Page 1

®

Laser 4

®

Laser 4 Plus

OPERATION MANUAL

Four Wheel Alignment

RTI Technologies, Inc.

York, PA 17402

800-468-2321 (Ext. 259)

Manual No. 040-80152-00

Page 2

TABLE OF CONTENTS

Four Wheel Alignment, Basics...................3

Pre-Alignment Checks .........................4

Four Wheel Alignment Procedures

Install Wheel Clamps .....................5

Compensating Wheel Runout ...............5

Camber Reading .........................7

Caster Reading ..........................9

Steering Axis Inclination (SAI) Reading.....11

Instrumentation Set-up ...................13

Front Wheel Toe Reading ................14

Front Wheel Alignment to Vehicle Centerline 16

Thrust Angle Alignment..................17

Total Vehicle Four Wheel Alignment .......18

Calibration Procedure.........................19

Battery Replacement ..........................22

CONGRATULATIONS: You have purchased one of the finest Four-wheel Alignment Systems available at

any price.

Fill out and return the Warranty Card within 90 days to activate the warranty and

free lifetime technical support.

Laser 4 & Laser 4 Plus - Instrumentation Only

Factory Technical Support

( 8 AM to 5 PM Eastern )

800-468-2321

(Consult the shop manual concerning methods for making alignment adjustments.)

Page 1

Page 3

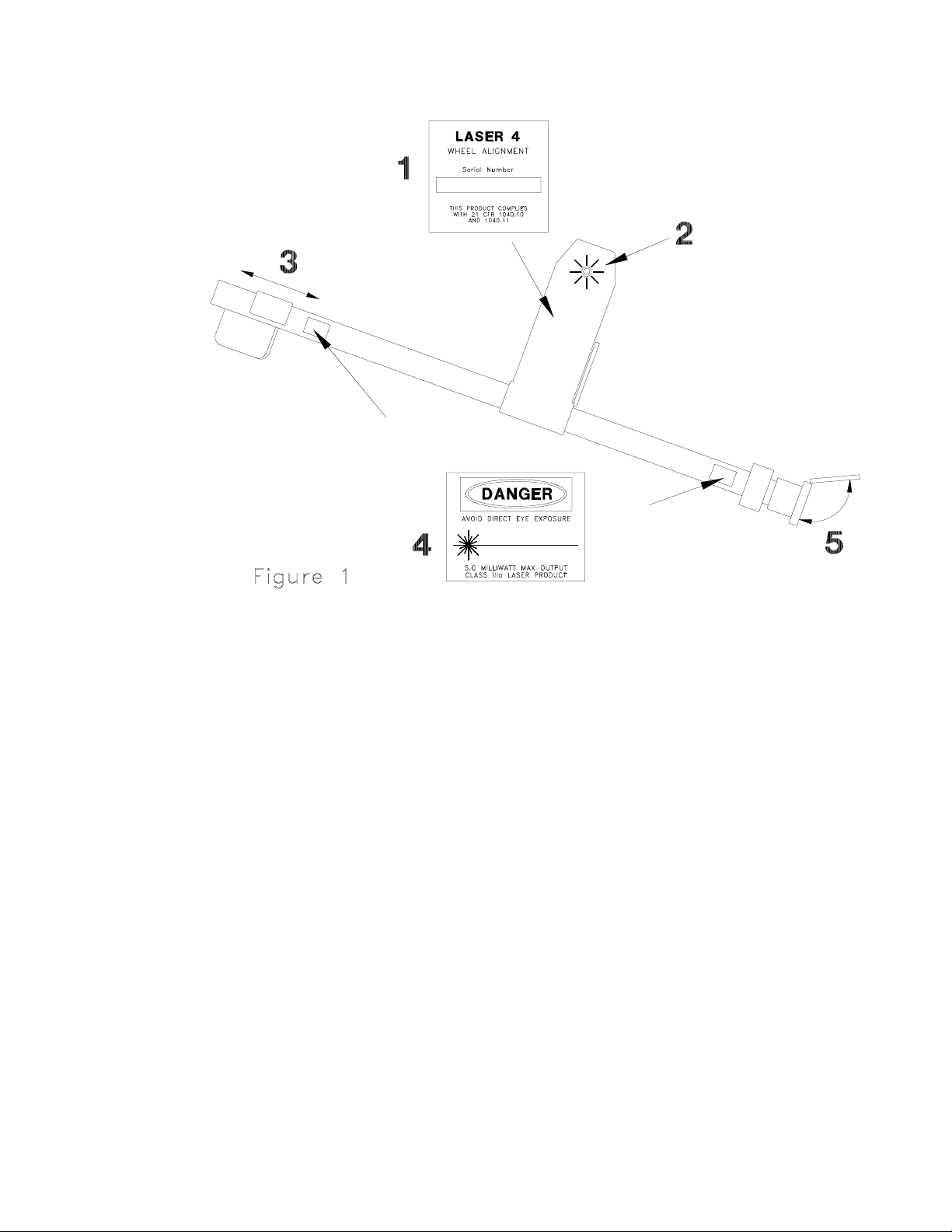

The Laser 4 Plus is a four-wheel alignment system t h a t uses three Class II laser products. These lasers have a

maximum output power of 5.0 milliwatts. The laser tubes meet all government safety standards, although

common sense dictates that one should not stare directly into the beam. Laser precision is unaffected by light,

temperature, and the concentrated light beam is clearly visible anywhere. The following precautions have been

taken to insure the safety of the system (See Fig. 1):

1) Serial Number label is located on underside of casting on power supply cover. Each serial number is

recorded for future identification.

2) LED light comes on as soon as power is activated to laser beam.

3) Slide cover must be slid toward casting to uncover laser beam (LH Toe Gauge only).

4) Caution decals are located on the unit.

5) Flip-open protective cap protects laser unit when not in use.

CAUTION: Use of controls or adjustments or performance of procedures other than those specified herein

may result in hazardous radiation exposure.

Page 2

Page 4

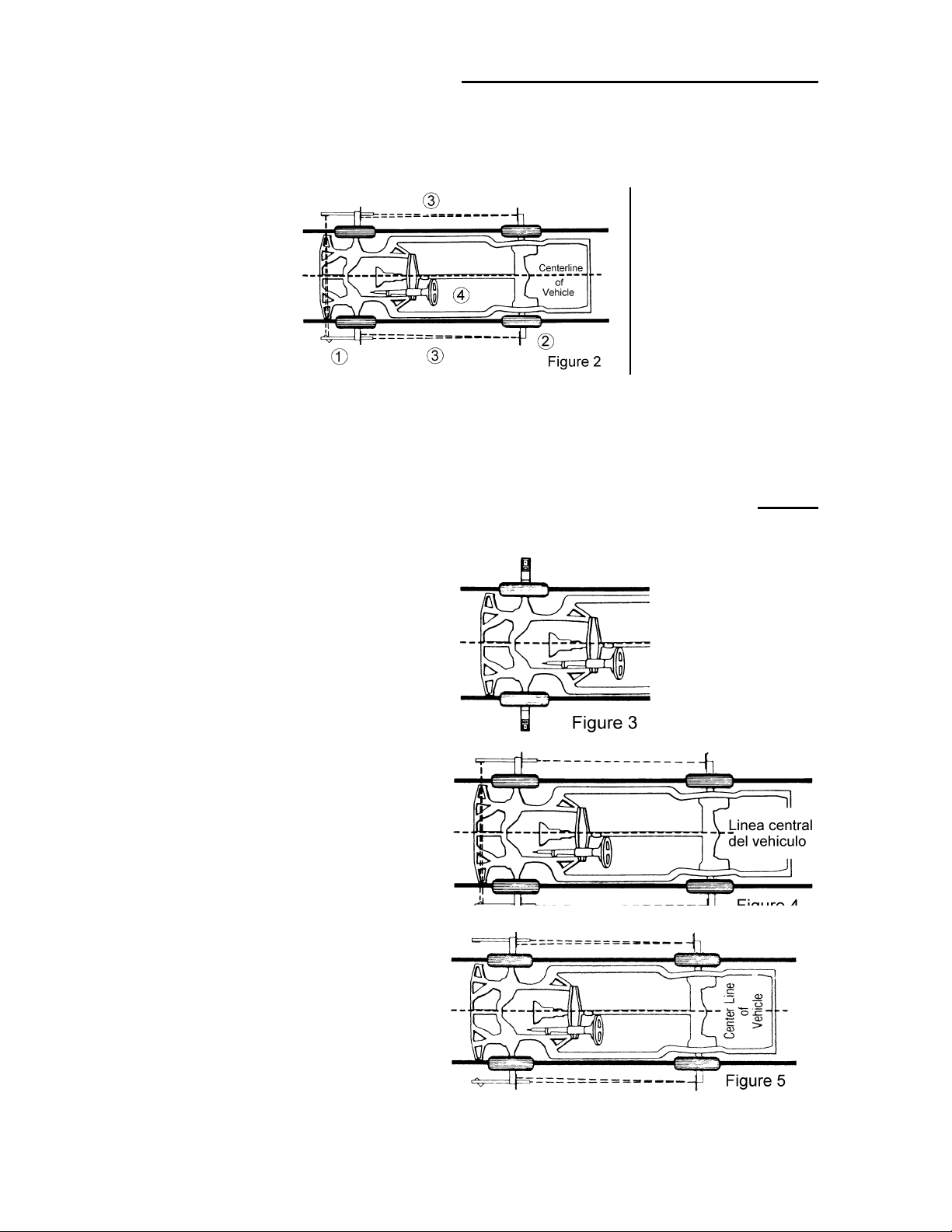

FOUR WHEEL ALIGNMENT

Rear wheels must track and foll ow the front wheels in

a parallel direction with all four wheel adjusted to the

common centerline of the vehicle. (See Fig. 2)

1)Front wheel alignment and

front wheel toe on car

manufacturer’s

specifications.

2)Rear wheel alignment and

rear wheel toe on car

manufacturer’s

specifications.

3)Front wheels track to rear

wheel thrust lines and to

centerline of vehicle.

4)Steering wheel centered in

straight ahead position.

BASIC STEPS TO DO FOUR WHEEL ALIGNMENTS

Step 1

Adjust front wheel camber and caster to car manufacturer’s

settings. (See Fig. 3)

Step 2

Center steering wheel. Adjust front wheel toe to

manufacturer’s setting. (See Fig.4)

Step 3

Adjust f ront wheels to rear wheel in relation to rear axle

position. (See Fig. 5)

Step 4

Adjust rear wheel camber and toe to car manufacturer’s

setting.

Page 3

Page 5

PRE-ALIGNMENT CHECKS

To mai ntain a true alignme nt job; ensure maximum tire mileage a nd steering safety , it is important to p erfor m

certain pre-alignment checks before doing wheel alignment adjustments. They are:

1. Inflate tires to proper inflation pressures.

2. Check car spring height.

3. Check shock absorbers and struts.

4. Inspect steering/suspension parts for wear or looseness. Replace

parts which are worn beyond manufacturer’s accepted tolerances.

5. Check calibrations of the Laser 4 wheel alignment equipment. See

Calibration Procedure section of this manual.

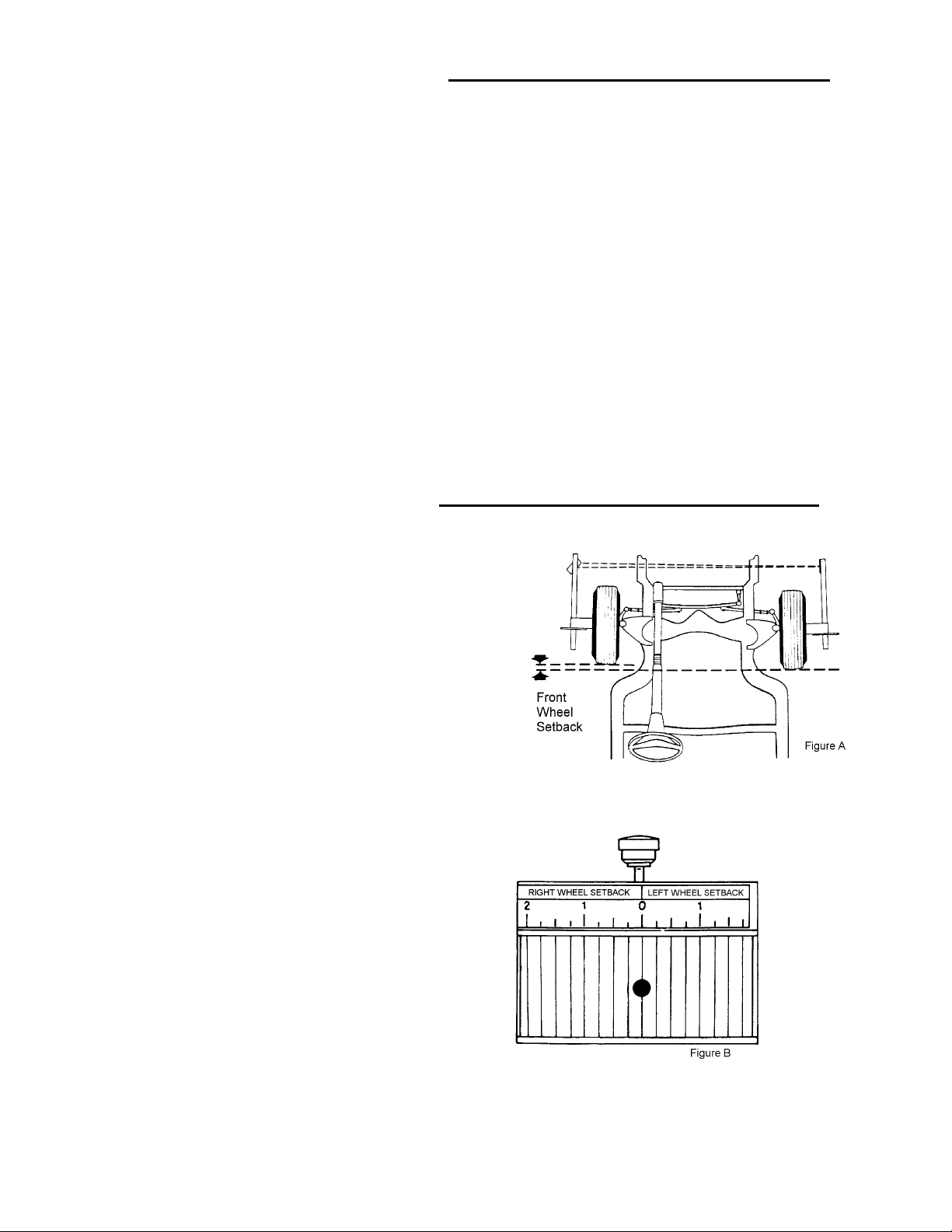

FRONT WHEEL SETBACK

Front wheel setback is a condition in which

one front wheel has been driven or pushed

back, out of alignment, from the opposite

wheel. It is caused by one wheel of the vehicle

striking a curb or pothole in the road forcing

that wheel back from the other (See Fig. A).

To measure front wheel setback with the Laser

4 wheel alignment system, adjust front wheel

toe; center steering wheel, and note the

location of the Laser beam on the wheel

setback scale (See Fig. B) of the passenger side

laser toe gauge. Make sure that the Laser toe

gauges are centered on the wheel clamps. The

scale reads eith er right or left wheel setback.

The front wheel suspension should be adjusted

if the setback is greater than 1/4 inch.

Excessive front wheel setback will cause a

change in caster.

The Laser 4 alignment system automatically

compensates for front wheel setback because

of the use of the tapered, precisely ground

magnets. When toe is adjuste d to zero, the tube

of the optical toe gauges become parallel to

each other. Front wheel toe reading is

unaffected by front wheel setback.

Page 4

Page 6

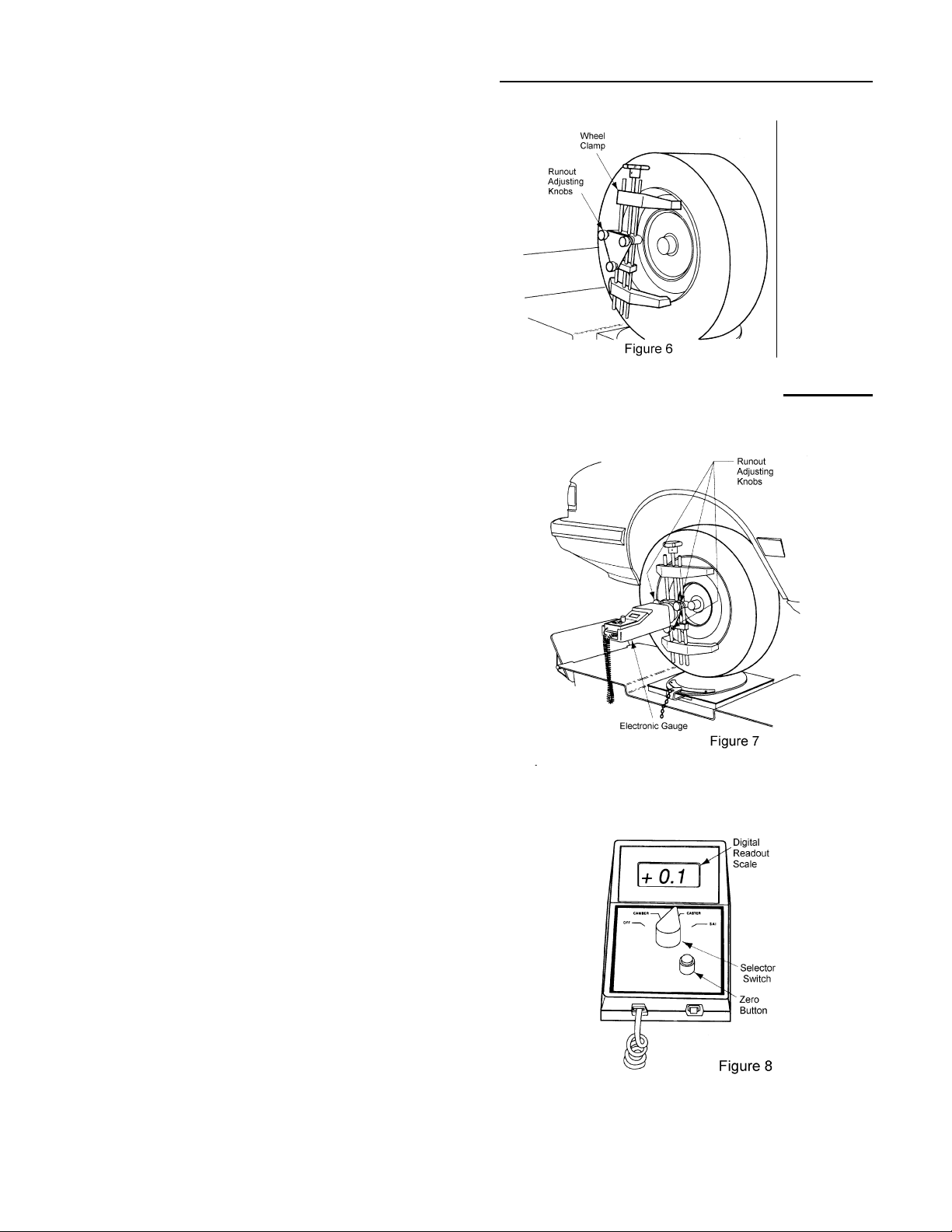

INSTALL WHEEL CLAMPS

Install Wheel Clamps on each wheel. (See Fig. 6) Adjust

the four bars in each clamp for t he best fit to the wheel

rim. Two sets of notches on one end or a threaded pin on

the other end provide for inside or outside mounting to the

wheel rim. Use d ouble-sided foam tape at contact points

on decorative or soft metal rims. Make sure that th e Wheel

Clamps are securely attached.

Select th e configuration which gives the most secure fit

with the least amount of pressure on the wheel rim.

COMPENSATING WHEEL RUNOUT (Laser 4 Plus)

Wheel Clamps must be adjusted to compensate for wheel

runout. This adjustment is made using the three Runout

Adjusting Knobs.

1) Raise wheel and tire from turning gauge or rear wheel

slip plate. Turn wheel so the large wheel clamping

knob is at the top (12 o’clock position).

2) Mount the Electronic Gauge on the Wheel Clamp as

shown (See Fig.7). Center the magnet on the Wheel

Runout Compensating Adapter. Turn the Electronic

Gauge so it is level.

3) Set the selector to CASTER and press the rocker

switch to ON. Press the Zero Button. (See Fig. 8)

4) Rotate the wheel so the wheel clamp adjusting knob

is at the 2 o’clock position. Turn the El ectronic gauge

so it is once ag ain level. Note the value on the Digital

Readout Screen. Ignore the + or - which appears

before the numbers.

Repeat at the 4, 6, 8, and 10 o’clock positions. Relevel the Electronic gauge at each position.

5) Turn the wheel to the position where the largest

numeric reading was observed. Turn the Runout

Adjusting Knobs to decrease this reading by one -half.

Press the Zero Button and repeat step 4, checking for

the largest numeric reading at each of the six

positions.

6) The wheel clamp is properly adjusted when the

Electronic Gauge reads within 0.1 at all six positions.

Page 5

Page 7

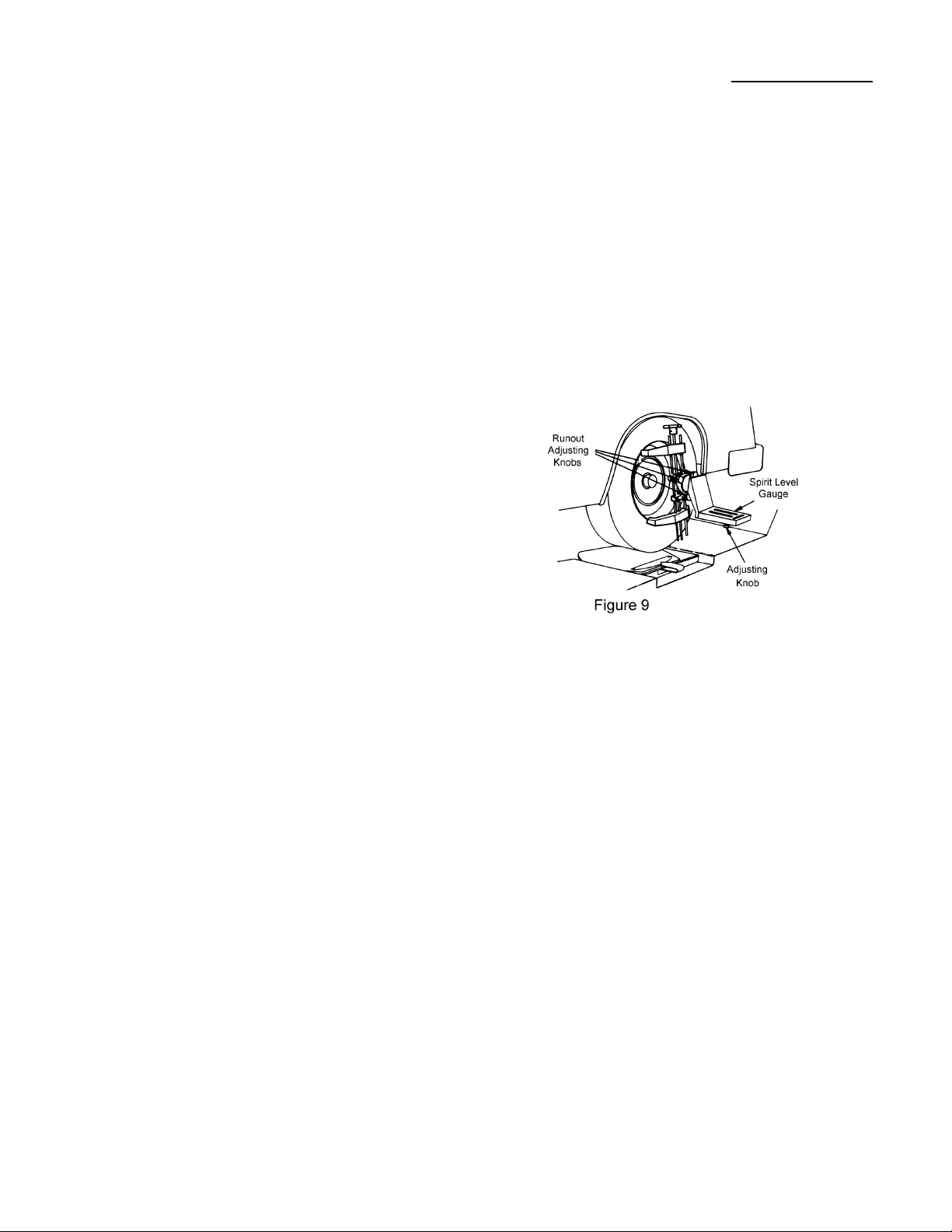

COMPENSATING WHEEL RUNOUT (Laser 4)

Wheel Clamps must be adjusted to compensate for wheel

runout. This adjustment is made using the three Wheel

Runout Adjusting Knobs.

1) Raise wheel and tire from turning gauge or rear wheel

slip plate. Turn wheel so the large wheel clam ping

knob is at the top (12 o’clock position).

2) Mount t he Spirit Level Gauge on the Wheel Clamp.

(See Figure 9) Center the magnet on the Wheel

Runout Compensating Adapter. Turn the Spirit L evel

Gauge so it is level.

3) Zero the Caster Spirit Level using the adjusting knob

on the bottom of the unit.

4) Rotate the wheel so the wheel clamp adjusting knob

is at the 2 o’clock position. Turn the Spirit Level

Gauge so it is once again level. Note the amount of

movement of the bubble away from zero.

Repeat at the 4, 6, 8, and 10 o’clock positions. Relevel the Spirit Level Gauge at each position.

5) Turn the wheel to the position where the largest

movement of the bubble was observed. Turn the

Runout Adjusting Knobs to decrease this reading by

one-half. Zero the Caster Spirit Level and repeat step

4, checking for the largest movement of the bubble

away from zero at each of the six positions.

6) The wheel clamp is properly adjusted when the

bubble does not move away from zero at all six

positions.

Page 6

Page 8

CAMBER READING (Laser 4 Plus)

Camber: The inward or outward tilt of the wheel at the top

Camber is measured in degrees.

Wheel exactly vertical: Zero camber

Top of wheel tilts in: Negative camber

Top of wheel tilts out: Positive camber

A vehicle with Negative Camber is shown in Fig. 10.

Proceed with the following steps to read Camber:

1) Place front wheels in straight ahead position with

steering wheel level. The eng ine must be started if the

vehicle has power steering. Remove locking pins

from the turning radius gauges and rear wheel slip

plates. Rotate each wheel until the large wheel clamp

adjusting knob is at the top.

2) Lower all four wheels until the front wheels rest on

the turning radius gauges and the rear wheels rest on

the rear wheel slip plates. Be sure turning radius

gauges are centered under the front tires.

3) Install brake pedal depressor. The engine must be

running if the vehicle has power brakes.

4) Bounce the vehicle at both front and rear to normalize

the suspension weight.

5) Mount the Electronic Gauge on the left front Wheel

Clamp. Be sure the magnet is centered on the

mounting disk (See Fig. 11).

6) Set the selector to CAMBER and press the switch to

ON (See Fig. 12).

7) Read Camber on the Digital Readout Scale (A

negative 0.3 is indicated in Fig. 12). The numeric read

out will be preceded by a + or - to indica te positive or

negative Camber.

8) Repeat the above procedure on the right front wheel.

If camber adjus tments and specifications are available

for the rear wheels, repeat the above on each wheel.

Page 7

Page 9

Camber Reading (Laser 4)

Proceed with the following steps to read Camber:

1) Place front wheels in straight ahead p osi tion with

steering wheel level. The engine must be started if

the vehicle has power steering. Remove locking

pins from the turning radius g auges and rear wheel

slip plates. Rotate each wheel until the large whee l

clamp adjusting knob is at the top.

2) Lower all f our wheels until the front whe els rest on

the turning radius gauges and the rear wheels rest

on the re ar wheel slip plates. B e sure turning radius

gauges are centered under the front tires.

3) Install brake pedal depressor. The engine must be

running if the vehicle has power brakes.

4) Bounce the vehicle at both front and rear to

normalize the suspension weight.

5) Mount the Spirit Level Gauge on the left front

Wheel Clamp. (See Fig. 13) Be sure the magnet is

centered on the mounting disk.

6) Read Camber at the center of the bubble on the

Camber Scale. The spirit level for Ca mber is loca ted

on the right side of the gauge. (See Fig. 14)

Camber is zero when the center of the bubble is on

zero of the scale.

Camber is positive when the bubble is away from

zero toward the wheel.

Camber is negative when the bubble is away from

zero, away from the wheel.

7) Repeat the above procedure on the right front wheel.

If camber adjustments and specifications are available

for the rear wheels, repeat the above on each wheel.

Page 8

Page 10

CASTER READING (Laser 4 Plus)

Caster: The backward or forward tilt of the ball joint or strut at the top

Caster is measured in degrees:

Spindle support arm straight up and down on the true vertical: Zero Caster

Spindle support arm is tilted forward at the top from true vertical: Negative Caster

Spindle support arm is tilted back at the top from true vertical: Positive Caster

A vehicle with Positive Caster is shown in Fig. 15.

Proceed with the following steps to read Caster:

1) With the Electronic Gauge mounted on the left

front wheel clamp, turn the left front wheel

outward at the front for a 20 degree reading on the

radius gauge. (See Fig. 16)

2) Turn the Electronic Gauge so it is level.

3) Set the selector to CASTER and press the switch to

ON. Press the Zero Button. (See Fig. 18)

4) Turn the wheel inward at t he front for a 20 degree

reading on the radius gauge. (See Fig. 17) This is a

total swing of 40 degrees.

5) Turn the Electronic Gauge so it is level.

6) Read Caster on the Digital Readout Scale (A positiv e

1.0 is indicated in Fig.18). The numeric reading will

be preceded by a + or - to indic ate positive or negative

Caster.

7) Repeat the above procedure on the right front wheel.

Page 9

Page 11

CASTER READING (LASER 4)

Proceed with the following steps to read Caster:

1) With the Spirit Level Gauge mounted on the left front

wheel clamp, turn the left front whe e l o utward at

the front for a 20 degree reading on the radius

gauge. (See Fig. 19)

2) Turn the Spirit Level Gauge so it is level.

3) Adjust the Caster bubble to zero with the adjusting

knob on the bottom of the gauge.

4) Turn the wheel inward at the front for a 20 degree

reading on the radius gauge. This is a total swing

of 40 degrees. (See Fig. 20)

5) Turn the Spirit Level Gauge so it is level.

6) Read Caster at the center of the bubble on the

Caster Scale. The spirit level for Caster is located

on the left side of the gauge. See the figure to the

right. (See Fig. 21)

Caster is zero when the center of the bubble is on zero

of the scale.

Caster is positive when the bubble is away from

zero, away from the wheel.

Caster is negative when the bubble is away from

zero, towards the wheel.

7) Repeat the above procedure on the rig ht front wheel.

Page 10

Page 12

STEERING AXIS INCLINATION

(SAI) READING

(LASER 4 Plus)

SAI: The inward tilt of the ball joint or strut at the top

.

Proceed with the following steps to read SAI:

1) With the Electronic Gauge mounted on the left front

wheel clamp, turn the left front wheel outward at the

front for a 20 degree reading on the radius gauge.

(Refer to Fig.19)

2) Turn the Electronic Gauge so it is level.

3) Set the selector to SAI and press the switch to ON.

Press the Zero Button. (See Fig. 23)

4) Turn the wheel inward at the front for a 20 degree

reading on the radius gauge. This is a total swing of

40 degrees. (See Fig. 20)

5) DO NOT RE-LEVEL THE ELECTRONI C GAUGE.

6) Read SAI on the Digital Readout Scale (A positive

14.5 is indicated Fig. 23)

7) Repeat the above procedure on the right front wheel.

INCLUDED ANGLE

Included Angle: Total of the Camber and SAI Readings

Subtract negative Camber from SAI (as for the above example):

SAI 14.5

Camber -0.3

Included Angle 14.2

Add positive Camber readings to SAI: SAI 14.5

Page 11

Camber +0.5

Included Angle 15.0

Page 13

STEERING AXIS INCLINATION (SAI) READING

(Laser 4)

SAI: The inward tilt of the ball joint or strut at the top

.

Proceed with the following steps to read SAI:

1) With the Spirit Level Gauge mounted on the left front

wheel clamp, turn the left front wheel outward at the

front for a 20 degree reading on the radius gauge. (See

Fig. 24)

2) Pivot the Spirit Le vel Gauge so that the SAI bubble reads

zero on scale “L”. (See Fig 26)

Note: The bottom scale marked “L” is for the left wheel

and the upper scale marked “R” is for the right wheel.

3) Turn the wheel inward at the front for a 20 degree

reading on the radius gauge. This is a total swing of 40

degrees. (See Fig. 25)

4) DO NOT RE-LEVEL THE ELECTRONIC GAUGE.

5) Read center of SAI bubble for SAI readout. (See Fig. 26)

If the SAI reading is higher than the scale on the gauge, turn

the wheel until an 8 degree r eading is reached. Re-adjust the

gauge for a reading of zero and continue turning the wheel.

Add the 8 degrees to the final reading to obtain the actual

SAI reading.

6) Repeat the above procedure on the right front wheel. Use the

scale labeled “R”. (See Fig. 26)

Page 12

Page 14

INSTRUMENTATION SET-UP

Center the Steering Wheel:

Center the steering wheel in the straight ahead position and clamp in place with the Steering Wheel Holder.

The engine must be running to set the steering wheel position on cars with power steering.

Mount the Left & Right Laser Toe Gauges:

1) Determine the manufacturer’s preferred total toe specification for the front wheels. Rotate the tapered

magnet on each Laser Toe Gauge to one-half this specified value. (See Fig. 27)

EXAMPLE: The manufacturer’s preferred total toe specification is 0.08 inches Toe In. Rotate both of

the tapered magnets to one-half this value which is 0.04 inches.

2) Mount the Laser Toe Gauges to the Wheel Clamps. Center the magnet on the Wheel Runout

Compensating Adapter. Connect the safety strap to the Wheel Clamp for extra protection against damage.

(See Fig. 28)

3) Level the Laser Toe Gauges using the spirit level located on the top.

4) Flip the power switch to ON and open the protective covers on the laser beams.

Mount the Rear Retro-screens:

1) Determine the manufacturer’s preferred total toe specification for the rear wheels. Rotate the tapered

magnet on each of the Rear Retro-screens to one-half this specified value. (See Fig. 27)

2) Mount the left and right R ear Retro-screens to the Wheel Clamps. Center the magnet on the Wheel

Runout Compensating Adapter. Connect the safety strap to the Wheel Clamp for extra protection against

damage.

Page 13

Page 15

FRONT WHEEL TOE READING

Toe: The difference in distance between the front and rear of the front wheels

Toe-in: Distance between front of wheels is less than distance between rear of wheels

Toe-out: Distance between front of wheels is greater than distance between rear of wheels

Adjust Laser Beam Mirror & Target:

The Left Laser Toe Gauge projects a laser beam onto the

right mirror (A). This beam is reflected back to the

graduated toe scale on the Left Lase r Toe Gauge.(See Fig.

29)

Adjust the laser beam vertically t o the cente r of the mirror

(A) by using the knob (E) on the Left Laser Toe Gauge.

Rotate the laser beam assembly inside the tube of the L eft

Laser Toe Gauge. Re-tighten knob.

If the laser beam, reflected back from the mirror (A),

doesn’t strike the graduated toe scale, loosen both knobs

(R) on the Right Laser Toe Gauge (See Fig. 30). Rotate the

mirror housing (A) until the laser beam image strikes the

graduated toe scale. Re-tighten both knobs.

Figure 30

Reading Front Wheel Toe:

Read Front Wheel Toe on the graduated toe scale on the

Left Laser Toe Gauge. (See Fig. 31)

Toe is within spec if the laser beam image is in the ce nter

of the scale at zero.

Figure 31

One-half of the manufacture r’s to tal toe specification is already dialed in with each of the magnets, so a

reading of zero on these scales means the toe is correctly adjusted to the manufacturer’s specification.

Page 14

Page 16

TOE READING ILLUSTRATIONS

Page 15

Page 17

FRONT WHEEL ALIGNMENT VEHICLE CENTERLINE

1) Project the laser beams from the Left and Right Toe

Gauges onto the Rear Retro-screens. If the beam does

not strike the rear mirror, check the level of the Laser

Toe Gauge. (See Fig. 32)

2) Note the readings on the scales of the rear screens.

Add both readings and divide by two.

3) Adjust both tie rods or tie rod adjusting sleeves

equally so that the rear screens register the desire d

reading determined in Step 2.

EXAMPLE:

One rear wheel screen registers 5 (See Fig. 33) and

the other one registers 7 (See Fig. 34), the total is 12.

Divide by 2 and adjust both tie rods equally until the

laser beam falls on 6 on each retro screen.

4) Re-check front wheel toe to be sure it remains on

zero. If not, re-adjust front wheel toe to zero. Recheck the rear retro-screens for equal readings.

This is a “Two Wheel Alignment”

Page 16

Page 18

THRUST ANGLE ALIGNMENT

1) Check that both Laser Toe Gauges are level. The laser beams should be visible on the rear Retro-screen

mirrors (See Fig. 35).

2) Rotate the rear Retro-screen a ssemblies out of level, if necessary , so that the laser beams will be refle cted

back to the front Toe Gauges and be visible on the Thrust Angle Scales.

3) Note the readings on the Thrust Angle Scales. Add both readings and divide by two.

4) Adjust both tie rods or tie rod adjusting sleeves equally so that the Thrust Angle Scales register the

desired reading determined in Step 3.

EXAMPLE:

One Thrust Angle Scale registers 4 (See Fig. 36)and the other one registers 6 (See Fig. 37), the total is

10.

Divide by 2 and adjust both tie rods equally until the laser beam falls on 5 on each Thr u st Ang le Scale.

(See Fig. 39 and Fig. 40)

This is a Thrust Angle Alignment where the front wheel position is corrected for rear wheel misalignment.

Page 17

Page 19

Total Vehicle Four-Wheel Alignment

1) Check that both Laser Toe Gauges are level. The laser beams should be visible on the rear Retro-screen

mirrors.(See Fig. 38)

2) Rotate th e rea r Ret ro-scree n assemblies out of level if necessa ry, so that the la ser beams will be reflected

back to the front Toe Gauges and be visible on the Thrust Angle Scales.

3) Note the reading on each of the Thrust Angle Scales. Adjust the toe of each rear wheel until the laser

beam image on the corresponding Thrust Angle Scale is in the middle at the number 5. (See Fig. 39 and

Fig. 40)

This completes a four-wheel alignment.

Page 18

Page 20

CALIBRATION PROCEDURE

Mount and level the Calibration Bar on Calibration Stands or the rear of the Storage Cart

Calibration of Front Wheel Toe Laser Beam (See Figure 42)

1) Rotate the tapered magnets on the Left and Right T oe

Gauges to zero.

2) Mount the Left and Right Toe Gauge s o n t h e ends of

the Calibration Bar. Be sure the centers of the

magnets fit over the raised machined surfaces at the

ends of the Calibration bar. (See Fig. 41)

3) Level both Toe Gauges and check the laser beam on the mirror screen (A). If the laser beam image is not

located midway up on the mirror screen (A), loosen the knob (E) on the Left Toe Gaug e and slide it up

or down. This moves the laser beam image vertically until it is on the mirror.

4) The center of the laser beam image should be on zero on the screen (A). If not, alternately adjust Allen

set screws of the laser diode bulb reta iner on the Left Toe Gaug e until the center of the beam image reads

zero on the Right Toe Gauge screen (A).

There are four Allen set scre ws on the laser diode retainer. The top and b ottom set screws (D) control the

vertical movement of the beam image. The left and right screws (B) control side-to-side movement of

the beam image.

5) Adjust the mirror (A) up or down as required so the reflected laser beam image is on the fron t toe sc al e.

Loosen knobs (R) to make any required adjustments.

6) Adjust Allen set screw s (F ) un til the center of the la ser beam image r eads zero on the front toe scale (C).

Page 19

Page 21

CALIBRATION PROCEDURE

The Gauges are now parallel - “Toe reads zero”

Calibration of Right & Left Toe Gauge Laser Beams

1) Rotate all tapered magnets on the Toe Gauges and

Rear Retro-screens to zero

2) Mount the Left Toe Gauge and Left Retro-screen to

the machined surfaces on the side of the C alibrati on

Bar. (See Fig. 43)

Page 20

Page 22

CALIBRATION PROCEDURE

Calibration of Right & Left Toe Gauge Laser Beams (continued)

3) Level the Toe Gauge and project the laser beam

image on the rear Retro-screen. (See Figure 44) The

center of the beam image must be on 6 and midway

up the mirror. If not, alternately loosen and tighten

Allen set screws on the laser diode retainer.

There are four Allen set screws on the laser diode

retainer. (See Figure 45) The top and bottom set

screws (D) control the vertical movement of the beam

image. The left and right screws (B) control si de-toside movement of the beam image.

4) Check the location of the reflected laser beam image

on the Thrust Angle Scale on the Laser Toe gauge.

With the Rear-retro Screen level, the center of the

image should be mid-way up and on 5 on the Thrust

Angle Scale.

If not, adjust the two screws (M) (See Fig. 44) until

the image is on 5 and adjust screw (L) until the im age

is mid-way up on the Thrust Angle Scale.

5) Remove the Left Toe Gauge and Left Retro-screen.

Mount the Right Toe Gauge and Right Retro-screen

and repeat steps 1 through 4.

The Retro-screen is now at a perfect 90 degree angle to the front Toe Gauge and the laser beam image

indicates zero toe on the Thrust Angle Screen.

Page 21

Page 23

BATTERY REPLACEMENT

The Laser 4 is powered by eight “C” batteries; four batteries located in each Toe Gauge. Alkaline batteries

are recommended for extended life.

The batteries should be replaced when the laser beam image becomes dim or can no longer be seen.

To replace the batteries (See Figure 46):

1) Flip the Laser Toe Gauge switch to OFF.

2) Place the Laser Toe Gauge on a workbench with the underside of the casting facing up.

3) Loosen the battery cover locking knobs and open the cover.

4) Replace the batteries foll owing the di agram in th e battery holder. Flip the switch t o ON t o be s u r e t h e

laser diode operates. Flip the switch to OFF.

5) Close the cover and secure with the battery cover locking knobs.

Page 22

Loading...

Loading...