Page 1

OPERATION

&

MAINTENANCE

MANUAL

750-SP1 UNDP

RTI Technologies, Inc.

4075 East Market Street

York, Pennsylvania, 17402 USA

Phone: 717-840-0678

Fax: 717-755-8304

www.rtitech.com

rti@rtitech.com

Manual P/N 035-80928-00

Page 2

TABLE OF CONTENTS

Before Using & Safety Precautions ............. 2

Preparing the Outlet Cylinder ................. 3

Setting Up the 750-SP1 to Recycle ............. 4

Recycling Refrigerant ....................... 5

When Inlet Cylinder is Empty ................. 6

Removing Air from Outlet Cylinder .............7

Pressure - Temperature Table ................ 8

Scheduled Maintenance ..................... 9

Flow Diagram ............................. 10

Circuit Diagram ............................ 11

Page 3

BEFORE USING

SAFETY PRECAUTIONS

Check for any shipping damage. Place a

claim with carrier if damage is discovered.

DO NOT USE A DAMAGED UNIT.

The machine should not be operated or

serviced by any person who has not read

all the contents of this manual. Failure to

read and comply with these instructions or

any one of the limitations noted herein

can result in serious injury and/or property

damage.

These general instructions describe

normal operation and maintenance

situations encountered. The instructions

should not be interpreted to anticipate

every possible contingency.

It is the responsibility of the owner/user to

operate the machine in accordance with

all specifications and laws which may

apply.

The following pages contain rules for safe

operation. Taking precedence over any

specified rule listed herein, however, is

the most important rule of all:

! Recover, Recycle, and Charge only

the refrigerant for which this machine

is configured.

! Wear safety glasses and protective

gloves. Refrigerant has a very low

boiling point and can cause frostbite.

! Follow operation procedures

sequentially to avoid prematurely

disconnecting hoses or opening

valves which may release refrigerant

to the atmosphere.

! Do not expose the machine to

moisture or operate in wet areas.

! Use the machine in locations with

mechanical ventilation that provides at

least four air changes per hour.

! Hoses have shutoff devices within 30

mm of the connection point to the

system being serviced to minimize the

introduction of Non-condensable Gas

(Air) into the machine and the release

of refrigerant when being

disconnected.

"USE COMMON SENSE"

A few minutes spent reading these

instructions can make an operator aware

of dangerous practices to avoid and

precautions to take for his own safety and

the safety of others.

A regular schedule of inspection should

be established and records maintained

with special attention given to Hoses and

Filters.

! Disconnect machine from power

before performing any maintenance or

service.

! Avoid using an extension cord. If

necessary, use a good condition, 3wire grounded, 2.5 mm

cord of the shortest possible length.

2

extension

! Connect the machine to a properly

protected, grounded receptacle. Do

not over load the circuit.

! Do not allow the machine to remain

unattended in the Charge Mode with

power On. The Internal Cylinder

Heater will be energized creating a

high pressure condition.

Page 2

Page 4

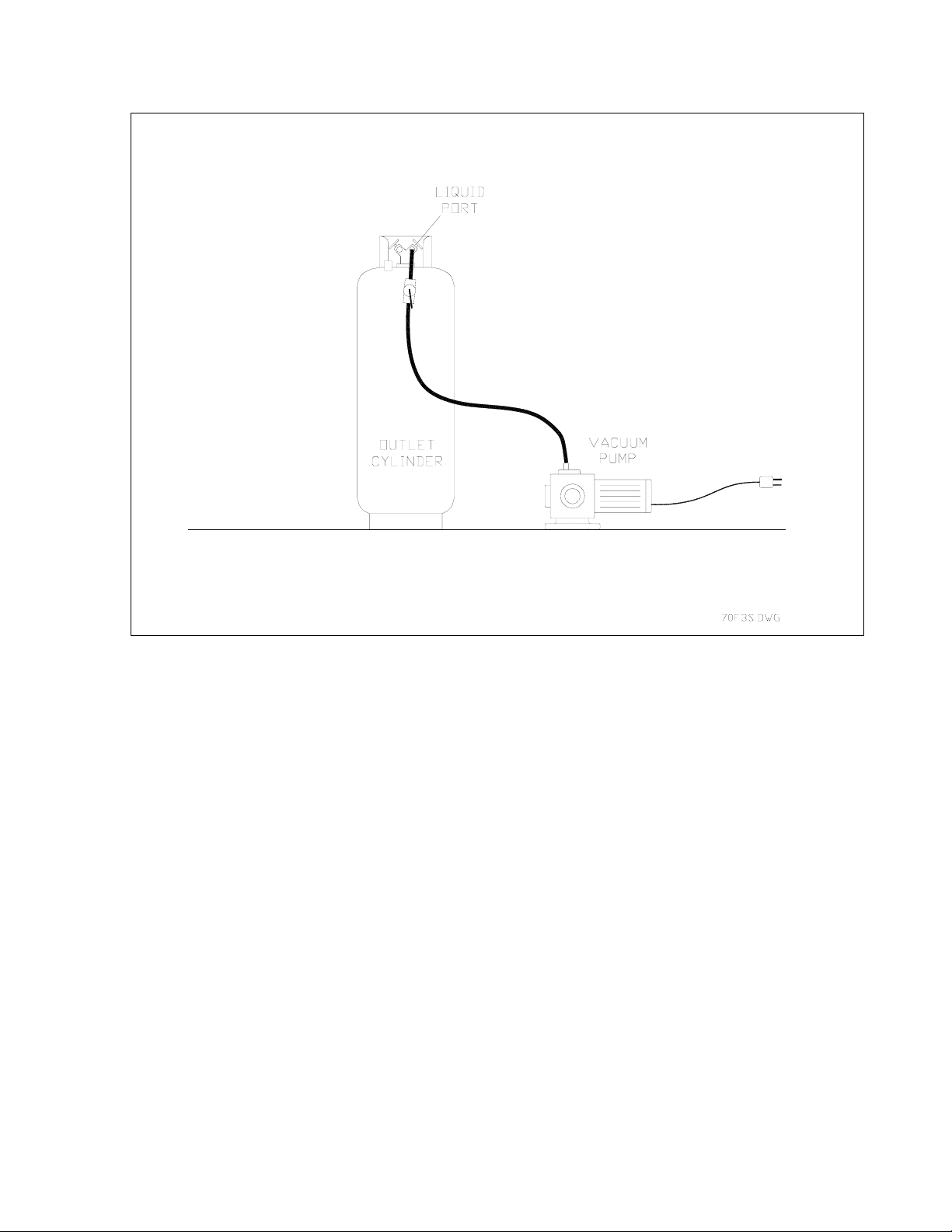

PREPARING THE OUTLET CYLINDER

1. Connect one end of a Yellow Hose to the Liquid Port of the Outlet Cylinder.

2. Connect other end of the Yellow Hose to a Deep Vacuum Pump.

3. Close Vapor Valve.

4. Open Liquid Valve and valve on Yellow Hose.

5. Connect Vacuum Pump to power source.

6. Draw a vacuum on the Outlet Cylinder for one hour.

7. Close Outlet Cylinder Liquid Valve and valve on Yellow hose.

8. Disconnect Yellow Hose from Vacuum Pump and connect to rear access port of the 750-SP1.

Page 3

Page 5

SETTING UP THE 750-SP1 TO RECYCLE

1. Connect Pressure Gauge to Vapor Port of Outlet Cylinder.

2. Position Inlet and Outlet Cylinders as shown.

3. Connect OFP Cord to Receptacle on Outlet Cylinder.

4. Connect Yellow Hoses to Inlet and Outlet Cylinders.

5. Open valves on both Yellow Hoses.

6. Open Liquid Valve on Inlet Cylinder and Liquid Valve on Outlet Cylinder.

7. Connect Power Cord to proper voltage supply.

Page 4

Page 6

RECYCLING REFRIGERANT

1. Set Mode Selector to RECYCLE.

2. Set Main Switch to RECYCLE/CHARGE. The READY Light will be on.

3. Set Access Valve to RECYCLE. The COMPRESSOR-ON light will be on and the 750-SP1 will

begin recovering refrigerant from the Inlet Cylinder. The 750-SP1 is specially designed to

process Liquid or Vapor refrigerant.

Refrigerant will be purified by the 750-SP1 and collected in the Internal Cylinder.

When the Internal Cylinder fills to capacity, the 750-SPl will automatically stop recovering from

the Inlet Cylinder. The CYLINDER FULL Light will be on and the COMPRESSOR-ON Light

will be off.

A timer will activate and the 750-SP1 will automatically charge refrigerant from the Internal

Cylinder to the Outlet Cylinder.

At the end of the timed charge the 750-SP1 will begin recovering refrigerant.

Page 5

Page 7

WHEN INLET CYLINDER IS EMPTY

The 750-SP1 will recover and recycle refrigerant from the Inlet Cylinder until it is empty. When all

of the refrigerant has been recovered and recycled, the COMPRESSOR-ON light will be off and

the 750-SP1 will automatically shut off.

Oil which has been removed from the refrigerant must be drained from the 750-SP1 as follows.

This procedure MUST be performed after emptying each Inlet Cylinder.

1. Set Main Switch to OFF.

2. Press and hold the Purge Button (Right side of machine) until the pressure on the Pressure

Gauge above the Purge Button drops one small graduation mark (approximately 5 PSIG).

3. SLOWLY open Oil Drain Valve (Lower left side on rear of machine) and drain any oil which

may have been removed from the refrigerant. A plastic cup is provided to collect the oil.

4. Close the Oil Drain Valve.

Page 6

Page 8

REMOVING AIR FROM OUTLET CYLINDER

The Pressure Gauge mounted on the Vapor Port of the Outlet Cylinder should be checked

periodically for an indication of excessive Air. The end of the Tee Fitting to which the Pressure

Gauge is attached must be capped. All Valve Cores, if any, must be removed from the Tee Fitting.

Open the Vapor Valve on the Outlet Cylinder to read the pressure in the cylinder.

Measure the ambient temperature and find the corresponding pressure for that temperature in the

following Pressure-Temperature Table.

If the Pressure Gauge reading is greater than the pressure determined from the table, the excess

air should be vented from the Outlet Cylinder as follows:

1. Close the Vapor Valve on the Outlet Cylinder.

2. Remove the cap from the Tee Fitting.

3. Slowly open the Vapor Valve to release Air until the Pressure Gauge reads the same as the

temperature determined from the table.

4. Close the Vapor Valve and replace cap on the Tee Fitting.

EXCESSIVE PRESSURE DUE TO AIR IN THE OUTLET CYLINDER WILL CAUSE THE 750-SP1

TO SHUT DOWN IN A "HIGH PRESSURE" CONDITION OR REFRIGERANT MAY NOT FLOW

FROM THE 750-SP1 TO THE OUTLET CYLINDER.

Page 7

Page 9

Page 8

Page 10

SCHEDULED MAINTENANCE

MONTHLY

Clean the Condenser to maintain high efficiency performance. Disconnect power and remove

the Compressor Compartment Cover and blow compressed air through the cooling fins of the

Condenser to remove any debris. It may be necessary to use a soft brush if the fins are

excessively dirty.

Do not bend the fins on the Condenser coil. Air flow will be restricted and cause damage to the

machine. Replace the Compressor Compartment Cover before applying power.

COMBO FILTER & FILTER-DRIER

Replace the Combo Filter and Filter-Drier after every 75 Hours of operation.

Combo Filter P/N: 026-80077-00

Filter-Drier P/N: 026-80044-00

To replace the Filters:

1 Disconnect machine from power.

2 Remove the Middle Cabinet Cover.

3 Locate the Filters mounted on a bracket on the left side of the machine. The Filter-Drier

has black insulation wrapped around it.

3.1 Disconnect Flare Fittings at top and/or bottom of Filters.

3.2 Remove mounting hardware and remove Filters.

3.3 Remove the black insulation and install on new Filter-Drier.

3.4 Install new Filters using hardware removed earlier.

3.5 Connect Flare Fittings to top and/or bottom of Filters.

4 Check for leaks and repair as required.

5 Replace Middle Cabinet Cover.

Page 9

Page 11

Page 10

Page 12

Page 11

Loading...

Loading...