings are described in the operating instructions.

1.3.2.6 Input pad

Each key is assigned a multiple character function, by

repeatedly pressing a key the next assigned character

will appear, for example:

2 -> A -> B -> C -> 2 -> A . . .

1.3.2.7 Quick-Mode

Activate / deactivate

1.3.2.8 Arrow keys

Arrow keys left / right - Cursor jumps 5 times left / right

Arrow keys up / down - Cursor jumps once up / down

– See chapter 4.8

19

Mahr GmbH • Digimar 817 CLM

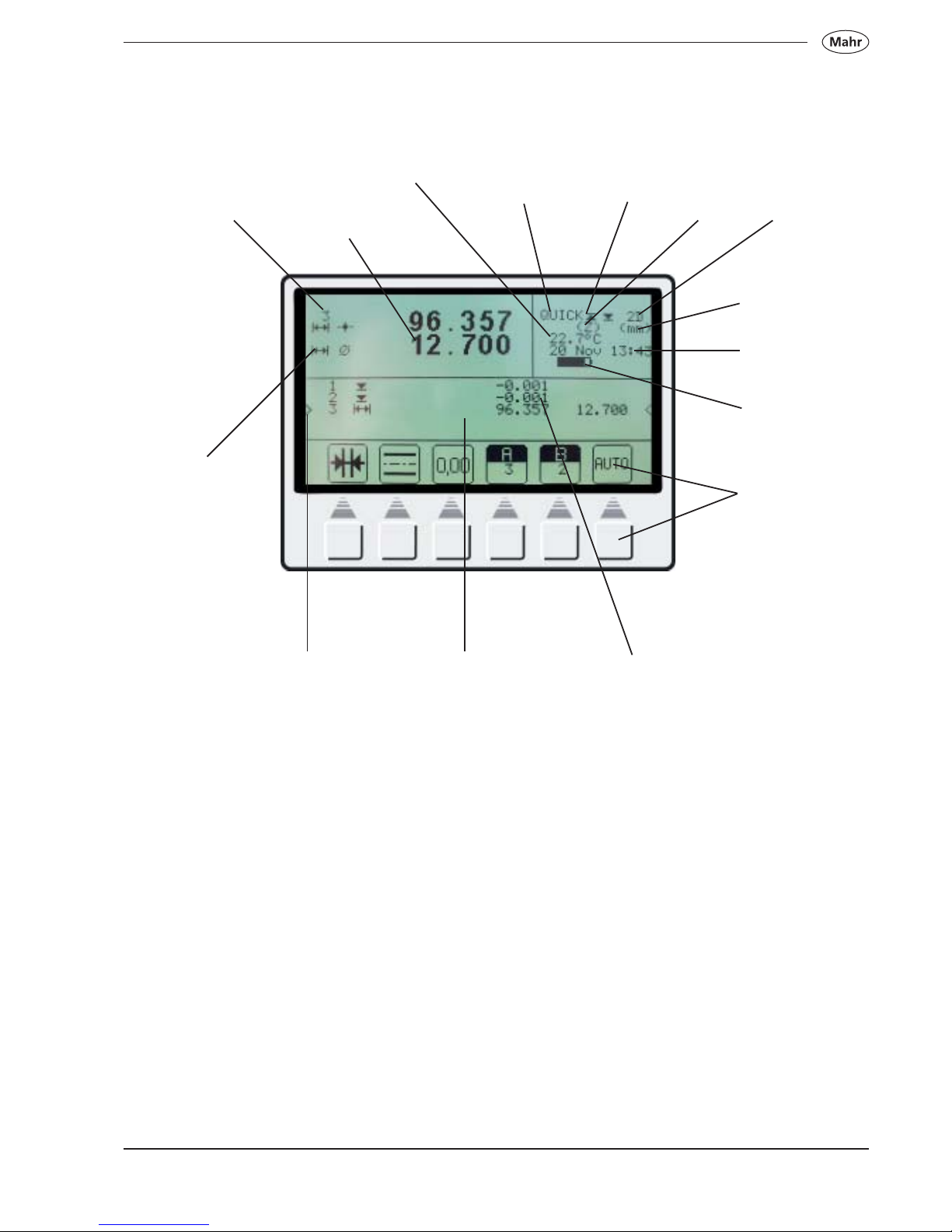

1.3.3 Display

Actual measured

value

Characteristic

number

Characteristic

symbol

Actual

character

Display field

Stored measured

values

Charging

condition of the

battery

Date and

time

Unit of

measurement

2 D Mode is

activated

Actual axis

Quick Mode

plane / bore

Quick Mode

activated/

deactivated

Temperature

Variable

function keys

20

Mahr GmbH • Digimar 817 CLM

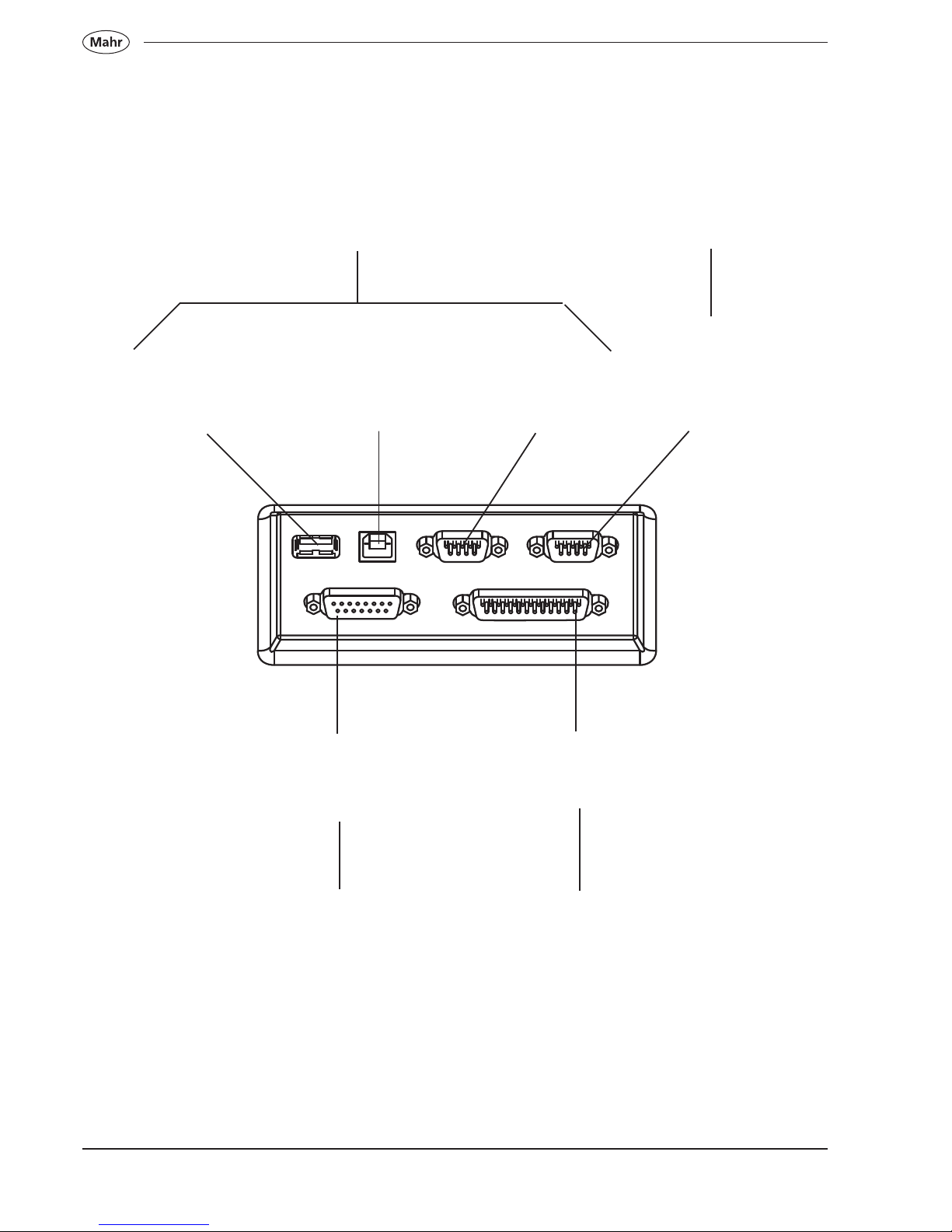

1.3.4 Interface connections

USB-Interface

Type A

Port for a USB printer

USB-Interface

Type B

PC port

RS 232

Interface

OUT

To connect either a PC

or statistics printer

RS 232

Interface

Input 1

To connect a digital

indicator (required for

perpendicularity

checks)

SUB D-Interface15-pin

To connect an

incremental probe, required

for perpendicularity checks

SUB D-Interface 25-pin

To connect to the measuring

column

See chapter 9.2 See chapter 4.4.2

See chapter

4.4.2

See chapter

1.2

21

Mahr GmbH • Digimar 817 CLM

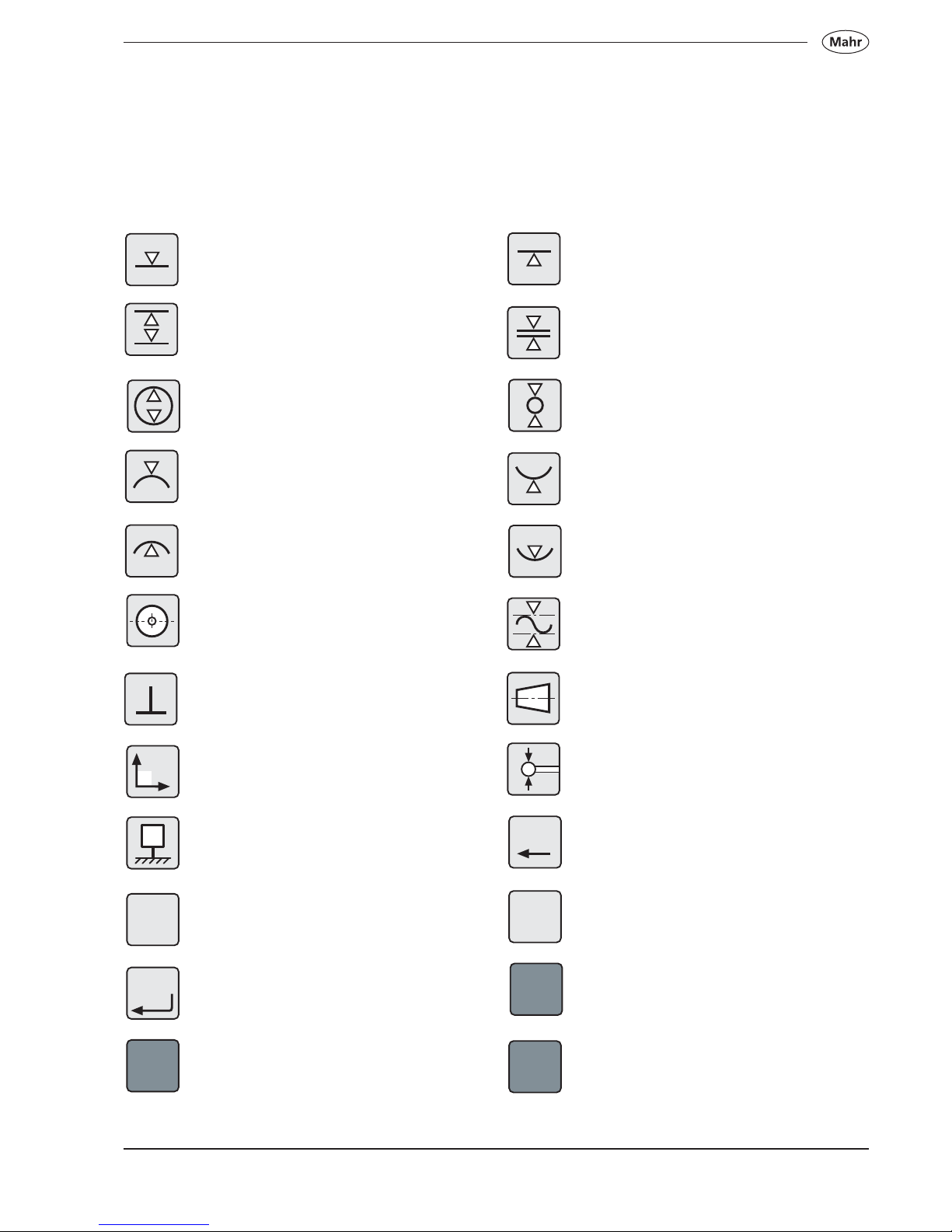

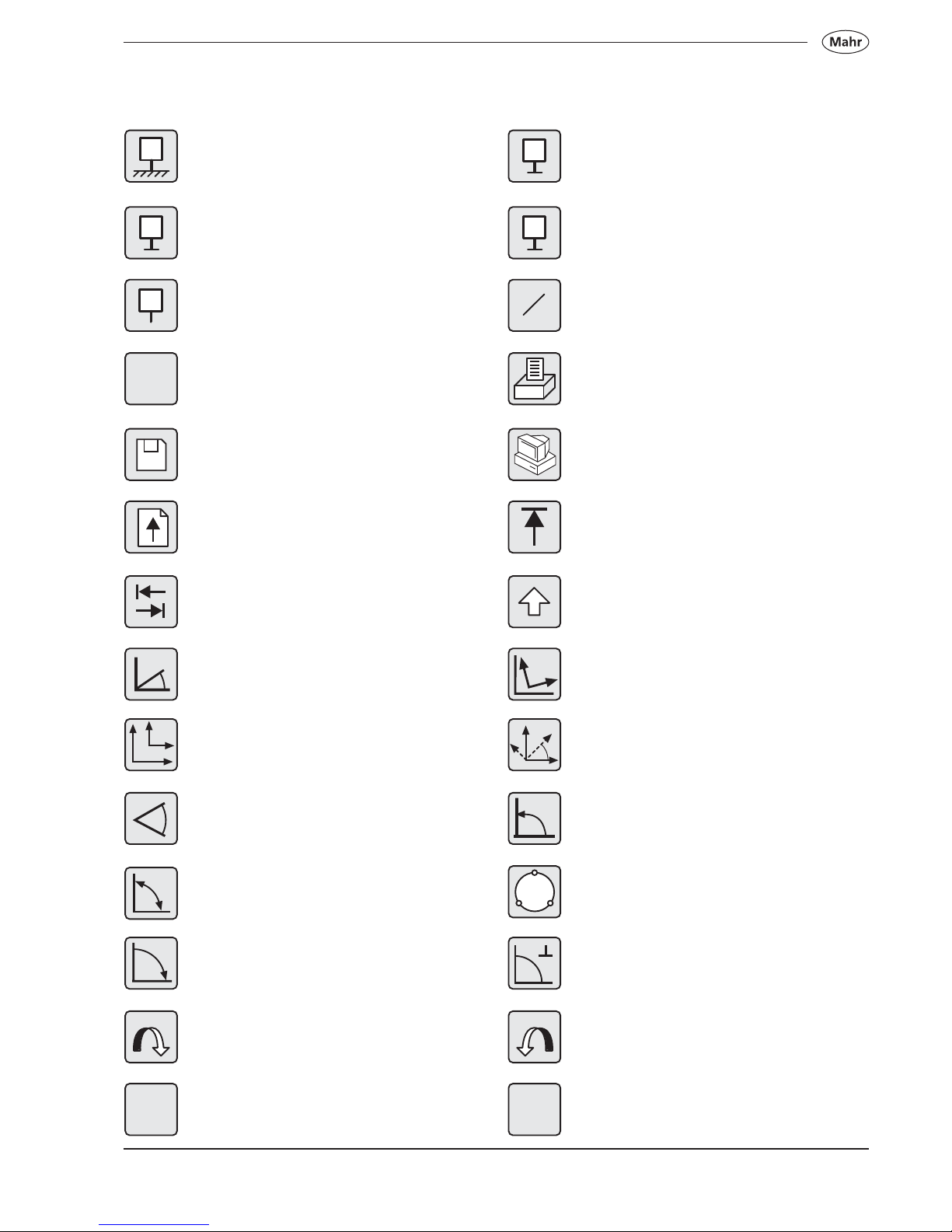

1.3.5 Description of the symbols

1.3.5.1 Keypad symbols

Contacting a plane / surface from above

Measuring a groove

Measuring a bore

Contacting a shaft from above

Contacting a bore from above

Determining the center of a bore /

displaying the position

Perpendicularity

2D-selection key

Zero point

Select data for transmission

ON / OFF / Confirm

Statistics function

2D

0

DATA

Contacting a plane / surface from below

Measuring a bar

Measuring a shaft

Contacting a shaft from below

Contacting a bore from below

Min-Max function

Measuring a taper / angle

Calibrating a probe

Delete / Return to last value

Menu settings

Measuring program functions

Display the list of measured values

ON / OFF

ON

OFF

STAT

CE

MENU

PROG

DISP

22

Mahr GmbH • Digimar 817 CLM

Calculate distance

Auto

Automatic zero point 01, last measured

value

Relative value

Stop / Accept

Repeat/ Continue

Delete last characteristic

Calibrate twin probe

Calibrate probe / groove

Calibrate ledge from below

Vertically contact a ledge

Select horizontal probe

Travel upwards

Contacting a bar from above

1.3.5.2 Symbols - function keys

Calculating the symmetry between

2 planes

Automatic calculation of the distance

Zero point, last measured value

Absolute value

Pause

Cancel

Delete all characteristics

Inferior calibrated value

Calibrate the probe / ledge

Calibrate ledge from above

Horizontally contact a ledge

Select vertical probe

Travel downwards

Contacting a shaft from above

AUTO

AUTO

01

REL

AUTO

0,00

ABS

?

23

Mahr GmbH • Digimar 817 CLM

Work piece, zero point 01

Work piece, zero point 03

Change between zero points

Print

Transfer a series of measurements to a

PC

Position the cursor to the beginning

Switch between upper and lower case

Coordinate transformation

Rotate according to angle

Tilting angle α

Index circle

Determine the tilting angle with a probe

Rotate anti-clockwise

Set Z-value to zero

Set the zero point on the base plate

Work piece, zero point 02

Enter Preset

Direct / select data transmission

Store on internal memory

Paper feed

TAB-function

Determining distance and angle

between

two elements

Rotate coordinates X / Z

Determining distance and angle

between

three elements

Tilting the workpiece arithmetically

Manually enter the tilting angle

Rotate clockwise

Set X-value to zero

DATA

X

Z

z

x

0

02

PR

a

X=0

+

02

01

a

01

a

Z=0

03

a

24

Mahr GmbH • Digimar 817 CLM

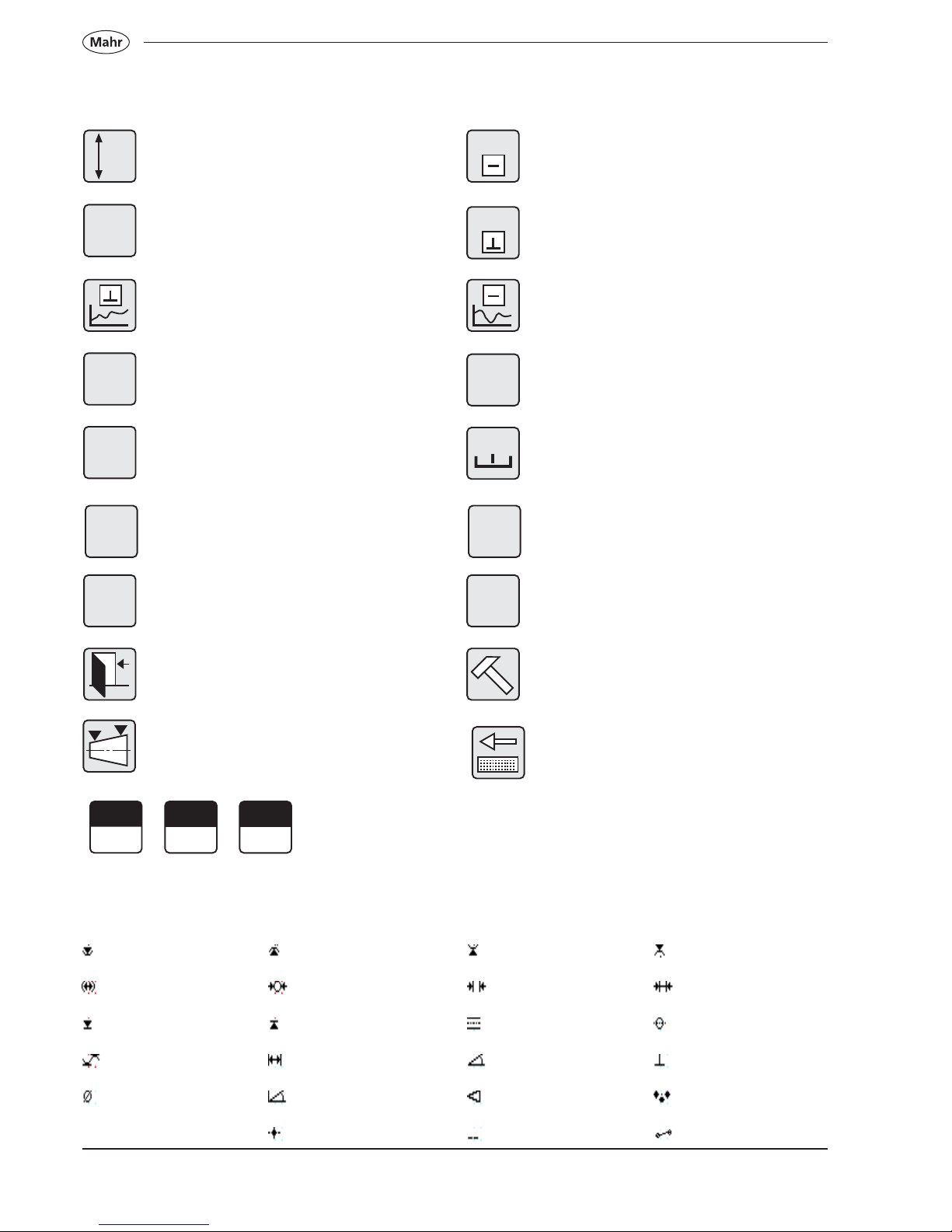

Enter the traverse path

Display only the diameter

Display a perpendicularity graphic (curve)

Accept the maximum value

Display the diameter

Error character number Z

Active 2D

Quit system

Taper measurement

Characteristic

Accept straightness value

Accept perpendicularity value

Display a straightness graphic (curve)

Accept the minimum value

Bar graph

Error character number X

Deactivate 2D

Change the production data

Taper probe

1.3.5.3 Symbols - display

Bore from above Bore from below Shaft from below Shaft from above

Bore Shaft Distance, bar Distance

Contacting from above Contacting from below Symmetry Position

Min Max Distance, groove Internal angle Perpendicularity

Display diameter External angle Taper Index circle

Coordinate Straightness Distance 2D

M =

M =

M =

MIN

Z

M =

Ø

M =

MAX

Ø

?

z

?

x

2D

ON

2D

OFF

A

C

B

25

Mahr GmbH • Digimar 817 CLM

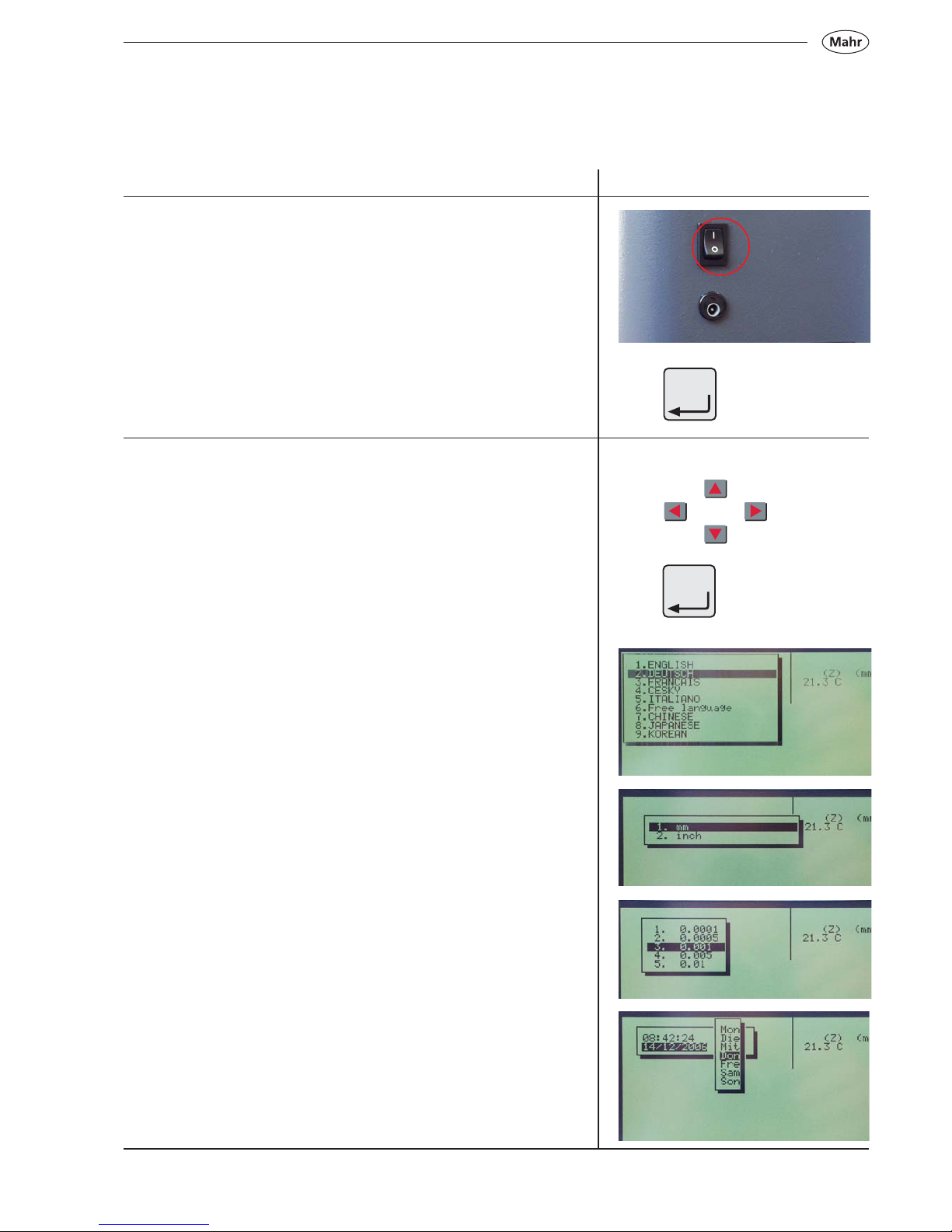

2.1 Switching ON

– Switch the mains power supply switch to ON = (1)

Press the ON/OFF key; this will start the boot up.

Note: At the first commissioning, by a RESET or when updating

the software, the following questions (the basic settings) will

appear:

2.2 Basic settings

These can be selected by using the arrow keys, confirm by pressing

the Enter key.

Enter the time and date via the keypad

Select: Language

Select: Unit of

measurement

Select: Resolution

Enter the date and time

2. Commissioning / First steps

Description / Sequence Symbols / Pictures

ON

OFF

ON

OFF

26

Mahr GmbH • Digimar 817 CLM

2.3 Setting the reference point

The measuring carriage moves automatically to the reference point

(reference point height ca. 50 mm) and sets the zero point on the base

plate.

Note: Once the zero point has been accepted, confirmation is given by

a twofold optical (LED) and acoustic signal (beep).

After the reference point has been confirmed, any zero point can be

selected.

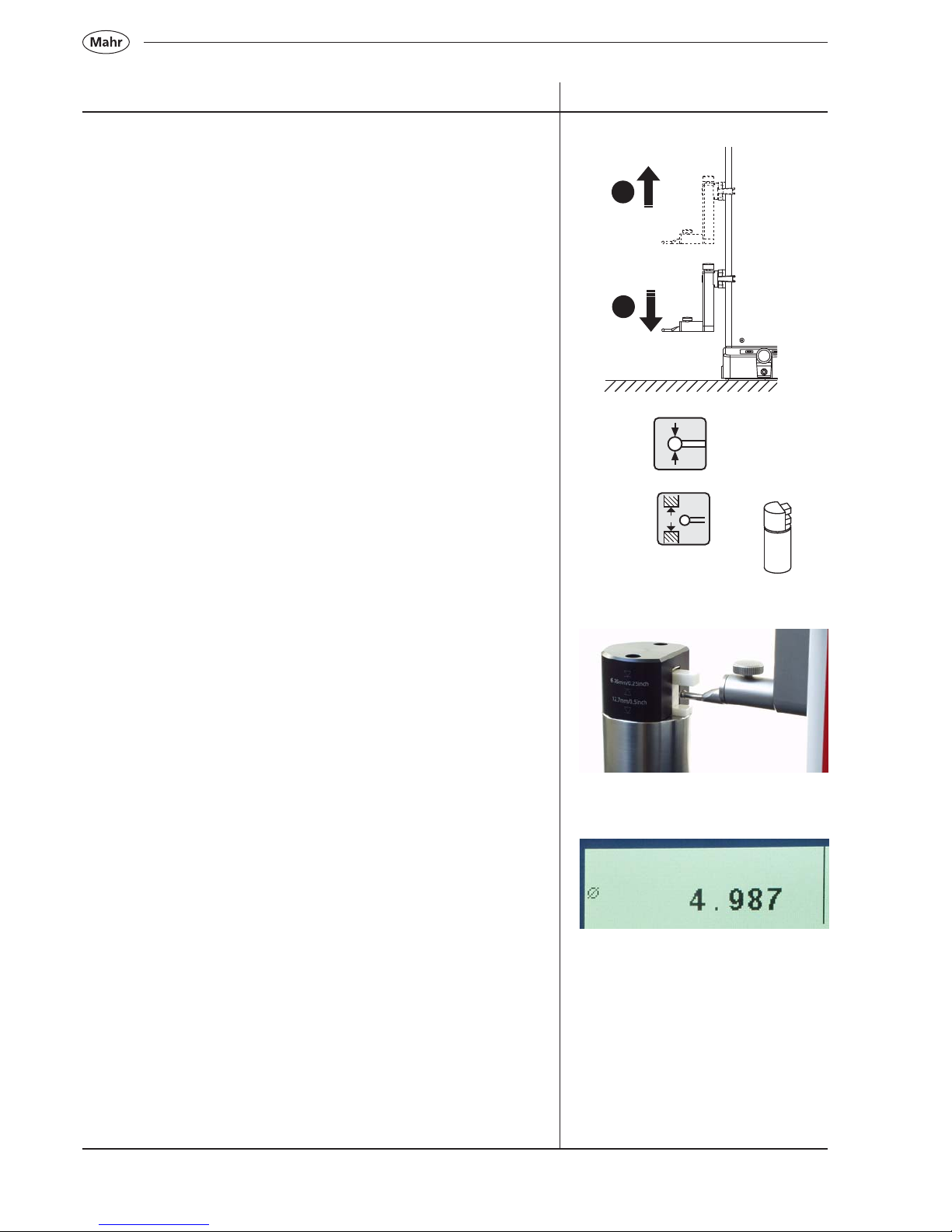

2.4 Calibrating a probe

a) Press the calibrate probe key

b) Press the function key „Calibrate in a groove“, the probe moves

automatically to the center of the groove of the setting standard.

c) Slide the setting standard, so that the probe is within the groove.

The groove will be automatically measured for a second time.

d) The determined probe constant will be displayed.

Description / Sequence Symbols / Pictures

Note:

The determined probe constant is always slightly smaller than the

actual diameter of the probe (please refer to 4.1).

a)

b)

c)

d)

2

1

27

Mahr GmbH • Digimar 817 CLM

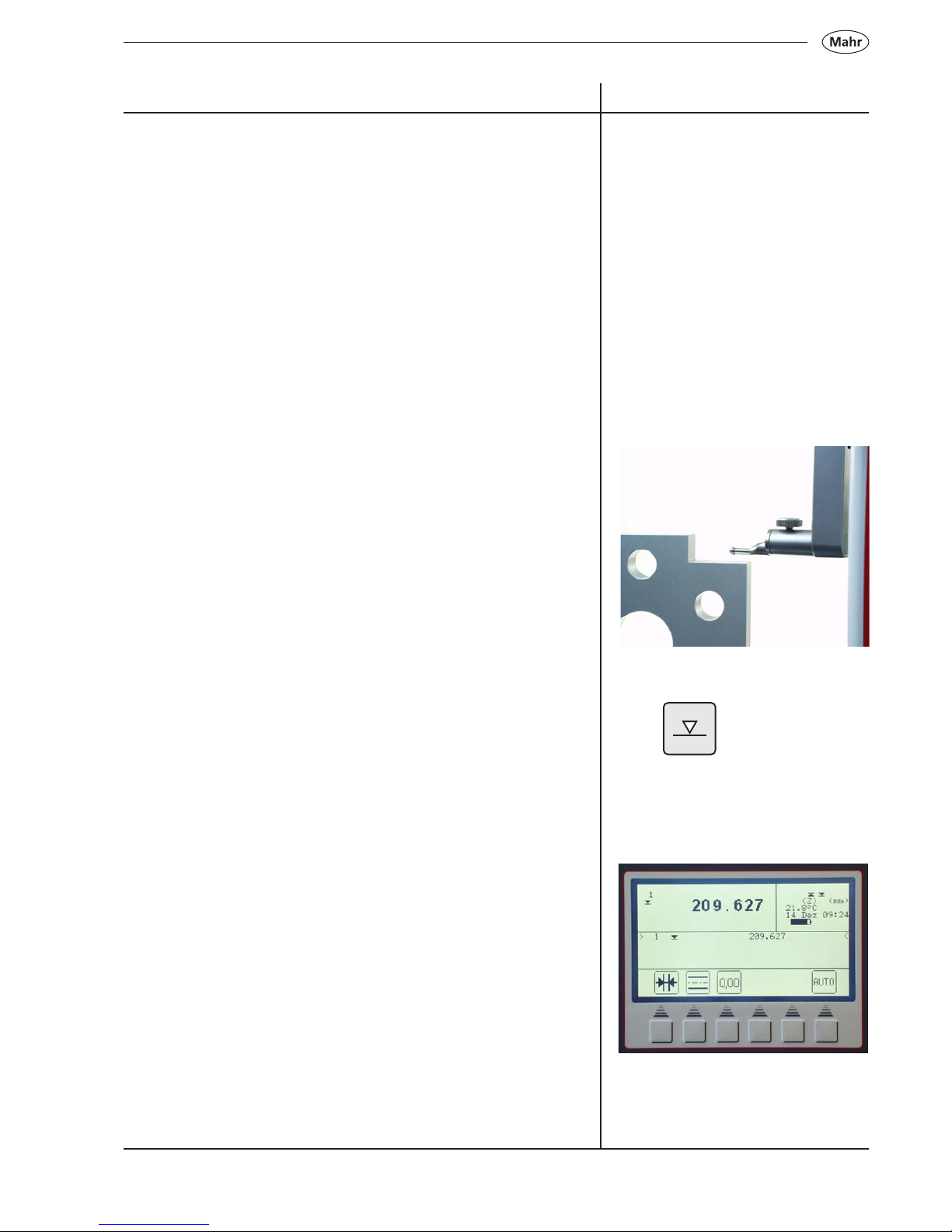

2.6 First measurement

Note:

In order to obtain highest accuracy the instrument requires at least a

warm-up period of 15 minutes.

2.6.1 Contacting a plane from above

– Position the probe

– Press key to start the measuring procedure

In the upper section of the display will appear the measured value

2.5 Auto-Off function

In the basic setting mode, the background lit display switches off after

1 minute, by pressing any key the background lit display will be

reactivated.

The height measuring instrument switches off after 5 minutes.

To change this basic setting, please refer to chapter 6.10

Note: No measuring results are lost when the height measuring

instrument switches off.

Description / Sequence Symbols / Pictures

28

Mahr GmbH • Digimar 817 CLM

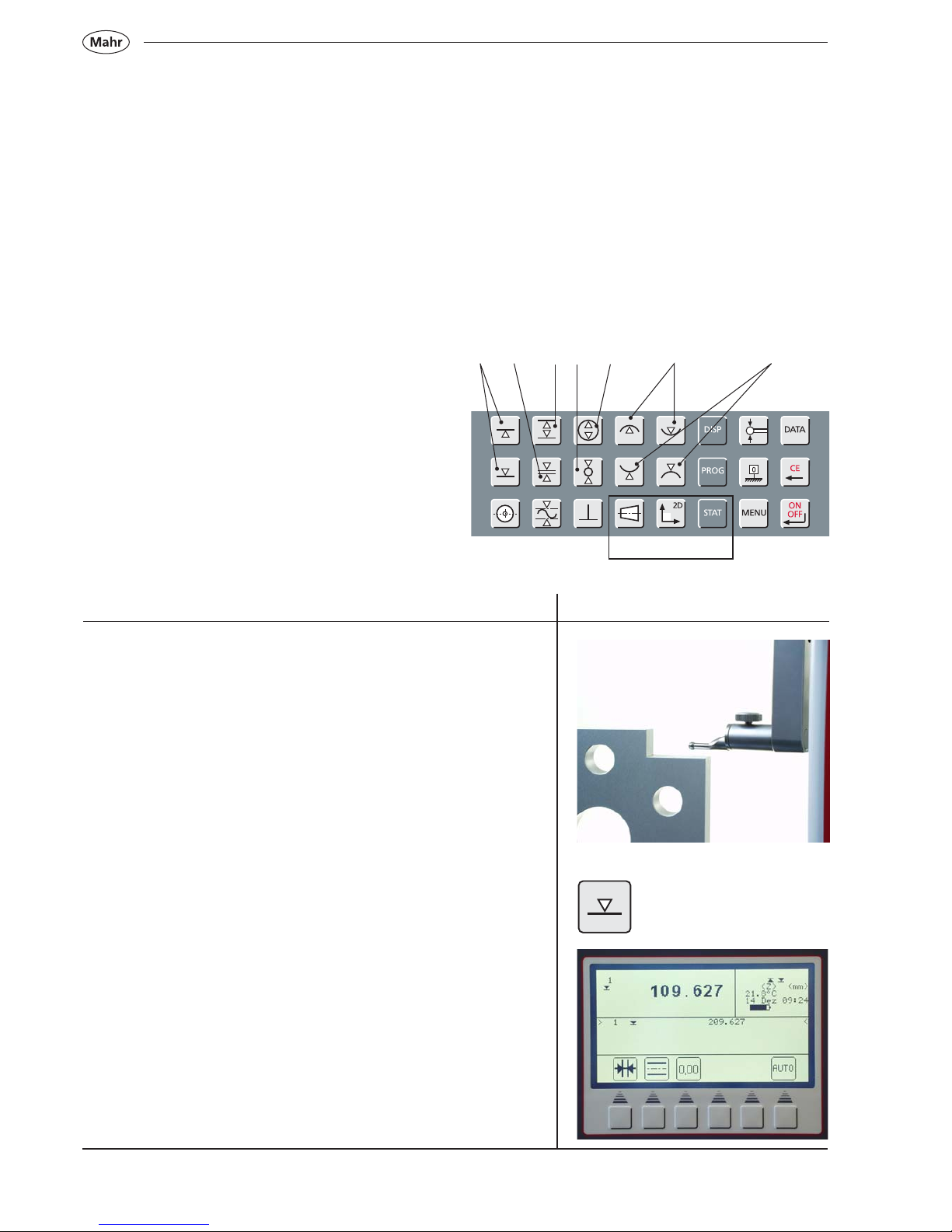

3.1 Start a measurement procedure with

the function keys

The function keys can be used to start different

measuring functions with one touch of a key.

The procedure is always the same:

– Position the probe either above or below the

point that is to be measured

– Press the function key to start the measuring

function

The probe automatically travels to the surface to be

measured and accepts the measured value. When

conducting dynamic measurements, where a maximum

or a minimum (bore or shaft) is to be measured either

the workpiece or the measuring instrument must then

is moved so that the measuring instrument can

determine an extreme value. When measuring with 2

contacts (e.g. a bore, groove or shaft), the first contact

must be upwards (from below).

Function keys:

1 Contacting a surface / plane from above or

below

2 Determining the center and width of a groove

3 Determining the center and width of a ledge

4 Determining the center and diameter of a bore

5 Determining the center and diameter of a shaft

6 Measuring a bore (maximum or minimum)

7 Measuring a shaft (maximum or minimum)

1 32 4 657

3 Brief guide to measurement methods

Optional

3.1.1 First measurement

3.1.2 Contacting a surface from above

– Position the probe

– Press the key to start the measuring procedure

The measured value will appear in the upper section of the display

29

Mahr GmbH • Digimar 817 CLM

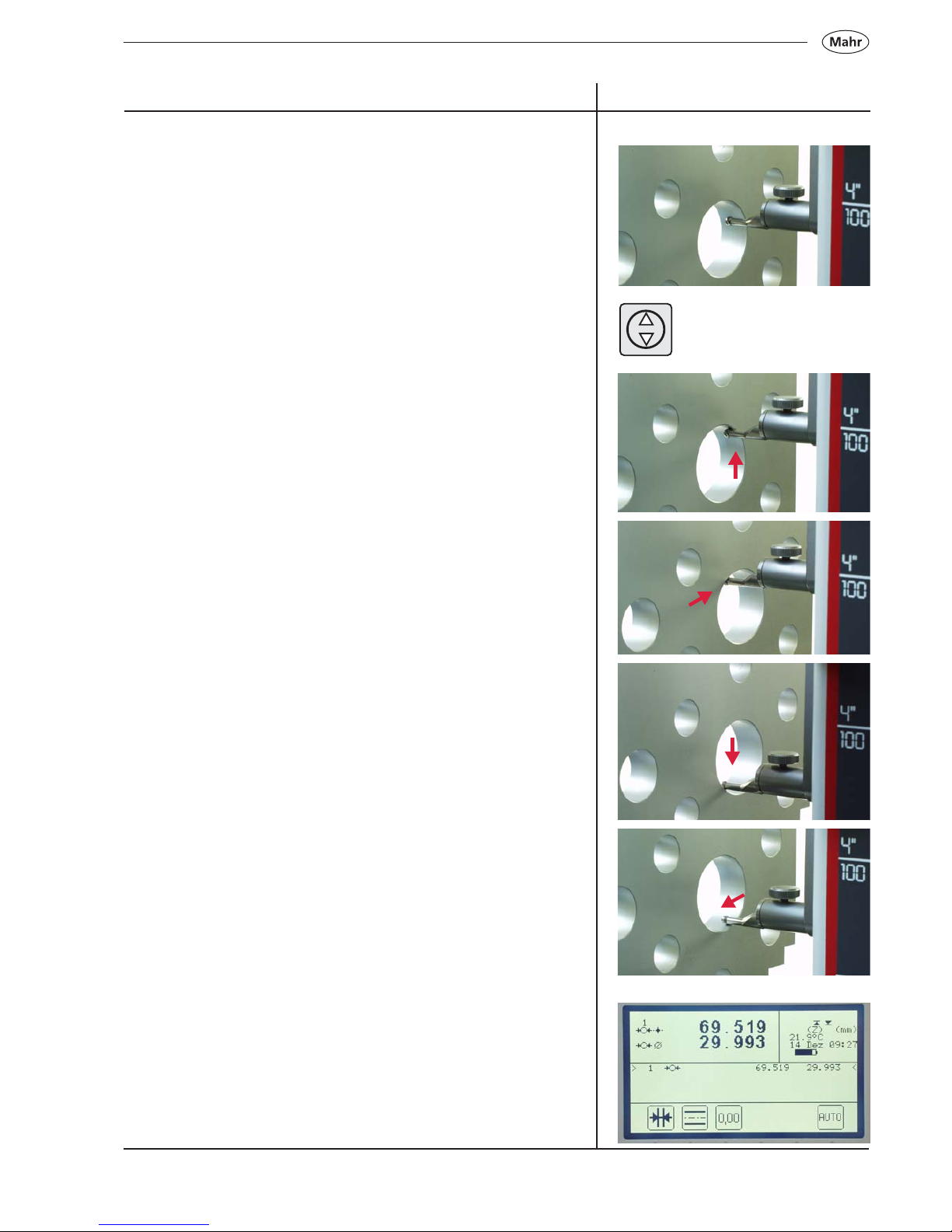

3.1.3 Measuring a bore

– Position the probe in the bore (not in the center / eccentrically)

– Press key to start the measuring procedure

– The probe will automatically travel upwards; the bore is contacted

from below

– Move the workpiece parallel to the stopping face in order to

determine the reversal point / maximum

– Acceptance of the reversal point will be confirmed by an acoustic

signal (beep)

– The probe will automatically travel downwards; the bore is

contacted from above

– Move the workpiece parallel to the stopping face in order to

determine the reversal point / maximum

– Acceptance of the reversal point will be confirmed by an acoustic

signal and the results (center and diameter) will appear in the

display

Description / Sequence Symbols / Pictures

30

Mahr GmbH • Digimar 817 CLM

3.1.4 Measuring a shaft

– Position the probe below the shaft (eccentrically)

– Press key to start the measuring procedure

– The probe will automatically travel upwards and make contact

from below

– Move the workpiece parallel to the stopping face in order to

determine the reversal point / maximum

– Acceptance of the reversal point will be confirmed by an acoustic

signal (beep)

– Position the probe above the shaft (eccentrically).

– Press the function key „Contacting a shaft from above“

– The probe will automatically travel downwards and make contact

– Move the workpiece parallel to the stopping face in order to

determine the reversal point / maximum

– Acceptance of the reversal point will be confirmed by an acoustic

signal (beep) and the results (center and diameter) will appear in

the display.

Description / Sequence Symbols / Pictures

Loading...

Loading...