Page 1

OPERATION

&

MAINTENANCE

MANUAL

RHS2680

Refrigerant Handling System

4075 East Market Street

York, Pennsylvania 17402

Phone: 717-840-0678

Fax: 717-755-8304

E-mail: rti@rtitech.com

Manual P/N 035-80958-00

Page 2

TABLE OF CONTENTS

Startup & Safe Operation ................... 1

Introduction to the RHS2680 ................. 2

Control Panel ............................. 3

Keypad Functions ......................... 4

Start-Up ................................. 5

Recover (Recycle) ......................... 6

Purge Air - Drain Oil ....................... 6

Vacuum ................................. 7

Charge .................................. 7

Maintenance ............................. 8

Parts Lists ............................... 9

FSC Adapter for DOT ......................11

CONGRATULATIONS

You have purchased one of the finest Recovery, Recycling,

and Charging Machines available!

Fill out and return the Warranty Card within 90 days to

activate the warranty and free lifetime technical support.

TECHNICAL SUPPORT

800-468-2321 (Ext. 259)

tech@rtitech.com

Page 3

STARTUP & SAFE OPERATION

9 Do not use a damaged unit. Check for shipping damage and place a claim with carrier if damage

is discovered.

9 Return the Warranty Card to activate technical support service and warranty coverage.

9 The RHS2680 should not be operated or serviced by any person who has not read all the

contents of this manual.

9 This manual describes normal operation and maintenance for the RHS2680. Failure to read and

comply with these instructions or any one of the limitations noted herein can result in serious

injury and/or property damage. The instructions should not be interpreted to anticipate every

possible contingency.

9 It is the responsibility of the owner/user to operate the RHS2680 in accordance with all laws and

specifications which may apply.

9 Recover (recycle) and charge only the refrigerants for which the RHS2680 is configured.

9 Avoid breathing refrigerant or lubricant vapor. Exposure may irritate eyes, nose and throat.

Ventilate work area if accidental system discharge occurs.

9 Wear safety glasses and protective gloves. Refrigerant has a very low boiling point and can

cause frostbite.

9 Follow the RHS2680 operating procedures sequentially to avoid prematurely disconnecting

hoses or opening valves which may release refrigerant to the atmosphere.

9 Do not expose the RHS2680 to moisture or operate in wet areas.

9 Use the RHS2680 in locations with ventilation that provides at least four air changes per hour.

9 Hoses must have shutoff devices within 12 inches of the connection point to the A/C to minimize

the introduction of air into the RHS2680 and the release of refrigerant when being disconnected.

9 Avoid using an extension cord with the RHS2680. If necessary use a good condition, three wire

grounded, #14 AWG or larger extension cord of the shortest possible length.

9 Disconnect power before performing any maintenance or service on the RHS2680.

9 Do not connect the red or blue hoses to the liquid port of a cylinder of refrigerant to fill the charge

cylinder. Doing so may cause the compressor to fail and void the warranty.

9 Do not connect the RHS2680 to the liquid side of any A/C with a capacity greater than 4 lbs.

Refrigerant in A/C Systems having larger capacities must be recovered from the vapor side only.

Special Considerations with R134a

R134a has been shown to be nonflammable at ambient temperature and atmospheric pressure.

However, tests under controlled conditions have indicated that at pressures above atmospheric and

with air concentrations greater than 60 percent by volume, R134a can form combustible mixtures.

While it is recognized that an ignition source is also required for combustion to occur, the presence

of combustible mixtures is a potentially dangerous situation and should be avoided.

Under no circumstances should any equipment be pressure tested or leak tested with air and R134a

mixtures. Do not use compressed air for leak detection in R134a systems.

Page 1

Page 4

INTRODUCTION TO THE RHS2680

The RHS2680 is a complete refrigerant management center featuring state-of-the-art electronic

control with digital weight scale measuring of refrigerant. Operation of the RHS2680 is intuitive and

very easy to master.

Following is an overview of the operation and features of the RHS2680:

RECOVER (RECYCLE)

Refrigerant is recovered from the A/C, impurities (particulates, oil, moisture and air) are removed

and the refrigerant is stored in the internal cylinder. The recovery process stops when the

RHS2680 senses an 8 InHg vacuum at the A/C. Wait for at least two minutes and watch the

pressure gauges to determine if there is an increasing pressure. If pressure in the A/C rises

during this time period due to vaporization of residual liquid refrigerant, the RHS2680 will restart

to recover this refrigerant. When the RHS2680 stays off continually for at least two minutes, the

recovery procedure is complete.

VACUUM

A deep vacuum should be drawn on the A/C to remove air, moisture and refrigerant dissolved

in the oil. A deep vacuum is especially important if the A/C was opened for replacement of

components.

PURGE AIR - DRAIN OIL

Excess air and recovered oil must be removed from the RHS2680 after all refrigerant has been

recovered from the A/C. Temperature and pressure readings are examined and air is released

using the purge valve. Oil is drained into the oil drain cup for measuring to determine the need

to replenish the A/C.

CHARGE

Refrigerant is charged into the A/C by weight. The amount to be charged is entered and the

RHS2680 automatically charges the refrigerant into the A/C.

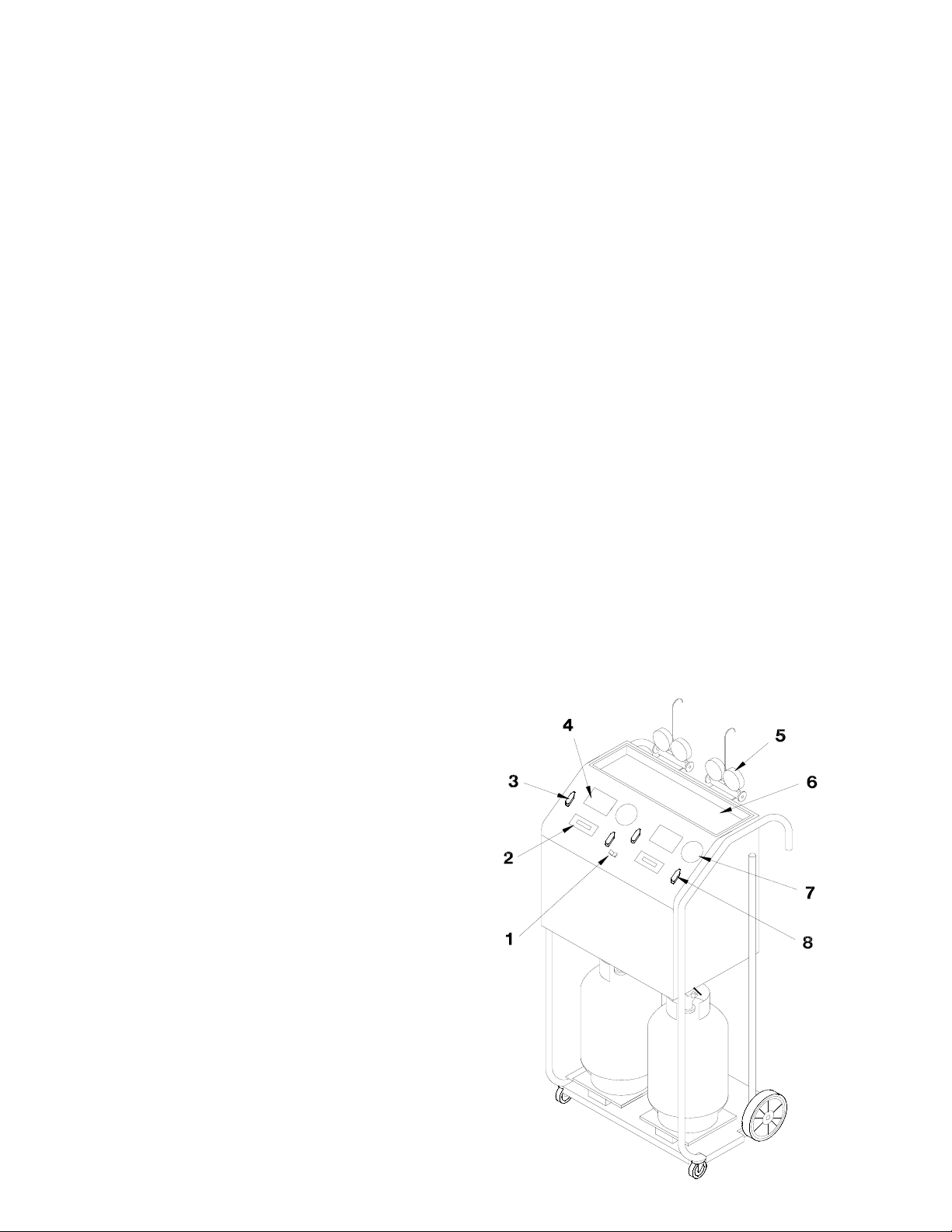

1 R12/R134a Selector Switch

2 Keypad

3 Function Valve

4 Purge Chart

5 Gauge Manifold

6 Tool Tray

7 Purge Gauge

8 Purge Valve

Page 2

Page 5

0

F

32

34

36

38

40

42

44

46

48

50

52

PSIG

44

46

48

50

52

54

57

59

61

64

66

CONTROL PANEL

PURGE CHART - R12

0

F

54

56

58

60

62

64

66

68

70

72

74

PSIG

69

72

74

77

80

83

85

88

92

95

98

0

F

76

78

80

82

84

86

88

90

92

94

96

PSIG

102

105

108

112

115

118

123

127

130

135

138

0

F

32

34

36

38

40

42

44

46

48

50

52

0

F

98

100

102

104

106

108

110

112

114

116

118

PSIG

42

44

46

49

51

54

56

59

61

64

67

PSIG

143

147

150

155

160

165

168

173

178

183

188

PURGE CHART - R134a

0

F

54

56

58

60

62

64

66

68

70

72

74

PSIG

70

72

76

78

82

85

88

92

95

97

104

0

76

78

80

82

84

86

88

90

92

94

96

F

PSIG

107

110

114

118

123

127

130

135

140

145

148

0

F

98

100

102

104

106

108

110

112

114

116

118

PSIG

153

157

163

167

173

180

185

190

195

200

207

Page 3

Page 6

KEYPAD FUNCTIONS

Scroll Key Press to scroll through function

options or to increase numeric

values shown on the display.

Cursor Key Press to move flashing cursor on

the display prior to numeric entries.

Go Key Press to confirm data entry and

continue.

Stop Key Press to halt program sequence.

Units Key Press to change unit of measure for

weight displays.

- CAUTION -

Always use fingers to operate keypad.

Use of sharp objects will cause damage.

Page 4

Page 7

START-UP

1. Turn Function Valves and Purge Valves on RHS2680

to OFF. Connect yellow hoses of gauge manifolds to

ports on rear of RHS2680. Close high and low valves

on gauge manifolds.

2. Connect red and blue hoses from the gauge manifold,

for the refrigerant to be processed, to A/C system and

open hose valves.

3. Connect power cord of RHS2680 to properly grounded

power source. Avoid using an extension cord. If

necessary use a good condition, three wire grounded,

#14 AWG or larger extension cord of the shortest

possible length.

4. Select refrigerant to be processed using the

R12/R134a Selector Switch. The corresponding display

and keypad will be energized.

5. RTI TECHNOLOGIES and 680/2860 SERIES will

display for ten seconds.

6. The display will show the weight of refrigerant in the

RHS2680 cylinder and prompt RECYCLE?

7. Press [5] key to begin a recycle procedure (Page 6) or

press [>] key to go to next screen (See next step).

8. The display will show the weight of refrigerant in the

charge cylinder and prompt VACUUM?

W W W W CAUTION W W W W

Make sure the A/C pressures are at zero or below. If

the gauges indicate positive pressure, refrigerant will

be vented to the atmosphere. Perform a recover

procedure before starting a vacuum procedure.

9. Press [

press [

5] key to begin a vacuum procedure (Page 7) or

>] key to go to next screen (See next step).

10. The display will show the weight of refrigerant in the

charge cylinder and prompt CHARGE?

11. Press [5] key to begin a charge procedure (Page 7) or

press [>] key to return to Step 6 above.

Page 5

Page 8

RECOVER (RECYCLE)

1. Turn Function Valve on RHS2680 to RECOVER.

2. Open high and low valves on gauge manifold.

3. The display will show the weight of refrigerant in the

RHS2680 cylinder and indicate the unit is recycling.

4. When the A/C system pressure is in a vacuum the

display will show RECYCLE COMPLETE CHECK

PRESSURES. Wait two minutes to see if the pressure

in the A/C increases (due to liquid refrigerant

vaporizing). The RHS2680 will automatically begin

recycling again if the pressure rises above zero.

5. Press the stop key and close the high and low valves on

the gauge manifold.

6. Turn Function Valve on RHS2680 to OFF.

Note:

The display will show CYLINDER FULL GO TO CHARGE

if the RHS2680 cylinder fills to capacity. Press the STOP

key and perform a charge procedure to transfer refrigerant

to another A/C system or an external storage cylinder.

PURGE AIR - DRAIN OIL

IMPORTANT: Oil must be drained and Air purged after each recover (recycle) procedure.

Failure to do so will cause excess air to be introduced into the A/C during charge and the

RHS2680 will fill with air causing a high-pressure shutdown.

1. The oil drain valve is accessible from the rear of the RHS2680, located under the main

enclosure. Slowly open the valve and drain any oil into the measuring cup to determine how

much oil (if any) should be added to the A/C.

2. Leave the oil drain valve open.

3. Measure the room temperature.

4. Find the corresponding pressure for this temperature on the purge chart printed on the RHS2680

top panel.

5. Compare this pressure from the chart with that indicated on the Purge Gauge. If the gauge

shows a higher pressure, slowly open the Purge Valve a small amount until the pressure drops

to approximately the pressure shown in the chart.

6. Turn the purge valve to OFF.

7. Close the oil drain valve.

Page 6

Page 9

VACUUM

1. MAKE SURE THE GAUGE MANIFOLD PRESSURES

ARE ZERO OR LESS. If not, a recover procedure must

be performed before starting the vacuum procedure.

2. Turn Function Valve on RHS2680 to VACUUM.

3. Open high and low valves on gauge manifold.

4. The display will show the weight of refrigerant in the

RHS2680 cylinder and indicate the unit is vacuuming.

5. At the end of the desired vacuum time, press the stop

key and close the high and low valves on the gauge

manifold.

6. Turn Function Valve on RHS2680 to OFF.

CHARGE

1. Open either the low or high valve on gauge manifold

and corresponding hose valve according to the A/C

manufacturer’s recommendation for charging the system.

2. Enter weight of charge desired using the keypad. Press

the [>] key to increase numeric value shown on display

and press [<] key to move flashing cursor to next

position. Press [5] key to start charging.

3. Turn Function Valve on RHS2680 to CHARGE.

4. Do not run the A/C during the charge procedure.

5. The display will show the amount of refrigerant being

charged into the A/C.

6. The display will show CHARGE COMPLETE

EVACUATE HOSES when the correct amount of

refrigerant has been charged.

7. Press the stop key and close the hose valve.

8. Turn function valve to OFF.

9. Evacuate the hose by running a recycle procedure.

Note:

The display will show LOW LEVEL GO TO RECYCLE if the

RHS2680 cylinder does not contain enough refrigerant to

complete the charge weight entered. Press the STOP key

and perform a recycle procedure to transfer refrigerant into

the RHS2680 cylinder.

Page 7

Page 10

MAINTENANCE

The RHS2680 will provide many years of reliable service if properly maintained. Following is a

checklist of items which will ensure the RHS2680 performs at peak efficiency and presents an image

to your customers that your shop performs high tech A/C service.

1. Use tool tray for storage of tools and accessory adapters.

2. Store gauge manifolds and hoses properly when not in use. Avoid hanging hoses over the

top of the unit.

3. Keep the exterior surfaces clean. Use a mild all purpose cleaner to wipe oil and dirt off the

cabinet.

4. Do not allow the unit to sit outside in direct sunlight or inclement weather. Excessive

exposure to sun light and moisture may cause damage and will void the warranty.

5. The RHS2680 is not intended to be used for mobile A/C service where the unit is

transported to customer sites. Excessive vibration will shorten component life.

6. Be gentle when moving the RHS2680 around the shop. Tip the unit and ease the front

casters over any obstacles such as door jams, air hoses and floor irregularities.

7. Periodically remove the front cover and check for refrigerant leaks inside the RHS2680

using a leak detector. A small leak detected early will prevent future undetected loss of

refrigerant.

8. Use regulated, clean shop air to remove debris from the fins of the condenser coil. Be

careful and do not disturb any internal components.

9. During filter changes every 25 hours, it is IMPERATIVE for the longevity of the

RHS2680, that two ounces of compressor Poly Ester Oil (POE) RTI P/N 011-80021-00

be added to the compressor to replenish oil lost during the previous 25 hours of

operation. Not adding oil at recommended intervals or using oil other than RTI P/N

011-80021-00 will void the warranty.

10. Change filters after every 25 hours of recovery operation. Filters must be changed at least

once per year for efficient recycling of refrigerant.

FILTER CHANGE & ADDITION OF COMPRESSOR OIL

Filters (see next page for RTI part numbers) must be changed and oil must be added to the

compressor after every 25 hours of recycling refrigerant. The display will show “CHANGE FILTERS

+2OZ - COMP OIL”. This reminder will be displayed whenever the RHS2680 is turned on or a new

procedure is started.

Disconnect power and remove tool tray from top of RHS2680. Use end wrench to loosen and tighten

copper tube fittings on filters. The foam insulation on the smaller outlet filter must be removed from

the old filter and reinstalled on the new one. Check for leaks after replacing filters.

Locate compressor oil fill port (tag attached to port). Remove plug from the fill tube using two end

wrenches. Fill the syringe (supplied with RHS2680) with two ounces of oil (RTI P/N 011-80021-00).

Apply power and place RHS2680 in Vacuum Mode. Insert tip of syringe in fill port and inject the two

ounces of oil. The vacuum will pull the oil into the compressor. Press Stop. Disconnect power and

install plug on fill tube using two end wrenches.

Apply power. The display will show “CHANGE FILTERS +2OZ - COMP OIL”. While this message

is displayed, press and hold the [<] key and the [>] key for two seconds to reset.

Page 8

Page 11

PARTS LIST

P/N DESCRIPTION P/N DESCRIPTION

1 360-81574-00 Expansion Valve Assy 8 026-80069-00 Combo Filter 3/8 Flare

(Short)

2 024-80037-00 Contactor ½ HP

120V 3NC/1NC

3 026-80077-00 Combo Filter 3/8

Flare (Long)

4 360-81307-00 High Pressure Switch

261 psig

5 360-81670-01 Compressor Assy

2680 (120V)

6 360-81547-01 Assy Heater Belt 13 360-80851-00 Oil Drain Assy

7 031-80000-00 Load Cell 35Kg 14 360-81428-00 Internal Cylinder (DOT)

9 025-80304-00 Solenoid Valve

120V

10 360-81309-00 Low Pressure Switch

3psig - 8InHg

11 360-80280-00 Condenser Assy

12 360-80416-00 Fan Assy w/Pins

120V

Page 9

Page 12

PARTS LIST

P/N DESCRIPTION

1 360-81739-00 Main Ball Valve Assy (2680)

2 024-80070-00 Keypad Overlay 680/550/2860

3 026-80071-02 Purge Gauge Assy 0-500 psig

4 360-81576-00 Purge Ball Valve Assy (2860)

5 024-80072-00 Circuit Board 680/550/2860

6 024-80066-00 Switch Rocker SPDT (on-on) Visi-Red

Page 10

Page 13

Page 11

Loading...

Loading...