Page 1

OPERATION

&

MAINTENANCE

MANUAL

TC670

Refrigerant Management Center

(Convertible For Use With R12 or R134a)

RTI TECHNOLOGIES, INC.

4075 East Market Street

York, PA 17402

Manual P/N 035-80342-02

Page 2

TC670

CONVERTIBLE

RECYCLING MACHINE

This Recycling Machine was

manufactured by RTI in compliance

with all applicable Underwriters

Laboratories (UL) and Society of

Automotive Engineers (SAE)

Standards and Specifications for

Refrigerant Recycling Equipment.

Your machine is initially configured

to recycle R12 or R134a.

An RTI Retrofit Kit is available for

field conversion of this machine to

recycle the alternate refrigerant for

which it is now configured. This kit

includes complete instructions, labels,

filters, hoses with service couplers, and

special tools required to make the

conversion.

Once converted by an RTI Authorized

Representative, a new Serial Label

(included in the kit) will be affixed to

the machine. This Serial Label will

certify that the machine is then in

compliance with all SAE and UL

Standards and Specifications for

Equipment to recycle the alternate

refrigerant.

Page 3

TABLE OF CONTENTS

TC670

Quick Reference Guide ........................... 1

Start-Up ....................................... 3

Safety Precautions ............................... 4

Filling the Charging Cylinder ....................... 6

Recover/Recycle................................. 8

Oil Drain & Air Purge ............................ 10

Deep Vacuum................................... 11

Hose Evacuation................................. 12

Charge/High Side................................ 13

Scheduled Maintenance & Filter Maintenance ......... 15

Problems & Solutions ............................ 16

Flow Diagram................................... Appendix

Circuit Diagram ................................. Appendix

R134a Cylinder Adapter Instructions ................. Appendix

CONGRATULATIONS: You have pur chased one of the finest Recovery, Recycling, and

Charging Machines available at any price.

Fill out and return the Warranty Card within 90 days to activate

warranty and free lifetime technical support.

Page 4

RTI Technologies, Inc.

February 5, 1996

Page 1

Page 5

RTI Technologies, Inc.

February 5, 1996

Page 2

Page 6

RTI Technologies, Inc.

START-UP INSTRUCTIONS

1) Check for any shipping damage. Place a claim with carrier if damage is discovered.

2) Complete and return the War ranty Card to activate Technical Support and Warranty Coverag e.

Warranty claims can not be honored without this warranty card on file.

BEFORE USING THE TC670

Check for any shipping damage. Place a claim with carrier if damage is discovered.

DO NOT USE A DAMAGED UNIT.

Complete and return the Warranty Card to activate technical support service and warranty coverage.

Warranty claims can not be honored without this warranty card on file.

The TC670 should not be operated or serviced by any person who has not read all the contents of

this manual. Failure to read and comply with these instructions or any one of the limitations noted

herein can result in serious injury and/or property damage.

These general instructions describe normal operation and maintenan ce situations encountered with

the TC670. The instructions should not be interpreted to anticipate every possible contingency.

It is the responsibility of the owner/user to operate the TC670 in accordance with all specificat ion s

and laws which may apply.

The following pages contain rules for safe operation of the TC670. Taking precedence over any

specified rule listed herein, however, is the most important rule of all:

"USE COMMON SENSE"

A few minutes spent reading these instructions can make an operator aware of dangerous practices

to avoid and precautions to take for his own safety and the safety of others.

A regular schedule of inspection of the TC670 should be established and records maintained with

special attention given to Hoses, Compressor Oil Level, Moisture Indicator, and Filters.

February 5, 1996

Page 3

Page 7

RTI Technologies, Inc.

SAFETY PRECAUTIONS

! Recover, Recycle, and Charge only the refrigerant for which the machine is configured.

! Wear safety glasses and protective gloves. Refrigerant has a very low boiling point and can

cause frostbite.

! Follow the TC670 operati ng procedures sequentially to avoid prematurely disconnecting hoses

or opening valves which may release refrigerant to the atmosphere.

! Do not expose the TC670 to moisture or operate in wet areas.

! Use the TC670 in locations with mechanical ventilation that provides at least four air changes

per hour.

! Hoses used with the TC670 must have shutoff devices within 12 inches of the connection point

to the system being serviced to minimize the introduction of Non-condensable Gas (Air) into

the TC670 and the release of refrigerant when being disconnected.

! Disconnect power before performing any maintenance or service on the TC670.

! Avoid using an extension cord with the TC670. If ne cessary, use a good condition, UL listed,

3-wire grounded, #14 AWG extension cord of the shortest possible length.

! Connect the TC670 to a properly protected, grounded receptacle. Do not over load the cir cuit.

! Do not allow the TC670 to remain unattended in the Charge Mode with power On. Th e Charg e

Cylinder Heater will be energized creating a high pressure condition.

NEVER TURN THE CYLINDER UP-SIDE-DOWN.

DO NOT CONNECT THE TC670 TO THE LIQUID SIDE OF ANY

A/C SYSTEM WITH A CAPACITY GREATER THAN 4 LBS.

REFRIGERANT IN A/C SYSTEMS HAVING LARGER CAPACITIES

MUST BE RECOVERED FROM THE VAPOR SIDE ONLY.

NEVER CONNECT THE TC670 TO THE LIQUID PORT OF A

CYLINDER OF REFRIGERANT TO FILL THE TC670 CHARGE CYLINDER.

FAILURE TO FOLLOW THE ABOVE MAY CAUSE THE TC670 COMPRESSOR TO

FAIL AND VOID THE WARRANTY.

February 5, 1996

Page 4

Page 8

RTI Technologies, Inc.

i

i CAUTION T

ii

Avoid breathing refrigerant or lubricant vapor or mist.

Exposure may irritate eyes, nose and throat.

If accidental system discharge occurs, ventilate work area before resuming

service.

Additional health and safety information may be obtained from refrigerant and

lubricant manufacturers.

Special Considerations with R134a

R134a has been shown to be nonflammable at ambient temperature and

atmospheric pressure. Howev er, tests under controlled conditions have indicated

that, at pressures above atmospheric and with air concentrations greater than 60%

by volume, R134a can form combustible m ixtures.

While it is recognized that an ignition source is also required for combustion to

occur, the presence of combustible mixtures is a potentially dangerous situation

and should be avoided.

Under n o c ircumstances s hould a ny e quipment b e p ressure t ested o r l eak

tested w ith A ir/R134a m ixtures. D o n ot u se c ompressed a ir ( shop a ir) f or l eak

detection in R134a systems.

February 5, 1996

Page 5

Page 9

RTI Technologies, Inc.

FILLING THE CHARGING CYLINDER

A/C Systems requiring service often do not ha ve a fu ll charge of refrig erant. To avoid unnecessary

repositioning of hoses it is recom men ded that the TC670 be filled until about 3 pounds of liquid

refrigerant can be seen in the Charging Cylinder Sight Glass. The Sight Glass is visible through a

slotted opening on the front of the TC670.

Figure 1 Filling the Cylinder

To fill the TC670 Charge Cylinder, refer to Figure 1 and follow these steps:

1. Connect the Low Side Blue Hose to the VAPOR port of a cylinder of new or recycled

refrigerant. An adapter is provided with the TC670 (R134a) which permits the Field Service

Coupler to be attached to the .500 ACME fitting on the cylinder of refriger an t (See instruction

sheet in Appendix).

If the cylinder has two ports, observe that the embossed marking on the cylinder knob says

VAPOR or GAS. Do not rely on color coding of the knobs on the valves.

DO NOT CONNECT TO THE LIQUID VALVE.

DO NOT TURN THE CYLINDER UP-SIDE-DOWN.

INTRODUCTION OF LIQUID INTO THE TC670 MAY DAMAGE THE

COMPRESSOR AND VOID THE WARRANTY.

February 5, 1996

Page 6

Page 10

RTI Technologies, Inc.

2. Press top (ON) of rocker switch marked RECOVER/RECYCLE.

The TC670 will recover and recy cle refrigera nt into the Charging Cy linder. Observe the liquid

refrigerant level rise in the Charging Cylinder Sight Glass and when at approximately 3 lbs.

close the valve on the refrigerant cylinder.

HINT: Heating of the cylinder of refrigerant with an RTI Heat Belt (P/N 026-80092-00)

will speed the recovery process.

Allow the TC670 to continue running until the Low Side Gauge shows a vacuum. This will

evacuate the Blue Hose.

3. Press bottom (OFF) of rocker switch marked RECOVER/RECYCLE.

... NOTE ...

As ref rigerant is processed by the TC670, temperature variations can cause

vapor to change to liquid which may temporarily settle in various internal

components.

If a known amount of refriger ant has b een introduced into the TC670 it may

not all be seen in the Charging Cylinder Sight Glass.

This is normal and nothing to be concerned about. Refrigerant has no t been

lost.

The sight glass does not indicate the am ount of refrigerant recovered.

It is only accurate for determining the amount of refrigerant charg ed out to

the vehicle A/C System while in the Charge Mode of operation.

February 5, 1996

Page 7

Page 11

RECOVER/RECYCLE

RTI Technologies, Inc.

Figure 2 Recover/Recycle

To Recover/Recycle, refer to Figure 2 and follow these steps:

1. Attach Red and Blue Hoses to the A/C system per the vehicle manufacturer's instructions.

Note For R134a Machines

Field Service Couplings on the ends of Service Hoses are of a special design.

The valves have LEFT HAND threads which makes operation opposite to that of others.

To Close... Turn Counter-clockwise

To Open... Turn Clockwise

The valves MUST BE CLOSED before connecting or disconnecting Field Service Couplings.

2. Open High and Low Gauge Valves.

3. Open Red and Blue Hose Valves.

4. Press top (ON) of rocker switch marked RECOVER/RECYCLE.

February 5, 1996

Page 8

Page 12

RTI Technologies, Inc.

The TC670 will automatically recover and recycle refrigerant from the A/C System until a

vacuum is sensed. This vacuum level can be seen on the Low Side Gauge.

!!!! DO NOT TURN THE TC670 OFF OR DISCONNECT HOSES !!!!

A small quantity of Liquid refrigerant will probably still remain in the A/C System. This can

be detected by observing an increasing pressure reading on the Low Side Gauge.

As pressure increases to a preset level, the TC670 will automatically cycle on and off to

continue recovering refrigerant.

Allow this automatic sequence to repeat until the va cuum le v e l re mains c onstant fo r at le ast 2

minutes.

... NOTE ...

Several audible changes may be heard during the recovery and recycling

process.

Refrigerant flow through check valves causes a "sizzle-type" sound.

These changing "noises" are normal and nothing to be concerned about.

5. Close Red and Blue Hose Valves.

6. Close High and Low Gauge Valves.

7. Press bottom (OFF) of rocker switch marked RECOVER/RECYCLE.

PURGE REQUIRED OR CYLINDER FULL LIGHT:

This Light will illuminate if either...

1) The Charging Cylinder has filled to capacity: Go to Page 13

2) Pressure on the Purge Gauge approaches 250 psig: Go to Page 10

February 5, 1996

OR

Page 9

Page 13

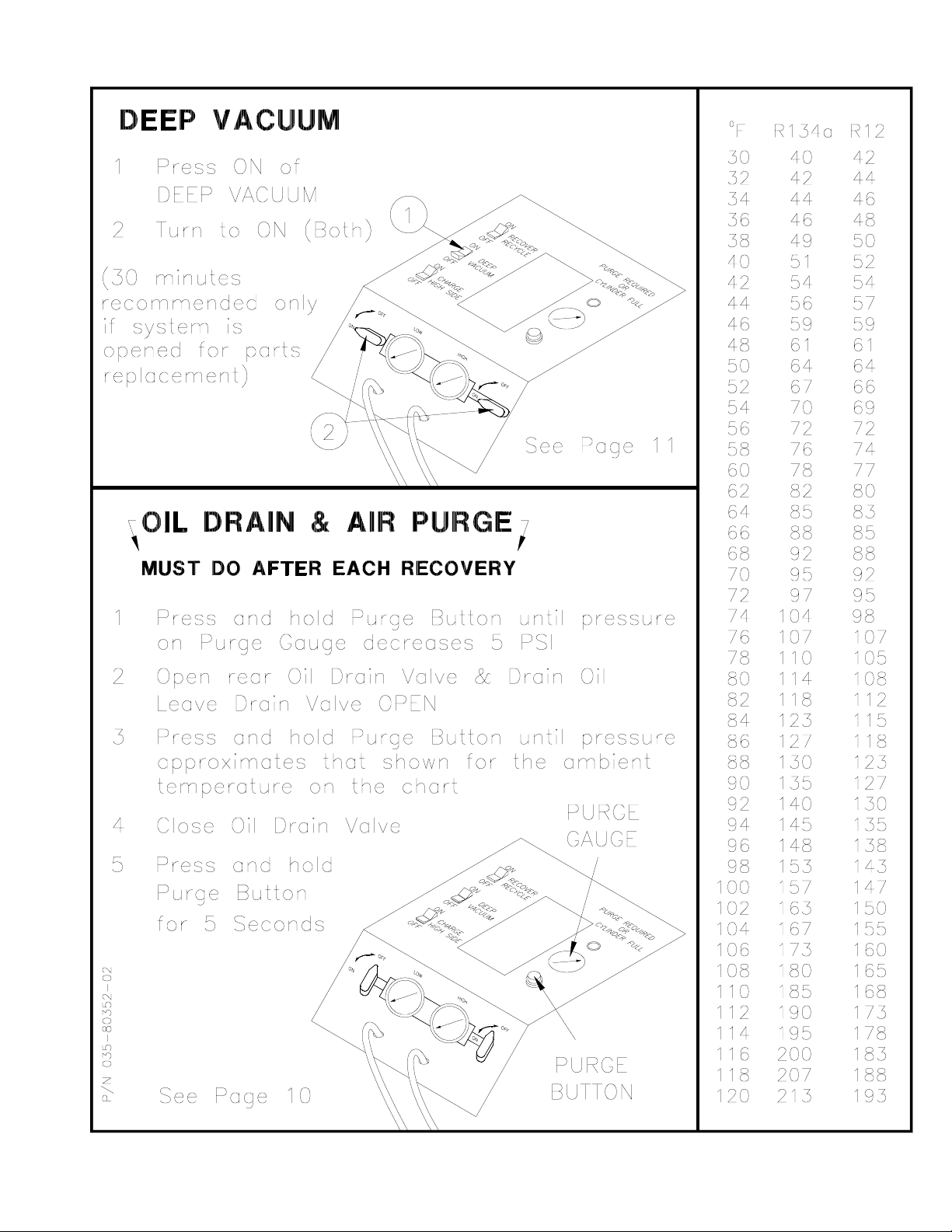

OIL DRAIN & AIR PURGE

Oil and Non-condensable Gas (Air) are separated from

the recovered refrigerant and MUST be removed

following EACH recycling procedure as follows:

1. MOMENTARILY turn the Purge Valv e (To the

right of the Purge Chart) clockwise and hold until

the pressure reading on the Pressure Gauge above

this valve drops one small graduation mark

(approximately 10 PSIG).

2. SLOWLY open the Oil Drain Valve (Lower left

side on back of TC670) to vent Non-condensable

Gas and drain any oil which may have been

removed from the A/C System. A plastic cup is

provided to collect the oil.

Unless the A/C System had previously been

overfilled, the TC670 will typically not remove

more than a tablespoon of oil, making replenishment

unnecessary.

Leave the Oil Drain Valve open.

3. Determine the room temperature.

4. Locate the pressure (PSIG) corresponding to this

room temperature ( 0 F) in the chart on the top of th e

TC670. This chart is reproduced at the right.

If the pressure indicated on the gauge is greater than

that determined from the chart...

SLOWLY turn clockwise and hold open the

Purge Valve until the gaug e pressure equals that

shown in the chart. Any Non-condensable Gas

will be vented through the Oil Drain Valve.

5. Close the Oil Drain Valve.

6. Turn the N/C Vent Valve clockwise and hold for

approximately 5 seconds. This permits any residual

Non-condensable Gas to be recirculated for

reprocessing during the next recycle procedure.

RTI Technologies, Inc.

0F R12 R134a

30 42 40

32 44 42

34 46 44

36 48 46

38 50 49

40 52 51

42 54 54

44 57 56

46 59 59

48 61 61

50 64 64

52 66 67

54 69 70

56 72 72

58 74 76

60 77 78

62 80 82

64 83 85

66 85 88

68 88 92

70 92 95

72 95 97

74 98 104

76 102 107

78 105 110

80 108 114

82 112 118

84 115 123

86 118 127

88 123 130

90 127 135

92 130 140

94 135 145

96 138 148

98 143 153

100 147 157

102 150 163

104 155 167

106 160 173

108 165 180

110 168 185

112 173 190

114 178 195

116 183 200

118 188 207

February 5, 1996

Purge Chart

Page 10

Page 14

RTI Technologies, Inc.

DEEP VACUUM

If the A/C System is " opened" for replacing components, it is important to draw a deep v acuum on

the system before recharging with refrigerant. This vacuuming process not only removes air from

the system, but just as importantly, will remove any moisture in the system.

A Vacuum Pump in the TC670 provides the capability of performing this "Deep Vacuum and

Dehydration". The following steps should be followed:

Figure 3 Deep Vacuum

To Deep Vacuum the A/C System, refer to Figure 3 and follow these steps:

1. Connect Red and Blue Hoses to the high and low sides of the A/C System.

2. Open Low and High Gauge Valves.

3. Open Red and Blue Hose Valves.

4. Press top (ON) of rocker switch marked DEEP VACUUM.

5. The Vacuum Pump will start and the TC670 will start drawing a vacuum which will be

indicated by a dropping pressure on the Low Gauge.

NOTE... If pressure is sensed at the Red and Blue Hoses on the TC670, the Vacuum Pump will

not start, as this would result in venting of refrigerant.

If this occurs, perform the recover/recycle operation described earlier.

ALSO... It may be necessary to momenta rily loosen the Blue Hose to break the vacuum a nd allow

the pump to start if its operation has been interrupted.

February 5, 1996

Page 11

Page 15

RTI Technologies, Inc.

HOSE EVACUATION

It's important that Air not be introduced into the A/C System during a Charging procedure. If a Deep

Vacuum procedure was performed previously, the following Hose Evacuation Procedure is not

required. If the service valves on the hoses have been open, the following procedure must be

performed:

Figure 4 Hose Evacuation

To Evacuate Hoses, refer to Figure 4 and follow these steps:

1. Close Red and Blue Hose Valves.

2. Open High and Low Gauge Valves.

3. Press top (ON) of rocker switch marked RECOVER/RECYCLE.

4. Let the TC670 run until a vacuum is seen on the Low Side Gauge.

5. Turn High and Low Gauge Valves to OFF.

6. Press bottom (OFF) of rocker switch marked REC OVER/RECYCLE. All Air has now been

removed from the Hoses.

7. Vent any Non-condensable Gas as described in the previous section.

February 5, 1996

Page 12

Page 16

CHARGE - HIGH SIDE

RTI Technologies, Inc.

Figure 5 Charge - High Side

To Charge Refrigerant, refer to Figure 5 and follow these steps:

1. Perform Hose Evacuation described previously.

2. Connect Red Hose to the A/C Syst em high side per the vehicle manufacturer's instructions. Do

not open the hose valve.

3. Press top (ON) of rocker switch marked CHARGE/HIGH SI DE. The Charge Cylinder will now

be heating to develop pressure for charging.

4. Open High Gauge Valve. The Low Gauge Valve and both Hose Valves should be closed.

5. Determine the refriger ant capacity of the A/C syste m to be charged. This data is usually printed

on a tag located on the accumulator or under the hood of t h e vehicle. Convert this quantity to

tenths of a pound for setting the TC670 charge indicator.

The following will determine where to set the indicator prior to starting the charge mode:

(TC670 Liquid Level) - (A/C System Capacity) = Indicator Setting

February 5, 1996

Page 13

Page 17

RTI Technologies, Inc.

EXAMPLE: The level of liquid visible in the TC670 Charging Cylinder Sight Glass is 7.4 lbs.

and the A/C system capacity is 3.2 lbs. The following calculation results...

(7.4) - (3.2) = 4.2

Therefore, the sliding indicator should be set at 4.2 lbs. in this example. When the

liquid level lowers to the 4.2 lb. mark, a charge of 3.2 lbs. will have been de livered

NOTE... The Sight Glass on the Char ging Cylinder has markings for both R12 and

R134a. Always use the correct scale for accurate charging.

6. Open Red Hose Valve. Do not start the Vehicle's Engine. Refrig erant will flow into the high

side of the A/C System. Closely monitor the liquid le vel as it lower s in the Charging Cy linder

Sight Glass.

7. Close High Gauge Valve as soon as the refrigerant level drops to the sliding indicator.

9. Press bottom (OFF) of rocker switch marked CHARGE/HIGH SIDE.

The vehicle can now be started and the A/C system checked by monitoring Gauge pressures.

Evacuate the hoses per the preceding section "Hose Evacuation"

Always close all valves before disconnecting hoses.

NOTE: The preceding is the recommended method of charging with the TC670.

Some vehicle manufacturers may specify connecting only to the Low Side of the

A/C System. Always follow the manufacturer ’s recommended procedures. The

above instructions would have to be modified accordingly.

February 5, 1996

Page 14

Page 18

RTI Technologies, Inc.

SCHEDULED MAINTENANCE

BEFORE EACH USE...

Check the oil level in the Compressor DAILY before using.

The Oil Level Sight Tube is vi sible throug h a cut-out in the left side of the black Compressor Cover

at the bottom of the TC670.

The oil level should be visible in the small nylon tube.

If oil is not visible or is above the middle of the cut-out call Technical Support at 800-468-2321.

MONTHLY...

Clean the Condenser to maintain high efficiency performance of the TC670. Disconnect power and

remove the Compressor Compartment Cover and blow compressed air through the cooling fins of

the Condenser to remove any debris.

Do not bend the fins on the Condenser coil. Air flow will be restricted and cause damage to the

TC670. Replace the Compressor Compartment Cover before applying power to the TC670.

FILTER MAINTENANCE

Monitor the Moisture Indicator for a color change from BLUE to PINK. When the TC670 is new

and immediate ly a fter c hanging Combo Filter s, the Moisture Indicator may show PINK. This is due

to the exposure to air and does not indicate inadequate filter performance.

Two Combo Filters are installed on the rear of the TC670.

Both Filters must be changed every year OR when the Moisture Indicator shows "Wet".

February 5, 1996

Page 15

Page 19

RTI Technologies, Inc.

PROBLEMS & SOLUTIONS

On rare occasion t he TC670 may seem to be performing differently or not at all. Experience has

shown that varying operating conditions can affect the performance characteristics of the TC670.

The temperature of the vehicle A/C System will affect how the TC670 performs.

Following are typical problems with explanations of the possible cause and solution.

PROBLEM: My TC670 worked fine all las t Summer. I got it out today for the first service job

this Spring and it is very slow in evacuating the system.

SOLUTION: Today's Spring temperature may be much lower than the average temperatures

during the summer months. Maybe the vehic le w as br ought in from outside where

the temperature is very low.

The refrigerant in the vehicle will not be under as high a pressure at lower

temperatures and the TC670 will take longer to dra w a va c uum. More cy cles may

be required to completely recover the refrigerant.

PROBLEM: I put 5 lbs. of refrigerant into the TC670 using the Recycle Mode. When I checked

the sight glass on the Charging Cylinder, there was less than 5 lbs. I lost

Refrigerant. The unit must leak.

SOLUTION: Due to temperature changes, some refrigerant may condense into liquid form and

stay in tubes and other components in the circuit preceding the Charging Cy linder.

This is normal and will explain wh y all refriger ant is not visible in the sight glass.

PROBLEM: I can not get the TC670 to draw a vacuum as indicated on the Low Side Gauge.

SOLUTION: Check Hoses for restrictions.

PROBLEM: When I try to fill the Charging Cylinder from an auxiliary cylinder of clean

refrigerant, the TC670 is really slow or shuts down.

SOLUTION: The auxiliary cy linde r will cool due to the vaporiz at ion of r efrig erant. This ca uses

the pressure to decrease.

Use a heat belt to increase the speed of recycling by the TC670.

February 5, 1996

Page 16

Page 20

RTI Technologies, Inc.

PROBLEM: I turned a 30 lb. cylinder of new refrigerant up-side-down to pre-charge the

Charging Cylinder with liquid. The Charging Cylinder didn't fill and now the

TC670 won't recover from an A/C system.

SOLUTION: The TC670 has been overloaded with liquid refrigerant (See Safety Precaution

Section at the beginning of this manual).

... WARNING ...

IF A CYLINDER IS TURNED UP-SIDE-DOWN, THE

TC670 WILL OVERFILL WITH LIQUID

REFRIGERANT. THIS OVER FILLS THE SUCTION

ACCUMULATOR WITH LIQUID.

FROST ON THE OIL DRAIN ON THE REAR OF THE

TC670 IS A GOOD INDICATION OF THIS

OCCURRENCE.

THIS SYMPTOM IS CAUSE FOR CONCERN AS LIQUID

REFRIGERANT WILL BE FORCED INTO THE

COMPRESSOR.

THIS CAN DESTROY THE COMPRESSO R AND WILL

VOID THE WARRANTY.

The safest method to remove the excess liquid which has collected in the Suction

Accumulator is to drain it from the Oil Drain on the ba ck of t he T C670 as follows:

Draw a deep vacuum (25 to 29 In. Hg.) on an empty cylinder and connect it to the

Oil Drain Valve. Open the cylinder valve and the Oil Drain valve.

Close the valves and disconnect the cylin der after the liquid has been drawn into the

cylinder. This refrigerant can now be recycled by the TC670 following normal

recycling procedures.

If the above suggested solutions do not solve the problem, call the phone number shown on the

Serial Label on the rear of the machine and one of our technicians will help diagnose the cause.

Please have the Serial Number available for reference.

February 5, 1996

Page 17

Page 21

Page 18

Page 22

Page 19

Page 23

Page 20

Loading...

Loading...