Page 1

®

RHS

980C

Operation Manual

10 Innovation Drive

York, Pennsylvania 17402 USA

Phone: 717-840-0678

Toll Free: 800-468-2321

Web-site: www.rtitech.com

MAHLE Clevite Inc., RTI Division.

Manifold Protected Under US Pat No. 7,726,343

Manual P/N: 035 81550 00 (Rev G)

Page 2

CONGRATULATIONS

You have purchased the finest Recovery,

Recycling and Charging Machine certified to SAE

Standard J2788!

Fill out and return the Warranty Card within 90

days to activate warranty and free lifetime

technical support.

1

Page 3

NOTES

2

Page 4

TABLE OF CONTENTS

Introduction ............................................................................................................ 5

Overview of the RHS980C and How to Operate it ................................................. 6

Startup & Safe Operation ...................................................................................... 7

Special Considerations with R134a ....................................................................... 7

Control Panel ......................................................................................................... 8

First Time Use ....................................................................................................... 9

Contaminated Refrigerant .................................................................................... 11

Automatic Operation ............................................................................................. 11

A/C System Test Mode ......................................................................................... 16

Printing Results .................................................................................................... 19

High Pressure Leak Detect ................................................................................... 20

High Voltage Oil Flush .......................................................................................... 21

Refrigerant Flush .................................................................................................. 23

Setup .................................................................................................................... 24

Selectable Options ............................................................................................... 24

Select Language

Enable Buzzer

Enable Refrigerant Identifier

Enable A/C Capacity Database

Enable Printer

Enable Print to Flash Drive

Enable Low Voltage Detect

Enable Micron Vacuum Sensor

Enable Password Protection

Enable VIN Entry

Enable Operator ID Entry

Enable AC Test Mode

Enable Vacuum Pump Oil Life

Enable Refrigerant Liquid Flush

Enable Tech Alert Demo

Enable High Pressure Leak Detect

Enable Automatic Weighing Oil Injection

Enable Automatic Weighing Oil Drain

Enable Automatic Weighing UV Dye

Enable High Voltage Oil Flush

Enable Fill Cylinder

Enable Manual Oil Injection

Default Values ................................................................................................. 28

Fill Cylinder Target Amount

Initial Vacuum Hold Level

Final Vacuum Level

Vacuum Run Time

Hoses Overcharge Amount

Minimum Line Voltage

Elevation from Sea Level

3

Page 5

Vacuum Pump Oil Life Rise Level

Oil Drain Maximum Level

Minimum Vacuum Leak Level

High voltage Flush

Maintenance Options ...................................................................................... 29

Calibration Check

Perform Load Cell Site Calibration

Perform Load Cell Shop Calibration

Perform Vacuum Sensor Calibration

Set Date and Time

Input/Output Diagnostics

Combo Filter Replacement

Vacuum Pump Oil Replacement

Change Operator Passwords

Change Service Manager Password

Print Parameters

Total Capacities .............................................................................................. 34

Combo Filter Life Remaining

Total Refrigerant Recycled

Total Refrigerant Charged

Vacuum Pump Oil Life Remaining

Reminders ....................................................................................................... 35

TechALERT Demo Mode ................................................................................ 35

Vacuum Pump Maintenance ........................................................................... 37

Combo Filter Maintenance .............................................................................. 37

Inline Filter Maintenance ................................................................................. 38

Printer Maintenance ........................................................................................ 39

Refrigerant Identifier Maintenance .................................................................. 39

Updating Program and Languages ................................................................. 39

Attaching Temperature Probes ....................................................................... 40

Frequently Used RTI Consumable Items ........................................................ 41

Parts Identification ........................................................................................... 42

TechALERT ..................................................................................................... 44

4

Page 6

INTRODUCTION

r

RTI RHS980C Refrigerant Handling System is designed for use on R134a vehicles and is compliant with J2788

standard. Unit recovers 95% of automobile refrigerant systems and has a refrigerant recharge accuracy of +/- ½

ounce. It features fully automatic operation. All control functions of the RHS980C are designed to provide intuitive

and rapid interaction with the service technician. Easily removable one piece composite cover allows gaining

unobstructed access to all interior components for service and maintenance.

Images below show the key features of RHS980C Refrigerant Handling System.

High Pressure

Gauge

Low Pressure

Gauge

Power Switch

Control Panel with

LCD Display

Oil Drain Bottle

and O-ring

Low Side Service

Hose with Coupler

High Side Service

Hose with Coupler

Refrigerant Identifier

(optional)

Removable

Cove

USB Port

Printer

Fill Cylinder Hose

TechALERT

Rotating Turret

Storage

Compartments

New Refrigerant

Storage Shelf

5

Page 7

OVERVIEW OF THE RHS980C AND HOW TO OPERATE IT

The RHS980C is designed for intuitive operation with menu driven prompts on the display.

A few minutes spent reviewing the contents of this operation manual will enable the technician to understand and

optimize the use of the RHS980C to provide customers with a professional A/C service.

The display shows data such as the internal cylinder weight and prompts the technician for input using the alphanumeric keypad and various navigation buttons.

The RHS980C can be used to perform a fully automatic A/C service. The technician will be prompted for entry of

data such as charge amount and given options like vacuum leak test. Once the necessary data has been entered,

the RHS980C will automatically perform the complete A/C service and alert the technician for interaction or that the

service is complete.

The RHS980C can also be used to perform individual functions like recycle, vacuum or charge. The keypad has

dedicated buttons (AUTOMATIC, RECYCLE, VACUUM and CHARGE) to allow the technician to jump directly to any

one of these functions.

Units of measure displayed can be changed at any time by repeatedly pressing the U/M key.

A setup routine can be used to select options, set default values, perform maintenance operations and manage fluid

capacities processed.

IMPORTANT – review the Startup & Safe Operation statements on the following page before operating the

RHS980C. Failure to do so may cause personal injury or cause the RHS980C to malfunction.

The Automatic Mode of operation is explained in the following pages. The screen which will be displayed for each

step is shown on the left. A description of the RHS980C operation is shown to the right of each screen.

► VERY IMPORTANT – MACHINE SHUTDOWN ◄

The new SAE Standard J2788 dictates that the filter must be changed at

set intervals to ensure that recycled refrigerant is pure.

The RHS980C has one filter which must be changed after recycling every

150 lbs. of refrigerant.

The technician will be alerted when the filter life is at 100 LB (45 KG). This

allows time to order a replacement filter kit (See “Parts Identification”).

When the filter has purified 150 LB (68 KG) of refrigerant, the RHS980C

will shut down and not perform any function.

A new filter must be installed to re-activate the RHS980C controller.

Fill out and return the Warranty Registration to activate the RHS980C warranty and free lifetime technical support.

This can also be done by calling RTI and providing information to one of the Technical Support Technicians.

Call 800-468-2321

6

Page 8

STARTUP & SAFE OPERATION

Do not use a damaged unit. Check for shipping damage and place a claim with carrier if

damage is discovered.

Return the Warranty Card to activate technical support service and warranty coverage.

The RHS980C should be operated by certified personnel only.

The RHS980C should not be operated or serviced by any person who has not read all the

contents of this manual.

This manual describes normal operation and maintenance for the RHS980C. Failure to read

and comply with these instructions or any one of the limitations noted herein can result in

serious injury and/or property damage. The instructions should not be interpreted to anticipate

every possible contingency.

It is the responsibility of the owner/user to operate the RHS980C in accordance with all laws

and specifications which may apply.

Recover, recycle, and charge only R134a.

Avoid breathing refrigerant or lubricant vapor. Exposure may irritate eyes, nose and throat.

Ventilate work area if accidental system discharge occurs.

Wear safety glasses and protective gloves. Refrigerant has a very low boiling point and can

cause frostbite.

Follow the RHS980C operating procedures sequentially to avoid prematurely disconnecting

hoses or opening valves which may release refrigerant to the atmosphere.

Do not expose the RHS980C to moisture or operate in wet areas.

Use RHS980C in areas with ventilation that provides at least four air changes per hour.

Service hoses must be constructed of the proper materials and with lengths as supplied with

the RHS980C (See “Parts Identification”). Hoses must have shutoff devices at the connection

point to the A/C to minimize the introduction of air into the RHS980C and the release of

refrigerant when being disconnected.

Avoid using an extension cord with the RHS980C. If necessary use a good condition, three

wire grounded, #14 AWG or larger extension cord of the shortest possible length.

Disconnect power before performing any maintenance or service on the RHS980C.

SPECIAL CONSIDERATIONS WITH R134a

R134a has been shown to be nonflammable at ambient temperature and atmospheric pressure.

However, tests under controlled conditions have indicated that at pressures above atmospheric

and with air concentrations greater than 60 percent by volume, R134a can form combustible

mixtures.

While it is recognized that an ignition source is also required for combustion to occur, the

presence of combustible mixtures is a potentially dangerous situation and should be avoided.

Under no circumstances should any equipment be pressure tested or leak tested with air and

R134a mixtures. Do not use compressed air for leak detection in R134a systems.

7

Page 9

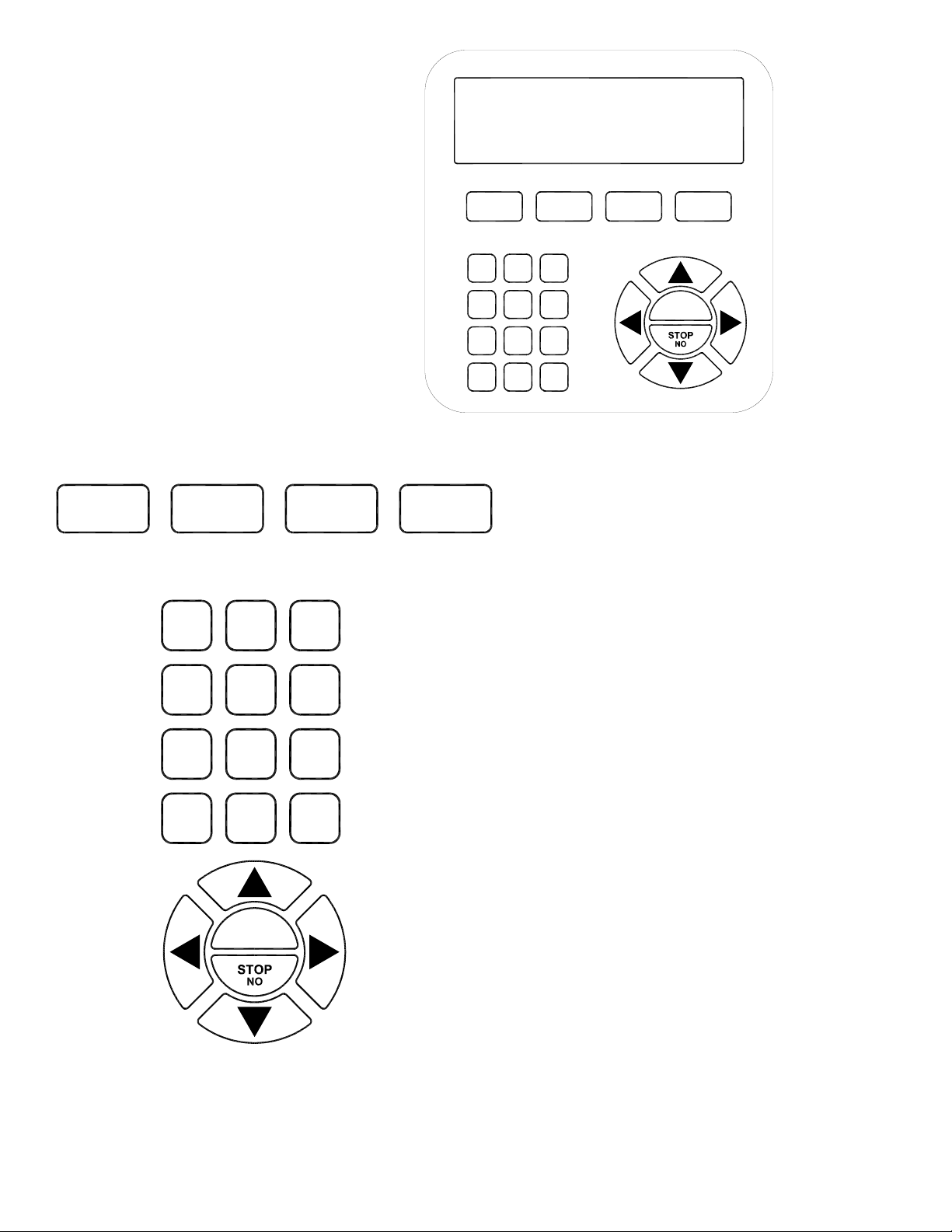

CONTROL PANEL

560-80450-00

AUTOMATIC RECYCLE VACUUM CHARGE

1

2

ABC

3

DEF

AUTOMATIC RECYCLE VACUUM CHARGE

1

4

GHI

PQRS7TUV8WXYZ

CLR

*

ABC2DEF

5

JKL

0

SPACE

MNO

U/M

3

6

9

#

YES

START

Pressing any one of these four buttons

causes the RHS980C to jump to the

respective procedure.

The alpha-numeric keypad is used to

enter data when prompted on the LCD

screen.

4

GHI

7

PQRS

CLR

*

5

JKL

8

TUV

0

SPACE

YES

START

6

MNO

9

WXYZ

#

U/M

Note: The # key also has U/M printed on

it. Pressing this key will toggle the units

of measure displayed on the LCD screen.

Note: Pressing the number 4 key

provides quick access to change

languages. Follow prompts to select

desired language.

Pressing any one of the arrow keys will

move the point of data entry on the LCD

screen in the respective direction.

Some screens provide options to select.

The arrow keys make it possible to select

the desired input.

The START and STOP buttons are used

to start or stop procedures as prompted

on the LCD screen.

8

Page 10

FIRST TIME USE

A

A

A

A

The first time a new RHS980C is powered up it will automatically perform a routine where the language is selected.

The language can be changed later if desired in the Setup Mode.

The RHS980C will arrive without any refrigerant. It will be necessary to put new refrigerant into the internal charge

cylinder before any other sequences can be run. The amount of refrigerant which to be transferred is factory set at 18

LB (8.16 KG). This amount can be adjusted if desired. Refer to SETUP section under DEFAULT VALUES to change

the factory setting. Connect the short yellow hose on the rear of the RHS980C to a new 30 lb. cylinder of refrigerant.

Open the cylinder valve, turn the cylinder up-side-down and place it on the platform. Secure with web belt.

Plug the power cord into an appropriate power source. Avoid using an extension cord. If necessary, use a good

condition, three wire grounded, #14 AWG or larger extension cord of the shortest possible length.

R T I - M A H L E C l e v i t e

R H S 9 8 0 C

# # # # ##

S E L E C T L A N G U A G E

► E N G L I S H E S P A Ñ O L

F R A N Ç A I S D E U T C H

▲ , ▼

E N T E R P

# # # #

S T A R T T O C O N T I N U E

S T O P T O E N D

P

S S W O R D A C C E P T E D

S T A R T T O C O N T I N U E

S T O P T O E N D

P

S S W O R D R E J E C T E D

S T A R T T O R E T R Y

S T O P T O E N D

W E I G H T = # # . # L B

U T O M A T I C

S T A RT?

W E I G H T = # # . # L B

R E C Y C L E

S T A RT?

W E I G H T = # # . # L B

V A C U U M

S T A RT?

S S W O R D

Press the Power Switch to turn on the RHS980C.

The screen shown to the left will be displayed and a

buzzer will sound.

Press ▲ or ▼ key to scroll the displayed arrow to the

desired language. Press START key.

(Refer to Section CHANGING LANGUAGES for

additional information on loading new languages)

Note: Pressing the #4 key from the main menu will

access the language selection option.

If password protection is NOT enabled then the next 3

subsequent screens will not be shown. Enter any of

the 11 stored passwords (10 operator and 1 service

manager) to gain access to operate the RHS980C.

The passwords will prevent non certified technicians

from performing A/C service. A service manager

password is required to change several machine

parameters. See section on Maintenance Options for

complete listing of passwords. Press START key to

continue.

If password is accepted, this screen is shown. Press

START key.

If password is rejected, this screen is shown. Check

the password and press START key to retry the entry

or press STOP key to end.

The screen shown to the left will be displayed. Press

the ▼ key to scroll to the next screen.

Press ▼ key.

Press ▼ key.

9

Page 11

W E I G H T = # # . # L B

S

C O

G

A

C H A R G E

S T A RT?

W E I G H T = # # . # L B

F I L L C Y L I N D E R

S T A RT?

Press ▼ key.

Press START key. If the internal cylinder capacity

is equal to or greater than the target amount

shown in DEFAULT VALUES, the FILL CYLINDER

process will not be available from the main menu.

T A R T I N G R E F R I G E R A N T

I D E N T I F I E R

D O N O T C O N N E C T H O S E S

P L E A S E W A I T . . .

E X A M I N E I D S A M P L E

H O S E / F I L T E R F O R O I L

S T A R T T O C O N T I N U E

S T O P T O E N D

N N E C T I D E N T I F I E R

S A M P L E H O S E T O L O W

S I D E

P R E S S Y E S W H E N D O N E

A S A N A L Y S I S I S I N

P R O C E S S . . P L E A S E

W A I T

R E M O V E I D E N T I F I E R

S A M P L E H O S E F R O M L O W

S I D E

P R E S S Y E S W H E N D O N E

I D R E S U L T S :

R 1 3 4 : # # . # % , A I R : # # . # %

H C : # # . # % P R E S S N O T O

R E J E C T , Y E S T O A C C E P T

> 5 % A I R S U G G E S T S

E X C E S S O I L I N S A M P L E

H O S E / F I L T E R . R E M E D Y

B E F O R E U S E . C O N T I N U E ?

C O N N E C T H O S E T O

S O U R C E T A N K

O P E N V A L V E

S T A RT?

F I L L C Y L I N P R O C E S S

M T F I L L E D # # . # L B

S T O P T O E N D

If the RHS980C has a refrigerant identifier installed,

the screen to the left and next 3 subsequent screens

will appear. The refrigerant identifier is an optional

item and can be installed in the field. Contact RTI for

more information.

Inspect the identifier hose for traces of oil

contamination. If oil is present in the hose, remove the

contaminated hose section or replace the entire hose

assembly. See REFRIGERANT IDENTIFIER

MAINTENANCE section of manual. Press START key.

Connect refrigerant identifier hose found on the rear of

the RHS980C to the cylinder of new refrigerant. Unit

includes an adapter to convert the ½ inch Acme fitting

on the cylinder to low side coupler. Cylinder of new

refrigerant must be upright with valve at top of

tank. Press YES key.

Sample of new cylinder refrigerant is processed and

the hose and coupler must be removed. Press

START key.

This shows the results from the identifier refrigerant

sample processed. Select NO key to reject these

results or YES key to accept the results. Pressing NO

will return to the initial screen.

If the results from the refrigerant identification show an

air percentage above 5%, this screen will appear.

Inspect the id filter, sample hose and coupler filter prior

to the next identification to ensure these devices are

free of oil contamination. See REFRIGERANT

IDENTIFIER MAINTENANCE section for more

information.

This is a reminder that the cylinder of new refrigerant

must be connected to the yellow hose on the rear of

the RHS980C. Press START key.

Refrigerant will be transferred from the cylinder on the

rear platform into the internal charge cylinder of the

RHS980C. Cylinder of new refrigerant must be

upside down with valve at bottom of tank.

10

Page 12

F I L L C Y L I N P R O C E S S

A

A

C O

GA S

T I M E L E F T # # . # #

S T O P T O E N D

F I L L C Y L C O M P L E T E

M T F I L L E D # # . # L B

S T O P T O E N D

The amount transferred will be displayed. Note:

Pressing the STOP key will start an internal

clearing process. This process must run to

completion to remove internal refrigerant.

The Fill Cylinder procedure is complete when desired

amount of refrigerant has been transferred. The Setup

procedure allows changing the value and is covered in

DEFAULT VALUES section in this manual.

Note: To fill to less than 18 LB (8.16 KG), close

valve on cylinder of new refrigerant and allow

procedure to complete. A minimum of 10 LB (4.53

KG) is suggested for truck service application.

REFRIGERANT BLENDS

The RHS980C is designed to recover, recycle and charge R134a. Take extreme precaution to ensure that other

refrigerants are not recovered into the RHS980C.

A refrigerant identifier is recommended for evaluating refrigerant in the A/C system prior to servicing.

Recovering other refrigerants will contaminate the refrigerant in the RHS980C charge cylinder.

Sealants and leak stop chemicals in A/C systems may cause serious damage to the RHS980C if they are present in

the refrigerant recovered intended for recovery.

Detection devices are readily available to check for the presence of these chemicals and are highly recommended

to protect the RHS980C.

Call RTI for more information about solutions for detection of refrigerant blends and leak sealers.

LEAK SEALERS

AUTOMATIC OPERATION

W E I G H T = # # . # L B

U T O M A T I C

S T A RT?

I D E N T I F I E R

D O N O T C O N N E C T H O S E S

P L E A S E W A I T . . .

E X A M I N E I D S A M P L E

H O S E / F I L T E R F O R O I L

S T A R T T O C O N T I N U E

S T O P T O E N D

N N E C T I D E N T I F I E R

S A M P L E H O S E T O L O W

S I D E

P R E S S Y E S W H E N D O N E

A N A L Y S I S I S I N

P R O C E S S . . P L E A S E

W A I T

At the main menu screen, press the START key.

If the RHS980C has the optional refrigerant identifier

installed, the screen to the left and next 6 subsequent

screens will appear.

Inspect the identifier hose for traces of oil

contamination. If oil is present in the hose, remove the

contaminated hose section or replace the entire hose

assembly. See REFRIGERANT IDENTIFIER

MAINTENANCE section of manual. Press START key.

Connect refrigerant identifier hose found on the rear of

the RHS980C to the vehicle low side service port.

Press YES key.

11

Page 13

R E M O V E I D E N T I F I E R

%

A

S

ACU U

A

A

A

A

S A M P L E H O S E F R O M L O W

S I D E

P R E S S Y E S W H E N D O N E

I D R E S U L T S :

R 1 3 4 : # # . # % , A I R : # # . #

H C : # # . # % P R E S S N O T O

R E J E C T , Y E S T O A C C E P T

> 5 % A I R S U G G E S T S

E X C E S S O I L I N S A M P L E

H O S E / F I L T E R . R E M E D Y

B E F O R E U S E . C O N T I N U E ?

Sample of vehicle A/C refrigerant is processed and the

hose and coupler must be removed. Press START

key.

This shows the results from the identifier refrigerant

sample processed. Select NO key to reject these

results or YES key to accept the results. Pressing NO

will return to the initial screen. A high air percentage

can be an indication of required maintenance, see

Identifier Maintenance section for more information.

If the results from the refrigerant identification show an

air percentage above 5%, this screen will appear.

Inspect the id filter, sample hose and coupler filter prior

to the next identification to ensure these devices are

free of oil contamination. See REFRIGERANT

IDENTIFIER MAINTENANCE section for more

information.

C H E C K O I L D R

I N

L E V E L , A D J U S T O R I N G

T O T O P O F L E V E L

C O N T I N UE?

E L E C T V A C U U M T Y P E

E N H A N C E D

S T A N D A R D

C O N T I N U E ?

E N T E R V

T I M E # # M I N

M

C O N T I N U E ?

U S E

C C A P A C I T Y

G U I D E T O D E T E R M I N E

C H A R G E A M O U N T ?

S E L E C T Y E S O R N O

U S E ▲ ▼ T O S C R O L L

◄ ► P A G E U P & D O W N

S T A R T T O C O N T I N U E

S T O P T O E N D

V E R I F Y I N G D

T A B A S E

P L E A S E W A I T . . .

S E L E C T Y E

R

> # # # #

> # # # #

> # # # #

S E L E C T M

K E

> # # # # # # #

> # # # # # # #

> # # # # # # #

Ensure that the oil drain bottle has enough remaining

capacity to perform a service. Adjust the o-ring slider

so it is level with the oil in the oil drain bottle. Press

START key.

Select vacuum type, Enhanced or Standard. If

enhanced is selected, the unit will draw a deeper

vacuum and use the onboard micron sensor. The

enhanced vacuum process will take longer than the

standard vacuum process. The standard procedure

will utilize a pressure transducer to measure vacuum

levels. Press START key.

Enter the time desired to vacuum the A/C system.

Press START key.

See SETUP SELECTABLE OPTIONS to enable or

disable AC Capacity Guide. To use the on board AC

capacity guide to determine the charge amount for the

vehicle, press YES key. Otherwise press NO key.

Pressing the YES key will show the next 9 subsequent

screens.

Screen shows the instructions for the navigation and

selection of the information shown on the next 5

screens. Press YES key to continue or NO key to

abort operation.

Screen to the left will appear after operator selections

are made and data is processed internally.

Select the year for the vehicle being serviced. Press

YES key on the highlighted value to continue. Use ▲

or ▼ key to scroll the displayed arrow to the desired

selection.

Select the make of the vehicle being serviced. Press

YES key on the highlighted value to continue. Use ▲

or ▼ key to scroll the displayed arrow to the desired

selection.

12

Page 14

S E L E C T M O D E L

A

A

A

A

> # # # # # # #

> # # # # # # #

> # # # # # # #

S E L E C T E N G I N E

> # # # # # # #

> # # # # # # #

> # # # # # # #

S E L E C T S Y S T E M

> # # # #

> # # # #

> # # # #

Y E A R, M O D E L, E N G I N E

S Y S T E M T Y P E X X, X X O Z

C O N D E N S E R C A P A C I T Y

X X O Z

Select the model of the vehicle being serviced. Press

YES key on the highlighted value to continue. Use ▲

or ▼ key to scroll the displayed arrow to the desired

selection.

Select the engine configuration of the vehicle being

serviced, if more than 1 option is available. Press YES

key on the highlighted value to continue. Use ▲ or ▼

key to scroll the displayed arrow to the desired

selection.

If required, a screen to select the system for the

vehicle being serviced will be shown. Press YES key

on the highlighted value to continue. Use ▲ or ▼ key

to scroll the displayed arrow to the desired selection.

The data will be shown for the vehicle parameters

entered on this screen. Year, make, model, type,

system and refrigerant capacity in OZ is detailed.

Press ▼ key to display the next screen or YES key to

accept the charge amount.

O I L T Y P E

# # # # #

T O T A L O I L C A P A C I T Y

# ## # # O Z

E N T E R C H

# # . # L B

C O N T I N UE?

C U R R E N T O I L T Y P E

P A G / P O E

< > T O C H AN G E

C O N T I N UE?

S E L E C T T O C H

H I G H / L O W / B O T H

C O N T I N UE?

C O N N E C T H O S E S

O P E N V A L V E S

S T A RT?

C L E

P L E A S E W A I T

S T O P T O E N D

R E C Y C L E I N P R O C E S S

M T R E C # # . # L B

S T O P T O E N D

R I N G I N P R O C E S S

R G E A M O U N T

R G E

The oil type and total oil capacity are shown on the

screen for the selected vehicle parameters. Press key

▲ to display the previous screen or YES key to accept

the charge amount.

Enter the amount of refrigerant to be charged into the

A/C system or the charge capacity will be

automatically entered if the AC database was used.

Press START key.

Press ► or ◄ key to change the type of oil which

exists on the A/C system being serviced. A HIGH

VOLTAGE OIL FLUSH will be started automatically if

the type is changed.

Press ► or ◄ key to select which side to charge to on

the A/C system. The word HIGH, LOW or BOTH will

display in bold letters. Note: If oil injection was

selected, only HIGH or BOTH will be enabled. Press

START key.

Connect the red hose to the high side and the blue

hose to the low side of the A/C system. Open the

valves on both hoses. Press START key.

A clearing procedure will run to remove refrigerant

from internal components.

The RHS980C will now recover and recycle

refrigerant. The amount of refrigerant recovered will be

displayed. The next screen will be displayed when

vehicle system pressure is in a vacuum.

13

Page 15

A

A

A

A

A

A

A

A

A

A

A

A

O I L D R

P L E A S E W A I T

S T O P T O E N D

R E C Y C L E I N P R O C E S S

M T R E C # # . # L B

T I M E L E F T # # M I N

S T O P T O E N D

V

C U U M I N P R O C E S S

T I M E L E F T # # M I N

L E V E L # # # # # M I C R O N

S T O P T O E N D

C H E C K I N G V

T I M E L E F T # # S E C

L E V E L # # # # # M I C R O N

S T O P T O E N D

V

C U U M I N P R O C E S S

T I M E L E F T # # M I N

L E V E L # # # # # M I C R O N

S T O P T O E N D

I N I N P R O C E S S

C U U M L EAK

When the vehicle system reaches 10 psi, the machine

will drain any recovered oil.

The RHS980C will continue to recycle refrigerant and

complete after the time shown is expired.

The RHS980C will draw a deep vacuum on the A/C

system for the time entered in the default vacuum run

time in the set up menus. The time left and the

vacuum level in micron will be displayed if Enhanced

vacuum is selected.

The vacuum leak test will begin. The time left and the

micron level will be displayed if Enhanced vacuum is

selected. If the vacuum level rises above leak level

set in set up default menu, an error screen will be

displayed.

A second deep vacuum process will run for the length

of time displayed.

P U R G E I N P R O C E S S

P L E A S E W A I T

S T O P T O E N D

C L E

P L E A S E W A I T

S T O P T O E N D

C H

M T C H G = # # . # L B

D O N O T D I S T U R B U N I T !

S T O P T O E N D

U T O M A T I C C O M P L E T E

M T R E C # # . # L B

M T C H G # # . # L B

C O N T I N UE?

S T

S T O P T O T E S T M O D E

R I N G I N P R O C E S S

R G E I N P R O C E S S

R T T O E V A C H O S E S

The RHS980C will purge air from the recovered

refrigerant if necessary. This process will be displayed.

A clearing procedure will run to remove refrigerant

from internal components.

The RHS980C will charge the amount of refrigerant

set previously into the A/C system. TO AVOID AN

INACCURATE CHARGE, DO NOT BUMP OR MOVE

THE RHS980C DURING THIS PROCESS.

The automatic cycle is complete when the desired

amount of refrigerant has been charged. The amount

of refrigerant recycled and the amount of refrigerant

charged will be displayed. Press START key.

Press START key to proceed to the hose evacuation

procedure as outlined below. Press STOP key to

perform AC system test mode. See A/C SYSTEM

TEST MODE for a description of this feature.

14

Page 16

A

A

A

A

A

D I S C O N N E C T H S H O S E

N D S T A R T A / C M A X

C O N T I N UE?

E Q U

P L E A S E W A I T

D I S C O N N E C T L O W S I D E

H O S E , S H U T O F F E N G I N E

C O N T I N UE?

L I Z I N G H O S E S

Close the high side coupler and disconnect from the

vehicle system coupler. Start the engine and place the

A/C system on max setting. Press START key.

While the engine and A/C system is running, liquid is

being removed from the services hoses. This ensures

only vapor remains in hoses.

Close the low side coupler and disconnect from the

vehicle system coupler. Turn off the vehicle engine.

Press START key.

C L E

P L E A S E W A I T

S T O P T O E N D

R I N G I N P R O C E S S

C L E A R I N G H O S E S

M T R E C # # . # L B

T I M E L E F T # # M I N

S T O P T O E N D

E V A C H O S E S C O M P L E T E

I N S T A L L S E R V I C E C APS

D D O I L I F R E Q U I R E D

S T O P T O E N D

A clearing procedure will run to remove refrigerant

from internal components.

Any vapor refrigerant remaining in the hoses will be

recovered into the RHS980C.

The automatic cycle is complete when the hose

evacuation process is ended. Check the level of oil

drained and add oil to the A/C system following

standard injection procedures. Reinstall service caps

onto vehicle A/C ports.

15

Page 17

A/C SYSTEM TEST MODE

A

A

A

A

A

W E I G H T = # # . # L B

U T O M A T I C

S T A RT?

W E I G H T = # # . # L B

/ C S Y S T E M T E S T M O D E

S T A RT?

At the main menu screen, press the ▲ key 7 times.

Press START key.

S T

R T I N G R E F R I G E R ANT

I D E N T I F I E R

D O N O T C O N N E C T H O S E S

P L E A S E W A I T . . .

E X

M I N E I D S A M P L E

H O S E / F I L T E R F O R O I L

S T A R T T O C O N T I N U E

S T O P T O E N D

C O N N E C T I D E N T I F I E R

S A M P L E H O S E T O L O W

S I D E

P R E S S Y E S W H E N D O N E

G

S A N A L Y S I S I S I N

P R O C E S S . . P L E A S E

W A I T

R E M O V E I D E N T I F I E R

S A M P L E H O S E F R O M L O W

S I D E

P R E S S Y E S W H E N D O N E

I D R E S U L T S :

R 1 3 4 : # # . # % , A I R : # # . # %

H C : # # . # % P R E S S N O T O

R E J E C T , Y E S T O A C C E P T

> 5 % A I R S U G G E S T S

E X C E S S O I L I N S A M P L E

H O S E / F I L T E R . R E M E D Y

B E F O R E U S E . C O N T I N U E ?

C O N N E C T H O S E S

O P E N V A L V E S

S T A RT?

If the RHS980C has the optional refrigerant identifier

installed, the screen to the left and next 6 subsequent

screens will appear.

Inspect the identifier hose for traces of oil

contamination. If oil is present in the hose, remove the

contaminated hose section or replace the entire hose

assembly. See REFRIGERANT IDENTIFIER

MAINTENANCE section of manual. Press START key.

Connect refrigerant identifier hose found on the rear of

the RHS980C to the vehicle low side service port.

Press YES key.

Sample of vehicle A/C refrigerant is processed and the

hose and coupler must be removed. Press START

key.

This shows the results from the identifier refrigerant

sample processed. Select NO key to reject these

results or YES key to accept the results. Pressing NO

will return to the initial screen. A high air percentage

can be an indication of required maintenance, see

Identifier Maintenance section for more information.

If the results from the refrigerant identification show an

air percentage above 5%, this screen will appear.

Inspect the id filter, sample hose and coupler filter prior

to the next identification to ensure these devices are

free of oil contamination. See REFRIGERANT

IDENTIFIER MAINTENANCE section for more

information.

Connect the red hose to the high side and the blue

hose to the low side of the A/C system. Open the

valves on both hoses. Press START key.

16

Page 18

A

A

A

A

A

P R E C H

M T C H G = # # . # L B

D O N O T D I S T U R B U N I T !

S T O P T O E N D

T T A C H T E M P P R O B E S

T O V E H I C L E A N D S T ART

E N G I N E W I T H A / C M AX

C O N T I N UE?

T 1 = # # # T 2 = # # # T 3 = # # #

H I G H P R E S = # # # R H = # # #

L O W P R E S = # # # * T O C L R

S T A R T T O C AP T U R E

T1, T2 and T3 are external temperature probes

attached to the rear of unit.

P R I N T R E S U L T S ?

S T A R T T O C O N T I N U E

S T O P T O E N D

E N T E R V I N N U M B E R

# # # # # # # # # # # # # # # # #

S T A R T T O C O N T I N U E

S T O P T O E N D

R G I N G H O S E S

The RHS980C will precharge the hoses with

refrigerant. Allow unit to automatically proceed to the

next step. Press STOP key will abort operation.

Attach temperature probes to vehicle following the

service manual vehicle performance test procedures.

Start vehicle engine with the A/C system on maximum.

Press START key.

The RHS980C will start displaying A/C performance

data. Units of measure can be changed by pressing

the U/M key. The lowest temperature is tracked and

updated on the LCD screen. The highest pressure is

tracked and updated. The lowest pressure is tracked

and updated. RH is the relative humidity. Press the

* key to refresh or reset the tracking of data. Press the

START key to capture the data and proceed to the

next step.

Press START key to print performance results

captured. Press STOP key to end. Refer to

PRINTING RESULTS section of manual for details on

printing.

Using the alpha-numeric keypad, enter the vehicle

identification number. Follow typical text messaging

methods to enter characters. After a brief delay during

entry, cursor position will move to the right. Press

START key when complete.

P R I N T I N G R E S U L T S

T O P R I N T E R

P L E A S E W A I T . . .

C L E A R R E S U L T S / D A T

C O L L E C T E D ?

S E L E C T Y E S O R N O

T E S T M O D E C O M P L E T E

S T A R T T O E V A C H O S E S

S T O P T O E N D

W I T H E N G I N E R U N N I N G

N D A / C M A X

D I S C O N N E C T H S H O S E

C O N T I N UE?

Screen to left will be shown when data is printing.

Press YES key if printing is complete or NO key if

another copy is required.

Press START key to begin hose evacuation

procedure.

Disconnect high side coupler from vehicle with the

engine running and A/C system on maximum. Press

START key to continue.

17

Page 19

E Q U A L I Z I N G H O S E S

A

A

A

P L E A S E W A I T

D I S C O N N E C T L O W S I D E

H O S E , S H U T O F F E N G I N E

C O N T I N UE?

C L E

P L E A S E W A I T

S T O P T O E N D

R I N G I N P R O C E S S

C L E A R I N G H O S E S

M T R E C # # . # L B

T I M E L E F T # # M I N

S T O P T O E N D

E V A C H O S E S C O M P L E T E

I N S T A L L S E R V I C E C APS

D D O I L R E Q U I R E D

S T O P T O E N D

While the engine and A/C system is running, liquid is

being removed from the services hoses. This ensures

only vapor remains in hoses.

Close the low side coupler and disconnect from the

vehicle system coupler. Turn off the vehicle engine.

Press START key.

A clearing procedure will run to remove refrigerant

from internal components.

Any vapor refrigerant remaining in the hoses will be

recovered into the RHS980C.

The A/C system test mode is complete when the hose

evacuation process is ended. Check the level of oil

drained and add oil to the A/C system following

standard injection procedures. Reinstall service caps

onto vehicle A/C ports.

18

Page 20

A

A

PRINTING RESULTS

W E I G H T = # # . # L B

U T O M A T I C

S T A RT?

W E I G H T = # # . # L B

P R I N T R E S U L T S

S T A RT?

E N T E R V I N N U M B E R

# # # # # # # # # # # # # # # # #

S T A R T T O C O N T I N U E

S T O P T O E N D

P R I N T I N G R E S U L T S

T O P R I N T E R

P L E A S E W A I T . . .

C L E A R R E S U L T S / D A T

C O L L E C T E D ?

S E L E C T Y E S O R N O

Example of printout:

**********************

R T I T E C H N O L O G I E S

R H S9 8 0 C

D A T E : # # - # # - # # # #

T I M E : # # : # #

S O F T W A R E R E V : 9 8 0 C # #

P R I N T O U T O F R E S U L T S

V I N : # # # # # # # # # # # # # # # # #

A M B I E N T D A T A

R E L A T I V E H U M I D I T Y :

# # %

T E M P E R A T U R E : # # # F

V E H I C L E D A T A

T 1 T E M P M I N : # # # F

T 2 T E M P M I N : # # # F

T 3 T E M P M I N : # # # F

H I G H S I D E M A X P R E S :

# # # P S I

L O W S I D E M I N P R E S :

# # # P S I

R E C Y C L E D : # # . # L B S

V A C L E A K T E S T : # # # # # #

M I N V A C : # # # # M I C R O N

C H A R G E D : # # . # L B S

* * * * * * * * * * * * * * * * * * * * * *

At the main menu screen, press the ▲ key 5 times.

See Printer Maintenance section if additional paper is

required.

Press START key.

Using the alpha-numeric keypad, enter the vehicle

identification number. Follow typical text messaging

methods to enter characters. After a brief delay during

entry, cursor position will move to the right. Press

START key when complete.

Screen to left will be shown when data is printing.

Press YES key if printing is complete or NO key if

another copy is required.

Printout will scroll from the rear of the machine. Pull

paper at a slight angle upright to remove. See picture

below.

Units of measure on print-out are dependent on

selected units during normal operation.

Depending on the process performed, selected data

will be available for printing. Data is stored when the

processes are allowed to run until full completion.

19

Page 21

A

A

A

A

A

A

A

HIGH PRESSURE LEAK DETECT

HIGH PRESSURE LEAK DETECT allows an operator to pressurize a component or system to detect a difficult

to locate leak prior to checking with an external leak detector. Recommend to start process with an internal

system capacity of 8 to 10 LB (3.63 to 4.54 KG). Use of a leak detector meeting newest standard SAE J2791

or later is suggested.

W E I G H T = # # . # L B

U T O M A T I C

S T A RT?

W E I G H T = # # . # L B

H I G H P R E S S U R E L E A K

D E T E C T S T A RT?

E N T E R F I N

P R E S S U R E # # # P S I

B E T W E E N 7 0 & 1 2 0 P S I

C O N T I N UE?

I N T E R N

B U I L D I N G P R E S S U R E

P L E A S E W AIT

H I G H P R E S S U R E L E

F A I L E D , U N A B L E T O

R E A C H T A R G E T , S E E

M A N U A L C O N T I N U E ?

C H

R G E I N P R O C E S S

M T C H G = # # . # L B

D O N O T D I S T U R B U N I T !

S T O P T O E N D

H P L E

P E R F O R M L E A K C H E C K

U S I N G E X T E R N A L L E AK

D E T E C T O R C O N T I N U E ?

L C Y L I N D E R

K D E T E C T D O N E

L T A R G E T

K

At the main menu screen, press the ▲ key 4 times.

Press START key.

Using the alphanumeric keypad, enter the final target

pressure for the system or component under test.

Recommend a setting of 90 PSI for most applications.

Press START key to continue.

The RHS980C will begin building internal pressure to

the specified target amount.

If the unit has failed to build the desired pressure after

30 minutes, the screen to left is displayed. Add

refrigerant to the internal cylinder and retry procedure.

Press START key to continue.

After reaching the target pressure, the unit will charge

the system or component with liquid refrigerant. Press

the STOP key to abort the operation.

When charge is complete, the screen shown will

appear. Check for system leaks using a leak detector.

Refrigerant must be recovered after leak check is

completed.

WARNING

DO NOT START VEHICLE AC SYSTEM IF HIGH PRESSURE LEAK DETECT

PROCEDURE WAS USED. COMPRESSOR DAMAGE COULD RESULT. A RECYCLE

PROCEDURE MUST FOLLOW LEAK DETECT.

20

Page 22

HIGH VOLTAGE OIL FLUSH

The RHS980C can be configured from the factory to have the ability to perform an internal oil flushing

process to eliminate cross contaminations between PAG oil used in a conventional R-134a system and POE

oil used in HIGH VOLTAGE HYBRID systems. The POE oil acts as a lubricant, but more importantly the POE

oil is required to keep the HIGH VOLTAGE system isolated from the chassis. If the HYBRID’s system

becomes conductive, the service technician can be at risk of electrical shock. During the HIGH VOLTAGE

OIL FLUSH process the residual PAG oil from previous services will be flushed from the HIGH - low side

couplers and hoses along with the corresponding internal passages of the RHS980C unit.

IMPORTANT – THE HIGH VOLTAGE OIL FLUSH PROCESS MUST BE PERFORMED

BEFORE A SERVICE ON A HYBRID VEHICLE WITH THIS MACHINE IS CONDUCTED!

IT IS THE SERVICE TECHNICIANS RESPONSIBILITY TO UNDERSTAND THE RISKS

INVOLVED IN SERVICING A HIGH VOLTAGE HYBRID A/C SYSTEM, AS WELL AS

DETERMING THE PROPER OIL REQUIRED FOR THE HYBRIDS A/C SYSTEM TO ENSURE

ITS ELECTRICAL ISOLATION FROM THE VEHICLES CHASSIS IS MAINTAINED.

With units configured for the High Voltage Oil Flush there will be a screen illustrated below that will start the

High Voltage Oil Flush process. The manual oil injection bottle and connections will NOT be present next to

the oil drain bottle. The High Voltage Oil Flush configured unit will also be shipped with a HIGH -LOW side

adapter so that the hoses can be connected to flush residual oil from previous services. To get to the HIGH

VOLTAGE OIL FLUSH FEATURE, follow the procedure below.

W E I G H T = # # . # L B

A U T O M A T I C

S T A RT?

W E I G H T = # # . # L B

R E C Y C L E

S T A RT?

The screen shown to the left will be displayed. Press

the ▼ key to scroll to the next screen.

Press ▼ key.

W E I G H T = # # . # L B

V A C U U M

S T A RT?

W E I G H T = # # . # L B

C H A R G E

S T A RT?

W E I G H T = # # . # L B

F I L L C Y L I N D E R

S T A RT?

Press ▼ key.

Press ▼ key.

Press ▼ key.

21

Page 23

W E I G H T = # # . # L B

T E C H A L E R T D E M O

S T A RT?

W E I G H T = # # . # L B

H I G H V O L T A G E O I L

F L U S H S T A RT?

C O N N E C T E X T F L U S H

D A P T E R T O L O W A N D

A

I G H S I D E C O U P L E R S

H

C O N T I N UE?

A R G E I N P R O C E S S

CH

A M T C H G = # #. # # L B

D O N O T D I S T U R B U N I T !

S T O P T O E N D

E C Y C L E I N P R O C E S S

R

A M T R E C # # . # # LB

T I M E L E F T # # : # #

S T O P T O E N D

H I G H V O L T A G E O I L

F L US H C O M P L E T E

S T O P T O E N D

Press ▼ key.

Press START key.

Connect the HIGH and LOW side couplers with the

supplied HIGH VOLTAGE OIL FLUSH adapter as shown

below, open HIGH and LOW side couplers. Press the

START key.

The RHS980C will perform the HIGH VOLTAGE OIL

FLUSH process at this time.

Press STOP key to end the process, disconnect the

HIGH and LOW service couplers from the adapter.

22

Page 24

REFRIGERANT FLUSH

A

A

A

REFRIGERANT FLUSH will force liquid refrigerant in a reverse flow through a component or components to

remove contaminates and oil. Special flush components and adapters are available through RTI to properly

connect to standard AC components.

W

E I G H T = # # . # L B

U T O M A T I C

S T A RT?

W E I G H T = # # . # L B

R E F R I G E R A N T F L U S H

S T A RT?

E N T E R T I M E F O R F L U S H

# # M I N

B E T W E E N 5 A N D 3 0 M I N

C O N T I N UE?

C H E C K O I L D R

L E V E L , A D J U S T O R I N G

T O T O P O F L E V E L

C O N T I N UE?

C H E C K I N G

P R E S S U R E S

P L E A S E W A I T

C O N N E C T F L U S H F I L T E R

T O L O W S I D E A N D

C O U P L E R S T O S Y S T E M

C O N T I N UE?

F L U S H I N P R O C E S S

T I M E L E F T ~ # # : # #

S T O P T O E N D

F L U S H C O M P L E T E

D IS C O N N E C T C O U P L E R S

N D F L U S H F I L T E R

C O N T I N UE?

C H E C K O I L B O T T L E

C L E A N F L U S H F I L T E R

C O N T I N UE?

I N

If system states “CHARGE FAILED”, check flush

filter, component or system for blockage.

Replace as required. Filter: 026 80561 00

At the main menu screen, press the ▲ key 1 time.

Press START key.

Enter the desired time to flush using the alphanumeric

keypad. Press START key to continue.

Empty oil bottle and adjust o-ring. Press START key to

continue.

Following adapter detailed installation instructions,

connect flush filter and service couplers to AC

component. Press START key to continue.

The RHS980C will pulse charge liquid and recycle

refrigerant through the component being serviced.

Contaminants will be captured in the service filter.

Press the STOP key to abort the operation.

Observe pressure shown on pressure gauges and if

pressure is less than 0 psi, carefully remove

connections from component under test. If pressure is

greater than 0 psi, perform a recycle before

disconnecting component. Press START key to

continue.

Check the oil bottle and empty if required. Flush filter

must be replaced after every service. Press START

key to continue.

Since refrigerant flushing removes all oil from the

component being serviced, ensure that the proper

quantity of oil is manually replenished.

23

Page 25

SETUP

A

A

A

A

A

A

The setup procedure provides a means of setting options for various operation functions of the RHS980C.

W E I G H T = # # . # L B

U T O M A T I C

S T A RT?

W E I G H T = # # . # L B

S E T U P

S T A RT?

SELECTABLE OPTIONS

S E L E C T

C O N T I N UE?

S E L E C T L

► E N G L I S H E S P A Ñ O L

F R A N Ç A I S

▲ , ▼

Default is ENGLISH.

B U Z Z E R E N

► Y E S

N O ▲

▼

Default is YES.

R E F R I G I D I N S T

Y E S

► N O ▲

▼

Default is NO.

C C A P D B I N S T A L L E D ?

► N O

I N T E R N A L ▲

E X T E R N A L ▼

Default is NO.

B L E O P T I O N S

N G U A G E

B L E D ?

L L E D ?

The initial screen displayed after turning on power will

be as shown to the left.

Press the ▼ key to scroll through screens until the

setup screen shown to the left is displayed. Press the

START key.

The first screen will be for SELECTABLE OPTIONS.

Press the ▼ key to scroll through other setup screens:

DEFAULT VALUES, MAINTENANCE OPTIONS and

TOTAL CAPACITIES. These four setup procedures

are described below. Press START key.

The first option is to select the language which is used

on LCD display screens.

Press ▲ or ▼ key to scroll the displayed arrow to the

desired language. Press START key.

Note: Pressing the #4 key from the main menu will

access the language selection option.

This enables or disables the buzzer on the RHS980C.

Press the ▲ or ▼ key to scroll to YES or NO. Press

START key.

This enables the RHS980C to interact with the RTI

Refrigerant Identifier. If this optional item was not

installed at the factory, visit the RTI web-site for more

information. Press the ▲ or ▼ key to scroll to YES or

NO. Press START key.

This enables the RHS980C to interact with the RTI

Refrigerant Capacity Database. If NO is selected, the

operator will not be prompted prior to charge to access

the AC Capacity Database for the vehicle charge

amount. Selecting external and having flash drive with

the optional Database attached to the unit USB port,

charge capacities will be available. Selection of

internal is not available on RHS980C, Press the ▲ or

▼ key to scroll to choices. Press START key.

Contact RTI for more information

24

Page 26

P R I N T E R I N S T A L L E D ?

A

A

A

A

A

A

A

A

A

► Y E S

N O ▲

▼

Default is YES.

P R I N T T O F L

► Y E S

N O ▲

▼

Default is YES.

L O W V O L T

E N A B L E D ?

► Y E S ▲

N O ▼

Default is YES.

MI CR ON V

SENSOR EN A B L E D ?

► Y E S ▲

N O ▼

Default is YES.

P

S S W O R D P R O T E C T I O N

EN A B L E D?

► Y E S ▲

N O ▼

Default is YES.

E N T E R P

# # # #

S T A R T T O C O N T I N U E ▲

S T O P T O E N D ▼

S T

EN A B L E D?

► Y E S ▲

Default is YES.

V I N E N T R Y E N

► Y E S ▲

Default is YES.

O P E R

► N O ▼

Default is NO.

EN A B L E D ?

► Y E S ▲

Default is YES.

R T U P P A S S W O R D

N O ▼

N O ▼

T O R I D E N T R Y

Y E S ▲

C T E S T M O D E

N O ▼

G E D E T E C T

S S W O R D

S H D R I V E

CUUM

B L E D ?

Use to enable or disable the on board printer on the

RHS980C . Press the ▲ or ▼ key to scroll to YES or

NO. Press START key.

Use to enable or disable printing service results or

setup parameters as files on the attached flash drive.

Press the ▲ or ▼ key to scroll to YES or NO. Press

START key.

Use to enable or disable the Low Voltage Detect on

the RHS980C. Press the ▲ or ▼ key to scroll to YES

or NO. Press START key.

Use to enable or disable the Micron Vacuum Sensor

on the RHS980C. Press the ▲ or ▼ key to scroll to

YES or NO. Press START key.

This feature can be enabled on the base RHS980CNAV. IMPORTANT The manager password will also

be required to make any changes in the Selectable

Options and the Default Values sections if enabled.

See Maintenance Options in regards to default

password and changing passwords. Press START

key. If NO is selected the following screen will be

shown.

Default Service Managers password is 5237, enter this

password to continue. Proceed to Maintenance

Section to see how to change default password to one

of the 20 optional passwords. Press START key.

An operator password will be required to proceed with

any operation after powering the unit if this feature has

been enabled.

This feature allows the vehicles VIN to be entered that

is being serviced. Press START key.

Use to enable or disable the Operator ID Entry feature

on the RHS980C. Press the ▲ or ▼ key to scroll to

YES or NO. Press START key.

Use to enable or disable the AC Test Mode feature on

the RHS980C. Press the ▲ or ▼ key to scroll to YES

or NO. Press START key.

25

Page 27

V AC U U M P U M P O I L L I F E

A

A

A

A

A

A

A

T E S T E N A B L E D ?

► Y E S ▲

N O ▼

Default is YES.

R E F R I G E R

F L U S H E N A B L E D ?

► Y E S ▲

N O ▼

Default is YES.

T E C H

E N A B L E D ?

► Y E S ▲

N O ▼

Default is YES.

H I G H P R E S S U R E L E

D E T E C T E NA B L E D ?

► Y E S ▲

N O ▼

Default is YES.

U T O M A T I C W E I G H I N G

O I L I N J E C T E N A B L E D ?

Y E S ▲

► N O ▼

Default is NO.

U T O M A T I C W E I G H I N G

O I L D R A I N E N A BLED?

Y E S ▲

► N O ▼

Default is NO.

U T O M A T I C W E I G H I N G

U V D Y E E N A BLED?

Y E S ▲

► N O ▼

Default is NO.

H I G H V O L T

F L U S H E N A B L E D ?

► Y E S ▲

N O ▼

Default is YES for RHS 980C

L E RT D E M O M O D E

N T L I Q U I D

K

G E O I L

Use to enable or disable the Vacuum Pump Oil Life

feature on the RHS980C. Press the ▲ or ▼ key to

scroll to YES or NO. Press START key.

Use to enable or disable the Refrigerant Liquid Flush

feature on the RHS980C. Press the ▲ or ▼ key to

scroll to YES or NO. Press START key.

Use to enable or disable the TechALERT demo mode

feature on the RHS980C. Press the ▲ or ▼ key to

scroll to YES or NO. Press START key.

Use to enable or disable the High Pressure Leak

Detect feature on the RHS980C. Press the ▲ or ▼

key to scroll to YES or NO. Press START key.

This feature is currently not applicable to the base

RHS980C. Enabling this feature will compromise the

functionality of the unit. Press START key.

This feature is currently not applicable to the base

RHS980C. Enabling this feature will compromise the

functionality of the unit. Press START key.

This feature is currently not applicable to the base

RHS980C. Enabling this feature will compromise the

functionality of the unit. Press START key.

Use to enable or disable the High Voltage Oil Flush

feature on the RHS980C. Press the ▲ or ▼ key to

scroll to YES or NO. Press START key.

WARNING DO NOT ENABLE THIS FEATURE IF

YOUR UNIT IS NOT CONFIGURED FOR HIGH

VOLTAGE OIL FLUSH. IF YOUR UNIT HAS AN OIL

INJECTION BOTTLE AND CONNECTION POINT TO

INJECT OIL INTO THE A/C SYSTEM

ENABLE THIS FEATURE.

Press START key.

DO NOT

26

Page 28

F I L L C Y L I N D E R

A

E N A B L E D?

► Y E S ▲

N O ▼

Default is YES.

M

N U A L O I L I N J E C T I O N

E N A B L E D?

Y E S ▲

► N O ▼

Default is NO.

This feature allows the operator to fill the internal

cylinder of the RHS980 from an external virgin

refrigerant tank to the preset amount, see Default

Values. Press START key.

This feature is currently not applicable to the base

RHS980C, due to this unit being configured to perform

a high voltage oil flush function. Enabling this feature

will compromise the functionality of the unit. Press

START key.

27

Page 29

DEFAULT VALUES

A

A

A

A

A

A

A

A

A

A

A

D E F

C O N T I N UE?

F I L L C Y L I N D E R T

M O U N T # # . # # L B

B E T W E E N 6 . 6 & 2 4 . 2 L B

C O N T I N UE?

I N I T I

# # # # # M I C R O N

B E T W E E N 3 K & 9 K

C O N T I N UE?

F I N

# # # # # M I C R O N

B E T W E E N 1 K & 9 K

C O N T I N UE?

V

# # M I N

B E T W E E N 1 & 9 9 M I N

C O N T I N UE?

U L T V A L U E S

R G E T

L V A C U U M H O L D

L V A C U U M L E V E L

C U U M R U N T I M E

Press START key.

The Fill Cylinder procedure will automatically transfer

refrigerant from a new cylinder of refrigerant to the

internal RHS980C charge cylinder. The value set here

will be the amount of refrigerant which will have been

transferred when the procedure stops automatically.

Enter an amount between 3 and 11 KG (6.6 and 24.2

LB). The value will be displayed as it is entered. Press

START key. (Default is 8.00 KG (17.6 LB))

The A/C system will be checked for leaks during the

vacuum process. This test will pull the A/C system into

a vacuum and then pause for a period of 60 seconds.

If the vacuum level decreases, it’s an indication that

the A/C system has a leak. Enter an amount between

3000 and 9000 micron of vacuum. The value will be

displayed as it is entered. Press START key. (Default

is 5000 MICRON)

This screen allows the adjustment of the final vacuum

micron level check performed. After the vacuum

procedure is completed, the level achieved must be at

least this value or a failure message is displayed.

Press START key. (Default is 2000 MICRON)

This screen prompts for the length of time the vacuum

pump will run during each cycle. There is one initial

cycle to pull the system for an initial vacuum leak test,

then a second cycle to obtain the final micron level.

Enter a number of minutes between 1 and 99. The

value will be displayed as it is entered. Press START

key. (Default is 10 MIN)

H O S E S O V E R C H

M O U N T # . # # K G

B E T W E E N 0 & 0 . 9 9 K G

C O N T I N UE?

D E F

V O L T A G E # # # V A C

B E T W E E N 9 0 & 1 2 0 V AC

C O N T I N UE?

E L E V

L E V E L # # # # # F T

B E T W E E N 0 & 3 0 K F E E T

C O N T I N UE?

U L T M I N I M U M L I N E

T I O N F R O M S E

R G E

A small overcharge of refrigerant is necessary to

compensate for refrigerant which will remain in the

hose after a charge procedure. Enter the number of

KG between 0 and 0.99 (0 and 2.2 LB). The value will

be displayed as it is entered. Press START key.

(Default is 0.02 KG (0.04 LB))

During machine operation, the line voltage is

monitored to remain above a threshold to ensure

correct operation. Enter number of volts between 90

and 120VAC. The value will be displayed as it is

entered. Press START key. (Default is 90 V AC)

Elevation from sea level to adjust pressure transducer

calibration. Enter a number in feet from 0 to 30,000

feet. The elevation can be obtained by calling your

local airport. (Default is 400 FT)

28

Page 30

O I L L I F E V A C U U M R I S E

A

A

A

A

A

A

A

A

L E V E L # # # M I C R O N

B E T W E E N 2 5 & 2 0 0

C O N T I N UE?

O I L D R

# # # M L

B E T W E E N 5 0 & 2 0 0 M L

C O N T I N UE?

M I N I M U M V

L E V E L # # I N H G

B E T W E E N 1 5 & 2 5 I N H G

C O N T I N UE?

H I G H V O L T

C H G A M T1 . 6 L B

B E T W E E N 0. 1 & 2. 0 L B

C O N T I N UE?

MAINTENANCE OPTIONS

P E R F O R M C

C H E C K ?

S E L E C T Y E S O R N O

RTI recommends checking calibration every 3 months

T T A C H W E I G H T T O

B O T T O M O F M A C H I N E

C O N T I N UE?

L I B R A T I O N A P P R O V E D

C

R E M O V E W E I G H T

C O N T I N UE?

Or the next screen may be displayed…

C

L I B R A T I O N R E J E C T E D

R E C A L I B R A T E U N I T O R

C A L L F O R S E R V I C E

C O N T I N UE?

P E R F O R M I N T E R N

C Y L I N D E R L O A D C E L L

S I T E C A L I B R A T I O N ?

S E L E C T Y E S O R N O

I N M A X L E V E L

C U U M L EAK

G E F L U S H

L I B R A T I O N

L

Enter the amount of rise in vacuum level used during

the vacuum pump oil life test. The value must be

between 25 and 200 micron. Press START key.

(Default is 50 micron)

This feature is currently not applicable to the base

RHS980C. Enabling this feature will compromise the

functionality of the unit. Press START key.

During vacuum leak test, this value is used to

determine a pass or fail. (Default is 29 in hg)

The Default value is 1.6 lbs for the HIGH VOLTAGE

OIL FLUSH. WARNING, DO NOT REDUCE THIS

SETTING TO LESS THAN 1.6 LBS AS THE

FLUSHING PROCESS WILL NOT BE COMPLETED

PROPERLY AND RESIDUAL OIL MAY BE LEFT IN

HOSES. Press START key.

The calibration of the weight scale in the RHS980C

can be easily checked using this procedure. A steel

ball of a precise weight is provided with the RHS980C

for performing this calibration check. Remove the

document pocket on the left side to gain access to the

calibration ball. Ball is under a bracket near the

bottom base, see PARTS IDENTIFICATION. Unit

must show positive weight on scale prior to

selecting this procedure. Press YES key. Access to

unit calibration must be verified by service manager by

entering a password.

The screen prompts to attach the steel ball to the

bottom of the machine. There is a small post which

protrudes through the bottom plate of the RHS980C

(see Parts Identification at rear of this Operation

Manual). This post is magnetic. Attach the calibration

weight to this post. Press START key.

This screen will display if the weight scale is in

calibration. If calibration check failed, the RHS980C

must be fully calibrated. See below.

This screen will display if the weight scale is not in

calibration. To perform a full load cell calibration

procedure, press START key.

Press YES key if a calibration is required. Otherwise,

press NO key. Special RTI 4 KG (8.8 LB) weight IS

required to calibrate the scale, do not use steel

ball supplied with the machine! Unit must show

positive weight on scale prior to selecting this

procedure. Load cell calibration should be performed

by qualified technicians only and should be performed

at least once per year. Call RTI technical support for

more information. 1-800-468-2321 X 1

29

Page 31

A

A

A

A

A

A

A

A

A

A

A

T T A C H W E I G H T T O

B O T T O M O F M A C H I N E

C O N T I N UE?

C

L I B R A T I O N A P P R O V E D

R E M O V E W E I G H T

C O N T I N UE?

Or the next screen may be displayed…

C

L I B R A T I O N R E J E C T E D

R E C A L I B R A T E U N I T O R

C A L L F O R S E R V I C E

C O N T I N UE?

P E R F O R M I N T E R N

C Y L I N D E R L O A D C E L L

S H O P C A L I B R A T I O N ?

S E L E C T Y E S O R N O

C O N N E C T C Y L I N D E R T O

L O W S I D E H O S E A N D

O P E N V A L V E

C O N T I N UE?

C H

R G E I N P R O C E S S

M T C H G = # # . # # L B

C O N T I N UE?

L I B R A T I O N M I N

C

W E I G H T O N

C O N T I N UE?

C

L I B R A T I O N M A X

W E I G H T O N

C O N T I N UE?

L I B R A T I O N C O M P L E T E

C

R E M O V E W E I G H T

M O U N T = # # # # # X X

C O N T I N UE?

Or the next screen may be displayed…

L I B R A T I O N F A U L T

C

I N S U F F I C I E N T W E I G H T

C O N T I N UE?

L

The screen prompts to attach the 4 KG (8.8 LB) weight

to the bottom of the machine. There is a small post

which protrudes through the bottom plate of the

RHS980 (see Parts Identification at rear of this

Operation Manual). This post is magnetic. Attach the 4

KG calibration weight to this post. Press START key.

The weight scale is now calibrated. Remove the

calibration weight. Press START key.

This screen will display if the weight applied does not

meet the minimum required. For example; attempting

to use the calibration ball instead of the approved 4

KG (8.8 LB) calibration weight. Perform a shop load

cell calibration procedure or call RTI technical support

for more information. 1-800-468-2321 X 1

Press YES key if a calibration is required. Otherwise,

press NO key. Special RTI 10 KG (22 LB) weights

are required to calibrate the scale, do not use steel

ball supplied with the machine! Load cell calibration

should be performed by qualified technicians only and

should be performed at least once per year. Call RTI

technical support for more information. 1-800-4682321 X 1

If YES key was pressed, this screen will display.

Connect the blue low side hose of the RHS980 to the

vapor port of a refillable DOT cylinder. Open the valve

on the cylinder. Press START key. Refrigerant will be

transferred from the RHS980 internal cylinder into the

externally connected DOT cylinder.

This screen will display a decreasing amount as

refrigerant is transferred to the DOT cylinder. Press

START key when the amount does not decrease any

more.

This screen indicates the weight scale is reading a

minimum weight since the charge cylinder is empty.

Press START key.

This screen prompts for maximum weight. Place the

calibration weights on top of the RHS980 charge

cylinder. The weight scale will now read a maximum

weight. Press START key.

The weight scale is now calibrated. Remove the

calibration weights. Press START key.

This screen will appear if the weight used does not

meet the required minimum. For example; attempting

to use the 4 KG (8.8 LB) weight or calibration ball

instead of the approved 10 KG (22 LB) calibration

weight. Call RTI technical support for more

information. 1-800-468-2321 X 1

30

Page 32

A

A

A

A

A

A

A

A

P E R F O R M V

S E N S O R C A L I B R A T I O N ?

S E L E C T Y E S O R N O

V

C C A L - S T A B L E

S E N S O R T AR G E T 1 0 0 0 M

T O G G L E P U M P W I T H # 1

P R E S S Y E S T O C A P T U R E

S E T D

# # - # # - # # # #

# # : # # : # #

S E L E C T Y E S O R N O

E N T E R P

# # # #

S T A R T T O C O N T I N U E

S T O P T O E N D

P

S S W O R D A C C E P T E D

S T A R T T O C O N T I N U E

S T O P T O E N D

Or the next screen may be displayed…

P

S S W O R D R E J E C T E D

S T A R T T O R E T R Y

S T O P T O E N D

T E A N D T I M E ?

C U U M

S S W O R D

Press YES key if vacuum sensor calibration is

required. Otherwise, press NO key. An external

micron sensor gauge is required and must be

connected to the low side port for this procedure.

Access to vacuum sensor calibration must be verified

by service manager by entering a password.

Vacuum process will start and external sensor will be

drawn into a vacuum. Press #1 key when level

reaches 1000 micron. Micron level must hold 1000 as

shown on the external micron sensor for 1 min prior to

pressing the YES key. Press NO key to end

procedure without capturing new value.

Press YES key if adjustment to the date and time is

required. Otherwise, press NO key.

If password protection is enabled the next 3

subsequent screens will be shown. The current service

manager password is entered, default is shown, 5237.

Call RTI for assistance if password is unknown or lost.

Press START key.

If service manager password is accepted, this screen

is shown. Press START key.

If service manager password is rejected, this screen is

shown. Check the password and press START key to

retry the entry or press STOP key to end.

S E T T H E D

Y Y Y Y - M M - D D ▲

M M - D D - Y Y Y Y ▼

C O N T I N UE?

S E T T H E Y E

# # # # ▲

▼

C O N T I N UE?

S E T T H E M O N T H

# # ▲

▼

C O N T I N UE?

T E F O R M AT

R

The format for the date is selected by pressing START

key. Change highlighted format with the ▲ or ▼ key.

Using ▲ or ▼ key, increase or decrease the year.

Press START key to continue.

Using ▲ or ▼ key, increase or decrease the month.

Press START key to continue.

31

Page 33

S E T T H E D A Y

A

A

A

A

# # ▲

▼

C O N T I N UE?

S E T T H E H O U R

# # : # # ▲

▼

C O N T I N UE?

S E T T H E M I N U T E S

# # : # # ▲

▼

C O N T I N UE?

C C E P T T H E S E V A L U E S ?

# # - # # - # # # #

# # : # #

S E L E C T Y E S O R N O

Using ▲ or ▼ key, increase or decrease the day.

Press START key to continue.

Using ▲ or ▼ key, increase or decrease the hour.

Press START key to continue.

Using ▲ or ▼ key, increase or decrease the minutes.

Press START key to continue.

Press YES key to accept the date and time changes,

press NO key to return without changes.

Unit is equipped with a battery backup feature to

save time and date. Battery life is dependent on

many conditions. See Parts Identification for

replacement battery part number.

P E R F O R M I N P U T / O U T P U T

D I A G N O S T I C S ?

S E L E C T Y E S O R N O

U S E ▲ ▼ T O C H

S E L E C T E D O U T P U T

S T A R T T O G G L E S O N & O F F

S T O P T O E N D

U S E ▲ ▼ T O C H

S E L E C T E D I N P U T

S T O P T O E N D

# # # # # # # # # # #

P E R F O R M C O M B O F I L T E R

R E P L A C E M E N T ?

S E L E C T Y E S O R N O

C H E C K I N G

P R E S S U R E S

P L E A S E W A I T

N G E

N G E

Inputs and outputs of devices in the RHS980C can be

checked for diagnostic purposes. Press YES key.

Press ▲ or ▼ key to select various outputs. The

output identification number will display on the screen.

For a selected output, press the START key to toggle

it on and off. Press STOP key to advance to next

screen.

Press ▲ or ▼ key to select various inputs. The input

identification number will display on the screen. For a

selected input, press the START key to toggle it on

and off and display units. Press STOP key to advance

to next screen.

The RHS980C combo filter must be replaced after

every 150 LB (68 KG) of refrigerant has been

recovered from A/C systems. A reminder message will

appear after the filter capacity reaches 125 LB (57 KG)

and the unit is powered ON. Press YES to start the

procedure to change the combo filter. This filter can be

accessed by removing the literature pocket on the left

side of the RHS980. Press YES key.

Internal pressure of the combo filter will be checked. If

pressure is detected a buzzer will sound and the

display will indicate the need to go to recycle mode to

eliminate the pressure.

R E M O V E

C O M B O F I L T E R

C O N T I N UE?

N D R E P L A C E

This screen will display if pressure was not detected.

Replace the combo filter. Note the serial number on

the new combo filter label as it may not be visible

when installed. Press START key.

32

Page 34

A

A

A

A

A

A

A

A

A

A

E N T E R F I L T E R S E R I

N U M B E R

# # # # # #

C O N T I N UE?

P E R F O R M V

O I L R E P L A C E M E N T

S E L E C T Y E S O R N O

P E R F O R M V