MAHLE RTI TX600 User Manual

OPERATION

&

MAINTENANCE

MANUAL

TX600

RTI TECHNOLOGIES, INC.

4075 East Market Street

York, PA 17402

Manual P/N 035-80118-00 (Rev B)

! TABLE OF CONTENTS !

TX600

Before Using Page 2

Safety Precautions Page 3

Recycle Mode Of Operation Page 5

Oil Drain & Rapid Air Purge System Procedure Page 8

How The TX600 Works Page 10

Scheduled Maintenance Page 12

Combo Filter Maintenance Page 12

Problems & Solutions Page 13

Flow Diagram Page 15

Circuit Diagram Page 16

TX600 Assembly Instructions Page 17

CONGRATULATIONS: You have purchased one of the finest Recovery and Recycling

Machines available at any price.

Save shipping carton for use in returning the TX600 to the

manufacturer in the event that service would be required.

RTI Technologies, Inc.

BEFORE USING THE TX600

Check for any shipping damage. Place a claim with carrier if damage is discovered.

DO NOT USE A DAMAGED UNIT.

Mount Wheels and Handle, following the assembly procedure provided in the Appendix and with

the Accessory Kit.

Complete and return the Warranty Card within 90 days to activate technical support service and

warranty coverage.

Warranty claims can not be honored without this warranty card on file.

The TX600 should not be operated or serviced by any person who has not read all the contents of

this manual. Failure to read and comply with these instructions or any one of the limitations noted

herein can result in serious injury and/or property damage.

These general instructions deal with the normal operation and maintenance situations encountered

with the TX600. The instructions should not be interpreted to anticipate every possible contingency.

It is the responsibility of the owner/user to operate the TX600 in accordance with all specifications

and laws which may apply.

The following pages contain rules for safe operation of the TX600. Taking precedence over any

specified rule listed herein, however, is the most important rule of all:

"USE COMMON SENSE"

A few minutes spent reading these instructions can make an operator aware of dangerous practices

to avoid and precautions to take for his own safety and the safety of others.

A regular schedule of inspection of the TX600 should be established and records maintained. with

special attention given to Hoses and Filters.

Page 2

RTI Technologies, Inc.

SAFETY PRECAUTIONS

! Recover and Recycle R12 or R134a refrigerant only.

! Wear safety glasses and protective gloves. Refrigerant has a very low boiling point and can

cause frostbite.

! Follow the TX600 operating procedures sequentially to avoid prematurely disconnecting hoses

or opening valves which may release refrigerant to the atmosphere.

! Do not expose the TX600 to moisture or operate in wet areas.

! Use the TX600 in locations with mechanical ventilation that provides at least four air changes

per hour or locate the unit 18 inches above the floor.

! Hoses used with the TX600 must have shutoff devices within 12 inches of the connection point

to the system being serviced to minimize the introduction of Non-condensable Gas (Air) into the

TX600 and the release of refrigerant when being disconnected.

! Disconnect power before performing any maintenance or service on the TX600.

! Avoid using an extension cord with the TX600. If necessary, use a good condition, UL listed,

3-wire grounded, #14 AWG extension cord of the shortest possible length.

! Connect the TX600 to a properly protected, grounded receptacle. Do not over load the circuit.

! Disconnect Power Cord from power source while connecting the OFP (Overfill Protection)

Device to avoid bodily injury due to electrical shock. Do not force plug into OFP Device.

Look at pins in plug and align them with sockets on OFP Device.

NEVER TURN THE CYLINDER UP-SIDE-DOWN.

DO NOT CONNECT THE TX600 TO THE LIQUID SIDE OF

ANY A/C SYSTEM WITH A CAPACITY GREATER THAN 4

LBS.

REFRIGERANT IN A/C SYSTEMS HAVING LARGER

CAPACITIES MUST BE RECOVERED FROM THE VAPOR

SIDE ONLY.

FAILURE TO FOLLOW THE ABOVE MAY CAUSE THE TX600

COMPRESSOR TO FAIL AND VOID THE WARRANTY.

Page 3

RTI Technologies, Inc.

L CAUTION 7

Avoid breathing refrigerant or lubricant vapor or mist.

Exposure may irritate eyes, nose and throat.

If accidental system discharge occurs, ventilate work area before resuming service.

Additional health and safety information may be obtained from refrigerant and

lubricant manufacturers.

Special Considerations with R134a

R134a has been shown to be nonflammable at ambient temperature and

atmospheric pressure. However, tests under controlled conditions have indicated

that, at pressures above atmospheric and with air concentrations greater than 60%

by volume, R134a can form combustible mixtures.

While it is recognized that an ignition source is also required for combustion to

occur, the presence of combustible mixtures is a potentially dangerous situation and

should be avoided.

Under no circumstances should any equipment be pressure tested or leak tested

with Air/R134a mixtures. Do not use compressed air (shop air) for leak detection

in R134a systems.

Page 4

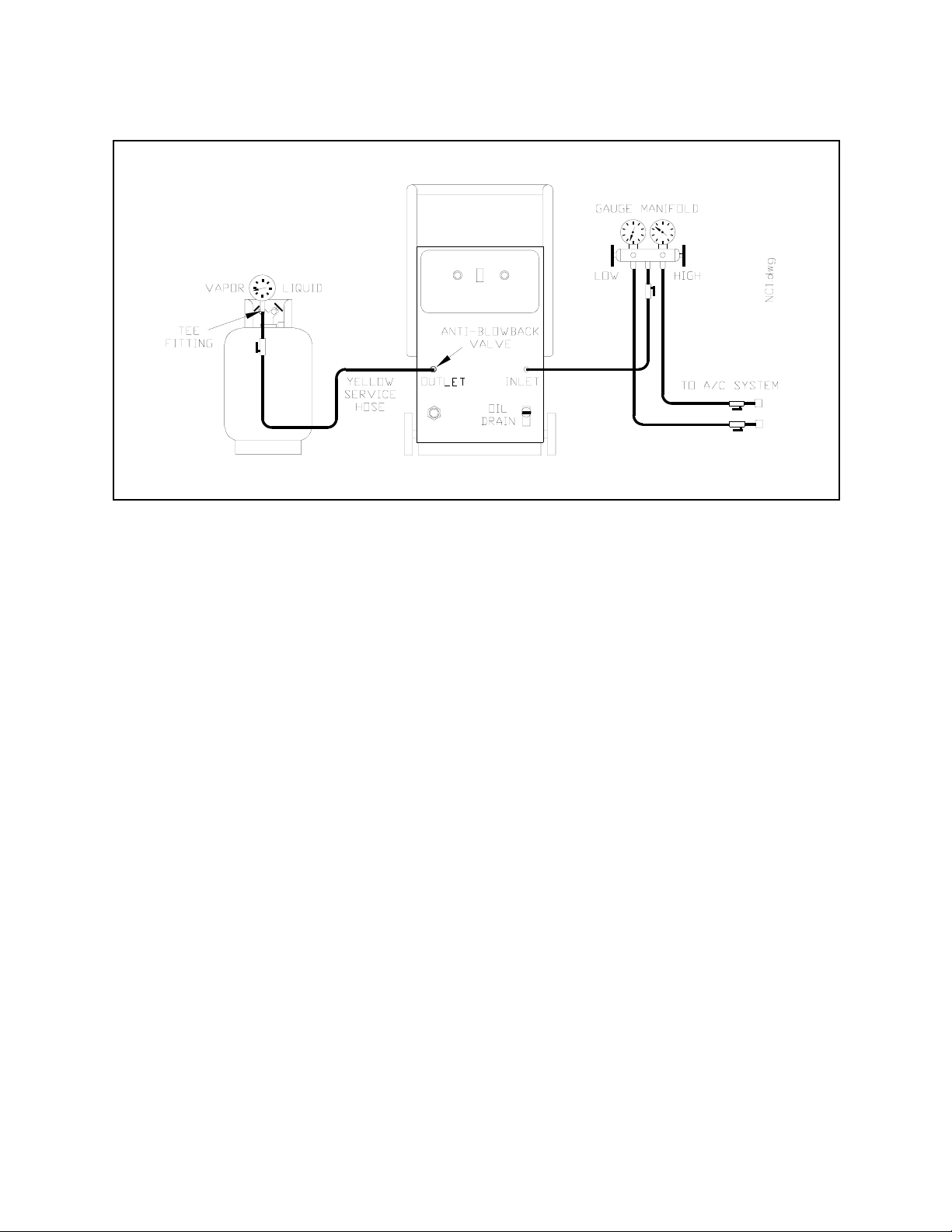

RECYCLE MODE (Refer To Figure I)

RTI Technologies, Inc.

FIGURE I Connections For Recycle Mode

Install Tee Fitting on VAPOR Port of Refrigerant Cylinder. Remove Valve Core, if any, from Tee

Fitting.

Connect Pressure Gauge on branch of Tee Fitting.

Connect end of Yellow Service Hose with Shut-off Valve to Tee Fitting. Install Anti-Blowback

Valve on other end of hose and connect to Outlet of TX600 (Refer to Figure I). Leave Hose

connected to Outlet unless TX600 repair or transport is required.

Connect Yellow Service Hose from Inlet Port of TX600 to center port of Gauge Manifold. Shut-off

Valve must be on end connected to Gauge Manifold (Refer to Figure I). Leave Hose connected to

Inlet unless TX600 repair or transport is required.

WARNING... Refrigerant Cylinder must have an Overfill Protection (OFP) Device.

Disconnect Power Cord from power source while connecting the OFP

(Overfill Protection) Device to avoid bodily injury due to electrical shock.

Connect Yellow Cable from rear of TX600 to OFP Device on Refrigerant Cylinder. A receptacle

on the lower rear of the TX600 can be used to store the Plug when not connected to OFP Device on

Cylinder during non-use to prevent debris from collecting inside the housing.

CAUTION... Do not force plug into OFP Device. Look at pins in plug and align

them with sockets on OFP Device.

Attach High and Low Gauge Manifold Hoses to A/C system per manufacturer's instructions.

Page 5

Loading...

Loading...