Page 1

A’GRAMKOW A/S

Augustenborg Landevej 19

DK-6400 Sønderborg

Denmark

A/S Reg. No. 17 12 31

Telephone: 45 74 12 36 36

Telefax: 45 74 43 36 46

Telex: 5 23 18

Bank: Unibank No. 22 37

INSTRUCTIONS RHS 900

Recovery, Recycling, Evacuation

and Charging Station

RHS 900

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 2

- 0.1 -

Contents

1. Application

2. Safety precautions

3. Components

4. Before use

- Service couplings

- Flow control - function and programming

5. Operating RHS 900

- Test

- Recovery/recycling

- Evacuation

- Oil charging

- Refrigerant charging

- Automatic process

- Charging of Leakdetector dye

6. Maintenance

7. Flow control, programming

8. Specifications

9. Service set

10. Accessories

11. Trouble shooting

12. Pos. no. location

- Mechanical diagram

- Electrical diagram

13. Appendixes

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 3

- 1.1 -

Application

Your new RHS 900 station represents the latest in equipment for servicing air

conditioning units (A/C units). The station is designed for refrigerants R12 and

R134a. It can, and must, only be used for one of these refrigerants.

RHS 900 is a test, recovery/recycling-(draining/cleaning), evacuation, oil/refrigerant charging station and is thus able to perform a total process cycle in

servicing A/C units for the automobile industry.

The recycling process is designed to follow SAE-standards J1989 and J2099 on

recycled refrigerant for A/C units.

The six processes - from test to charging - are performed by operating six

different process switches. This reduces the risk of error operation to a minimum.

After each evacuation, RHS 900 automatically performs a vacuum test and

indicates whether or not there is any leakage in the A/C unit. In addition, the

station incorporates an automatic process which ensures that subsequent processes

are performed fully automatically and in the correct sequence: evacuation,

vacuum test and refrigerant charging.

Constant monitoring ensures that the automatic process sequence does occur

correctly. Safety devices are built into the station to stop operation and indicate

faults in processes, e.g. excessively high pressure, overcharging of charging

cylinder.

During the recycling process a small quantity of oil is drained from the A/C unit.

On completion of the recovery process this quantity can be drained into a

measuring beaker. The same quantity of new oil must be filled into the A/C unit.

Refer to the A/C unit instructions and use only the type of oil specified.

The filter drier has a very high capacity (300 kg) and is easy to replace during

servicing.

A system built into the station ensures that non-condensable gases are automatically blown off and that the discharge of refrigerant to the atmosphere is kept to

a minimum.

Before using RHS 900, read these instructions carefully to ensure that the processes are performed correctly.

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 4

- 1.2 -

Application

We reserve the right to make constructional and design changes and accept no

responsibility for printing errors.

RHS 900 complies with European standards on “Safety and health” and is GSapproved.

See appendixes, "Declaration of Conformity" and TÜV Certificat.

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 5

- 2.1 -

Safety precautions

1. Always wear protective goggles and gloves when working with

refrigerant.

2. Do not allow refrigerant to come into contact with the skin or eyes.

3. Before disconnecting RHS 900 from the A/C unit, make sure that the

process is completed so that refrigerant does not escape to the atmosphere.

4. RHS 900 is for use only in dry indoor surroundings.

5. Disconnect the electrical supply before performing maintenance on RHS

900.

6. To reduce the risk of fire, avoid using an extension cord. If, however, an

extension cord is necessary, it must have a minimum cross-sectional area

of 2.5 mm

7. In the event of fire, remove any external refrigerant cylinders.

8. When oil which accompanies the refrigerant drained from the A/C unit is

tapped from the suction accumulator into the measuring beaker supplied,

ensure that it is handled according to existing national legislation. A

suitable container can be obtained from the refrigerant supplier.

9. Always brake the two front wheels of the station when parking.

2

.

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 6

- 3.1 -

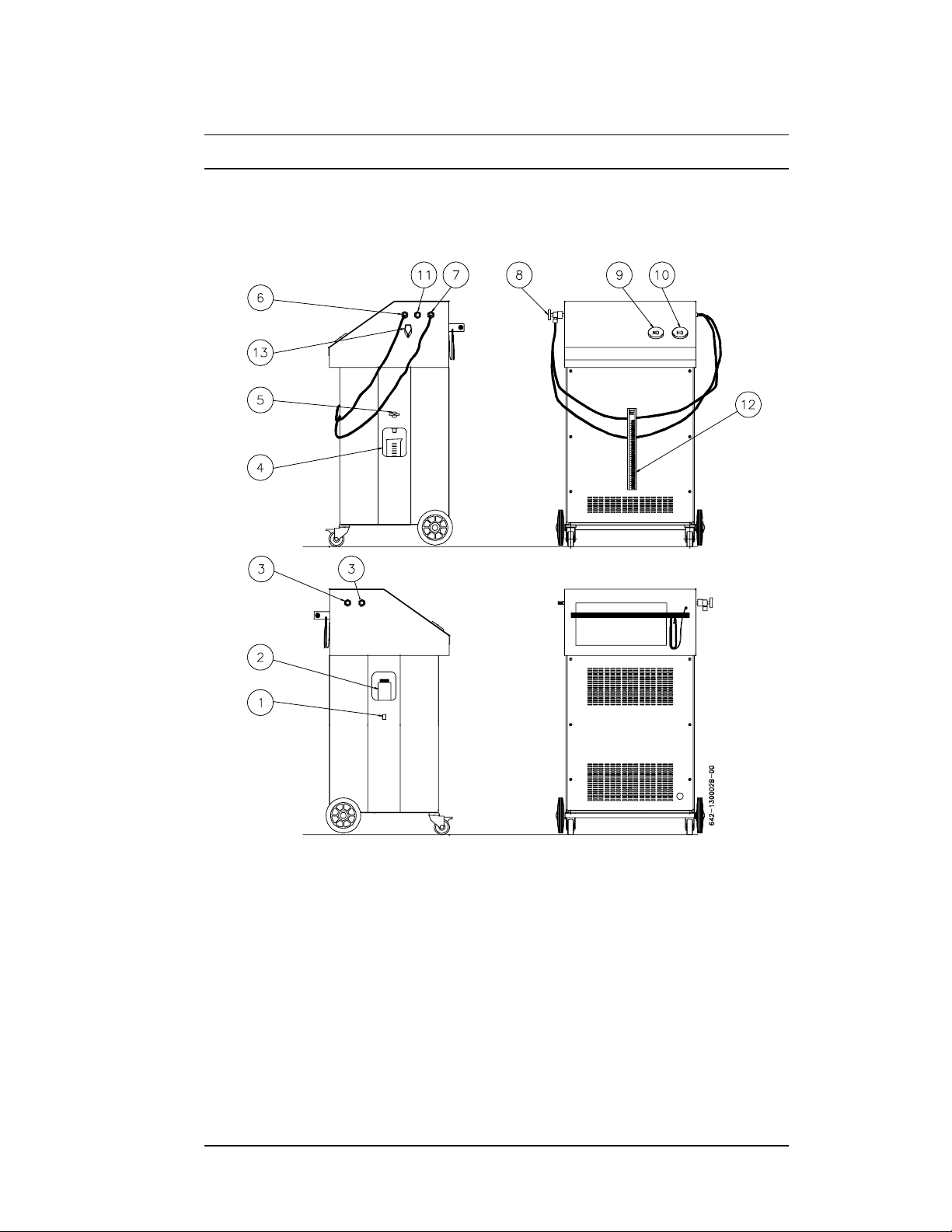

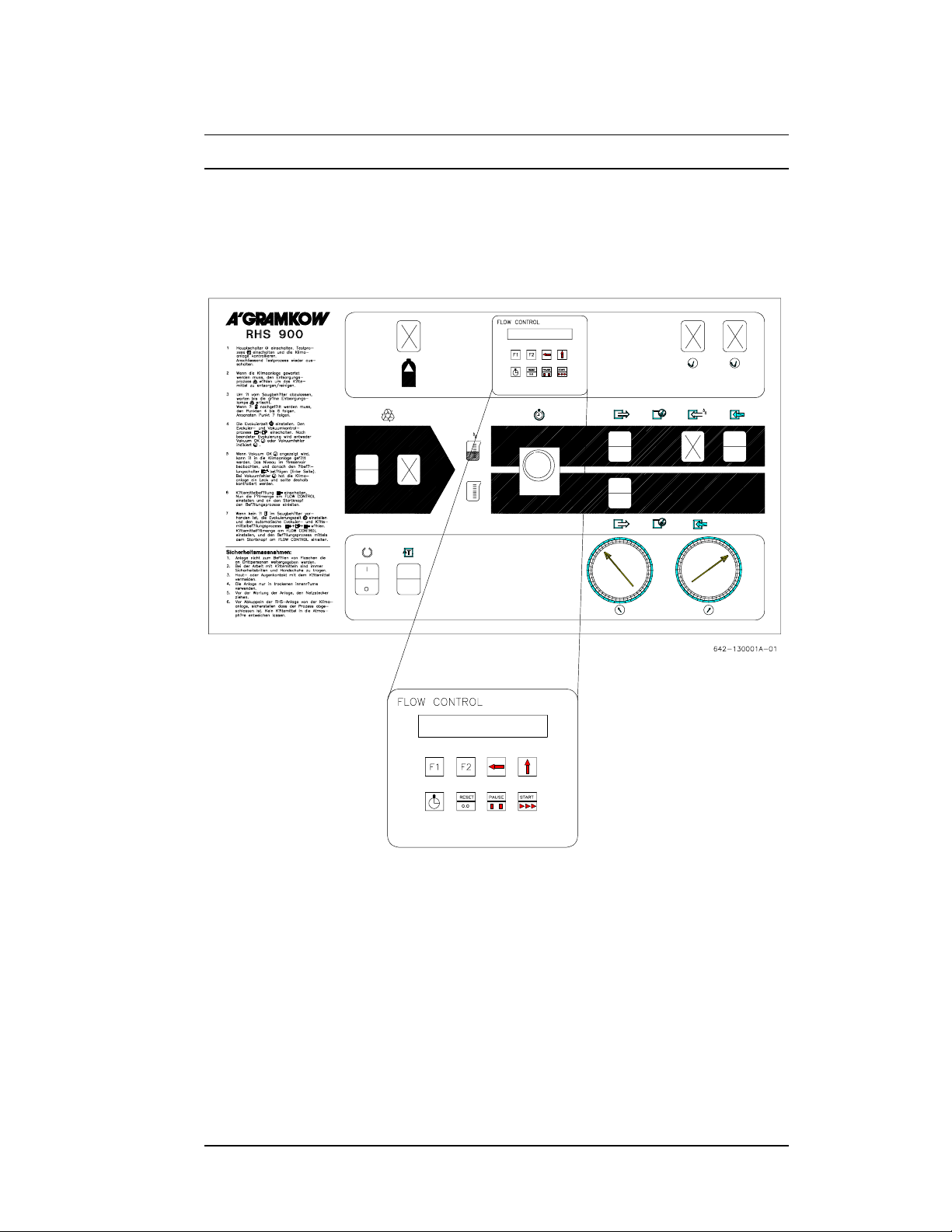

Components

1) Oil charging: Oil charging switch.

2) Oil tank

3) Parking sockets: The high and low-pressure valves can be parked here.

4) Measuring beaker: For drained oil.

5) Oil draining valve: For draining oil received from the A/C unit.

6) Connection: Low-pressure, hose connection for the low-pressure side of the

A/C unit.

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 7

- 3.2 -

Components

7) Connection: High-pressure, hose connection for the high-pressure side of

the A/C unit.

8) High and low-pressure valves.

9) Low-pressure gauge: Indicates the pressure on the low-pressure side in the

test function.

10) High-pressure gauge: Indicates the pressure on the high-pressure side in

the test function.

11) Connection: For leak detector dye, or alternative type off oil.

12) Levelindication: Showing the actual level in the internal cylinder.

13) Quickcharge: For quick refilling of internal cylinder.

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 8

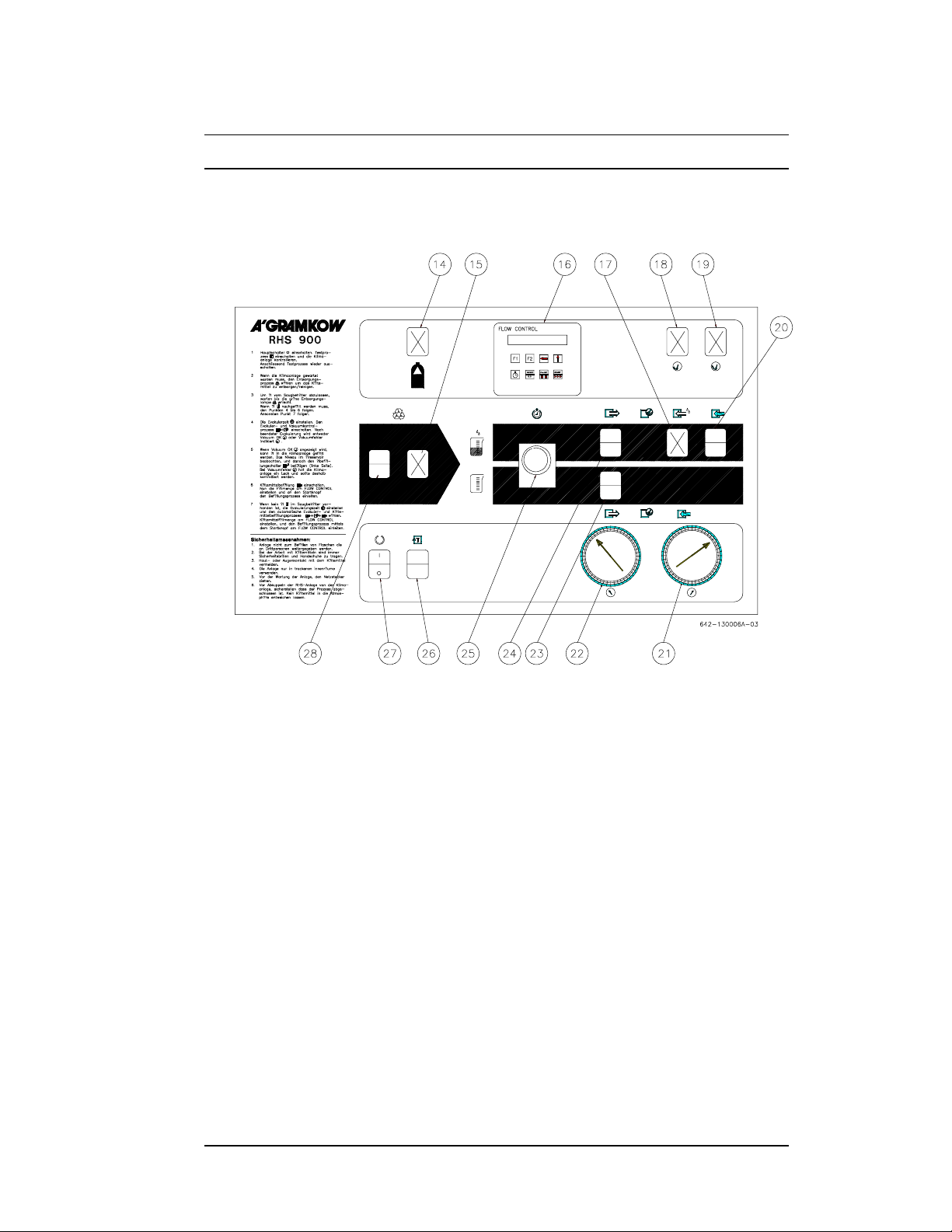

- 3.3 -

Components

14) Charging cylinder full - lamp (yellow): lights up when the

charging cylinder is full and stops the process.

15) Compressor lamp (green): remains on for as long as the A/C unit is

subject to pressure, i.e. when vacuum reaches -0.2 bar the lamp goes

out.

16) Flow control: Display and keyboard.

17) Oil charging lamp (green): lights up when the evacuation process

is complete, and indicates oil charging. Oil charging is activated by

the switch (pos. 1).

18) Vacuum OK - lamp (white): indicates that no leakage was found

during vacuum test.

19) Vacuum defect - lamp (yellow): indicates that the vacuum has risen

to more than -0.8 bar during the vacuum test.

20) Refrigerant charging switch/lamp (green): cuts in the refrigeration

charging process and lights up when the connection is made.

21) High-pressure gauge

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 9

- 3.4 -

Components

22) Low-pressure gauge

23) Automatic process switch/lamp (green): cuts in the automatic

process and lights up when the connection is made.

24) Evacuation switch/lamp (green): cuts in the evacuation process

and lights up when the connection is made. After completed

evacuation, a vacuum test is carried out automatically. The vacuum

lamps light up to indicate “OK” or “Fault”.

25) Evacuation timer: Evacuation time can be set between 0 and 60

minutes.

26) Reset/test switch/lamp (green): cuts in the test process and lights

up when the connection is made.

27) Mains switch/lamp (white): on/off switch for mains supply to

station; lights up when the connection is made.

28) Recovery switch/lamp (green): cuts in the recovery process and

lights up when the connection is made.

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 10

- 4.1 -

Before use

Check the following:

- whether the station has been damaged in transit - if so, contact supplier

immediately;

- oil level in vacuum pump: it must not be below the centre of the sight glass.

If the level is too low, see section MAINTENANCE for vacuum oil

replenishment instructions;

- whether the mains supply is as stated on the station nameplate;

- whether the refrigerant in the A/C unit is as stated on the station nameplate.

Preparation:

- Connect mains plug to mains supply.

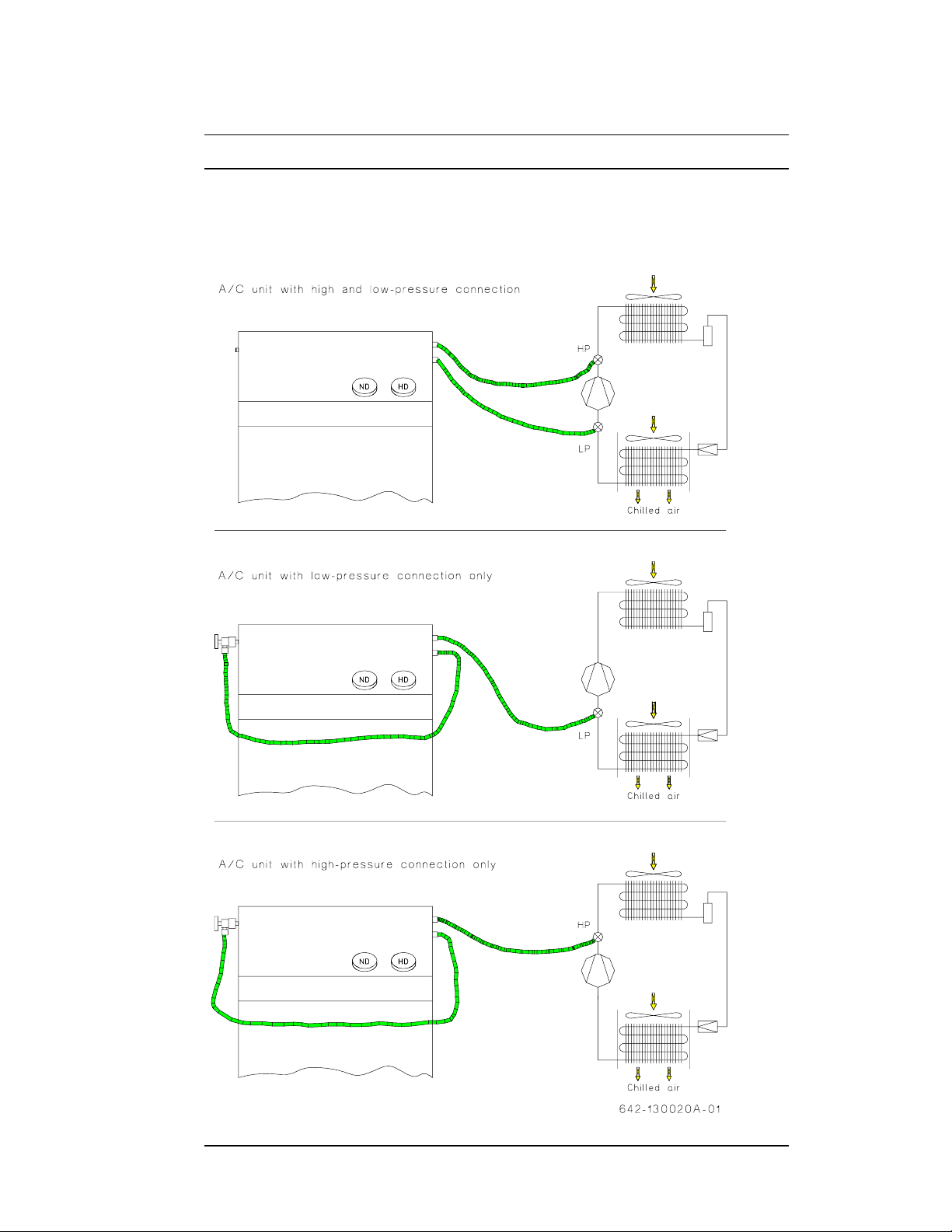

- Connect the red and blue hoses to their stubs on the side of the station. Blue

hose to low-pressure side, red hose to high-pressure side. (See the next two

pages.)

- Make sure that the shut-off valves on hoses and pos. 5 are closed.

- Connect high and low-pressure hoses to their respective sides (using the

service couplings) on the A/C unit. (See the next two pages.)

- RHS 900 is now ready for operation.

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 11

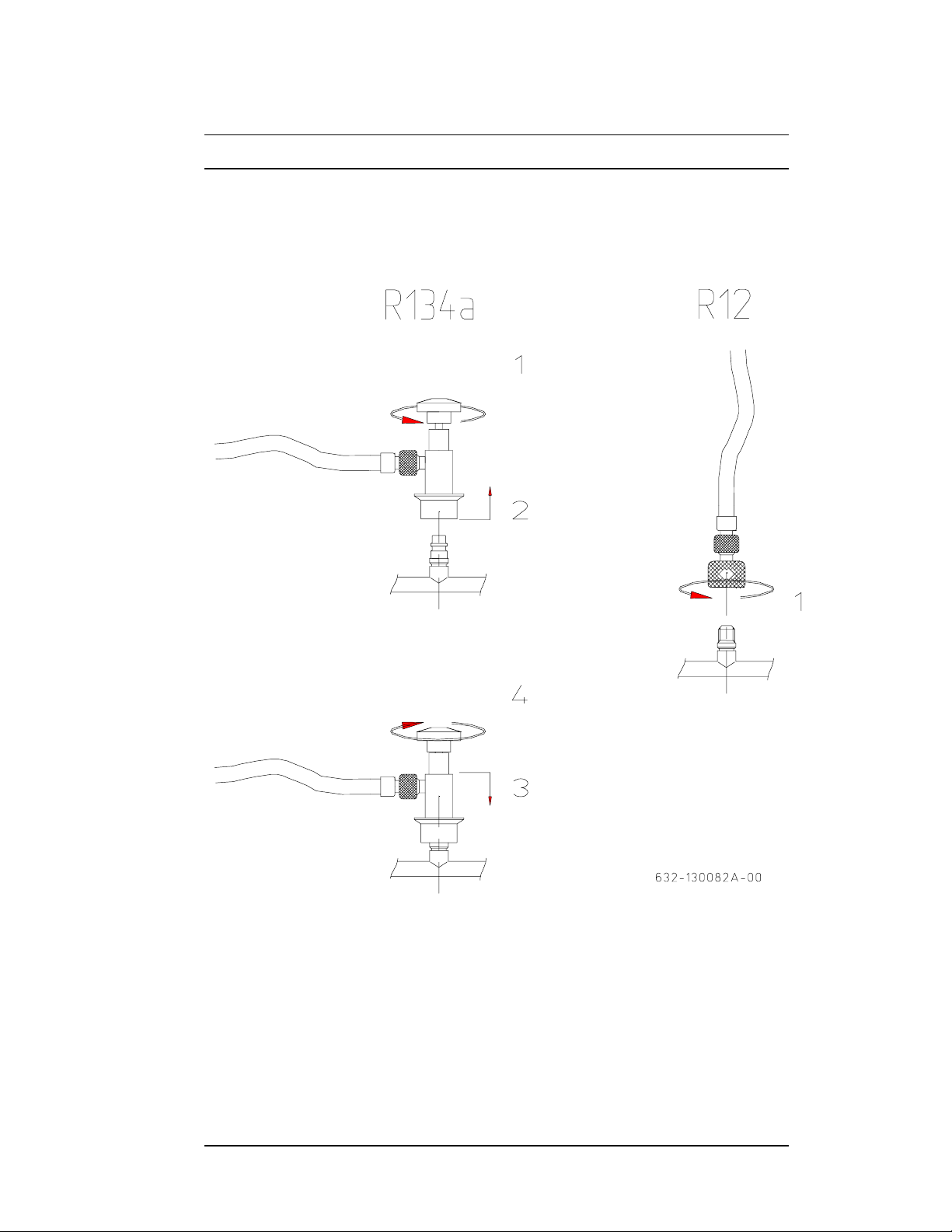

Before use

Connection of service couplings

- 4.2 -

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 12

- 4.3 -

Before use

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 13

- 4.4 -

Before use

Flow control - function and programming

The Flow Control system - the “FC” - monitors and controls the different

processes of RHS 900. FC can be programmed by the operator.

Variables can be altered when process switch TEST is selected (see Section 7 for

further information).

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 14

- 4.5 -

Before use

The functions of the various processes are described below.

TEST: - Operation time

- Oilchange

- Maintenance time (for filter replacement)

- Variable programming.

RECYCLING:- - Display is showing processcycle and indicating the

elapsed time.

EVACUATION: - Display is showing processcycle and indicating the

elapsed time.

PRESSURERIZING: - Indicates that pressure is being built up for 2 min. , and

that the charging process will follow automatically.

CHARGING: - Monitoring/control of charging process

- Data storage

- Fault indication

- PAUSE (charging process cuts off)

Note: Operation and display texts for the various processes are described in the

operating instructions.

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 15

- 5.1 -

Operating RHS 900

Test

- Open valves on service couplings.

- Activate test switch.

- Station mains switch ON (pos. 27).

- The station now performs a test function. Connect the automobile A/C unit.

The high and low-pressure gauges now indicate whether the A/C unit needs

maintenance work.

- Perform a condition diagnosis in accordance with the A/C unit supplier

instructions.

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 16

- 5.2 -

0

FLOW CONTROL

T

E

1

Operating RHS 900

Test

- FLOW CONTROL function in TEST process:

On pressing the clock-key the display shows how much time remains before

servicing is necessary.

FLOW CONTROL

SERVICE TIME = 25

F1 F2

RESET STARTPAUSE

0.0

634- 130041A- 0

On pressing the clock-key and “F1” simultaneously the display shows for how

long the unit has been in operation.

OPERATION TIM E= 125

F2

RESE STAR

PAUS

0.

634-130042A-

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 17

- 5.3 -

Operating RHS 900

Recovery/recycling

- Press process switch (pos. 12) RECOVERY.

- Open valves on service couplings (pos. 8).

- The compressor starts and the RECOVERY lamp (pos. 15) lights up.

- The recovery process now proceeds automatically until the A/C unit is

empty.

- The recovery process is finished when the RECOVERY lamp goes out.

Wait 5-8 minutes to ensure that the unit is completely empty.

- When the A/C unit is empty, the quantity of oil drained from the unit must

be measured. This can be done by opening the oil drain valve (pos. 5) and

allowing the oil to flow into the measuring beaker supplied. The A/C unit

must be filled with a corresponding amount of new oil. See “Oil charging”.

Follow the A/C unit supplier instructions and use only the type of oil

specified.

- At this point, if it is necessary to repair the A/C unit the service couplings

can be disconnected from the unit and servicing performed. If no repairs are

necessary, the evacuation process can be performed.

NOTE:

At the level indication Pos 12 it can before start of the recycling proces, be

noted the actual level of refrigerant. In this way, the recovered amount of

refrigant can be calculated after finishing the recovery process.

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 18

- 5.4 -

Operating RHS 900

- The recovery and recycling time can be read from the FLOW CONTROL

display.

- If the A/C unit requires oil charging, the process sequence must be

EVACUATION, OIL CHARGING and REFRIGERANT CHARGING. If

oil replenishment is not necessary, AUTOMATIC PROCESS (page 5.8) can

be selected.

Evacuation

- Set the evacuation time on the timer (pos. 25).

- Press process switch (pos. 24) EVACUATION.

- If overpressure remains in the A/C unit, the vacuum pump will not start. If

this is the case, press RESET/TEST and then the RECOVERY switch. Now

wait until the compressor has created underpressure. The RECOVERY lamp

(pos. 15) will go out and EVACUATION must be pressed again.

- After evacuation is complete, a vacuum test follows automatically (leakage

test). If for a period of 3 minutes the vacuum remains lower than -0.8 bar,

the white lamp VACUUM OK lights up.

If the vacuum rises above -0.8 bar, the yellow lamp (pos. 19) lights up to

indicate VACUUM FAULT. If this is the case the leakage must be located

and repaired.

IMPORTANT! If the evacuation time selected is too short, the oil in the A/C

unit may still contain a small quantity of refrigerant. During vacuum test

such refrigerant might cause a vacuum fault even though no leakage exists.

Thus always evacuate minimum 30 minutes.

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 19

- 5.5 -

Operating RHS 900

Oil charging

IMPORTANT! When the A/C unit has been charged with refrigerant, oil

charging is not possible. Oil charging must always be performed before

refrigerant charging.

Oil charging is only possible after evacuation is complete and only when the lamp

VACUUM OK (pos. 18) lights up.

Proceed as follows:

- Check to make sure that there is sufficient oil in the oil tank or replenish the

tank as described below.

- Press the oil charging switch and observe the level in the oil tank (pos. 2)

until the quantity required has been sucked into the A/C unit.

- The A/C unit is now ready for refrigerant charging. See instructions for

refrigerant charging.

Oil tank replenishment

When the level in the oil tank has reached the lower edge of the scale, oil

replenishment is necessary. Simply remove the oil tank cover and refill with oil.

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 20

- 5.6 -

Operating RHS 900

Refrigerant charging

- Before the charging process, check the quantity of refrigerant necessary for

the A/C unit concerned. This information can be found on a nameplate in

the vehicle engine compartment.

- Press process switch (pos. 20) REFRIGERANT CHARGING.

- If PAUSE is indicated, push the RESET /0.0 button and following the

STARt-button to accept it.

- Key in the charging quantity required:

- The value of each numeral can be changed with the arrow-up key.

- Use the arrow-left key to move to the numeral to be changed, then use

the arrow-up key to change the value of that numeral.

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 21

- 5.7 -

Operating RHS 900

- The charging process must be cut in with the START key.

- The charging process can be monitored on the display.

- If the process has to be stopped for a short period, press the PAUSE key.

- When the process is to be cut in again, press the START key.

- If the entire process is to be annulled, first press the PAUSE key and then

the RESET key. Now press the START key to confirm the annulment.

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 22

- 5.8 -

Operating RHS 900

For further information on trouble shooting and GAS, BLOCK-ALARM etc., see

Section 7.

- It is now possible to check whether the A/C unit has been charged with the

correct quantity of refrigerant. To do this, start the unit and then read off

high and low pressure from the appropriate unit pressure gauges. The

correct pressures are given in the A/C unit supplier instructions.

- When charging is complete, wait 30 seconds before disconnecting quick-

coupling hoses from the A/C unit.

- As hoses will contain refrigerant residue, drain them by closing the service

hose valves and by pressing the process switch RECOVERY. The compressor will then automatically empty refrigerant from the hoses.

NOTE:

To guarantie the charging accuracy, the charging amount lost in the service

hoses, must be compensated. The loses are depending on variables such as

length of the hoses and ambient temperature.

Automatic process

When it is not necessary to charge the A/C unit with oil, AUTOMATIC

PROCESS can be selected. Evacuation, vacuum test and refrigerant charging will

then be performed automatically:

- Set the evacuation time on the timer (pos. 25).

- Press process switch (pos. 23) AUTOMATIC.

- If pressure remains on the A/C unit, the vacuum pump will not start! If this

is the case, press RESET/TEST (pos. 26) and then RECOVERY SWITCH

(pos. 12) and wait until the compressor has built up underpressure (green

recovery lamp pos. 15 goes out). AUTOMATIC can then be reactivated.

- The required quantity of refrigerant must now be entered in the Flow Con-

trol (see description under process REFRIGERANT CHARGING).

- When evacuation is complete, a vacuum test follows automatically (leakage

test!). If within 3 minutes the vacuum stays below -0.8 bar the lamp

VACUUM OK lights up and REFRIGERANT CHARGING follows

automatically.

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 23

- 5.9 -

Operating RHS 900

- If, however, vacuum rises above -0.8 bar the yellow lamp indicates

VACUUM FAULT (pos. 19) and no refrigerant is charged.

- If in any case refrigerant is to be charged, refrigerant charging can be started

by activating the CHARGING switch.

- Before the actual charging process starts, the display will be indicating

“ PRESS. RIZING” in 2 minutes, where pressure is build up.

NOTE:

If the charging cylinder needs to be drained or replenished, connect the high

pressure service coupling to an external refrigerant bottle, (use the delivered

adapter if necessary). Open the high pressure valve on the RHS unit and the

service coupling.

If the charging cylinder must be drained, select the CHARGING process, (make

sure the refrigerant bottle can hold the amount).

If the charging cylinder must be replenished, select the RECYCLING process.

Also open the QUICKCHARGE-valve (pos.13), and wait till the desired amount

has been filled into the cylinder. Opening the Quickcharge valve will speed up the

process,- but remember to close the valve again during normal Recycling process,

otherwise the refrigerant quality can not be guaranteed.

Charging of Leakdetector Dye

The RHS900 is equipped with a third conection (pos. 11), wich can be used for

charging leakdetector dye or another oiltype if needed:

- Connect the oilcharging bottle (pos.B) or the Tracer Kit (pos.C) to the

connection pos.11, and wait untill the Evakuation process has been

completed.

- When using the oilcharging bottle , follow the instruction on the bottle.

When using the Tracer Kit, first connect a Tracer on the Kit. Then open the

valve, until the colored dye has disapeared from the Tracer. Then close the

valve again.

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 24

- 6.1 -

Maintenance

29) Acid filter.

30) Filter drier.

31) Charging stub.

32) Charging stub.

33) Oil level vacuum pump.

34) Oil draining plug.

35) Nut.

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 25

- 6.2 -

Maintenance

To observe the warranty on RHS 900, all components used for maintenance must

be identical to those in the service set, see Section 9

To ensure problem-free operation of RHS 900, the station must be maintained in

accordance with the following:

The power supply to the station must be switched off.

For each 25 operating hours:

The vakuumpump oil in time absorbs moisture, which in the end gives bad

vacuum level. Therefore the oil must be changed frequiently. It will be indicated

in the FLOWCONTROL when to change the oil. After 25 operating hours OIL

CHANGE will blink for 2 min. in the display. Resetting is done automatcally.

Change oil as follows:

- Place an oil cup below the oil draining plug Pos. 34, and loosen the plug.

Let the old oil flow into the oil cup.

- Take off the oil charging stub Pos. 32.

- Mount the oil draining plug again, and pure in new oil into the oil charging

stub Pos 32, untill the oil level can be seen in the center of the sight glass

Pos. 33.

For each 75 operating hours:

Via the FLOW CONTROL it is possible to see when maintenance is necessary by

simply pressing the clock-key on the FLOW CONTROL during the test process.

The FLOW CONTROL gives an alarm 5 hours before maintenance is due.

SERVICE will flash for 10 seconds in the display.

On reaching 75 hours of operation, SERVICE flashes for 2 minutes in the display.

After maintenance is complete, the number of operating hours to the next

maintenance must be set at zero as follows:

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 26

- 6.3 -

Maintenance

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 27

- 6.4 -

Maintenance

The condenser surface must be kept clean:

- Remove the rear panel of the station (4 screws).

- Clean the condenser with compressed air and perhaps a soft brush. Be

careful not to bend the fins since this would reduce the air flow and impair

condenser capacity.

- Replace rear panel.

Check the oil level in the vacuum pump:

- Oil level check: Start the evacuation process and allow it to run for a few

minutes. Switch off the process and wait for one minute and check then the

oil leviel in the sight glass (pos. 33). Replenish with oil if below the center

of the sight glass.

- Remove cap (pos. 32) to replenish vacuum pump.

- Replenish (slowly) with vacuum oil to the correct level.

- Replace cap.

Check oil level in compressor:

− Switch on the mains switch and press the recovery switch.

− Wait until the underpressure has reached 0 bar and switch off the main

switch. Do not wait, until the RECOVERY/RECYCLING-lamp goes out otherwise the pressure will be built up again in the evaporator.

− Unsrew the cap of the oil fill stub (pos 31).

− The oil level should be seen at the oil fill stub.

− When necessary, recharge the oil using the syringe supplied - up to the

mentioned level. Each time an amount is injected, wait 5 minutes to allow

the oil to ‘settle’.

− Screw cap on oil fill stub.

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 28

- 6.5 -

Maintenance

For each 75 operating hours:

Replace acid filter (pos. 28)

- Remove front panel (4 screws).

- Replace filter by loosening the two 3/8" flare nuts and fit new filter. Use

only new filters fitted with protective caps on connections and make sure

the filter is oriented correctly (arrow pointing downwards).

Replace filter drier (pos. 29)

- Remove filter by first loosening end unions. Slowly loosen nuts (pos. 35)

and take out filter.

- Draw insulation off filter drier.

- Draw insulation on the new filter drier.

- Refit the new filter on station and connect unions.

On replacing filter driers a small quantity of refrigerant escapes - therefore

follow the appropriate safety precautions.

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 29

- 7.1 -

Flow control - programming

The following programming is possible:

1) Display text language

2) Contrast/illumination of display background

The following variables for the charging process can be programmed:

1) The additional quantity of refrigerant to be charged to compensate for the

quantity in the hoses.

The following faults can be set at zero in the charging process:

1) Gas alarm

2) Block alarm

The processes that can be changed are described in the following:

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 30

Flow control - programming

Changing the language:

- 7.2 -

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 31

- 7.3 -

Flow control - programming

Changing contrast/illumination of display background.

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 32

- 7.4 -

Flow control - programming

Compensation for refrigerant still in the charging hoses during charging.

An extra stroke corresponds to approx. 5 g.

The factory setting is 25 g corresponding to the maintenance hose supplied with

the station, and an ambient temp. Of 20

o

C.

Resetting of Gasalarm/Block Alarm

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 33

- 7.5 -

Flow control - programming

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 34

- 7.6 -

Flow control - programming

If the gas alarm cannot be turned into OFF position the charging cylinder is

probably full. Shift to Process draining/recycling and connect refrigerant bottle.

If the block alarm cannot be turned into OFF position the valve on high pressure

hose is closed or the hose is blocked. Check hose gaskets or contact the supplier.

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 35

- 8.1 -

Specifications

General:

Supply voltage: See nameplate

Amperage: See nameplate

Power consumption: See nameplate

Starting current: See nameplate

Weight: 95 kg

Dimensions: 1030 x 670 x 800 mm

Test function:

High-pressure gauge: 0 to 34 bar

Low-pressure gauge: -1 to 8 bar

Recovery/recycling process:

Refrigerant: See nameplate

Oil level measurement: Drain at side of station, measuring beaker

supplied

Recycling capacity: 4 kg/h (3-5 vehicles/h)

Non-condensable gases: Automatic blow-off, temperature-compensated

Suctionaccumolator: 2,4 L.

Charging capacity: 7 Kg. Optional 14 Kg.

Charging accuracy: ±2% with 40 cm. hoses.

Dryer: Exchangeable (after 75 operating houers)

Evacuation process:

Suction capacity: Approx. 3 m

Vacuum level: < 0.5 mbar absolute

Oil charging: Oil reservoir : 250 ml

Operating panel

3

/h

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 36

- 8.2 -

Specifications

Mains switch - white: Power supply cut in

Test switch - green: Test process in function

Recovery switch - green: Recovery process in function

Recovery lamp - green: Pressure in A/C unit

Evacuation switch - green: Evacuation process in function

Oil charging switch - green: Oil charging in process

Refrigerant charging switch - green: Refrigerant charging in process

Automatic process switch - green: Evacuation of A/C unit, vacuum check

and refrigerant charging in process

Vacuum check lamp - green: Vacuum OK

Vacuum check lamp - yellow: Vacuum fault / leakage

Charging cylinder lamp - yellow: Cylinder full

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 37

- 8.3 -

Specifications

Service and maintenance

Acid filter: Replaceable, 3/8" SAE

Oil filter: 0.6 µm (built into oil separator)

Filter drier: Replaceable, (capacity 75 hours or 300 kg

refrigerant)

Compressor oil level: Sight glass + charging stub

Vacuum pump oil level: Sight glass + charging stub

Safety equipment: Mechanical safety valve on charging cylinder

Overfilling protection on charging cylinder

Suction pressure regulator on compressor

High-pressure control on compressor

Code number of RHS 900: See nameplate

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 38

- 9.1 -

Service set

Quantity Description Code no.

1

1

2

0.25 l

0.25 l

To order complete service set - state code no. (see nameplate).

Acid filter

Filter drier

Gasket for filter drier

Compressor oil - mineral

Oil for vacuum pump

069-2910127

069-7480044

065-7751920

290-0001250

290-0001272

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 39

- 10.1 -

Accessories

Qty Description Code no.

1 Operating instructions, English 642-400012A

1 Service coupling, high pressure (R134a) 290-7480095

1 Service coupling, low pressure (R134a) 290-7480096

1 Service coupling (R12) 066-7390234

1 Service hose, blue (R134a) = 72" 634-140002A

1 Service hose, red (R134a) = 72" 634-140001A

1 Service hose, blue (R12) = 180 cm 080-4665015

1 Service hose, red (R12) = 180 cm 080-4665017

1 Service hose, yellow (R12) = 90 cm 080-4665002

1 Gasket for R134a hose, gasket outside dia. 8.3 mm 087-7481010

1 Gasket for R134a hose, gasket outside dia. 9.6 mm 087-7482130

1 O-ring for R134a hose 087-7481341

1 O-ring for R134a hose, gasket outside dia. 14 mm 087-7470210

1 Gasket for R12 hose, gasket outside dia. 8.5 mm 066-7750950

1 Injector, 60 ml 290-5390268

1 Oil beaker, 250 ml 290-0780096

1 Oil beaker, 225 ml, with handle 146-7489012

1 Label, English operating instructions 642-420010A

1 Oilcharging bottle, 300 ml German instruction 642-040003A

1 Oilcharging bottle, 300 ml Englisch instruction 642-040003B

1 Tracer Kit, R134a 643-040002A

1 Tracer Kit, R12 634-040007A

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 40

- 11.1 -

Trouble shooting

Test process

Problem Fault Remedy

Pressure gauge shows no

pressure

Pressure gauge shows

the same reading all the

time

Recovery process:

Problem Fault Remedy

Recovery process does

not start - green recovery

lamp does not light up

Recovery process does

not stop

Recovery process runs

only for a short period

1. and 2. Valve not opened

2. No refrigerant in A/C unit

1. A/C unit defective

2. A/C unit not cut in

1. RHS 900 not cut in

2. Valves not opened

3. No refrigerant in A/C unit

4. System pressure is 16 bar

5. Internal cylinder full

6. Internal component fault

1. Oil drain valve not closed

2. A/C unit leakage

3. Internal component fault

1. Valves on service couplings not opened

2. System pressure is 16 bar

3. Internal cylinder full

4. Internal component fault

1. Open high and low-pressure valves on service

couplings

2. Repair A/C unit.

1. Empty A/C unit and repair

2. Cut in A/C unit

1. Cut in RHS 900

2. Open high and low-pressure valves on

service couplings

3. Repair A/C unit

4. Contact RHS 900 supplier

5. Empty cylinder

6. Contact RHS 900 supplier

1. Close valve

2. Contact RHS 900 supplier

3. Contact RHS 900 supplier

1. Open valves

2. Contact RHS 900 supplier

3. Empty cylinder

4. Contact RHS 900 supplier

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 41

- 11.2 -

Trouble shooting

Evacuation process:

Problem Fault Remedy

Vacuum pump does not

run

Vacuum pump runs but

does not build up enough

vacuum

Charging process:

Problem Fault Remedy

No refrigerant flow 1. High-pressure valve on service coupling

Lamps "Vacuum OK"

and "Vacuum fault" light

up together

1. RHS 900 not cut in

2. Overpressure in A/C unit

3. Internal component fault

1. Service couplings not fitted correctly

2. A/C unit defective/leaking

3. Internal component fault

not opened

2. Internal component fault

1. Solenoid valve Y14 in RHS 900 leaking 1. Replace valve or contact RHS 900 supplier

1. Cut in RHS 900

2. Cut in recovery process

3. Contact RHS 900 supplier

1. Fit service couplings correctly

2. Repair A/C unit

3. Contact RHS 900 supplier

1. Open valve

2. Contact RHS 900 supplier!

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 42

Mecanical diagram

- 12.1 -

Pos. no. location

642-120001A-01

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 43

Electrical diagram:

- 12.2 -

Pos. no. location

642-120002A-01

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 44

- 12.3 -

Pos. no. location

2) Check valve 10) Check valve

3) Suction accumulator 11) Check valve

5) Acid filter 17) Check valve

6) Check valve M1) Compressor

8) Oil filter M2) Condenser/Fan

9) Filter drier M3) Vacuum pump

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 45

- 13.1 -

Appendixes

Example of trouble shooting in an A/C unit:

Conditions:

1. Ambient temperature 30-35°C (86-95°F)

2. Motor speed 2000 rpm

3. A/C unit temperature setting Maximum

Under the above conditions the pressure values for an intact A/C unit will be

as follows during the TEST process:

High pressure 15 bar

Low pressure 2 bar

Follow the TEST process as in Section 5:

- Connect service couplings to A/C unit.

- Close high and low-pressure valves on RHS 500.

- Open service coupling valves.

- Start in A/C unit.

- Now the station will perform a test function.

Perform a condition diagnosis for the A/C unit in accordance with supplier

instructions.

- Stop A/C unit after the test process has been completed.

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 46

- 13.2 -

Appendixes

Test - 1:

High pressure 8 - 9 bar

Low pressure Approx.

Fault/Problem Symptom Possible cause Remedy

Unsatisfactory

refrigeration

Test - 2:

High pressure Approx.

Low presure Approx.

Fault/Problem Symptom Possible cause Remedy

Unsatisfactory

refrigeration

Test - 3:

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

0.8 bar

Conditioned air not

cold

Air bubbles in sight

glass

20 bar

2.5 bar

Leakage in A/C unit

Insufficient refrigerant

in A/C unit

Insufficient condenser

cooling

Fan does not run

Condenser performance

impaired by oil or dirt

deposits

Insufficient oil in A/C

unit (compressor friction)

Refrigerant overcharge

Locate leak and

repair

Replenish with

refrigerant

Clean condenser

Repair fan

Clean condenser

Replenish oil

check the refrigerant

quantity in the A/C unit empty the A/C unit,

evacuate and recharge thr

correct quantity

If none of these remedies

are successful, check the

refrigerant quantity in the

A/C unit - empty the A/C

unit, evacuate and

recharge

Page 47

- 13.3 -

Appendixes

High pressure Approx.

Low pressure Approx.

Fault/Problem Symptom Possible cause Remedy

Periodic

disturbances in

A/C unit

Test - 4:

High pressure Approx.

Low pressure Approx.

Fault/Problem Symptom Possible cause Remedy

Little or no

refrigeration from

A/C unit

7 - 15 bar

1.5 bar

Varying pressure on

high and low-pressure sides

6 bar

-0.3 bar

Hoses before or after expansion valve

or filter drier covered with moisture

or ice

Moisture in A/C unit

causes ice formation on

expansion valve resulting in reduced output,

ore filter drier

saturated.

Expansion valve or

filter drier blocked with

ice because of moisture

in A/C unit

Empty A/C unit,

evacuate and recharge. After the

recovery process,

replace filter drier.

If necessary, remove

expansion valve,

clean it and refit or

replace as necessary.

Disconnect A/C

unit, wait a few

minutes and then

empty the unit,

evacuate and

recharge

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 48

- 13.4 -

Appendixes

Test - 5:

High pressure Approx.

Low pressure Approx.

Fault/Problem Symptom Possible cause Remedy

Unacceptable

refrigeration

Test - 6:

High pressure Approx.

Low pressure Approx.

Fault/Problem Symptom Possible cause Remedy

A/C unit does not

refrigerate

19 - 20 bar

2.5 bar

Ice or moisture on

hoses on low

pressure/suction side

of A/C unit

7 - 10 bar

4 - 6 bar

Pressure on lowpressure side too

high or pressure on

high-pressure side

too low

Expansion valve

defective or sensor

placed incorrectly.

Expansion valve opens

too much.

Internal compressor

leakage

Check expansion

valve sensor

placing.

Replace expansion

valve.

Repair or replace

compressor

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 49

- 13.5 -

Appendixes

Pressure vessel declaration

We confirm herewith that the condition of the pressure vessel in this unit

conforms to regulations laid down by the appropriate authorities:

Suction accumulator, pos. 3:

Manufacturer: A'GRAMKOW A/S

Augustenborg Landevej 19

DK-6400 Sønderborg

Denmark

Type: 642-010017A

Permissible working pressure: PS = 25 bar

Permissible working temperature:

Volume: V = 1.53 litres

Oil separator, pos. 8:

Manufacturer: AC & R Components

Chatham, Ill.

USA

Type: S-5920F

Permissible working pressure: PS = 31.05 bar

Permissible working temperature:

Volume: V = 0.83 litres

-40/70°C

10/120°C

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Page 50

- 13.6 -

Appendixes

Filter drier, pos. 9:

Manufacturer: RTI Technologies Inc.

Type: 026-80044-00

Permissible working pressure: PS = 31.05 bar

Permissible working temperature:

Volume: V = 0.83 litres

Charging cylinder, pos. 13

Manufacturer: Henry Valve (UK)

Type: 642-100027B

Permissible working pressure: PS = 25 bar

Permissible working temperature:

Volume: V =7.0 litres

10/120°C

-20/120°C

C:\RHS Computer Files\Instructions\RHS\GB\642-40\0012B-01.doc 1997.09.11

RHS 900

Loading...

Loading...