Page 1

OPERATION

&

MAINTENANCE

MANUAL

RR750X

RTI Technologies, Inc.

York, PA 17402

800-468-2321

P/N 035-80052-01

Page 2

!!

!! TABLE OF CONTENTS !!

!!!!

RR750X

Before Using Page 2

Safety Precautions Page 3

Preparation For Use Page 4

Recycle Operation Page 4

Charging Capability Page 6

How The RR750X Works Page 9

Scheduled Maintenance Page 12

Problems & Solutions Page 14

Flow Diagram Page 15

Circuit Diagram Page 16

Wiring Diagram Page 17

Page 3

BEFORE USING THE RR750X

Check for any shipping damage. If damaged, place a claim with carrier.

DO NOT USE A DAMAGED UNIT.

Verify that you have received the following:

RR750X Machine

Eight Foot Refrigerant Hose (Qty=2)

Tee Fitting

Oil Syringe

Oil Drain Cup

DOT Approved Cylinder

Refrigerant Technologies, Inc.

The RR750X should not be operated or maintained by any person who has not read all the contents

of this manual. Failure to read and comply with these instructions or any one of the limitations noted

herein can result in serious injury and/or property damage.

These general instructions deal with the normal operation and maintenance situations encountered

with the RR750X. The instructions should not be interpreted to anticipate every possible

contingency.

It is the responsibility of the owner/user to operate the RR750X in accordance with all specifications

and laws which may apply.

The following pages contain rules for safe operation of the RR750X. Taking precedence over any

specified rule listed herein, however, is the most important rule of all:

"USE COMMON SENSE".

A few minutes spent reading these instructions can make an operator aware of dangerous practices

to avoid and precautions to take for his own safety and the safety of others.

A regular schedule of inspection of the RR750X should be established and records maintained with

special attention given to hoses and replaceable filters.

May 24, 1993 Page 2

Page 4

Refrigerant Technologies, Inc.

SAFETY PRECAUTIONS

! Wear safety glasses and protective gloves. Refrigerant has a very low boiling point and can cause

frostbite.

! Follow the RR750X operating procedures sequentially to avoid prematurely disconnecting hoses

or opening valves which may release refrigerant to the atmosphere.

! Do not expose the RR750X to moisture or operate in wet areas.

! Use the RR750X in locations with mechanical ventilation that provides at least four air changes

per hour or locate the unit 18 inches above the floor.

! Service hoses used with the RR750X must have shutoff devices within 12 inches of the

connection point to the system being serviced to minimize the introduction of non-condensable

gases into the recovery unit and the release of refrigerant when being disconnected.

! Disconnect power before performing any maintenance or service on the RR750X.

! Avoid using an extension cord with the RR750X. If necessary, use a good condition, UL listed,

3-wire grounded, #14 AWG extension cord of the shortest possible length.

! Do not introduce refrigerant in the liquid state into the RR750X from any source having greater

than a 4.5 lb. capacity. Steady introduction of large amounts of liquid refrigerant may cause the

RR750X to malfunction.

! Connect RR750X to grounded and protected 115 VAC - 60 HZ power source.

! Recover R-12 refrigerant only.

May 24, 1993 Page 3

Page 5

PREPARATION FOR USE

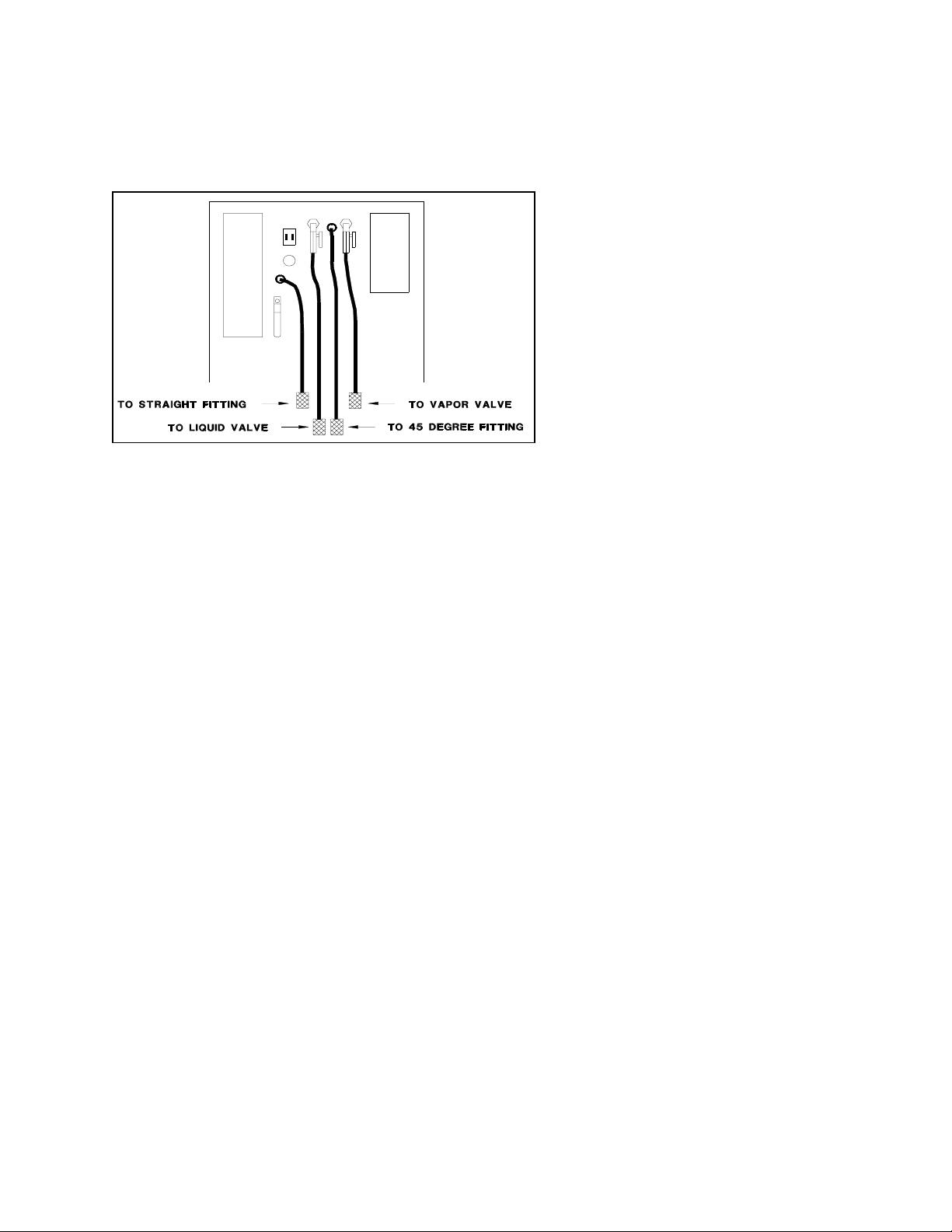

Figure 1 Hose Connections

Refrigerant Technologies, Inc.

Place the External Cylinder on the

Weight Scale Platform on the rear of

the RR750X.

Connect the four hoses to the External

Cylinder as shown in Figure 1.

NOTE:

Color standards for cylinder valve

knobs were changed by the

manufacturer during 1992.

Therefore, do not depend on color to

indicate liquid or vapor valves on the

External Cylinder. Look for

“LIQUID” or “VAPOR” embossed

on the knobs.

Tighten fittings FINGER-TIGHT only. Over tightening may cause damage to the fittings or valves

and result in leaks.

It is recommended that ALL connections be checked with an electronic leak detector each time hoses

are reconnected.

RECYCLE OPERATION

Set valves on the RR750X as follows in preparation for performing a Recover/Recycle operation:

! Red Valve on External Cylinder OPEN (Counter-clockwise)

! Blue Valve on External Cylinder OPEN (Counter-clockwise)

! Ball Valve on Red Hose OPEN (Handle parallel to hose)

! Ball Valve on Blue Hose OPEN (Handle parallel to hose)

! Yellow Filter Bypass Valve OFF (Handle vertical)

May 24, 1993 Page 4

Page 6

Refrigerant Technologies, Inc.

Connect one end of the 8 Ft. yellow hose to the Inlet Port of the RR750X. Connect the other end to

the center port of a Gauge Manifold. The hose can also be connected directly to the low side of the

vehicle A/C system. The Pressure Gauge on the RR750X can then be used to monitor pressure.

If using a Gauge Manifold, connect it to the A/C system as specified by the manufacturer of the

vehicle.

Open the Gauge Manifold Valves (Counter-clock-wise).

NOTE: It is recommended that the High and Low Gauge Manifold Hoses have shut-off devices

within 12 in. of the ends connected to the vehicle A/C system. This will permit the

recovery of refrigerant from the hoses.

The yellow Service Hose could be connected directly to the low side of the A/C System

and the RR750X Inlet Pressure Gauge used to monitor pressure.

Turn the Main Power Switch to On.

The Ready Light and Compressor-On light will illuminate. The Compressor High Pressure Light

will flash momentarily. The Compressor and Condenser Fan will be heard operating as refrigerant

is recovered from the vehicle.

NOTE: Several audible changes may be heard during the recovery process. The oil

re-circulation and non-condensable gas venting circuits will cycle

periodically.

Refrigerant flow through check valves causes a "sizzle-type" sound.

These changing "noises are normal and nothing to be concerned

about.

The RR750X will recover refrigerant from the A/C system. The Compressor-On Light will then turn

off.

!!!! DO NOT TURN THE RR750X OFF OR DISCONNECT HOSES !!!!

A small quantity of Liquid refrigerant will probably remain in the A/C system of the vehicle. This

liquid will vaporize as the system components again warm to ambient temperature. This can be

detected by noticing an increase in pressure readings on the Gauge Manifold.

May 24, 1993 Page 5

Page 7

Refrigerant Technologies, Inc.

If the pressure increases to a preset level, the RR750X will again start to recover refrigerant. The

Compressor will turn on and the Compressor-On Light will illuminate.

Allow this sequence to repeat until the Compressor-On Light remains off continuously for 2 minutes.

Close the valves on the 8 Ft. hose and the Gauge Manifold.

Turn the Main Power Switch to OFF.

Slowly open the Oil Drain Valve on the back of the RR750X to drain any oil which may have been

removed from the A/C system. Use the cup provided to measure the amount of oil which was

removed during the recovery procedure. Refer to the A/C system manufacturer's manual for

recommendations concerning the need to add lubrication during the charging procedure.

Hoses can now be disconnected and the A/C system serviced.

CHARGING WITH THE RR750X

Refrigerant is recycled by the RR750X and stored in the External Cylinder. An Accessory Charging

Cylinder or Auxiliary Charging Tank with a Weighing Scale can be used to charge an A/C System

with this recycled refrigerant.

Refer to Figure 1 to determine which hose on the back of the RR750X is connected to the External

Cylinder “LIQUID” Valve.

Disconnect this hose from the External Cylinder and install the Liquid Line Tee Tap supplied with

the RR750X.

Connect one end of the Yellow Service Hose to the Tee. Make all connections finger tight only.

Refer to Figures 2 and 3 for connection configurations to transfer refrigerant from the RR750X

External Cylinder to a Charging Cylinder or Auxiliary Charging Tank.

Pressure in a Charging Cylinder or Auxiliary Charging Tank must be less than the pressure in the

RR750X External Cylinder. The RR750X can be used to create this pressure differential without

releasing refrigerant to the atmosphere as follows:

Connect the Yellow Service Hose from the Inlet Port of the RR750X to the Vapor Port of the

RR750X to the Vapor Port of a Charging Cylinder or Auxiliary Charging Tank.

Open ball valve on the Yellow Service Hose.

MOMENTARILY (10 to 15 Seconds) turn the RR750X Power Switch On.

Close ball valve and reconnect the Yellow Service Hose for transferring liquid from the RR750X

External Cylinder (Refer to Figures 2 and 3).

May 24, 1993 Page 6

Page 8

Refrigerant Technologies, Inc.

The Charging Cylinder or Auxiliary Tank can now be filled and used to charge the A/C System

according to the Manufacturer’s instructions.

A pressure differential is required to encourage flow of refrigerant into the A/C System.

Some Charging Cylinders have a heating element for the purpose of creating this differential in

pressures.

Mild heating of the Auxiliary Tank will develop this pressure differential. Immersion in warm

water is the least risky method.

... CAUTION ...

CONSULT THE CHARGING CYLINDER OR WEIGHT SCALE INSTRUCTIONS FOR

SAFE OPERATING PROCEDURES.

CARELESS OPERATION MAY RESULT IN A DANGEROUS CONDITION CAUSED BY

OVERFILLING THE CHARGING CYLINDER OR AUXILIARY TANK.

DO NOT EXCEED THE MAXIMUM RATED PRESSURE OF A CHARGING CYLINDER

OR AUXILIARY TANK.

CAREFULLY MONITOR THE LIQUID LEVEL OF REFRIGERANT IN THE CHARGING

CYLINDER OR WEIGHT OF AUXILIARY TANK DURING A FILL PROCEDURE.

OVERFILLED CHARGING CYLINDERS OR AUXILIARY TANKS MAY DAMAGE THE

RR750X COMPRESSOR DURING THE MOMENTARY PRESSURE DIFFERENTIAL

PROCEDURE AND VOID THE WARRANTY!

May 24, 1993 Page 7

Page 9

Refrigerant Technologies, Inc.

Figure 2 Using the RR750X to Charge with Charging Cylinder

Figure 3 Using the RR750X to Charge with Auxiliary Charging Tank

May 24, 1993 Page 8

Page 10

Refrigerant Technologies, Inc.

HOW THE RR750X RECOVERS & RECYCLES REFRIGERANT

Following is a description of the purpose and performance characteristics of the components within

the RR750X. The items are discussed in the order as seen by refrigerant as it flows through the unit

from the Inlet Port to the External Cylinder.

Refer to the Flow Diagram and Circuit Diagram in the Appendix.

INLET PRESSURE GAUGE

Indicates pressure of refrigerant at the Inlet Port of the RR750X.

CHECK VALVE

Prevents escape of refrigerant to the atmosphere.

SUCTION ACCUMULATOR

This device may be designated by several different names, the most common being:

! SUCTION ACCUMULATOR

! SUCTION RECEIVER

! SUCTION OIL SEPARATOR

Vapor and/or saturated liquid refrigerant from the vehicle A/C system enters the Suction

Accumulator through the Inlet Port.

Refrigerant still in the liquid state will vaporize in the Suction Accumulator due to the increase in

volume.

As the refrigerant changes direction of travel while flowing through the Suction Accumulator, oil

droplets (with greater mass than the refrigerant vapor) are slung towards the container walls where

they collect and migrate to the bottom.

This oil is removed from the Suction Accumulator through the Oil Drain Valve and measured after

each recovery cycle to determine the need to add oil to the A/C system.

The Low Pressure Switch mounted on the Suction Accumulator opens when a vacuum of 8 ± 2 In.

Hg. is detected. This stops the recovery process. This switch closes again when a pressure greater

than 3 ± 3 PSIG is reached.

ACID FILTER

Refrigerant enters the Acid Filter through a port on the top and travels through a solid desiccant core

where organic and volatile contaminates are filtered, moisture is absorbed, and acid is removed. The

refrigerant travels from the outside to the inside of the desiccant core and then out through the

bottom port.

May 24, 1993 Page 9

Page 11

Refrigerant Technologies, Inc.

Refrigerants react with water to form hydrochloric and hydrofluoric acids which are corrosive to

equipment and contaminate oil. Removal of acid at this stage is important to protect the Compressor

and other RR750X components.

The Acid Filter must be replaced after every 500 hours of operation.

CHECK VALVE (1 PSI)

The Check Valve permits forward refrigerant flow when the output pressure from the Acid Filter is

1 lb. or greater than pressure at the output side of the Check Valve. The primary purpose of this

check valve is to prevent flow of oil backwards towards the Acid Filter during the Oil Return Cycle

from the Oil Separator.

SUCTION SHUTDOWN SOLENOID VALVE S-11

Prevents flow of refrigerant to the Compressor when not operating.

SUCTION PRESSURE REGULATING VALVE

This valve is sensitive only to the pressure at the outlet port. The pressure range at which the valve

is open is increased or decreased by adjusting a spring which acts on an internal bellows.

Inlet pressure to the valve is exerted on the bellows and the top of the seat disk. Since the effective

areas of the bellows and seat disk are equal, the inlet pressure has no affect on the valve operation.

The output pressure of the valve acts on the underside of the seat disk and exerts a pressure in the

closing direction. This force is opposed by a spring which is adjusted to set the pressure at which

the valve closes.

During production of the RR750X, this valve is adjusted to limit the mass flow rate to 10 ± 2 PSIG

during normal operation.

COMPRESSOR

Refrigerant is compressed, resulting in an increase of temperature. This temperature rise is due to

the total heat of the vapor being squeezed into a smaller space.

The compression of gaseous refrigerant in a compressor is considered to be near a state of Adiabatic

Compression. Adiabatic refers to the process whereby a gas is compressed (or expanded) without

any transfer of heat into it during the compression (or expansion).

A very slight increase in temperature may be due to frictional heat generated within the Compressor.

A sight tube is mounted on the Compressor for monitoring the oil level. The Maintenance Section

of this manual describes procedures for adding oil as required.

May 24, 1993 Page 10

Page 12

Refrigerant Technologies, Inc.

HIGH PRESSURE SWITCH

The High Pressure Switch opens-on-rise at a pressure of 261 ± 7 PSIG and closes on-fall at 203 ±

7 PSIG. The Compressor turns off and Solenoid Valve S11 closes to prevent flow of refrigerant

through the system.

OIL SEPARATOR

Filtering of the refrigerant to remove oil is accomplished by a fine composition filter element.

Refrigerant enters through the top of the canister to the inside of the element, passes through the

element towards the outside, and then exits from the bottom of the canister.

The removal of oil is important to prevent clogging the Filter-Drier which removes moisture from

the refrigerant.

CHECK VALVE (5 PSI)

The Check Valve permits forward refrigerant flow when pressure from the outlet of the Oil Separator

is 5 lbs. or more than the outlet pressure of the Check Valve.

FILTER BY-PASS VALVE

Manual operation of 3-way Filter By-Pass Valve facilitates purging refrigerant from the filters prior

to their removal. Operation of this valve is described in the Maintenance Section of this manual.

FILTER-DRIER

Refrigerant enters the top of the canister and flows through a perforated plate and then through

moisture absorbing desiccant. Moisture removal is very important due to the formation of acids

which result when water and refrigerant are allowed to mix.

The Filter-Drier must be changed after every 75 hours of operation.

CONDENSER (COOLED BY FAN)

The high temperature, high pressure refrigerant vapor is cooled by air moving over the finned

Condenser. The vapor condenses into liquid form as it is cooled.

EXTERNAL CYLINDER

Refrigerant flows to the External Cylinder until the weight switch shuts the RR750X off due to a full

cylinder.

DIFFERENTIAL PRESSURE SWITCH (DPS)

The venting of non-condensable gases (Air) is performed by the DPS Assembly. A refrigerant/Air

mixture will exhibit a higher pressure than pure refrigerant. Pressure inside a sealed bulb of pure

refrigerant is compared to the refrigerant/Air mixture at the External Cylinder at equal temperatures.

When the Air concentration in the Internal Cylinder reaches a preset amount, the DPS activates the

Non-condensable Gas Discharge Solenoid (S8). The Air is slowly vented until the pressures again

equalize.

May 24, 1993 Page 11

Page 13

Refrigerant Technologies, Inc.

SCHEDULED MAINTENANCE

DAILY BEFORE USE...

Check the oil level in the Compressor daily before operating the RR750X.

The oil level tube can be seen next to the Compressor by looking through the vent openings on the

side of the RR750X nearest the Main Power Switch.

Oil should be visible in the clear tube, but at a level less than one inch.

If the oil level is not visible, proceed with the Recover/Reclaim operation and recheck the oil level

when complete.

If the level is still not visible, oil must be added.

Remove the front cover. Slowly remove the Oil Fill Cap on the Compressor. Allow the pressure

to equalize.

Use the Oil Syringe to add Refrigeration Oil until the level is visible and less than one inch. Add

one syringe full at a time. Wait 5 minutes between each syringe full for the oil to settle.

THE OIL LEVEL MUST NEVER BE MORE THAN ONE INCH HIGH

Replace the Oil Fill Cap on the Compressor before applying power to the RR750X.

AFTER EVERY 10 HOURS OF OPERATION...

Clean the Condenser to maintain high efficiency performance of the RR750X. Remove both side

covers and blow compressed air through the coil to remove any debris. It may be necessary to use

a soft brush if the coil is very dirty.

Do not bend the fins on the Condenser coil. Air flow will be restricted and cause damage to the

RR750X. Replace both side covers before applying power to the RR750X.

AFTER EVERY 75 HOURS OF OPERATION

Replace Filter-Drier as described in the following steps:

! Turn on Filter By-pass Valve by turning yellow handle on rear of cabinet to HORIZONTAL

position.

! Remove larger filter cover on rear of cabinet.

! Remove cap on access fitting of Filter-drier and connect 8 Ft. hose from this fitting to the Inlet

Port of the RR750X.

! Turn on the Main Power Switch and recover all the refrigerant from the Filter-drier.

! Remove and replace the Filter-drier. Reuse the black insulation around the filter. Disposal

of old filter requires no special handling as it contains no hazardous substances.

MAKE ALL CONNECTIONS FINGER-TIGHT ONLY

May 24, 1993 Page 12

Page 14

Refrigerant Technologies, Inc.

USE CAUTION TO NOT MOVE CONNECTING TUBES AS LEAKS COULD DEVELOP

! Turn off Filter By-pass Valve by turning yellow handle on rear of cabinet to VERTICAL

position.

! Operate the RR750X in Recover Mode and check for leaks. Repair as necessary.

! Record Hour Meter reading on label provided. Replace the Filter-drier cover.

AFTER EVERY 500 HOURS OF OPERATION

Replace Acid Filter as described in the following steps:

! Cap the RR750X Inlet Port.

! Turn on the Main Power Switch and allow RR750X to run until Compressor-On Light goes

off.

! Turn off the Main Power Switch.

! Remove the smaller filter cover on rear of cabinet.

! Remove and replace the Acid Filter. Note direction of flow indicated on the new Acid Filter.

The arrow must point DOWN.

! Operate the RR750X in Recover Mode and check for leaks. Repair as necessary.

! Record Hour Meter reading on label provided. Replace the Acid Filter cover.

May 24, 1993 Page 13

Page 15

Refrigerant Technologies, Inc.

PROBLEMS & SOLUTIONS

On rare occasion the RR750X may seem to be performing differently or not at all. Experience has

shown that varying operating conditions can affect the performance characteristics of the RR750X.

The temperature of the vehicle A/C System will affect how the RR750X performs.

Following are typical problems with explanations of the possible cause and solution.

PROBLEM: My RR750X worked fine all last Summer. I got it out today for the first service job

this Spring and it is very slow in evacuating the system.

SOLUTION: Today's Spring temperature may be much lower than the average temperatures

during the summer months. Maybe the vehicle was brought in from outside where

the temperature is very low.

The refrigerant in the vehicle will not be under as high a pressure at lower

temperatures and the RR750X will take longer to draw a vacuum. More cycles may

be required to completely recover the refrigerant.

PROBLEM: I used the RR750X to service an A/C system earlier today and it worked great. This

afternoon it won't recover. The Compressor-On Light doesn't even come on.

SOLUTION: The pressure switch on the Suction Accumulator has a close-on-rise setting of 3 ±

3 PSIG. If there is less than 6 PSIG of refrigerant pressure in the vehicle's A/C

System, the RR750X may fail to start.

Connect a source of refrigerant pressure (for example, the External Cylinder) to the

Inlet Port of the RR750X. This will reset the pressure switch so the RR750X will

run when reconnected to the vehicle A/C. It will continue until a vacuum is

achieved.

PROBLEM: I can not get the RR750X to draw a vacuum.

SOLUTION: Connect the Gauge Manifold to the Oil Drain Valve on the RR750X. Close the Inlet

Port and, with the unit running in Recover/Reclaim Mode, determine if a vacuum

can be drawn. If yes, check the charging hoses and Gauge Manifold for possible

obstructions.

May 24, 1993 Page 14

Page 16

Refrigerant Technologies, Inc.

May 24, 1993 Page 15

Page 17

Refrigerant Technologies, Inc.

May 24, 1993 Page 16

Page 18

Refrigerant Technologies, Inc.

May 24, 1993 Page 17

Loading...

Loading...