Page 1

Operation Manual

SPOOTER

4075 East Market Street

York, Pennsylvania 17402 USA

Phone: 717-840-0678

Fax: 717-755-8304

www.rtitech.com

Manual Number 035-80812-00 (English)

Page 2

OPERATION

The SPOOTER is a manually operated refrigerant recovery device. It will give you long-lasting service with

a minimal amount of maintenance. Just follow these simple instructions.

It’s recommended for use on systems with less than 3 pounds of refrigerant. It is capable of recovering

larger amounts, but lubrication will be required during the recovery operation.

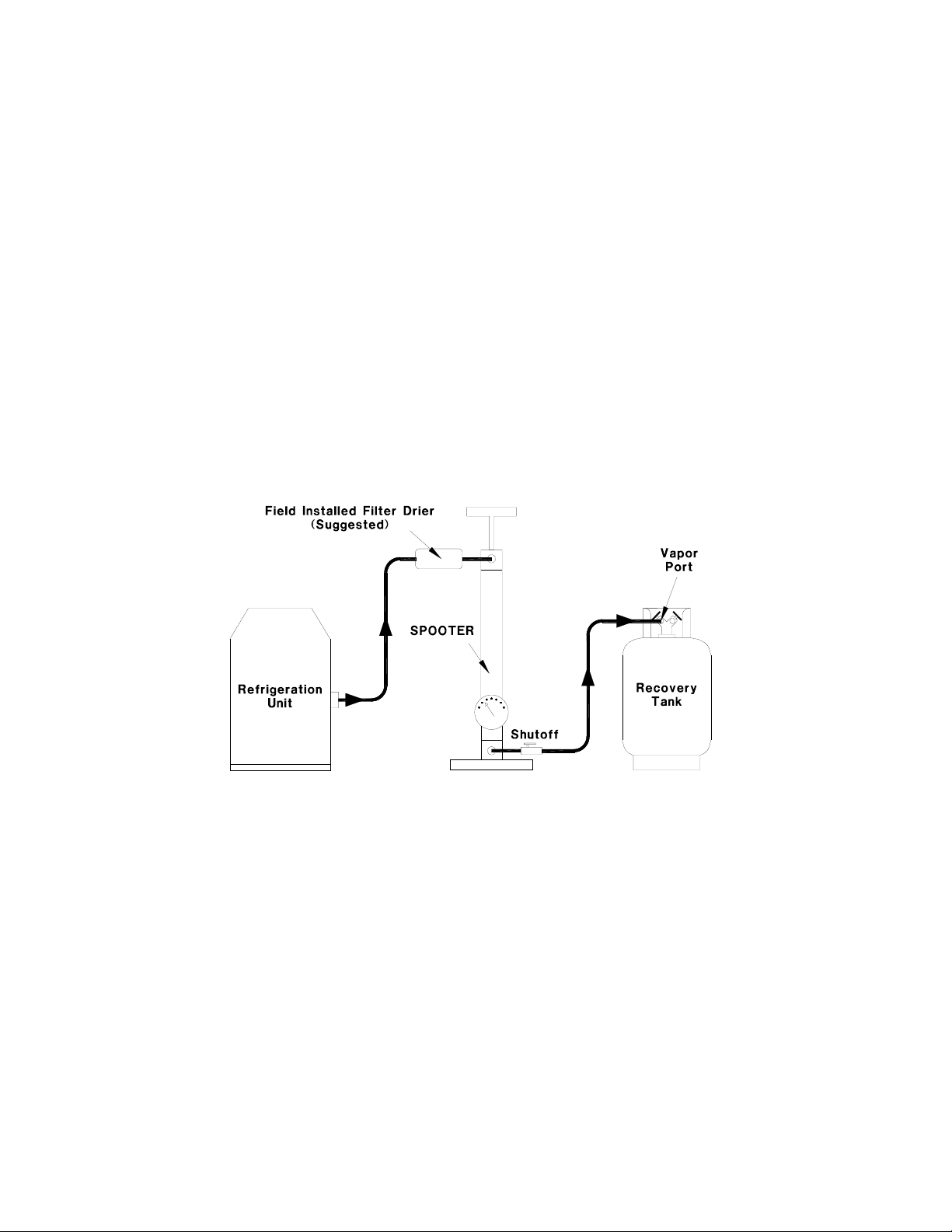

The inlet port is the top port (closest to the handle). This port should be connected to the refrigeration

system to be evacuated.

The bottom port is the outlet port and should be connected to an empty orpartially-filled recovery tank. The

shutoff end of the hose should be connected to the SPOOTER outlet port.

The SPOOTER should always be used with a scale that has an automatic shut-off, or the operator must

monitor the tank weight during operation to determine that the tank is not filled over 70 percent capacity.

Recovery tanks have the empty weight stamped on the handle. This weight is usually indicated by “TW ” or

Tare Weight. For example, if you are using a 30 lb. ta nk, you may put 21 lbs. or 70 percent of the total

capacity into the tank. If the empty weight, or tare weight, of the tank is 15 lbs., you may fill the tank to a

gross weight of 36 lbs., or the tare weight plus the weight of the refrigerant.

Moving the handle up and down will transfer refrigerant from the refrigeration unit into the recovery tank.

Hose should be hooked to the vapor port as shown.

After the system is evacuated to a level of 10 In-Hg, the SPOOTER should be left connected to the system

and left idle for five minutes. If pressure in the system rises above the level of 10 In-Hg, pumping should

again be initiated to bring the system below 10 In-Hg. Repeat this procedure until the below 10 In-Hg

vacuum level remains constant for five minutes.

After the refrigerant recovery operation is completed, the entire SPOOTER will be in the same amount of

vacuum as the equipment being evacuated. Refrigerant will remain in the outlet hose and recovery tank.

The outlet hose shut off should be closed and the hose should be left connected to the tank until the next

evacuation is initiated. This will minimize the amount of refrigerant vented.

LUBRICATION

The SPOOTER must be lubricated after each use. If the handle becomes hard to pump during use,

additional oiling may be needed. To lubricate the pump, simply put a few drops of refrigerant oil into the

inlet port and pump the handle up and down. This may need to be repeated a few times before the seals

and O-rings are fully lubricated. Oil may come from the outlet port, but this is normal. Keeping the pump

well lubricated is the best way to ensure long seal life. USE ONLY MINERAL OIL TO LUBRICATE THE

SPOOTER

1

Page 3

WARNINGS

Do not attempt to pump refrigerant that has a pressure exceeding 200 PSI. Do not attempt to recover

refrigerant from an operating refrigeration system.

Servicing refrigeration or air-conditioning systems improperly can cause pressurized refrigerant gas to

violently explode. Precautions must be observed to protect both the person doing the work and the

equipment involved.

The SPOOTER is intended only for use by professional service people familiar with the equipment being

serviced and the precautions necessary to satisfactorily complete the intended service operation in

accordance with the instructions furnished.

Always follow the service procedures and do not exceed the maximum working pressure ratings.

MAINTENANCE

Check Valves:

The SPOOTER is dependent on a series of three check valves that must all be operational. Most problems

encountered are because of check valves not functioning properly. Most check valve failures occur

because of foreign particles getting stuck in them.

The best way to avoid check valve malfunction is to use a small refrigerant filter on the inlet side of the

pump. If the SPOOTER doesn’t seem to work, try the following:

First, put a finger over the top port and pump the SPOOTER. If it is operating properly, the gauge should

pull down to a 30 In-Hg vacuum in about two pumps and stay there. Remove your finger and the pressure

should return to zero. If it does, the SPOOTER is probably alright.

If the plunger pumps up and down easily but the gauge stays at zero with your finger over the top port, this

is almost always an indication that the middle check valve is stuck open. This check valve is a fitting that

looks like a close nipple right under the T fitting that the gauge is installed into. Sometimes this check valve

can be freed by removing the 10 inch hose between the bottom and the top and inserting a piece of wire

into the T fitting to push the valve open and closed. Pumping oil through the pump will sometimes also

clean this valve out.

The other two check valves are very easy to check. They are the ¼” male flare fittings where the hoses are

hooked to perform an evacuation. These check va lves can be taken out and blown through to see if they

are operational. You should be able to blow through them one way, but not the other. Also, by inserting a

wire into the outlet side of these check valves, the piston should pop up and down freely.

Seals:

The two locations for seals in the SPOOTER are surrounding the piston and around the rod at the top.

Refrigerant leaking around the rod at the top indicates that the shaft seal needs to be replaced. This seal is

included in the SPOOTER Repair Kit (RTI Part Number 026-80169-00).

The seals around the piston rarely fail. They should be the last thing investigated on an inefficient pump.

You can remove the 10 inch hose, unscrew the rod end cap and pull the whole piston assembly out to

check these seals. If they don’t look nicked or torn, they are probably alright. Replacement seals are also

included in the SPOOTER Repair Kit (RTI Part Number 026-80169-00).

2

Loading...

Loading...