Page 1

OPERATION

&

MAINTENANCE

MANUAL

RHS780

Refrigerant Handling Station

RTI Technologies, Inc.

4075 E. Market St., P.O. Box 3099

York, PA (USA) 17402

800-468-2321 (Ext. 259)

http://www.rtitech.com

tech@rtitech.com

Manual P/N 035-80591-00

Page 2

TABLE OF CONTENTS

RHS780

Before Using the RHS780 .................... 2

Safety Precautions .......................... 2

Using the RHS780 .......................... 3

Setup .................................... 4

Filling the Charge Cylinder ................... 5

Recover/Recycle ........................... 6

Draining Recovered Oil ...................... 7

Deep Vacuum ............................. 8

Charging ................................. 9

Automatic ................................. 10

Accessing Stored Data ....................... 12

Setting Over Charge Amount .................. 13

Scheduled Maintenance & Filter Maintenance .... 14

CONGRATULATIONS:

You have purchased one of the finest Recovery, Recycling, and Charging Machines available!

Fill out and return the Warranty Card within 90 days to activate warranty and free lifetime

technical support.

Page 3

BEFORE USING THE RHS780

Check for any shipping damage. Place a claim with carrier if damage is discovered. DO NOT USE A DAMAGED UNIT.

Complete and return the Warranty Card to activate technical support service and warranty coverage.

These general instructions describe normal operation and maintenance situations encountered with the RHS780. Failure

to read and comply with these instructions or any one of the limitations noted herein can result in serious injury and/or

property damage.

A few minutes spent reading these instructions can make an operator aware of dangerous practices to avoid and

precautions to take for his own safety and the safety of others. The instructions should not be interpreted to anticipate

every possible contingency.

The RHS780 should not be operated or serviced by any person who has not read all the contents of this manual.

It is the responsibility of the owner/user to operate the RHS780 in accordance with all specifications and laws which may

apply.

A regular schedule of inspection of the RHS780 should be established and records maintained with special attention

given to Hoses, Compressor Oil Level, Vacuum Pump Oil Level, and Filters.

SAFETY PRECAUTIONS

Recover, Recycle, and Charge only the refrigerant for which the machine is configured.

Wear safety glasses and protective gloves. Refrigerant has a very low boiling point and can cause frostbite.

Follow the RHS780 operating procedures sequentially to avoid prematurely disconnecting hoses or opening valves which

may release refrigerant to the atmosphere.

Do not expose the RHS780 to moisture or operate in wet areas.

Use the RHS780 in locations with mechanical ventilation that provides at least four air changes per hour.

Hoses used with the RHS780 must have shutoff devices within 12 inches (30 centimeters) of the connection point to the

A/C System to minimize the introduction of Non-Condensable Gas (Air) into the RHS780 and the release of refrigerant

when being disconnected.

Disconnect power before performing any maintenance or service on the RHS780.

Connect the RHS780 to a properly grounded receptacle. Do not over load the circuit.

Avoid using an extension cord with the RHS780. If necessary use a good condition three wire, grounded, #14 AWG (2.0

mm2) or larger extension cord of the shortest possible length.

Do not connect the RHS780 to the liquid side of any A/C System with a capacity greater than 4 lbs (1.8 Kg.) Refrigerant

in A/C Systems having larger capacities must be recovered from the vapor side only.

Never connect the Red or Blue Hose on the rear of the RHS780 to the Liquid Port of a Cylinder of Refrigerant to fill the

Charge Cylinder. Doing so may cause the Compressor to fail and void the warranty.

Avoid breathing refrigerant or lubricant vapor or mist. Exposure may irritate eyes, nose and throat. If accidental system

discharge occurs, ventilate work area before continuing.

Additional health and safety information may be obtained from refrigerant and lubricant manufacturers.

Special Considerations with R134a

R134a has been shown to be nonflammable at ambient temperature and atmospheric pressure. However, tests under

controlled conditions have indicated that at pressures above atmospheric and with air concentrations greater than 60

percent by volume, R134a can form combustible mixtures.

While it is recognized that an ignition source is also required for combustion to occur, the presence of combustible

mixtures is a potentially dangerous situation and should be avoided.

Under no circumstances should any equipment be pressure tested or leak tested with Air and R134a mixtures. Do not

use compressed air (shop air) for leak detection in R134a systems.

September 24, 1999 Page 2

Page 4

USING THE RHS780

external vacuum measuring device. When programmed to do so, the RHS780 will pause and start a “count up” timer

The RHS780 will always go through the Recover/Recycle procedure, but will go immediately to the Recycle Hold Timer

the A/C System is empty. The following matrix outlines the most commonly used options that can be programmed to occur

Note: The purpose of this discussion is to familiarize the user with the features and functions of the RHS780 Refrigerant

Handling Station. The procedures discussed in this manual assume that the RHS780 has been set up in accordance

with the figures which are referred to and that the RHS780 has been connected to the proper power supply. This

manual does not illustrate correct A/C service but rather how to correctly use the RHS780.

The RHS780 is microprocessor controlled with a menu driven user interface. All of the functions of the RHS780 are accessed

by pressing a few simple key strokes and following the prompts. See Page 4 items (2) and (6). The on board Charging

Cylinder is attached to a strain gauge measuring device and the weight is electronically displayed.

The RHS780 has a Fill Cylinder feature that allows refrigerant to be loaded directly into the Charging Cylinder without going

through the normal Recover/Recycle mode. When selected, this feature allows the RHS780 Charging Cylinder to be re-filled

in just a few minutes at which point it will automatically stop at approximately 13 lbs (6 Kg.)

The RHS780 Recovers and Recycles simultaneously in a true “single pass” through the filters and stores the refrigerant in

the Charging Cylinder where it is immediately available for use. This process automatically stop’s at 17.5 lbs (8 Kg) or when

a 15"Hg (-0.5 Bar) vacuum is sensed. The RHS780 will wait for a factory default of two minutes for “out gassing” and cold

refrigerant to raise the pressure back up to 3 psig (0.2 Bar) which would cause the Recover/Recycle process to start again

and reset this two minute Recycle Hold Timer before displaying that the process is complete. The Recycle Hold Timer can

be changed every time a Recover/Recycle procedure is run. Longer times should be selected on colder days or on A/C

Systems with large liquid capacities. Increasing this value may increase total time to Recover/Recycle while decreasing the

time may result in an incomplete Recovery of the A/C System. Refer to the chart below for guidelines on setting the Recycle

Hold Timer. The value entered is stored in the memory of the RHS780 and becomes the “default” value each time it is set.

Non-Condensable Gases are vented automatically during Recovery/Recycle. The Amount of refrigerant Recycled is displayed

at the end of the procedure. This value is added to the Total amount Recycled and stored in the memory of the RHS780 (see

Accessing Stored Data on Page 12.)

Temperature < 50F (10C) 50F (10C) to 80F > 80F (26.5C)

Recycle Hold Time 10 min 5 min 2 min

An integrated 3 CFM (1.4 L/s) rotary vane style Deep Vacuum Pump draws on both the High and Low Hoses, items (13) and

(14), ensuring complete evacuation of the A/C System. The amount of time that the Vacuum Pump has been programmed

to run will “count down” on the display (6). The value entered is stored in the memory of the RHS780 and becomes the

“default” value each time it is set. A special Vacuum Check Gauge (4) mounted between the High (5) and Low (1) Pressure

Gauges can be used to monitor a rise in A/C System pressure. An Auxiliary Vacuum Gauge Port(8) is also provided to attach

an

indicating how long the Vacuum Pump has been off, thus allowing the operator to determine if a vacuum leak is present

based on increasing pressure over time. A rapid rise in pressure indicates the presence of a large leak that should be

repaired. A slow rise in pressure may simply indicate that a longer Recycle Hold Timer or Vacuum Time value should have

been entered. A relatively constant vacuum reading over a long period of time (i.e. less than 2"Hg [0.05 Bar] rise over ten

minutes) is the most accurate way to check for vacuum leaks. The RHS780 can also be programmed to pause to allow oil

to be added, (9) and (16) to the A/C System after vacuuming and prior to Charging.

Charging is done via the on board Charging Cylinder. The A/C Capacity is entered via the Keypad (2). The value entered

is stored in the memory of the RHS780 and becomes the “default” value each time it is set. The RHS780 can dispense liquid

refrigerant through either the High (14) or Low (13) Side Hose by changing the position of a selector switch (10). As refrigerant

leaves the RHS780, the display (6) will show an increasing weight to the programmed charge amount plus a factory set 0.03

Kg (one ounce) Over Charge Amount necessary for compensation of refrigerant loss in the hoses. This Over Charge Amount

can be changed to accommodate different operating conditions (see Setting Over Charge Amount [only] on Page 13.) An

integrated Heater automatically engages whenever Charging occurs. The Amount of refrigerant Charged is added to the Total

amount Charged and stored in the memory of the RHS780 (see Accessing Stored Data on Page 12.)

The RHS780 can be programmed to perform the Recover/Recycle, Deep Vacuum and Charge in a completely Automatic

mode.

if

after the Recycle Hold Timer “times out”:

Recover/Recycle X X X X X X X X

Deep Vacuum X X X X X X

Vacuum Leak X X X

Add Oil X X

Charging X X X X X

September 24, 1999 Page 3

Page 5

SETUP

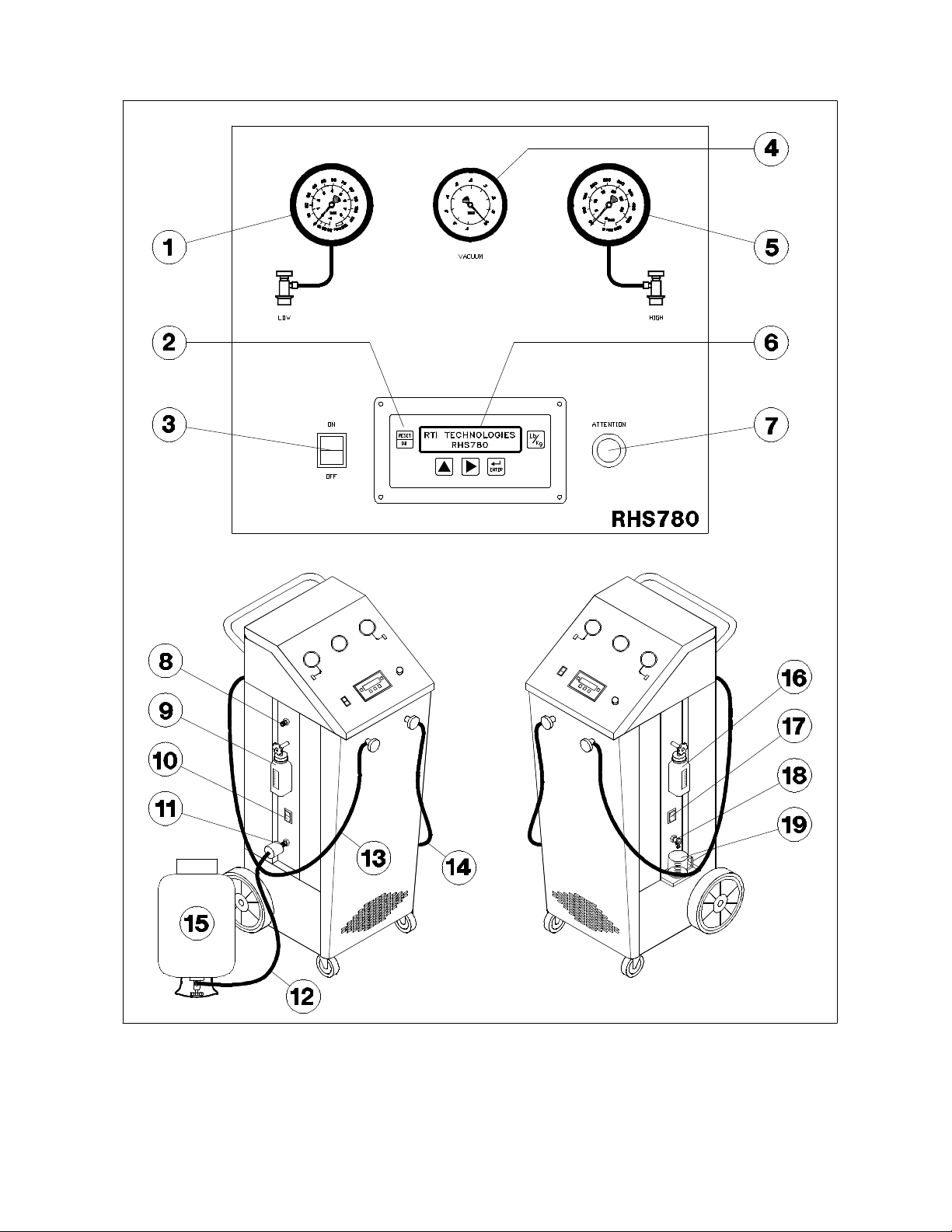

(1) Low Pressure Gauge (2) Keypad (3) Main Power Switch (4) Vacuum Check Gauge (5) High Pressure Gauge

(6) Display (7) Attention Light (8) Auxiliary Vacuum Gauge Port (9) Oil Charge Bottle {Low Side}

(10) High-Low Charge Selector Switch (11) Fill Port (12) Yellow Hose with Anti-Blowback Valve

(13) Blue Hose {Low Side} (14) Red Hose {High Side} (15) Refrigerant Cylinder (16) Oil Charge Bottle {High Side}

(17) Oil Drain Re-pressurization Switch (18) Oil Drain Valve (19) Measuring Cup

September 24, 1999 Page 4

Page 6

W E I G H T = X X . X L B

A U T O M A T I C ?

>>>>

W E I G H T = X X . X L B

F I L L C Y L I N D E R ?

FILLING THE CHARGE CYLINDER

Note: For large capacity or multiple A/C Systems where recharge will

5

NOT be done between successive recoveries, it may be desirable to

skip this procedure.

1. Setup the RHS780 as shown on Page 4 and then turn the Main Power

Switch (3) ON. An adapter is provided with the RHS780 (R134a) which

5

permits the Yellow Hose (12) to be attached to the 1/4 SAE Flare fitting

that is on some cylinders of R134a refrigerant.

ENTER

C H E C K H O S E S

S T A R T ?

ENTER

W E I G H T = X X . X L B

C O M P R E S S O R O N

F I L L C O M P L E T E

F I L L E D = X X . X L B 5

ENTER

*

H I G H P R E S S U R E

S E E M A N U A L

**

C Y L I N D E R F U L L

G O T O C H A R G E 5

Note: The RHS780 uses 15.4 lbs (7 Kg) of refrigerant when Filling the first

time. If the Refrigerant Cylinder (15) is emptied the RHS780 will

appear to stop filling (the Weight will stop rising) and will stay in

5

2. Using the Keypad (2), press the “Up Arrow” key four times to display

3. Open the LIQUID Valve on the Refrigerant Cylinder (15) connected to

4. Press the ENTER key when ready to start filling the RHS780.

this condition until the RESET key is pressed.

“WEIGHT= XX.X LB” “FILL CYLINDER? 5” and press the ENTER key.

The Display (6) will read “CHECK HOSES” “START? 5”.

the Fill Port (11) on the left side of the RHS780 with the Yellow Hose

(12).

The Display (6) will read “WEIGHT=XX.X LB” “COMPRESSOR ON”.

When the level is approximately 13 lbs (6 kg) {75% of the full capacity}

the RHS780 will turn OFF, the Display (6) will read “FILL COMPLETE”

“FILLED= XX.X LB 5” (the amount of refrigerant removed from the

cylinder) and the Attention Light (7) will turn ON. Close the Liquid Valve

on the Refrigerant Cylinder (15).

Note: Press the RESET button on the Keypad to stop the

Fill Cylinder procedure at any time.

5. Press the ENTER key to return to the Main Menu.

* While filling the Charging Cylinder, this screen will display periodically

concurrent with the Attention Light (7) turning ON. This is normal and

nothing to be concerned about. The screen should revert to normal

after a few seconds.

** This screen will display when the Charging Cylinder fills to capacity,

approximately 17.5 lbs (8 Kg). If this occurs, the Weight can be

lowered using the Charging procedure on Page 9 before the RHS780

can be used to recover more refrigerant. Press the ENTER key to

return to the Main Menu.

Note: The RHS780 Charging Cylinder can also be filled from the GAS or

VAPOR side of a cylinder by following the Recover/Recycle

procedure on Page 6.

Note: The RHS780 will use 1.1 Lb (0.5 Kg) more refrigerant than the

displayed value the very first time it is used or after performing a

Calibration Procedure in order to prime the internal components.

Note: The Yellow Hose (12) can be removed from the Fill Port (11) and

connected to either the Blue (13) {Low side} or Red (14) {High Side}

Hose connection port on the rear of the RHS780 to allow recovering

the refrigerant left over in the Yellow Hose (12) using the

Recover/Recycle procedure on Page 6.

September 24, 1999 Page 5

Page 7

W E I G H T = X X . X L B

will automatically cycle ON to continue recovering refrigerant if

A U T O M A T I C ?

>

W E I G H T = X X . X L B

R E C Y C L E ?

ENTER

R E C Y C L E H O L D

T I M E X X M I N 5

RECOVER/RECYCLE

1. Setup the RHS780 as shown on Page 4 and then turn the Main Power Switch (3)

5

ON.

2. Attach the Red (14) and Blue (13) Hoses to the A/C System per the vehicle

manufacturer's instructions, open the Red and Blue Hose Valves.

3. Using the Keypad (2), press the “Up Arrow” key one time to display “WEIGHT=

5

XX.X LB” “RECYCLE? 5” and press the ENTER key. The Display (6) will read

“RECYCLE HOLD” “TIME XX MIN 5”.

The Recycle Hold Time is the amount of time that the RHS780 waits for “outgassing” or for the pressure in the A/C System being recovered to rise enough

to automatically restart the recovery process. The minimum value is two (02)

minutes. The value entered is stored in memory and comes up as the default

value the next time the procedure is used.

>< ENTER

C H E C K H O S E S

S T A R T ?

ENTER

W E I G H T = X X . X L B

C O M P R E S S O R O N

W E I G H T = X X . X L B

C O M P R E S S O R O F F

A M O U N T R E C Y C L E D =

X X . X L B 5

ENTER

*

H I G H P R E S S U R E

S E E M A N U A L

4. Press the “Up Arrow” key to change the value of the field. Press the “Right

Arrow” key to change to a different field. Press the ENTER key to accept the

value. The Display (6) will then read “CHECK HOSES” “START? 5”.

5. Press the ENTER key to start recovering and recycling with the RHS780.

5

The Display (6) will read the “WEIGHT= XX.X LB” “COMPRESSOR ON”. The

RHS780 will recover and recycle refrigerant from the A/C System and

automatically cycle OFF when a vacuum is sensed. This vacuum level can be

seen on the Low (1) Pressure Gauge. The Display (6) will read “WEIGHT= XX.X

LB” “COMPRESSOR OFF”

A small quantity of refrigerant will probably remain in the A/C System as

observed by an increasing pressure on the Low (1) Pressure Gauge. The

RHS780

pressure rises to a preset level. This automatic cycling will repeat resetting the

Recycle Hold Timer each time. When the RHS780 remains OFF for the duration

of the Recycle Hold Timer value entered in Step 4 the Display (6) will read

“AMOUNT RECYCLED=” “XX.X LB 5” from the A/C System and the Attention

Light (7) will turn ON.

6. Close the Red (14) and Blue (13) Hose Valves and disconnect the hoses from

the A/C System.

7. Press the ENTER key to return to the Main Menu.

* This screen will display if there is an internal fault. Please contact RTI

Technical Support. Turn the RHS780 Main Power Switch (3) OFF.

** This screen will display when the Charging Cylinder fills to capacity,

approximately 17.5 lbs (8 Kg.) If this occurs, the Weight can be lowered

using the Charging procedure on Page 9 before the RHS780 can be used

to recover more refrigerant. Press the ENTER key to return to the Main

Menu.

**

8. Drain any recovered oil using the Drain Recovered Oil procedure on Page 7.

C Y L I N D E R F U L L

G O T O C H A R G E 5

September 24, 1999 Page 6

Page 8

DRAINING RECOVERED OIL

Oil is separated from the recovered refrigerant and MUST be removed following

EACH Recover/Recycle procedure to determine the amount (if any) necessary to add

into the A/C System as follows:

Note: The RHS780 must be connected to power source. Draining Recovered

Oil may be done while the RHS780 Vacuum Pump is ON.

1. Setup the RHS780 as shown on Page 4 and press and hold the Oil Drain Re-

pressurization Switch (17) for 5 seconds and then release it.

2. Slowly open the Oil Drain Valve (18) to drain any oil which may have been

removed from the A/C System. A Measuring Cup (19) is provided to collect the

oil.

Unless the A/C System had previously been overfilled, the RHS780 will typically

not remove enough oil to make replenishment necessary.

3. Close the Oil Drain Valve (18).

4. Press and hold the Oil Drain Re-pressurization Switch (17) for 5 seconds. This

permits any residual Non-Condensable Gas to be re-circulated for reprocessing

during the next recycle procedure.

September 24, 1999 Page 7

Page 9

W E I G H T = X X . X L B

the valve on the Oil Charge Bottle, (16) or

DEEP VACUUM

A U T O M A T I C ? 5

>>

W E I G H T = X X . X L B

V A C U U M ? 5

ENTER

*

A / C H A S P R E S S U R E

G O T O R E C Y C L E 5

ENTER

E N T E R V A C U U M

T I M E X X M I N 5

>< ENTER

P E F O R M L E A K

T E S T ? Y / N 5

< ENTER

1. Setup the RHS780 as shown on Page 4 and then turn the Main Power Switch (3)

ON.

2. Attach the Red (14) and Blue (13) Hoses to the A/C System per the vehicle

manufacturer's instructions and open the Red (14) and Blue (13) Hose Valves.

3. Using the Keypad (2), press the “Up Arrow” key two times to display “WEIGHT=

XX.X LB” “VACUUM? 5” and press the ENTER key. The Display (6) will read

“ENTER VACUUM” “TIME XX MIN 5”.

* This screen will display if the RHS780 senses a pressure in either the High (14)

or Low (13) Pressure Hoses. When this occurs, the A/C System must be emptied

using the Recover/Recycle procedure on Page 6. Press the ENTER key to return

to the Main Menu.

4. Press the “Up Arrow” key to change the value of the field. Press the “Right

Arrow” key to change to a different field. The value entered must be greater than

zero. Press the ENTER key to accept the value. The Display (6) will read

“PERFORM LEAK” “TEST? Y/N5”.

5. Press the “Right Arrow” key to move the cursor between Y and N to select

whether or not the RHS780 pauses at the end of Vacuuming so that a vacuum

leak can be detected in the A/C System. Press the ENTER key to accept the Yes

or No choice. The choice entered is stored in memory and comes up as the

default the next time the procedure is used. The Display (6) will read “ADD OIL?

Y/N5”.

6. Press the “Right Arrow” key to move the cursor between Y and N to select

whether or not the RHS780 pauses at the end of Vacuuming (or Vacuum Leak

Checking) to allow the Adding of Oil to the A/C System. Press the ENTER key

to accept the Yes or No choice. The choice entered is stored in memory and

comes up as the default the next time the procedure is used. The Display (6) will

read “START? 5”.

A D D O I L ? Y / N 5

< ENTER

S T A R T ? 5

ENTER

T I M E L E F T = X X M I N

P U M P O N

P U M P O F F X X M I N

C O N T I N U E ?

ENTER

A D D O I L N O W

C O N T I N U E ?

7. Press the ENTER key to start the Vacuum Pump.

The Vacuum Pump will turn On, the Display (6) will read “TIME LEFT=XX MIN”

“PUMP ON” and the minutes remaining will count down on the Display (6). The

Vacuum Pump will turn OFF when the Display (6) reads zero minutes.

8. If a Vacuum Leak Check was selected by choosing Y in Step 5 the Display (6)

will read “PUMP OFF XX MIN” “CONTINUE? 5” and the Attention Light (7) will

turn ON. The elapsed time since the Vacuum Pump turned OFF will count up on

the Display (6). An increasing pressure on the Vacuum Check Gauge (4) is

evidence of a vacuum leak in the A/C System. Press the ENTER key to return

to the Main Menu or to Add Oil if selected in Step 6.

9. If Adding Oil was selected by choosing Y in Step 6 the Display (6) will read “ADD

OIL NOW” “CONTINUE? 5”, and the Attention Light (7) will turn ON. Refer to

Figure 4 and add oil to the side, either High (16) or Low (9) based on the vehicle

manufacturer’s instructions, of the A/C System that will then be Charged during

the Charging procedure on Page 9 by opening the valve on the Oil Charge

Bottle, (16) or (9), and leaving it open until the correct amount of oil has left the

Oil Charge Bottle, (16) or (9). Close

5

(9), and press the ENTER key to return to the Main Menu.

5

ENTER

September 24, 1999 Page 8

Page 10

W E I G H T = X X . X L B

than the entered value. When this occurs, the charging Cylinder

ng the top or bottom (respectively) of the High-Low Charge Selector

the Charge Amount entered in Step 5 plus a one ounce (0.03 KG) “Over

set at the factory to compensate for hose loss. (See Setting Over

CHARGING

A U T O M A T I C ? 5

>>>

W E I G H T = X X . X L B

C H A R G E ? 5

ENTER

E N T E R C H A R G E

A M O U N T = X X . X L B 5

>< ENTER

*

L O W L E V E L

F I L L C Y L I N D E R

ENTER

C H E C K H I G H - L O W

C H A R G E S W I T C H

ENTER

W E I G H T = X X . X L B

G O T O

,

1. Setup the RHS780 as shown on Page 4 and then turn the Main Power Switch (3)

ON.

2. Attach the Red (14) and Blue (13) Hoses to the A/C System per the vehicle

manufacturer's instructions and open the Red (14) and Blue (13) Hose Valves.

3. Determine the refrigerant capacity of the A/C System to be charged.

Note: 1 oz = 0.02835 Kg & 1 Lb = 0.45359 Kg

4. Using the Keypad (2), press the “Up Arrow” key three times to display

“WEIGHT= XX.X LB” “CHARGE? 5” and press the ENTER key. The Display (6)

will read “ENTER CHARGE” “AMOUNT= XX.X LB 5”.

5. Press the “Up Arrow” key to change the value of the field. Press the “Right

Arrow” key to change to a different field. The value entered must be greater than

zero. Press the ENTER key to accept the value. The Display (6) will read

“CHECK HIGH-LOW” “CHARGE SWITCH 5”.

* This screen will display if the RHS780 Charge Cylinder contains less

refrigerant

should be filled using the Fill Cylinder procedure on Page 5. Press the

5

6. Based on the vehicle manufacturer’s instructions, choose Charging through

5

Note: Do Not Turn On The A/C System. SAE compliant refrigerant handling

ENTER key to return to the Main Menu.

either the High (14) Pressure Hose (preferred) or the Low (13) Pressure Hose by

pressi

Switch (10) located on the left side of the RHS780 above the Fill Cylinder Port

(11).

stations, like the RHS780, supply refrigerant in the liquid phase.

Adding liquid refrigerant to a running A/C System may cause

immediate A/C compressor failure.

C H A R G I N G

C H A R G E C O M P L E T E

E V A C H O S E S 5

ENTER

7. Press the ENTER key to start charging.

The Display (6) will read “WEIGHT= XX.X LB” “CHARGING” as refrigerant

leaves the Charging Cylinder. The weight displayed will be increasing from zero

to

Charge”

Charge Amount [only] on Page 13 to change the default value.) When the

RHS780 has finished the Display (6) will read “CHARGE COMPLETE” “EVAC

HOSES” and the Attention Light (7) will turn ON.

8. Press the ENTER key to return to the Main Menu. The A/C System can now be

turned on and tested by monitoring the High (5) and Low (1) Pressure Gauges.

9. Close the Red (14) and Blue (13) Hose Valves, disconnect them from the A/C

System, and go to Page 6 (Recover/Recycle) to Evacuate the refrigerant from

the Hoses.

September 24, 1999 Page 9

Page 11

W E I G H T = X X . X L B

the top or bottom (respectively) of the High-Low Charge Selector

A U T O M A T I C ?

ENTER

R E C Y C L E H O L D

T I M E X X M I N 5

AUTOMATIC

1. Setup the RHS780 as shown on Page 4 and then turn the Main Power Switch (3)

5

ON.

2. Attach the Red (14) and Blue (13) Hoses to the A/C System per the vehicle

manufacturer's instructions and open the Red (14) and Blue (13) Hose Valves.

3. Determine the refrigerant capacity of the A/C System to be charged.

Note: 1 oz = 0.02835 Kg & 1 Lb = 0.45359 Kg

>< ENTER

E N T E R V A C U U M

T I M E X X M I N 5

>< ENTER

P E F O R M L E A K

T E S T ? Y / N 5

< ENTER

A D D O I L ? Y / N 5

< ENTER

E N T E R C H A R G E

A M O U N T = X X . X L B 5

>< ENTER

*

L O W L E V E L

G O T O

,

4. Using the Keypad (2), press the ENTER key when the Display (6) reads

“WEIGHT= XX.X LB” “AUTOMATIC? 5” (this is the default screen of the Main

Menu.) The Display (6) will read “RECYCLE HOLD” “TIME XX MIN 5”.

The Recycle Hold Time is the amount of time that the RHS780 waits for “outgassing” or for the pressure in the A/C System being recovered to rise enough

to automatically restart the recovery process. The minimum value is two (02)

minutes. The value entered is stored in memory and comes up as the default the

next time the procedure is used.

5. Press the “Up Arrow” key to change the value of the field. Press the “Right

Arrow” key to change to a different field. Press the ENTER key to accept the

value. The Display (6) will read “ENTER VACUUM” “TIME XX MIN 5”.

6. Press the “Up Arrow” key to change the value of the field. Press the “Right

Arrow” key to change to a different field. Press the ENTER key to accept the

value. The Display (6) will read “PERFORM LEAK” “TEST? Y/N5”.

7. Press the “Right Arrow” key to move the cursor between Y and N to select

whether or not the RHS780 pauses at the end of Vacuuming so that a vacuum

leak can be detected in the A/C System. Press the ENTER key to accept the Yes

or No choice. The choice entered is stored in memory and comes up as the

default the next time the procedure is used. The Display (6) will read “ADD OIL?

Y/N5”.

8. Press the “Right Arrow” key to move the cursor between Y and N to select

whether or not the RHS780 pauses at the end of Vacuuming (or Vacuum Leak

Checking) to allow the Adding of Oil to the A/C System. Press the ENTER key

to accept the Yes or No choice. The choice entered is stored in memory and

comes up as the default the next time the procedure is used. The Display (6) will

read “ENTER CHARGE” “AMOUNT= XX.X LB5”.

F I L L C Y L I N D E R

ENTER

C H E C K H I G H - L O W

C H A R G E S W I T C H 5

9. Press the “Up Arrow” key to change the value of the field. Press the “Right

5

Arrow” key to change to a different field. The value entered must be greater than

zero. Press the ENTER key to accept the value. The Display (6) will read

“CHECK HIGH-LOW” “CHARGE SWITCH 5”.

* This screen will display if the RHS780 Charge Cylinder contains less refrigerant

than the entered value. When this occurs, the charging Cylinder should be filled

using the Fill Cylinder procedure on Page 5. Press the ENTER key to return to

the Main Menu.

ENTER

10. Based on the vehicle manufacturer’s instructions, choose Charging through

C H E C K H O S E S

S T A R T ? 5

ENTER

W E I G H T = X X . X L B

C O M P R E S S O R O N

September 24, 1999 Page 10

either the High (14) Pressure Hose (preferred) or the Low (13) Pressure Hose by

pressing

Switch (10) located on the left side of the RHS780 above the Fill Cylinder Port

(11). Press the ENTER key when finished programming. The Display (6) will

read “CHECK HOSES” “START? 5”.

Note: Do Not Turn On The A/C System. SAE compliant refrigerant

handling stations, like the RHS780, supply refrigerant in the liquid

phase. Adding liquid refrigerant to a running A/C System may cause

immediate A/C compressor failure.

11. Press the ENTER key to start the RHS780 Automatic sequence.

Page 12

W E I G H T = X X . X L B

AUTOMATIC (continued...)

C O M P R E S S O R O F F

*

H I G H P R E S S U R E

S E E M A N U A L

**

C Y L I N D E R F U L L

G O T O C H A R G E 5

T I M E L E F T = X X M I N

P U M P O N

P U M P O F F X X M I N

C O N T I N U E ?

ENTER

A D D O I L N O W

C O N T I N U E ? 5

ENTER

W E I G H T = X X . X L B

C H A R G I N G

The Display (6) will read the “WEIGHT= XX.X LB” “COMPRESSOR ON”. The

RHS780 will recover and recycle refrigerant from the A/C System and

automatically cycle OFF when a vacuum is sensed. This vacuum level can be

seen on the Low (1) Pressure Gauge. The Display (6) will read “WEIGHT= XX.X

LB” “COMPRESSOR OFF”

A small quantity of refrigerant will probably remain in the A/C System as

observed by an increasing pressure on the Low (1) Pressure Gauge. The

RHS780 will automatically cycle ON to continue recovering refrigerant if

pressure rises to a preset level. This automatic cycling will repeat resetting the

Recycle Hold Timer each time. If a Vacuum Time greater than zero minutes was

entered in Step 6, the Vacuum Pump will turn ON, the Display (6) will read

“TIME LEFT=XX MIN” “PUMP ON” and the minutes remaining will count down

on the Display (6). The Vacuum Pump will turn OFF when the Display (6) reads

zero minutes.

12. Drain any recovered oil using the Drain Recovered Oil procedure on Page 7.

* This screen will display if there is an internal fault. Please contact RTI

Technical Support. Turn the RHS780 Power Switch OFF.

** This screen will display when the Charging Cylinder fills to capacity,

approximately 17.5 lbs (8 Kg.) If this occurs, the Weight can be lowered using

the Charging procedure on Page 9 before the RHS780 can be used to

recover more refrigerant. Press the ENTER key to return to the Main Menu.

5

13. If a Vacuum Leak Check was selected by choosing Y in Step 7 the Display (6)

will read “PUMP OFF XX MIN” “CONTINUE? 5” and the Attention Light (7) will

turn ON. The elapsed time since the Vacuum Pump stopped will count up on the

Display (6). An increasing pressure on the Vacuum Check Gauge (4) is evidence

of a vacuum leak in the A/C System. Press the ENTER key to continue with the

Automatic sequence or RESET to return to the Main Menu.

14. If Adding Oil was selected by choosing Y in Step 8 the Display (6) will read “ADD

OIL NOW” “CONTINUE? 5” and the Attention Light (7) will turn ON. Refer to

figure 4 and add oil to the side, either High (16) or Low (9) based on the vehicle

manufacturer’s instructions, of the A/C System that will then be Charged during

the Charging portion of the Automatic sequence by opening the valve on the Oil

Charge Bottle, (16) or (9), and leaving it open until the correct amount of oil has

left the Oil Charge Bottle, (16) or (9). Close the valve on the Oil Charge Bottle,

(16) or (9), and press the ENTER key to continue.

R E C Y C L E D = X X . X L B

E V A C H O S E S 5

September 24, 1999 Page 11

15. If a Charge Amount greater than zero pounds was entered in Step 9 the Display

(6) will read “WEIGHT= XX.X LB” “CHARGING”as refrigerant leaves the

Charging Cylinder. The weight displayed will be increasing from zero to the

Charge Amount entered plus a one ounce (0.03 KG) “Over Charge” set at the

factory to compensate for hose loss. (See Setting Over Charge Amount [only]

on Page 13 to change the default value.) When the RHS780 has finished the

Display (6) will read “RECYCLED=XX.X LB” “EVAC HOSES” and the Attention

Light (7) will turn ON.

16. Press the ENTER key to return to the Main Menu. The A/C System can now be

turned on checked by monitoring the High (5) and Low (1) Pressure Gauges.

17. Close the Red (14) and Blue (13) Hose Valves, disconnect them from the A/C

System and go to Page 6 (Recover/Recycle) to Evacuate the refrigerant from

the Hoses.

Page 13

W E I G H T = X X . X L B

shown on Page 4 and then turn the Main Power

procedure to change the filters. The normal Filter Change Interval is after

A U T O M A T I C ?

>>>>> ENTER

W E I G H T = X X . X L B

S E T U P ?

Accessing Stored Data

1. Setup the RHS780 as

5

Switch (3) ON.

2. Using the Keypad (2), press the “Up Arrow” key five times to display

“WEIGHT= XX.X LB” “SETUP? 5” and then press the ENTER key. The

Display (6) will read “FILTER HOURS=” “XX.X HOURS”.

5

See the Filter Maintenance section of the manual, Page 14, for the

ENTER

F I L T E R H O U R S =

X X . X H O U R S

>

T O T A L R E C Y C L E D =

X X X X . X K G

>

T O T A L C H A R G E D =

X X X X . X K G

>

every 25 hours.

Note: Press and hold the “Right Arrow” key and press the RESET key

to remove the “CHANGE FILTERS 5” message.

3. Press the “Up Arrow” key. The Display (6) will read “TOTAL

RECYCLED=” “XXXX.X KG”.

4. Press the “Up Arrow” key. The Display (6) will read “TOTAL CHARGED=”

“XXXX.X KG”.

5. Press the “Up Arrow” key to return to the Main Menu.

September 24, 1999 Page 12

Page 14

W E I G H T = X X . X L B

A U T O M A T I C ?

>>>>> ENTER

W E I G H T = X X . X L B

S E T U P ?

Calibration Switch

W E I G H T = X X . X L B

C H A R G I N G

>

O V E R C H A R G E

A M O U N T = X . X X K G 5

Setting Over Charge Amount

1. Remove the front panel of the RHS780.

5

2. Setup the RHS780 as shown on Page 4 and then turn the Main Power Switch (3)

ON. Refer to the figure below to locate the access hole to the Calibration Switch

(B) which is on the underside of the Circuit Board Cover (C) left of the LCD.

3. Remove the plastic “Calibration Tool”(A) from the lower mounting hole of the

Circuit Board Cover (C) next to the access hole to the Calibration Switch(B).

5

4. Using the Keypad (2), press the “Up Arrow” key five times to display “WEIGHT=

XX.X LB” “SETUP? 5”and press the Calibration Switch (B). The Display (6) will

read “WEIGHT= XX.X LB” “CHARGING”.

5. Press the “Up Arrow” key. The Display (6) will read “OVER CHARGE”

“AMOUNT= X.XX KG5”.

6. Press the “Up Arrow” key to change the value of the field. Press the “Right

Arrow” key to change to a different field. The value entered will be stored until

this procedure is run again and a new value is entered. Press the ENTER key

to accept the value. The Display (6) will then return to the Main Menu.

Note: 1 oz = 0.02835 Kg and 1 Lb = 0.45359 Kg

7. Replace the front panel of the RHS780.

><ENTER

Note: Calibration Tool Part No. 360-81214-00

September 24, 1999 Page 13

Page 15

SCHEDULED MAINTENANCE

the Condenser to maintain high efficiency performance of the RHS780. Disconnect power and remove the lower rear

on the Condenser coils. Air flow will be restricted causing damage to the RHS780. Replace the panel before applying power

DAILY...

Check the oil level in the Vacuum Pump while the pump is running. The Vacuum Pump Oil Level Sight Glass is visible through

a hole in the Lower Rear Panel of the RHS780. The oil level should be at the “half-way” point of the glass. If oil is not visible

call Technical Support at 800-468-2321 extension 259.

MONTHLY...

Check the oil level in the Compressor while the motor is not running. The Compressor Oil Level Sight Tube is on the left side

of the lower section of the RHS780 as viewed from the front. Remove the front panel from the RHS780. The oil level should

be approximately one half inch high in the Sight Tube. If oil is not visible or is above the top of the Sight Tube call Technical

Support at 800-468-2321 extension 259.

Clean

perforated panel and blow compressed air through the cooling fins of the Condenser to remove any debris. Do not bend the

fins

to the RHS780.

FILTER MAINTENANCE

The RHS780 automatically keeps track of Compressor Run Time. The Display (6) will read “CHANGE FILTERS 5” after every

25 hours every time the program returns to the Main Menu or whenever the RHS780 is turned on as a reminder to change the

filters. Press ENTER 5 to go to the Main Menu.

The “INLET” Combo Filter (left side) must be changed after every 25 hours of operation. RTI part number 026-80077-00.

The “OUTLET” Combo Filter (right side) must be changed after every 50 hours of operation. RTI part number 026-80069-00.

The Hours Counter is reset when the “CHANGE FILTERS 5” message is cleared. Record the filter changes performed to track

when only the “INLET” Combo Filter is changed versus when both are changed.

Change the filters as described below:

1. Remove front panel to service the Combo Filters.

2. Disconnect Flare Fittings from top and bottom of filters.

3. Remove mounting nuts and filters.

4. Transfer filter insulation material to new filter as applicable.

5. Install new Combo Filters using hardware removed in Step 3.

6. Connect Flare Fittings to top and bottom of filters.

7. Check for leaks and repair as necessary.

8. Replace front panel.

9. Go to Page 12, Accessing Stored Data, for instructions on how to remove the “CHANGE FILTERS 5” message.

September 24, 1999 Page 14

Loading...

Loading...