Page 1

NTF-230

Operation Manual

10 Innovation Drive

York, Pennsylvania 17402 USA

Phone: 717-840-0678

Toll Free: 800-468-2321

Web-site: www.rtitech.com

Manual P/N: 035 81607 00

RTI Technologies, Inc.

Page 2

TABLE OF CONTENTS

Pictograms 2

Health, Safety and Environmental Aspects......................2

Description of the NTF-230 Membrane 3

Process Parameters 4

Unpack & Check Equipment 5

Safety Precautions 5

Operation 5

Automatic Tire Filling

Cycle Counter Access

OPS and N2P Settings and Adjustment 7

Testing Nitrogen Purity 8

Maintenance 9

Trouble Shooting Guide 10

6

7

Flow and Electric Diagram 11

Parts Identification and Maintenance Parts 12

Nitrogen is generated by the NTF-230 and retained in the storage

tank. Nitrogen generation stops when the user manually turns off

the air flow to the NTF-230.

The pressure in the NTF-230 storage tank may drop after extended

non-use (over night for example). This is normal, and is similar to

air compressors that will periodically cycle on to replenish pressure

lost in the air storage tank and attached delivery system.

Permeation through service hoses, fill nozzles, valves and other

components directly associated with nitrogen generation is to be

expected, and does not impact normal operation.

It may take a few minutes to replenish the pressure in the storage

tank to maximum next time the NTF-230 is used. This is normal.

NORMAL OPERATION – LOSS OF PRESSURE

1

Page 3

PICTOGRAMS

Warning: Hazard that can cause death or serious injury. Follow the instructions.

Caution: Danger that can cause damage to the equipment. Follow the

instructions.

Warning: Risk of death due to suffocation.

Risk of fire: Oxygen-enriched air leads to an increased risk of fire in the event of

contact with flammable products.

High pressure risk: Follow the instructions with respect to compressed gasses.

Instructions with respect to the environment.

HEALTH, SAFETY AND ENVIRONMENTAL ASPECTS

GENERAL

Correct use of the NTF-230 Nitrogen generator is important for your personal safety and for trouble-free

functioning. Incorrect use can cause damage to the NTF-230 or can lead to incorrect gas supply to the

customer’s process.

Warning: Read this manual before you start operating the NTF-230. Prevent

accidents and damage. Contact RTI if you detect a problem that you cannot

solve with this manual.

COMPRESSED AIR

2

Warning: Ensure that the inlet air pressure can not exceed 190 psig.

Page 4

NITROGEN AND OXYGEN

The NTF-230 generates Nitrogen as a product. Oxygen enriched air is released as waste.

Warning

Nitrogen can cause suffocation. Oxygen enriched air leads to increased risk of

fire in the event of contact with flammable products. Make sure that there is

adequate ventilation at all times!

Do not install the NTF-230 in an area where explosive substances may be

present.

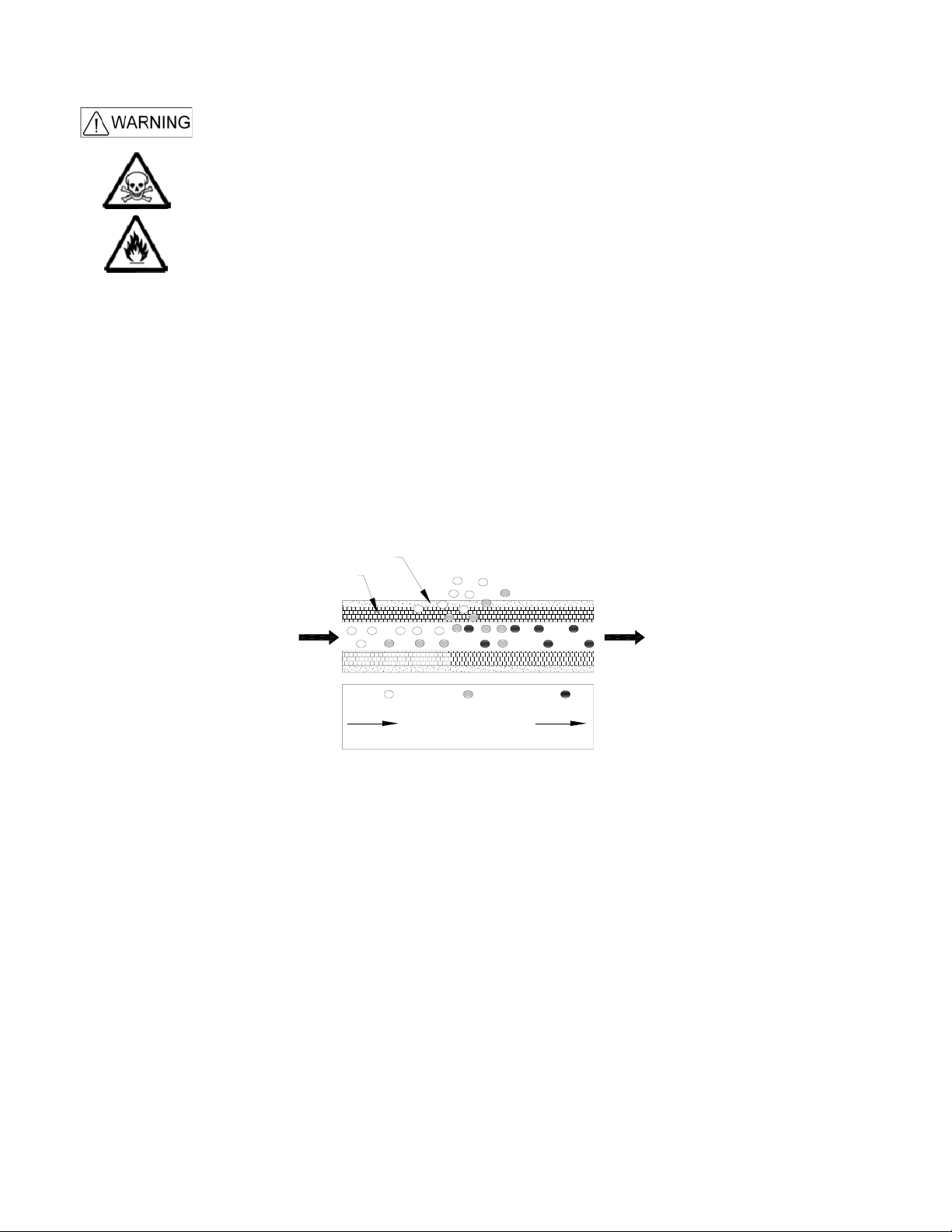

DESCRIPTION OF THE NTF-230 MEMBRANE

GENERAL

The NTF-230 separates compressed air into nitrogen and an oxygen enriched air stream. The

separation system is based on membrane technology. The compressed air comes from a central

system or from a dedicated compressor.

The nitrogen produced is stored in the nitrogen storage vessel. The NTF-230 manually switches on and

off, depending on the nitrogen demand.

Separation Principle

Separation Layer

Support Layer

Pressurized

Air

A C

B

Nitrogen

HO,H

22

FS

O

2

N

2

A Pressurized air inlet F Fast

B Hollow fiber membrane S Slow

C Nitrogen outlet

Ambient air contains nitrogen (78.1%), oxygen (20.9%), argon (1%), carbon dioxide, water vapor and

traces of other inert gasses. Pressurized air (A) is fed through the hollow fiber membrane (B). The

various air components diffuse through the wall of the membrane.

The diffusion rate differs for the various gases:

Oxygen and water vapor have a high diffusion rate and permeate rapidly through the membrane

wall.

Nitrogen has a low diffusion rate and permeates slowly through the membrane wall.

At the exit of the membrane (C), pressurized nitrogen is released.

3

Page 5

PROCESS PARAMETERS

The nitrogen production depends on these parameters:

Flow rate

Temperature

Membrane

pressure

External

pressure

The lower the flow rate of compressed air through the hollow fiber membrane, the

more oxygen can permeate through the membrane wall. As a result, the nitrogen

produced at the outlet will have a higher purity. Nitrogen purity can be adjusted with

the flow control valve.

The NTF-230 operates at a temperature between 40-110

0

F (70-800F optimally). If

the temperature increases, the pressurized air consumption will also increase. Do

not place the system in a room where the temperature may rise unnecessarily high.

Allow enough piping between the compressor exit and the NTF-230 inlet so that the

hot compressed gas has time to cool within the specifications listed in this manual.

A higher membrane pressure will increase the capacity (i.e. nitrogen output) of the

NTF-230.

There must be atmospheric pressure at the outlet. The capacity and the purity of

the nitrogen gas decreases strongly if the vent pressure exceeds the atmospheric

pressure.

CLEAN SHOP AIR – PROPER FLOW & PRESSURE

Many shop air supplies have an oiler installed to provide lubrication for air tools. The life of the filters in

the NTF-230 will be increased if the shop air supply is free from moisture and oil.

Recommendation - install a separate air line without an oiler to connect to the NTF-230. If this is not

practical, consider installing a separate pre-filter before connecting the NTF-230 to limit potential

contamination to the NTF-230 filters.

Also, ensure the shop air supply meets the pressure and flow ratings stated in the NTF-230 Operation

Manual for maximum nitrogen generation.

... IMPORTANT ...

The condition of the Filter Element (mounted on front of unit) can

only be checked when shop air is connected to the unit and the

valve is turned so the handle is HORIZONTAL so Nitrogen is being

generated and filling the tank. At all other times the Indicator will

not be visible.

The Filter Element must be changed when the indicator moves into

the CHANGE area and at least annually to protect the membrane

warranty.

4

Page 6

UNPACK & CHECK EQUIPMENT

Ensure that all components were delivered.

Ensure that the compressed air source meets specification:

Oil content of the compressed air is below 0.01mg/m

Ensure that the compressed air pressure and quality is always as prescribed.

Ensure that the air capacity is sufficient.

CHARGE BATTERY FOR AT LEAST 5 HOURS PRIOR TO FIRST USE

SAFETY PRECAUTIONS

Warning

Ensure there is sufficient ventilation.

Only feed the NTF-230 with air.

Keep the air feed to the NTF-230 clean and free of vapors of organic solvents and

other contaminants. Do not place the NTF-230 in a room where organic solvent

vapors may be present.

Keep the ambient temperature between 40 and 110 °F. Do not connect hot

compressed air directly from a compressor to the inlet of the NTF-230.

3

.

Regular maintenance should be performed on the NTF-230 to ensure proper and

safe operation. Ensure that instructions concerning health and safety are compliant

with local regulations

.

ENVIRONMENTAL ASPECTS

The use and maintenance of the NTF-230 do not include environmental dangers.

Most parts are made of metal and can be disposed of in a manner consistent with

local regulations.

Make sure that instructions concerning health, safety and environment are

compliant with all local regulations.

OPERATION

FOREIGN SUBSTANCES IN TIRES

Tires which have been in service may contain foreign substances such as leak sealers. It is important

that these substances are not pulled into the NitroPRO unit during the deflation process, resulting in

possible performance issues and costly repairs not covered by RTI’s warranty.

When servicing a vehicle, first check the valve stems and valve stem caps for any type of fluid or

foreign substance. If there is any concern of a foreign substance or leak sealer in the tires, manually

deflate the tires and just inflate them with the NTF-230. Manually deflate the tires a second time for

maximum purity. Then check the deflators for any indication of fluids or foreign substances. Follow a

four step “deflate-inflate-deflate-inflate” process to achieve desired nitrogen purity.

5

Page 7

AUTOMATIC TIRE FILLING

PURGE/FILL AND TOP OFF CYCLES

1. Attach air supply (150 PSI max) to the unit.

2. Turn control valve so it is HORIZONTAL. Verify pressure indicated on AIR PRESSURE gauge

is between 120 - 150 PSI.

3. Allow unit to build pressure in nitrogen tank as shown on N

120 PSI).

4. Turn on POWER switch on control panel. PCB will display battery charge status (HI or LO).

Ensure that 12VDC battery is charged. See section on Battery charging for more information.

The NTF-230 will display a target pressure.

5. Connect hoses to tires. NTF-230 is equipped with four service hoses. The two 12 FT long

hoses should be connected to tires closest to the operator. The two 24 FT long hoses should

be connected to farthest tires on the vehicle. Ensure the air chucks are fully engaged with valve

stems for proper service (this is crucial for equal tire inflation and proper nitrogen purity).

6. Set the final target pressure (the pressure that should be in the tires) by pressing + or – buttons.

7. To change the Over Pressure and Nitrogen Purge Cycles settings, see following sections.

8. Press and hold START button for two seconds (until long beep). This will start Purge/Fill cycle.

For Top Off cycle, press START button momentarily and release it. Top Off cycle will start

immediately.

One complete Nitrogen Purge Cycle will deflate all tires to 10% of target pressure

(approximately 3 PSI for 30 PSI target), inflate to the target pressure, deflate to 50% of the

target pressure, and then inflate to the final target pressure. (If two or more Nitrogen Purge

Cycles are programmed the above process will be repeated).

9. Unit will beep at the end of service and the word END will appear on LCD.

10. Wait 10-15 seconds after the end of the service before disconnecting hoses.

11. Press any key to stop process.

12. Once service is completed, leave control valve knob HORIZONTAL to allow the tank to

replenish the supply of nitrogen. If another service is to be done immediately afterward, the

control valve knob can remain in the HORIZONTAL position. If no further services are to be

performed for an extended period of time, turn control valve knob to VERTICAL position to end

production of nitrogen. This will prolong the life of the filters.

PRESSURE gauge (approximately

2

6

Page 8

TOP OFF AND NITROGEN PURGE CYCLE COUNTER

NTF-230 will total the number of Top Offs and Nitrogen Purge Cycles performed.

1. Press and hold + and - buttons simultaneously until unit beeps.

2. Press + or – button.

3. First displayed number shows thousands of Top Offs.

4. Press + or - button. Hundreds, tens and ones of Top Offs will be displayed.

5. Press + or - button. Thousands of Nitrogen Purge Cycles will be displayed.

6. Press + or - button. Hundreds, tens and ones of Nitrogen Purge Cycles will be displayed.

7. Press + or - button to exit counter mode.

OVER PRESSURE SETTING (OPS) AND NITROGEN PURGE CYCLES (N2P)

The Over Pressure Setting can be used to improve the purity of the tire(s). The Over Pressure

Setting over inflates the target pressure on the first inflation by the OPS amount. For example,

if the OPS is set at 5 PSI and the initial target pressure is set to 30 PSI, then the Nitrogen Purge

Cycle

will deflate to 3 PSI, inflate to 35 PSI, deflate to 15 PSI, then inflate to 30 PSI. Inflating to

35 PSI during the first inflation instead of 30 PSI will result in higher nitrogen purity in the tires.

The number of Nitrogen Purge Cycles can be set. One Nitrogen Purge Cycle consists of deflating,

inflating, deflating to 50% of the target pressure, and inflating to the target pressure. This

entire process can be automatically repeated by changing the number of Nitrogen Purge Cycles.

This is another method to obtain higher nitrogen purity in the tire(s).

1. Turn POWER switch on.

2. Press N

3. Press + or – buttons to change the Over Pressure Setting.

4. Press START button to save the Over Pressure Setting.

5. Press N

6. Press + or – buttons to select desirable number of Nitrogen Purge Cycles.

7. Press START button to save the number of Nitrogen Purge Cycles.

button once.

2

button twice.

2

When unit is turned off, it will save the changed settings until they are changed again.

NOTE: If the number of Nitrogen Purge Cycles is set to 0, the unit will perform inflations only.

BATTERY CHARGING

NTF-230 is powered by an internal 12VDC battery. Charge the battery for at

least 5 hours prior to first use. Battery charge level is displayed immediately

upon unit powering. HI indicates that battery is charged. LO indicates low

charge and battery needs to be recharged. Plug battery charger in 110VAC

wall outlet and insert plug into battery charging port. Unit can be operated

during recharging process. Typical recharge time is 3-5 hours, depending on

battery condition.

Note: While not using the NTF-230 to fill tires, generate Nitrogen and increase the

Nitrogen pressure in the internal storage tank by turning the panel valve to

STANDBY.

Note: While using the NTF-230, the automatic drain feature of the filters may

activate to remove excess water and oil. This is normal with the standard operation

of the unit.

7

Page 9

TESTING NITROGEN PURITY

An optional item available for the NTF-230 is the NitroPRO Nitrogen Purity Tester.

NitroPRO Nitrogen Purity Tester

RTI P/N: 355 80022 00

The NitroPRO Nitrogen Purity Tester can be used to determine the percent of nitrogen produced by the

NTF-230 by connecting to the Test Port (see picture below). It can also be used to determine the

percent of nitrogen in the tires after performing a service.

The NTF-230 is factory preset at 95% nitrogen purity and can be set as high as 98%. Contact RTI

Technical Support for assistance with nitrogen purity setting adjustment: 1-800-468-2321 x 1.

HELPFUL HINT – PURITY TESTING

When using the Nitrogen Tester to measure nitrogen purity in a tire and in the tank, you

can minimize the pressure loss, and corresponding refill requirements, by removing the

Tester from the valve stem after a sample has been obtained.

You will notice that the reading continues to climb after the Tester has been removed;

this a function of the response time of the internal sensor. Once the rate of change in the

reading begins to slow down or stabilize, reapply the Tester to the valve stem to obtain

another sample.

This method is particularly effective at the beginning of the test procedure, when large

changes in nitrogen purity readings quickly occur.

Even if you follow this method, you should ALWAYS RECHECK THE TIRE PRESSURE

when purity testing is complete and refill tire with nitrogen as necessary.

8

Page 10

MAINTENANCE

Part Action Frequency

Yearly or when indicator on the filter head

Filter Element Replace

Automatic Drain Clean When required

moves to the CHANGE area as shown in the

illustration to the right (change all 3 filters).

... IMPORTANT ...

The condition of the Filter Element (mounted inside NTF-230) can only be checked when shop air

is connected to the unit and it is in the FILL TIRE mode of operation with Nitrogen being generated

and filling the tank. If this is not done, the Indicator will not be visible.

The Filter Elements must be changed when the indicator moves into the CHANGE area or annually

to protect the membrane warranty.

REPLACE FILTER ELEMENT

Disconnect the air supply.

Let the system depressurize until the air pressure gauge reads 0 PSI.

Unscrew the bleed screw (F) slowly to ensure that the filter is

depressurized.

Turn the filter bowl (E) counter- clockwise one eighth of a turn and pull

the filter bowl down from the filter housing (A).

Unscrew the blue knob (D).

Remove the old filter element (C).

Clean the sieve (B) and the filter house, if necessary.

Install a new filter element (C).

Assemble the parts in the reverse order.

Note: A periodic check of the automatic drains is necessary to ensure maximum membrane life. To

verify float is functioning correctly, open the filter bowl by turning one quarter turn counterclockwise. Inspect for water or oil, an inactive float will be submerged, an active float will not. If

float is found to be inactive follow clean automatic drain procedure or if necessary replace with

part number 026-80386-00.

9

Page 11

CLEAN AUTOMATIC DRAIN

Turn the filter bowl (A) counter-clockwise one eighth of a turn and

pull the filter bowl down from the filter housing.

Unscrew the nut (F).

Remove the drain unit (B-E) from the filter bowl (A).

Remove the O-ring (E).

Carefully pull the floating house (B) from the seat (D). Do not bend

the needle (C).

Clean the parts with soap and water. Make sure that the needle

bore is open and clean.

Assemble the parts in the opposite direction. Make sure that the

parts are dry before reassembly.

TROUBLE SHOOTING GUIDE AND POSSIBLE ERROR MESSAGES

Problem Possible Cause Solution

1. Display does not light Dead Battery Recharge battery

2. Inflation process starts, but does

not complete

3. Air chucks will not seal to the

tire valve stem(s)

4. Air chucks leak while not

connected to tires

5. E4 on display

6. E6/E16 on display

Low supply pressure or leaks

exist

Air chucks worn or not

completely pushed on tire(s)

Air chucks worn Replace air chucks

Over inflation due to

blocked/kinked hose

Unit powered ON while

connected to tires

Check supply pressure & confirm

leaks do not exist

Make sure air chucks are pushed

on tires or replace connectors

Remove blockage/kink or replace

hose

Remove hoses from tires and turn

power OFF/ON again

7. E5/E8/E9 on display PCB or sensor error Contact RTI Technologies

8. E10 or Lo on display Low battery charge Charge battery for 3-5 hours

9. E11/E12 on display PCB fault Contact RTI Technologies

10

Page 12

ELECTRIC DIAGRAM

FLOW DIAGRAM

11

Page 13

PARTS IDENTIFICATION

2

Part Number Description

1 026 80452 00 2 inch Gauge 0-160 psig/bar 1/4MPT

2 023 80364 00 FTG Test Port 1/4 MPT X valve stem

3 022 80579 00 30 gal vertical tank

4 026 80394 00 nitrogen membrane (2.1 CFM)

5 022 80151 00 needle valve 3/8 FPT

6 026 80381 00 water filter with auto drain

7 026 80386 00 auto drain float

8 026 80382 00 oil filter with auto drain

9 026 80383 00 moisture filter

10 040 80213 00 12 VDC battery

11 026 80513 00 battery charger

12 355 80176 00 circuit board with sensor

13 025 80414 00 solenoid manifold

14 025 80415 00 diverter valve

15 023 80390 00 air chuck

16 021 80169 01 hose clamp

17 060 81638 12 12 foot hose

18 060 81638 24 24 foot hose

19 024 80066 00 power switch

Filter Replacement Kit

355 80025 00 (Includes filters for Items 6, 8 and 9)

N2 Caps for Valve Stem (Qty = 200)

P/N: 355 80026 00

N2 Purity Tester

P/N: 355 80022 00

18

12

Loading...

Loading...