Page 1

NTO-200

Operation Manual

RTI Technologies, Inc.

10 Innovation Drive

York, PA 17402 USA

Phone: 717-840-0678

Equipment for the Most Productive Technicians in the World

Visit www.rtitech.com

for the most up to date information.

035 81679 00 (Rev A)

Page 2

TABLE OF CONTENTS

Pictograms............................................... 2

Safety Information ................................... 2

Components............................................4

Introduction..............................................5

Specifications .......................................... 5

Overview..................................................6

Changing Display Units ...........................7

Resetting Zero Point................................ 7

Setting Up Air Supply .............................. 7

Inflating Tires...........................................8

Replacing Membrane Cartridge............... 9

Maintenance............................................10

Spare Parts.............................................. 10

Error Messages.......................................11

Troubleshooting....................................... 12

Warranty Information............................... 14

1

Page 3

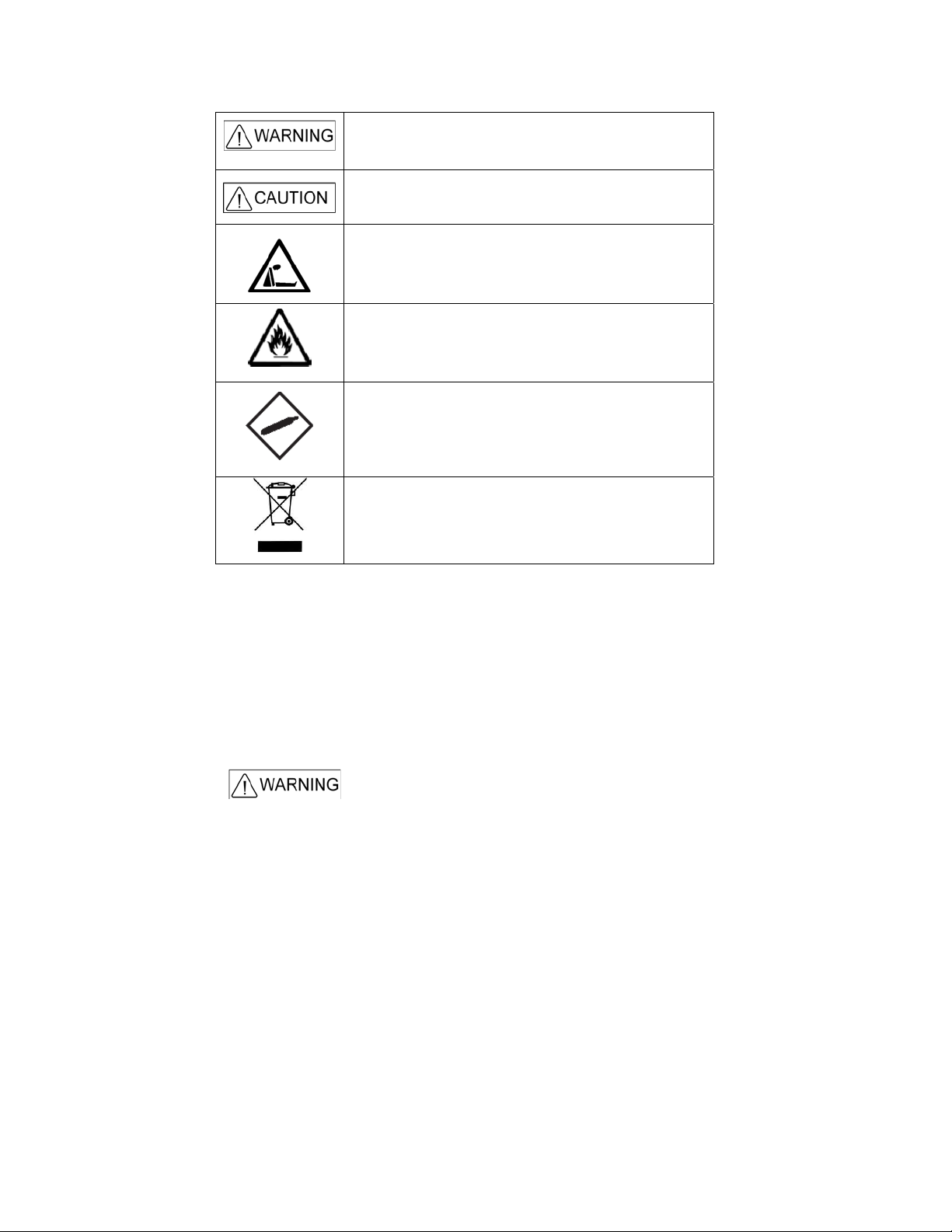

PICTOGRAMS

The following symbols will be used in this manual and found on the

equipment:

Warning: Hazard that can cause death or

serious injury. Follow the instructions.

Caution: Danger that can cause damage to the

equipment. Follow the instructions.

Warning: Risk of death due to suffocation.

Risk of fire: Oxygen-enriched air leads to an

increased risk of fire in the event of contact with

flammable products.

High pressure risk: Follow the instructions with

respect to compressed gasses.

Instructions with respect to the environment.

SAFETY INFORMATION

GENERAL SAFETY

Correct use of the NTO-200 Nitrogen TopOFF is important for your

personal safety and for trouble-free functioning. Incorrect use can cause

damage to the NTO-200 or can lead to incorrect gas supply to the

customer’s process.

Warning: Read this manual before you start

operating the NTO-200 to prevent accidents and

damage. If you detect a problem that you cannot

solve with this manual, contact RTI Technical

Support at 1-(800)-468-2321 x 1.

2

Page 4

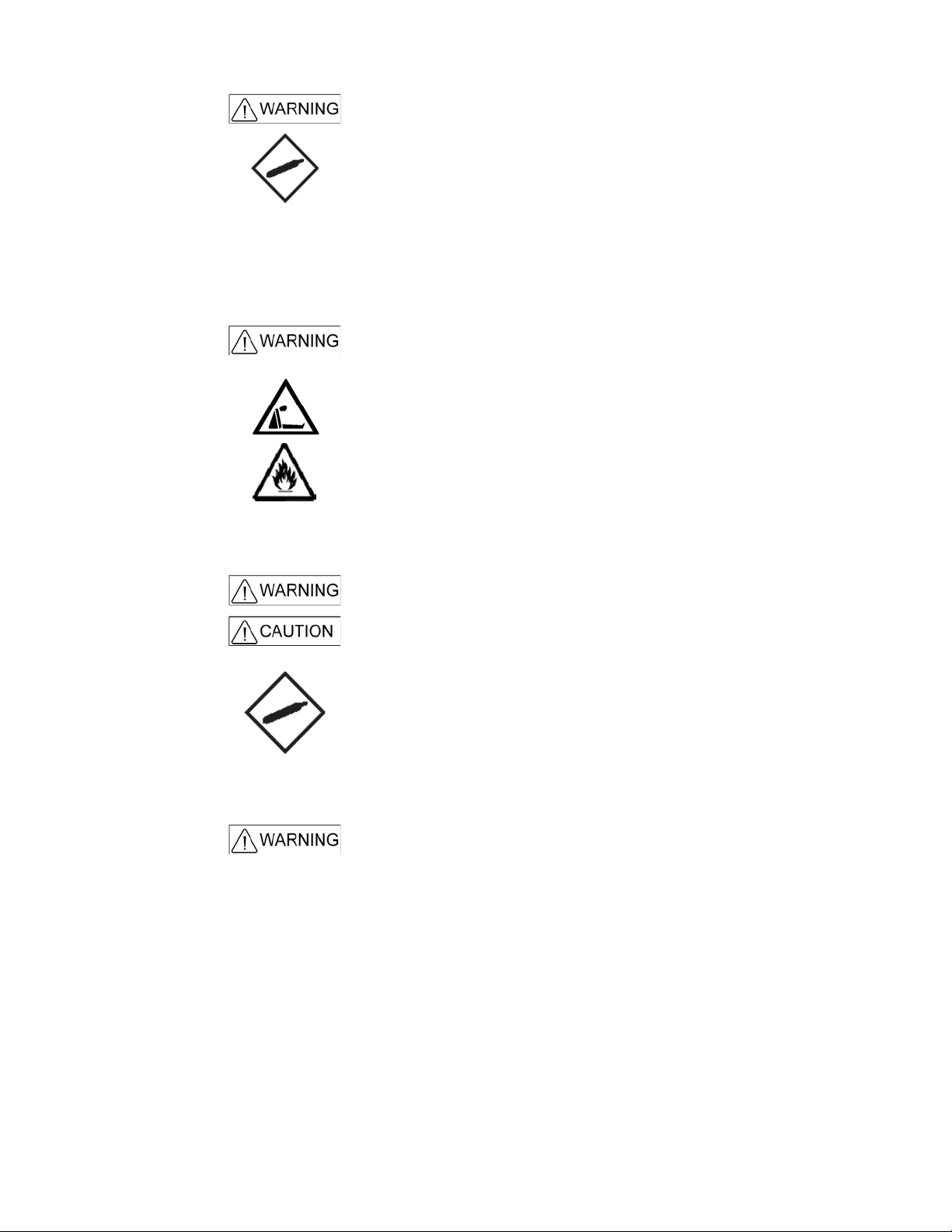

SAFETY INFORMATION (Continued)

COMPRESSED AIR

Warning: Ensure that the feed air pressure does

not exceed 160 psig.

The user is ultimately responsible for selecting the

correct air supply system and components. They

are also responsible for maintaining the system so

it does not cause damage to the NTO-200.

NITROGEN AND OXYGEN

The NTO-200 generates nitrogen as a product. Oxygen enriched air is

released as waste.

Warning

Nitrogen can cause suffocation. Oxygen enriched

air leads to increased risk of fire in the event of

contact with flammable products. Make sure that

there is adequate ventilation at all times!

Do not install the NTO-200 in an area where

explosive substances may be present.

OTHER IMPORTANT SAFETY INFORMATION

Warning: There are no user maintainable parts on

the NTO-200. The grip is part of the pressure

chamber and so it should not be disassembled.

Failure to follow these warnings could result in an

unexpected release of pressure, causing serious

injury or damage.

Use of the NTO-200 in any other way than

specified in this manual could result in an

unexpected release of pressure, causing serious

injury or damage.

Warning: When handling, installing, or operating

the NTO-200, user must use safe engineering

practices and observe all related rules and

health/safety information.

3

Page 5

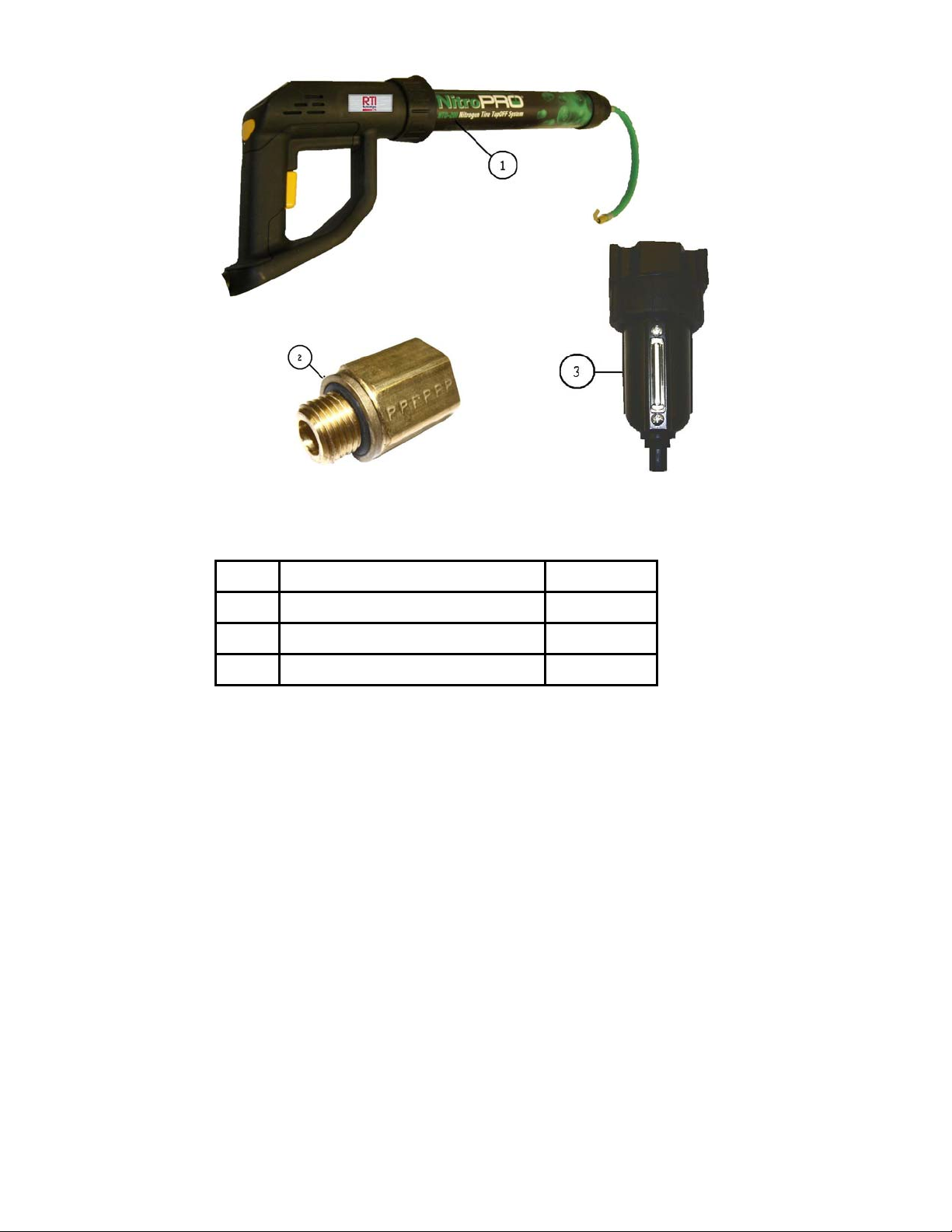

COMPONENTS

When the NTO-200 is delivered, check the box to ensure that all items

are included. The following is a list of included items:

Item # DESCRIPTION QUANTITY

1 NTO-200 Nitrogen TopOFF System 1

2 ¼” NPT Adapter 1

3 Filter Assembly 1

If it is found that anything is missing, or appears damaged, please inform

delivery company and contact NTO-200 supplier immediately.

4

Page 6

INTRODUCTION

The NTO-200 is a hand held, battery powered nitrogen tire inflation

system created primarily for tire top-offs and small tire fills such as

motorcycle and bicycle tires. It is well-suited for other types of nitrogen

inflation of small pneumatic tires found in the industrial, recreational and

agricultural industries. The NTO-200 can also be used to nitrogen inflate

a wide variety of sporting goods equipment and any other applications

that utilize pneumatic pressure for support.

SPECIFICATIONS

Technical Specifications

Lifetime grip* 50,000 tire fills

Lifetime cartridge* 12,000 tire fills

Lifetime cartridge* 55,000 tire top-offs @ 120 PSI

Lifetime cartridge* 40,000 tire top-offs @ 125 PSI

Lifetime cartridge* 30,000 tire top-offs @ 130 PSI

Lifetime cartridge* 19,000 tire top-offs @ 135 PSI

Nitrogen Capacity**

Purity 95% N2 average

Inlet air quality

Inlet pressure 72-160 psi

Max Tire Pressure*** 50% of inlet pressure

Temperature -4°F to 122°F

Overall Weight 2.6 lbs

Cartridge Weight 1.3 lbs

Overall Dimensions (HxWxD) 9.1 x 3.5 x 25.2 inches

Cartridge Dimensions 17.7 inches long x 3.5 inch diameter

Certification CE conforming (EMC and PED art.3.3)

Warranty - grip */** RTI Warranty

Warranty - cartridge */** RTI Warranty

Maintenance None

Patent Pending

Technical Specs based on:

*205/55R16 Tire Size

**Reference condition at 14.7 PSI and 68°F

***Fill tires up to max 5.5 bar / 80 psi / 0.55 MPa

1.8CFM @ 68°F (average)

(at 145 psi inlet pressure)

ISO 8573-1: 2001 Class 3.-.3

It is not allowed to feed liquid/aerosol

condensate, water or oil into NTO-200.

5

Page 7

OVERVIEW

KEY

Compressed Air

Inlet

1

ON / OFF and air

2

release button

Nitrogen inflation

3

button 8 Thumb lever 13

4 Digital Display 9 Tire Valve connector 14 Pressure Units

5 Locking ring 10

6

7 Nitrogen filling hose 12 Filter Icon

Exchangeable

cartridge

1/4 BSPP x 1/4 NPT

Fitting 15 Filter

11 Error Icon

Pressure

reading/Error Code

6

Page 8

CHANGING DISPLAY UNITS

Warning: Ensure the NTO-200 is relieved of

pressure before changing units.

The membrane cartridge must be removed from grip before changes can

be made to the setup. Unscrew locking ring from the grip and remove

the cartridge. (Note: This will create error message E4 when grip is

powered up. It will clear itself when the NTO-200 is reassembled.)

Press and hold ON/OFF button until desired units (bar/psi/MPa) are

shown on the display. Release button to save the new unit setting and

turn off NTO-200. (Note: If you scroll through all the units back to

current setting, the NTO-200 will automatically shut down.)

RESETTING ZERO POINT

To reset the zero point of the NTO-200, unscrew locking ring and remove

cartridge. Press ON/OFF button, the NTO-200 will power up and will

reset the zero point. After this is complete, it will automatically shut

down.

SETTING UP AIR SUPPLY

Before performing Nitrogen fills with the NTO-200, customer must first

set up the compressor to supply the NTO-200 with clean, dry (oil less

and waterless) air. To do this effectively, RTI Technologies has supplied

a filter with ¼” NPT ports to install in air supply.

When installing the filter, mount so the automatic drain is pointing

downwards. This drain will automatically bleed any fluids that collect in

the bowl when it detects a certain amount present.

After the filter is installed, the customer should take the ¼ BSPP x ¼

NPT fitting (Item 10 on previous page) and install it on the back side of

the NTO-200 grip, (Item 1 on previous page). NOTE: The customer

must also provide the hose that connects the filter to the NTO-200

grip assembly.

7

Page 9

INFLATING TIRES

Warning: The maximum tire pressure

capability for the NTO-200 is 5.5bar / 80psi /

0.55MPa. Small tire sizes inflate very quickly.

Make sure you do not over-inflate tires during

Begin by connecting filtered air supply (Figure 1). Then push down

thumb lever on air chuck at end of Nitrogen Fill Hose. While holding in

lever, push onto valve stem and then release (Figure 2). Press ON/OFF

button to turn on NTO-200. Hold the NTO-200 as shown in Figure 3

below and squeeze the Nitrogen inflation button to fill tires with nitrogen.

Fill tire to pressure specified by manufacturer.

NOTE: The pressure displayed (when squeezing inflation button)

represents the filling pressure; not the tire pressure. To view tire

pressure, user must release inflation button.

Continue filling tire and checking tire pressure until desired pressure is

achieved. If the tire goes above desired inflation value, press and hold

ON/OFF button to release pressure from inside tire. Check tire pressure

by releasing ON/OFF button periodically. When desired pressure is

achieved, disconnect air chuck from tire by squeezing thumb lever and

pulling off valve stem. Replace valve cap (Figure 4).

NOTE: If tire has been filled with compressed air, fully deflate using

appropriate valve release tool. Then inflate to target pressure using

the NTO-200, deflate to 50% of target pressure and refill to target

pressure. This technique increases nitrogen purity in the tires.

the nitrogen inflation process.

Figure 1 Figure 2 Figure 3 Figure 4

8

Page 10

REPLACING MEMBRANE CARTRIDGE

When the cartridge’s usable life is diminished, (code E6 will be on the

display) it will need to be replaced.

Disconnect air supply from NTO-200 (Figure 5) and remove Nitrogen fill

hose from end of cartridge. Next, unscrew locking ring from grip (Figure

6) and remove cartridge from grip cautiously (Figure 7). Use caution

when removing the cartridge as to not damage electrical contacts.

Remove gasket from grip and insert replacement. Make certain gasket

is correctly placed in the profile of the grip to obtain best seal (Figure 8).

When installing replacement cartridge, ensure that key on side of

cartridge is aligned with groove inside grip.

Confirm the key is

aligned with groove

inside grip before

tightening lock ring.

Carefully push cartridge into grip and use lock ring to hold in place. The

lock ring must be fully engaged before continuing use of product. Make

sure the lock ring is completely tightened to ensure proper nitrogen

purity. Insufficient tightening will lead to a reduction in nitrogen

purity.

Remove nitrogen fill hose from old membrane and reconnect to new

membrane. Torque fitting to 15 ft-lbs.

Figure 5

Figure 6 Figure 7 Figure 8

9

Page 11

MAINTENANCE

There are no serviceable parts on the NTO-200.

The NTO-200 should be wiped down with a damp cloth only. Keep

excessive moisture from the area around the display. A mild detergent

may be used for heavy dirt. Do not use abrasives/solvents as they may

damage the NTO-200. NOTE: Keep clothes away from exhaust

holes and fibers located under locking ring.

SPARE PARTS

1

Ref Description Part Number

1 NTO-200 Complete 455 80025 00

2

3

4

Ref Description Part Number

NTO-200 Cartridge

2

& Gasket

Ref Description Part Number

NTO-200 Filter

3

Replacement

Ref Description Part Number

Tire Filling Hose

4

Replacement (12 inch)

026 80615 00

026 80617 00

026 80616 00

10

Page 12

ERROR MESSAGES

The warnings below will appear on the display when NTO-200 is

operated outside the limits specified in the technical specifications

section of the manual. The warnings will automatically clear themselves

when the NTO-200 is back to normal operating parameters.

Indication Condition

If error icon is flashing, the pressure sensor is no longer in calibration.

Check that membrane cartridge is installed correctly (See section “Replacing Membrane Cartridge”). Contact NTO-200 Supplier if

problem persists.

If filter icon is flashing, membrane cartridge has exceeded 90% of

lifetime.

Pressure reading will flash when tire pressure exceeds 95 psi (6.5 bar /

0.65 MPa). Press and hold ON/OFF button to release pressure.

Pressure reading will change to P and error indicator will flash when

tire pressure rises above 102 PSI (7 bar / 0.7 MPa). Press and hold

ON/OFF button to release pressure.

Error Code Condition

The NTO-200 is at end of its life.

Contact NTO-200 supplier if problem continues.

The measurement is out of range (negative). Calibrate measurement

as described in manual.

Contact NTO-200 supplier if error does not reset itself.

The measurement is out of range (positive). Calibrate measurement

as described in manual.

Contact NTO-200 supplier if error does not reset itself.

No membrane cartridge or non-genuine RTI Technologies cartridge

detected. Remove cartridge from grip and check if metallic contact on

cartridge is clean. Reinstall cartridge into grip correctly. See section

- “Replacing Membrane Cartridge”.

Cartridge became corrupted or cartridge installed is a non-genuine

RTI Technologies cartridge. Replace cartridge.

The membrane cartridge has exceeded lifetime. Replace cartridge.

11

Page 13

TROUBLESHOOTING

Fault Probable Cause Solution

NTO-200 will only

power up for 5

seconds.

An error occurred during

operation

No pressure at inlet

Power up generator and note error

codes on display. Refer to previous

page for more details

Check the following:

1.) NTO-200 is connected to

compressed air supply.

2.) Compressed air supply pressure

meets required specification.

3.) Hoses for any damage.

No flow of nitrogen

from NTO-200

Reduced flow of

nitrogen from NTO200

Internal leak

Internal blockage

An error has occurred Refer to error codes for more details.

Internal blockage Check cartridge.

Cartridge is incorrectly

installed.

Gasket damaged or

incorrectly installed.

Inlet pressure too low

Internal leak

Ensure cartridge is correctly installed

in grip and lock ring is secure.

Contact NTO-200 supplier.

Check cartridge.

Refer to "Reduced flow of nitrogen

from NTO-200.”

Disconnect NTO-200 from

compressed air supply and check that

cartridge correctly connected.

Remove cartridge and check that

gasket is correctly installed.

Check the following:

1.) Hoses for any damage.

2.) Check compressor.

Ensure cartridge correctly installed in

grip.

Contact NTO-200 supplier.

Check inlet pressure falls within range

Outlet pressure exceeded

50% of inlet pressure.

specified in Tech Specifications.

Check tire pressure. If pressure too

high, press and hold ON/OFF button

to reduce pressure.

12

Page 14

TROUBLESHOOTING (Continued)

Fault Probable Cause Solution

Compressed air supply does

not meet specified

requirements of ISO 8573-1:

2001 Class 3.-.3

It is not allowed to feed

Reduced Purity of

nitrogen

Tire pressure does

not fall when

ON/OFF button

held in.

Pressure

continually high.

liquid/aerosol/condensate

water or oil into NTO-200.

Inlet pressure too low or too

high.

Cartridge nearing end of life. Replace cartridge

Internal blockage Contact NTO-200 supplier.

Cartridge not installed

correctly.

Internal fault Contact NTO-200 supplier.

Cartridge not installed

correctly.

There is internal component

fault

Check the following:

1.) Compressor operating correctly

and fully maintained.

2.) No contaminants near

compressor's intake.

3.) Compressed air system has

suitable filtration and is correctly

maintained.

Ensure inlet pressure is within limits

specified under “Technical

Specification” section.

Ensure cartridge correctly fitted in grip

Ensure cartridge correctly fitted in grip

Contact NTO-200 supplier.

13

Page 15

RTI ONE-YEAR NTO-200 LIMITED WARRANTY

(Applies only to equipment owned and operated in North America)

During the One-Year Warranty period, RTI Technologies, Inc. (RTI) is solely responsible for

costs associated with parts and labor for repairs needed due to defects in material and/or

workmanship. RTI is not responsible for the costs associated with repairs needed due to

improper use, damage due to physical or chemical abuse or a lack of normal maintenance.

RTI’s goal is to provide a timely turn-around of any NTO-200 requiring warranty repair.

The Customer is responsible to ASSIST AND PARTICIPATE with RTI Technical Support in

the over-the-phone diagnosis process of:

a) Determining that a legitimate failure has occurred and that the complaint is not just the

result of inadequate training and/or improper use that could be easily remedied by overthe-phone instructions.

b) Determining the nature of the failure and that it is reasonable for RTI Technical Support

to judge over the phone that the failure is warrantable.

During the One Year Warranty period for failures that are deemed by RTI to be

warrantable, RTI is solely responsible for providing Service and/or Replacement Product

when appropriate within a reasonable period of time after a warrantable failure is reported.

RTI shall make the repairs at RTI’s factory location and shall be responsible for the cost of

transportation to and from the factory. It is the customer’s responsibility to package the

NTO-200 in its original packaging or in packaging sufficient to ensure safe transit for

shipment to the factory.

It is the Customer’s responsibility to maintain the NTO-200 according to instructions in

RTI’s Operation Manual as well as to operate the equipment in a commercially reasonable

manner as generally described in the RTI Operation Manual.

RTI provides free Technical Support over toll-free telephone lines in the USA to assist the

customer in this regard for the life of the NTO-200.

The Customer should review the legal Warranty Disclaimer below for more details of

coverage and limitations.

Warranty Disclaimer of RTI Technologies, Inc.

1. RTI’S WARRANTY

This is to certify that RTI Technologies, Inc. (RTI) warrants to the first retail purchaser only,

the described new product manufactured by it to be free from defects in materials and

workmanship, when properly maintained, under normal use and service for a period of

ONE YEAR OR 12,000 tire fills for the membrane and ONE YEAR OR 50,000 tire fills

for the grip (WHICHEVER COMES FIRST). All spare parts supplied by RTI will have a 90

day warranty. This warranty includes the reasonable cost of parts and materials as well as

non-overtime labor. RTI shall be the sole judge of whether failure is warrantable.

2. PURCHASER’S REMEDY

Purchaser's sole and exclusive remedy under this warranty shall be limited to the repair or

replacement, at RTI’s option, of any defective part of the product. Purchaser shall call RTI

Technical Support who will assist Purchaser in diagnosing the problem and, if deemed

necessary, make arrangements to have the NTO-200 returned to RTI for repair.

3. PURCHASER’S DUTIES

(a) Register the NTO-200 with RTI by returning completed Warranty Registration within 90

days of delivery.

(b) Transportation Expense: Transportation expenses to and from the RTI's facility for

warranty repair are to be borne by RTI.

(c) Notice of breach: Purchaser shall give written notice to RTI of any alleged refusal or

failure of RTI to repair or replace as promised by this warranty no later than fifteen (15)

days after the Purchaser learns of such alleged failure or refusal.

Continued Next Page

14

Page 16

WARRANTY (Continued)

4. DISCLAIMER

THE EXPRESS WARRANTY HEREIN IS IN LIEU OF ANY AND ALL OTHER

WARRANTIES, EXPRESSED OR IMPLIED. NO IMPLIED WARRANTY OF

MERCHANTABILITY IS MADE AND THERE ARE NO WARRANTIES WHICH EXTEND

BEYOND THE DESCRIPTION ON THE FACE HEREOF.

5. EXCLUSIONS

The warranty and obligations stated here shall not apply to:

(a) Any product not registered within 90 days of delivery.

(b) Any product repaired or altered without prior approval of RTI so as to affect adversely

its stability or reliability.

(c) Any product subjected to misuse, abuse or accident as well as products used in a

manner contrary to written instructions or normal operating procedures.

(d) Any damage to product during original shipment or subsequent shipments to and from

RTI for service.

(e) Portions of products which are subject to warranties, if any, given by their

manufacturers. RTI does not adopt these warranties.

(f) Parts, accessories or other items manufactured by others which are used or installed

on the product as a result of Purchaser's specifications.

(g) Used items furnished by the Purchaser for installation on the product.

(h) Items which are not defective, but must be replaced during the warra nty period as a

result of fair wear and tear or scheduled maintenance.

6. EXCLUSION OF LOST PROFITS AND OTHER CONSEQUENTIAL DAMAGES

RTI will have no liability for any lost profit, cargo loss, usage loss or other consequential

damages alleged to have been caused by any defect in the NTO-200 or any failure of RTI

to meet any obligation under this agreement including the obligation to repair and replace

set forth in Paragraph 2.

7. LIMITATIONS OF ACTIONS

No action for breach of this warranty shall commence more than one year after the accrual

of the cause of action.

8. MERGER

This written warranty is the complete, final and exclusive agreement of the parties with

respect to the quality or performance of the goods and any and all warranties and

representations, except warranty extensions, if any, in writing as applicable.

9. NO ORAL MODIFICATIONS OR WAIVERS

No modification of this warranty or waiver of its terms shall be binding on either party

unless approved in writing by an authorized official of the parties.

10. GOVERNING LAW

This warranty and the rights and duties of the parties under this warranty shall be governed

by the law of Pennsylvania, the state of RTI’s principle place of business.

15

Loading...

Loading...