Page 1

OPERATION MANUAL

VCX-4

Vacuum Coolant Exchanger

RTI Technologies, Inc

10 Innovation Drive

York, PA 17402

800-468-2321

www.rtitech.com

Manual P/N 035-81446-00

Page 2

Table of Contents

Component Description ........................2

Safety Precautions ...........................3

Home Position ...............................4

Fill New Tank through Hose .................... 5

Empty Radiator .............................. 6

Special Hookups ............................. 8

Fill Radiator ................................. 9

Top Off & Flush Radiator...................... 10

Empty Waste Tank .......................... 11

Empty New Tank ............................ 12

Troubleshooting ............................. 13

Parts Identification ........................... 14

Flow...................................... 15

Page 1

Page 3

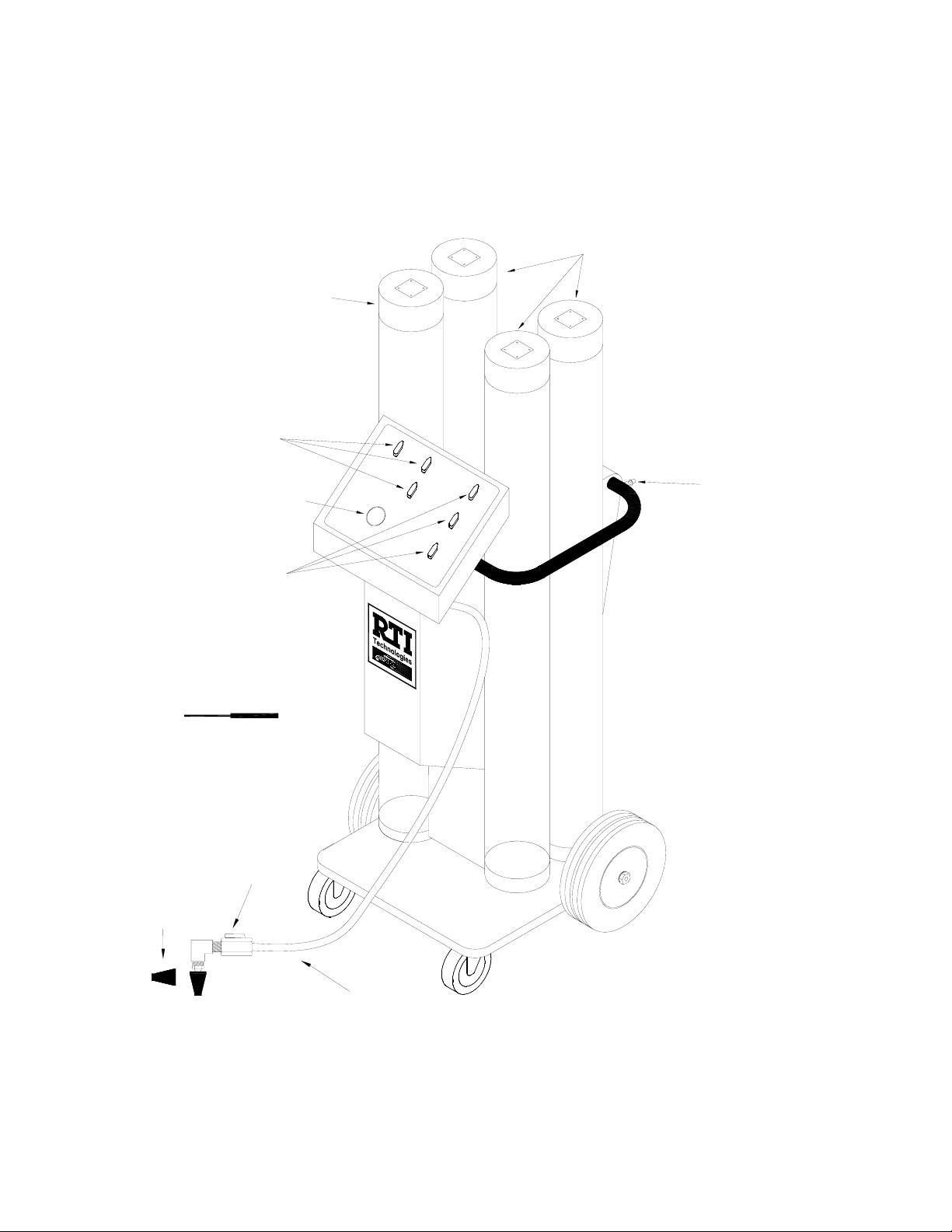

Component Description

Unpack all components and verify quantities per this illustration.

Contact RTI if any items are missing.

NEW COOLANT

TANKS

WASTE COOLANT

DUAL 2-WAY

PANEL VALVE

SYSTEM

VACUUM GAUGE

3-WAY

PANEL VALVE

ADAPTER HOSE

TANK

Waste

3

New

1

New

2

New

SHOP AIR COUPLER

CONE PLUG

ADAPTER

QTY=2

CONE ADAPTER

VALVE

CLEAR REINFORCED

HOSE 12FT

Page 2

Page 4

Safety Precautions

WARNING: Failure to follow these precautions can result in serious injury or death.

• Your VCX Vacuum Coolant Exchanger was developed to provide you with years of trouble-free service in

accordance with the utilization of proper inspection and maintenance techniques. It is important to understand

this machine functions with its coolant cylinders either under pressure or vacuum, so it is imperative all cylinders

receive proper inspection to ensure the proper and safe operation of the equipment is maintained throughout its

life cycle.

• Read and understand the Operation Manual completely before operating this unit.

• Always wear proper skin protection when operating and maintaining this equipment.

• Always wear safety glasses when operating and maintaining this equipment.

• Before any VCX machine use it is required for the operator to visually inspect the coolant cylinders for defects

such as cracks, nicks, gouges, chips, impact marks, fractures, hairline cracks, crazing, severe discoloration,

cloudiness or hazing or other physical damage. VISUAL TUBE INSPECTION IS REQUIRED PRIOR TO EACH

MACHINE USE! IF ANY TUBES EXHIBIT ANY DEFECTS, THEY MUST BE REPLACED BEFORE MACHINE

OPERATION! FAILURE TO COMPLY MAY RESULT IN TUBE FAILURE AND POSSIBLE INJURY!

• Automotive cooling systems can be under pressure and extremely hot. Place a rag over the radiator cap during

removal to avoid injury. Use extreme caution when removing caps.

• Coolants are corrosive and poisonous to people and animals. Clean up any spills immediately.

• Do not allow waste coolant tank to overflow. Immediately clean up any coolant spills. Damage to the vehicle and

equipment can result from the corrosiveness of coolant.

• Continuous monitoring of the coolant exchange process is required.

• Unit is equipped with factory preset pressure regulator. Do not attempt pressure adjustment without RTI

Technical Support authorization.

• If cracks appear in the cylinders, hoses or adapters these parts must be replaced.

• If VCX unit tipped over, resulting in a fall of the machine onto any side, it is mandatory all

replaced immediately before the machine is placed back into service.

• If leaks occur at the bottom or top of the cylinders, contact RTI for troubleshooting instructions.

• The cylinders, hoses and adapters are plastic and rubber products and are in contact with oil and chemicals

which may lessen their durability. Therefore, when soiled, they should be cleaned with water and a mild

detergent. Caution: Do not clean with thinners, solvents or any other chemical cleaners.

• Only disassemble or reassemble unit parts when directed by an RTI representative.

• Take precautions to keep clothing, hair, hands, hoses, etc. away from all moving parts of the vehicle.

• Comply with local, state and federal regulations for fluid disposal.

• Material Safety Data Sheets (MSDS) must be obtained on all chemicals and placed in a shop file for reference.

These are available for down load and printing on the RTI web-site (www.rtitech.com). Go to TECHNICAL HELP

and look under Technical Bulletins.

coolant tubes be

CAUTION: Failure to follow the precautions as outlined in the operation manual can result

in damage to the engine, vehicle or equipment which will not be supported or

covered under warranty.

Page 3

Page 5

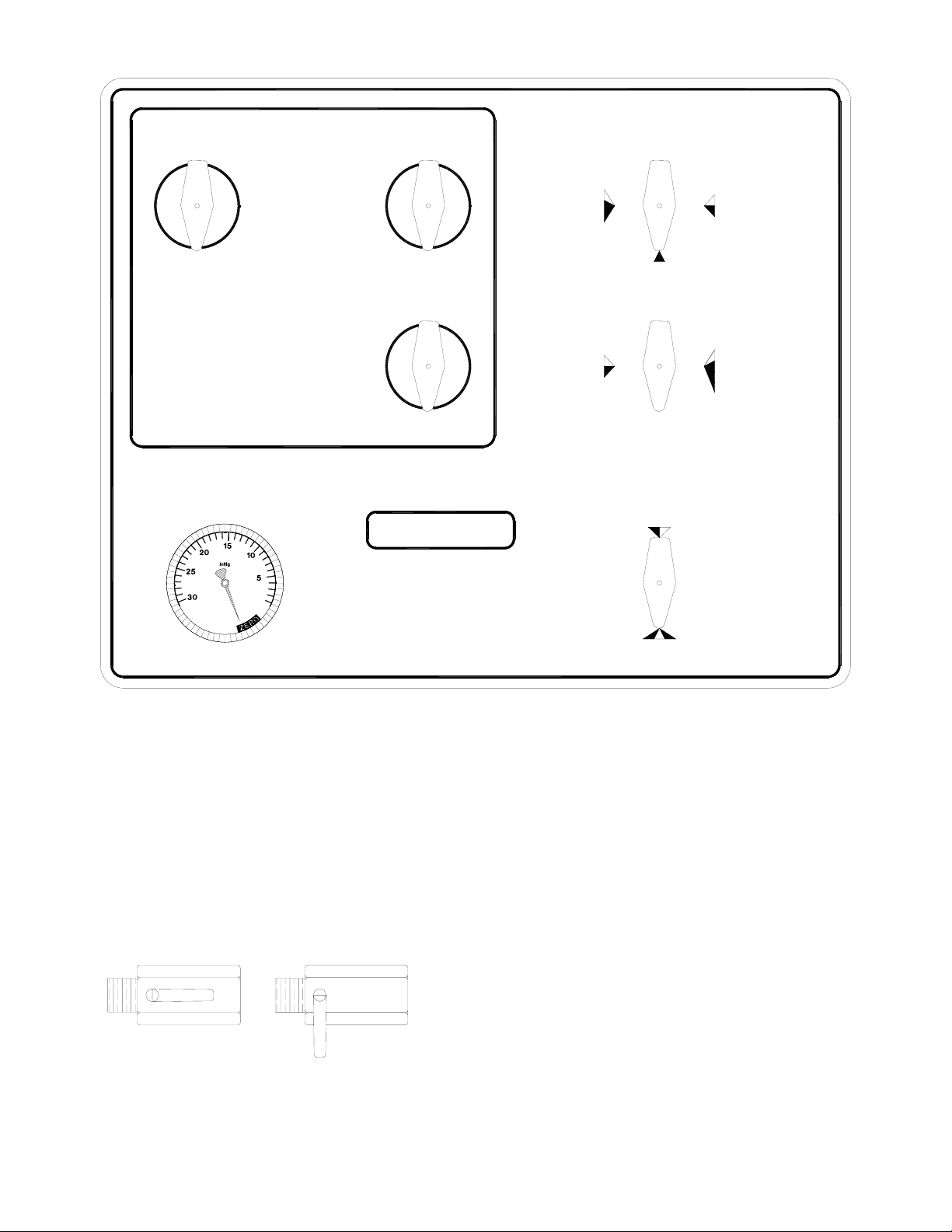

Home Position

NEW 3

ON

HOME

TURN ONE VALVE ON TO

SELECT NEW COOLANT SOURCE

VACUUM GAUGE

NEW 2

ON

HOME

NEW 1

ON

HOME

TURN ALL VALVES TO HOME

AFTER EVERY PROCEDURE

(PRESSURE)

EMPTY WASTE TANK

EMPTY NEW TANK

TOP OFF

EMPTY WASTE TANK

EMPTY RADIATOR

HOME

HOME

FILL NEW TANK

EMPTY NEW TANK

TOP OFF

(VACUUM)

FILL NEW TANK

EMPTY RADIATOR

FILL NEW TANK

FILL RADIATOR

EMPTY NEW TANK

TOP OFF

VCX-4

HOME

The above valve configuration is set before the VCX is connected to the shop air supply. This

is also the position that the valves are returned to after each procedure. To select a procedure

turn all of the valves to the colored triangle that corresponds with the desired procedure. While

performing certain functions the appropriate NEW tank valve must be set to the ON position.

Cone Adapter Valve

Valve Open Valve Closed

This illustration demonstrates the open and

closed position on the Cone Adapter Valve. The

closed position is 90 degrees clockwise from

center.

Page 4

Page 6

Fill New Tank through Hose

1. Turn all panel valves to the Home position.

2. Connect shop air to VCX Shop Air Coupler.

3. Turn the appropriate New Tank Valve to fill the corresponding tank. Note that New Tank 1

is used in the illustration shown below.

4. Turn the other panel valves to the Fill New Tank position as shown in the illustration below.

This orientation can also be obtained by positioning the panel valves toward the green

highlights closest to each valve.

4. Place the Cone Adapter, with the Adapter Hose attached, into the container of new

coolant. Open the Cone Adapter Valve to draw coolant into the New Coolant Tank.

5. Raise the hose out of the container of new coolant when the desired fluid level is reached

in the New Coolant Tank.

6. Close the Cone Adapter Valve.

7. Turn all valves to the Home position when done.

Note: DO NOT OVERFILL.

3

New

Waste

New

2

New

1

Clear Hose

Adapter Hose

NEW 3

ON

HOME

TURN ONE VALVE ON TO

SELECT NEW COOLANT SOURCE

VACUUM GAUGE

Cone Adapter

NEW 2

EMPTY WASTE TANK

ON

HOME

NEW 1

EMPTY WASTE TANK

ON

HOME

TURN ALL VALVES TO HOME

AFTER EVERY PROCEDURE

VCX-4

(PRESSURE)

EMPTY NEW TANK

TOP OFF

EMPTY RADIATOR

HOME

HOME

FILL NEW TANK

EMPTY NEW TANK

TOP OFF

HOME

(VACUUM)

FILL NEW TANK

EMPTY RADIATOR

FILL NEW TANK

FILL RADIATOR

EMPTY NEW TANK

TOP OFF

50/50 Mix Water/Coolant

Page 5

Page 7

Empty Radiator

1. Run the vehicle with the heater turned on to bring the engine to operating temperature.

Turn the engine off.

2. Turn all panel valves to the Home Position as shown on page 4.

3. Connect shop air to VCX Shop Air Coupler.

4. Turn all panel valves to the Empty Radiator position as shown in the illustration below.

This orientation can also be obtained by positioning the panel valves toward the black

highlights closest to each valve.

5. Insert the Adapter Hose into the Cone Adapter. Insert end of Adapter hose into overflow

tank. Turn the Adapter Hose Valve to the open position to withdraw the coolant.

Waste

3

New

1

New

2

New

NEW 3

HOME

TURN ONE VALVE ON TO

SELECT NEW COOLANT SOURCE

VACUUM GAUGE

Cone Adapter

Valve

Adapter Hose

NEW 2

(PRESSURE)

EMPTY WASTE TANK

EMPTY NEW TANK

HOME

NEW 1

HOME

ON

EMPTY WASTE TANK

ON

EMPTY RADIATOR

TOP OFF

HOME

HOME

FILL NEW TANK

EMPTY NEW TANK

TOP OFF

HOME

ON

TURN ALL VALVES TO HOME

AFTER EVERY PROCEDURE

VCX-4

(VACUUM)

FILL NEW TANK

EMPTY RADIATOR

FILL NEW TANK

FILL RADIATOR

EMPTY NEW TANK

TOP OFF

Clear Hose

Radiator

Overflow

Water

Pump

Engine

Block

Heater

Core

Page 6

Page 8

Empty Radiator continued

6. Connect the Adapter Hose to the radiator overflow port to relieve radiator pressure. Watch

the System Vacuum Gauge and make sure the vacuum level increases and then stays

greater than 20 InHg. Carefully remove radiator cap. Use a shop rag over the cap when

removing to avoid injury in case there is still pressure. Remove the Adapter Hose.

7. Place VCX Cone Adapter snugly into the radiator spout. Do not force the Cone Adapter

into the spout, the suction

pressure from the VCX should

Waste

3

New

1

New

2

New

Clear Hose

PINCH

HOSE

Radiator

Hose

Cone

Plug Adapter

Overflow

Water

Pump

Engine

Block

secure it adequately. Verify that

the Cone Adapter Valve is in the

open position.

8. Start the engine once fluid

starts to move through the

clear hose and into the VCX

Waste Coolant Tank. Verify

that the System Vacuum

gauge reads at least 22

InHg.

9. Once the waste coolant

from the vehicle stops

flowing through the clear

hose, turn all of the panel

valves to Home Position

and turn the engine off.

DO NOT REMOVE CONE ADAPTER FROM THE RADIATOR!

Note: In some cases it may be necessary to pinch off the hose going from the radiator

neck to the overflow container. This is only necessary when the vacuum leaks

through this hose. The hose should be opened only after the Fill Radiator

procedure.

WARNING

Do not overfill the

Waste Tank

Page 7

Page 9

C

Special Hookups

Seal Tight Radiator

1. Insert the Adapter Hose into the end of the Cone Plug Adapter.

2. Place the Cone Adapter snugly into the radiator, coiling the excess length of Adapter Hose at

the bottom.

3. Follow the Empty Radiator procedure steps 1-9.

More Effective Setup for Empty Radiator

During the Empty Radiator procedure clamp off the upper radiator hose and follow steps 1-9 of the

Empty Radiator section.

PINCH

HOSE

Radiator

Hose

Adapter Seal

1. In some cases it may be necessary to cut up to 0.75" off

of the Cone Plug Adapter. This is only necessary when a

tight seal can not be created due to bottoming out against

the inside of a shallow radiator neck.

2. Take care to cut a clean edge free of loose debris.

Overflow

PINCH

HOSE

ut back

0.750

Page 8

Page 10

Fill Radiator

Fill Radiator

1. Turn all panel valves to the Home position.

2. Connect shop air to VCX Shop Air Coupler.

3. Turn all panel valves to the Fill Radiator position shown in the illustration below, this orientation can

also be obtained by positioning the panel valves toward the magenta highlights closest to each valve.

Verify that the Cone Adapter Valve is open.

4. Turn the appropriate New Tank Valve to fill from the corresponding tank. Note that New Tank 1 is

used in the illustration shown below.

5. New coolant is automatically pulled out of the VCX New Coolant Tank and into the vehicle radiator

through the clear hose.

NOTE: IF THE CONE ADAPTER BECOMES DISLODGED BEFORE YOU CAN BEGIN THIS

PROCESS YOU MUST RERUN THE EMPTY RADIATOR FUNCTION, WITHOUT STARTING

THE VEHICLE, TO REGAIN THE VACUUM NEEDED TO FILL THE VEHICLE COOLANT

SYSTEM.

6. Once the coolant stops moving through the clear hose turn all of the panel valves back to the Home

position and remove the Cone Adapter from the radiator.

7. Turn all valves to the Home position.

8. Close the Cone Adapter Valve.

Waste

3

New

1

New

2

New

Clear Hose

Radiator

Hose

NEW 3

ON

HOME

TURN ONE VALVE ON TO

SELECT NEW COOLANT SOURCE

VACUUM GAUGE

NEW 2

EMPTY WASTE TANK

ON

HOME

NEW 1

EMPTY WASTE TANK

ON

HOME

TURN ALL VALVES TO HOME

AFTER EVERY PROCEDURE

VCX-4

Engine

Block

(PRESSURE)

EMPTY NEW TANK

TOP OFF

EMPTY RADIATOR

HOME

HOME

FILL NEW TANK

EMPTY NEW TANK

TOP OFF

HOME

(VACUUM)

FILL NEW TANK

EMPTY RADIATOR

FILL NEW TANK

FILL RADIATOR

EMPTY NEW TANK

TOP OFF

PINCH

HOSE

Cone

Plug Adapter

Overflow

Water

Pump

Page 9

Page 11

Top Off

1. Turn all panel valves to the Home position.

2. Connect shop air to VCX Shop Air

Coupler.

3. Turn the Cone Adapter Valve to the

closed position.

4. Turn the appropriate New Tank Valve to

fill from the corresponding tank. Note

that New Tank 1 is used in the

illustration shown.

5. Turn all panel valves to the Top Off

position as shown in the illustration. This

orientation can also be obtained by

positioning the panel valves toward the

blue highlights closest to each valve.

6. Open the Cone Adapter Valve to fill the

radiator and overflow to the proper

levels.

7. Turn all valves to the Home position.

8. Close the Cone Adapter valve when

done.

9. Replace radiator and overflow caps.

NEW 3

ON

HOME

TURN ONE VALVE ON TO

SELECT NEW COOLANT SOURCE

VACUUM GAUGE

NEW 2

EMPTY WASTE TANK

ON

HOME

NEW 1

EMPTY WASTE TANK

ON

HOME

TURN ALL VALVES TO HOME

AFTER EVERY PROCEDURE

VCX-4

(PRESSURE)

EMPTY NEW TANK

TOP OFF

EMPTY RADIATOR

HOME

HOME

FILL NEW TANK

EMPTY NEW TANK

TOP OFF

HOME

(VACUUM)

FILL NEW TANK

EMPTY RADIATOR

FILL NEW TANK

FILL RADIATOR

EMPTY NEW TANK

TOP OFF

Flush Radiator

1. The New Coolant Tank needs to be filled with water. See Empty Waste Tank and Fill New Tank

procedures.

2. The Empty Radiator function must be run to completion.

3. Run the Fill Radiator procedure.

4. The Empty Radiator function must be run again to extract all of the water inside the cooling system.

5. Repeat steps 3 and 4 until the desired results are achieved. Once completed new coolant needs to

be added to the vehicle system.

Page 10

Page 12

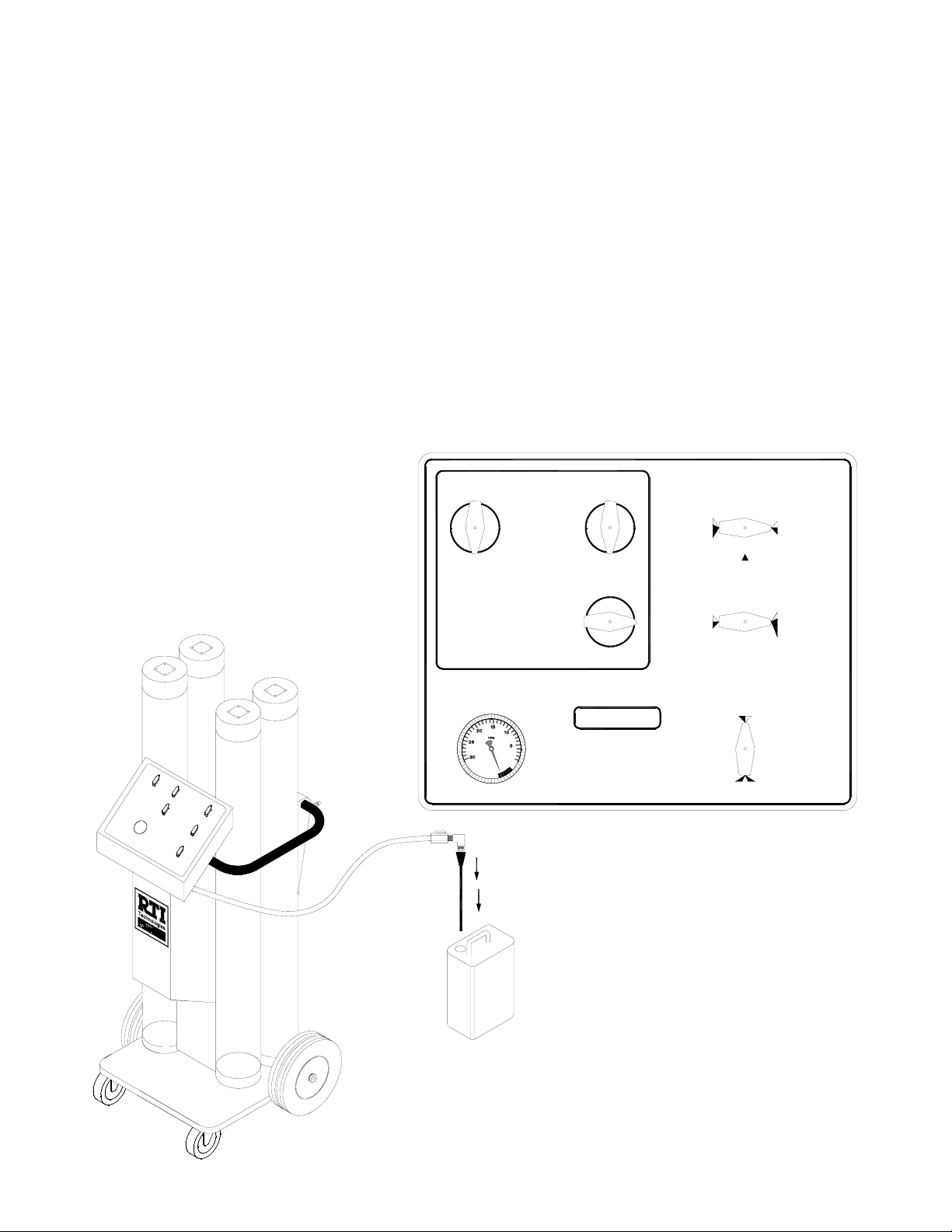

Empty Waste Tank

1. Turn all panel valves to the Home position.

2. Connect shop air to VCX Shop Air Coupler.

3. Close Cone Adapter Valve.

4. Turn all panel valves to the Empty Waste Tank position shown in the illustration below. This

orientation can also be obtained by positioning the panel valves toward the red highlights closest to

each valve.

5. Place the end of the clear hose into a bulk waste container and open the Cone Adapter Valve.

6. Waste coolant will begin leaving the VCX from the Waste Coolant Tank through the clear hose. Be

cautious not to spill waste coolant onto the floor as th e hose may “jump” when the Waste Coolant

Tank is nearing empty. Clean up any spills that may occur immediately.

7. Once the Waste Coolant Tank is empty, close the Cone Adapter Valve and turn all valves to the

Home position.

Waste

3

New

1

New

2

New

Clear Hose

NEW 3

ON

HOME

TURN ONE VALVE ON TO

SELECT NEW COOLANT SOURCE

VACUUM GAUGE

NEW 2

ON

HOME

NEW 1

ON

HOME

TURN ALL VALVES TO HOME

AFTER EVERY PROCEDURE

VCX-4

Cone Adapter

Valve

(PRESSURE)

EMPTY WASTE TANK

EMPTY NEW TANK

TOP OFF

EMPTY WASTE TANK

EMPTY RADIATOR

HOME

HOME

FILL NEW TANK

EMPTY NEW TANK

TOP OFF

HOME

(VACUUM)

FILL NEW TANK

EMPTY RADIATOR

FILL NEW TANK

FILL RADIATOR

EMPTY NEW TANK

TOP OFF

Bulk Waste Container

Page 11

Page 13

Empty New Tank

1. Turn all panel valves to the Home position.

2. Connect shop air to VCX Shop Air Coupler.

3. Close Cone Adapter Valve.

4. Turn the appropriate New Tank Valve to empty from the corresponding tank. Note that New Tank 1

is used in the illustration shown below.

5. Turn all panel valves to the Empty New Tank position shown in the illustration below. This orientation

can also be obtained by positioning the panel valves toward the blue highlights closest to each valve.

6. Place the end of the clear hose into a bulk storage container and open the Cone Adapter Valve.

7. Coolant will begin leaving the VCX from the New Coolant Tank through the clear hose. Be cautious

not to spill coolant onto the floor as the hose may “jump” when the New Coolant Tank is nearing

emptiness. Clean up any spills that may occur immediately.

8. Once the Waste Coolant Tank is empty, close the Cone Adapter Valve and turn all valves to the

Home position.

Waste

3

New

1

New

2

New

Clear Hose

NEW 3

ON

HOME

TURN ONE VALVE ON TO

SELECT NEW COOLANT SOURCE

VACUUM GAUGE

NEW 2

EMPTY WASTE TANK

ON

HOME

NEW 1

EMPTY WASTE TANK

ON

HOME

TURN ALL VALVES TO HOME

AFTER EVERY PROCEDURE

VCX-4

Cone Adapter

Valve

(PRESSURE)

EMPTY NEW TANK

TOP OFF

EMPTY RADIATOR

HOME

HOME

FILL NEW TANK

EMPTY NEW TANK

TOP OFF

HOME

(VACUUM)

FILL NEW TANK

EMPTY RADIATOR

FILL NEW TANK

FILL RADIATOR

EMPTY NEW TANK

TOP OFF

Bulk Waste Container

Page 12

Page 14

Troubleshooting

Problem Solution

Vacuum becomes weak Inside of the VCX, there is a venturi vacuum generator that

may have collected debris during the operation of the unit.

If this occurs, the vacuum will become weak resulting in a

lower vacuum reading on the System Vacuum gauge and poor

performance. Remove the venturi from the line and blow shop

air through it. Use the Parts Identification (page 14) to locate

the venturi. Reconnect to correct lines when done.

There may be a vacuum leak at either the top or bottom

sealing point on the tanks. Fill the tank to the top with water

and turn all valves to the Home position. Close the Cone

Adapter Valve and turn all valves to the Empty (leaking tank)

position. Check for leaks and follow guidelines from the

Leakage section.

Leakage Debris may have collected at the bottom of the tank.

Disassemble tank and clean the base of tank. Take care when

reassembling not to over tighten the hex nut (use 60 lb/in

torque wrench). Do not use pneumatic or power tools.

Over time, the o-ring at the bottom or top of the cylinder may

become worn. Inspect and replace if needed. See part break

down on left.

Tank Overflow If fluid is ever filled to the top of the tank while using the unit

there is a device that will release excess to the inside of the

cabinet.

External Clear Hose Using the VCX to remove coolant from a vehicle creates high

temperatures throughout the unit particularly where the clear

hose connects to the Cone Adapter.

Repeated exposure to these temperatures may cause

deterioration of the hose. If possible cut affect area off and

reconnect Cone Adapter. If replacement of the hose is

required call RTI.

Page 13

Page 15

Parts Identification

P/N Description

1 060-81693-00 Top Cylinder Plate

2 060-81692-00 Bottom Cylinder Plate

3 060-81695-00 Fiberglass Tube (52 inches)

4 035-81433-00 Tank Level Decal

5 028-80465-00 Large O-Ring

6 026-80238-00 Vacuum Gauge 30"-0 PSIG

7 022-80028-00 Ball Valve 3-Way 1/4 FPT (BHD)

8 028-80228-00 Small O-Ring

9 022-80123-00 2-way dual valve

10 022-80153-00 Valve Relief 1/4 MPT X 1/4 FPT

11 370-80095-00 Clear Hose Assy

12 026-80197-00 Vacuum Pump (Venturi)

10

3

13 370-80075-00 Pressure Regulator

1

1/4 FPT X 1/4 FPT (BHD)

New

Waste

2

New

1

New

9

6

7

14 060-81215-00 Cone Plug Adapter

3

15 370-80168-00 Cone Adapter Valve Assy

4

16 370-80095-00 Adapter Hose

8

16

14

15

1

5

3

2

11

Page 14

Page 16

Flow

a ste

3Ne

W

w New12

N e w

Page 15

Page 17

This Page Intentionally Blank

Page 16

Loading...

Loading...